Sustainable Fire Protection: Reducing Carbon Footprint with Advanced Coating Technologies

Abstract

:1. Introduction

1.1. Advancement in Sustainable Construction with Metallum Fire-Resistant (MFR) Paint

1.2. Mitigating Fire Hazards in Tunnels and Buildings

2. Materials and Methods

2.1. Materials

2.2. Metallic Applications

2.3. Comparison with Other Systems

2.3.1. Intumescent Paints

- Adhesion:

- Cork paint (MFR): According to ISO 4624 (Paints and Varnishes—Pull-Off Test for Adhesion) [11] MFR demonstrated adhesion greater than 5 MPa on metallic surfaces. This level of adhesion ensures coating durability, even in adverse conditions.

- Intumescent paints: Intumescent paints typically exhibit adhesion in the range of 2–4 MPa, depending on the type of paint and surface preparation. Although this value is adequate for many applications, it may not be sufficient in environments where maximum coating durability is required.

- Required Thickness:

- Cork paint (MFR): The typical application thickness of MFR ranges between 3000 and 5000 microns (3–5 mm). This thickness allows for effective protection with a minimal impact on the weight added to the structure.

- Intumescent paints: To achieve an equivalent level of fire protection, intumescent paints require greater thicknesses, generally between 4 mm and 10 mm or more. This significantly increases the weight and can affect structural integrity over the long term.

- Thermal Conductivity:

- Cork paint (MFR): Cork is known for its low thermal conductivity, with values between 0.037 and 0.040 W/m·K. This not only contributes to fire resistance, but also provides effective thermal insulation, crucial for the protection of metallic structures.

- Intumescent paints: While intumescent paints offer thermal insulation during a fire, their thermal conductivity in normal conditions is generally higher (0.1–0.3 W/m·K), making them less effective in preventing heat transfer in normal conditions.

- Corrosion Protection:

- Cork paint (MFR): Studies have shown that cork-based coatings can reduce corrosion rates on steel surfaces by up to 60% compared to untreated surfaces, according to salt spray tests (Progress in Organic Coatings, 2020) [14].

- Intumescent paints: Intumescent paints do not provide corrosion protection on their own, requiring the application of additional anti-corrosive coatings to ensure the steel is protected, thus increasing the complexity and cost of the coating system.

2.3.2. Refractory Mortars

2.4. Laboratory Tests

2.4.1. Test Methods

- Ignition of the cotton pad.

- Penetration of 25 mm and 6 mm diameter gauges.

- Appearance of sustained flames on the unexposed face.

- Insulation Criteria:

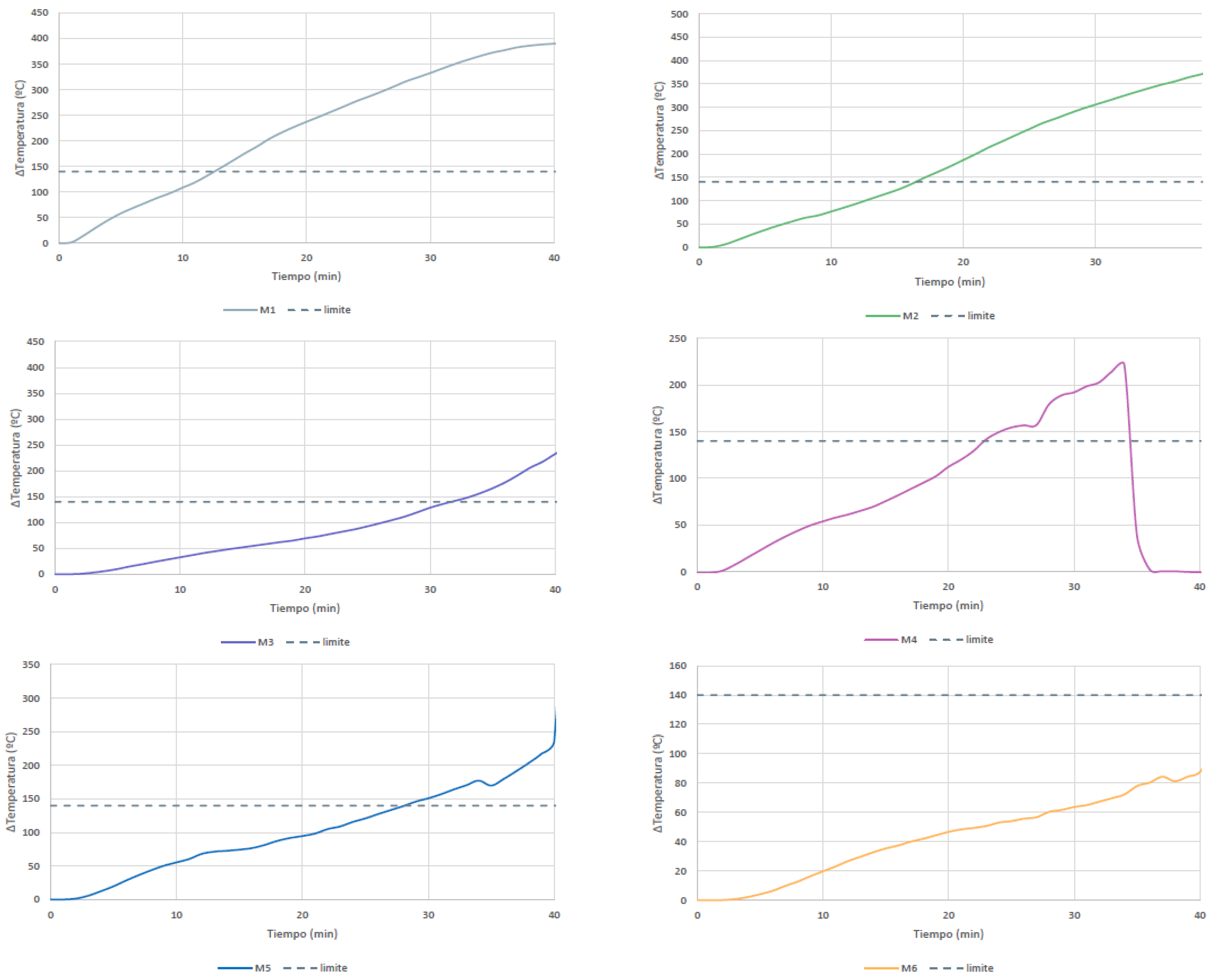

- Increase in the average temperature of the unexposed face of the sample limited to 140 °C.

- Increase in temperature at any point of the sample limited to 180 °C.

2.4.2. Analysis of Results

- Since the data are categorized by different measures (integrity, insulation, avg. temp, and max temp), we would perform a separate ANOVA for each measure across all samples.

- Calculate the mean for each measure: Find the mean values for integrity, insulation, avg. temp, and max temp across all samples.

- Sum of squares: Calculate the sum of squares between groups (SSB) and within groups (SSW).

