Study on the Effects of Influence Factors on the Stress and Deformation Characteristics of Ultra-High CFRDs

Abstract

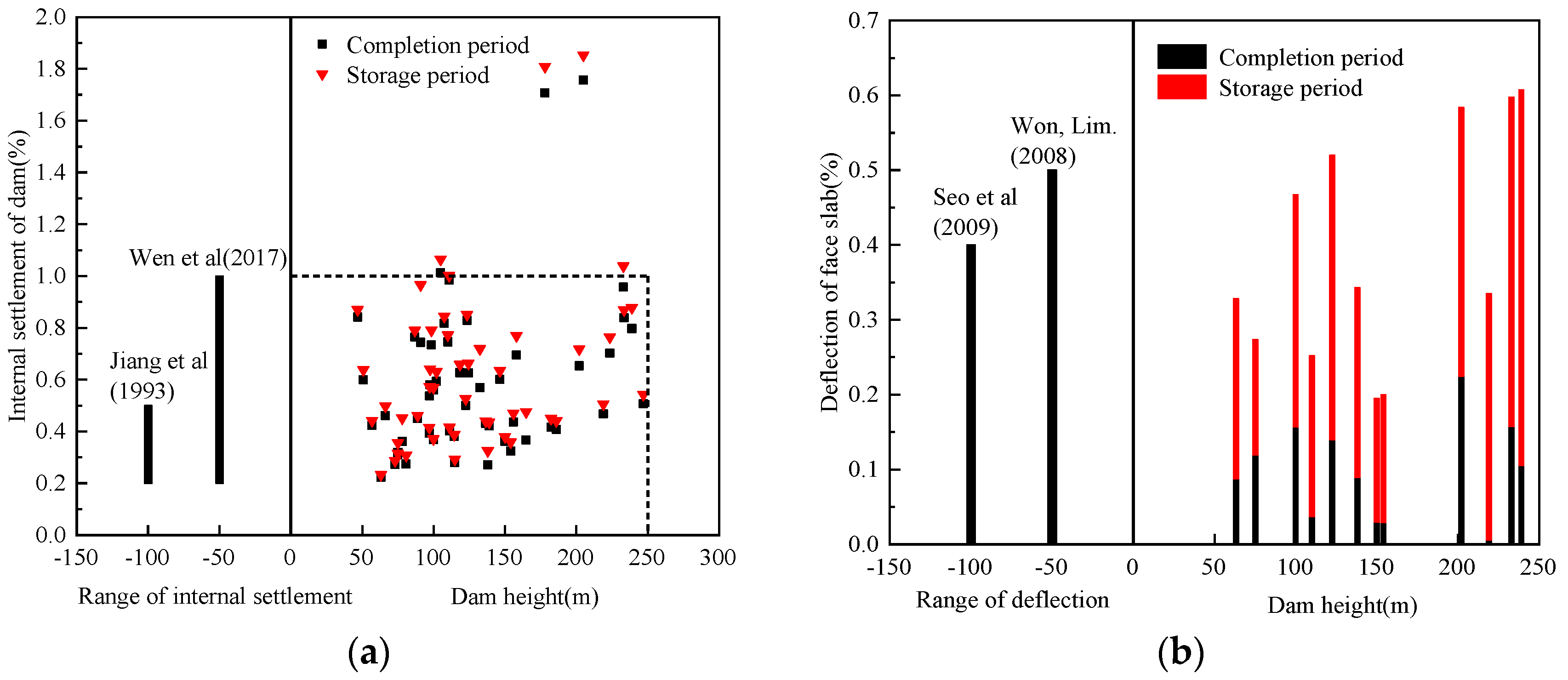

:1. Introduction

2. Projection Pursuit Regression Model

3. Sensitivity Analysis of Influencing Factors on Stress and Deformation of CFRDs

3.1. Calculation Scheme

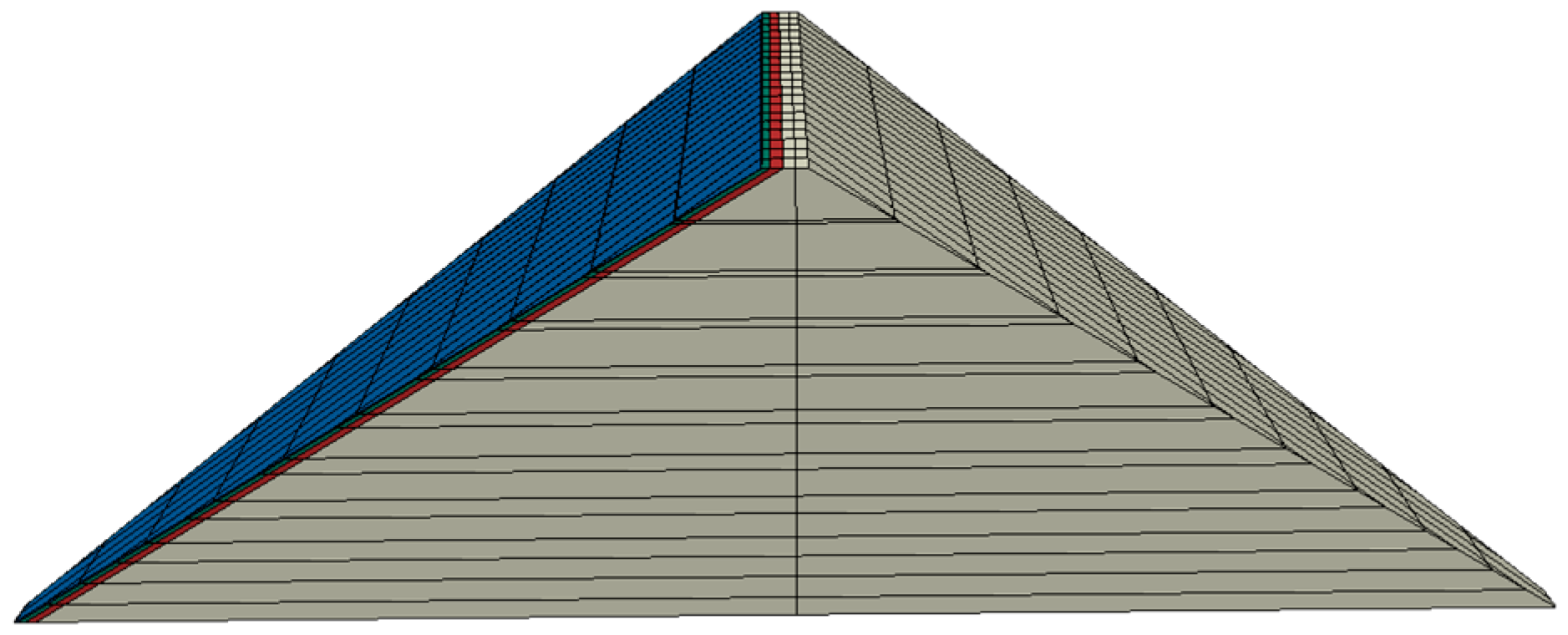

3.2. Finite Element Model

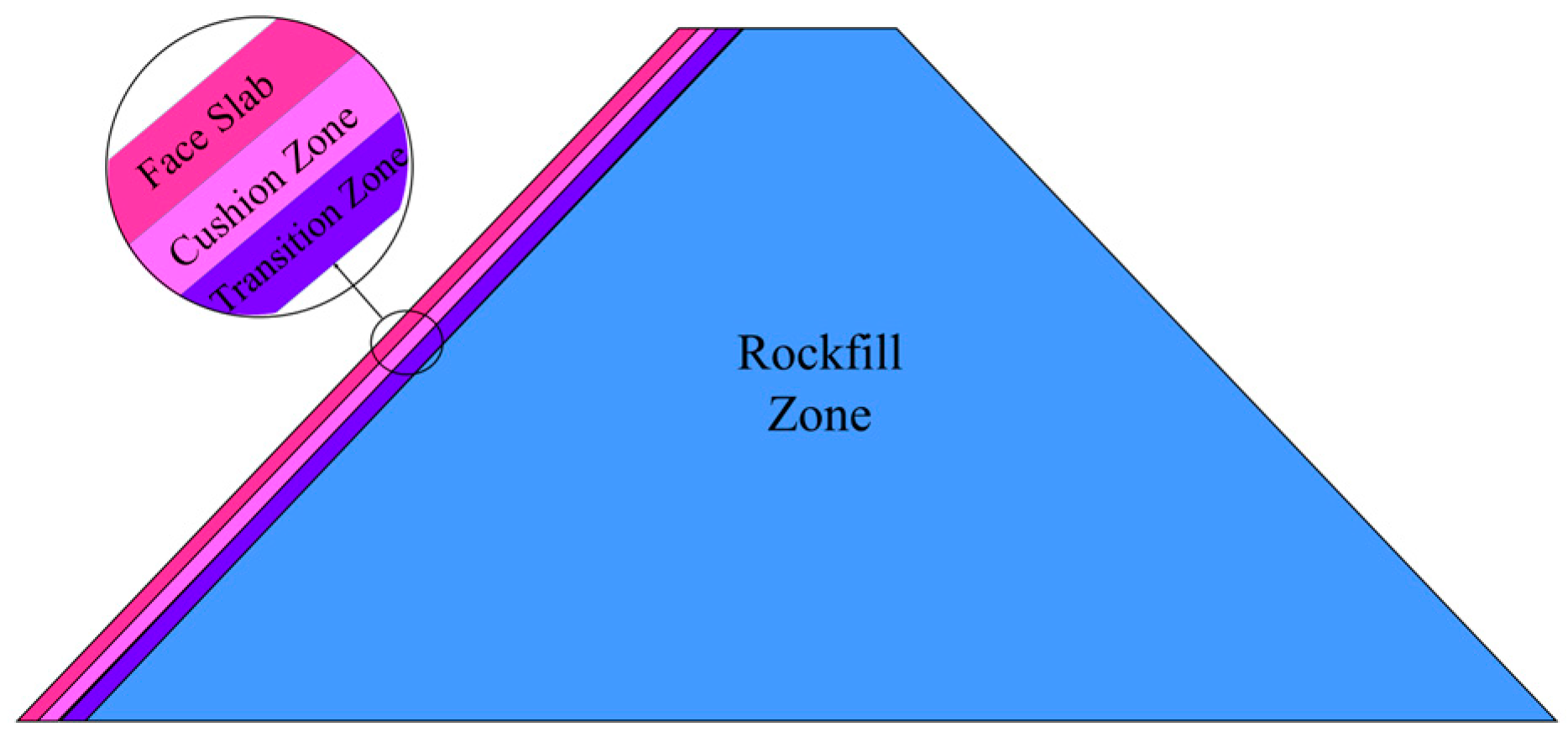

3.2.1. Geometric Model

3.2.2. Calculation Parameters

3.3. Sensitivity Analysis of Factors Affecting Stress and Deformation

4. Research on Stress and Deformation Characteristics of CFRDs under Different Factors

4.1. Calculation Scheme

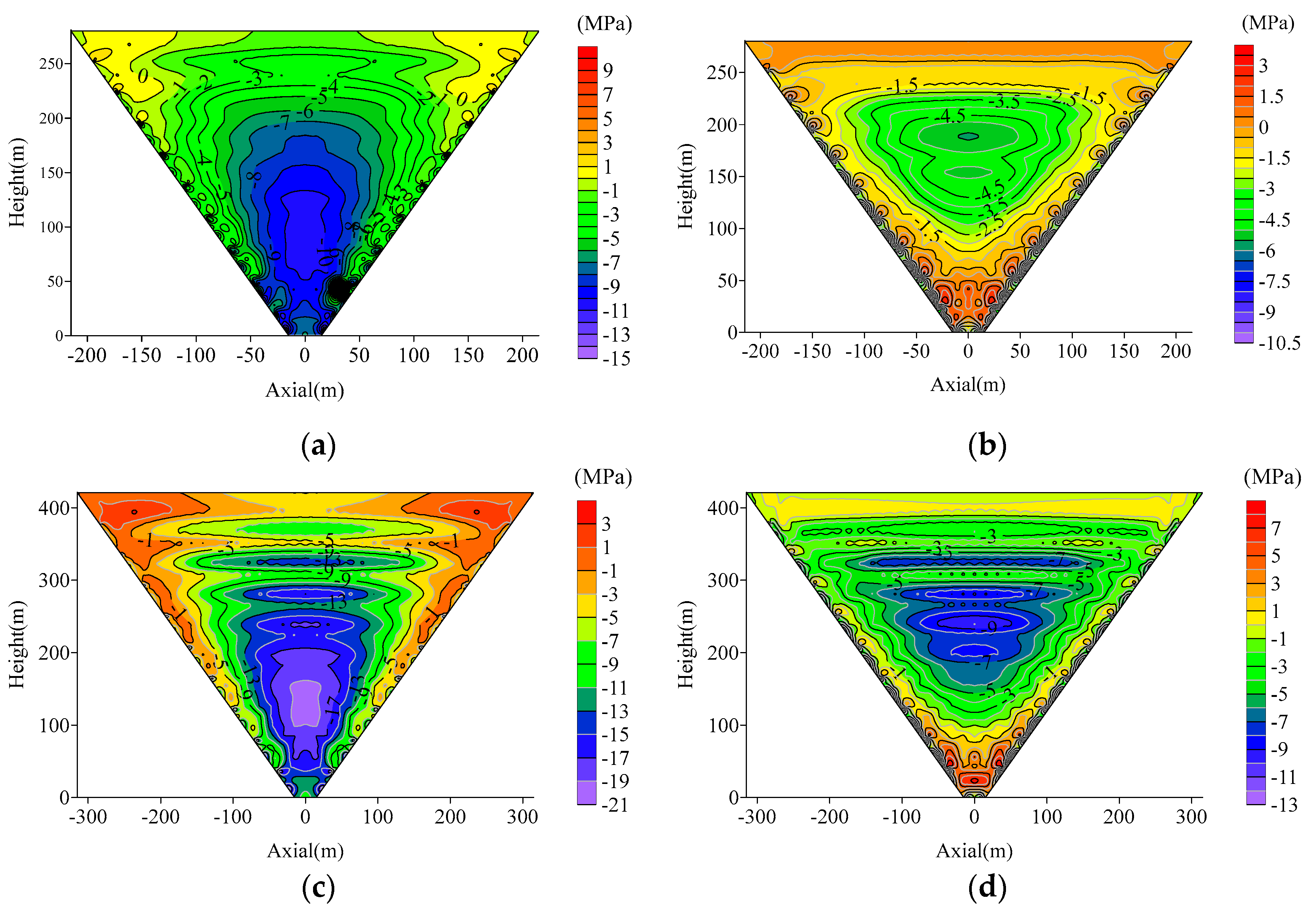

