Large-Scale Physical Simulation Experiment of Water Invasion Law for Multi-Well Development in Sandstone Gas Reservoirs with Strong Water Drive

Abstract

:1. Introduction

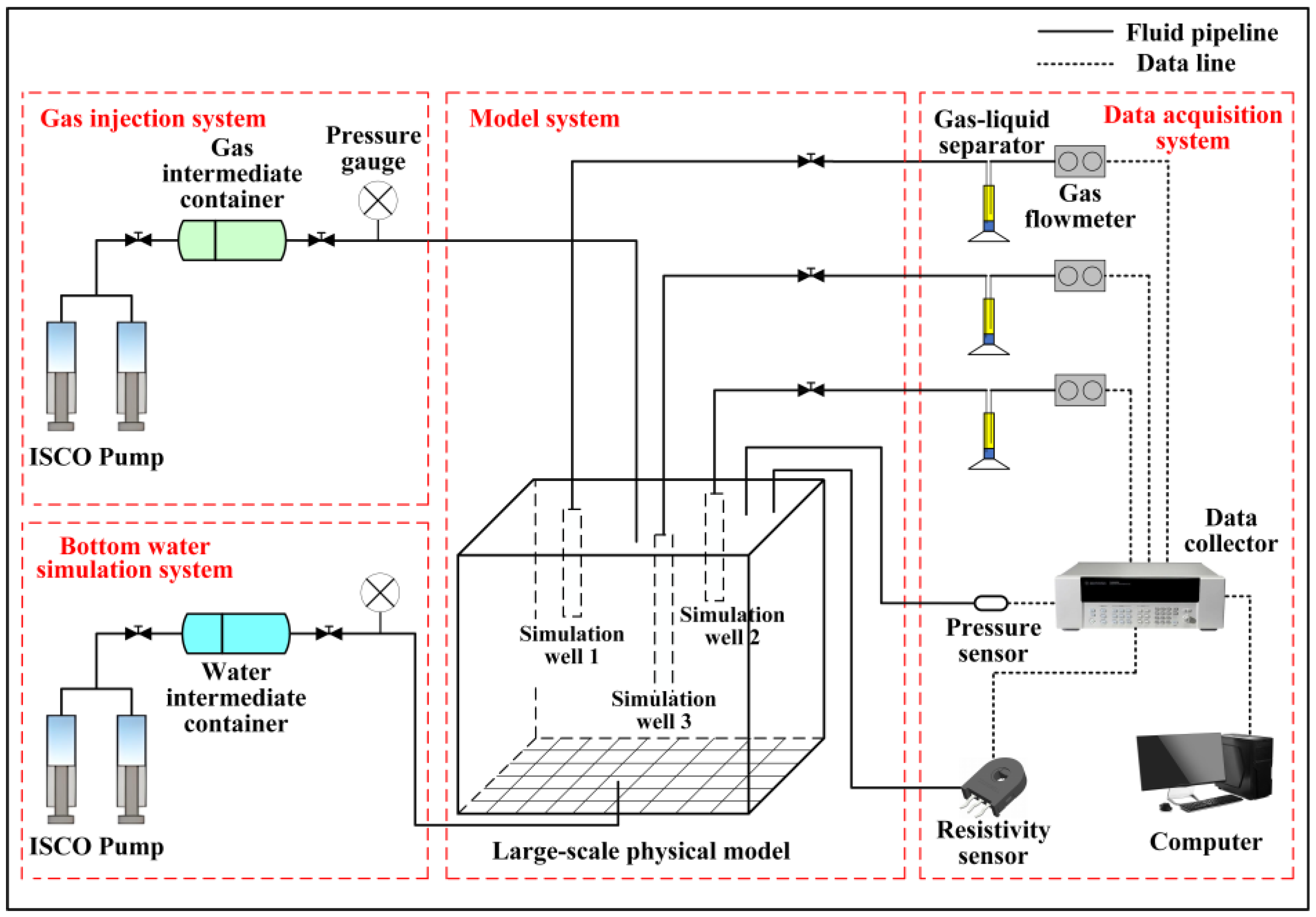

2. Methods

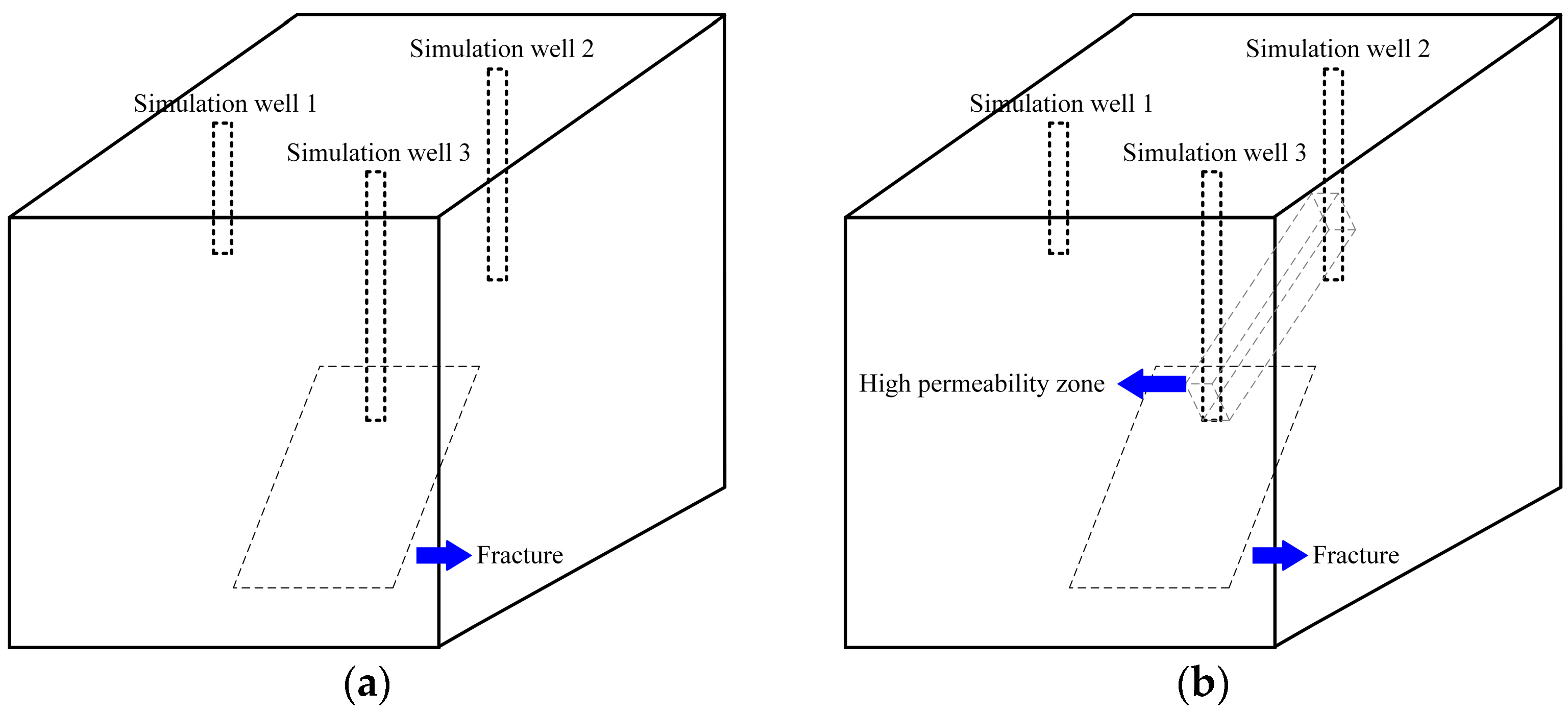

2.1. Experimental Model Design

2.2. Experimental Scheme and Steps

- (1)

- The prepared physical model was loaded into a three-dimensional model holder and the confining pressure was added to 25 MPa.