- Calculate mean squares: For each measure, calculate the mean squares for between groups (MSB) and within groups (MSW)

F-statistic: 0.55

p-value: 0.655

3. Results and Discussion

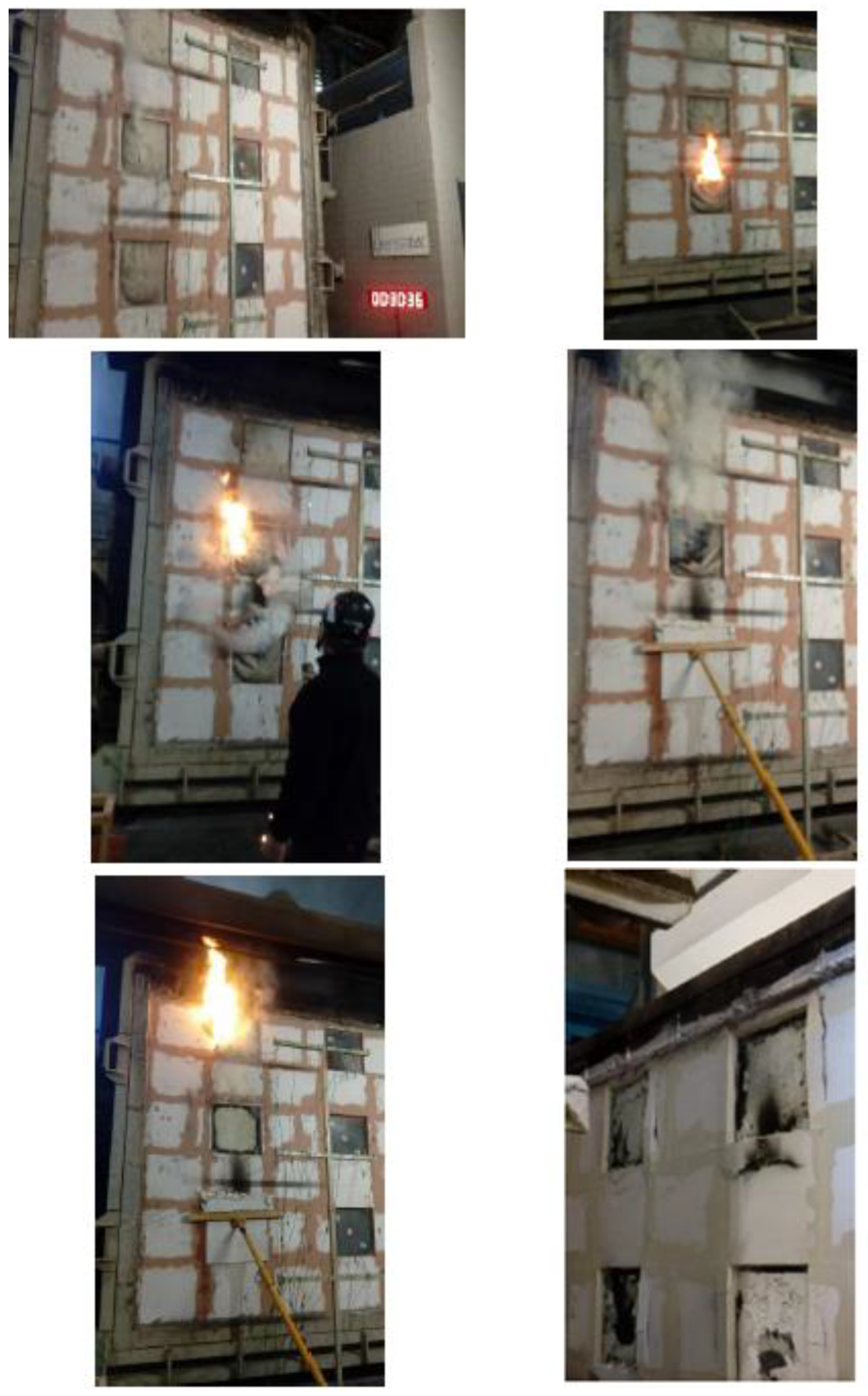

3.1. Fire Resistance

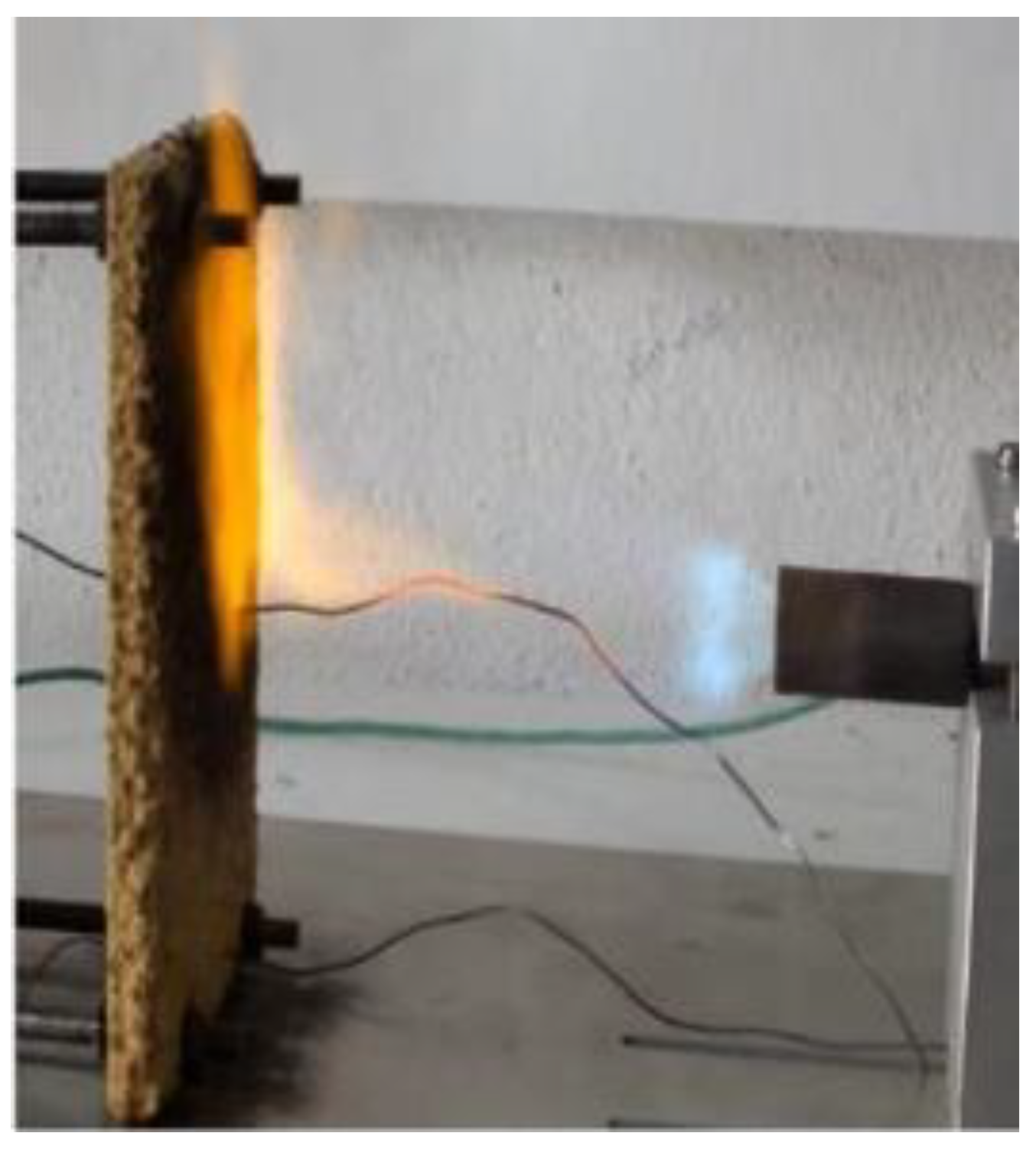

