Investigation of Yarrow Essential Oil Composition and Microencapsulation by Complex Coacervation Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomaterial

2.2. Yarrow Essential Oil

2.3. Shell Materials

2.4. Chemicals

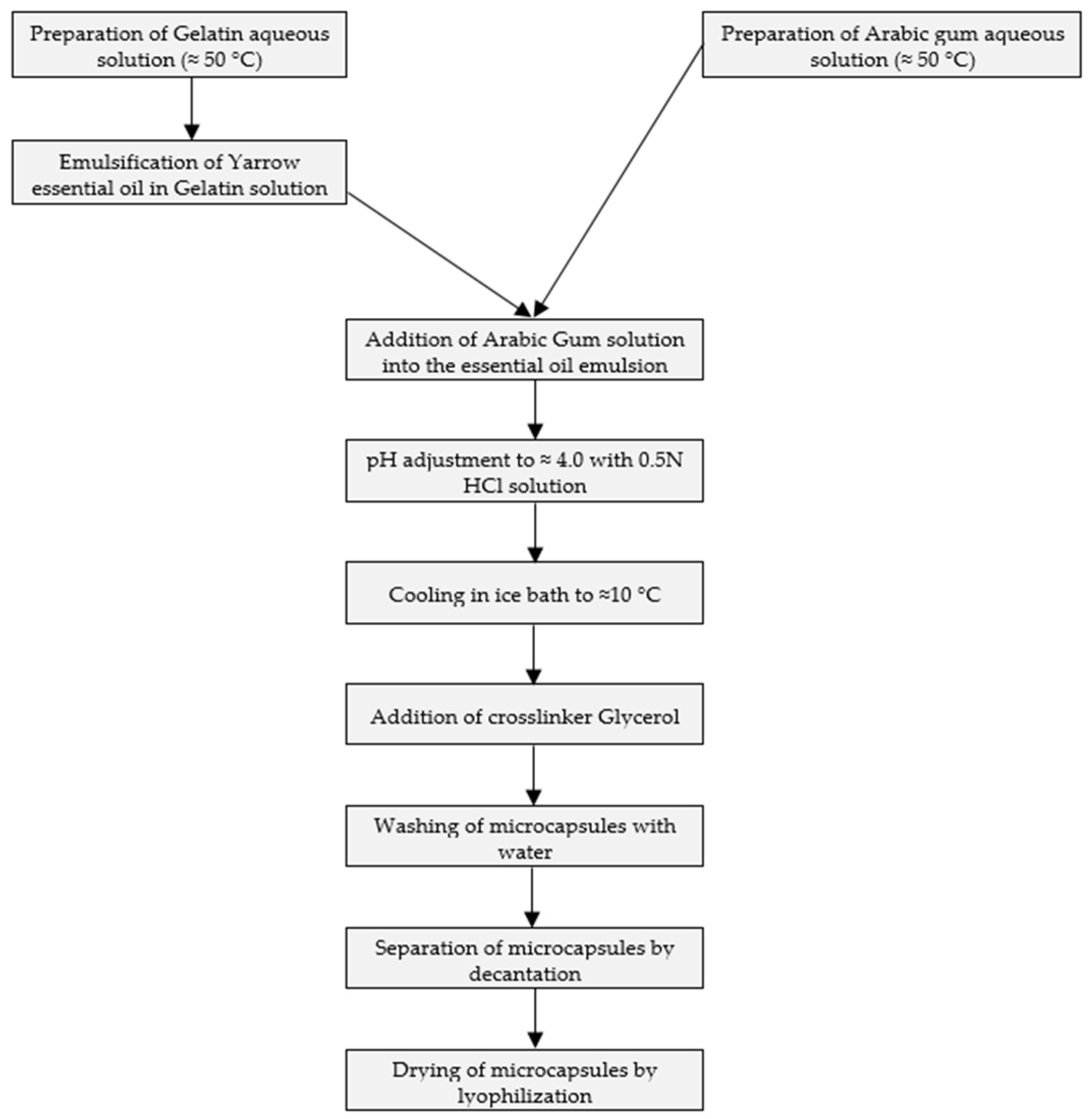

2.5. Microencapsulation Method

2.6. Freeze-Drying

2.7. Optical Microscopic Investigation

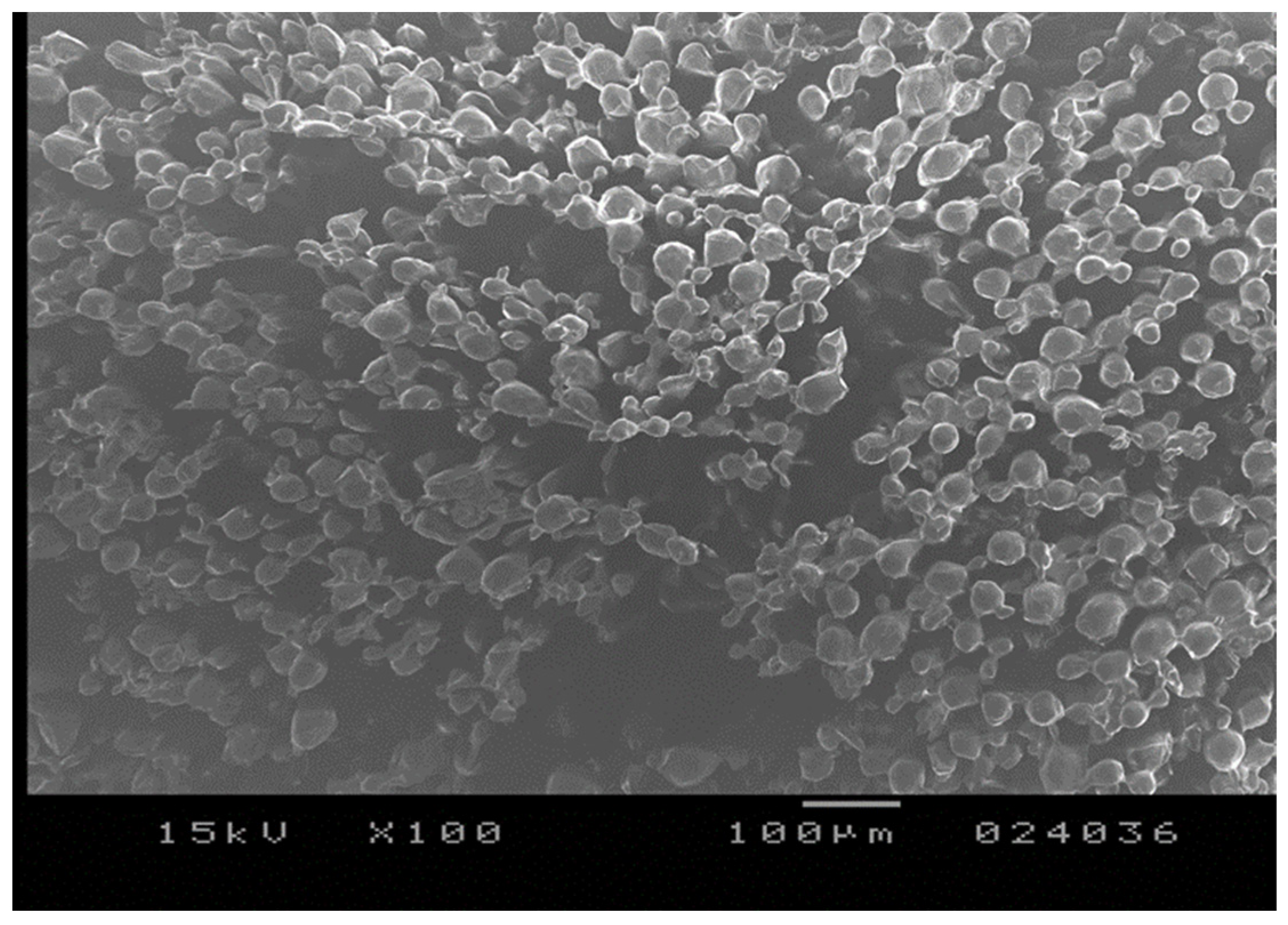

2.8. SEM Investigation

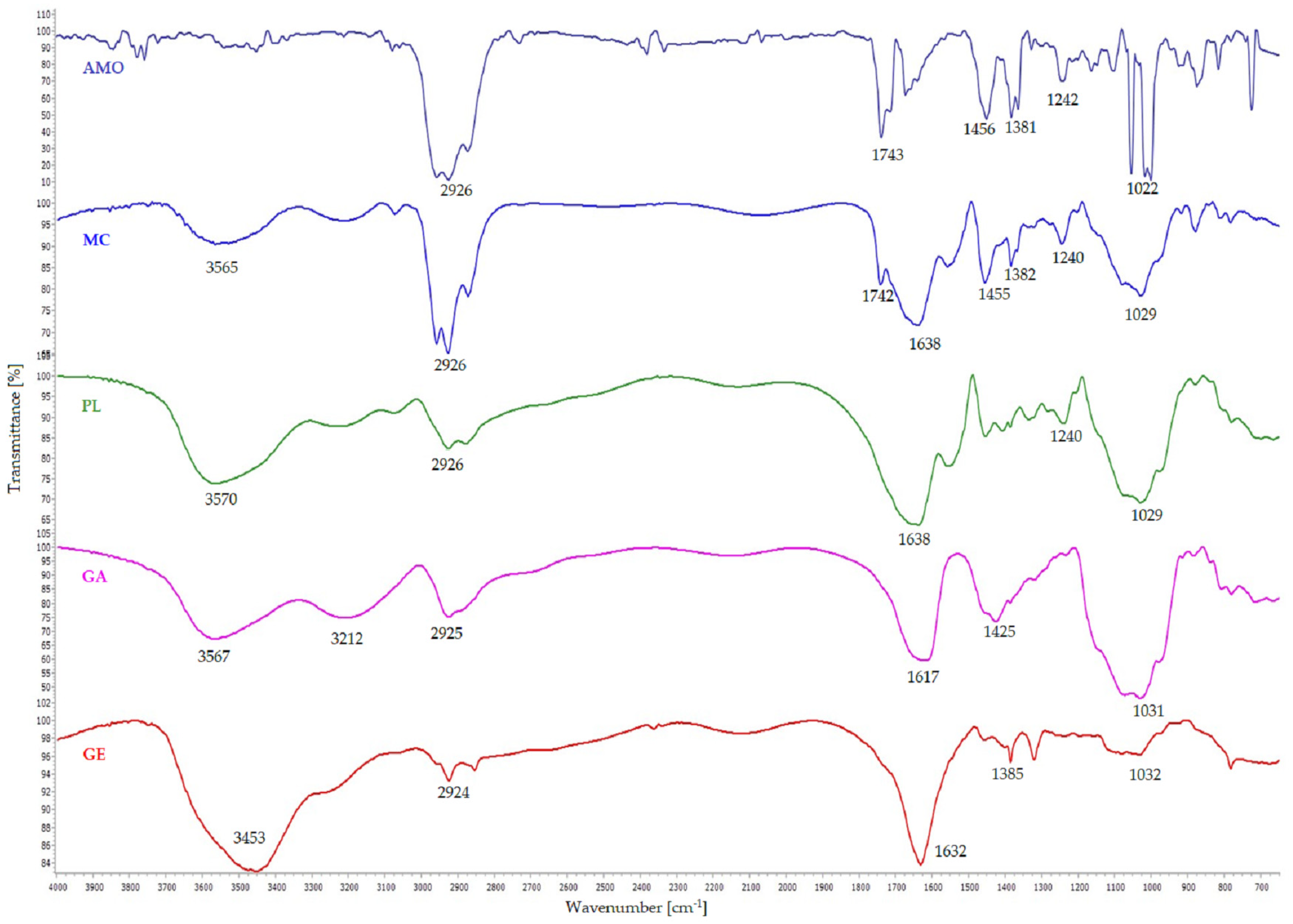

2.9. FT-IR Spectroscopy

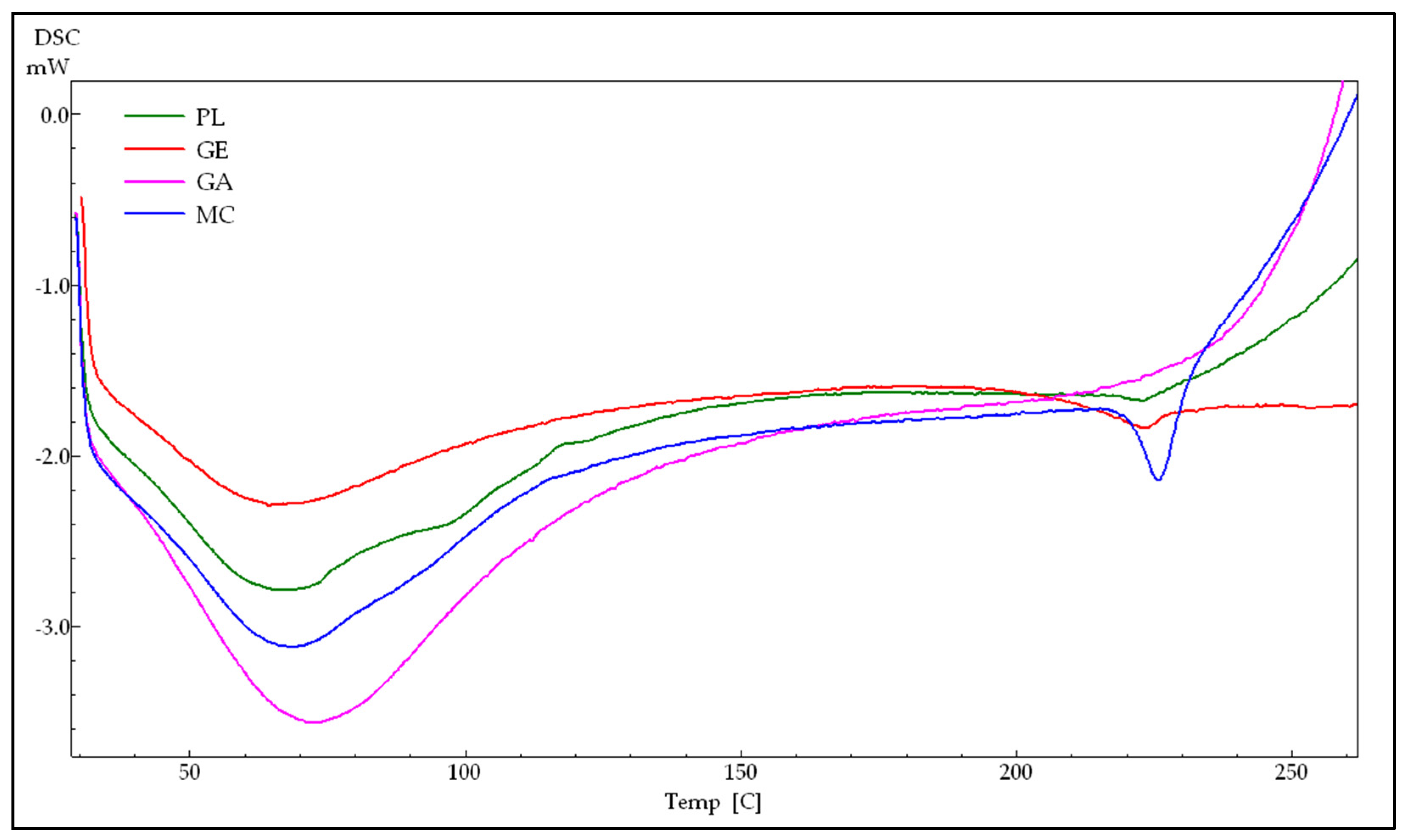

2.10. Differential Scanning Calorimetry (DSC)

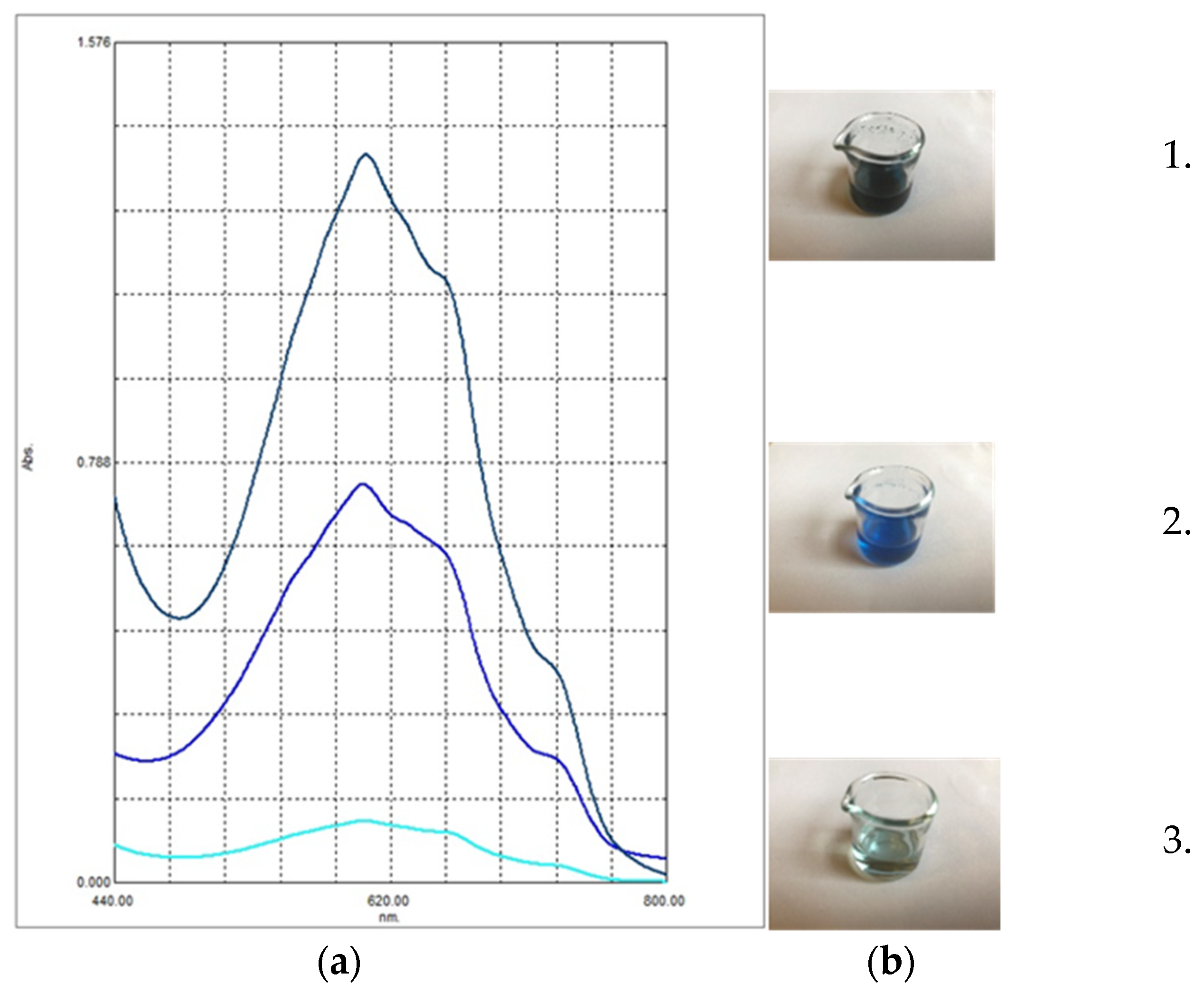

2.11. Visible Spectroscopic Analyses

2.11.1. Qualitative Analyses

2.11.2. Quantitative Analyses

2.12. GC—MS Investigation

3. Results and Discussion

3.1. Chemical Composition of Yarrow Essential Oils

3.1.1. Chemical Composition of Self-Prepared Yarrow Essential Oils

3.1.2. Comparison of Yarrow Essential Oils of Different Origins

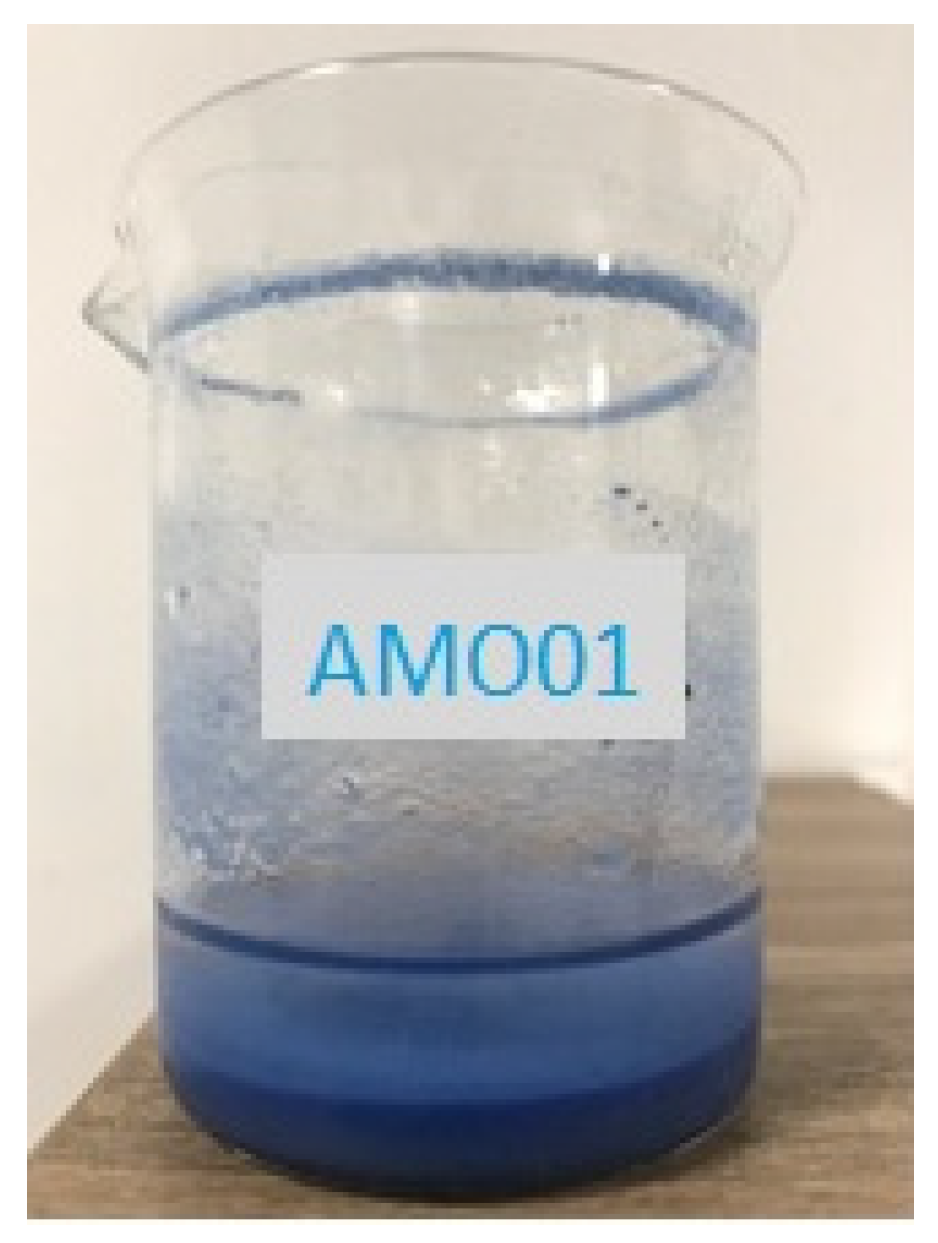

3.2. Macroscopic and Microscopic Investigation of Complex Coacervate Formation

3.2.1. Macroscopic Aspect of Coacervates

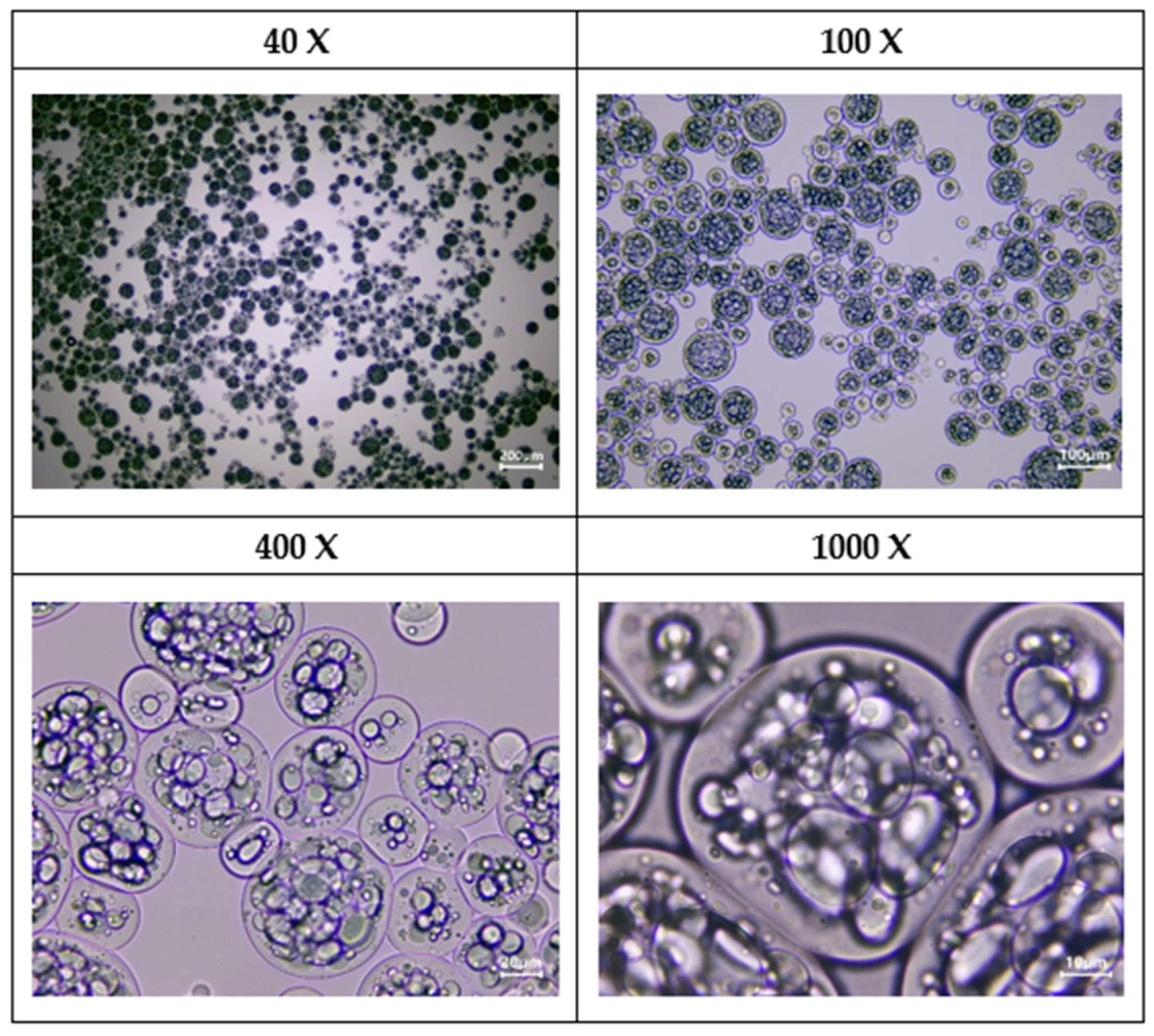

3.2.2. Microscopic Aspect of Coacervates

3.3. Macroscopic and Microscopic Investigation of Solid Microcapsules

3.3.1. Macroscopic Aspect of Microcapsules

3.3.2. Microscopic Aspect of Microcapsules

3.4. Determination of Encapsulation Efficiency and Loading Capacity by UV Spectroscopy

3.5. GC—MS Investigation of Microcapsules

3.6. FT-IR Analysis of Microcapsules

3.7. Thermal Analysis of Microcapsules

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aziz, E.; Badawy, E.; Zheljazkov, V.; Nicola, S.; Fouad, H. Yield and Chemical Composition of Essential Oil of Achillea Millefolium L. as Affected by Harvest Time. Egypt. J. Chem. 2018, 62, 533–540. [Google Scholar] [CrossRef]

