Multimodal Interference-Based Fiber Optic Sensors for Glucose and Moisture Content Detection in Honey

Abstract

:1. Introduction

2. Theoretical Description

2.1. Multimode Interference (MMI) Sensor Principle

2.2. Rheological and Optical Characteristics of Honey

3. Materials and Methods

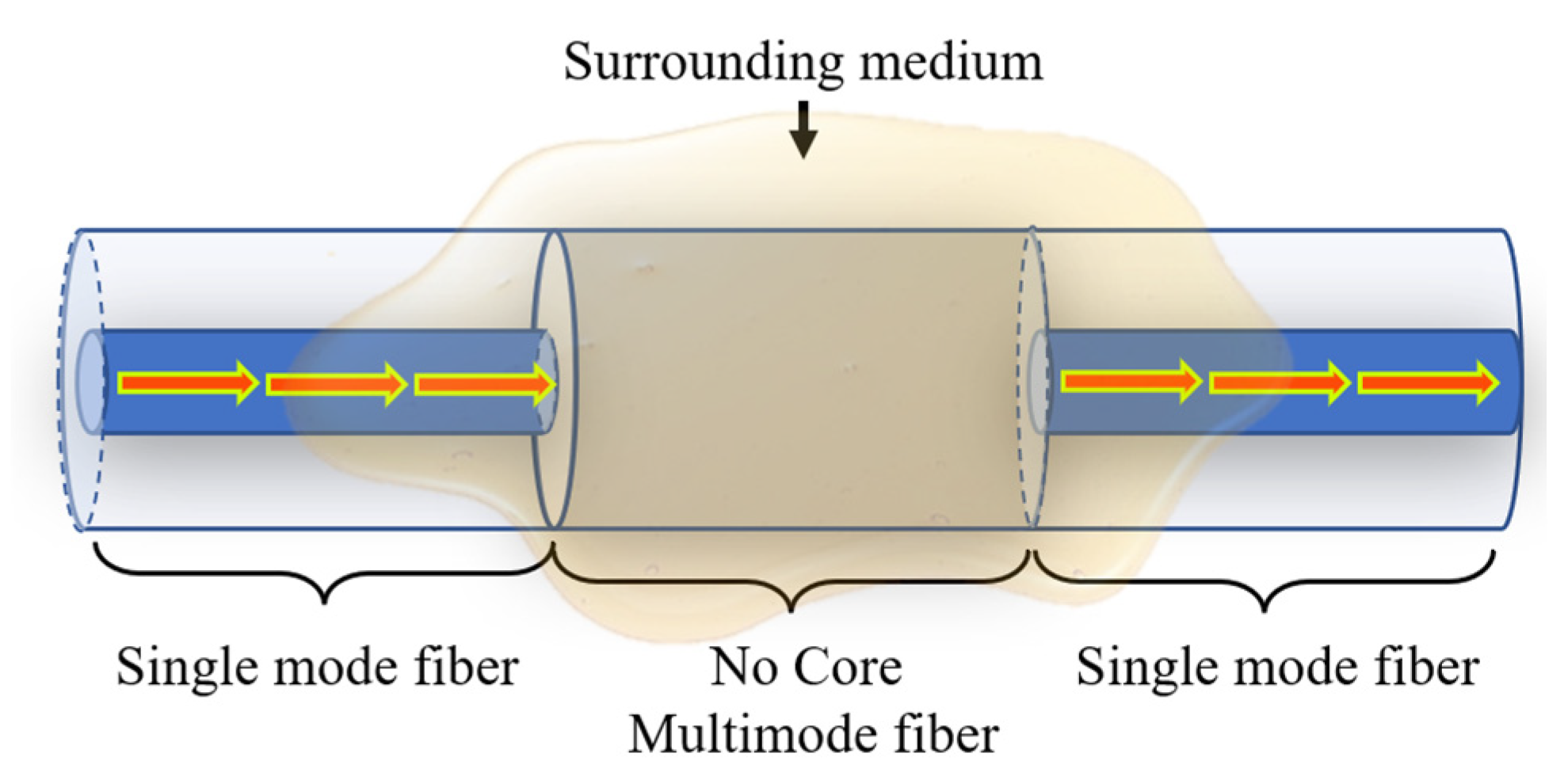

3.1. Sensor Fabrication and Experimental Set-Up

3.2. Samples Preparation

3.2.1. Preparation of Samples Adulterated with Glucose

3.2.2. Preparation of Honey Samples with Moisture Content

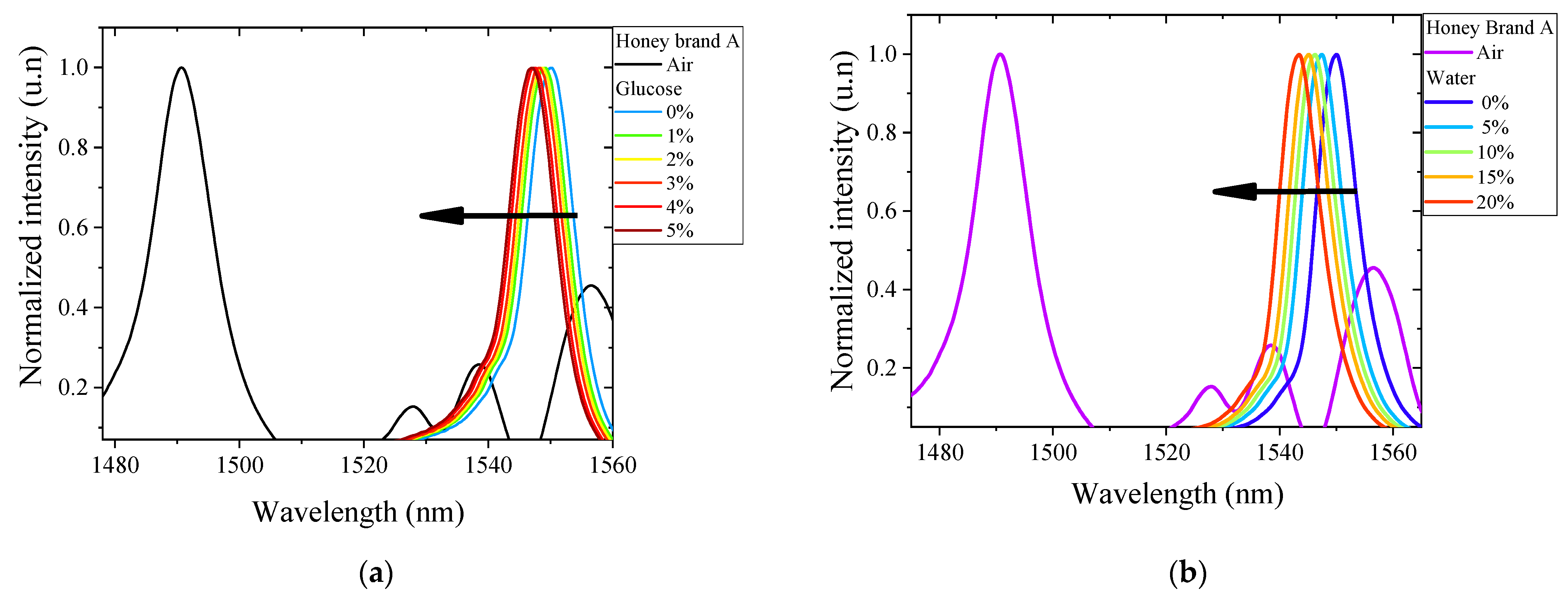

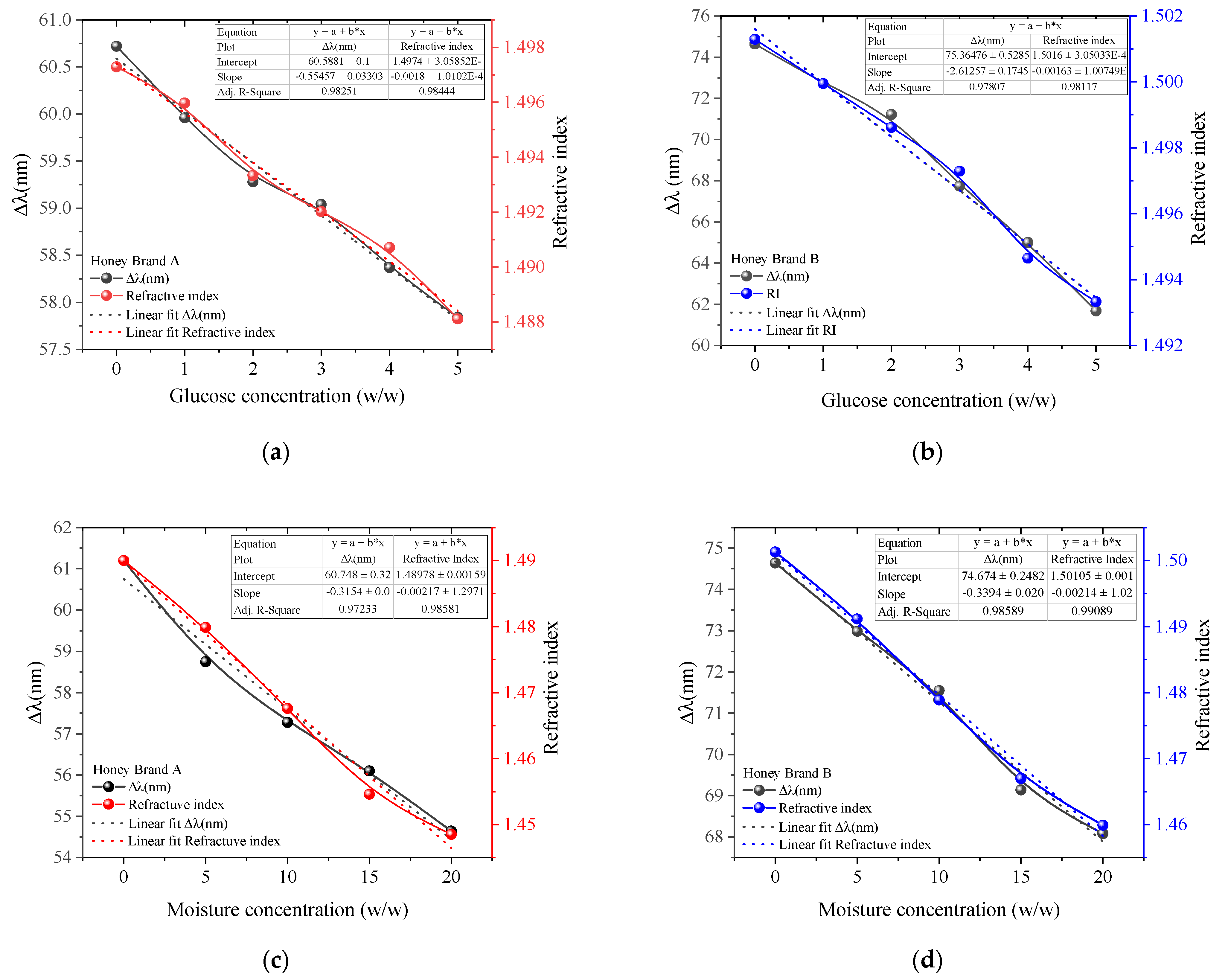

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gholamzadeh, B.; Nabovati, H. Fiber optic sensors. Int. J. Electron. Commun. Eng. 2008, 2, 1107–1117. [Google Scholar]