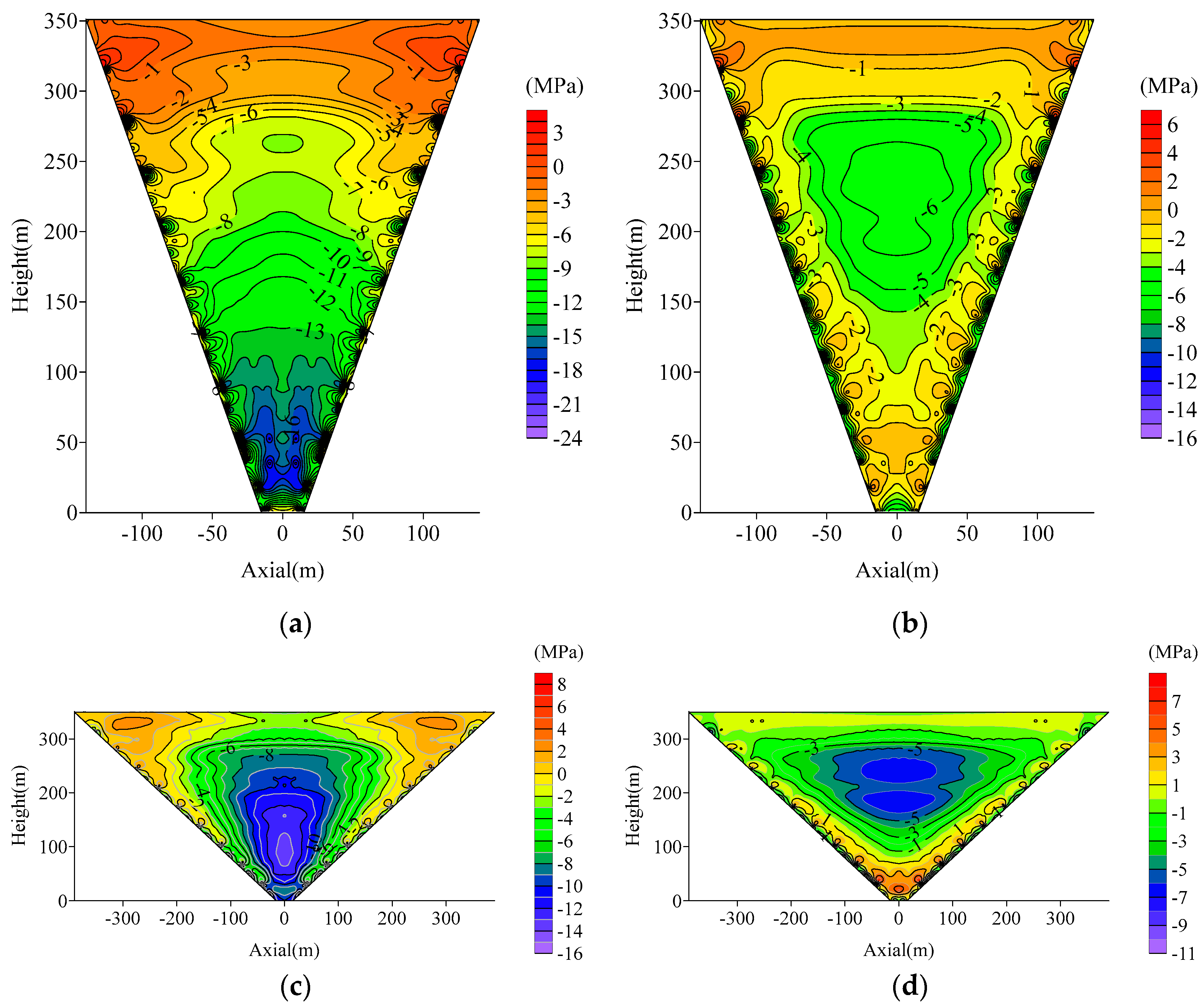

4.2. The Influence of Dam Height on the Stress and Deformation of CFRDs

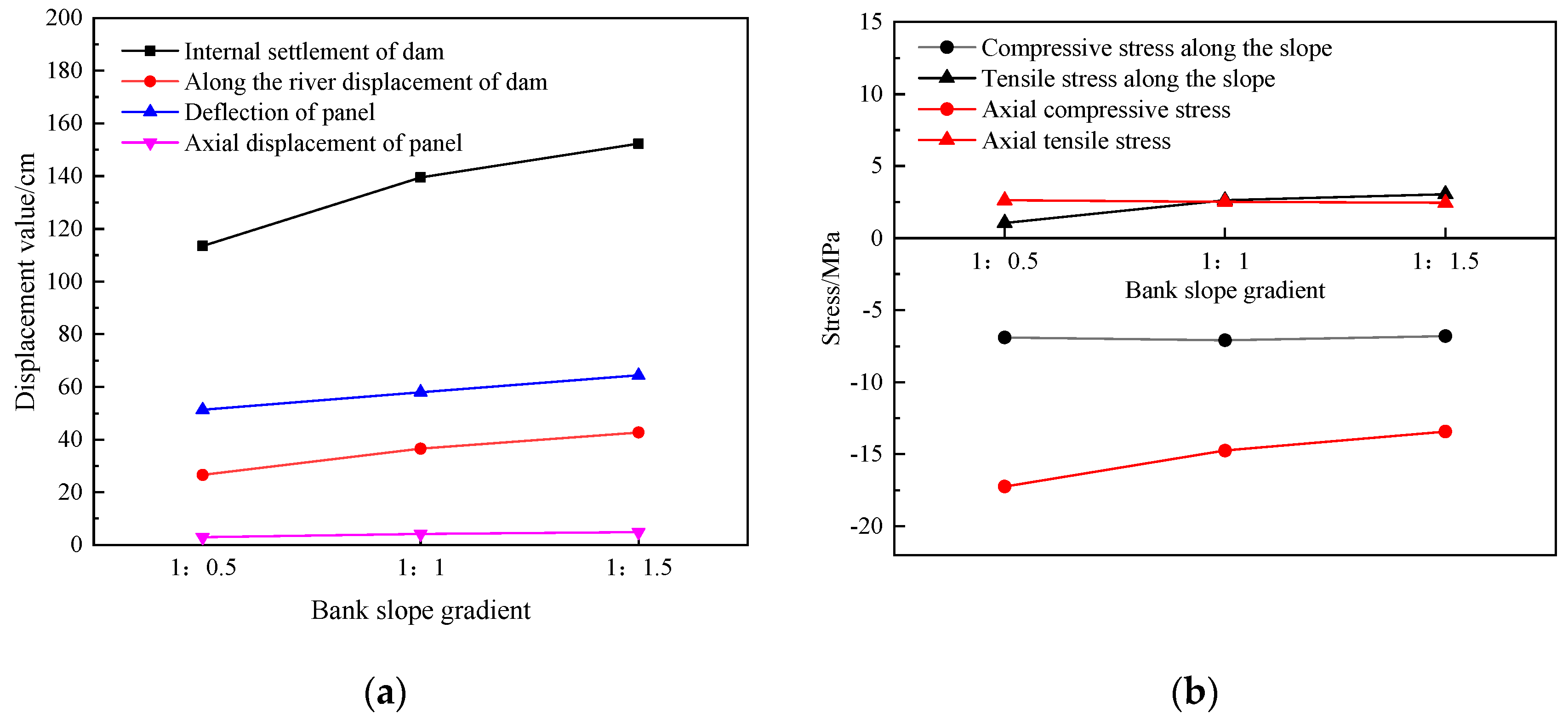

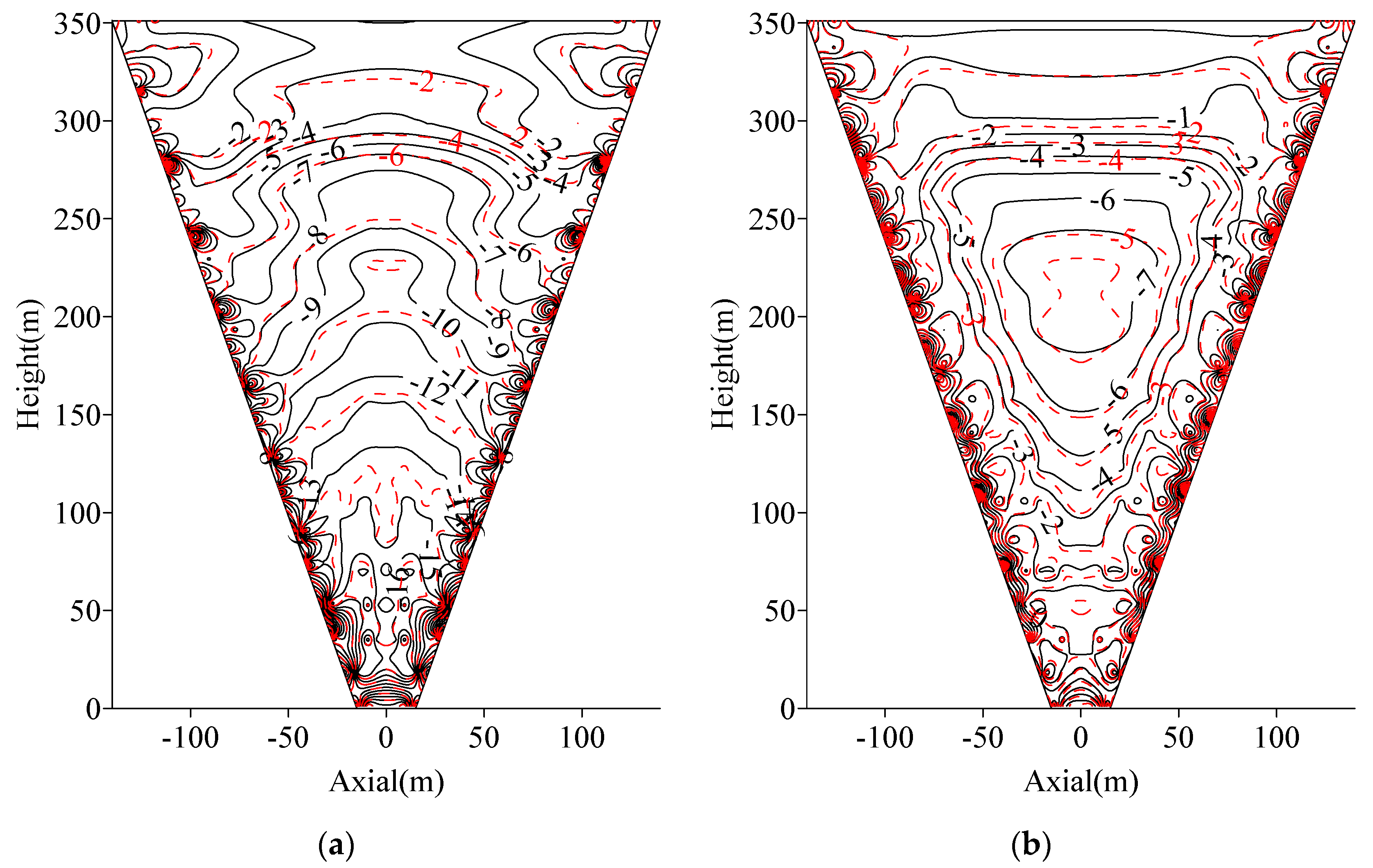

4.3. The Influence of Bank Slope Gradient on the Stress and Deformation of CFRDs

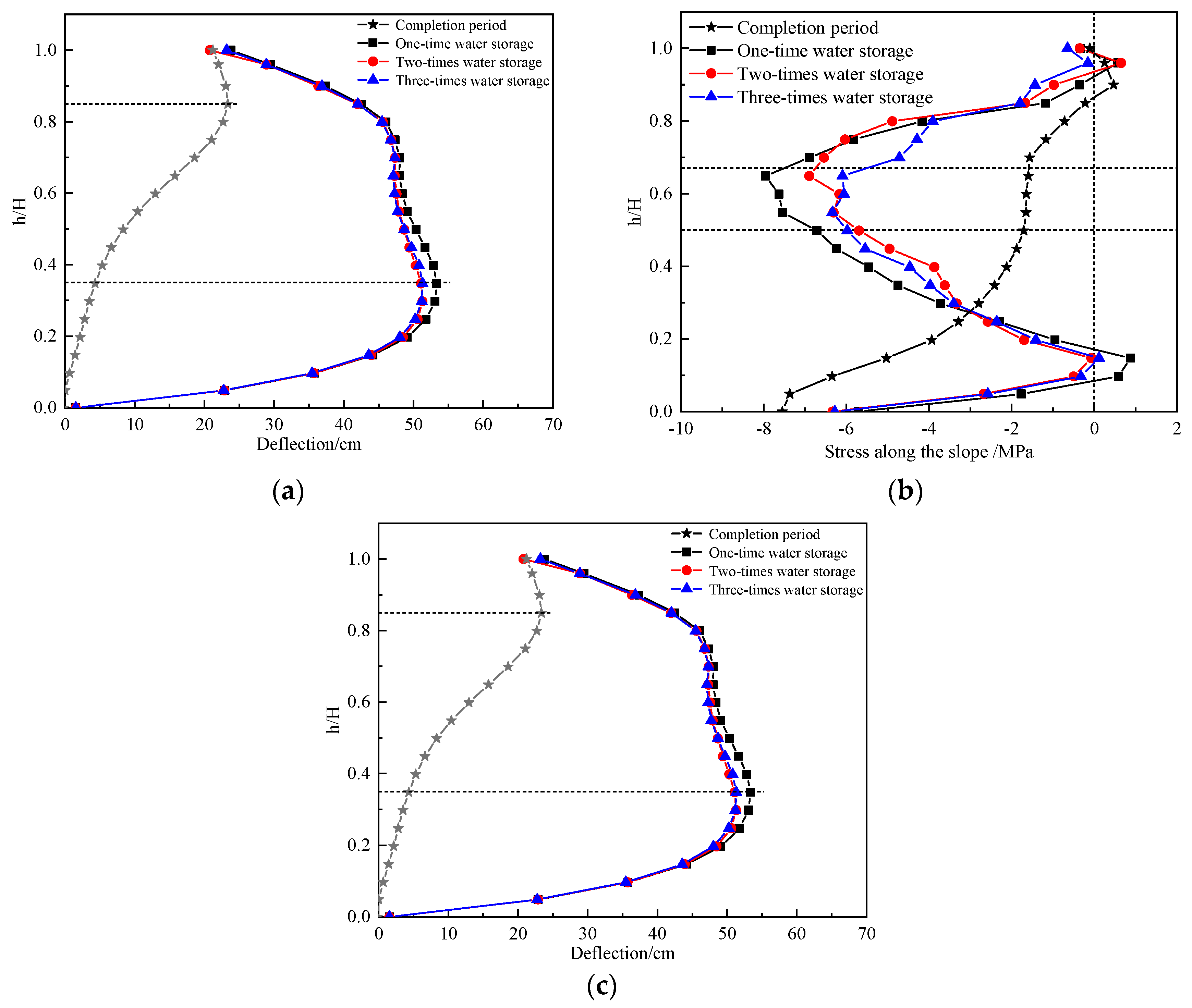

4.4. The Influence of Water Storage on the Stress and Deformation of CFRDs

5. Conclusions

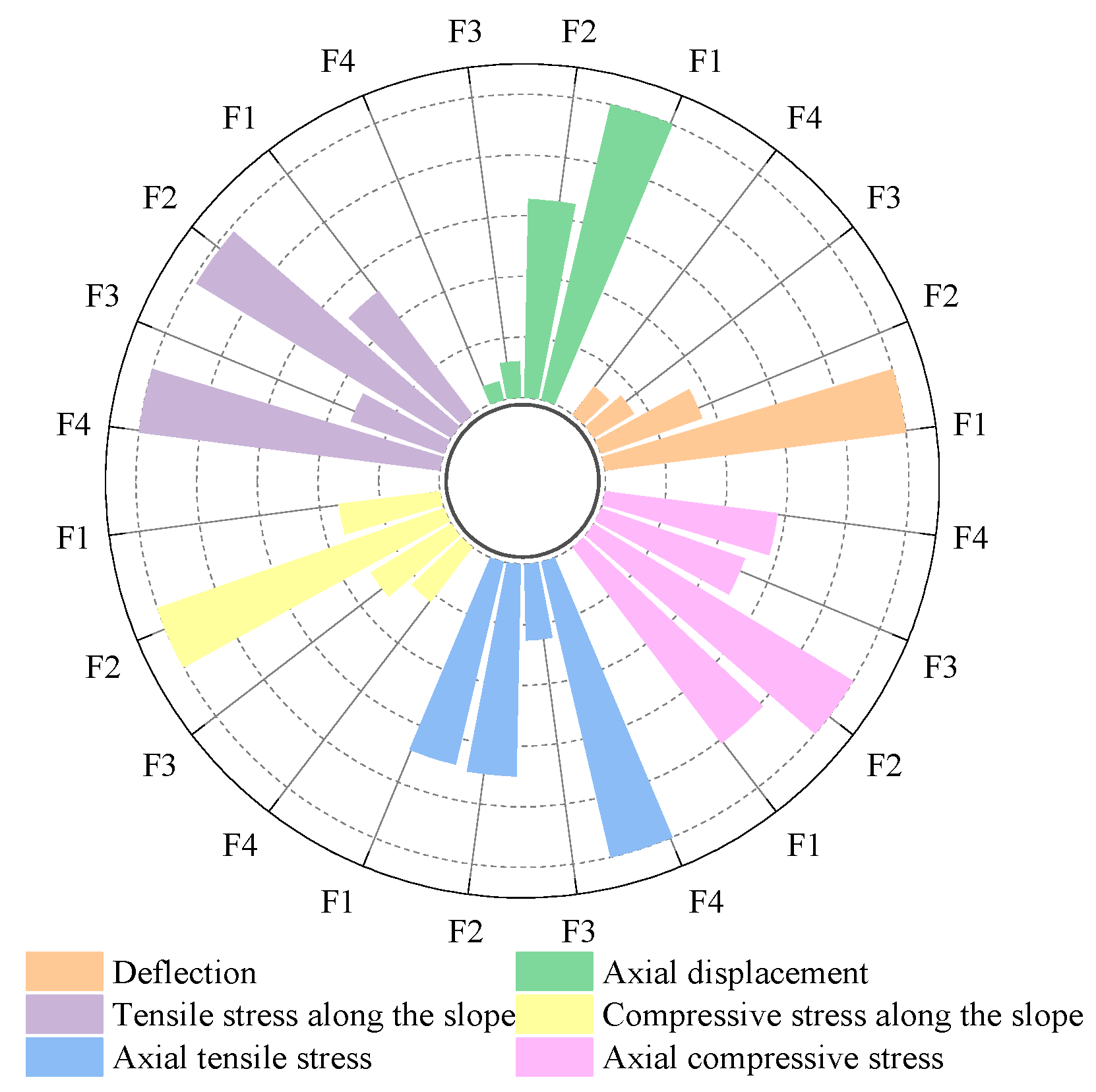

- Utilizing orthogonal experimental design and projection pursuit regression technology, the relative weights of influences on the deformation characteristics of the dam body were determined. Taking dam settlement during the impinging period as an example, the