- Stevanovic, Z.D.; Pljevljakušic, D.; Ristic, M.; Šoštaric, I.; Kresovic, M.; Simic, I.; Vrbnièanin, S. Essential Oil Composition of Achillea Millefolium Agg. Populations Collected from Saline Habitats in Serbia. J. Essent. Oil Bear. Plants 2015, 18, 1343–1352. [Google Scholar] [CrossRef]

- Benedek, B.; Rothwangl-Wiltschnigg, K.; Rozema, E.; Gjoncaj, N.; Reznicek, G.; Jurenitsch, J.; Kopp, B.; Glasl, S. Yarrow (Achillea Millefolium L. s.l.): Pharmaceutical Quality of Commercial Samples. Pharmazie 2008, 63, 23–26. [Google Scholar] [CrossRef] [PubMed]

- Kindlovits, S.; Cserháti, B.; Inotai, K.; Németh, É.Z. Ontogenetic Variation of Active Agent Content of Yarrow (Achillea Collina Becker). J. Appl. Res. Med. Aromat. Plants 2016, 3, 52–57. [Google Scholar] [CrossRef]

- Karlová, K.; Petříková, K. Variability of the Content of Active Substances during Achillea Collina Rchb. Alba Ontogenesis. Hortic. Sci. 2005, 32, 17–22. [Google Scholar] [CrossRef]

- Orav, A.; Kailas, T.; Ivask, K. Composition of the Essential Oil from Achillea Millefolium L. from Estonia. J. Essent. Oil Res. 2001, 13, 290–294. [Google Scholar] [CrossRef]

- European Scientific Cooperative on Phytotherapy. ESCOP Monographs. The Scientific Foundation for Herbal Medicinal Products; Online Series—Millefolii Herba (Yarrow); ESCOP: Berlin, Germany, 2021. [Google Scholar]

- EDQM Council of Europe. Monograph: Millefolii Herba (07/2014: 1382). In European Pharmacopoeia (Ph. Eur.), 11th ed.; EDQM Council of Europe: Strasbourg, France, 2022; pp. 1781–1782. [Google Scholar]