- Culshaw, B.; Kersey, A. Fiber-optic sensing: A historical perspective. J. Light. Technol. 2008, 26, 1064–1078. [Google Scholar] [CrossRef]

- Udd, E.; Spillman, W.B., Jr. Fiber Optic Sensors: An Introduction for Engineers and Scientists; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Al-Azzawi, A. Fiber Optics: Principles and Advanced Practices, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, R49–R61. [Google Scholar] [CrossRef]

- Zhang, T.; Zheng, Y.; Wang, C.; Mu, Z.; Liu, Y.; Lin, J. A review of photonic crystal fiber sensor applications for different physical quantities. Appl. Spectrosc. Rev. 2017, 53, 486–502. [Google Scholar] [CrossRef]

- Jarzebinska, R.; Cheung, C.S.; James, S.W.; Tatam, R.P. Response of the transmission spectrum of tapered optical fibres to the deposition of a nanostructured coating. Meas. Sci. Technol. 2009, 20, 034001. [Google Scholar] [CrossRef]

- Mehta, A.; Mohammed, W.; Johnson, E.G. Multimode interference-based fiber-optic displacement sensor. IEEE Photonics Technol. Lett. 2003, 15, 1129–1131. [Google Scholar] [CrossRef]

- Wang, K.; Dong, X.; Köhler, M.H.; Kienle, P.; Bian, Q.; Jakobi, M.; Koch, A.W.J.I.S.J. Advances in optical fiber sensors based on multimode interference (MMI): A review. IEEE Sens. J. 2020, 21, 132–142. [Google Scholar] [CrossRef]

