Fast and Nondestructive Proximate Analysis of Coal from Hyperspectral Images with Machine Learning and Combined Spectra-Texture Features

Abstract

:1. Introduction

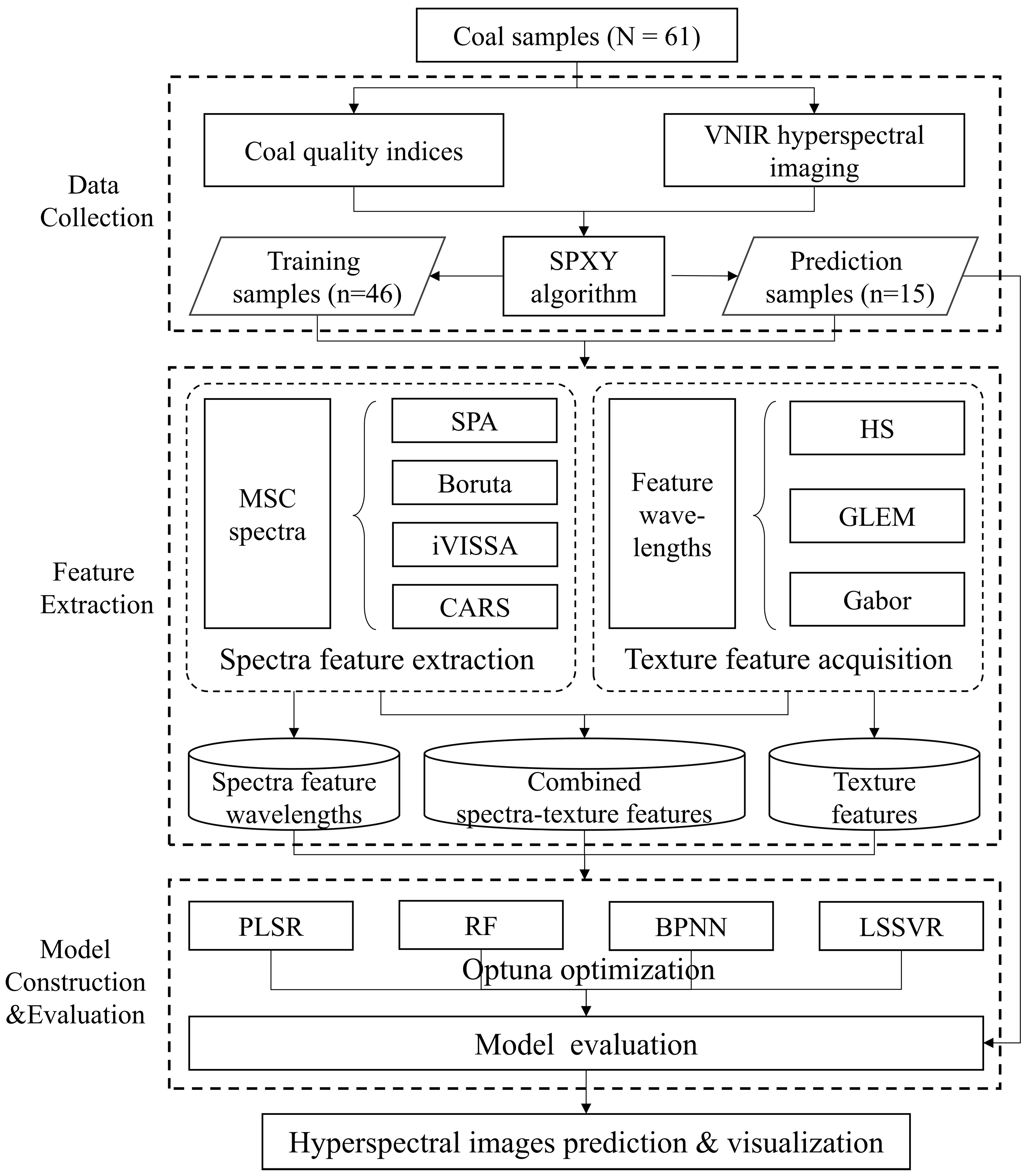

2. Materials and Methods

2.1. Sample Preparation

2.2. Hyperspectral Image Collection

2.2.1. Image Acquisition

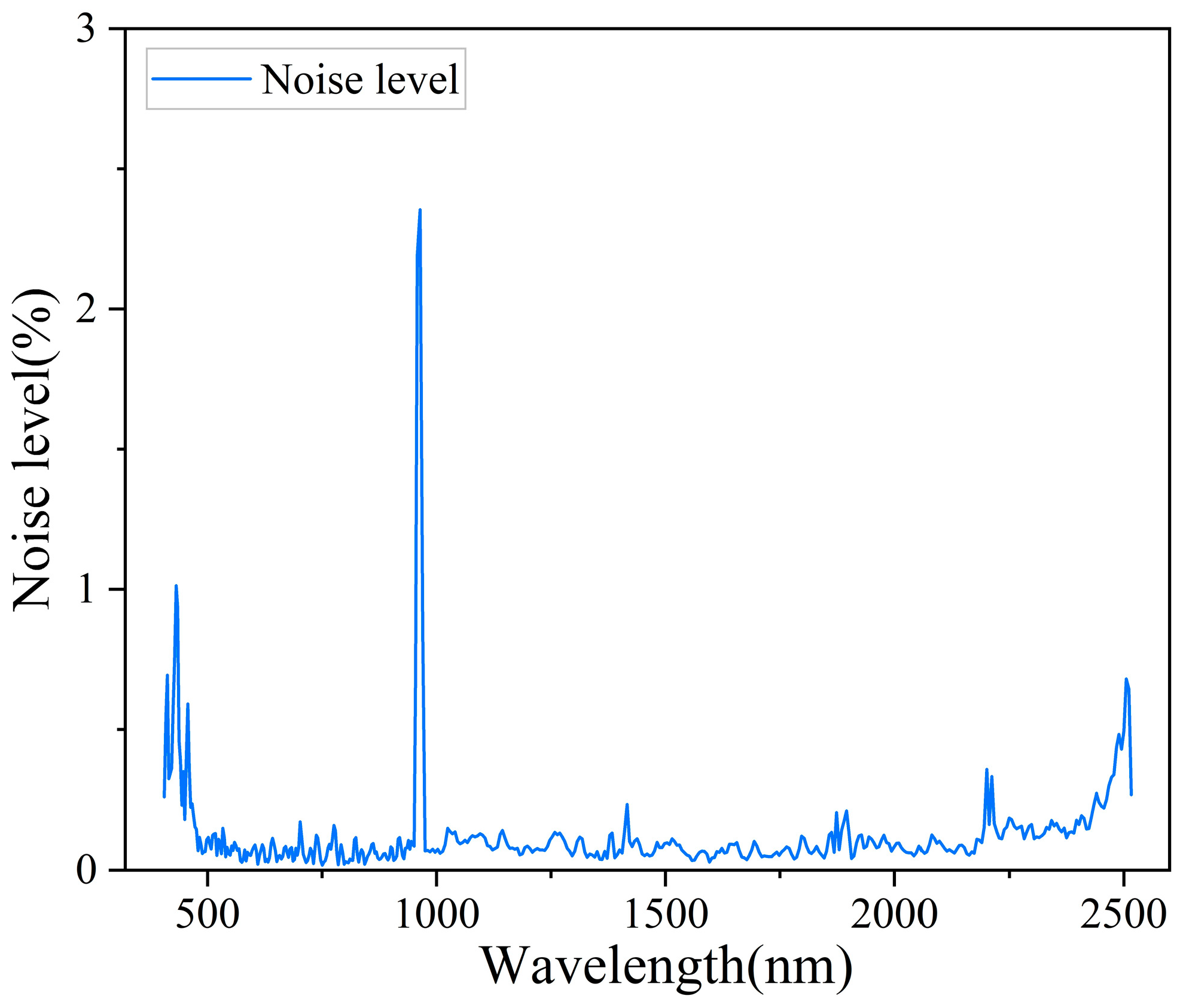

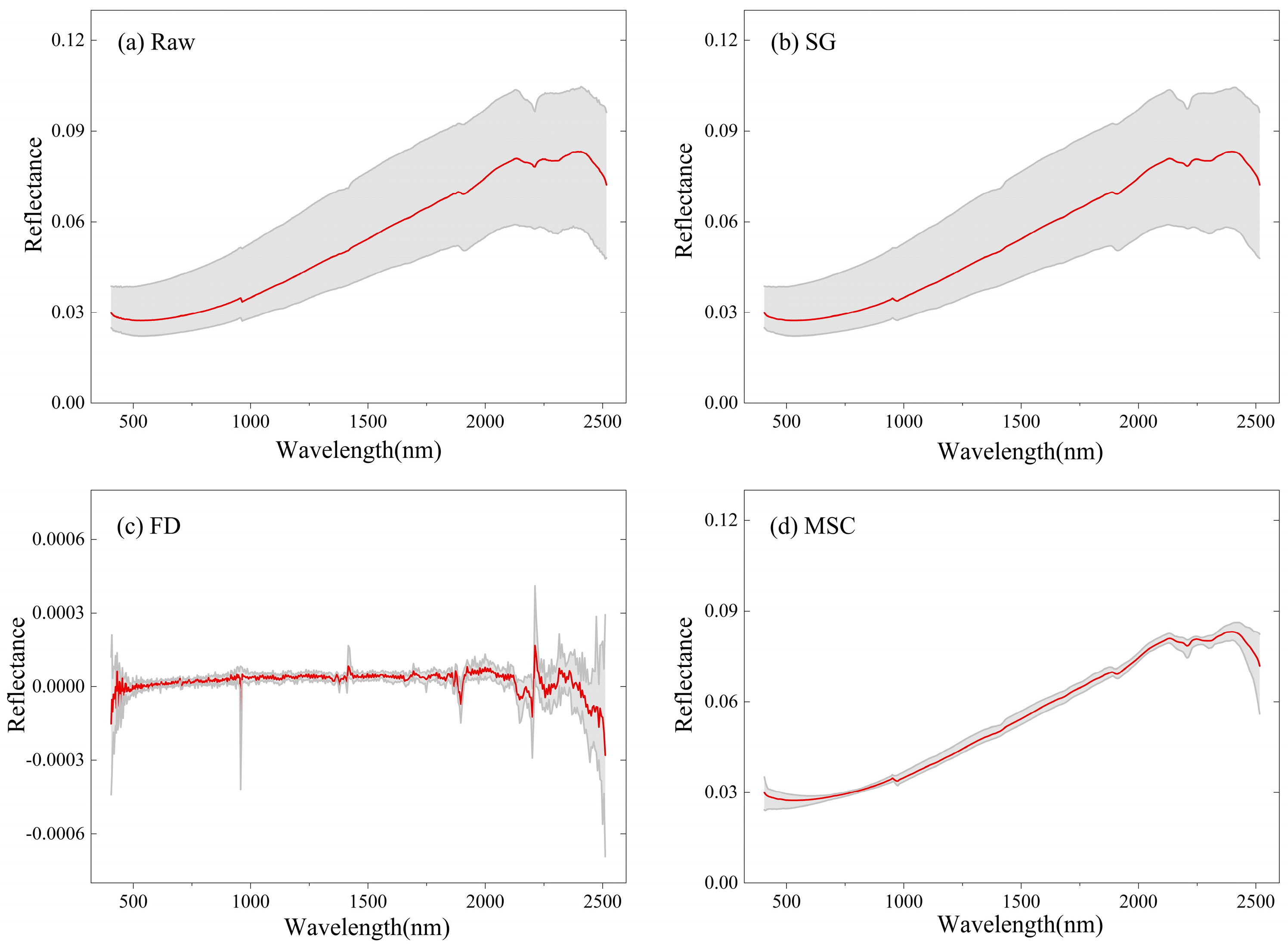

2.2.2. Data Preprocessing

2.3. Data Processing and Modeling Methods

2.3.1. Spectra Data Processing

2.3.2. Feature Wavelengths Selection

2.3.3. Extraction of Image Texture Features

2.4. Model Development

2.5. Model Performance Evaluation

2.6. Shapley Additive Explanations (SHAP)

2.7. Software

3. Results

3.1. Statistics Analysis of Coal Indices Reference

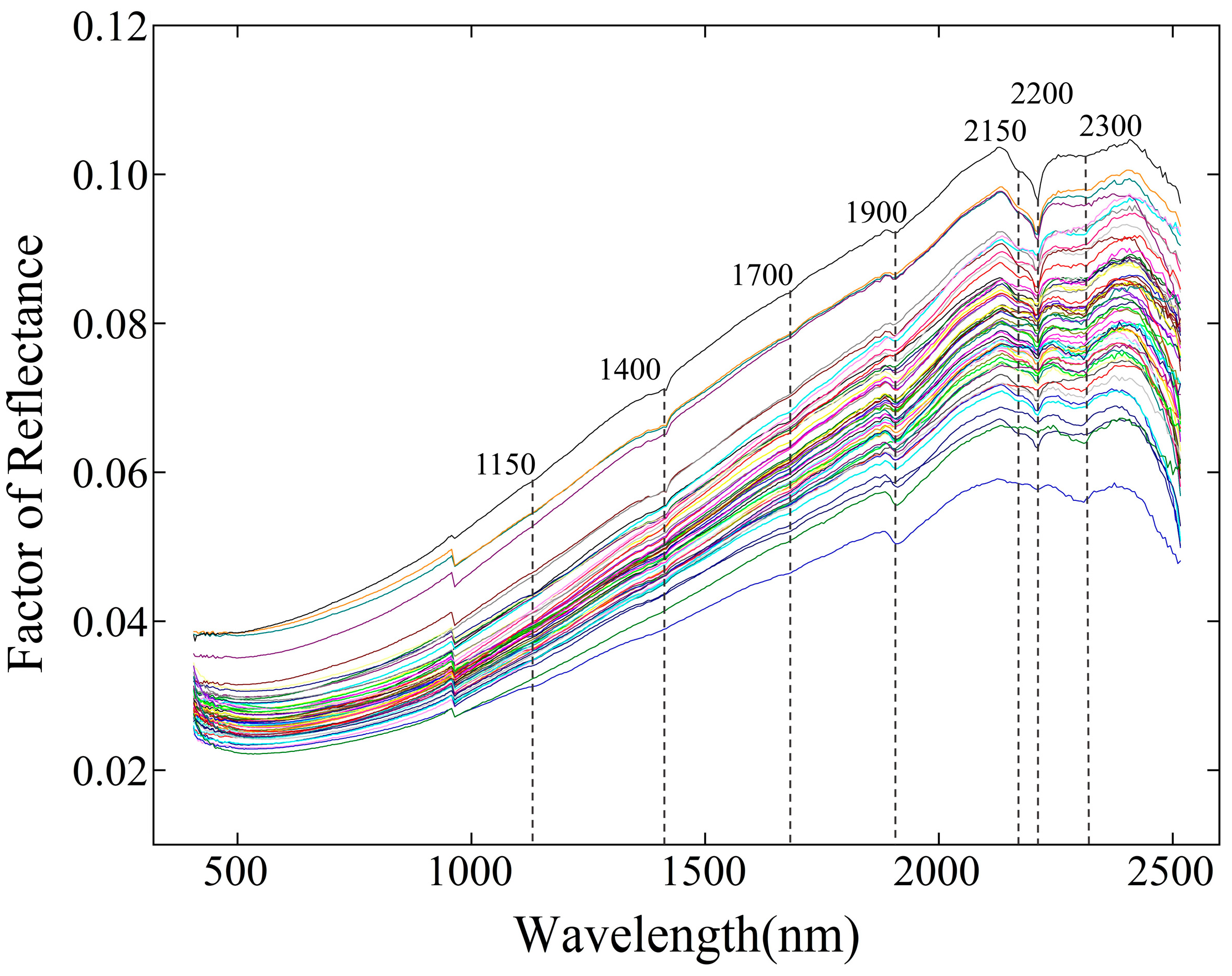

3.2. Spectra Analysis and Preprocessing Results

3.3. Results of Feature Wavelengths Extracted in Coal Spectra

3.4. Results of Combined Features by Wavelengths and Texture Information

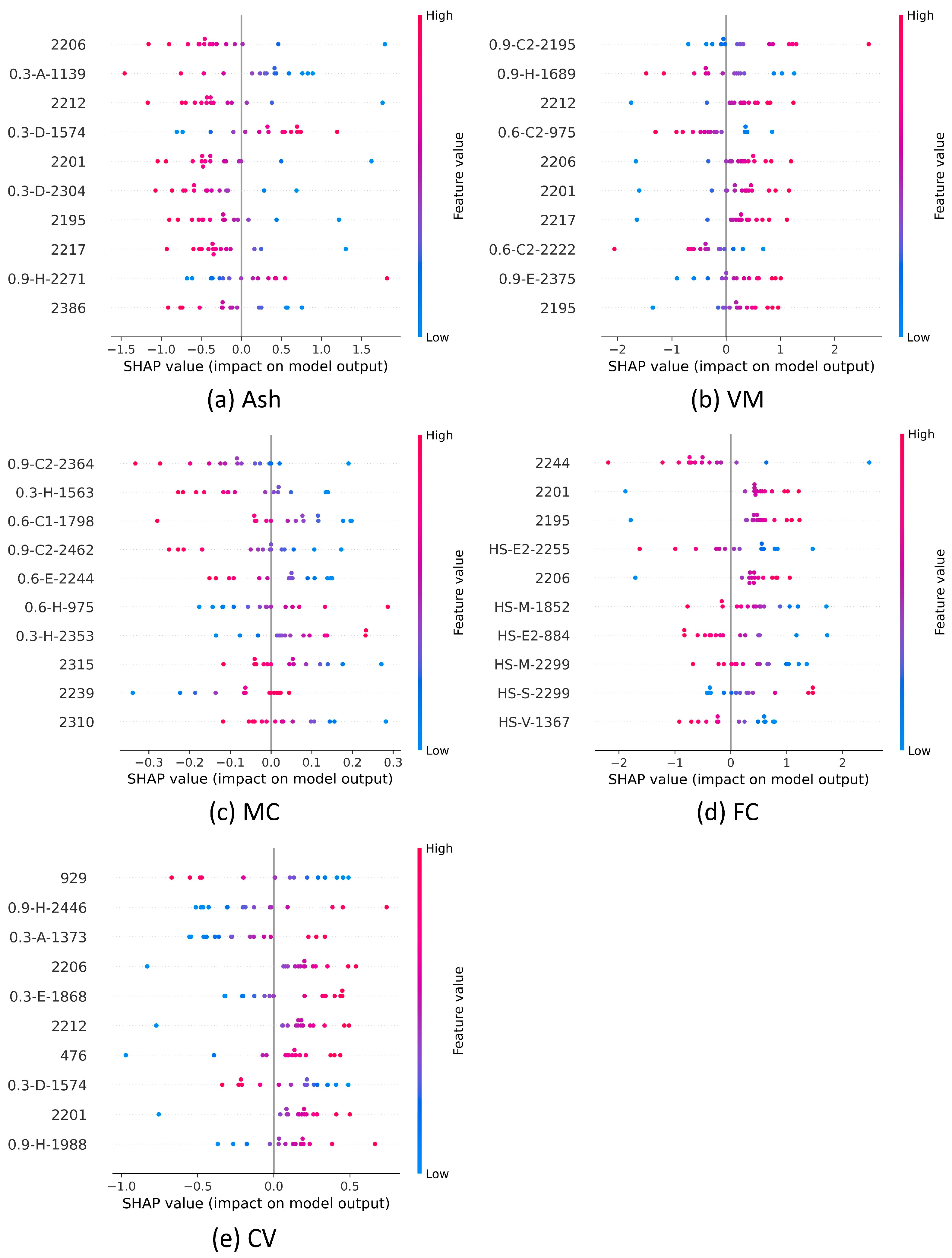

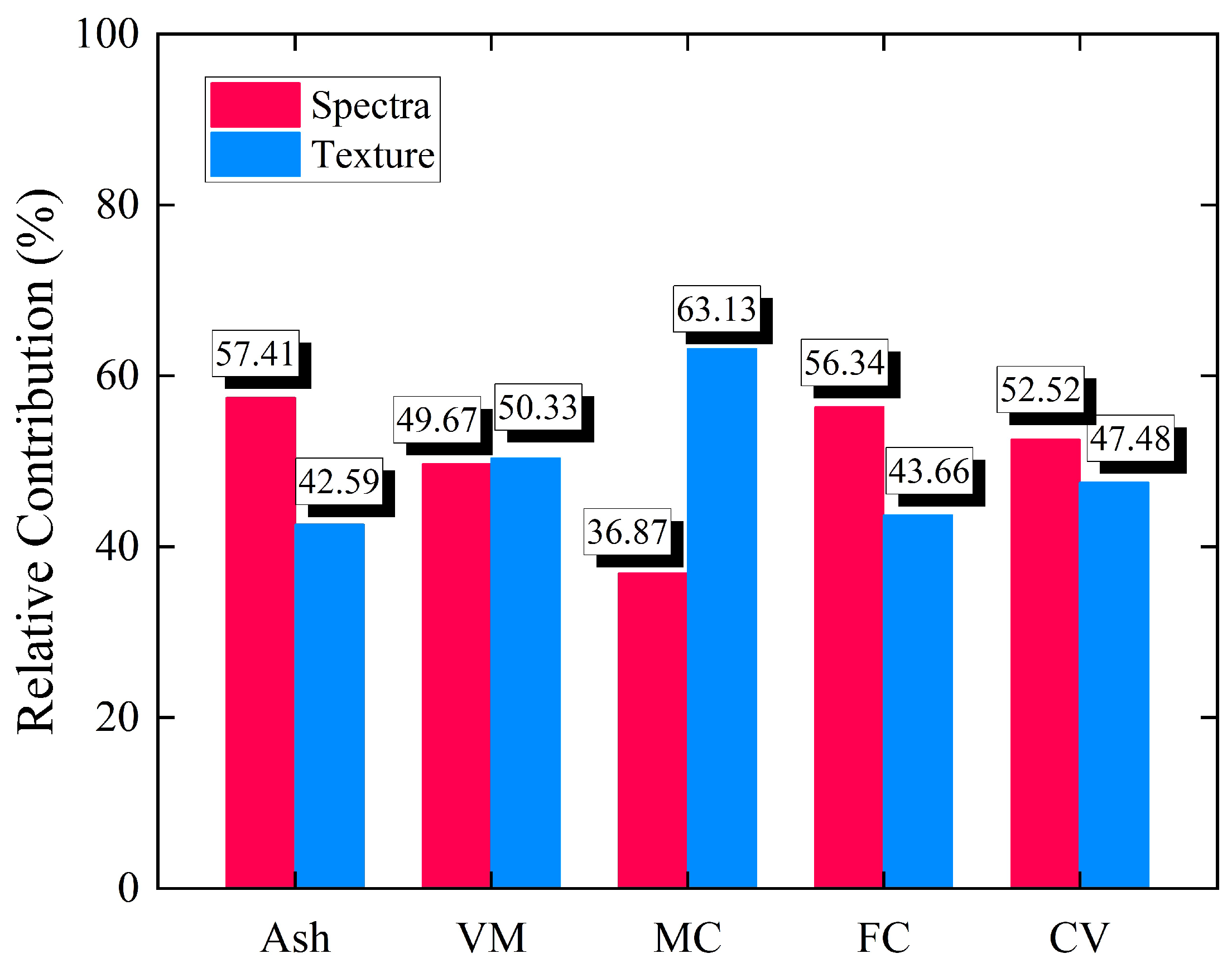

3.5. Influence of Variables on Coal Quality Indices

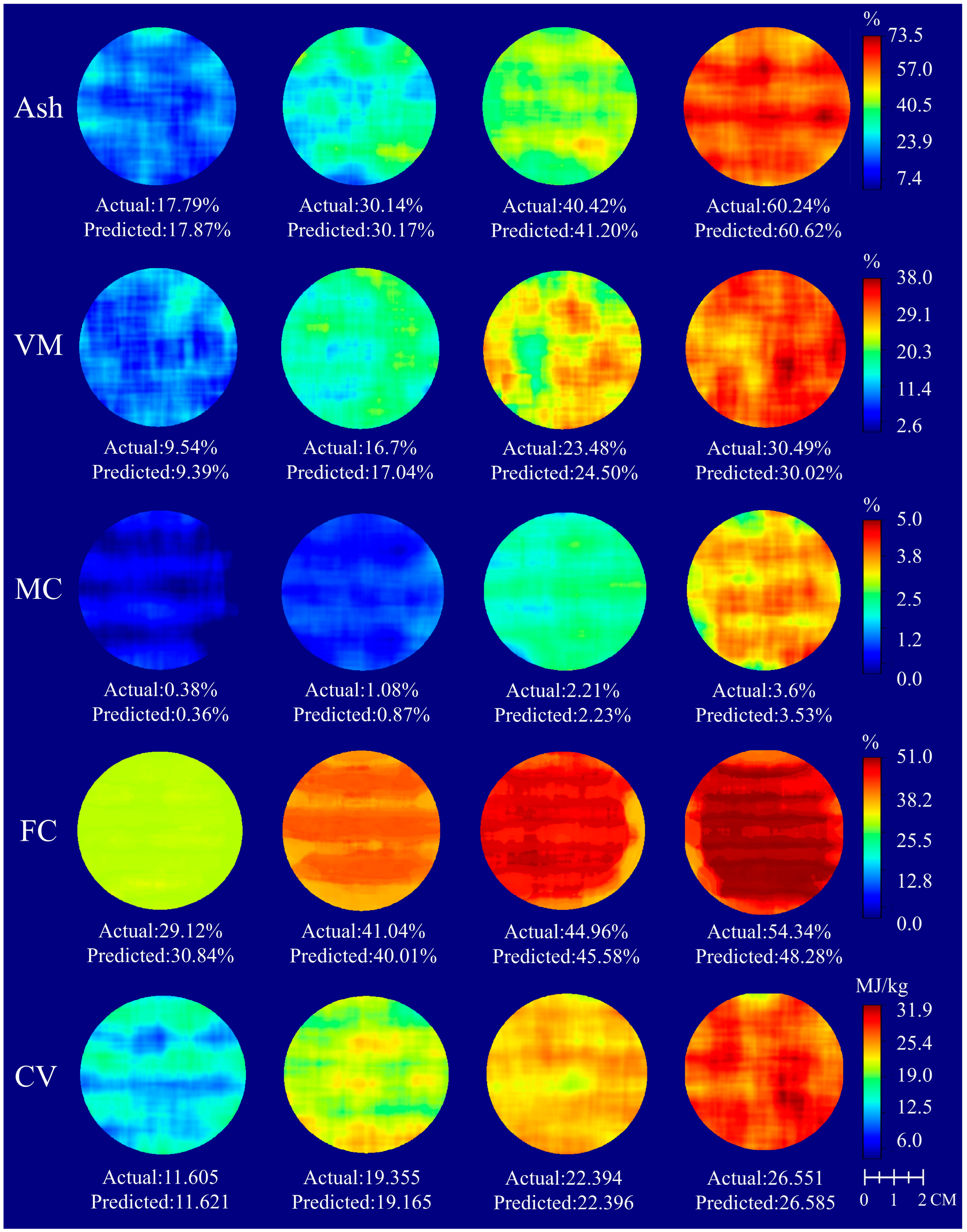