- Kindlovits, S. A mezei cickafark (Achillea collina Becker) produkcióját és hatóanyagait befolyásoló tényezők. Ph.D. Thesis, Szent István University, Budapest, Hungary, 2017. [Google Scholar] [CrossRef]

- Smelcerovic, A.; Lamshoeft, M.; Radulovic, N.; Ilic, D.; Palic, R. LC-MS Analysis of the Essential Oils of Achillea Millefolium and Achillea Crithmifolia. Chromatographia 2010, 71, 113–116. [Google Scholar] [CrossRef]

- Bakun, P.; Czarczynska-Goslinska, B.; Goslinski, T.; Lijewski, S. In Vitro and in Vivo Biological Activities of Azulene Derivatives with Potential Applications in Medicine. Med. Chem. Res. 2021, 30, 834–846. [Google Scholar] [CrossRef]

- Pazouki, L.; Memari, H.R.; Kännaste, A.; Bichele, R.; Niinemets, Ü. Germacrene A Synthase in Yarrow (Achillea Millefolium) Is an Enzyme with Mixed Substrate Specificity: Gene Cloning, Functional Characterization and Expression Analysis. Front. Plant Sci. 2015, 6, 111. [Google Scholar] [CrossRef]

- Mustakerova, E.; Todorova, M.; Tsankova, E. Sesquiterpene Lactones from Achillea Collina Becker. Z. Für Naturforschung C 2002, 57, 568–570. [Google Scholar] [CrossRef]

- Li, H.; Li, J.; Liu, M.; Xie, R.; Zang, Y.; Li, J. Phytochemistry Guaianolide Sesquiterpene Lactones from Achillea Millefolium L. Phytochemistry 2021, 186, 112733. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Akber Aisa, H.; Li, J. Germacrane-Type Sesquiterpene Lactones from Achillea Millefolium L. and Their Anti-Inflammatory Activity. Chem. Biodivers. 2023, 20, e202300079. [Google Scholar] [CrossRef]

- Gómez de Cedrón, M.; Siles-Sánchez, M.D.L.N.; Martín Hernández, D.; Jaime, L.; Santoyo, S.; Ramírez de Molina, A. Novel Bioactive Extract from Yarrow Obtained by the Supercritical Antisolvent-Assisted Technique Inhibits Lipid Metabolism in Colorectal Cancer. Front. Bioeng. Biotechnol. 2024, 12, 1256190. [Google Scholar] [CrossRef] [PubMed]