relative influence weights of dam height, bank slope gradient, panel phased construction, and storage on dam settlement are 1.000, 0.439, 0.014, and 0.025, respectively. In other words, the sensitivity of each influencing factor to dam settlement during the storage period ranges from strong to weak, as follows: dam height > bank slope gradient > water storage > panel phased construction. Similarly, the sensitivity of each influencing factor to dam body settlement, river displacement, and dam axial displacement remains consistent, regardless of completion period or water storage period. Overall, for the dam body, the most sensitive influencing factor was found to be dam height, followed by bank slope gradient and water storage, with panel phased construction being the least sensitive.

- Similarly, the relative weights of influence on the stress and deformation characteristics of the panel were established. Using panel deflection as an example, the relative influence weights of dam height, bank slope gradient, water storage, and panel phased construction on panel deflection are 1.000, 0.352, 0.115, and 0.154, respectively. In this case, the sensitivity of influencing factors on panel deflection during the water storage period also ranges from strong to weak: dam height > bank slope gradient > panel phased construction > water storage. Similarly, as for the sensitivity of influencing factors to the tensile stress of the panel, the ranking is as follows: water storage > bank slope gradient > dam height > panel phased construction. Regarding sensitivity to axial compressive stress, the ranking is as follows: bank slope gradient > dam height > water storage > panel phased construction. Finally, sensitivity to compressive stress along the slope is ranked as follows: bank slope gradient > dam height > panel phased construction > water storage. Overall, among the four factors, dam height, bank slope gradient, and water storage have a significant impact on the stress and deformation of the panel.

- Based on the results of aforementioned sensitivity analysis, priority design and construction factors can be identified. For instance, dam height exhibits a substantial influence on the settlement of the dam body and the deflection of the panels; accordingly, as the dam height increases, so too do the settlement of the dam body and the deflection of the panels. Consequently, to maintain optimal control over the settlement of the dam body and the deflection of the panels, it is imperative that the height of the dam body is not excessively high. This analysis can also pinpoint the factors with the most significant impact on structural performance, allowing for further risk assessment and management. Enhancing structural performance through adjusting influential factors and optimizing existing engineering design is achievable.