3.6. Visualization of Coal Quality Indices Distribution

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Models | Hyperparameter List | Range |

|---|---|---|

| PLSR | n_compoments | [2, min (5, n 1)] |

| RF | n_estimators | [55,300] step = 50 |

| max_depth | [2,23] step = 1 | |

| BPNN | Input_dim | n |

| hidden_dim | m1 | |

| output_dim | 1 | |

| learning_rate | [0.001, 0.5] | |

| LSSVR | Kernel | ‘linear’, ‘rbf’ |

| C | [0.1, 30.0] | |

| Gamma | [Sqrt(n)/2, Sqrt(n), Sqrt(n)×2] |

References

- IEA. Coal. 2023. Available online: https://www.iea.org/reports/coal-2023 (accessed on 14 August 2024).

- Li, D.; Wu, D.; Xu, F.; Lai, J.; Shao, L. Literature overview of Chinese research in the field of better coal utilization. J. Clean. Prod. 2018, 185, 959–980. [Google Scholar] [CrossRef]

- Hower, J.C.; Finkelman, R.B.; Eble, C.F.; Arnold, B.J. Understanding coal quality and the critical importance of comprehensive coal analyses. Int. J. Coal Geol. 2022, 263, 104120. [Google Scholar] [CrossRef]

- Kiang, Y.-H. Fuel Property Estimation and Combustion Process Characterization: Conventional Fuels, Biomass, Biocarbon, Waste Fuels, Refuse Derived Fuel, and Other Alternative Fuels; Academic Press: London, UK; San Diego, CA, USA, 2018. [Google Scholar]