- Bocevska, M.; Sovová, H. Supercritical CO2 Extraction of Essential Oil from Yarrow. J. Supercrit. Fluids 2007, 40, 360–367. [Google Scholar] [CrossRef]

- Villanueva-Bermejo, D.; Zahran, F.; García-Risco, M.R.; Reglero, G.; Fornari, T. Supercritical Fluid Extraction of Bulgarian Achillea Millefolium. J. Supercrit. Fluids 2017, 119, 283–288. [Google Scholar] [CrossRef]

- Ivanović, M.; Grujić, D.; Cerar, J.; Islamčević Razboršek, M.; Topalić-Trivunović, L.; Savić, A.; Kočar, D.; Kolar, M. Extraction of Bioactive Metabolites from Achillea Millefolium L. with Choline Chloride Based Natural Deep Eutectic Solvents: A Study of the Antioxidant and Antimicrobial Activity. Antioxidants 2022, 11, 724. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Abd-Elraouf, M.; Sulaiman, G.M.; Almahmoud, S.A.; Hamada, F.A.; Khan, R.A.; Hegazy, M.M.; Abd-El-Wahab, M.F.; Kedra, T.A.; Ismail, A. Variability in the Volatile Constituents and Biological Activities of Achillea Millefolium L. Essential Oils Obtained from Different Plant Parts and by Different Solvents. Arab. J. Chem. 2023, 16, 105103. [Google Scholar] [CrossRef]

- Gabbanini, S.; Neba, J.N.; Matera, R.; Valgimigli, L. Photochemical and Oxidative Degradation of Chamazulene Contained in Artemisia, Matricaria and Achillea Essential Oils and Setup of Protection Strategies. Molecules 2024, 29, 2604. [Google Scholar] [CrossRef]

- Farasati, B.; Behzad, G.; Khalili, H. Achillea Millefolium: Mechanism of Action, Pharmacokinetic, Clinical Drug-Drug Interactions and Tolerability. Heliyon 2023, 9, e22841. [Google Scholar] [CrossRef]