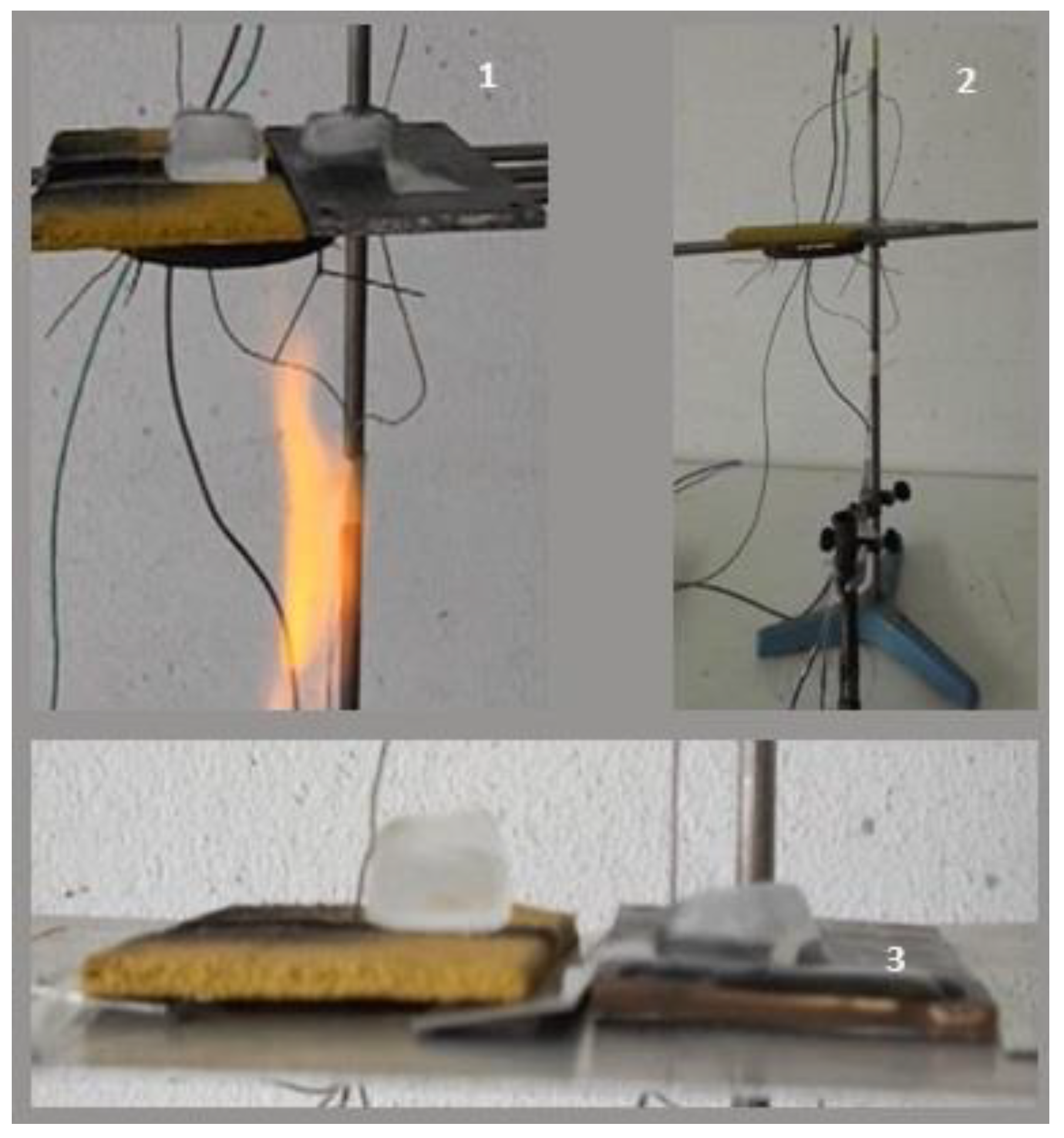

Performance during Direct Fire Exposure

3.2. New Formulation

3.3. Additional Properties

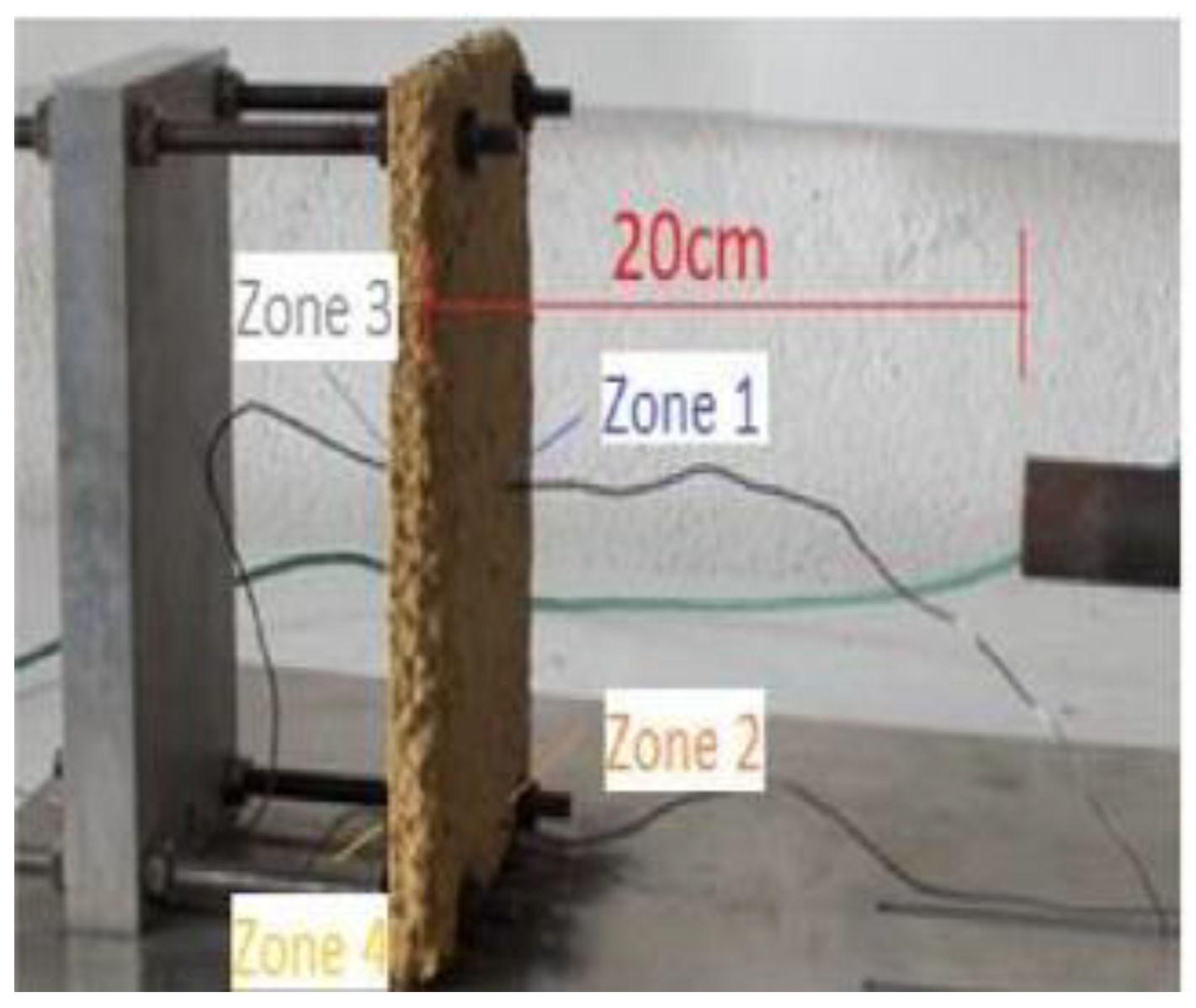

3.3.1. Thermal Insulation Based on Expanded Natural Cork

3.3.2. Pending New Tests with the New Formulation

