Numerical Study of Internal Flow Field in a Disc Stack Centrifuge Based on Mixture-PBM Model

Abstract

1. Introduction

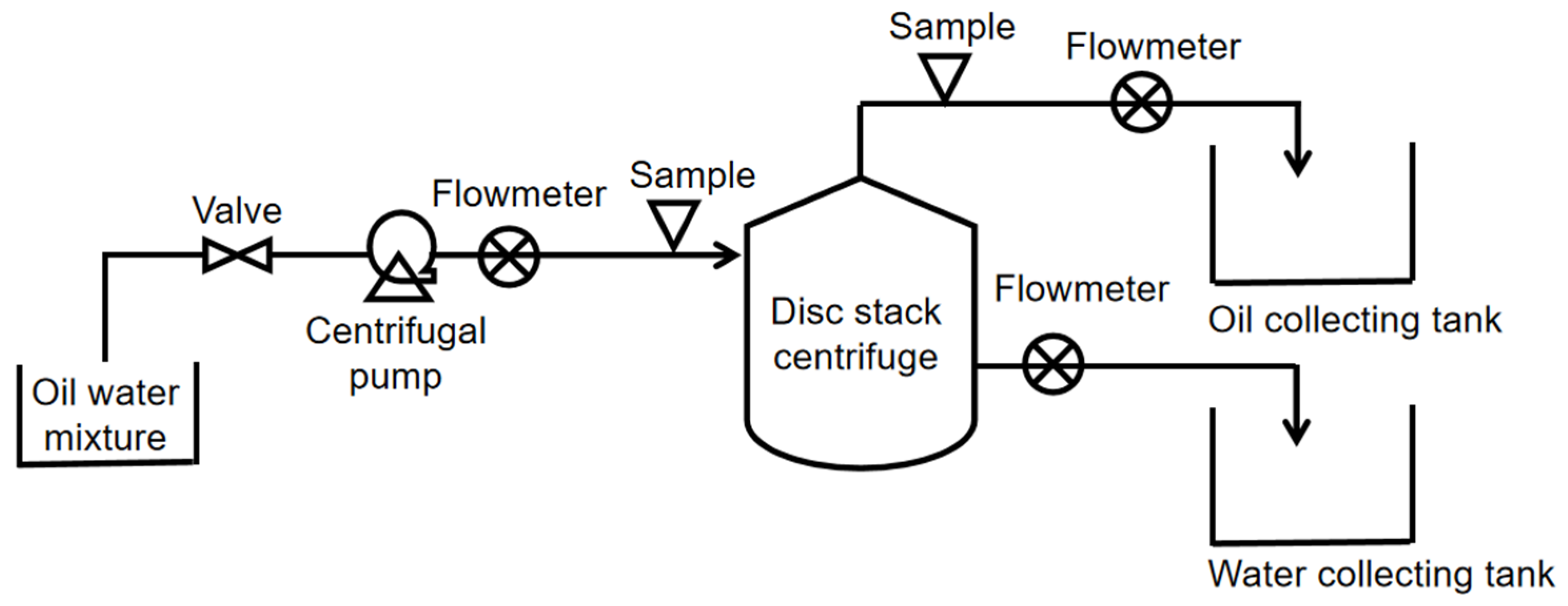

2. Physical Models and Numerical Simulation

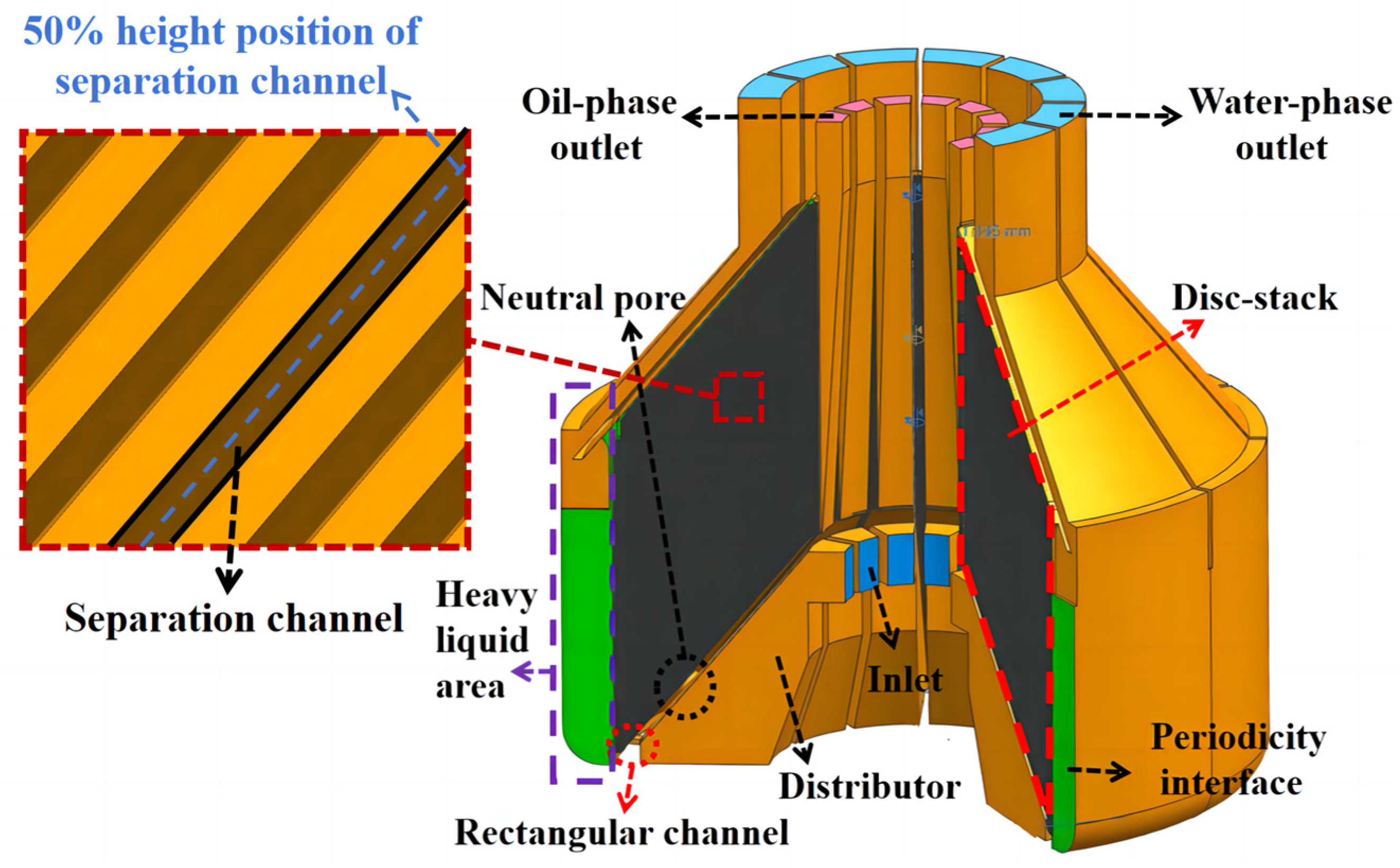

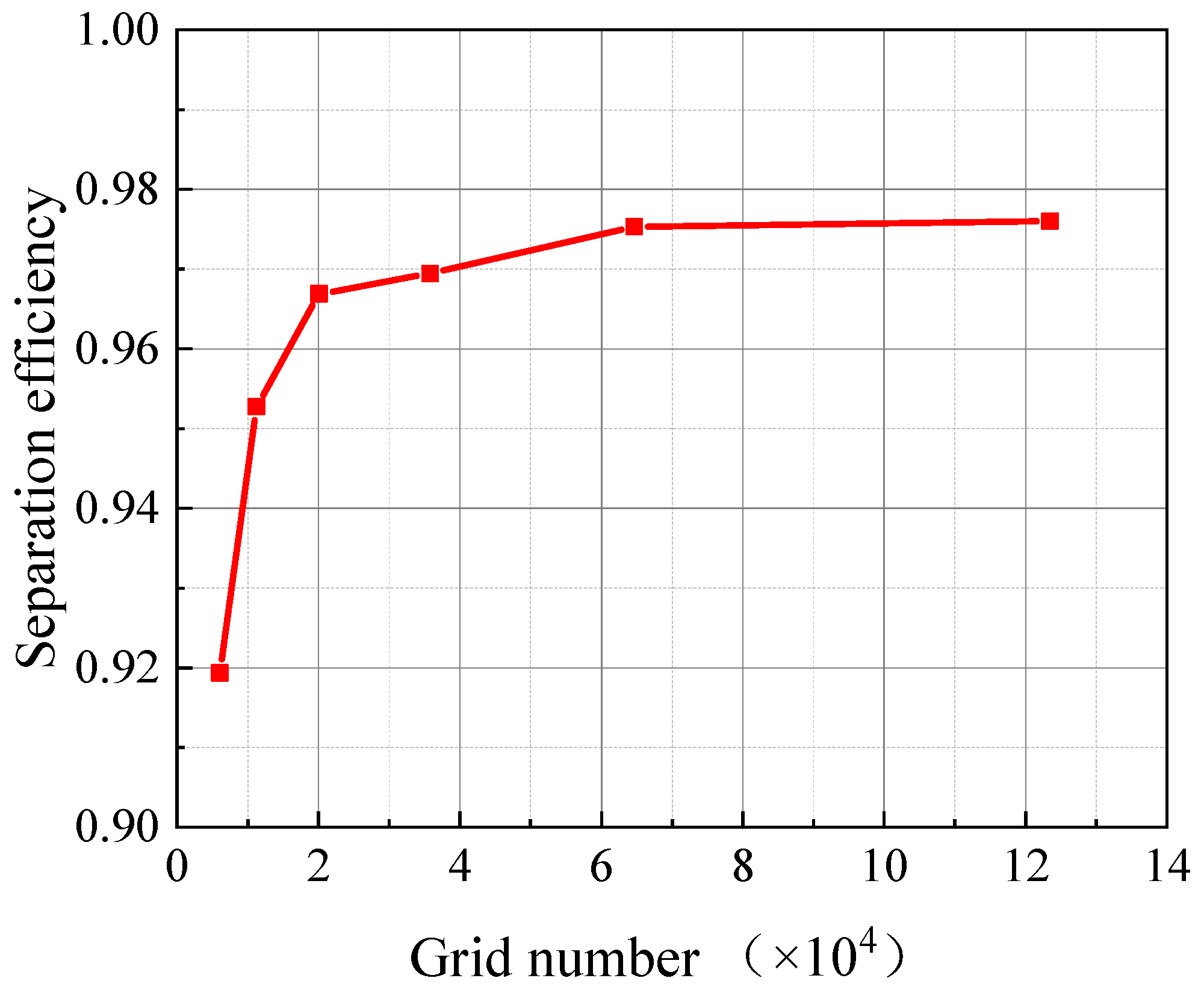

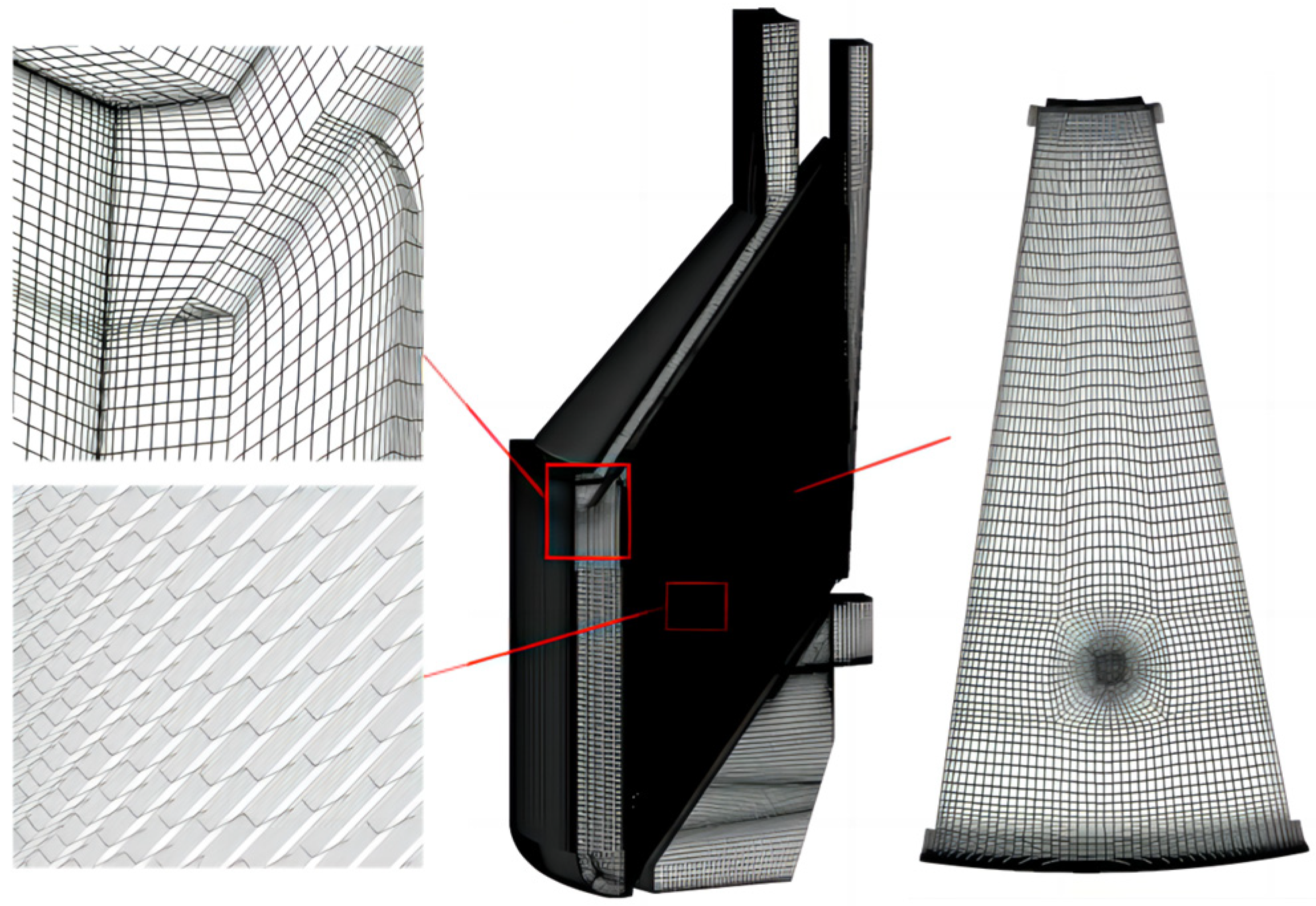

2.1. Model and Meshing

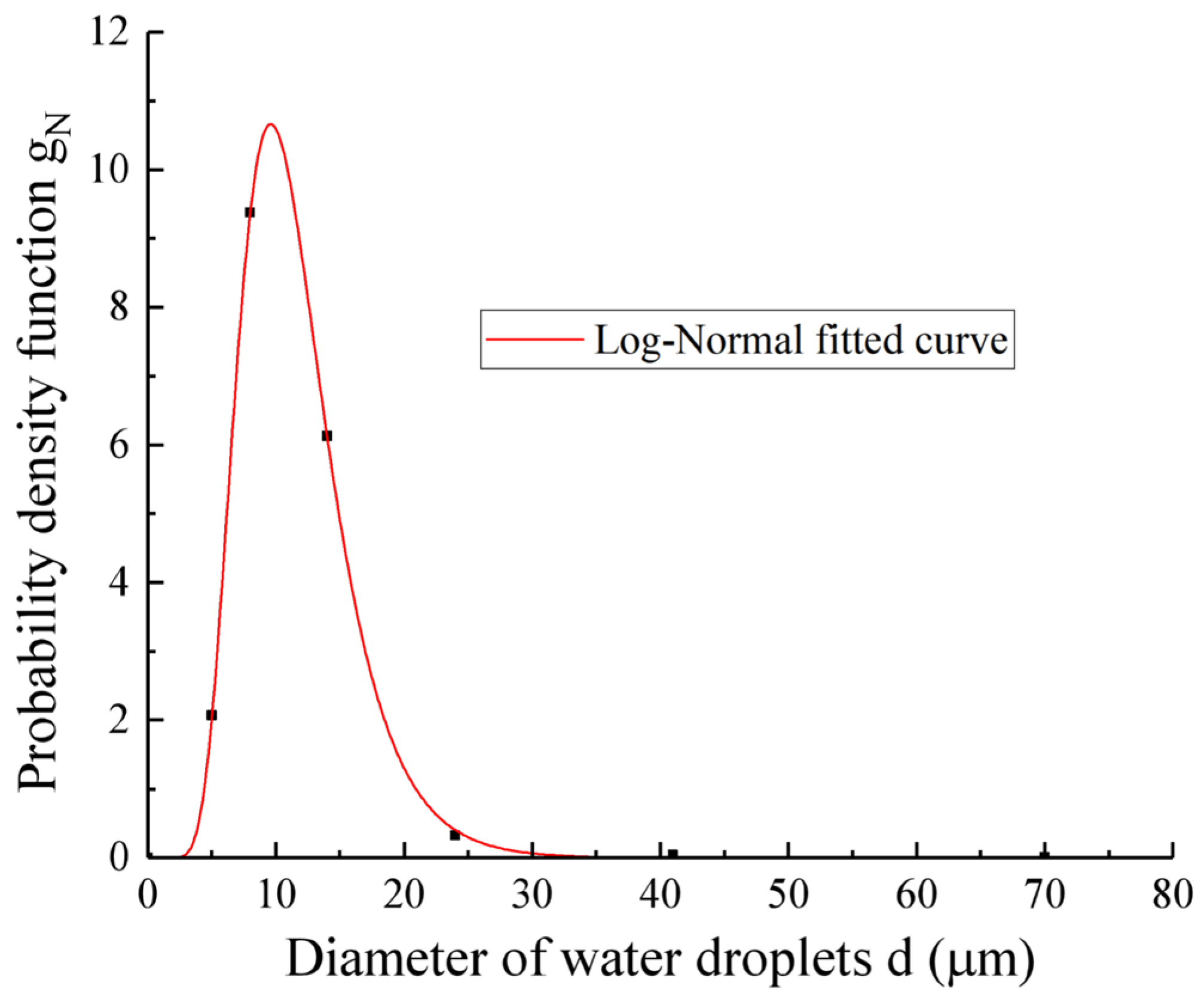

2.2. Numerical Methods and Boundary Conditions