- Applequist, W.L.; Moerman, D.E. Yarrow (Achillea Millefolium L.): A Neglected Panacea ? A Review of Ethnobotany, Bioactivity, and Biomedical Research. Econ. Bot. 2011, 65, 209–225. [Google Scholar] [CrossRef]

- Tadić, V.; Arsić, I.; Zvezdanović, J.; Zugić, A.; Cvetković, D.; Pavkov, S. The Estimation of the Traditionally Used Yarrow (Achillea Millefolium L. Asteraceae) Oil Extracts with Anti-Inflamatory Potential in Topical Application. J. Ethnopharmacol. 2017, 199, 138–148. [Google Scholar] [CrossRef]

- European Medicines Agency (EMA). Community Herbal Monograph on Yarrow Herb (Achillea Millefolium L., Herba); European Medicines Agency (EMA): Amsterdam, The Netherlands, 2020; Volume EMA/513753. [Google Scholar]

- European Medicines Agency (EMA). Community Herbal Monograph on Yarrow Flower (Achillea Millefolium L., Flos); European Medicines Agency (EMA): Amsterdam, The Netherlands, 2019; Volume EMA/165822. [Google Scholar]

- Chou, S.T.; Peng, H.Y.; Hsu, J.C.; Lin, C.C.; Shih, Y. Achillea Millefolium L. Essential Oil Inhibits LPS-Induced Oxidative Stress and Nitric Oxide Production in RAW 264.7 Macrophages. Int. J. Mol. Sci. 2013, 14, 12978–12993. [Google Scholar] [CrossRef] [PubMed]

- Alomair, M.K.; Alabduladheem, L.S.; Almajed, M.A.; Alobaid, A.A.; Alkhalifah, E.A.R.; Younis, N.S.; Mohamed, M.E. Achillea Millefolium Essential Oil Mitigates Peptic Ulcer in Rats through Nrf2/HO-1 Pathway. Molecules 2022, 27, 908. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, M.E.; Elsayed, S.A.; Madkor, H.R.; Eldien, H.M.S.; Mohafez, O.M. Yarrow Oil Ameliorates Ulcerative Colitis in Mice Model via Regulating the NF-κB and PPAR-γ Pathways. Intest. Res. 2021, 19, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Ma, D.; He, J.; He, D. Chamazulene Reverses Osteoarthritic Inflammation through Regulation of Matrix Metalloproteinases (MMPs) and NF-Kβ Pathway in in-Vitro and in-Vivo Models. Biosci. Biotechnol. Biochem. 2020, 84, 402–410. [Google Scholar] [CrossRef]

- Csupor-Löffler, B.; Hajdú, Z.; Zupkó, I.; Réthy, B.; Falkay, G.; Forgo, P.; Hohmann, J. Antiproliferative Effect of Flavonoids and Sesquiterpenoids from Achillea Millefolium s.l. on Cultured Human Tumour Cell Lines. Phyther. Res. 2009, 23, 672–676. [Google Scholar] [CrossRef]

- Turek, C.; Stintzing, F.C. Stability of Essential Oils: A Review. Compr. Rev. Food Sci. Food Saf. 2013, 12, 40–53. [Google Scholar] [CrossRef]

- Sousa, V.I.; Parente, J.F.; Marques, J.F.; Forte, M.A.; Tavares, C.J. Microencapsulation of Essential Oils: A Review. Polymers 2022, 14, 1730. [Google Scholar] [CrossRef]

- Arenas-Jal, M.; Suñé-Negre, J.M.; García-Montoya, E. An Overview of Microencapsulation in the Food Industry: Opportunities, Challenges, and Innovations. Eur. Food Res. Technol. 2020, 246, 1371–1382. [Google Scholar] [CrossRef]

- Rakmai, J.; Cheirsilp, B.; Torrado-agrasar, A.; Simal-, J.; Mejuto, J.C.; Torrado-agrasar, A. Encapsulation of Yarrow Essential Oil in Hydroxypropyl-Beta-Cyclodextrin: Physiochemical Characterization and Evaluation of Bio-Efficacies. CyTA-J. Food 2017, 15, 409–417. [Google Scholar] [CrossRef]

- Ahmadi, Z.; Saber, M.; Bagheri, M.; Mahdavinia, G.R. Achillea Millefolium Essential Oil and Chitosan Nanocapsules with Enhanced Activity against Tetranychus Urticae. J. Pest Sci. 2018, 91, 837–848. [Google Scholar] [CrossRef]

- Timilsena, Y.P.; Akanbi, T.O.; Khalid, N.; Adhikari, B.; Barrow, C.J. Complex Coacervation: Principles, Mechanisms and Applications in Microencapsulation. Int. J. Biol. Macromol. 2019, 121, 1276–1286. [Google Scholar] [CrossRef] [PubMed]

- Thies, C. Encapsulation by Complex Coacervation. In Encapsulation and Controlled Release Technologies in Food Systems; Lakkis, J.M., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 41–77. ISBN 9781118946893. [Google Scholar]

- Milano, F.; Masi, A.; Madaghiele, M.; Sannino, A.; Salvatore, L.; Gallo, N. Current Trends in Gelatin-Based Drug Delivery Systems. Pharmaceutics 2023, 15, 1499. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, S.; Nicoletti, V.R. Microencapsulation of Ginger Oil by Complex Coacervation Using Atomization: Effects of Polymer Ratio and Wall Material Concentration. J. Food Eng. 2021, 291, 110214. [Google Scholar] [CrossRef]

- Yang, X.; Gao, N.; Hu, L.; Li, J.; Sun, Y. Development and Evaluation of Novel Microcapsules Containing Poppy-Seed Oil Using Complex Coacervation. J. Food Eng. 2015, 161, 87–93. [Google Scholar] [CrossRef]

- Gonçalves, N.D.; de Lima Pena, F.; Sartoratto, A.; Derlamelina, C.; Duarte, M.C.T.; Antunes, A.E.C.; Prata, A.S. Encapsulated Thyme (Thymus Vulgaris) Essential Oil Used as a Natural Preservative in Bakery Product. Food Res. Int. 2017, 96, 154–160. [Google Scholar] [CrossRef]

- Eratte, D.; Wang, B.; Dowling, K.; Barrow, C.J.; Adhikari, B.P. Complex Coacervation with Whey Protein Isolate and Gum Arabic for the Microencapsulation of Omega-3 Rich Tuna Oil. Food Funct. 2014, 5, 2743–2750. [Google Scholar] [CrossRef]

- Khan, M.; Al-Saleem, M.S.M.; Alkhathlan, H.Z. A Detailed Study on Chemical Characterization of Essential Oil Components of Two Plectranthus Species Grown in Saudi Arabia. J. Saudi Chem. Soc. 2016, 20, 711–721. [Google Scholar] [CrossRef]

- Jianu, C.; Misca, C. Composition, Antioxidant and Antimicrobial Activity of the Essential Oil of Achillea Collina Becker Growing Wild in Western Romania. Hem. Ind. 2014, 69, 381–386. [Google Scholar] [CrossRef]

- Iuliana Costescu, C.; Rădoi, B.P.; Hădărugă, N.G.; Gruia, A.T.; Riviş, A.; Pârvu, D.; David, I.; Hădărugă, D.I. Obtaining and Characterization of Achillea Millefolium L. Extracts. J. Agroaliment. Process. Technol. 2014, 20, 142–149. [Google Scholar]

- Yildirim, B.; Ekici, K.; Kocak, M.Z. Essential oil composition of yarrow species (Achillea millefolium L. and Achillea wilhelmsii L.): Antioxidant and antibacterial activities. Stud. UBB Chem. 2023, 68, 145–157. [Google Scholar] [CrossRef]

- Abdossi, V.; Kazemi, M. Bioactivities of Achillea Millefolium Essential Oil and Its Main Terpenes from Iran. Int. J. Food Prop. 2015, 19, 1798–1808. [Google Scholar] [CrossRef]

- Farhadi, N.; Babaei, K.; Farsaraei, S.; Moghaddam, M.; Ghasemi Pirbalouti, A. Changes in Essential Oil Compositions, Total Phenol, Flavonoids and Antioxidant Capacity of Achillea Millefolium at Different Growth Stages. Ind. Crop. Prod. 2020, 152, 112570. [Google Scholar] [CrossRef]

- Cristina Figueiredo, A.; Barroso, J.G.; Salomé, M.; Pais, S.; Scheffer, J.J.C. Composition of the Essential Oils from Two Populations of Achillea Millefolium L Ssp. Millefolium. J. Chromatogr. Sci. 1992, 30, 392–395. [Google Scholar] [CrossRef]

- Daniel, P.S.; Lourenço, E.L.B.; da Cruz, R.M.S.; De Souza Gonçalves, C.H.; Das Almas, L.R.M.; Hoscheid, J.; da Silva, C.; Jacomassi, E.; Brum, L.; Alberton, O. Composition and Antimicrobial Activity of Essential Oil of Yarrow (Achillea Millefolium L.). Aust. J. Crop Sci. 2020, 14, 545–550. [Google Scholar] [CrossRef]