- (2)

- After stabilizing the confining pressure, the physical model was slowly saturated with nitrogen (99.99%) to 20 MPa.

- (3)

- The simulated formation water (80 g/L) was loaded into the water body simulation system, pressurized to 20 MPa, and the water body multiple was set as required.

- (4)

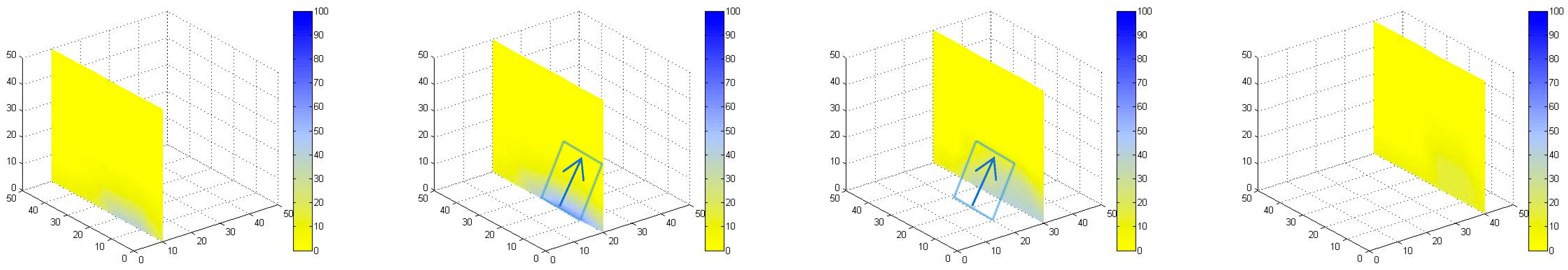

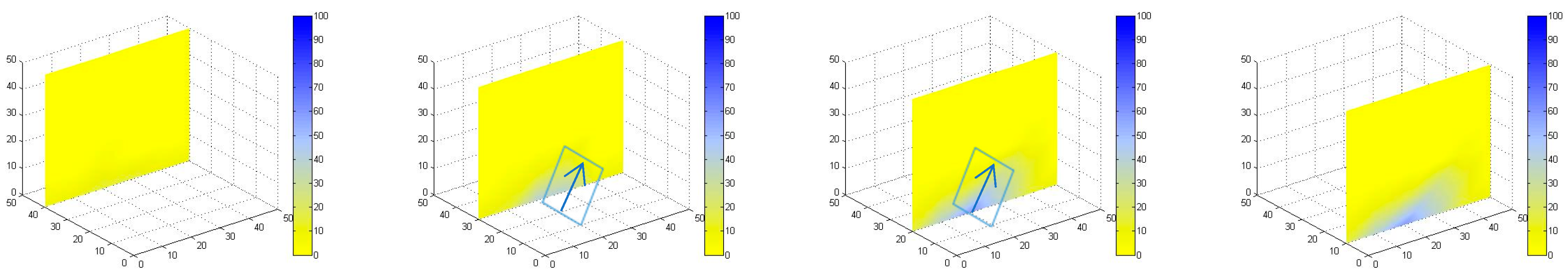

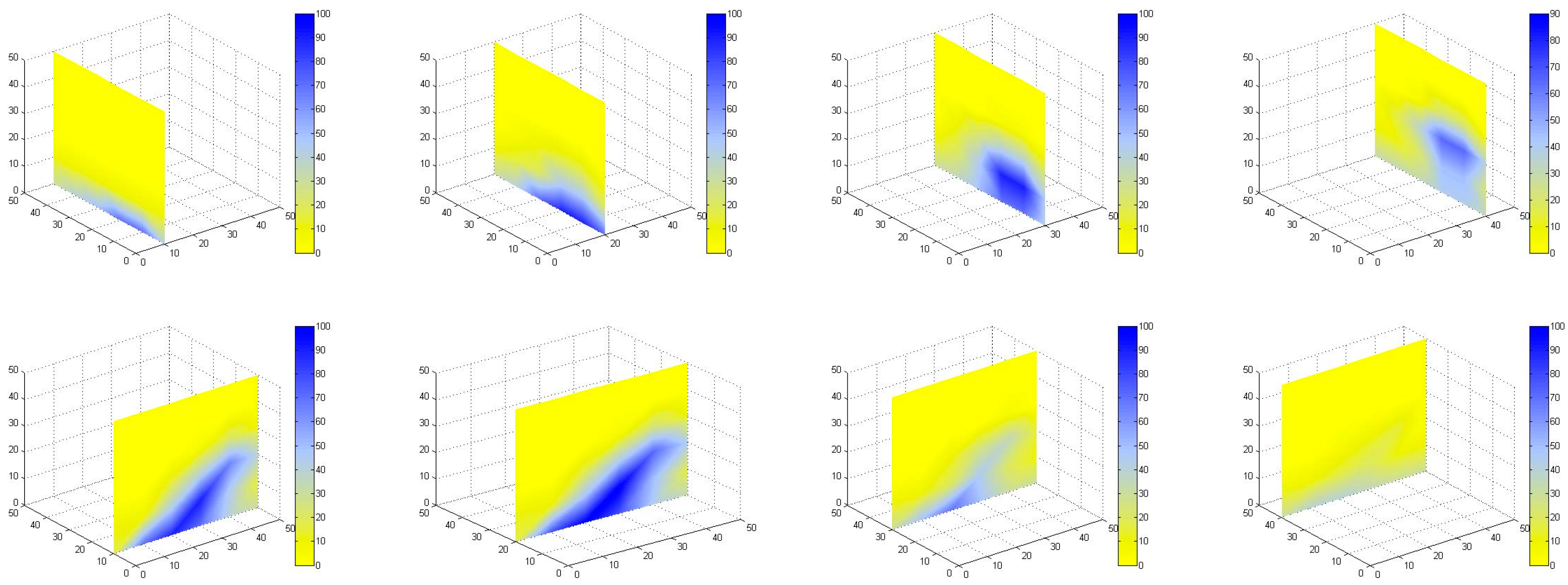

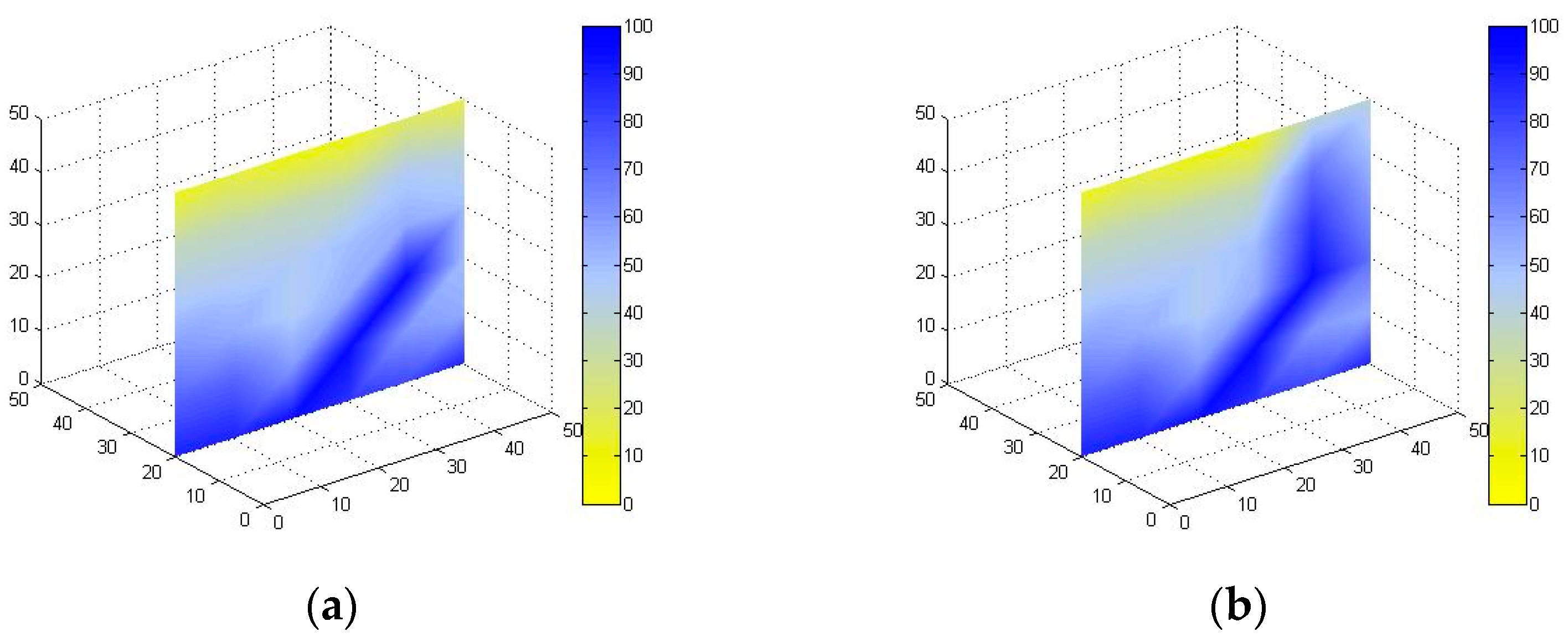

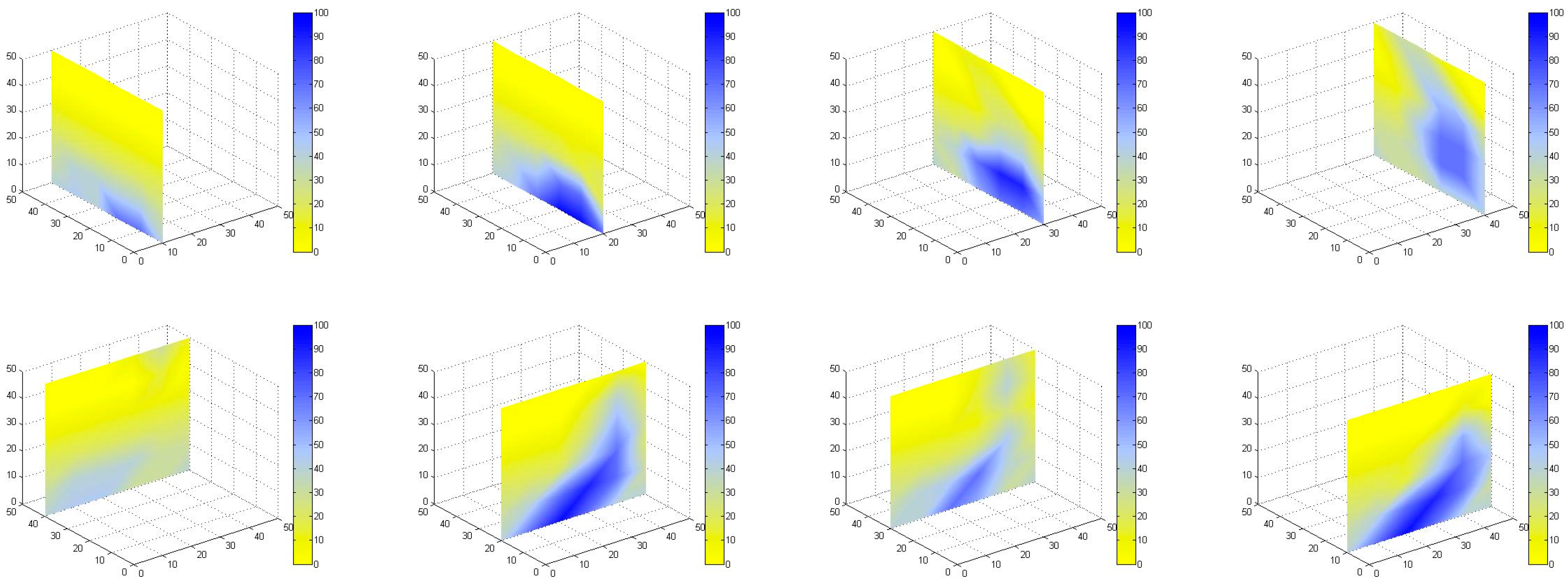

- The formation water simulation system was connected to the physical model of saturated gas. According to the experimental scheme, the production allocation for three simulated wells was set to simulate the depletion of the gas reservoir. Through the pressure sensor, resistivity sensor, and gas flowmeter, the instantaneous gas (water) flow rate, cumulative gas (water) production, and pressure (resistivity) in different areas of the model could be recorded in real time during the experiment. Notably, the resistivity needed to be converted into saturation data, and the variation diagram of water saturation in different regions was obtained using Matlab. In the diagram, yellow represents gas, and blue represents water.

- (5)

- During the experiment, the experiment ended when the gas flow rate was not detected at the outlet of the experiment.