- ISO11722; Solid Mineral Fuels—Hard Coal—Determination of Moisture in the General Analysis Test Sample by Drying in Nitrogen. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO562; Hard Coal and Coke—Determination of Volatile Matter. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO1171; Coal and Coke—Determination of Ash. International Organization for Standardization: Geneva, Switzerland, 2024.

- Wang, Z.; Hou, Z.; Zhang, L.; Yao, S.; Sheta, S.; Afgan, M.S. Chapter 21—Coal analysis. In Laser-Induced Breakdown Spectroscopy, 2nd ed.; Singh, J.P., Thakur, S.N., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 473–498. [Google Scholar] [CrossRef]

- Sheta, S.; Afgan, M.S.; Hou, Z.; Yao, S.-C.; Zhang, L.; Li, Z.; Wang, Z. Coal analysis by laser-induced breakdown spectroscopy: A tutorial review. J. Anal. At. Spectrom. 2019, 34, 1047–1082. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, M.; Wu, Y.; Mao, J.; Xie, Y.; Jin, Q.; Liu, S.; Tang, G. Fast and nondestructive discrimination of coal types based on spectral feature parameters. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2024, 322, 124749. [Google Scholar] [CrossRef]

- Bian, X.; Liu, Y.; Zhang, R.; Sun, H.; Liu, P.; Tan, X. Rapid quantification of grapeseed oil multiple adulterations using near-infrared spectroscopy coupled with a novel double ensemble modeling method. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2024, 311, 124016. [Google Scholar] [CrossRef] [PubMed]

- Bian, X.; Zhao, Z.; Liu, J.; Liu, P.; Shi, H.; Tan, X. Discretized butterfly optimization algorithm for variable selection in the rapid determination of cholesterol by near-infrared spectroscopy. Anal. Methods 2023, 15, 5190–5198. [Google Scholar] [CrossRef]

- Andrés, J.M.; Bona, M.T. Analysis of coal by diffuse reflectance near-infrared spectroscopy. Anal. Chim. Acta 2005, 535, 123–132. [Google Scholar] [CrossRef]

- Andrés, J.M.; Bona, M.T. ASTM clustering for improving coal analysis by near-infrared spectroscopy. Talanta 2006, 70, 711–719. [Google Scholar] [CrossRef]

- Bona, M.T.; Andrés, J.M. Coal analysis by diffuse reflectance near-infrared spectroscopy: Hierarchical cluster and linear discriminant analysis. Talanta 2007, 72, 1423–1431. [Google Scholar] [CrossRef]