- Verma, R.S.; Joshi, N.; Padalia, R.C.; Goswami, P.; Singh, V.R.; Chauhan, A.; Verma, S.K.; Iqbal, H.; Verma, R.K.; Chanda, D.; et al. Chemical Composition and Allelopathic, Antibacterial, Antifungal and in Vitro Acetylcholinesterase Inhibitory Activities of Yarrow (Achillea Millefolium L.) Native to India. Ind. Crop. Prod. 2017, 104, 144–155. [Google Scholar] [CrossRef]

- Konarska, A.; Weryszko-Chmielewska, E.; Sulborska-Różycka, A.; Kiełtyka-Dadasiewicz, A.; Dmitruk, M.; Gorzel, M. Herb and Flowers of Achillea Millefolium Subsp. Millefolium L.: Structure and Histochemistry of Secretory Tissues and Phytochemistry of Essential Oils. Molecules 2023, 28, 7791. [Google Scholar] [CrossRef]

- El-Kalamouni, C.; Venskutonis, P.; Zebib, B.; Merah, O.; Raynaud, C.; Talou, T. Antioxidant and Antimicrobial Activities of the Essential Oil of Achillea Millefolium L. Grown in France. Medicines 2017, 4, 30. [Google Scholar] [CrossRef]

- Comunian, T.A.; Thomazini, M.; Alves, A.J.G.; de Matos Junior, F.E.; de Carvalho Balieiro, J.C.; Favaro-Trindade, C.S. Microencapsulation of Ascorbic Acid by Complex Coacervation: Protection and Controlled Release. Food Res. Int. 2013, 52, 373–379. [Google Scholar] [CrossRef]

- Alvim, I.D.; Grosso, C.R.F. Microparticles Obtained by Complex Coacervation: Influence of the Type of Reticulation and the Drying Process on the Release of the Core Material. Ciência Tecnol. Aliment. 2010, 30, 1069–1076. [Google Scholar] [CrossRef]

- Saravanan, M.; Rao, K.P. Pectin–Gelatin and Alginate–Gelatin Complex Coacervation for Controlled Drug Delivery: Influence of Anionic Polysaccharides and Drugs Being Encapsulated on Physicochemical Properties of Microcapsules. Carbohydr. Polym. 2010, 80, 808–816. [Google Scholar] [CrossRef]

- Rocha-Selmi, G.A.; Bozza, F.T.; Thomazini, M.; Bolini, H.M.A.; Fávaro-Trindade, C.S. Microencapsulation of Aspartame by Double Emulsion Followed by Complex Coacervation to Provide Protection and Prolong Sweetness. Food Chem. 2013, 139, 72–78. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Huang, L.; Xiong, X.; Qian, M.C.; Ji, H. Preparation and Release Mechanism of Lavender Oil Microcapsules with Different Combinations of Coating Materials. Flavour Fragr. J. 2020, 35, 157–166. [Google Scholar] [CrossRef]

- Baghi, F.; Ghnimi, S.; Dumas, E.; Gharsallaoui, A. Microencapsulation of Antimicrobial Trans-Cinnamaldehyde: Effect of Emulsifier Type, PH, and Drying Technique. Appl. Sci. 2023, 13, 6184. [Google Scholar] [CrossRef]

- Calderón-Oliver, M.; Pedroza-Islas, R.; Escalona-Buendía, H.B.; Pedraza-Chaverri, J.; Ponce-Alquicira, E. Comparative Study of the Microencapsulation by Complex Coacervation of Nisin in Combination with an Avocado Antioxidant Extract. Food Hydrocoll. 2017, 62, 49–57. [Google Scholar] [CrossRef]

- Shaddel, R.; Hesari, J.; Azadmard-Damirchi, S.; Hamishehkar, H.; Fathi-Achachlouei, B.; Huang, Q. Use of Gelatin and Gum Arabic for Encapsulation of Black Raspberry Anthocyanins by Complex Coacervation. Int. J. Biol. Macromol. 2018, 107, 1800–1810. [Google Scholar] [CrossRef]

- Musa, H.H.; Ahmed, A.A.; Musa, T.H. Chemistry, Biological, and Pharmacological Properties of Gum Arabic; Springer: Cham, Switzerland, 2019; pp. 797–814. [Google Scholar]

- Larkin, P.J. IR and Raman Spectra–Structure Correlations: Characteristic Group Frequencies. Infrared Raman Spectrosc. 2018, 85–134. [Google Scholar] [CrossRef]

- Rousi, Z.; Malhiac, C.; Fatouros, D.G.; Paraskevopoulou, A. Complex Coacervates Formation between Gelatin and Gum Arabic with Different Arabinogalactan Protein Fraction Content and Their Characterization. Food Hydrocoll. 2019, 96, 577–588. [Google Scholar] [CrossRef]

- Stuart, B.H. Infrared Spectroscopy: Fundamentals and Applications. In Analytical Techniques in the Sciences; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2004; pp. 71–80. ISBN 9780470854273. [Google Scholar]

- Long, Y.; Song, K.; York, D.; Zhang, Z.; Preece, J.A. Composite Microcapsules with Enhanced Mechanical Stability and Reduced Active Ingredient Leakage. Particuology 2016, 26, 40–46. [Google Scholar] [CrossRef]

- Santos, M.G.; Bozza, F.T.; Thomazini, M.; Favaro-Trindade, C.S. Microencapsulation of Xylitol by Double Emulsion Followed by Complex Coacervation. Food Chem. 2015, 171, 32–39. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Saidi, G.; Guizani, N.; Abdullah, A. Development of State Diagram of Bovine Gelatin by Measuring Thermal Characteristics Using Differential Scanning Calorimetry (DSC) and Cooling Curve Method. Thermochim. Acta 2010, 509, 111–119. [Google Scholar] [CrossRef]

- Ang, L.; Darwis, Y.; Por, L.; Yam, M. Microencapsulation Curcuminoids for Effective Delivery in Pharmaceutical Application. Pharmaceutics 2019, 11, 451. [Google Scholar] [CrossRef]

- Yüksel, A.; Şahin-Yeşilçubuk, N. Encapsulation of Structured Lipids Containing Medium- and Long Chain Fatty Acids by Complex Coacervation of Gelatin and Gum Arabic. J. Food Process Eng. 2018, 41, e12907. [Google Scholar] [CrossRef]

- Outuki, P.M.; de Francisco, L.M.B.; Hoscheid, J.; Bonifácio, K.L.; Barbosa, D.S.; Cardoso, M.L.C. Development of Arabic and Xanthan Gum Microparticles Loaded with an Extract of Eschweilera Nana Miers Leaves with Antioxidant Capacity. Colloids Surfaces A Physicochem. Eng. Asp. 2016, 499, 103–112. [Google Scholar] [CrossRef]

- Singh, B.; Sharma, S.; Dhiman, A. Acacia Gum Polysaccharide Based Hydrogel Wound Dressings: Synthesis, Characterization, Drug Delivery and Biomedical Properties. Carbohydr. Polym. 2017, 165, 294–303. [Google Scholar] [CrossRef]

- Daoub, R.M.A.; Elmubarak, A.H.; Misran, M.; Hassan, E.A.; Osman, M.E. Characterization and Functional Properties of Some Natural Acacia Gums. J. Saudi Soc. Agric. Sci. 2018, 17, 241–249. [Google Scholar] [CrossRef]

- Duhoranimana, E.; Karangwa, E.; Lai, L.; Xu, X.; Yu, J.; Xia, S.; Zhang, X.; Muhoza, B.; Habinshuti, I. Effect of Sodium Carboxymethyl Cellulose on Complex Coacervates Formation with Gelatin: Coacervates Characterization, Stabilization and Formation Mechanism. Food Hydrocoll. 2017, 69, 111–120. [Google Scholar] [CrossRef]

- Huang, G.Q.; Sun, Y.T.; Xiao, J.X.; Yang, J. Complex Coacervation of Soybean Protein Isolate and Chitosan. Food Chem. 2012, 135, 534–539. [Google Scholar] [CrossRef] [PubMed]