3. Results and Discussion

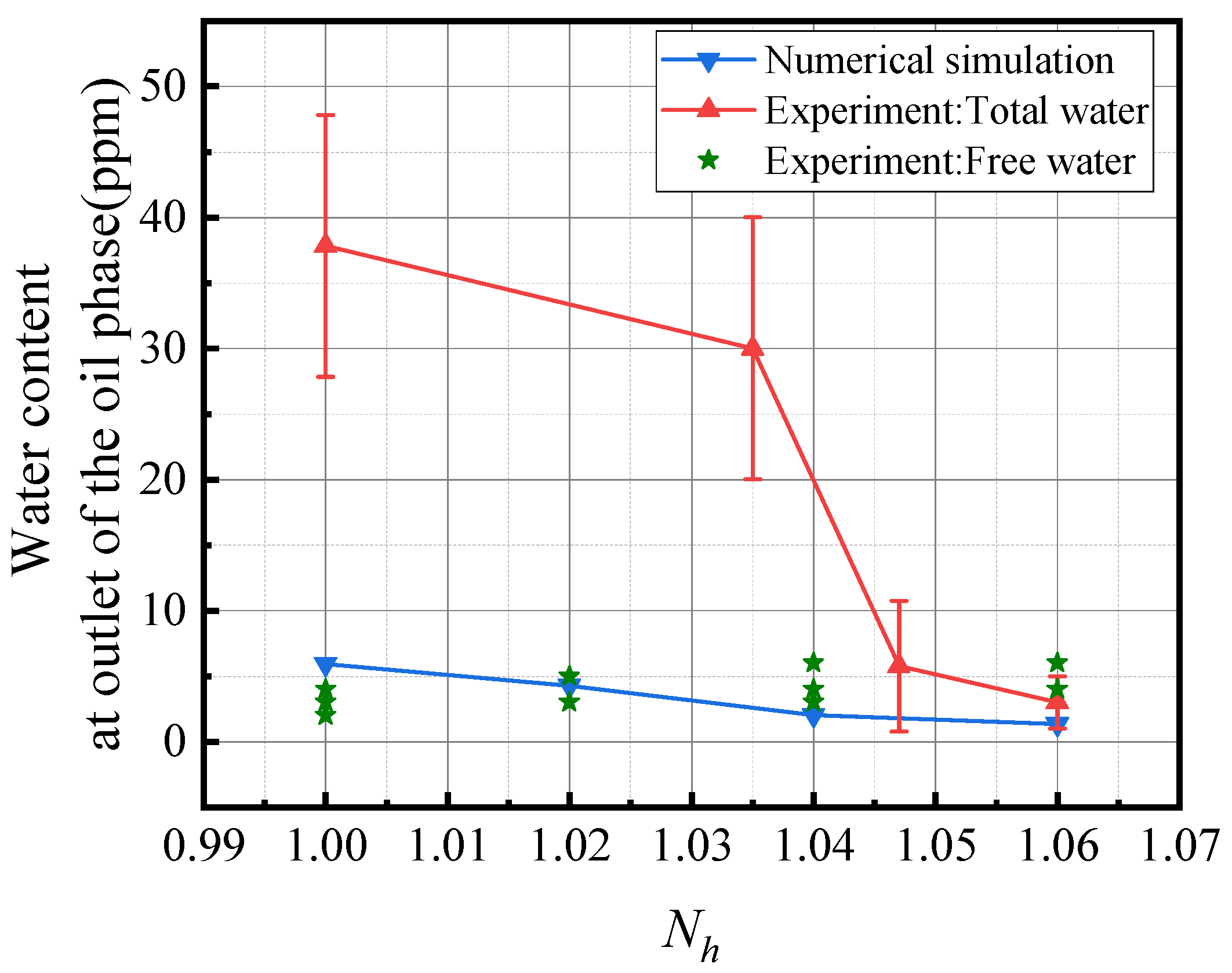

3.1. Comparison of Experimental and Numerical Simulation Results

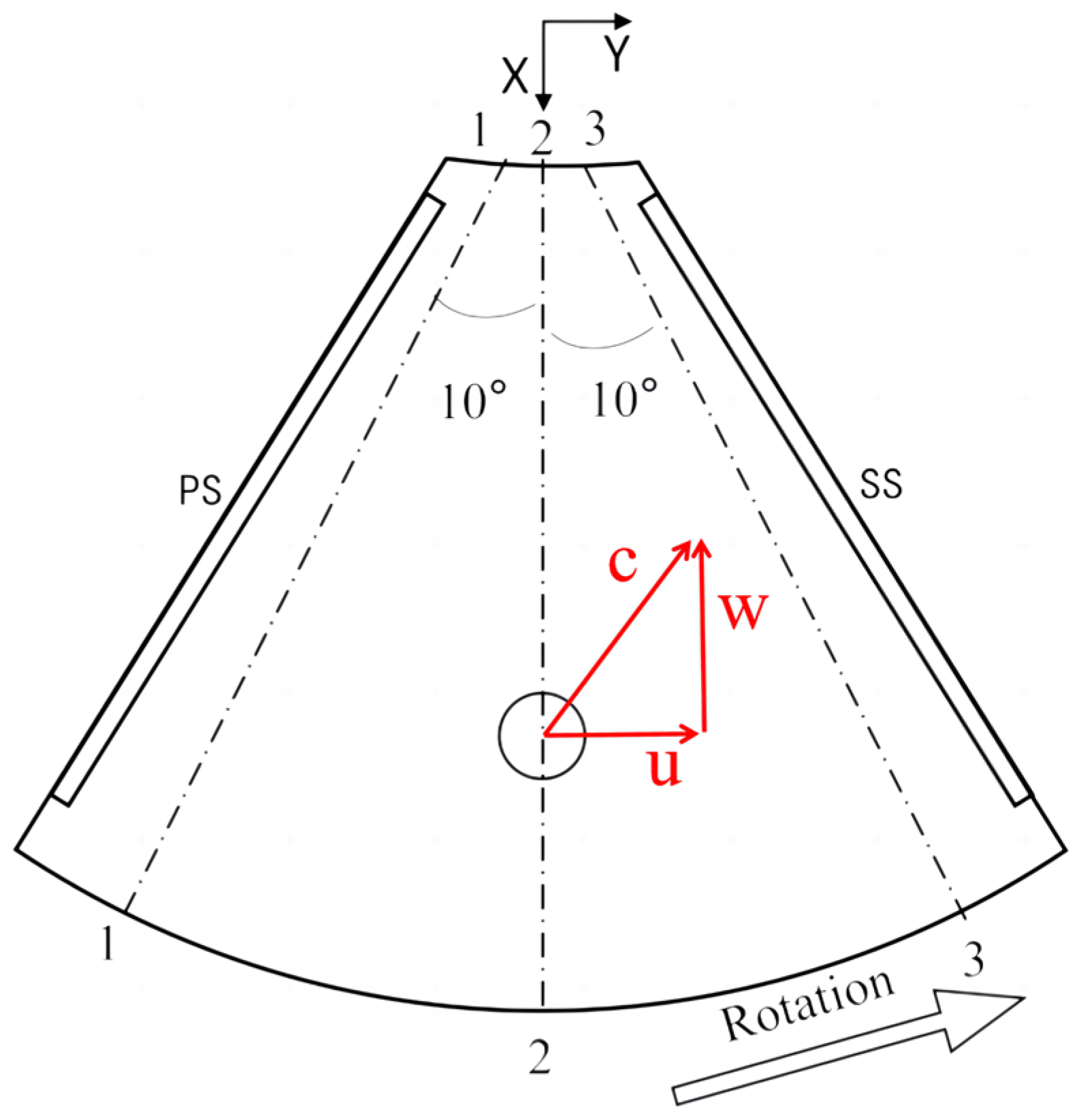

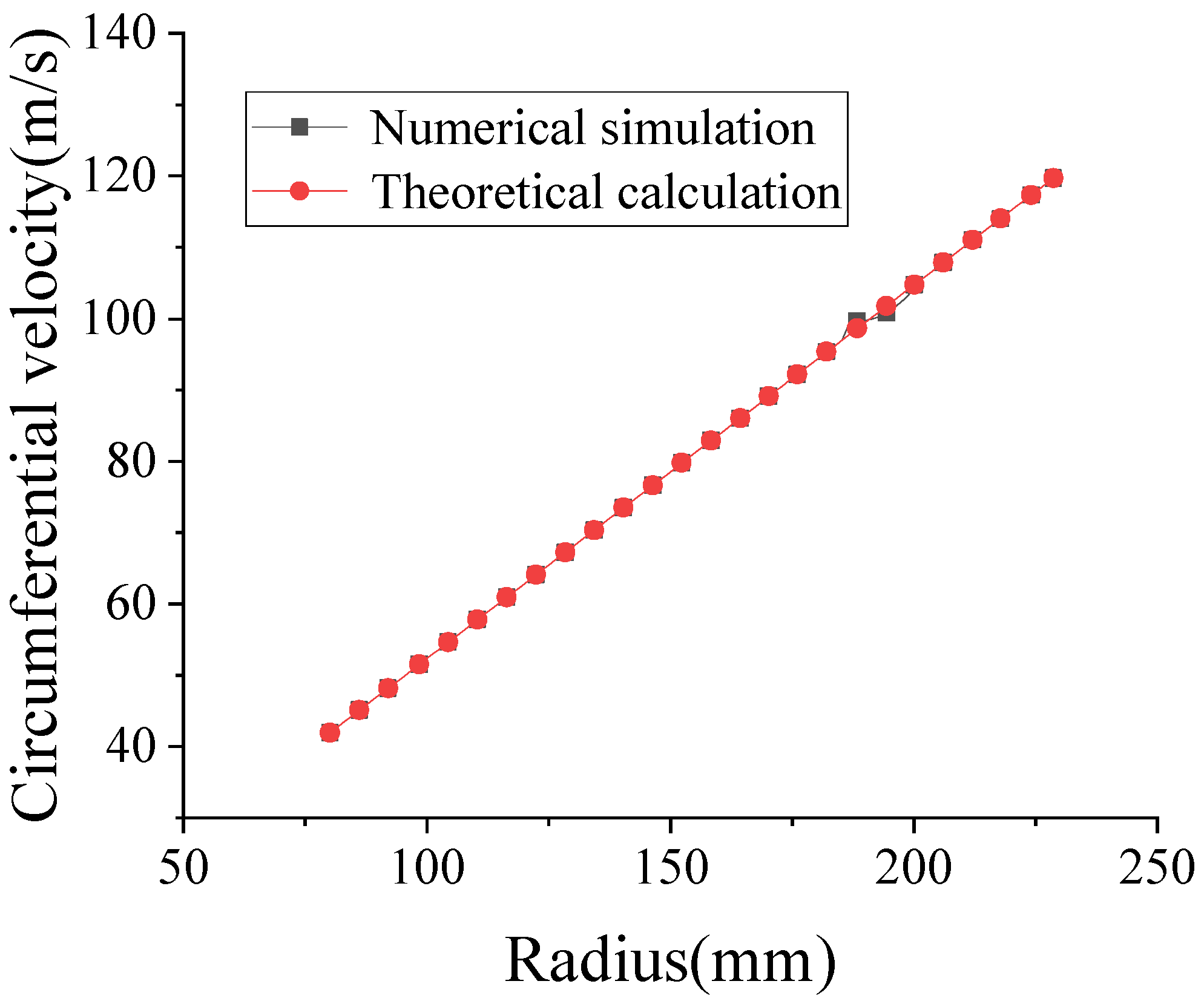

3.2. Effect of Ribs on the Distribution of Flow Field Parameters

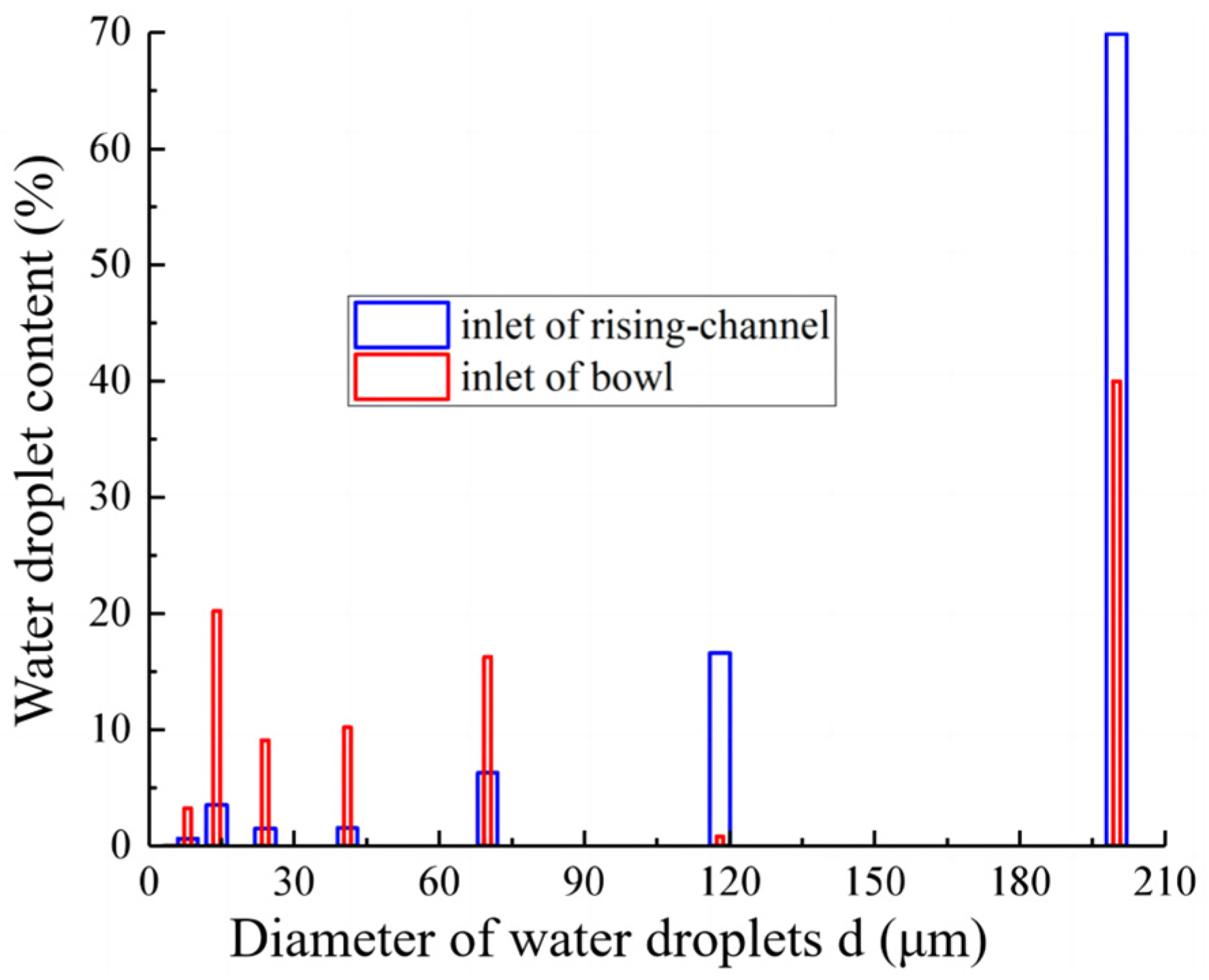

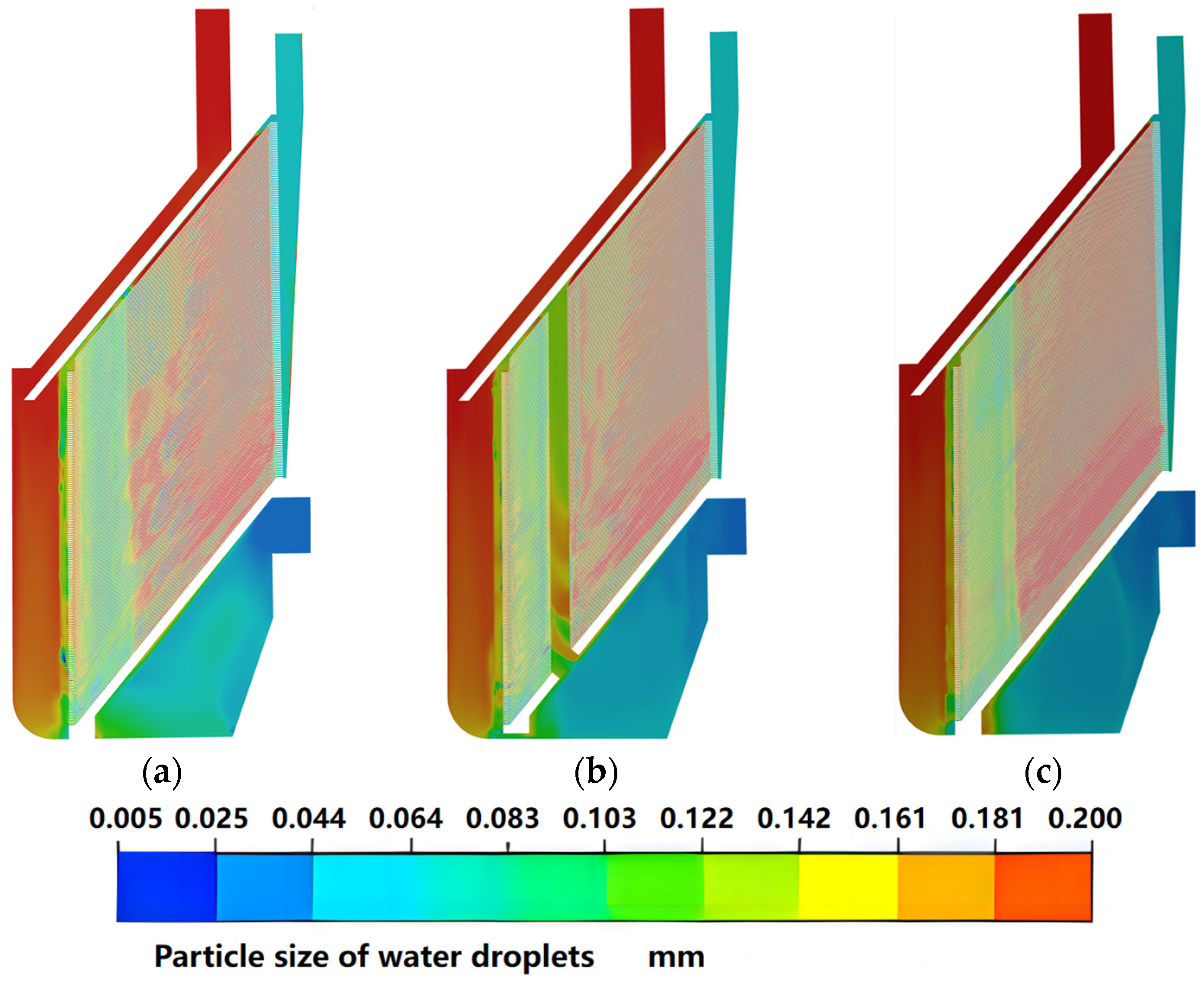

3.3. Coalescence and Breakup of Water Droplets