3.3.3. Antifreeze Properties

3.3.4. Acoustic Tests

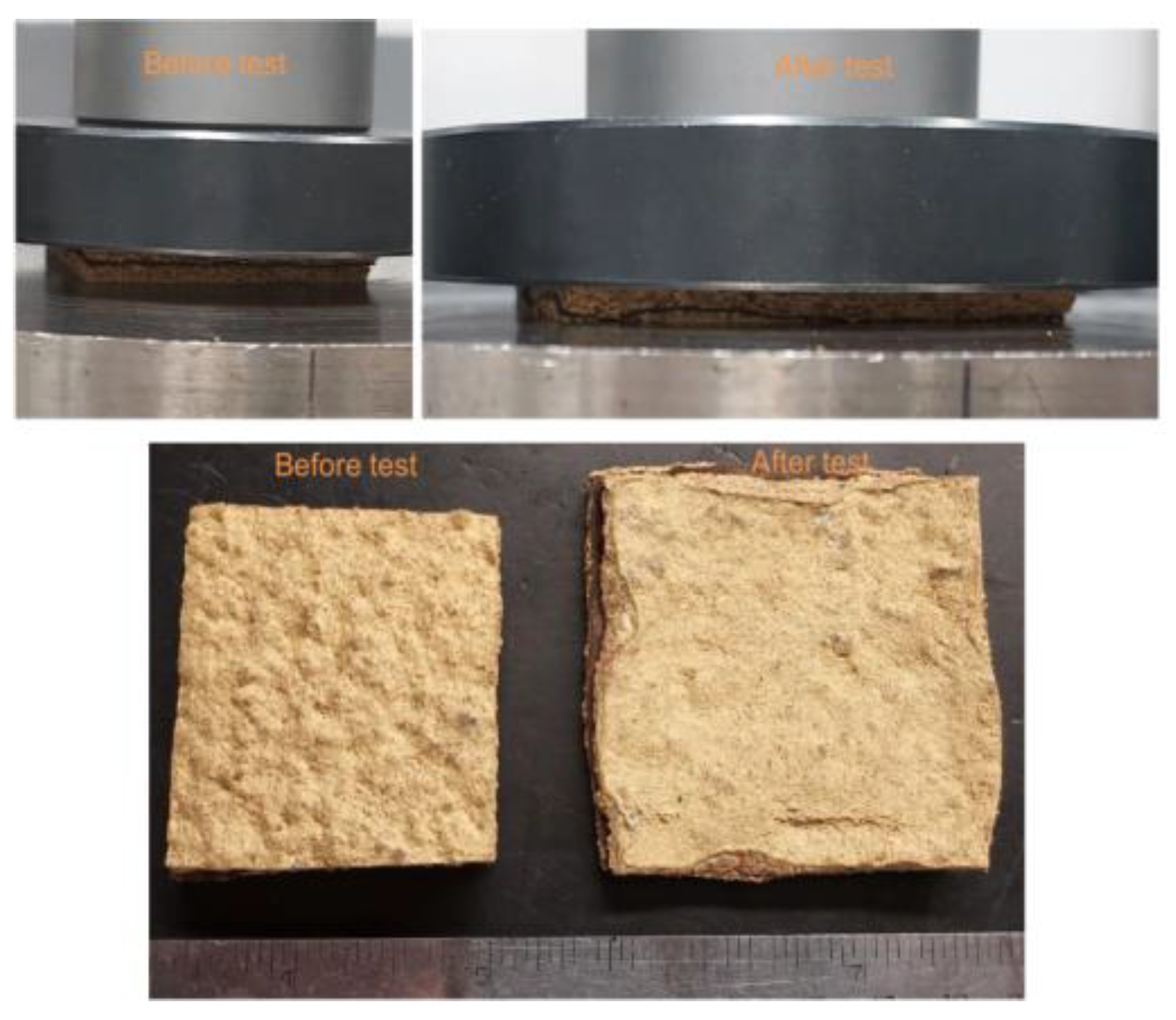

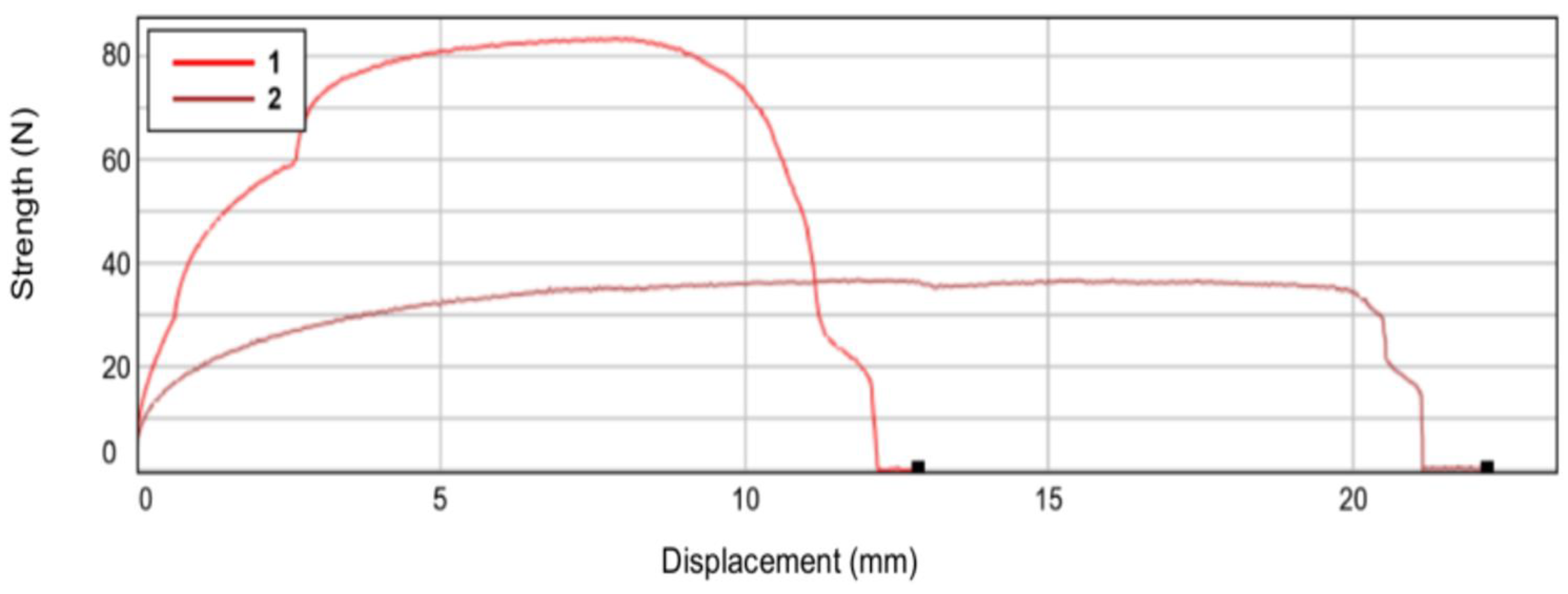

3.3.5. Compression and Tensile Tests

3.3.6. Smoke Production

3.3.7. Abrasion Resistance TABER Test

3.3.8. Easy Repair and Application