- Research into the rule of stress and deformation influence on CFRDs indicated that an increase in dam height correlates with escalating stress and deformation in the dam and panel. The deformation characteristics of the panels amplify as the bank slope gradient decreases. The axial stress and compressive stress along the slope of the panel gradually decreases with the decrease in the bank slope, while the tensile stress along the slope exhibits an opposing trend; and after the slope of the bank slows down, the range of tensile stresses along the slope and axial of the panel also increases. According to the sensitivity analysis results, the effect of water storage on the stress and deformation characteristics of the dam body is not significant compared to the panel, and only the influence of water storage on the stress and deformation of the panel is discussed. Compared to a single storage event, deflection, axial horizontal displacement, stress along the slope direction, and axial tensile stress of the panel are reduced under multiple storage scenarios. Furthermore, with an increasing number of storage events, the tensile zone at the bottom of the face slab transitions into a compressive zone. It is concluded that multiple storage schemes for the face slab are more advantageous than a single storage scheme.

- The data pertaining to seismic damage on CFRDs indicate the substantial impact of earthquakes on the stress and deformation characteristics of such CFRDs. Nevertheless, the current investigation is primarily concerned with static computations and analyses, thus neglects to examine the stress and deformation properties of CFRDs subjected to dynamic conditions. It is recommended that subsequent research incorporates dynamic assessments under seismic influence to ascertain and enhance a dam’s seismic resilience under extreme scenarios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, R.H.; Chai, J.R.; Xu, Z.G.; Qin, Y.; Cao, J. Influence of Abutment Slope Angle Variety on the Deformation and Stress of the Concrete-Faced Rockfill Dam during Initial Impoundment. Int. J. Civ. Eng. 2019, 17, 581–595. [Google Scholar] [CrossRef]

- Wang, R.Y.; Yu, K.P. Stress and Deformation Analysis of High Concrete Face Rockfill Dam Based on COMSOL Multiphysics. IOP Conf. Ser. Earth Environ. Sci. 2021, 643, 012013. [Google Scholar] [CrossRef]

- Chen, S.S.; Fu, Z.Z.; Mi, Z.K. Technical challenges and design features of the 247-m DaShixia concrete-faced sand-gravel dam. Pract. Period Struct. Des. Constr. 2022, 27, 04021073. [Google Scholar] [CrossRef]

- Modares, M.; Quiroz, J.E. Structural Analysis Framework for Concrete-Faced Rockfill Dams. Int. J. Geomech. 2015, 16, 04015024. [Google Scholar] [CrossRef]

- Zhou, W.; Hua, J.J.; Chang, X.L.; Zhou, C.B. Settlement analysis of the Shuibuya concrete-face rockfill dam. Comput. Geotech. 2011, 38, 269–280. [Google Scholar] [CrossRef]

- Jia, J.S.; Xu, Y.; Hao, J.T.; Zhang, L.M. Localizing and Quantifying Leakage through CFRDs. J. Geotech. Geoenviron. Eng. 2016, 142, 06016007. [Google Scholar] [CrossRef]

- Ma, H.Q.; Chi, F.D. Technical progress on researches for the safety of high concrete-faced rockfill dams. Engineering 2016, 2, 332–339. [Google Scholar] [CrossRef]

- Xu, H.; Zou, D.G.; Kong, X.J.; Hu, Z.Q. Study on the effects of hydrodynamic pressure on the dynamic stresses in slabs of high CFRD based on the scaled boundary finite-element method. Soil Dyn. Earthq. Eng. 2016, 88, 223–236. [Google Scholar] [CrossRef]

- Wen, L.F.; Chai, J.R.; Xu, Z.G.; Qin, Y.; Li, Y.L. Preliminary statistical analysis of behavior of concrete face rockfill dams. Chin. J. Geotech. Eng. 2017, 39, 1312–1320. (In Chinese) [Google Scholar]

- Jiang, G.; Cao, K. Concrete face rockfill dams in China. In Proceedings of the International Symp on High Earth–Rockfill Dams, Beijing, China, 26–29 October 1993; pp. 25–37. [Google Scholar]

- Seo, M.W.; Ha, I.S.; Kim, Y.S.; Oison, S.M. Behavior of concrete–faced rockfill dams during initial impoundment. J. Geotech. Geoenviron. Eng. 2009, 135, 1070–1081. [Google Scholar] [CrossRef]

- Won, M.S.; Kim, Y.S. A case study on the post–construction deformation of concrete face rockfill dams. Can. Geotech. J. 2008, 45, 845–852. [Google Scholar] [CrossRef]

- Yang, Z.H.; Yang, W.; Yang, H.H.; Liu, L.; He, J.X. Study of stress-strain relationship of hydraulic asphalt concrete at low to intermediate temperatures based on experimental data regression. Constr. Build. Mater. 2023, 409, 134059. [Google Scholar] [CrossRef]

- Qi, X.N.; Liu, Z.Y.; Li, D.D. Prediction of the performance of a shower cooling tower based on projection pursuit regression. Appl. Therm. Eng. 2007, 28, 1031–1038. [Google Scholar] [CrossRef]

- Qin, C.; Gong, J.W.; Xie, G.C. Modeling hydration kinetics of the Portland-Cement-Based cementitious systems with mortar blends by Non-Assumptive projection pursuit regression. Thermochim. Acta 2021, 705, 179035. [Google Scholar] [CrossRef]

- Gong, J.W.; Jiang, C.M.; Tang, X.J.; Zheng, Z.G.; Yang, L.X. Optimization of mixture proportions in ternary low-heat Portland cement-based cementitious systems with mortar blends based on projection pursuit regression. Constr. Build. Mater. 2019, 238, 117666. [Google Scholar] [CrossRef]

- Gong, J.W.; Zheng, R.X.; Qin, C.; Chen, R.; Cao, G. Prediction of thermal conductivity of concrete under variable temperatures in cold regions using projection pursuit regression. Cold Reg. Sci. Technol. 2022, 203, 103642. [Google Scholar] [CrossRef]