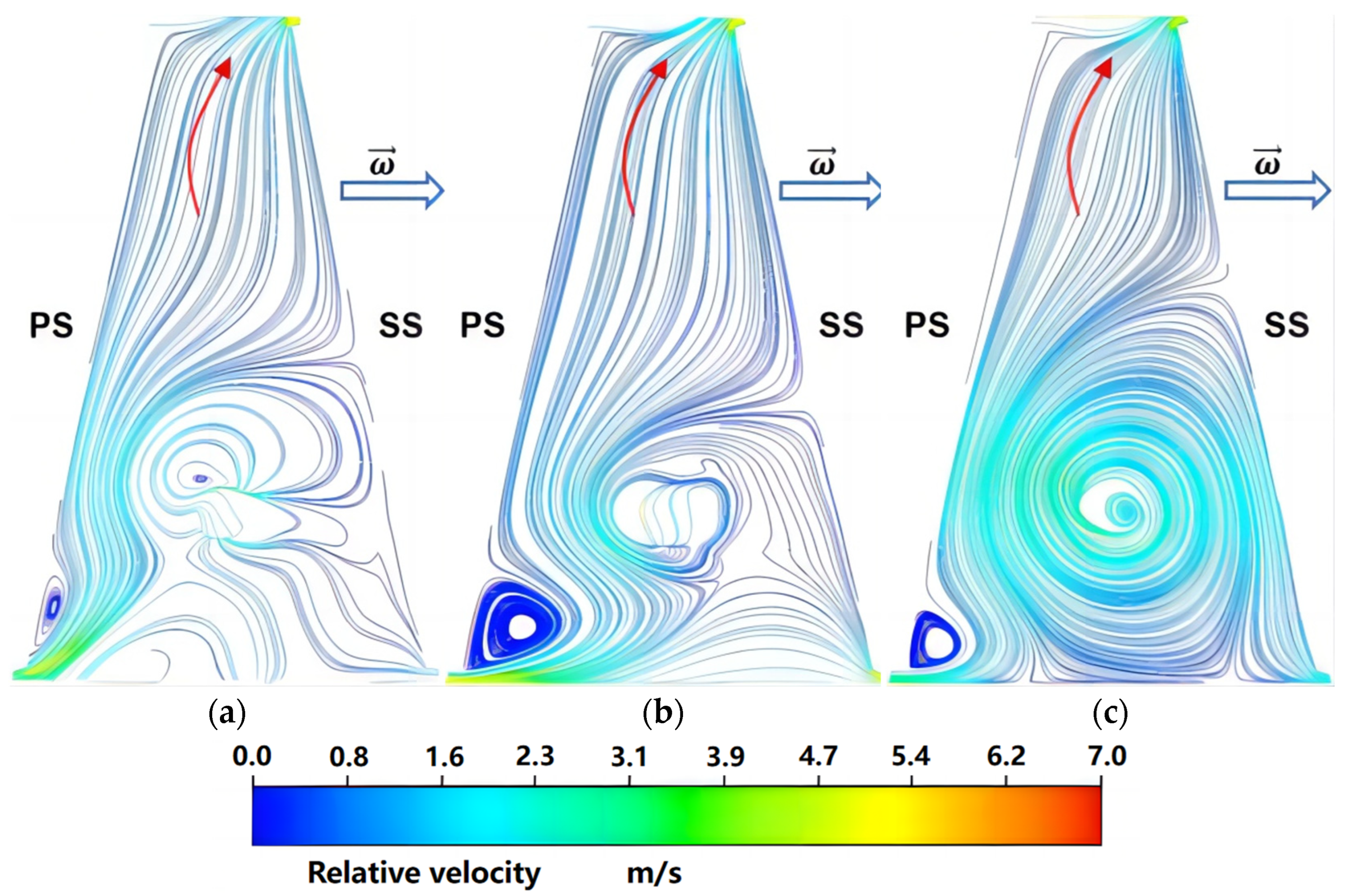

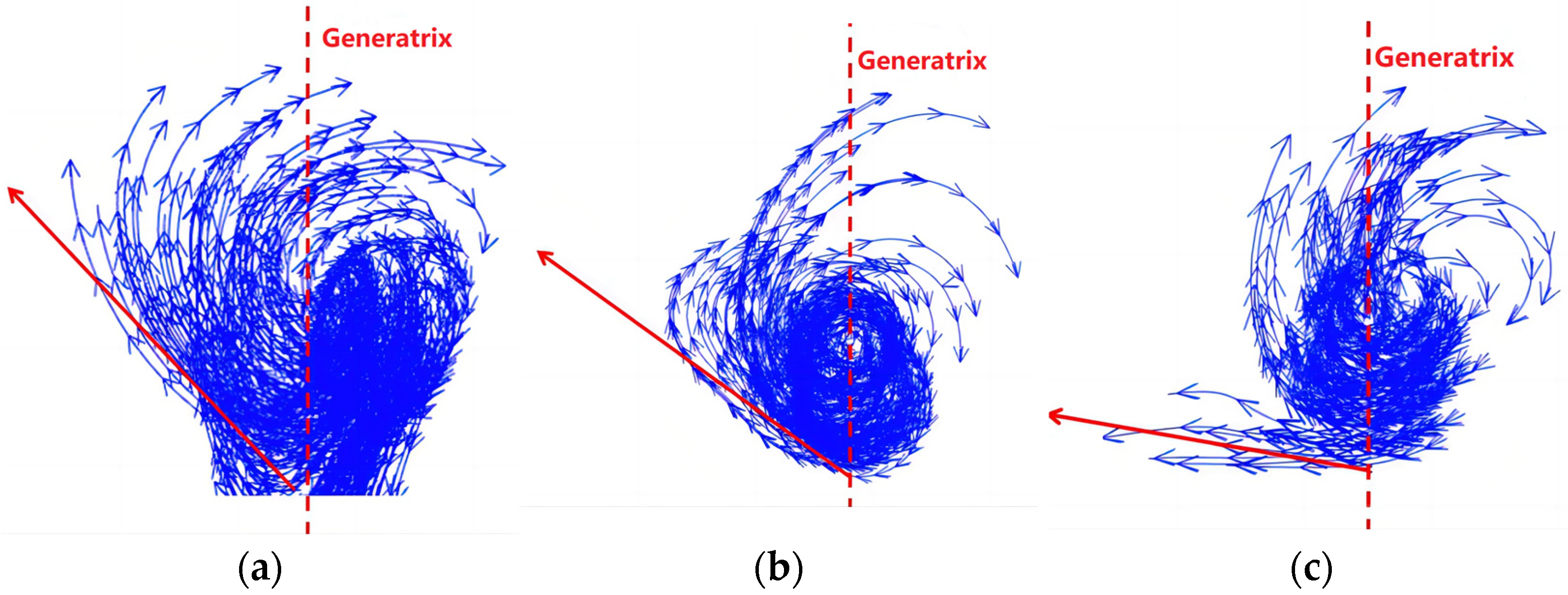

3.4. Three-Dimensional Flow Characteristics of the Internal Flow Field

4. Conclusions

- The error between the numerical simulation results and the separation efficiency of the test results is less than 1%. When Nd = 1~1.06, the separation efficiency of the disc stack centrifuge increases with the increase in rotational speed. When Nd = 1.06, the separation efficiency η = 99.99%.