- Le, B.T.; Xiao, D.; Mao, Y.; He, D. Coal analysis based on visible-infrared spectroscopy and a deep neural network. Infrared Phys. Technol. 2018, 93, 34–40. [Google Scholar] [CrossRef]

- Begum, N.; Chakravarty, D.; Das, B.S. Estimation of Gross Calorific Value of Bituminous Coal using various Coal Properties and Reflectance Spectra. Int. J. Coal Prep. Util. 2022, 42, 979–985. [Google Scholar] [CrossRef]

- Begum, N.; Maiti, A.; Chakravarty, D.; Das, B.S. Reflectance spectroscopy based rapid determination of coal quality parameters. Fuel 2020, 280, 118676. [Google Scholar] [CrossRef]

- Potgieter-Vermaak, S.; Maledi, N.; Wagner, N.; Van Heerden, J.; Van Grieken, R.; Potgieter, J. Raman spectroscopy for the analysis of coal: A review. J. Raman Spectrosc. 2011, 42, 123–129. [Google Scholar] [CrossRef]

- Liu, K.; He, C.; Zhu, C.; Chen, J.; Zhan, K.; Li, X. A review of laser-induced breakdown spectroscopy for coal analysis. TrAC Trends Anal. Chem. 2021, 143, 116357. [Google Scholar] [CrossRef]

- Ibarra, J.V.; Moliner, R. Coal characterization using pyrolysis-FTIR. J. Anal. Appl. Pyrolysis 1991, 20, 171–184. [Google Scholar] [CrossRef]

- Román Gómez, Y.; Cabanzo Hernández, R.; Guerrero, J.E.; Mejía-Ospino, E. FTIR-PAS coupled to partial least squares for prediction of ash content, volatile matter, fixed carbon and calorific value of coal. Fuel 2018, 226, 536–544. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, M.; Cheng, L.; Wei, L.; Cai, J.; Lu, J. Improved measurement in quantitative analysis of coal properties using laser induced breakdown spectroscopy. J. Anal. At. Spectrom. 2020, 35, 810–818. [Google Scholar] [CrossRef]

- Matlala, I.V.; Moroeng, O.M.; Kalaitzidis, S.; Wagner, N.J. Raman Spectroscopy for the characterization of the macromolecular structure of Highveld coals (South Africa). Int. J. Coal Geol. 2024, 288, 104531. [Google Scholar] [CrossRef]

- Imani, M.; Ghassemian, H. An overview on spectral and spatial information fusion for hyperspectral image classification: Current trends and challenges. Inf. Fusion 2020, 59, 59–83. [Google Scholar] [CrossRef]

- Yan, Y.; Ren, J.; Zhao, H.; Windmill, J.F.C.; Ijomah, W.; De Wit, J.; Von Freeden, J. Non-destructive testing of composite fiber materials with hyperspectral imaging—Evaluative studies in the EU H2020 FibreEUse project. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Martin, M.E.; Wabuyele, M.B.; Chen, K.; Kasili, P.; Panjehpour, M.; Phan, M.; Overholt, B.; Cunningham, G.; Wilson, D.; DeNovo, R.C. Development of an advanced hyperspectral imaging (HSI) system with applications for cancer detection. Ann. Biomed. Eng. 2006, 34, 1061–1068. [Google Scholar] [CrossRef] [PubMed]

- Guo, A.; Huang, W.; Ye, H.; Dong, Y.; Ma, H.; Ren, Y.; Ruan, C. Identification of Wheat Yellow Rust Using Spectral and Texture Features of Hyperspectral Images. Remote Sens. 2020, 12, 1419. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, W.; Tian, X.; Long, Y.; Li, L.; Fan, S. Rapid and Non-destructive Classification of New and Aged Maize Seeds Using Hyperspectral Image and Chemometric Methods. Front. Plant Sci. 2022, 13, 849495. [Google Scholar] [CrossRef] [PubMed]

- Hashim, N.; Adebayo, S.E.; Abdan, K.; Hanafi, M. Comparative study of transform-based image texture analysis for the evaluation of banana quality using an optical backscattering system. Postharvest Biol. Technol. 2018, 135, 38–50. [Google Scholar] [CrossRef]

- Mondal, C.; Pandey, A.; Kumar Pal, S.; Samanta, B.; Dutta, D. Hyperspectral measurement technique based rapid determination of coal quality parameters of Jharia and Raniganj basin coal. Infrared Phys. Technol. 2023, 128, 104504. [Google Scholar] [CrossRef]

- GB/T 212-2008; Proximate Analysis of Coal. Standardization Administration of the People’s Republic of China: Beijing, China, 2009.

- GB/T 213-2008; Determination of Calorific Value of Coal. Standardization Administration of the People’s Republic of China: Beijing, China, 2009.

- Yang, E.; Wang, S.; Ge, S. Study on the Visible and Near-Infrared Spectra of Typical Types of Lump Coal. Spectrosc. Spectr. Anal. 2019, 39, 1717–1723. [Google Scholar] [CrossRef]

- Fysh, S.A.; Swinkels, D.A.J.; Fredericks, P.M. Near-Infrared Diffuse Reflectance Spectroscopy of Coal. Appl. Spectrosc. 1985, 39, 354–357. [Google Scholar] [CrossRef]

- Van Dyk, J.C.; Benson, S.A.; Laumb, M.L.; Waanders, B. Coal and coal ash characteristics to understand mineral transformations and slag formation. Fuel 2009, 88, 1057–1063. [Google Scholar] [CrossRef]

- Liu, C.; Yang, S.X.; Li, X.; Xu, L.; Deng, L. Noise level penalizing robust Gaussian process regression for NIR spectroscopy quantitative analysis. Chemom. Intell. Lab. Syst. 2020, 201, 104014. [Google Scholar] [CrossRef]

- Hu, Y.; Huang, P.; Wang, Y.; Sun, J.; Wu, Y.; Kang, Z. Determination of Tibetan tea quality by hyperspectral imaging technology and multivariate analysis. J. Food Compos. Anal. 2023, 117, 105136. [Google Scholar] [CrossRef]

- Huang, Z.; Sanaeifar, A.; Tian, Y.; Liu, L.; Zhang, D.; Wang, H.; Ye, D.; Li, X. Improved generalization of spectral models associated with Vis-NIR spectroscopy for determining the moisture content of different tea leaves. J. Food Eng. 2021, 293, 110374. [Google Scholar] [CrossRef]

- Xue, H.; Xu, X.; Yang, Y.; Hu, D.; Niu, G. Rapid and Non-Destructive Prediction of Moisture Content in Maize Seeds Using Hyperspectral Imaging. Sensors 2024, 24, 1855. [Google Scholar] [CrossRef]

- Zhang, S.; Yin, Y.; Liu, C.; Li, J.; Sun, X.; Wu, J. Discrimination of wheat flour grade based on PSO-SVM of hyperspectral technique. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 302, 123050. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Lu, Y.; Peng, Y.; Zhao, L.; Wang, G.; Hu, Y. Estimation of Soil Heavy Metal Content Using Hyperspectral Data. Remote Sens. 2019, 11, 1464. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, F.; Chen, W.; Xiong, Q.; Chen, Z.; Yao, H.; Ge, J.; Hu, Y.; Du, Y. A variable informative criterion based on weighted voting strategy combined with LASSO for variable selection in multivariate calibration. Chemom. Intell. Lab. Syst. 2019, 184, 132–141. [Google Scholar] [CrossRef]

- Paschos, G.; Petrou, M. Histogram ratio features for color texture classification. Pattern Recognit. Lett. 2003, 24, 309–314. [Google Scholar] [CrossRef]

- Arebey, M.; Hannan, M.A.; Begum, R.A.; Basri, H. Solid waste bin level detection using gray level co-occurrence matrix feature extraction approach. J. Environ. Manag. 2012, 104, 9–18. [Google Scholar] [CrossRef]