- Guzmán-Sepúlveda, J.R.; Guzmán-Cabrera, R.; Castillo-Guzmán, A.A.J.S. Optical sensing using fiber-optic multimode interference devices: A review of nonconventional sensing schemes. Sensors 2021, 21, 1862. [Google Scholar] [CrossRef]

- Rivero, P.J.; Goicoechea, J.; Arregui, F.J. Localized Surface Plasmon Resonance for Optical Fiber-Sensing Applications; InTech: Nappanee, IN, USA, 2017. [Google Scholar]

- Narsaiah, K.; Jha, S.N.; Bhardwaj, R.; Sharma, R.; Kumar, R. Optical biosensors for food quality and safety assurance-a review. J. Food Sci. Technol. 2012, 49, 383–406. [Google Scholar] [CrossRef]

- Verissimo, M.I.S.; Gamelas, J.A.F.; Fernandes, A.J.S.; Evtuguin, D.V.; Gomes, M. A new formaldehyde optical sensor: Detecting milk adulteration. Food Chem. 2020, 318, 126461. [Google Scholar] [CrossRef] [PubMed]

- Fuentes-Rubio, Y.A.; Zuniga-Avalos, Y.A.; Guzman-Sepulveda, J.R.; Dominguez-Cruz, R.F. Refractometric Detection of Adulterated Milk Based on Multimode Interference Effects. Foods 2022, 11, 1075. [Google Scholar] [CrossRef] [PubMed]

- Fakhlaei, R.; Selamat, J.; Khatib, A.; Razis, A.F.A.; Sukor, R.; Ahmad, S.; Babadi, A.A. The Toxic Impact of Honey Adulteration: A Review. Foods 2020, 9, 1538. [Google Scholar] [CrossRef] [PubMed]

- Jaafar, M.B.; Othman, M.B.; Yaacob, M.; Talip, B.A.; Ilyas, M.A.; Ngajikin, N.H.; Fauzi, N.A.M. A Review on Honey Adulteration and the Available Detection Approaches. Int. J. Integr. Eng. 2020, 12, 125–131. [Google Scholar] [CrossRef]

- Zak, N.; Wilczynska, A. The Importance of Testing the Quality and Authenticity of Food Products: The Example of Honey. Foods 2023, 12, 3210. [Google Scholar] [CrossRef] [PubMed]

- Soares, S.; Amaral, J.S.; Oliveira, M.; Mafra, I. A Comprehensive Review on the Main Honey Authentication Issues: Production and Origin. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1072–1100. [Google Scholar] [CrossRef]

- Bogdanov, S. Authenticity of honey and other bee products: State of the art. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca 2007, 63, 64. [Google Scholar]

- Seraglio, S.K.T.; Bergamo, G.; Molognoni, L.; Daguer, H.; Silva, B.; Gonzaga, L.V.; Fett, R.; Costa, A.C.O. Quality changes during long-term storage of a peculiar Brazilian honeydew honey: “Bracatinga”. J. Food Compos. Anal. 2021, 97, 103769. [Google Scholar] [CrossRef]

- Acquarone, C.; Buera, P.; Elizalde, B. Pattern of pH and electrical conductivity upon honey dilution as a complementary tool for discriminating geographical origin of honeys. Food Chem. 2007, 101, 695–703. [Google Scholar] [CrossRef]

- Mantha, M.; Urban, J.R.; Mark, W.A.; Chernyshev, A.; Kubachka, K.M. Direct Comparison of Cavity Ring Down Spectrometry and Isotope Ratio Mass Spectrometry for Detection of Sugar Adulteration in Honey Samples. J. AOAC Int. 2018, 101, 1857–1863. [Google Scholar] [CrossRef]

- Tosun, M. Detection of adulteration in honey samples added various sugar syrups with 13C/12C isotope ratio analysis method. Food Chem. 2013, 138, 1629–1632. [Google Scholar] [CrossRef] [PubMed]

- Cinar, S.B.; Eksi, A.; Coskun, I. Carbon isotope ratio (13C/12C) of pine honey and detection of HFCS adulteration. Food Chem. 2014, 157, 10–13. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.M.; Xue, X.F.; Du, X.J.; Cheng, N.; Chen, L.Z.; Zhao, J.; Zheng, J.B.; Cao, W. Identification of Acacia Honey Adulteration with Rape Honey Using Liquid Chromatography-Electrochemical Detection and Chemometrics. Food Anal. Method 2014, 7, 2003–2012. [Google Scholar] [CrossRef]