- Timilsena, Y.P.; Wang, B.; Adhikari, R.; Adhikari, B. Preparation and Characterization of Chia Seed Protein Isolate-Chia Seed Gum Complex Coacervates. Food Hydrocoll. 2015, 52, 554–563. [Google Scholar] [CrossRef]

| No. | Component | Obtained in | No. | Component | Obtained in | ||

|---|---|---|---|---|---|---|---|

| 2021 | 2022 | 2021 | 2022 | ||||

| % | % | ||||||

| 1. | alpha-pinene | 0.64 | 0.85 | 24. | caryophyllene | 16.39 | 12.88 |

| 2. | beta pinene | 6.10 | 12.45 | 25. | beta copaene | 0.29 | 0.26 |

| 3. | beta myrcene | 0.11 | 0.14 | 26. | humulene | 2.56 | 1.99 |

| 4. | 4-carene | 0.11 | 0.09 | 27. | cis beta farnesene | 0.14 | - |

| 5. | o-cymene | 0.13 | 0.23 | 28. | germacrene D | 21.28 | 21.13 |

| 6. | beta terpinene | - | 0.47 | 29. | beta selinene | - | 0.16 |

| 7. | eucalyptol | 3.38 | 3.81 | 30. | bicyclo germacrene | 2.08 | 1.62 |

| 8. | trans beta ocimene | 0.13 | 0.49 | 31. | alpha muurolene | 0.21 | 0.13 |

| 9. | beta ocimene | 0.15 | 0.40 | 32. | alpha farnesene | 0.16 | - |

| 10. | gamma terpinene | 0.49 | 0.38 | 33. | gamma muurolene | 0.42 | 0.27 |

| 11. | linalool | 0.45 | 0.13 | 34. | cadinene | 1.04 | 0.64 |

| 12. | alpha campholenal | - | 0.29 | 35. | nerolidol | 0.61 | 0.14 |

| 13. | pinocarveol | 0.25 | 0.23 | 36. | aromadendrane | 0.52 | 0.75 |

| 14. | camphor | 0.11 | 0.15 | 37. | caryophyllene oxide | 3.02 | 3.38 |

| 15. | pinocarvone | 0.78 | 1.13 | 38. | valerena-4,7(11)-diene | 0.35 | - |

| 16. | terpinen-4-ol | 0.49 | - | 39. | alpha elemene | 0.22 | - |

| 17. | alpha terpineol | 1.05 | 0.43 | 40. | alloaromadendrene | 0.17 | 0.1 |

| 18. | 3-carene | 1.16 | 0.29 | 41. | tau cadinol | 0.53 | 0.42 |

| 19. | lavandulyl propionate | 0.22 | - | 42. | alpha cadinol | 0.36 | 0.47 |

| 20. | eugenol | 0.13 | - | 43. | chamazulene | 21.97 | 25.37 |

| 21. | gamma limonene | 0.68 | - | 44. | homosalate | 0.14 | - |

| 22. | alfa copaene | 0.21 | 0.29 | 45. | geranil alpha terpinene | 0.43 | 1.45 |

| 23. | beta bourbonene | 0.45 | 2.09 | 46. | trans alpha bergamotene | 0.23 | 0.59 |

| Total identified | 90.34 | 96.09 | |||||

| No. | Compound 1 | AMO Peak% (Bulgarian Market) | No. | Compound 1 | AMO Peak% (Bulgarian Market) |

|---|---|---|---|---|---|

| 1. | thujene | 1.08 | 24. | D-carvone | 0.60 |

| 2. | alpha pinene | 4.47 | 25. | piperitone | 5.85 |

| 3. | camphene | 0.60 | 26. | sabinil acetate trans | 0.32 |

| 4. | sabinene | 8.31 | 27. | bornyl acetate | 2.68 |

| 5. | beta pinene | 8.59 | 28. | thymol | 1.31 |

| 6. | beta myrcene | 0.41 | 29. | diosphenol | 0.40 |

| 7. | alpha terpinene | 0.47 | 30. | carvacrol | 1.41 |

| 8. | p cymene | 1.55 | 31. | piperitenone | 0.52 |

| 9. | D limonene | 2.14 | 32. | 4-Acetyl-1-methylcyclohexene | 1.86 |

| 10. | eucalyptol | 5.09 | 33. | beta bourbonene | 0.76 |

| 11. | gamma terpinene | 2.18 | 34. | beta elemene | 0.54 |

| 12. | artemisia keton | 1.93 | 35. | caryophyllene | 7.74 |

| 13. | terpinolene | 0.32 | 36. | humulene | 1.57 |

| 14. | linalool | 6.78 | 37. | beta farnesene | 1.07 |

| 15. | alpha thujone | 2.84 | 38. | gamma muurolene | 0.28 |

| 16. | beta thujone | 0.46 | 39. | germacrene D | 6.10 |

| 17. | 2-bornanone (camphor) | 7.84 | 40. | trans alpha bergamotene | 0.63 |

| 18. | 1-menthone | 0.27 | 41. | cis-γ-Bisabolene | 0.38 |

| 19. | endo borneol | 1.77 | 42. | cadinene | 0.79 |

| 20. | terpinen 4-ol | 1.66 | 43. | caryophyllene oxide | 1.09 |

| 21. | alpha terpineol | 0.42 | 44. | bisabolon oxide A | 0.20 |

| 22. | cis dihydrocarvone | 0.56 | 45. | chamazulene | 3.80 |

| 23. | pulegone | 0.30 | Total identified | 99.94% |

| No. | Compound 1 | AMO Peak% (Romanian Market) |

|---|---|---|

| 1. | thujene | 0.08 |

| 2. | alpha pinene | 17.93 |

| 3. | camphene | 0.36 |

| 4. | sabinene | 2.82 |

| 5. | beta-pinene | 2.76 |

| 6. | beta myrcene | 1.47 |

| 7. | p-cymene | 0.15 |

| 8. | limonene | 3.34 |

| 9. | 1,8 cineole | 7.37 |

| 10. | gamma terpinene | 0.07 |

| 11. | fenchone | 27.22 |

| 12. | linalool | 2.57 |

| 13. | alpha thujone | 2.99 |

| 14. | beta-thujone | 0.42 |

| 15. | terpinen-4-ol | 0.12 |

| 16. | geraniol | 2.29 |

| 17. | beta bourbonene | 0.06 |

| 18. | beta farnesene | 4.48 |

| 19. | germacrene D | 0.39 |

| 20. | gamma elemene | 0.23 |

| 21. | gamma cadinene | 0.10 |

| 22. | delta cadinene | 0.11 |

| 23. | spathulenol | 0.25 |

| 24. | tau cadinol | 0.30 |

| 25. | bisabolol oxide B | 2.26 |

| 26. | bisabolon oxide A; | 2.43 |

| 27. | chamazulene | 0.46 |

| 28. | estragole | 15.36 |

| Total identified | 98.39% |

| Country/ Region | The Five Most Abundant Components Identified in Yarrow Essential Oil (Relative Amount) | Yield | Authors | Refs. | ||||

|---|---|---|---|---|---|---|---|---|

| Romania (western part) | chamazulene (38.89%) | germacrene D (12.90%) | β-caryophyllene (11.52%) | β-pinene (10.66%) | n.d.* | 0.47% | Jianu et al. | [45] |

| Romania (north-western) | Flowers | Costescu et al. | [46] | |||||

| β-pinene (17.2%) | chamazulene (12.9%) | β-phellandrene (12.1%) | 1,8-cineole (6.8%) | β-caryophyllene (6.0%) | 0.5% | |||

| Leaves | ||||||||

| α-bisabolol (16.0%) | β-pinene (9.9%) | chamazulene (9.7%) | β-phellandrene (8.0%) | 1,8-cineole (7.7%) | 0.7% | |||

| Root | ||||||||

| chamazulene (33.82%) | α-bisabolol (10.27%) | β-caryophyllene (5.04%) | caryophyllene oxide (4.43%) | β -pinene (4.2%) | 0.9% | |||

| Stem | ||||||||

| chamazulene (45.79%) | β-caryophyllene (7.67%) | β-cubebene (5.6%) | ledol (3.24%) | β-phellandrene (3.18%) | 1.2% | |||

| Egypt (west of Nile delta) | β-pinene (24.1–54.6%) | chamazulene (10.1–26.7%) | germacrene D (1.3–10.3%) | β-caryophyllene (11.52%) | limonene (6.4–11.9%) | 0.067–0.186% | Aziz et al. | [1] |

| Turkey (Eastern Anatolia) | 1,8-cineole (75.19%) | α-phellandrene (5.53%) | p-eugenol (5.53%) | camphor (5.45%) | α-terpineol (2.09%) | n.d.* | Yildirim et al. | [47] |

| Iran (El.: 1339 m, Lat. east: 33.638, Long. n | borneol (20.14–36.35%) | thymol (10.01–10.14%) | carvacrol (8.14–10.14%) | α-pinene (6.45–7.45%) | camphene (2.14–4.65%) | 1.54% v/w, 2.01% v/w | Abdossi and Kazemi | [48] |

| Iran (West Azerbaijan Province) | 1,8-cineole (21.28–34.51%) | camphor (7.27–14.07%) | chamazulene (4.18–11.34%) | α-eudesmol (2.09–9.63%) | α-cadinol (2.35–7.73%) | 0.14–0.24% v/w | Farhadi et al. | [49] |

| Portugal (Lisbon botanical garden) | Flowers | Figueiredo et al. | [50] | |||||