- Considering the ribs of the disc, the hysteresis phenomenon of the liquid flow in the disc stack centrifuge is significantly reduced, and the results of numerical simulation (parameter distribution of the flow field) can reach 98% of the theoretical results, which verifies the reliability of the numerical simulation results. The ribs of the disc have an indispensable role.

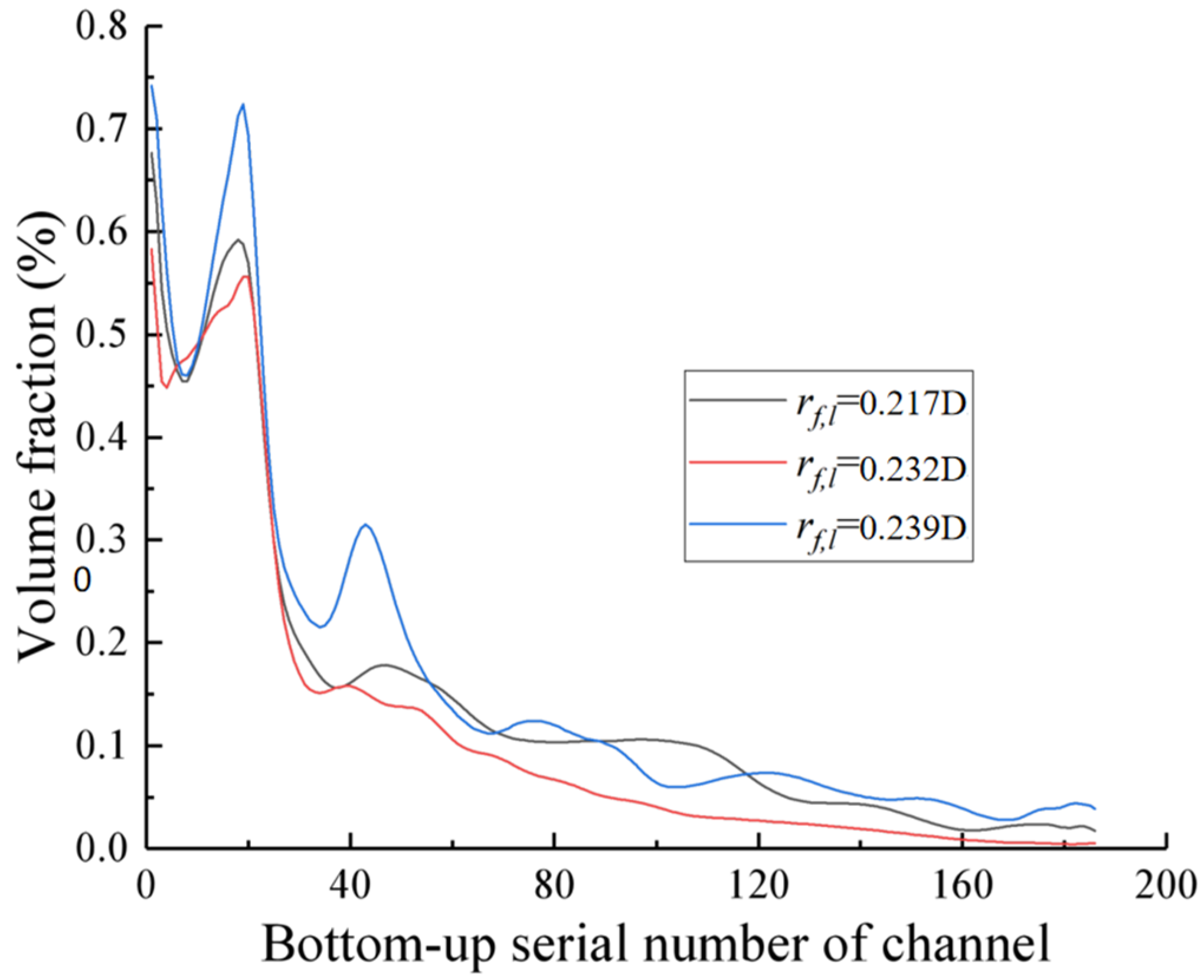

- A total of 90% of the water droplets in the oil–water mixture complete coalescence and precipitation in the distributor and do not pass through the rising channel but enter the heavy liquid area of the bowl through the rectangular channel and are discharged to the disc stack centrifuge through the water-phase outlet. The coalescence phenomenon of the water droplets entering the separation channel is greater than the breakup phenomenon.