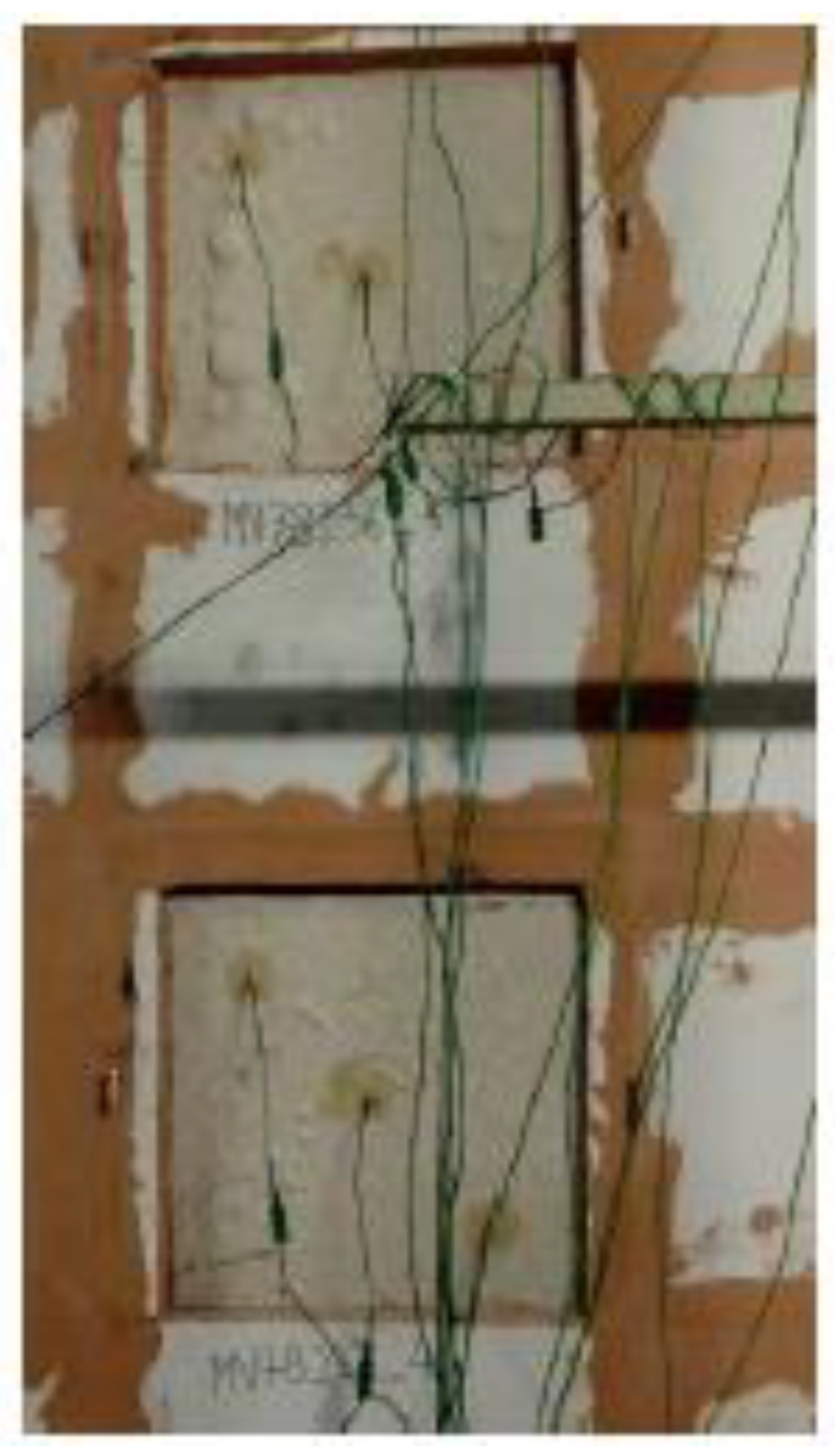

3.3.9. Fire Resistance Test

3.3.10. Evaluation Criteria

3.3.11. Insulation Criteria

- -

- Increase in the average temperature of the unexposed face of the sample limited to 140 °C.

- -

- Increase in temperature at any point on the sample limited to 180 °C.