- Gabor, D. Theory of communication. Part 1: The analysis of information. J. Inst. Electr. Eng.—Part III Radio Commun. Eng. 1946, 93, 429–441. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, Z.; Lin, C.; Hu, Y.; Zhao, L.; Zou, R.; Wen, Y.; Mao, X. A New Method for Estimating Soil Fertility Using Extreme Gradient Boosting and a Backpropagation Neural Network. Remote Sens. 2022, 14, 3311. [Google Scholar] [CrossRef]

- Pravin, P.S.; Tan, J.Z.M.; Yap, K.S.; Wu, Z. Hyperparameter optimization strategies for machine learning-based stochastic energy efficient scheduling in cyber-physical production systems. Digit. Chem. Eng. 2022, 4, 100047. [Google Scholar] [CrossRef]

- Akiba, T.; Sano, S.; Yanase, T.; Ohta, T.; Koyama, M. Optuna: A Next-generation Hyperparameter Optimization Framework. In Proceedings of the 25th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, Anchorage, AK, USA, 4–8 August 2019. [Google Scholar]

- Maxwell, A.E.; Sharma, M.; Donaldson, K.A. Explainable Boosting Machines for Slope Failure Spatial Predictive Modeling. Remote Sens. 2021, 13, 4991. [Google Scholar] [CrossRef]

- Zhao, N.; Wu, Z.-S.; Zhang, Q.; Shi, X.-Y.; Ma, Q.; Qiao, Y.-J. Optimization of parameter selection for partial least squares model development. Sci. Rep. 2015, 5, 11647. [Google Scholar] [CrossRef] [PubMed]

- Zornoza, R.; Guerrero, C.; Mataix-Solera, J.; Scow, K.M.; Arcenegui, V.; Mataix-Beneyto, J. Near infrared spectroscopy for determination of various physical, chemical and biochemical properties in Mediterranean soils. Soil Biol. Biochem. 2008, 40, 1923–1930. [Google Scholar] [CrossRef] [PubMed]

- Lundberg, S.M.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. arXiv 2017, arXiv:1705.07874. [Google Scholar]

- Marcílio, W.E.; Eler, D.M. From explanations to feature selection: Assessing SHAP values as feature selection mechanism. In 2020 33rd SIBGRAPI Conference on Graphics, Patterns and Images (SIBGRAPI), Porto de Galinhas, Brazil, 7–10 November 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Tang, Y.; Duan, A.; Xiao, C.; Xin, Y. The Prediction of the Tibetan Plateau Thermal Condition with Machine Learning and Shapley Additive Explanation. Remote Sens. 2022, 14, 4169. [Google Scholar] [CrossRef]

- Mathews, J.P.; Krishnamoorthy, V.; Louw, E.; Tchapda, A.H.N.; Castro-Marcano, F.; Karri, V.; Alexis, D.A.; Mitchell, G.D. A review of the correlations of coal properties with elemental composition. Fuel Process. Technol. 2014, 121, 104–113. [Google Scholar] [CrossRef]

- Sengupta, A.N. An assessment of grindability index of coal. Fuel Process. Technol. 2002, 76, 1–10. [Google Scholar] [CrossRef]

- Laskowski, J.S. Chapter 3 Coal surface properties. In Developments in Mineral Processing; Elsevier: Amsterdam, The Netherlands, 2001; Volume 14, pp. 31–94. [Google Scholar]

- Morley, R.J.; Scaroni, A.W.; Pisupati, S.V.L.N. Coal Utilization. Available online: https://www.britannica.com/technology/coal-utilization (accessed on 14 August 2024).

- Zhang, Z.; Yan, X.; Gao, F.; Thai, P.; Wang, H.; Chen, D.; Zhou, L.; Gong, D.; Li, Q.; Morawska, L.; et al. Emission and health risk assessment of volatile organic compounds in various processes of a petroleum refinery in the Pearl River Delta, China. Environ. Pollut. 2018, 238, 452–461. [Google Scholar] [CrossRef]

- He, K.; Shen, Z.; Zhang, B.; Sun, J.; Zou, H.; Zhou, M.; Zhang, Z.; Xu, H.; Ho, S.S.H.; Cao, J. Emission profiles of volatile organic compounds from various geological maturity coal and its clean coal briquetting in China. Atmos. Res. 2022, 274, 106200. [Google Scholar] [CrossRef]

- EI; BP. Statistical Review of World Energy 2023. Available online: https://www.energyinst.org/statistical-review (accessed on 14 August 2024).

- Jayaranjan, M.L.D.; Van Hullebusch, E.D.; Annachhatre, A.P. Reuse options for coal fired power plant bottom ash and fly ash. Rev. Environ. Sci. Bio/Technol. 2014, 13, 467–486. [Google Scholar] [CrossRef]

- Gülcan, E.; Gülsoy, Ö.Y.; Can, I.B. Ash content estimation of lignite with visible light and near-infrared sensors. Int. J. Coal Prep. Util. 2020, 40, 438–458. [Google Scholar] [CrossRef]

- Xiao, D.; Yan, Z.; Li, J.; Fu, Y.; Li, Z. Rapid proximate analysis of coal based on reflectance spectroscopy and deep learning. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 287, 122042. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Lin, T.; Xu, J.; Luo, X.; Ying, Y. DeepSpectra: An end-to-end deep learning approach for quantitative spectral analysis. Anal. Chim. Acta 2019, 1058, 48–57. [Google Scholar] [CrossRef]

- Ryan, B.; Leeder, R.; Price, J.T.; Gransden, J.F. The effect of coal preparation on the quality of clean coal and coke. Geol. Fieldwork 1999, 247–275. [Google Scholar]

- Pulungan, L.; Arbianto, V. Coal handling quality from pits to stockpiles to market specifications. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Yin, J.; Liu, M.; Zhao, Y.; Wang, C.; Yan, J. Dynamic performance and control strategy modification for coal-fired power unit under coal quality variation. Energy 2021, 223, 120077. [Google Scholar] [CrossRef]

- Zaid, M.Z.S.M.; Wahid, M.A.; Mailah, M.; Mazlan, M.A.; Saat, A. Coal fired power plant: A review on coal blending and emission issues. In AIP Conference Proceedings; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

| Featured Wavelength (nm) | Groups or Ions | References |

|---|---|---|

| 1150 | Electron leaps in -dominated metals | [34] |

| 1400 | Combined bands of vibrations | [34] |

| 1700 | First overtones of symmetric/asymmetric stretch. | [34,35] |

| 1900 | Combined bands of vibrations | [35] |

| 2150 | Combination of aromatic C-H stretch and C-C stretch | [35] |

| 2200 | Combination Al-OH vibration | [35,36] |

| 2300 | Combination of asymmetric stretch and bend | [34,35] |

| Coal Quality Indices | Calibration Set (46) | Prediction Set (15) | ||||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Mean | Min | Max | Mean | |||