- Puscas, A.; Hosu, A.; Cimpoiu, C. Application of a newly developed and validated high-performance thin-layer chromatographic method to control honey adulteration. J. Chromatogr. A 2013, 1272, 132–135. [Google Scholar] [CrossRef] [PubMed]

- Gallardo-Velázquez, T.; Osorio-Revilla, G.; Loa, M.Z.-d.; Rivera-Espinoza, Y. Application of FTIR-HATR spectroscopy and multivariate analysis to the quantification of adulterants in Mexican honeys. Food Res. Int. 2009, 42, 313–318. [Google Scholar] [CrossRef]

- Roussel, S.; Bellon-Maurel, W.; Roger, J.M.; Grenier, P. Authenticating white grape must variety with classification models based on aroma sensors, FT-IR and UV spectrometry. J. Food Eng. 2003, 60, 407–419. [Google Scholar] [CrossRef]

- Isa, N.M.; Irawati, N.; Rosol, A.H.A.; Rahman, H.A.; Ismail, W.I.W.; Yusoff, M.H.M.; Naim, N.F. Silica Microfiber Sensor for the Detection of Honey Adulteration. Adv. Sci. Lett. 2017, 23, 5532–5535. [Google Scholar] [CrossRef]

- Bidin, N.; Zainuddin, N.H.; Islam, S.; Abdullah, M.; Marsin, F.M.; Yasin, M. Sugar detection in adulterated honey via fiber optic displacement sensor for food industrial applications. IEEE Sens. J. 2016, 16, 299–305. [Google Scholar] [CrossRef]

- Vikas; Yadav, M.K.; Kumar, P.; Verma, R.K. Detection of adulteration in pure honey utilizing Ag-graphene oxide coated fiber optic SPR probes. Food Chem. 2020, 332, 127346. [Google Scholar] [CrossRef]

- Rosli, N.N.F. Fibre optic displacement sensor for honey purity detection in distilled water. Enhanc. Knowl. Sci. Technol. 2022, 2, 328–336. [Google Scholar] [CrossRef]

- Hida, N.; Bidin, N.; Abdullah, M.; Yasin, M. Fiber optic displacement sensor for honey purity detection in distilled water. Optoelectron. Adv. Mater. 2013, 7, 565–568. [Google Scholar]

- Zhao, Y.; Zhao, J.; Zhao, Q. Review of no-core optical fiber sensor and applications. Sens. Actuators A Phys. 2020, 313, 112160. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, J.; Zhang, C.; Guo, C.; Bai, H.; Xu, W.; Chen, L.; Miao, C. Refractive Index Fiber Laser Sensor by Using Tunable Filter Based on No-Core Fiber. IEEE Photonics J. 2016, 8, 6805008. [Google Scholar] [CrossRef]

- Pachon, E.G.; Franco, M.A.; Cordeiro, C.M. Spectral bandwidth analysis of high sensitivity refractive index sensor based on multimode interference fiber device. In Proceedings of the OFS2012 22nd International Conference on Optical Fiber Sensors, Beijing, China, 15–19 October 2012; pp. 1208–1211. [Google Scholar]

- Mohammed, W.S.; Mehta, A.; Johnson, E.G. Wavelength Tunable Fiber Lens Based on Multimode Interference. J. Light. Technol. 2004, 22, 469–477. [Google Scholar] [CrossRef]

- Soldano, L.B.; Pennings, E.C.M. Optical multi-mode interference devices based on self-imaging: Principles and applications. J. Light. Technol. 1995, 13, 615–627. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G.; Yan, W. Investigation on Single-Mode–Multimode– Single-Mode Fiber Structure. J. Light. Technol. 2008, 26, 512–519. [Google Scholar] [CrossRef]

- Antonio-Lopez, J.E.; LiKamWa, P.; Sanchez-Mondragon, J.J.; May-Arrioja, D.A. All-fiber multimode interference micro-displacement sensor. Meas. Sci. Technol. 2013, 24, 055104. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.K.; Gupta, P.K.; Singh, A.; Sharma, S.K.; Bindra, K.S.; Oak, S.M. Note: Broadly tunable all-fiber ytterbium laser with 0.05 nm spectral width based on multimode interference filter. Rev. Sci. Instrum. 2014, 85, 056101. [Google Scholar] [CrossRef]

- Younus, S.I.; Al-Dergazly, A.A.; Abass, A. Characterization of Multimode Interference Based Optical Fiber. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; p. 012060. [Google Scholar]