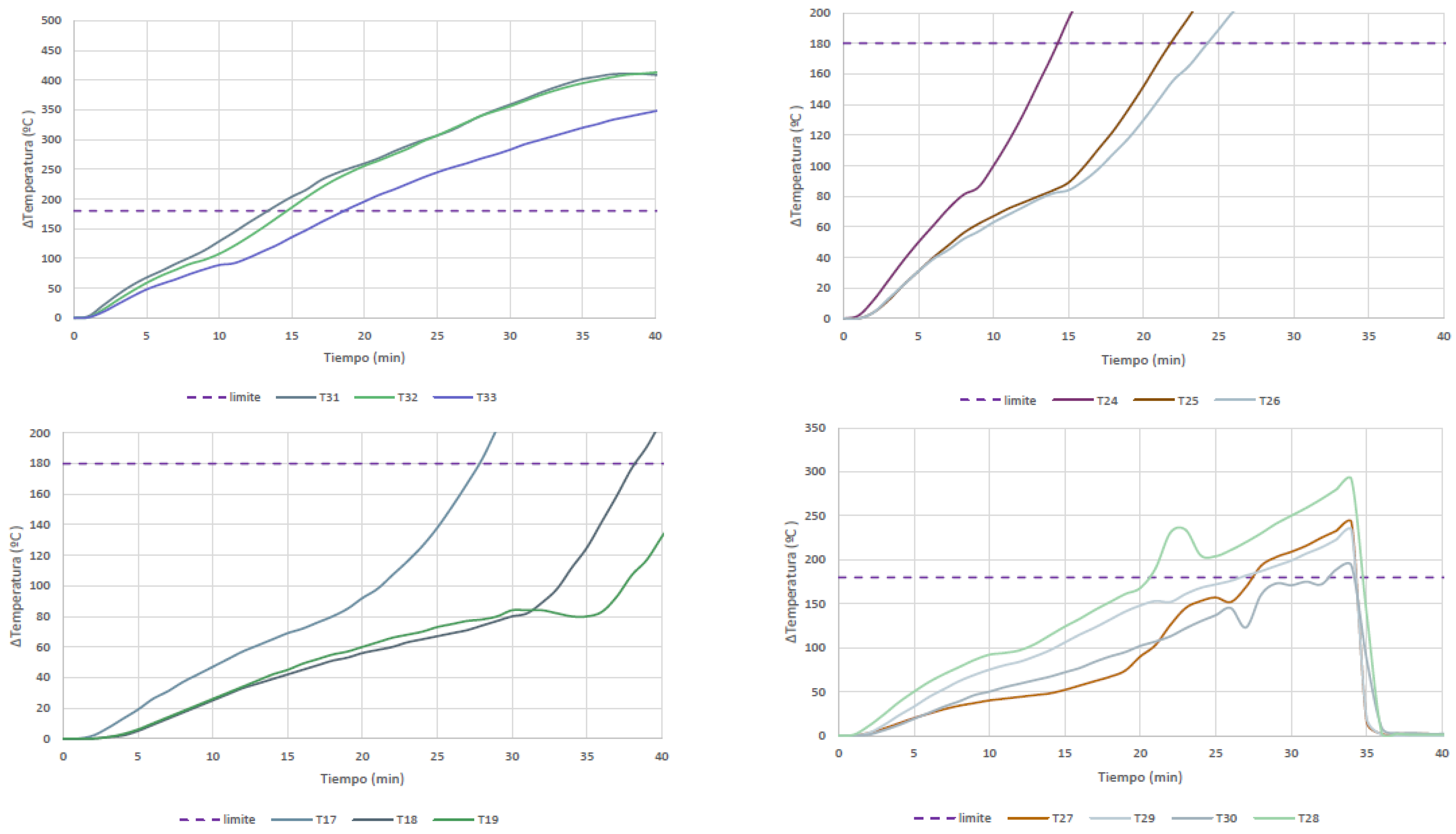

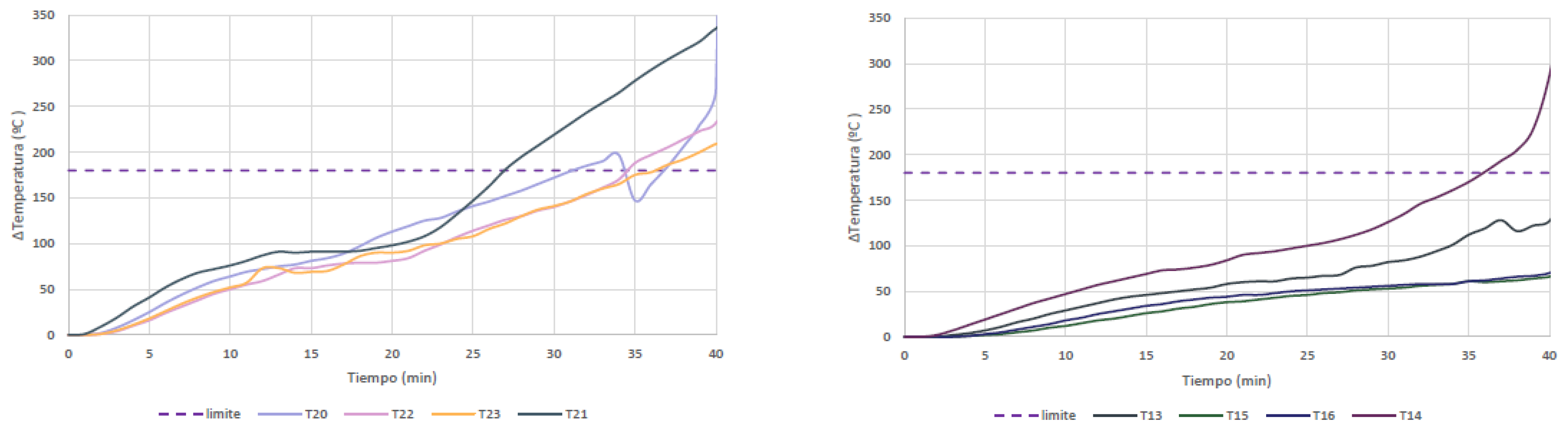

3.4. Plate Temperature Graphics

3.5. Graphics Summary

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Zhu, P.; Yan, X.; Xu, X.; Wang, X. Exploring the Application Potential and Performance of SiO2 Aerogel Mortar in Various Tunnel High-Temperature Environments. Fire 2023, 6, 407. [Google Scholar] [CrossRef]

- Jeon, Y.; Park, J.; Park, J.; Kang, C. Fire Risk of Polyethylene (PE)-Based Foam Blocks Used as Interior Building Materials and Fire Suppression through a Simple Surface Coating: Analysis of Vulnerability, Propagation, and Flame Retardancy. Fire 2023, 6, 350. [Google Scholar] [CrossRef]

- Santos-Reyes, J.; Beard, A. An analysis of the emergency response system of the 1996 Channel tunnel fire. Tunn. Undergr. Space Technol. 2017, 65, 121–139. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, T.; Guo, Q.; Yu, T.; Fang, Z.; Yan, Z. Full-scale experimental study on fire characteristics induced by double fire sources in a two-lane road tunnel. Tunn. Undergr. Space Technol. 2023, 131, 104768. [Google Scholar] [CrossRef]

- Liu, C.; Deng, T.; Zhou, S.; Yan, R.; Huang, L. Experimental investigation on fire assessment for typical interior wallpapers. Fire Technol. 2022, 58, 991–1009. [Google Scholar] [CrossRef]

- Mitton, M. Interior Design Visual Presentation: A Guide to Graphics, Models and Presentation Techniques; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Yang, H.-S.; Kim, D.-J.; Kim, H.-J. Combustion and Mechanical Properties of Fire Retardant Treated Waste Paper Board for Interior Finishing Material. J. Fire Sci. 2022, 20, 505–517. [Google Scholar] [CrossRef]

- Konecki, M.; Galaj, J. Flame transfer through the external walls insulation of the building during a fire. Procedia Eng. 2017, 172, 529–535. [Google Scholar] [CrossRef]

- MEST EN ISO 14040:2011; Environmental Management—Life Cycle Assessment—Principles and Framework. Instituto Catalán del Corcho ICSURO: Girona, Spain, 2011.

- ISO 13787:2003; Thermal Insulation Products for Building Equipment and Industrial Installations—Determination of Declared Thermal Conductivity. International Organization for Standardization, ISO Norm: Geneva, Switzerland, 2003.

- ISO 4624:2023; Paints and Varnishes—Pull-Off Test for Adhesion. International Organization for Standardization, ISO Norm: Geneva, Switzerland, 2023.

- ISO 8501-1:2007; Preparation Steel Surface before Application of Paints and Related Products. International Organization for Standardization, ISO Norm: Geneva, Switzerland, 2007.

- Morgan, A.B.; Wilkie, C.A. Flame Retardant Polymer Nanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- ASTM B117; Progress in Organic Coatings Salt Spray Test. ASTM American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Sarkar, R. Refractory Technology: Fundamentals and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- UNE EN 1364-1:2019; Fire Resistance Tests for Non-Loadbearing Elements—Part 1: Walls. AENOR: Madrid, Spain, 2019.