| Ash (%) | 17.79 | 60.24 | 36.48 | 11.51 | 22.56 | 57.70 | 34.16 | 8.06 |

| MC (%) | 0.38 | 3.60 | 1.71 | 0.79 | 0.38 | 2.82 | 1.25 | 0.80 |

| VM (%) | 9.54 | 30.49 | 20.00 | 6.52 | 10.5 | 30.18 | 21.97 | 5.77 |

| FC (%) | 29.12 | 54.34 | 41.60 | 5.25 | 31.44 | 49.63 | 43.23 | 3.81 |

| CV () | 11.61 | 26.55 | 19.96 | 3.87 | 12.75 | 25.05 | 21.41 | 3.00 |

| Coal Quality Indices | Spectra | PCs | Calibration Set | Prediction Set | ||

|---|---|---|---|---|---|---|

| Ash (%) | OR | 7 | 0.957 | 2.297 | 0.930 | 2.242 |

| SG | 7 | 0.955 | 2.333 | 0.929 | 2.250 | |

| FD | 7 | 0.995 | 0.741 | 0.971 | 1.723 | |

| MSC | 7 | 0.985 | 1.387 | 0.972 | 1.342 | |

| VM (%) | OR | 7 | 0.964 | 1.255 | 0.930 | 1.378 |

| SG | 7 | 0.963 | 1.272 | 0.928 | 1.399 | |

| FD | 7 | 0.996 | 0.436 | 0.948 | 1.030 | |

| MSC | 7 | 0.982 | 0.919 | 0.969 | 0.801 | |

| MC (%) | OR | 7 | 0.755 | 0.418 | 0.803 | 0.300 |

| SG | 7 | 0.747 | 0.424 | 0.803 | 0.300 | |

| FD | 4 | 0.961 | 0.167 | 0.473 | 0.438 | |

| MSC | 6 | 0.806 | 0.384 | 0.581 | 0.366 | |

| FC (%) | OR | 7 | 0.895 | 1.678 | 0.812 | 1.618 |

| SG | 7 | 0.890 | 1.724 | 0.828 | 1.550 | |

| FD | 7 | 0.982 | 0.699 | 0.850 | 1.534 | |

| MSC | 7 | 0.942 | 1.256 | 0.859 | 1.426 | |

| CV (MJ/kg) | OR | 16 | 0.999 | 0.116 | 0.908 | 0.869 |

| SG | 10 | 0.981 | 0.537 | 0.964 | 0.545 | |

| FD | 7 | 0.992 | 0.343 | 0.967 | 0.516 | |

| MSC | 13 | 0.995 | 0.283 | 0.973 | 0.440 | |

| Coal Quality Indices | Methods | Number of Wavelengths | Modeling | Calibration Set | Prediction Set | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ash (%) | SPA | 6 | PLSR | 0.838 | 4.502 | 0.799 | 5.024 | 0.740 | 4.176 | 2.032 |