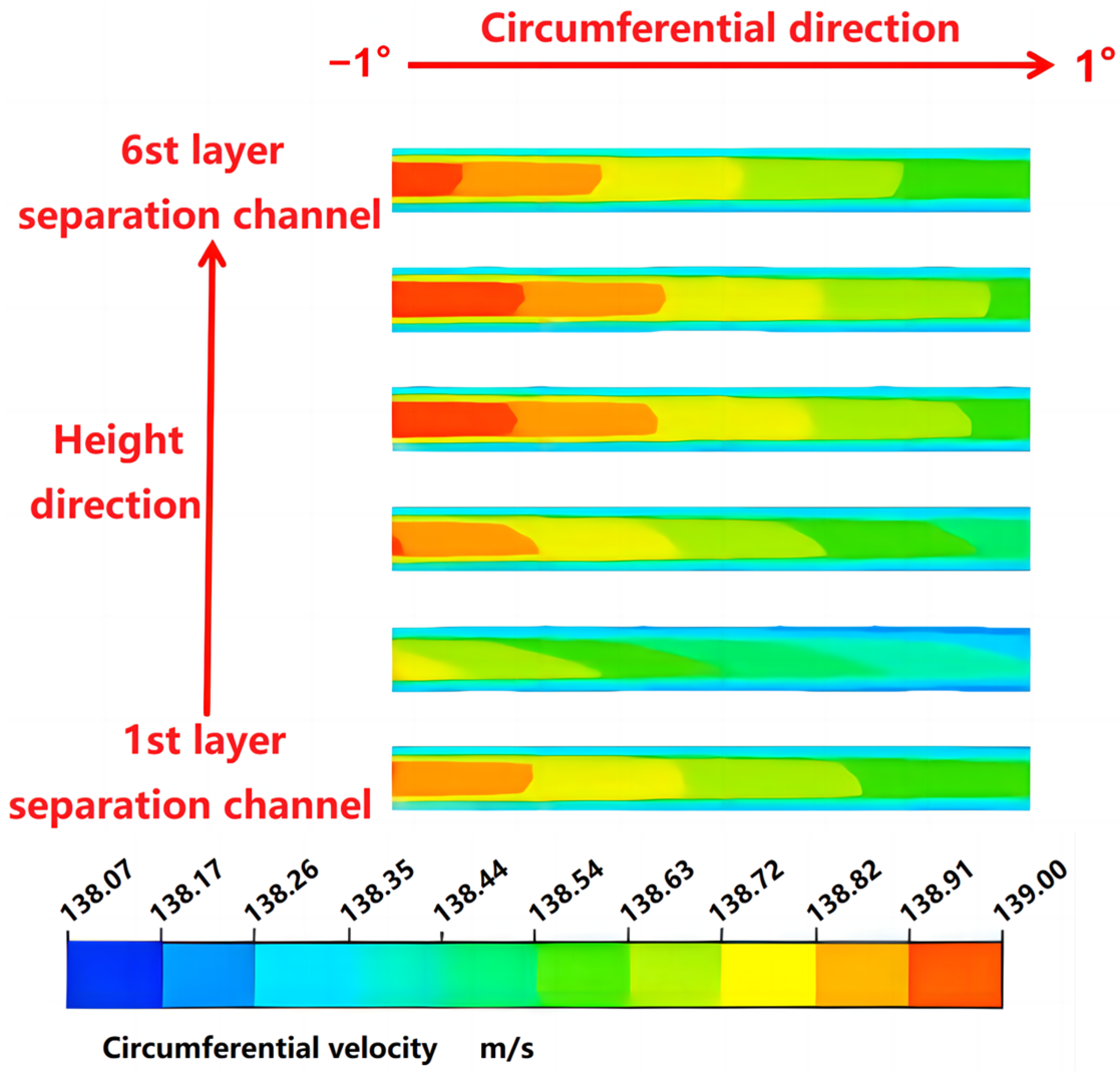

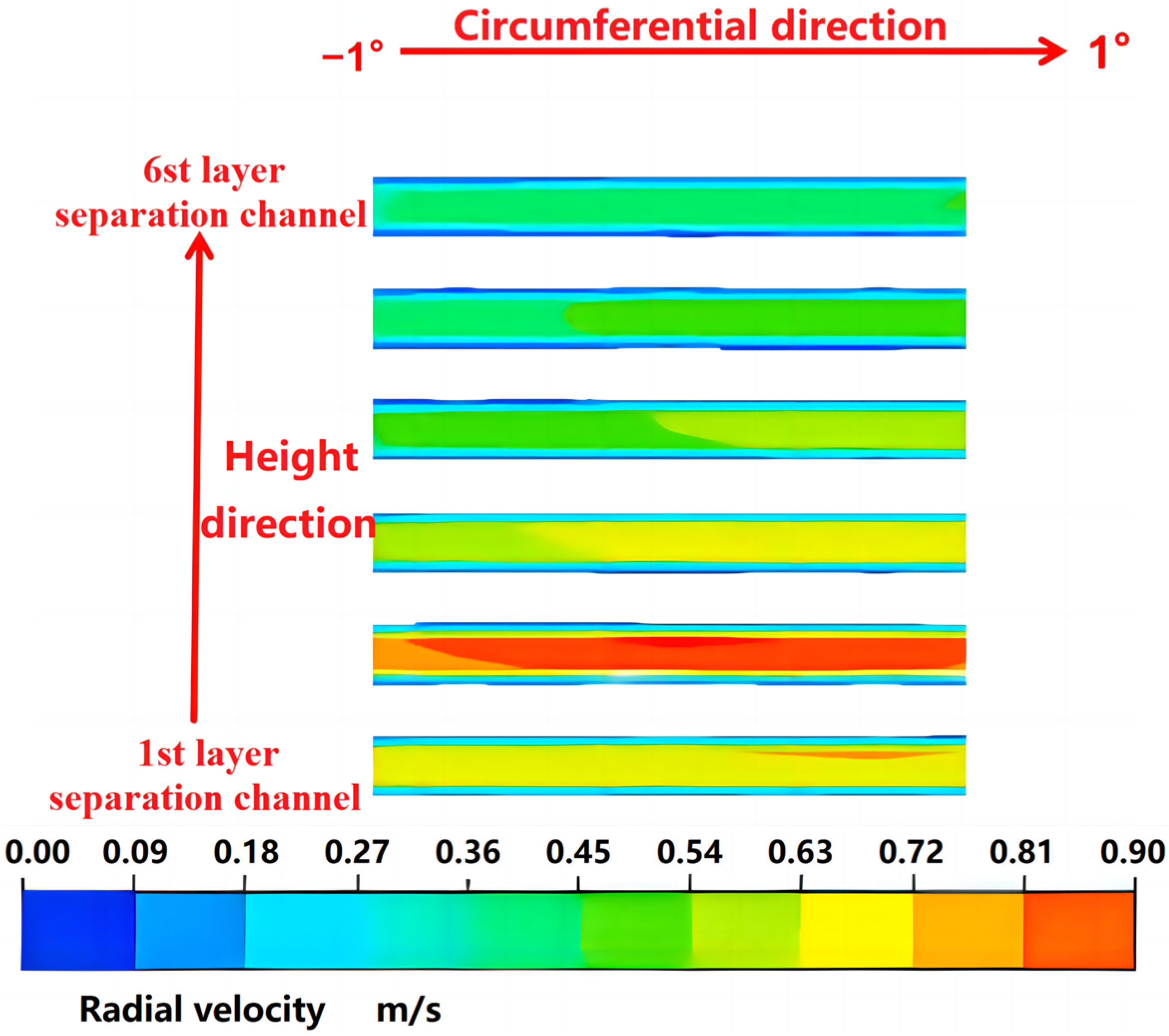

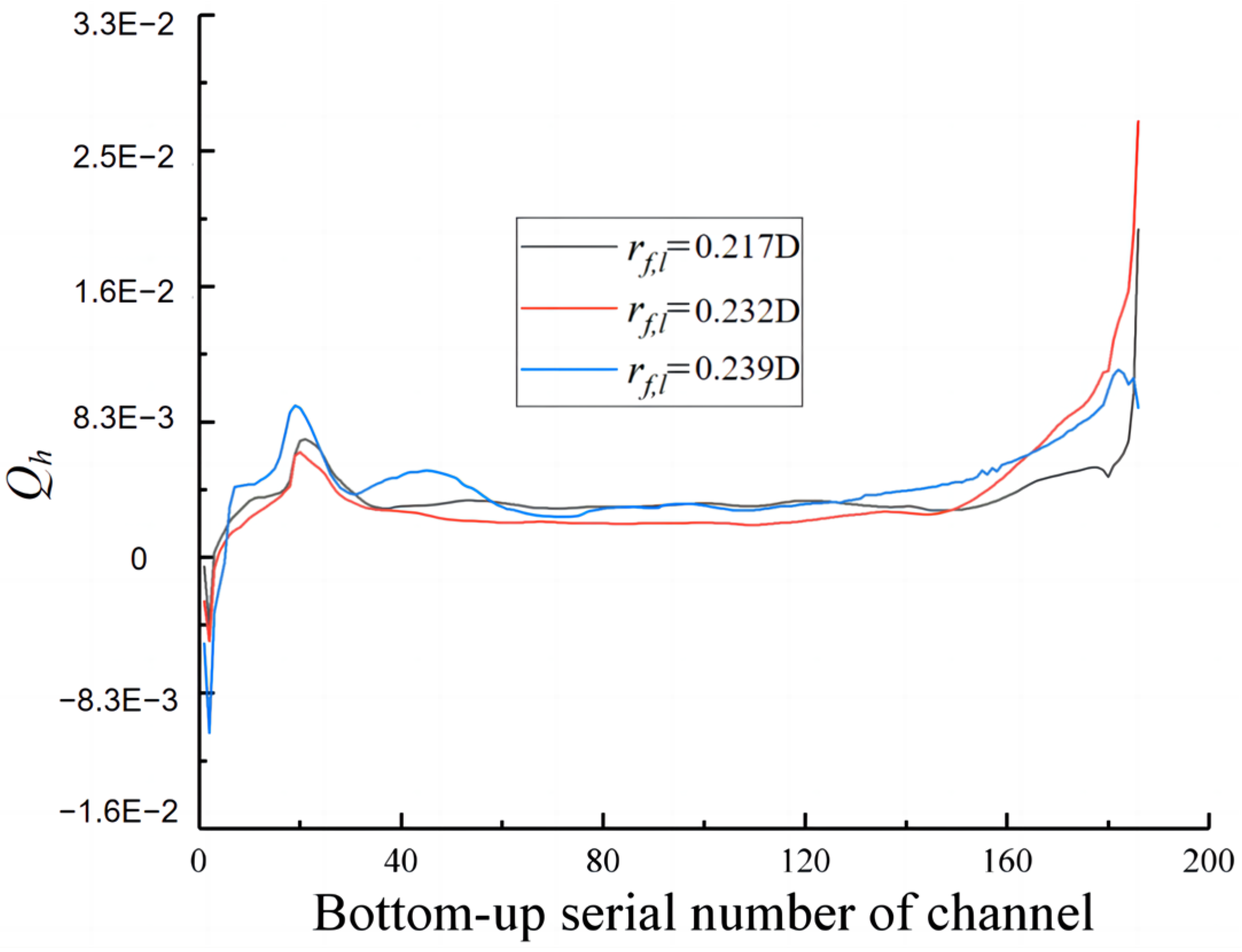

- The water content in the rising channel gradually decreases, and 95% of the water enters the bottom separation channel of the bowl component. The processing capacity of each layer of the separation channel gradually increases, showing the law of having a small bottom layer, large top layer, and uniform middle layer.

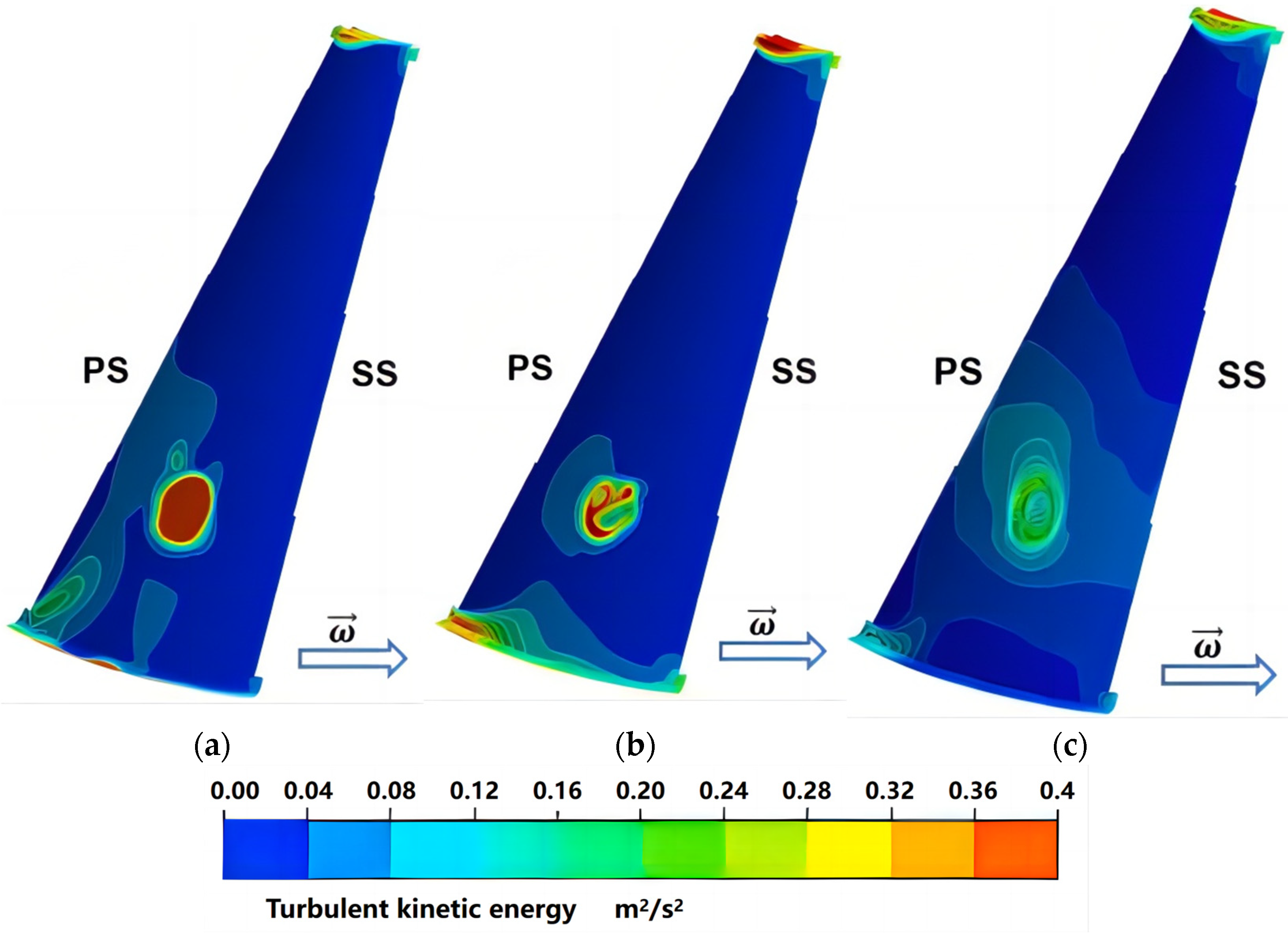

- After the oil–water mixture enters the separation channel from the neutral pore, under the action of Coriolis force, the motion trajectory is not parallel to the generatrix of the disc but forms a vortex near the neutral pore, and the area of the vortex is small at the bottom and large at the top. The coalescence phenomenon and the water content of the water droplets affect the vortex scale, which is different from the classical two-dimensional simplified model with obvious three-dimensional characteristics. With the increase in λ, the motion trajectory of the liquid is more and more deviating from the generatrix direction of the disc. In addition, the circumferential and radial velocities in the separation channel show a law of being large in the middle and small near the wall.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| η | Separation efficiency of disc stack centrifuge |

| c0 | Volume fraction of the water phase at the inlet of the computational domain |

| c1 | Volume fraction of the water phase at the outlet of the oil phase of the computational domain |

| Qd | Design flow of the disc stack centrifuge (m3/h) |

| Q | Actual flow of the disc stack centrifuge (m3/h) |

| Qd | Design flow of the disc stack centrifuge (m3/h) |

| Nh | Rotational speed coefficient of the disc stack centrifuge |