- UNE-EN 1363-1:2012; Fire Resistance Tests—Part 1: General Requirements. AENOR Norma Española: Madrid, Spain, 2012.

- 476-20:1987/BS; Fire Tests on Building Materials and Structures—Method for Determination of the Fire Resistance of Elements of Construction (General Principles). The British Standards Institution: London, UK, 2014.

- 476-22:1987/BS; Fire Tests on Building Materials and Structures—Method for Determination of the Fire Resistance of Non-Loadbearing Elements of Construction. The British Standards Institution: London, UK, 2014.

- UNE-EN 1363-1:2021; Fire Resistance Tests—Part 1: General Requirements. AENOR Norma Española: Madrid, Spain, 2021.

- ISO 354:2003; Measurement of Sound Absorption in a Reverberation Room. AENOR: Madrid, Spain, 2003.

- UNE EN 13823: 2012; Reaction to Fire according to Standard. AENOR: Madrid, Spain, 2011.

- UNE 48250:1992; Paints and Varnishes. Abrasion Resistance. Taber Method. AENOR: Madrid, Spain, 1992.

- ISO 8501-3:2006; Preparation of Steel Substrates before Application of Paints and Related Products Visual Assessment of Surface Cleanliness. International Organization for Standardization, ISO Norm: Geneva, Switzerland, 2006.

- UNE EN 13501-2:2023; Fire Classification of Construction Products and Building Elements. Classification Using Data from Fire Resistance and/or Smoke Control Tests, Excluding Ventilation Services. AENOR: Madrid, Spain, 2023.

- Alonso-Jiménez, A.; Suárez-Fino, J.; Regueiro y González-Barros, M.; López-Jimeno, C. Study of the Behavior of Excavations and Support Systems for an Alternative Construction Model of the Tunnels in Mexico City. Appl. Sci. 2023, 13, 3601. [Google Scholar] [CrossRef]