3. Analysis of Experimental Results

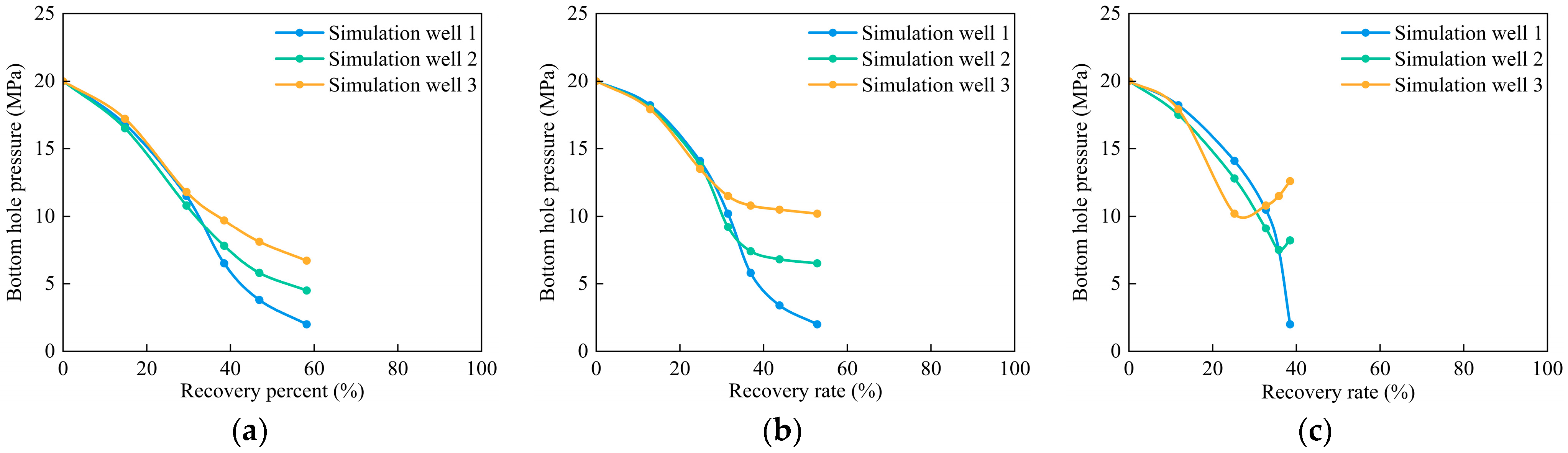

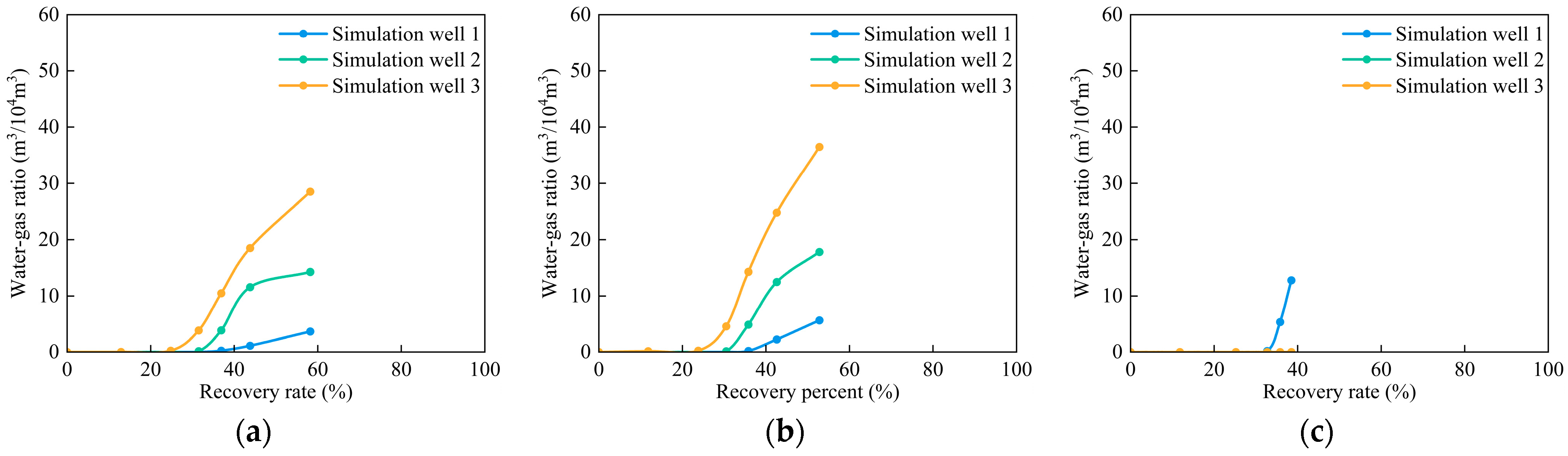

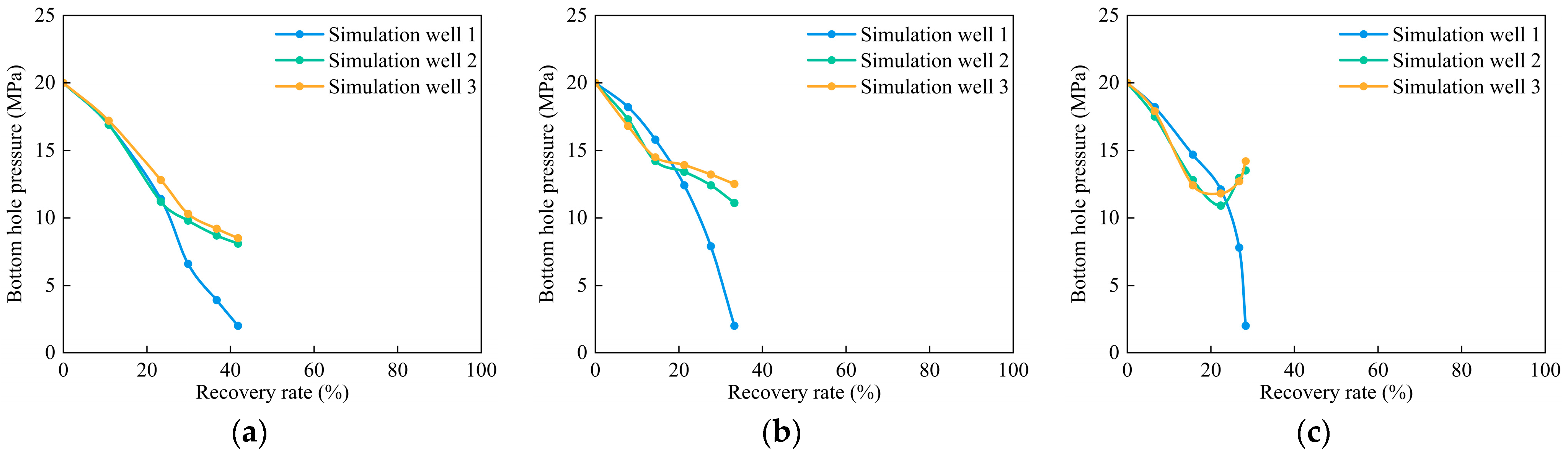

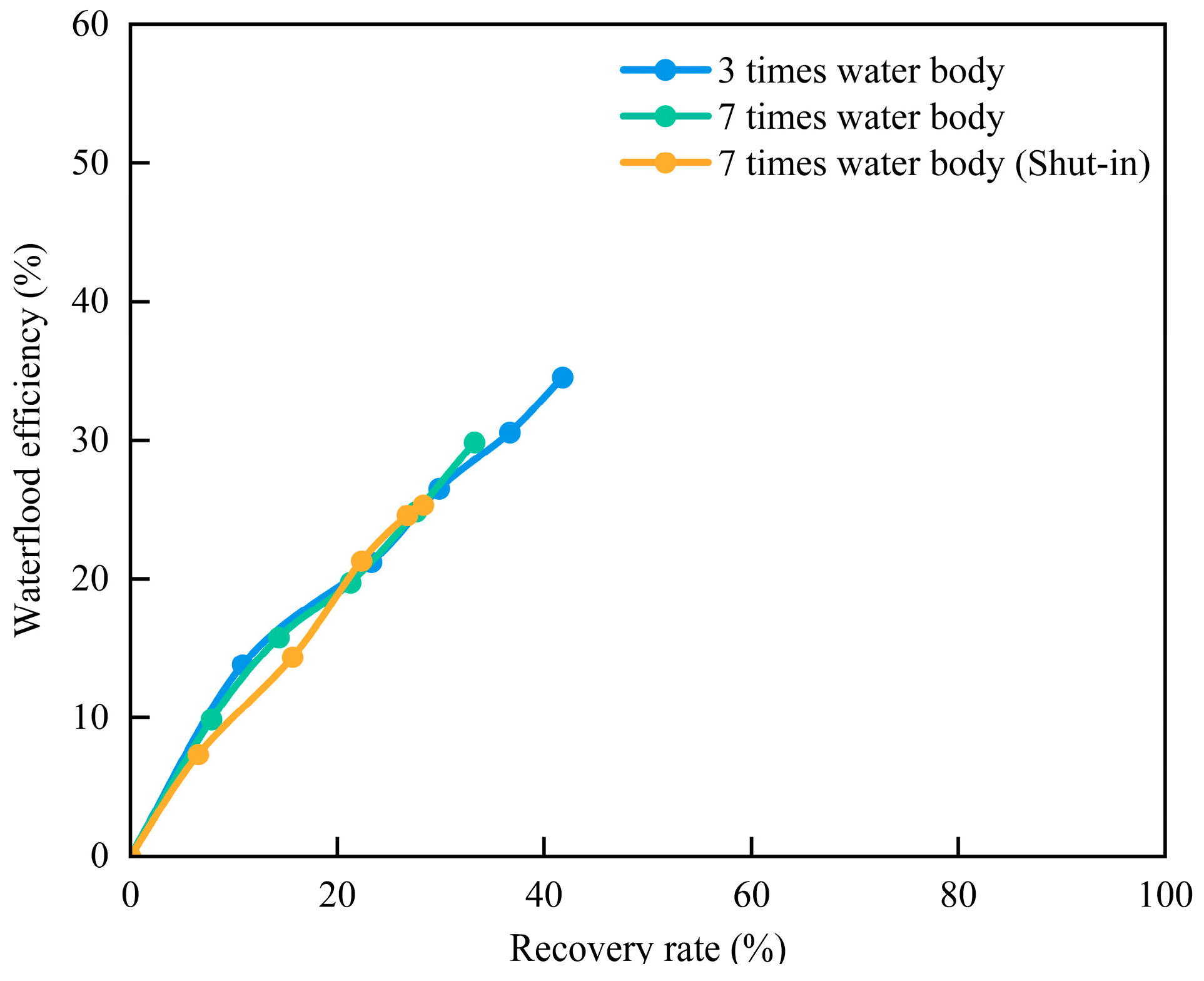

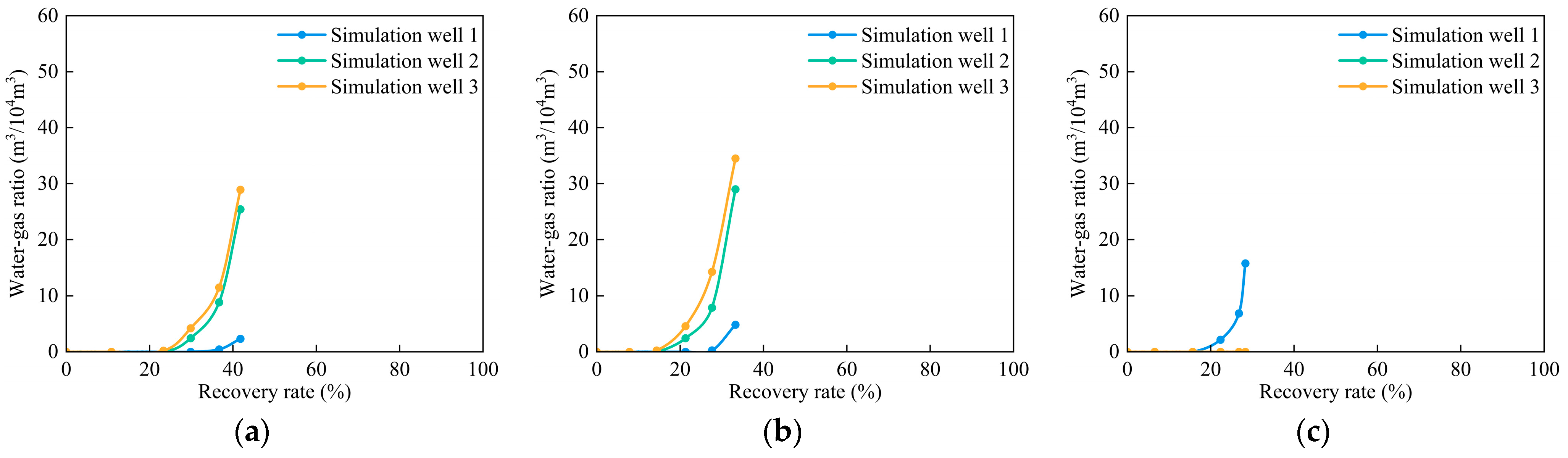