| N | Actual rotational speed of the disc stack centrifuge (rpm) |

| Nd | Design rotational speed of the disc stack centrifuge (rpm) |

| D | Maximum radius of the disc stack centrifuge (m) |

| P | Centrifugal hydraulic pressure difference at the free liquid surface and the inlet of the flow channel (Pa) |

| Vc | Circumferential velocity (m/s) |

| Density of the liquid (kg/m3) | |

| Rotational angular speed of the liquid (rad/s) | |

| r | Radius at any position in the computational domain (m) |

| rf | Radius of the free liquid surface at the outlet of the oil phase or water phase (m) |

| rf,l | Radius of the free liquid surface at the outlet of the oil phase (m) |

| rf,h | Radius of the free liquid surface at the outlet of the water phase (m) |

| PS | Represents the pressure surface |

| SS | Represents the suction surface |

| λ | Dimensionless number that describes the regularity of the flow of a liquid in a separation channel |

| h | Height of the separation channel (m) |

| α | Angle between the generatrix of the disc and the rotation axis (°) |

| ν | Kinematic viscosity of the liquid (m2/s2) |

| CFD | Computational Fluid Dynamics |

| PBM | Population Balance Model |

| VOF | Volume of Fluid |

| SIMPLE | Semi-Implicit Method for Pressure-Linked Equations |

| RNG | Re-Normalization Group |

| u | Rotational velocity of the liquid (m/s) |

| c | Absolute velocity of the liquid (m/s) |

| w | Relative velocity of the liquid (m/s) |

| k | Turbulence kinetic energy |

| ε | Turbulence dissipation rate |

| Gk | Generation of turbulence kinetic energy due to the mean velocity gradients |

| Gb | Generation of turbulence kinetic energy due to buoyancy |

| YM | Contribution of the fluctuating dilatation in compressible turbulence to the overall dissipation rate |