| RF | 0.981 | 1.534 | 0.904 | 3.462 | 0.940 | 2.008 | 4.225 | |||

| BPNN | 0.992 | 0.995 | 0.873 | 3.988 | 0.885 | 2.785 | 3.047 | |||

| LSSVR | 0.978 | 1.670 | 0.967 | 2.043 | 0.942 | 1.975 | 4.296 | |||

| CARS | 65 | PLSR | 0.945 | 2.627 | 0.924 | 3.094 | 0.932 | 2.184 | 3.971 | |

| RF | 0.985 | 1.362 | 0.872 | 4.020 | 0.921 | 2.359 | 3.676 | |||

| BPNN | 0.992 | 0.924 | 0.819 | 4.789 | 0.754 | 4.159 | 2.085 | |||

| LSSVR | 0.997 | 0.636 | 0.987 | 1.278 | 0.984 | 1.057 | 8.202 | |||

| Boruta | 12 | PLSR | 0.976 | 1.809 | 0.971 | 1.980 | 0.951 | 1.455 | 4.656 | |

| RF | 0.988 | 1.275 | 0.919 | 3.319 | 0.963 | 1.256 | 5.392 | |||

| BPNN | 0.974 | 1.883 | 0.904 | 3.614 | 0.786 | 3.027 | 2.237 | |||

| LSSVR | 0.977 | 1.790 | 0.971 | 2.004 | 0.949 | 1.481 | 4.572 | |||

| iVISSA | 84 | PLSR | 0.980 | 1.592 | 0.968 | 1.998 | 0.974 | 1.364 | 6.400 | |

| RF | 0.986 | 1.306 | 0.906 | 3.435 | 0.930 | 2.228 | 3.919 | |||

| BPNN | 0.986 | 1.291 | 0.826 | 4.666 | 0.699 | 4.626 | 1.887 | |||

| LSSVR | 0.992 | 1.008 | 0.980 | 1.571 | 0.971 | 1.425 | 6.128 | |||

| VM (%) | SPA | 10 | PLSR | 0.936 | 1.723 | 0.905 | 2.096 | 0.888 | 1.388 | 3.094 |

| RF | 0.975 | 1.068 | 0.812 | 2.958 | 0.847 | 1.623 | 2.647 | |||

| BPNN | 0.951 | 1.502 | 0.888 | 2.276 | 0.909 | 1.249 | 3.438 | |||

| LSSVR | 0.965 | 1.274 | 0.935 | 1.744 | 0.945 | 0.977 | 4.398 | |||

| CARS | 26 | PLSR | 0.905 | 2.056 | 0.864 | 2.462 | 0.829 | 1.896 | 2.504 | |

| RF | 0.954 | 1.435 | 0.682 | 3.766 | 0.824 | 1.922 | 2.470 | |||

| BPNN | 0.983 | 0.855 | 0.868 | 2.430 | 0.782 | 2.140 | 2.218 | |||

| LSSVR | 0.991 | 0.647 | 0.977 | 1.014 | 0.971 | 0.787 | 6.030 | |||

| Boruta | 11 | PLSR | 0.801 | 3.012 | 0.772 | 3.227 | 0.923 | 1.288 | 3.725 | |

| RF | 0.955 | 1.434 | 0.807 | 2.970 | 0.982 | 0.621 | 7.729 | |||

| BPNN | 0.967 | 1.224 | 0.900 | 2.142 | 0.856 | 1.760 | 2.725 | |||

| LSSVR | 0.893 | 2.213 | 0.867 | 2.469 | 0.967 | 0.846 | 5.669 | |||

| iVISSA | 136 | PLSR | 0.912 | 1.956 | 0.872 | 2.366 | 0.887 | 1.738 | 3.076 | |

| RF | 0.938 | 1.643 | 0.573 | 4.323 | 0.790 | 2.368 | 2.257 | |||

| BPNN | 0.985 | 0.740 | 0.812 | 2.870 | 0.707 | 2.797 | 1.911 | |||

| LSSVR | 0.989 | 0.701 | 0.941 | 1.607 | 0.929 | 1.373 | 3.894 | |||

| MC (%) | SPA | 4 | PLSR | 0.656 | 0.491 | 0.608 | 0.525 | 0.704 | 0.359 | 1.902 |

| RF | 0.832 | 0.343 | 0.398 | 0.651 | 0.584 | 0.425 | 1.605 | |||

| BPNN | 0.878 | 0.293 | 0.731 | 0.435 | 0.770 | 0.313 | 2.178 | |||

| LSSVR | 0.695 | 0.463 | 0.635 | 0.507 | 0.771 | 0.314 | 2.174 | |||

| CARS | 25 | PLSR | 0.672 | 0.496 | 0.560 | 0.574 | 0.601 | 0.373 | 1.640 | |

| RF | 0.781 | 0.405 | 0.276 | 0.737 | −0.255 | 0.662 | 0.924 | |||

| BPNN | 0.844 | 0.341 | 0.586 | 0.557 | 0.539 | 0.401 | 1.524 | |||

| LSSVR | 0.965 | 0.163 | 0.904 | 0.268 | 0.772 | 0.282 | 2.165 | |||

| Boruta | 8 | PLSR | 0.566 | 0.546 | 0.510 | 0.580 | 0.661 | 0.430 | 1.778 | |

| RF | 0.754 | 0.411 | 0.516 | 0.577 | 0.784 | 0.343 | 2.225 | |||

| BPNN | 0.816 | 0.354 | 0.413 | 0.635 | 0.473 | 0.535 | 1.426 | |||

| LSSVR | 0.643 | 0.495 | 0.546 | 0.558 | 0.714 | 0.395 | 1.934 | |||

| iVISSA | 91 | PLSR | 0.717 | 0.460 | 0.641 | 0.518 | 0.363 | 0.451 | 1.297 | |

| RF | 0.778 | 0.407 | 0.438 | 0.648 | 0.394 | 0.440 | 1.329 | |||

| BPNN | 0.821 | 0.366 | 0.648 | 0.513 | 0.083 | 0.541 | 1.081 | |||

| LSSVR | 0.771 | 0.414 | 0.657 | 0.506 | 0.449 | 0.419 | 1.395 | |||

| FC (%) | SPA | 6 | PLSR | 0.802 | 2.308 | 0.731 | 2.694 | 0.845 | 1.539 | 2.631 |

| RF | 0.971 | 0.877 | 0.789 | 2.385 | 0.830 | 1.614 | 2.507 | |||

| BPNN | 0.864 | 1.913 | 0.727 | 2.715 | 0.236 | 3.418 | 1.184 | |||

| LSSVR | 0.877 | 1.818 | 0.810 | 2.262 | 0.794 | 1.774 | 2.283 | |||

| CARS | 35 | PLSR | 0.898 | 1.752 | 0.829 | 2.269 | 0.121 | 1.857 | 1.104 | |

| RF | 0.959 | 1.108 | 0.715 | 2.929 | 0.208 | 1.763 | 1.163 | |||

| BPNN | 0.896 | 1.764 | 0.774 | 2.608 | −3.790 | 4.333 | 0.473 | |||

| LSSVR | 0.981 | 0.755 | 0.925 | 1.503 | 0.649 | 1.172 | 1.748 | |||

| Boruta | 14 | PLSR | 0.888 | 1.789 | 0.846 | 2.099 | 0.865 | 1.179 | 2.813 | |

| RF | 0.966 | 0.979 | 0.767 | 2.582 | 0.909 | 0.964 | 3.439 | |||

| BPNN | 0.801 | 2.383 | 0.603 | 3.375 | 0.717 | 1.703 | 1.947 | |||

| LSSVR | 0.894 | 1.743 | 0.845 | 2.105 | 0.884 | 1.093 | 3.033 | |||

| iVISSA | 104 | PLSR | 0.819 | 2.231 | 0.720 | 2.776 | 0.817 | 1.539 | 2.422 | |

| RF | 0.937 | 1.312 | 0.533 | 3.584 | 0.816 | 1.543 | 2.414 | |||

| BPNN | 0.863 | 1.938 | 0.622 | 3.224 | 0.042 | 3.523 | 1.058 | |||

| LSSVR | 0.899 | 1.665 | 0.799 | 2.353 | 0.878 | 1.256 | 2.965 | |||

| CV (MJ/kg) | SPA | 8 | PLSR | 0.886 | 1.304 | 0.855 | 1.471 | 0.897 | 0.938 | 3.232 |

| RF | 0.973 | 0.637 | 0.935 | 0.983 | 0.935 | 0.745 | 4.066 | |||

| BPNN | 0.959 | 0.786 | 0.919 | 1.096 | 0.933 | 0.756 | 4.007 | |||

| LSSVR | 0.983 | 0.510 | 0.973 | 0.630 | 0.973 | 0.480 | 6.315 | |||

| CARS | 48 | PLSR | 0.953 | 0.842 | 0.923 | 1.074 | 0.947 | 0.646 | 4.490 | |

| RF | 0.981 | 0.535 | 0.867 | 1.413 | 0.911 | 0.835 | 3.474 | |||

| BPNN | 0.988 | 0.428 | 0.801 | 1.732 | 0.653 | 1.651 | 1.757 | |||

| LSSVR | 0.995 | 0.267 | 0.981 | 0.535 | 0.991 | 0.260 | 11.156 | |||

| Boruta | 14 | PLSR | 0.974 | 0.636 | 0.964 | 0.750 | 0.956 | 0.550 | 4.958 | |

| RF | 0.975 | 0.619 | 0.886 | 1.334 | 0.937 | 0.663 | 4.113 | |||

| BPNN | 0.962 | 0.774 | 0.919 | 1.127 | 0.909 | 0.793 | 3.439 | |||

| LSSVR | 0.975 | 0.626 | 0.964 | 0.755 | 0.962 | 0.512 | 5.321 | |||

| iVISSA | 122 | PLSR | 0.874 | 1.357 | 0.826 | 1.596 | 0.768 | 1.425 | 2.148 | |

| RF | 0.916 | 1.109 | 0.423 | 2.904 | 0.447 | 2.200 | 1.392 | |||

| BPNN | 0.988 | 0.397 | 0.683 | 2.152 | 0.367 | 2.354 | 1.301 | |||

| LSSVR | 0.987 | 0.441 | 0.949 | 0.860 | 0.945 | 0.696 | 4.401 | |||

| Coal Quality Indices | Feature Data | Number of Features | Calibration Set | Prediction Set | |||||

|---|---|---|---|---|---|---|---|---|---|

| Ash (%) | HS | 50 | 0.986 | 1.331 | 0.852 | 4.326 | 0.783 | 3.901 | 2.223 |

| GLEM | 44 | 0.980 | 1.661 | 0.580 | 7.591 | 0.644 | 3.569 | 1.736 | |

| Gabor | 37 | 0.992 | 1.027 | 0.947 | 2.601 | 0.811 | 3.452 | 2.379 | |

| Combined | 71 | 0.998 | 0.476 | 0.986 | 1.341 | 0.993 | 0.659 | 12.217 | |

| VM (%) | HS | 41 | 0.980 | 0.880 | 0.822 | 2.623 | 0.846 | 2.371 | 2.634 |

| GLEM | 44 | 0.991 | 0.616 | 0.856 | 2.414 | 0.892 | 1.999 | 3.149 | |

| Gabor | 49 | 0.994 | 0.509 | 0.923 | 1.878 | 0.927 | 1.135 | 3.842 | |

| Combined | 43 | 0.999 | 0.230 | 0.994 | 0.497 | 0.989 | 0.583 | 9.904 | |

| MC (%) | HS | 37 | 0.963 | 0.152 | 0.730 | 0.412 | 0.583 | 0.486 | 1.603 |

| GLEM | 18 | 0.856 | 0.299 | 0.638 | 0.476 | 0.502 | 0.563 | 1.467 | |

| Gabor | 33 | 0.991 | 0.075 | 0.923 | 0.218 | 0.957 | 0.174 | 4.991 | |

| Combined | 56 | 0.995 | 0.055 | 0.961 | 0.154 | 0.979 | 0.112 | 7.159 | |

| FC (%) | HS | 41 | 0.865 | 1.960 | 0.472 | 3.875 | 0.514 | 2.259 | 1.485 |

| GLEM | 62 | 0.967 | 0.975 | 0.357 | 4.315 | −0.932 | 2.847 | 0.745 | |

| Gabor | 22 | 0.942 | 1.311 | 0.736 | 2.794 | −0.904 | 2.261 | 0.750 | |

| Combined | 78 | 0.989 | 0.553 | 0.923 | 1.438 | 0.948 | 0.838 | 4.544 | |

| CV (MJ/kg) | HS | 37 | 0.979 | 0.567 | 0.874 | 1.391 | 0.565 | 1.481 | 1.570 |

| GLEM | 49 | 0.970 | 0.665 | 0.595 | 2.452 | 0.646 | 1.771 | 1.741 | |

| Gabor | 56 | 0.992 | 0.365 | 0.864 | 1.487 | 0.619 | 0.994 | 1.676 | |

| Combined | 45 | 0.998 | 0.157 | 0.989 | 0.409 | 0.994 | 0.217 | 13.849 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, J.; Zhao, H.; Xie, Y.; Wang, M.; Wang, P.; Shi, Y.; Zhao, Y. Fast and Nondestructive Proximate Analysis of Coal from Hyperspectral Images with Machine Learning and Combined Spectra-Texture Features. Appl. Sci. 2024, 14, 7920. https://doi.org/10.3390/app14177920

Mao J, Zhao H, Xie Y, Wang M, Wang P, Shi Y, Zhao Y. Fast and Nondestructive Proximate Analysis of Coal from Hyperspectral Images with Machine Learning and Combined Spectra-Texture Features. Applied Sciences. 2024; 14(17):7920. https://doi.org/10.3390/app14177920

Chicago/Turabian StyleMao, Jihua, Hengqian Zhao, Yu Xie, Mengmeng Wang, Pan Wang, Yaning Shi, and Yusen Zhao. 2024. "Fast and Nondestructive Proximate Analysis of Coal from Hyperspectral Images with Machine Learning and Combined Spectra-Texture Features" Applied Sciences 14, no. 17: 7920. https://doi.org/10.3390/app14177920