3.1. Water Invasion Simulation Experiment for Multi-Well Development of Fracture Model

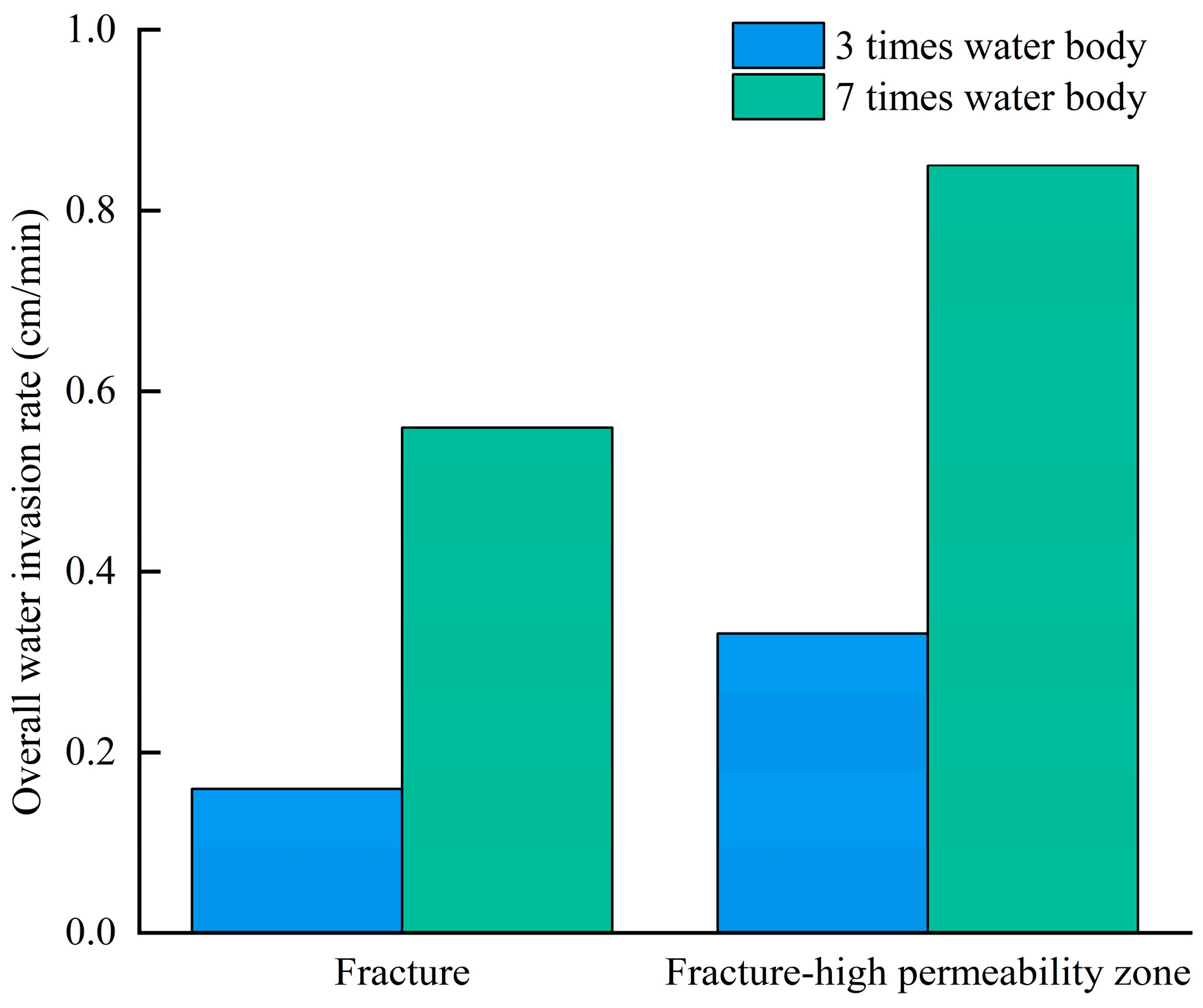

3.2. Water Invasion Simulation Experiment for Multi-Well Development of Fracture–High-Permeability Zone Model