- Okamoto, K. Fundamentals of Optical Waveguides; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Antonio-Lopez, J.E.; Sanchez-Mondragon, J.J.; LiKamWa, P.; May-Arrioja, D.A. Fiber-optic sensor for liquid level measurement. Opt. Lett. 2011, 36, 3425–3427. [Google Scholar] [CrossRef]

- Ma, L.; Qi, Y.; Kang, Z.; Bai, Y.; Jian, S. Tunable fiber laser based on the refractive index characteristic of MMI effects. Opt. Laser Technol. 2014, 57, 96–99. [Google Scholar] [CrossRef]

- Faustino, C.; Pinheiro, L. Analytical Rheology of Honey: A State-of-the-Art Review. Foods 2021, 10, 1709. [Google Scholar] [CrossRef] [PubMed]

- Bambang, N.; Ikhsan, M.; Sukri, N. Rheological Properties of Honey and its Application on Honey Flow Simulation through Vertical Tube. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012041. [Google Scholar]

- Machado De-Melo, A.A.; Almeida-Muradian, L.B.d.; Sancho, M.T.; Pascual-Maté, A. Composition and properties of Apis mellifera honey: A review. J. Apic. Res. 2017, 57, 5–37. [Google Scholar] [CrossRef]

- Bogdanov, S.; Lüllmann, C.; Martin, P.; von der Ohe, W.; Russmann, H.; Vorwohl, G.; Oddo, L.P.; Sabatini, A.-G.; Marcazzan, G.L.; Piro, R.; et al. Honey quality and international regulatory standards: Review by the International Honey Commission. Bee World 2015, 80, 61–69. [Google Scholar] [CrossRef]

- Mar-Abundis, N.; Fuentes-Rubio, Y.A.; Dominguez-Cruz, R.F.; Guzman-Sepulveda, J.R. Sugar Detection in Aqueous Solution Using an SMS Fiber Device. Sensors 2023, 23, 6289. [Google Scholar] [CrossRef] [PubMed]

- CXS 12-1981; Standard for Honey. Food and Agriculture Organization of the United Nations: Rome, Italy, 2019.

- NOM-004-SAG/GAN-2018; Producción de Miel y Especificaciones. Secretaría de Agricultura y Desarrollo Rural: Guadalajara, Mexico, 2020.

- Ruiz-Perez, V.I.; Velasco-Bolom, P.M.; May-Arrioja, D.A.; Sepulveda, J.R.G. Measuring the Thermo-Optic Coefficient of Liquids With Athermal Multimode Interference Devices. IEEE Sens. J. 2021, 21, 3004–3012. [Google Scholar] [CrossRef]

- Ruiz-Perez, V.I.; May-Arrioja, D.A.; Guzman-Sepulveda, J.R. An All-Solid Athermal Multimode-Interference Cascaded Device for Wavelength-Locking. IEEE Photonics Technol. Lett. 2018, 30, 669–672. [Google Scholar] [CrossRef]

| % Glucose | % Moisture Content | Standard Deviation |

|---|---|---|

| 1% | 0.13856 | |

| 3% | 0.24 | |

| 5% | 0.59003 | |

| 5% | 0.14142 | |

| 10% | 0.21046 | |

| 15% | 0.24170 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Rosas, M.A.; García-Guevara, Y.N.; Fuentes-Rubio, Y.A.; Domínguez-Cruz, R.F.; Baldovino-Pantaleón, O.; Romero-Galván, G. Multimodal Interference-Based Fiber Optic Sensors for Glucose and Moisture Content Detection in Honey. Appl. Sci. 2024, 14, 7914. https://doi.org/10.3390/app14177914

Pérez-Rosas MA, García-Guevara YN, Fuentes-Rubio YA, Domínguez-Cruz RF, Baldovino-Pantaleón O, Romero-Galván G. Multimodal Interference-Based Fiber Optic Sensors for Glucose and Moisture Content Detection in Honey. Applied Sciences. 2024; 14(17):7914. https://doi.org/10.3390/app14177914

Chicago/Turabian StylePérez-Rosas, Mayeli Anais, Yahir Nicolás García-Guevara, Yadira Aracely Fuentes-Rubio, René Fernando Domínguez-Cruz, Oscar Baldovino-Pantaleón, and Gerardo Romero-Galván. 2024. "Multimodal Interference-Based Fiber Optic Sensors for Glucose and Moisture Content Detection in Honey" Applied Sciences 14, no. 17: 7914. https://doi.org/10.3390/app14177914