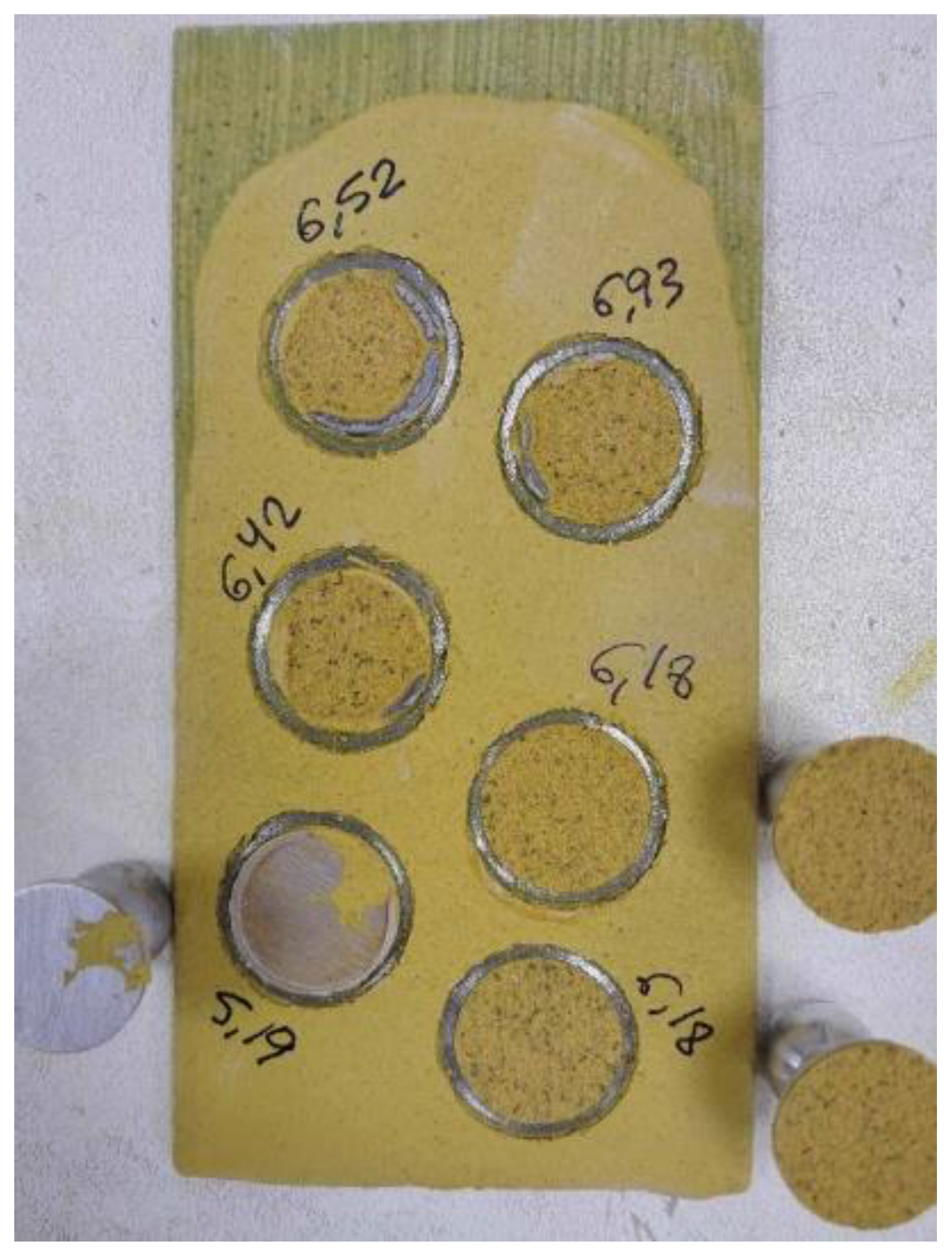

| Parameter | Details |

|---|---|

| Number of samples | 6. |

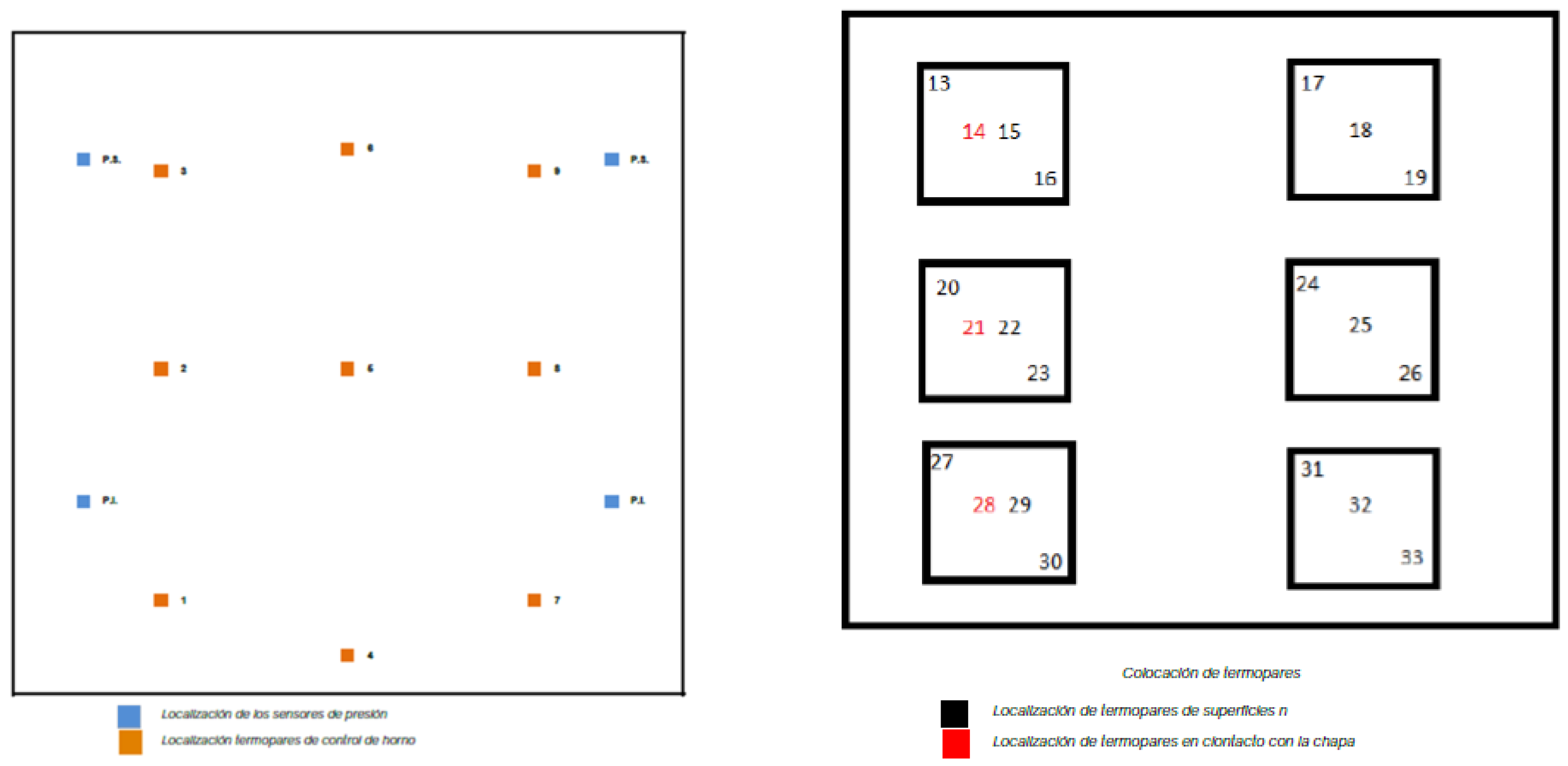

| Pressure | Four sensors were used to measure the pressure inside the furnace, positioned as follows: two at 0.90 m from the furnace floor and the other two 1.60 m above the previous ones. |

| Thermocouples | Nine plate thermocouples were used to control the temperature inside the furnace, and strategically placed within the furnace. The neutral pressure line was established at 0.5 m above the theoretical floor, located 0 m from the furnace floor. |

| Pressure settings | 3.4 Pa to 17 Pa. |

| Temperature control | Nine plate thermocouples were used to control the temperature inside the furnace, and strategically placed within the furnace. |

| Sample temperature | Standardized disc thermocouples were used to control the temperature of the samples (see thermocouple location diagram). |

| Deformations | To monitor deformations during the test, the most vulnerable points of the sample were considered, with periodic measurements taken throughout the test. |

| Fuel | Natural gas. |

| Test temperature | Initial: 10 °C to final: 10 °C. |

| Test humidity (HR) | 56. |

| Time (min) | Observation |

|---|---|

| 0 | Start of the test. |

| 10 | Small blisters appear on MV78236_M4 and larger ones on MV78236_M5. |

| 11 | A blister appears on MV78236_M6. |

| 13 | Average temperature failure in MV78236_M1. |

| 14 | Maximum temperature failure in MV78236_M1 in thermocouple 31 upper zone. |

| 15 | Maximum temperature failure in MV78236_M2 in thermocouple 24 upper zone. |

| 17 | Average temperature failure in MV78236_M2. |

| 16 | Continued blistering on MV78236_M4, M5, and M6. |

| 22 | A large blister forms on MV78236_M4. |

| 23 | Average temperature failure in MV78236_M4. |

| 25 | Visual inspection of the rears of MV78236_M1 and MV78236_M2, showing that the coating has fallen off in the darkened areas. |

| 28 | Maximum temperature failure in MV78236_M3 in thermocouple 17 upper zone. |

| 29 | Average temperature failure in MV78236_M5. |

| 32 | Average temperature failure in MV78236_M3. |

| 32 | Maximum temperature failure in MV78236_M4 in thermocouple 27 upper zone. |

| 32 | Maximum temperature failure in MV78236_M5 in thermocouple 20 upper zone. |

| 35 | Integrity failure in MV78236_M4, silicate is applied to continue the test. Failure also in MV78236_M5, but this may be due to the failure of MV78236_M4. The test continues with MV78236_M6. |

| 36 | Maximum temperature failure in MV78236_M6 in thermocouple 27 upper zone. |

| 40 | MV78236_M6 detaches and the test is concluded. |

| Sample | Integrity (E) | Insulation (I) | Average Temperature | Maximum Temperature | Conclusions |

|---|---|---|---|---|---|

| MV78236_1 | 14 min | 13 min | 13 min | 14 min | Average temperature failure at minute 13 and maximum temperature failure at minute 14. No integrity failure. |

| MV78236_2 | 17 min | 15 min | 17 min | 15 min | Average temperature failure at minute 17 and maximum temperature failure at minute 15. No integrity failure. |

| MV78236_3 | 32 min | 28 min | 32 min | 28 min | Average temperature failure at minute 32 and maximum temperature failure at minute 28. |

| MV78236_4 | 35 min | 23 min | 23 min | 28 min | Integrity failure at minute 35 and insulation failure at minute 23. |

| MV78236_5 | 32 min | 29 min | 29 min | 32 min | Integrity failure at minute 35. |

| MV78236_6 | 36 min | - | - | 36 min | Maximum temperature failure at minute 36. |

| Freq. (Hz) | αw |

|---|---|

| 125 | 0 |

| 250 | 0.02 |

| 500 | 0.03 |

| 1000 | 0.06 |

| 2000 | 0.1 |

| 4000 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso-Jiménez, A.; Alonso, P.M.; Hormaza-Polo, E. Sustainable Fire Protection: Reducing Carbon Footprint with Advanced Coating Technologies. Appl. Sci. 2024, 14, 7826. https://doi.org/10.3390/app14177826

Alonso-Jiménez A, Alonso PM, Hormaza-Polo E. Sustainable Fire Protection: Reducing Carbon Footprint with Advanced Coating Technologies. Applied Sciences. 2024; 14(17):7826. https://doi.org/10.3390/app14177826

Chicago/Turabian StyleAlonso-Jiménez, Antonio, Pedro M. Alonso, and Exabier Hormaza-Polo. 2024. "Sustainable Fire Protection: Reducing Carbon Footprint with Advanced Coating Technologies" Applied Sciences 14, no. 17: 7826. https://doi.org/10.3390/app14177826