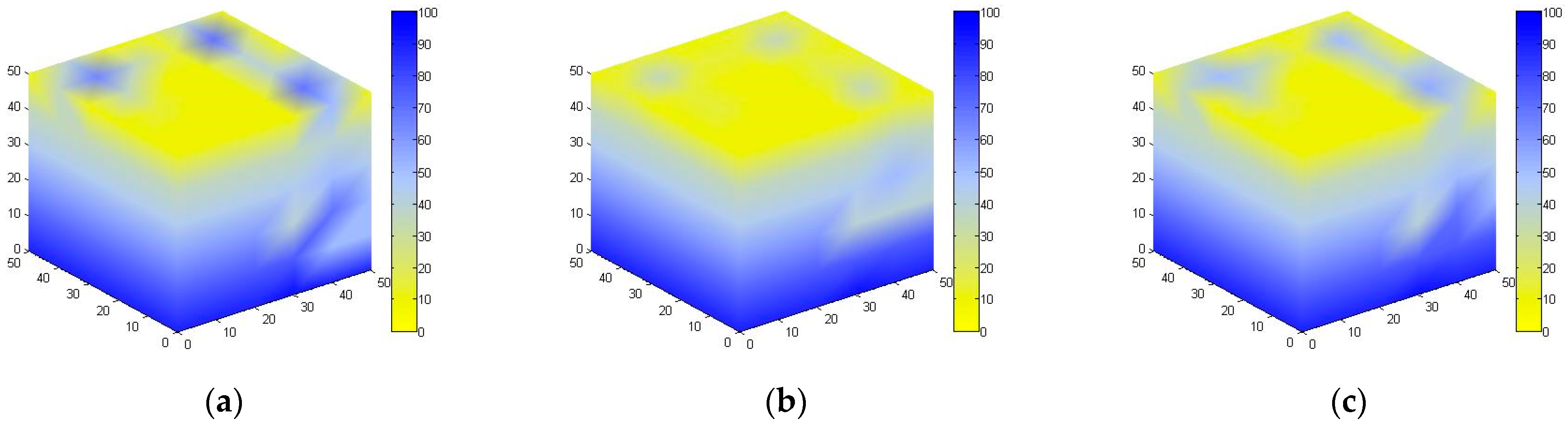

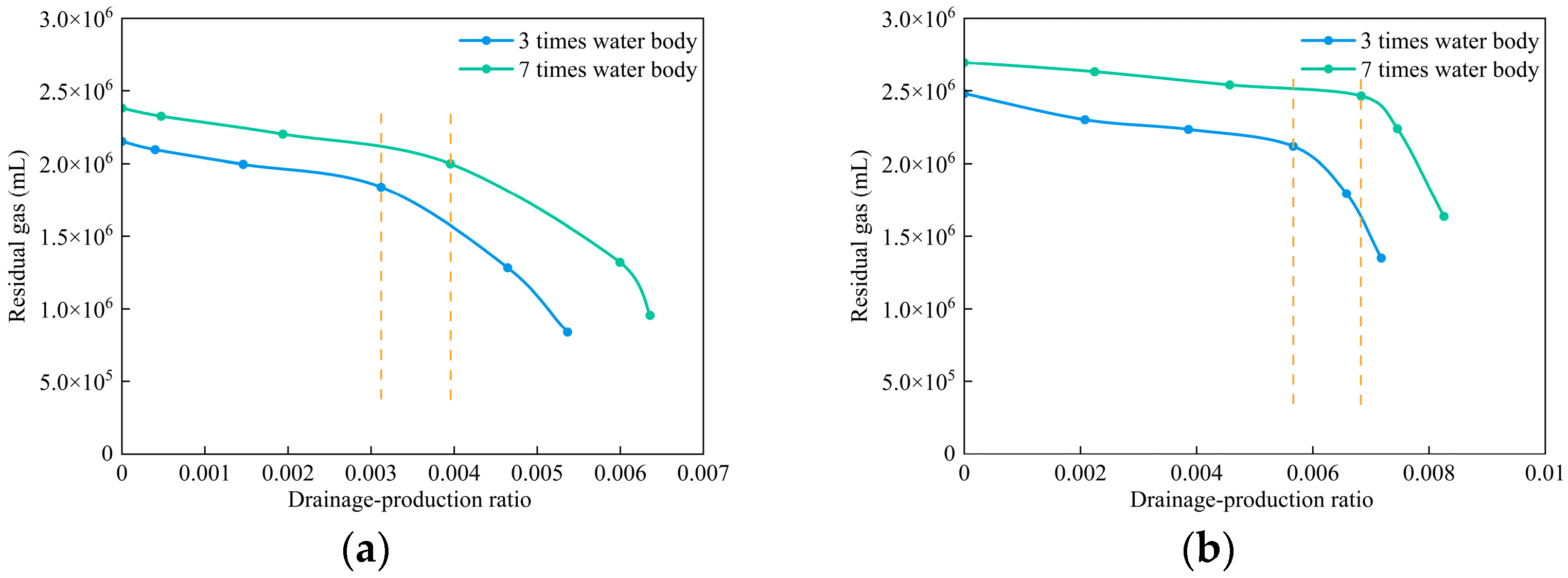

3.3. Characteristics of Residual Gas Distribution in Multi-Well Development of Sandstone Gas Reservoir with Strong Water Drive

4. Conclusions

- (1)