References

- Costagli, G. The use of disc stack centrifuge in the virgin olive oil industry. J. Agric. Eng. 2018, 49, 75. [Google Scholar] [CrossRef]

- Liu, S.; Dong, H.; Li, S.; Song, X. Study on the Influence of Working Characteristics of Centripetal Pump Based on VOF/Mixture Model. Processes 2024, 12, 1376. [Google Scholar] [CrossRef]

- Yuan, H. Separation Engineering; China Petrochemical Press: Beijing, China, 2002; pp. 113–115. [Google Scholar]

- Kombélé, A.; Steve, C.; Emmanuel, J.; Joseph, K. White-flesh guava juice clarification by a fixed-angle conical rotor centrifuge laboratory and characterization of continuous disk stack centrifuges. Heliyon 2022, 8, e11606. [Google Scholar] [CrossRef]

- Abu-Shamleh, A.; Najjar, Y. Optimization of mechanical harvesting of microalgae by centrifugation for biofuels production. Biomass Bioenergy 2020, 143, 105877. [Google Scholar] [CrossRef]

- Häggmark, C.; Königsson, S. Rheological Characterization of Solids Phase in Biomass Processes of Disc-Stack Centrifuges. Chem. Eng. Technol. 2018, 41, 2289–2297. [Google Scholar] [CrossRef]

- Fu, S.; Deng, G.; Dong, H.; Mou, Y.; Hu, Y.; Zhou, F.; Yuan, H. Numerical simulation of oil dewatering in a disc centrifuge based on PBM model. Exp. Comput. Multiph. Flow. 2023, 5, 212–220. [Google Scholar] [CrossRef]

- Shekhawat, L.; Sarkar, J.; Gupta, R.; Hadpe, S.; Rathore, A. Application of CFD in Bioprocessing: Separation of mammalian cells using disc stack centrifuge during production of biotherapeutics. J. Biotechnol. 2018, 267, 1–11. [Google Scholar] [CrossRef]

- Parvaneh, E.; Monireh, H. Optimization of industrial-scale centrifugal separation of biological products: Comparing the performance of tubular and disc stack centrifuges. Biochem. Eng. J. 2022, 178, 108281. [Google Scholar] [CrossRef]

- Xue, X.; Ni, Z.; Mu, F.; Liu, H.; Zhang, Q.; Lu, W.; He, J. ANSYS Stress Analysis and Measuring Verification on Disc Separator’s High Speed Bowl. Light Ind. Mach. 2021, 39, 37–42. [Google Scholar]

- Xu, P.; Zhao, L.; Wu, J.; Ding, Y.; Tian, Y.; Zhan, Y.; Hou, T. Study on influence of rotor systems structural parameters on dynamic characteristics of the disc separator. Mach. Des. Manuf. Eng. 2023, 52, 99–102. [Google Scholar]

- He, S.; Wang, D.; Yang, J.; Cai, B.; Zhao, G. Influence of Structural Parameters on Critical Speed of Vertical Shaft System of a Dish Centrifuge. Trans. Chin. Soc. Agric. Mach. 2005, 7, 57–60. [Google Scholar]

- Zhang, Q.; He, X. Field Dynamic Balance Test System Based on LabVIEW for Disc Separator. Mech. Eng. Autom. 2015, 3, 165–167. [Google Scholar] [CrossRef]

- Yuan, J.; Xie, C.; Zhu, D. Design and Analysis of Health Management Based on Logical Control of Disc Centrifugal Separator. Mech. Electr. Equip. 2020, 37, 43–48. [Google Scholar]

- Yang, M.; Liu, X.; Howell, J.; Cheng, H. Analysis and estimation/prediction of the disk stack centrifuge separation performance—Scaling from benchtop fixed rotor type to disk stack centrifuges. Sep. Sci. Technol. 2020, 55, 2615–2621. [Google Scholar] [CrossRef]

- Zheng, M. The symmetries and invariant solutions for laminar boundary layer of disc centrifuge. Chin. J. Comput. Mech. 2022, 39, 450–454. [Google Scholar]

- Cambiella, A.; Benito, J.; Pazos, C.; Coca, J. Centrifugal separation efficiency in the treatment of waste emulsified oils. Chem. Eng. Res. Des. 2006, 84, 69–76. [Google Scholar] [CrossRef]

- Janoske, U.; Piesche, M. Hydrodynamic investigations on the separation behavior of suspensions in a gap of a disk stack centrifuge with caulks. Chem. Eng. Technol. 2000, 23, 850–853. [Google Scholar] [CrossRef]

- Xue, X.; Shi, K. Numerical Analysis on Flow-field Characteristics of High-Speed Bowl of Latex Disc-separator. Fluid Mach. 2016, 44, 22–27. [Google Scholar]

- Zhang, Y.; Wang, K.; Liu, Y.; Shi, D.; Zhang, Y. Numerical Simulation Analysis of Oil Water Solid Three-phase Separation in Disc Separator. Mach. Des. Res. 2023, 39, 187–190. [Google Scholar]

- Geng, T.; Zhou, Y. Numerical Simulation of Inner Flow Field in the Drum. Chem. Eng. Mach. 2018, 45, 648–651. [Google Scholar]

- Yuan, H.; Zhang, Y.; Fu, S.; Zhu, H.; Liao, W. Separation Law of Thin Layer Two-phase Flow between Disc in Disc Centrifuge. Fluid Mach. 2019, 47, 27–32. [Google Scholar]

- Zhao, Z.; Shi, B. Numerical simulation of oil-water separation process in disc separator. In Proceedings of the International Conference on Remote Sensing, Environment and Transportation Engineering, Nanjing, China, 24–26 June 2011; pp. 8369–8372. [Google Scholar] [CrossRef]

- Zhou, F.; Deng, G.; Fu, S.; Yuan, H.; Hu, Y.; Cao, G. Numerical Simulation of Oil Droplets Coalescence and Breakup in Oil-Water Separating Disc Centrifuge. J. Chang. Univ. Nat. Sci. Ed. 2022, 34, 65–73. [Google Scholar]

- Available online: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v211/en/flu_th/flu_th_sec_turb_rng.html (accessed on 26 August 2024).

- Saffman, P.; Turner, J. On the collision of drops in turbulent clouds. J. Fluid Mech. 1956, 1, 16–30. [Google Scholar] [CrossRef]

- Luo, H.; Svendsen, H. Theoretical model for drop and bubble breakup in turbulent dispersions. AIChE J. 1996, 42, 1225–1233. [Google Scholar] [CrossRef]

- Sun, Q.; Jin, D. Centrifuge Principle Structure and Design Calculation; China Machine Press: Beijing, China, 1987; pp. 530–533. [Google Scholar]

- Ye, A. Research for the Problem of Disc in the Separators Processing. J. Filtr. Sep. 2011, 21, 32–33. [Google Scholar]

- Cui, J.; Lei, H.; Wang, L.; Yuan, M.; Shi, G. Analysis of Internal Flow Field of Kaolin Disc Separator. Agric. Equip. Veh. Eng. 2021, 59, 14–18. [Google Scholar]

- Chen, A.; Luo, G.; Xu, J. Research progress on quantitative exploration of the interaction mechanism between droplets. CIESC J. 2021, 72, 5955–5964. [Google Scholar]

| Material | Density (kg/m3) | Dynamic Viscosity (Pa·s) |

|---|---|---|

| Oil | 814 | 0.0031 |

| Water | 998 | 0.0010 |

| Scheme | Number of Grids in the Circumferential Direction | Number of Grids in the Direction of the Generatrix | Number of Grids in The NORMAL Direction | Total Number of Grids |

|---|---|---|---|---|

| 1 | 24 | 61 | 2 | 6088 |

| 2 | 29 | 73 | 3 | 11,249 |

| 3 | 37 | 88 | 4 | 20,130 |

| 4 | 44 | 106 | 5 | 35,800 |

| 5 | 53 | 127 | 6 | 64,652 |

| 6 | 60 | 147 | 7 | 123,480 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Wan, R.; Huang, C.; Liu, S.; Luo, S.; Chen, L.; Li, S.; Song, X. Numerical Study of Internal Flow Field in a Disc Stack Centrifuge Based on Mixture-PBM Model. Appl. Sci. 2024, 14, 8070. https://doi.org/10.3390/app14178070

Dong H, Wan R, Huang C, Liu S, Luo S, Chen L, Li S, Song X. Numerical Study of Internal Flow Field in a Disc Stack Centrifuge Based on Mixture-PBM Model. Applied Sciences. 2024; 14(17):8070. https://doi.org/10.3390/app14178070

Chicago/Turabian StyleDong, Hefeng, Ran Wan, Changan Huang, Shoulie Liu, Shamiao Luo, Liangbin Chen, Shaobin Li, and Xizhen Song. 2024. "Numerical Study of Internal Flow Field in a Disc Stack Centrifuge Based on Mixture-PBM Model" Applied Sciences 14, no. 17: 8070. https://doi.org/10.3390/app14178070

APA StyleDong, H., Wan, R., Huang, C., Liu, S., Luo, S., Chen, L., Li, S., & Song, X. (2024). Numerical Study of Internal Flow Field in a Disc Stack Centrifuge Based on Mixture-PBM Model. Applied Sciences, 14(17), 8070. https://doi.org/10.3390/app14178070