| 1,8-cineole (28.7%) | sabinene (15.4%) | terpinene-4-ol (3.4%) | camphor (3.3%) | γ-terpinene (3.2%) | 0.2% v/w | |||

| Leaves during flowering | ||||||||

| 1,8-cineole (24.5%) | trans-sabinene hydrate (10.2%) | germacrene D (7.2%) | terpinene-4-ol (5.6%) | sabinene (5.4%) | 0.2% v/w | |||

| Leaves during vegetative period | ||||||||

| germacrene D (65.1%) | α-farnesene (12.0%) | δ-elemene (4.6%) | bicyclogermacrene (3.7%) | β-caryophyllene (2.1%) | 0.1% v/w | |||

| Serbia (southern part) | 1,8-cineole (28.8%) | camphor (11.0%) | borneol (5.9%) | β-pinene (5.4%) | caryophyllene oxide (3.3%) | n.d.* | Smelcerovic et al. | [10] |

| Brazil (Umuarama, Parana State) | α-farnesene (31.66%) | chamazulene (17.17%) | β-caryophyllene (10.27%) | sabinene (8.77%) | bicyclo-germacrene (5.84%) | 0.4% | Daniel et al. | [51] |

| Estonia | β-pinene (14.9–29.2%) | 1,8-cineole (6.9–18.3%) | sabinene (2.9–17.6%) | chamazulene (0.1–12.7%) | guaiol (0.3–11.8%) | 2–4 mg/g | Orav et al. | [6] |

| India (subtropical region) | germacrene D (1.1–46.6%) | sabinene (4.0–38.9%) | borneol (4.7–24.9%) | camphor (0.6–17.6%) | α-pinene (0.8–11.7%) | 0.10–0.70% | Verma et al. | [52] |

| Serbia (saline habitats: northern parts—Vojvodina province) | trans-chrysanthenyl acetate (5.84–21.33%) | chamazulene (1.51–15.84%) | lavandulyl acetate (0.90–14.88%) | trans-caryophyllene (7.57–9.53%) | β-pinene (3.18–8.89%) | 0.32–1.01% | Stevanovic et al. | [2] |

| Poland (south eastern part) | Flowers | 0.598% | Konarska et al. | [53] | ||||

| β-pinene (12.22%) | (E)-nerolidol (7.34%) | 1,8-cineole (6.45%) | sabinene (6.04%) | camphor (5.28%) | ||||

| Herb | 0.235% | |||||||

| β-pinene (9.90%) | bornyl acetate (9.23%) | borneol (6.18%) | 1,8-cineole (5.83%) | camphor (5.81%) | ||||

| France (Midi-Pyrenees region Toulouse) | camphor (12.8%) | germacrene D (12.0%) | (E)–nerolidol (7.3%) | sabinene (6.7%) | (E)-p-metha-2,8-dien-1-ol (4.5%) | 0.07% (raported to fresh weight) | El-Kalamouni et al. | [54] |

| Saudi Arabia | Stems | 0.33% | Mohammed et al. | [20] | ||||

| α-Thujone (29.54%) | β-Thujone (18.05%) | 1,8-cineole (14.19%) | Trans-sabinene hydrate (3.70%) | |||||

| Leaves | 0.65% | |||||||

| α-Thujone (37.02%) | β-Thujone (21.58%) | 1,8-cineole (13.90%) | Trans-sabinene hydrate (8.29%) | Thymol (3.51%) | ||||

| Herb | 0.61% | |||||||

| α-Thujone (23.59%) | Germacrene D (14.73) | β-Thujone (14.70%) | Viridiflorol (10.62%) | 1,8-cineole (8.29%) | ||||

| Particle Size (µm) | SD | RSD% | Median (µm) | Polydispersity Index | ||

|---|---|---|---|---|---|---|

| Average 1 | Min. | Max. | ||||

| 47 | 14 | 132 | 20.71 | 44.31 | 42 | 0.20 |

| Yarrow Essential Oil in Microcapsules | AMO Concentration mg/mL 1 | Concentration of MC Solution mg/mL | Oil Content mg/100 mg MC | Total (Initial) Oil mg/100 mg MC | EE% | LC% |

|---|---|---|---|---|---|---|

| Total oil content | 5.961 | 15 | 39.74 | 40.29 | 87.60 | 35.29 |

| Surface oil content | 0.667 | 15 | 4.45 | 40.29 |

| No. | Compound | Free AMO Peak% | Microencapsulated AMO Peak% |

|---|---|---|---|

| 1. | thujene | 1.08 | 1.12 |

| 2. | alpha pinene | 4.47 | 4.68 |

| 3. | camphene | 0.60 | 0.51 |

| 4. | sabinene | 8.31 | 9.05 |

| 5. | beta pinene | 8.59 | 10.81 |

| 6. | beta myrcene | 0.41 | - |

| 7. | alpha terpinene | 0.47 | - |

| 8. | p cymene | 1.55 | 1.44 |

| 9. | D limonene | 2.14 | 1.79 |

| 10. | eucalyptol | 5.09 | 2.73 |

| 11. | gamma-terpinene | 2.18 | 1.88 |

| 12. | artemisia ketone | 1.93 | 1.87 |

| 13. | terpinolene | 0.32 | - |

| 14. | linalool | 6.78 | 6.00 |

| 15. | alpha thujone | 2.84 | 3.04 |

| 16. | beta thujone | 0.46 | - |

| 17. | 2-bornanone (camphor) | 7.84 | 6.68 |

| 18. | 1-menthone | 0.27 | - |

| 19. | endo borneol | 1.77 | 1.75 |

| 20. | terpinen 4-ol | 1.66 | 1.16 |

| 21. | alpha terpineol | 0.42 | - |

| 22. | cis dihydrocarvone | 0.56 | 0.43 |

| 23. | pulegone | 0.30 | - |

| 24. | D-carvone | 0.60 | 0.53 |

| 25. | piperitone | 5.85 | 4.72 |

| 26. | sabinil acetate trans | 0.32 | - |

| 27. | bornyl acetate | 2.68 | 3.74 |

| 28. | thymol | 1.31 | 2.25 |

| 29. | diosphenol | 0.40 | - |

| 30. | carvacrol | 1.41 | 1.27 |

| 31. | piperitenone | 0.52 | - |

| 32. | 4-acetyl-1-methylcyclohexene | 1.86 | 0.98 |

| 33. | beta bourbonene | 0.76 | 0.71 |

| 34. | beta elemene | 0.54 | 0.43 |

| 35. | caryophyllene | 7.74 | 9.82 |

| 36. | humulene | 1.57 | 1.74 |

| 37. | beta farnesene | 1.07 | 0.73 |

| 38. | gamma muurolene | 0.28 | - |

| 39. | germacrene D | 6.10 | 7.10 |

| 40. | trans alpha bergamotene | 0.63 | 0.33 |

| 41. | cis-γ-bisabolene | 0.38 | - |

| 42. | cadinene | 0.79 | 0.90 |

| 43. | caryophyllene oxide | 1.09 | 1.65 |

| 44. | bisabolon oxide A | 0.20 | 0.39 |

| 45. | chamazulene | 3.80 | 5.14 |

| Total | 99.94% | 97.37% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Székely-Szentmiklósi, I.; Rédai, E.M.; Kovács, B.; Gergely, A.-L.; Albert, C.; Szabó, Z.-I.; Székely-Szentmiklósi, B.; Sipos, E. Investigation of Yarrow Essential Oil Composition and Microencapsulation by Complex Coacervation Technology. Appl. Sci. 2024, 14, 7867. https://doi.org/10.3390/app14177867

Székely-Szentmiklósi I, Rédai EM, Kovács B, Gergely A-L, Albert C, Szabó Z-I, Székely-Szentmiklósi B, Sipos E. Investigation of Yarrow Essential Oil Composition and Microencapsulation by Complex Coacervation Technology. Applied Sciences. 2024; 14(17):7867. https://doi.org/10.3390/app14177867

Chicago/Turabian StyleSzékely-Szentmiklósi, István, Emőke Margit Rédai, Béla Kovács, Attila-Levente Gergely, Csilla Albert, Zoltán-István Szabó, Blanka Székely-Szentmiklósi, and Emese Sipos. 2024. "Investigation of Yarrow Essential Oil Composition and Microencapsulation by Complex Coacervation Technology" Applied Sciences 14, no. 17: 7867. https://doi.org/10.3390/app14177867

APA StyleSzékely-Szentmiklósi, I., Rédai, E. M., Kovács, B., Gergely, A.-L., Albert, C., Szabó, Z.-I., Székely-Szentmiklósi, B., & Sipos, E. (2024). Investigation of Yarrow Essential Oil Composition and Microencapsulation by Complex Coacervation Technology. Applied Sciences, 14(17), 7867. https://doi.org/10.3390/app14177867