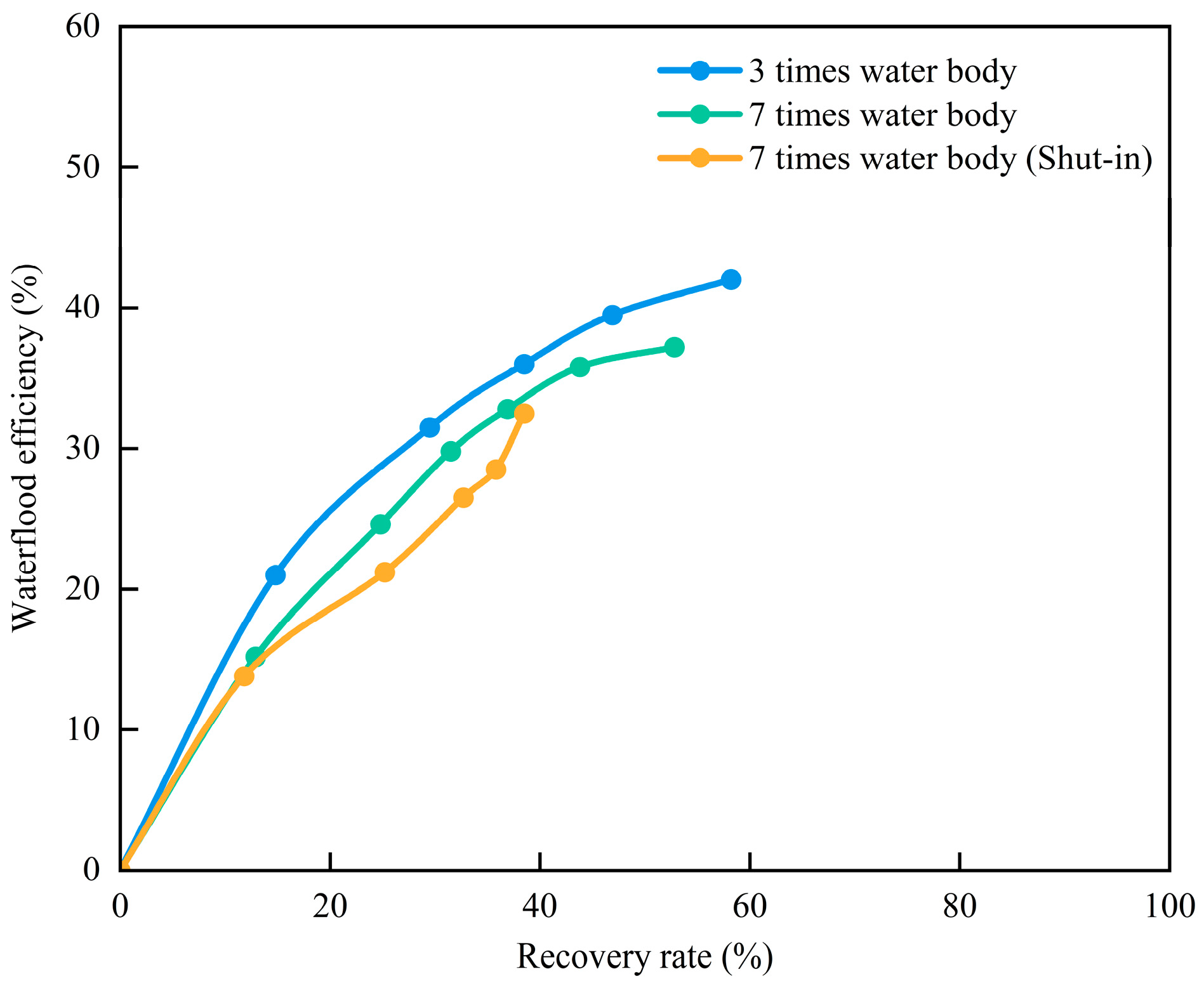

- Under the same production system conditions, the water invasion effect is heightened as the water body multiple increases. The strength of the edge and bottom water of the gas reservoir can be assessed by monitoring the change in the bottom hole pressure, allowing for the anticipation and prevention of potential water invasion risks.

- (2)

- In the late production stage, the water body rapidly advances along the fractures and high-permeability zones, resulting in gas wells waterflooding, lowering the ultimate recovery rate, and increasing the residual gas volume. Therefore, it is suggested that the low-position gas wells should be drained after water breakthrough to reduce the overall energy of water invasion, delay the water invasion rate in the high-position gas well area, improve the development effect, and increase the ultimate recovery rate of the gas reservoir. However, it is necessary to do an excellent job in treating produced water.

- (3)

- Under the same water body multiple conditions, shutting in the gas well immediately after water breakthrough reduces water production and increases the water-free production period but decreases the recovery rate. This production system is applicable when the water treatment capacity of the gas reservoir is poor, as it aims to maximize the water-free recovery rate and obtain the maximum economic benefits.

- (4)

- The residual gas is mainly distributed around the fracture–high-permeability zone and at the edge of the gas reservoir. It is suggested that well pattern thickening be implemented or the drainage–production ratio be increased in the residual gas enrichment area, the residual gas volume at abandonment be reduced, and the recovery rate be increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Sun, X.; Xiao, X. Efficient development technologies for ultradeep, overpressured and fractured sandstone gas reservoirs: A cased study of the Kelasu Gas Field in the Tarim Basin. Nat. Gas Ind. 2018, 38, 87–95. [Google Scholar] [CrossRef]

- Xu, X.; Wan, Y.; Chen, Y.; Hu, Y.; Mei, Q.; Jiao, C. Physical simulation of water invasion and water control for the fractured water-bearing gas reservoirs. Nat. Gas Geosci. 2019, 30, 1508–1518. [Google Scholar] [CrossRef]

- Lyu, Z.; Tang, H.; Liu, Q.; Tang, Y.; Wang, Q.; Chang, B.; Nie, Y. Dynamic evaluation method of water sealed gas for ultra-deep fractured tight gas reservoir in Kuqa Depression, Tarim Basin. Nat. Gas Geosci. 2022, 33, 1874–1882. [Google Scholar] [CrossRef]

- Guo, P.; Jing, S.; Peng, C. Technology and countermeasures for gas recovery enhancement. Nat. Gas Ind. 2014, 34, 48–55. [Google Scholar] [CrossRef]

- Jia, A.; Yan, H.; Guo, J.; He, D.; Wei, T. Characteristics and experiences of the development of various giant gas fields all over the world. Nat. Gas Ind. 2014, 34, 33–46. [Google Scholar] [CrossRef]

- Sun, Y.; Lu, J.; Wan, Y.; Han, Y.; Tang, H.; Li, Q. Enlightenments of Lacq and Meillon gas fields in France to the development of Longwangmiao Fm gas reservoirs in the Anyue Gas Field, Sichuan Basin. Nat. Gas Ind. 2016, 36, 37–45. [Google Scholar] [CrossRef]

- Wen, D. Study on Oil and Gas Reservoir Calculation and Hydrocarbon Accumulation of Ouge Basin-Taking Kelu and Hela Gas Fields as Examples. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2017. [Google Scholar]

- Mu, L.; Chen, Y.; Xu, A.; Wang, R. Technological progress and development directions of PetroChina overseas oil and gas field production. Petrol. Explor. Develop. 2020, 47, 120–128. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Gao, S.; Ye, L.; Liu, H.; Zhu, W.; Fang, F. Water production mechanism of tight sandstone gas reservoir and its influence on percolation capacity. Nat. Gas Geosci. 2019, 30, 1519–1530. [Google Scholar] [CrossRef]

- Lyu, J.; Lu, X.; Wang, W.; Xie, K.; Hu, Y. Visual test of gas-water distribution in tight sandstone pores. Spec. Oil Gas Reserv. 2019, 26, 136–141. [Google Scholar] [CrossRef]

- Fan, H.; Zhong, B.; Li, X.; Liu, Y.; Yang, H.; Feng, X.; Zhang, Y. Studies on water invasion mechanism of fractured-watered gas reservoir. Nat. Gas Geosci. 2012, 23, 1179–1184. [Google Scholar] [CrossRef]

- Li, T. Characteristics of water influx in the development of the Puguang Gas Field, Sichuan Basin. Nat. Gas Ind. 2014, 34, 65–71. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, T.; Chen, W.; Zhu, G.; Wang, X. Pore-scale simulation of gas-water two phase flow in carbonate reservoir with different combinations of pore, network and hole. J. Southwest Pet. Univ. Sci. Technol. Ed. 2023, 45, 88–96. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, J.; Guo, J.; Cheng, Y.; Zhang, Q. A visualized experiment on gas-water two-phase seepage through oolitic reservoirs in the Longgang Gas Field, Sichuan Basin. Nat. Gas Ind. 2012, 32, 64–66. [Google Scholar] [CrossRef]

- Fang, F.; Li, X.; Gao, S.; Xue, H.; Zhu, W.; Liu, H.; An, W.; Li, C. Visual simulation experimental study on water invasion rules of gas reservoir with edge and bottom water. Nat. Gas Geosci. 2016, 27, 2246–2252. [Google Scholar] [CrossRef]

- Fang, F.; Liu, H.; Xiao, Q.; Qing, H.; Yang, Q. Experimental simulation study on water invasion laws of heterogeneous gas reservoir. Lab. Res. Explor. 2019, 38, 85–89. [Google Scholar] [CrossRef]

- Liu, H.; Ren, D.; Gao, S.; Hu, Z.; Ye, L.; Liu, X. Water influx mechanism and development strategy of gas reservoirs with edge and bottom water. Nat. Gas Ind. 2015, 35, 47–53. [Google Scholar] [CrossRef]

- Jia, A.; Yan, H. Problems and countermeasures for various types of typical carbonate gas reservoirs development. Acta Pet. Sin. 2014, 35, 519–527. [Google Scholar] [CrossRef]

- Gao, S.; Yang, M.; Ye, L.; Liu, H.; Zhu, W. Simulation experiment of water invasion performance in low-permeability bottom water gas reservoir and its influence on recovery factor. Nat. Gas Ind. 2022, 42, 61–70. [Google Scholar] [CrossRef]

- Shen, W.; Li, X.; Liu, X.; Lu, J.; Jiao, C. Physical simulation of water influx mechanism in fractured gas reservoirs. J. Cent. South Univ. Sci. Technol. 2014, 45, 3283–3287. [Google Scholar]

- Wang, L.; Yang, S.; Liu, Y.; Xu, W.; Deng, H.; Meng, Z.; Han, W.; Qian, K. Experiments on gas supply capability of commingled production in a fracture-cavity carbonate gas reservoir. Petrol. Explor. Develop. 2017, 44, 779–787. [Google Scholar] [CrossRef]

- Huang, X.; Guo, X.; Zhou, X.; Shen, C.; Lu, X.; Qi, Z.; Xiao, Q.; Yan, W. Effects of water invasion law on gas wells in high temperature and high pressure gas reservoir with a large accumulation of water-soluble gas. J. Nat. Gas Sci. Eng. 2019, 62, 68–78. [Google Scholar] [CrossRef]

- Fang, F.; Shen, W.; Li, X.; Gao, S.; Liu, H.; Li, J. Experimental study on water invasion mechanism of fractured carbonate gas reservoirs in Longwangmiao Formation, Moxi block, Sichuan Basin. Environ. Earth Sci. 2019, 78, 316. [Google Scholar] [CrossRef]

- Zhou, M.; Yue, P.; Guo, C.; Chen, P. Dynamic simulation of water invasion in fractured gas reservoir. Lab. Res. Explor. 2020, 39, 104–109. [Google Scholar] [CrossRef]

- Liu, H.; Gao, S.; Ye, L.; Zhu, W.; An, W. Change laws of water invasion performance in fractured–porous water-bearing gas reservoirs and key parameter calculation methods. Nat. Gas Ind. 2020, 40, 90–99. [Google Scholar] [CrossRef]

- Hu, Y.; Li, X.; Jiang, L.; Wan, Y.; Guo, C.; Jiao, C.; Cai, X.; Jing, W.; Xu, X.; Zhou, M.; et al. Production experiment of multi-layer edge-water loose sandstone gas reservoir in Qaidam Basin. Nat. Gas Geosci. 2022, 33, 1499–1508. [Google Scholar] [CrossRef]

- Yang, D.; Xie, K.; Yin, Q.; Lu, X.; Xiao, J.; Shen, W. Research status and prospect of water intrusion law in edge and bottom water gas reservoirs. Nat. Gas Geosci. 2024, 35, 1304–1322. [Google Scholar] [CrossRef]

- Xu, X.; Mei, Q.; Chen, Y.; Han, Y.; Tang, H.; Jiao, C.; Guo, C. Experimental analysis method for water invasion and development performance of gas reservoir. Nat. Gas Geosci. 2020, 31, 1355–1366. [Google Scholar] [CrossRef]

- Fang, F.; Gao, S.; Liu, H.; Xiao, Q.; Ma, X.; Zhang, C. Experimental simulation study on water invasion law of gas reservoir with multiwell development. Lab. Res. Explor. 2019, 38, 42–45. [Google Scholar]

- Fang, F.; Li, X.; Gao, S.; Liu, H.; Zhu, W.; An, W.; Li, C.; Gui, T. Study on dynamic physical simulation experiment of water invasion in carbonate gas reservoir. In Proceedings of the 2016 Annual Natural Gas Academic Conference, Yinchuan, China, 28 September 2016. [Google Scholar]

- Jiang, T.; Zhang, H.; Wang, H.; Yin, G.; Xiao, X. Effects of faults geomechanical activity on water invasion in Kela 2 Gasfield, Tarim Basin. Nat. Gas Geosci. 2017, 28, 1735–1744. [Google Scholar] [CrossRef]

| Experimental Scheme | Water Body Multiples (PV) | Number of Simulation Wells | Single-Well Production Allocation (mL·min−1) | Production System |

|---|---|---|---|---|

| Different water body multiples | 0 | 3 | 5000, 10,000, 15,000 | No shut-in after water breakthrough |

| 3 | 3 | |||

| 7 | 3 | |||

| Different production systems | 7 | 3 | 5000, 10,000, 15,000 | Shut-in after water breakthrough |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, F.; He, S.; Zhuang, J.; Zhang, J.; Bian, Y. Large-Scale Physical Simulation Experiment of Water Invasion Law for Multi-Well Development in Sandstone Gas Reservoirs with Strong Water Drive. Appl. Sci. 2024, 14, 8067. https://doi.org/10.3390/app14178067

Fang F, He S, Zhuang J, Zhang J, Bian Y. Large-Scale Physical Simulation Experiment of Water Invasion Law for Multi-Well Development in Sandstone Gas Reservoirs with Strong Water Drive. Applied Sciences. 2024; 14(17):8067. https://doi.org/10.3390/app14178067

Chicago/Turabian StyleFang, Feifei, Sijie He, Jian Zhuang, Jie Zhang, and Yanan Bian. 2024. "Large-Scale Physical Simulation Experiment of Water Invasion Law for Multi-Well Development in Sandstone Gas Reservoirs with Strong Water Drive" Applied Sciences 14, no. 17: 8067. https://doi.org/10.3390/app14178067