- Qin, C.; Gong, J.W.; Xie, G.C.; He, J.X.; Liu, L.; Yang, H.H.; Deng, C.L. Non-hypothetical projection pursuit regression for the prediction of hydration heat of Portland-cement-based cementitious system. Heliyon 2023, 9, e19471. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.W.; Zhan, X.H.; Gong, M.M.; Wang, L.; Xie, G.C. Mechanical strength characteristics of saline soil stabilized by all-solid waste cementitious material based on projection pursuit regression modeling. J. Mater. Cycles Waste Manag. 2023, 25, 3490–3507. [Google Scholar] [CrossRef]

- Zhang, W.B.; Shen, Z.Z.; Ren, J.; Gan, L.; Xu, L.Q.; Sun, Y.Q. Phase-field simulation of crack propagation in quasi-brittle materials: COMSOL implementation and parameter sensitivity analysis. Model. Simul. Mater. Sci. Eng. 2021, 29, 055020. [Google Scholar] [CrossRef]

- Xing, H.F.; Gong, X.N.; Zhou, X.G.; Fu, H.F. Construction of concrete-faced rockfill dams with weak rocks. J. Geotech. Geoenviron. Eng. 2006, 132, 778–785. [Google Scholar] [CrossRef]

- Saboya, F., Jr.; Byrne, P.M. Parameters for stress and deformation analysis of rockfill dams. Can. Geotech. J. 1993, 30, 690–701. [Google Scholar] [CrossRef]

- Jia, Y.F.; Xu, B.; Chi, S.C.; Xiang, B.; Xiao, D.; Zhou, Y. Joint back analysis of the creep deformation and wetting deformation parameters of soil used in the Guanyinyan composite dam. Comput. Geotech. 2018, 96, 167–177. [Google Scholar] [CrossRef]

| No. | Dam | Height/m | Bank Slope Gradient/° | Maximum Settlement of Dam/cm | Maximum Deflection of Panel/cm | ||

|---|---|---|---|---|---|---|---|

| Completion Period | Storage Period | Completion Period | Storage Period | ||||

| 1 | Gongboxia | 139.00 | The valley is asymmetric, with 30 on the left bank and 40~50 on the right bank | 58.60 | 60.60 | 9.60 | 22.10 |

| 2 | Yutiao | 110.00 | Asymmetric V-shaped valley, left bank 35~50, right bank 55~70 | 82.00 | 85.00 | 2.90 | 16.90 |

| 3 | Zipingpu | 156.00 | Asymmetric V-shaped valley, left bank 40~50, right bank 20~25 | 68.10 | 73.40 | — | 40.00 |

| 4 | Xianyou | 75.10 | V-shaped valley, 40~60 | 24.00 | 26.80 | 6.40 | 8.30 |

| 5 | Jiangpinghe | 219.00 | — | 102.40 | 110.80 | 0.90 | 51.50 |

| 6 | Jiudianxia | 136.50 | About 85 below the elevation of 2145 m on the left bank, 30 to 40 above, and 30 to 45 on the right bank | 58.80 | 60.10 | 1.60 | 3.40 |

| 7 | Uruwati | 138.00 | U-shaped | 37.40 | 44.90 | 8.80 | 25.00 |

| 8 | Shuibuya | 233.00 | Asymmetric V-shaped valley, with an average of 52 on the left bank and 35 on the right bank | 223.00 | 242.00 | 26.20 | 73.30 |

| 9 | Shanxi | 132.50 | U-shaped valley, left bank 30~40, right bank 40~45 | 75.40 | 95.30 | — | 20.00 |

| 10 | Jiayan | 154.00 | Asymmetric V-shaped | 49.80 | 55.40 | 3.21 | 18.80 |

| 11 | Tianshengqiao | 178.00 | V-shaped valley, left bank 20~30, right bank 18~30 | 304.00 | 322.00 | — | 81.00 |

| 12 | Jiayan | 154.00 | Asymmetric V-shaped | 49.80 | 55.40 | 3.21 | 18.80 |

| 13 | Hekoucun | 122.50 | U-shaped | 61.40 | 64.50 | 12.24 | 33.28 |

| 14 | Dashixia | 247.00 | Asymmetric V-shaped, 45~75 | 125.30 | 134.00 | 4.60 | 47.20 |

| 15 | Cihaxia | 202.00 | V-shaped valley, 42~45 | — | 145.00 | 32.42 | 51.84 |

| 16 | Hongjiadu | 182.30 | Asymmetric V-shaped valley, with a steep left bank of 70 and a right bank of 25~40 | 75.90 | 82.05 | — | 46.00 |

| 17 | Taoshui | 102.00 | Left bank 46~49, right bank 27~29 | 60.60 | 64.30 | 5.57 | 24.47 |

| 18 | Dongjin | 150.00 | Slightly wide and asymmetrical V-shaped valley, left bank 35, right bank 25–28 | — | 194.50 | — | 59.70 |

| No. | Dam Height/m | Bank Slope Gradient | Panel Phased Construction | Water Storage |

|---|---|---|---|---|

| 1 | 200 | 1:0.50 | 1 | 1 |

| 2 | 200 | 1:1.00 | 3 | 2 |

| 3 | 200 | 1:1.50 | 2 | 3 |

| 4 | 250 | 1:0.50 | 3 | 3 |

| 5 | 250 | 1:1.00 | 2 | 1 |

| 6 | 250 | 1:1.50 | 1 | 2 |

| 7 | 300 | 1:0.50 | 2 | 2 |

| 8 | 300 | 1:1.00 | 1 | 3 |

| 9 | 300 | 1:1.50 | 3 | 1 |

| Materials | Rf | K | n | /° | Kb | m | Kur | /(g·cm−3) |

|---|---|---|---|---|---|---|---|---|

| Cushion material | 0.82 | 850 | 0.45 | 49.90 | 350 | 0.08 | 1700 | 2.29 |

| Transition material | 0.70 | 870 | 0.52 | 55.30 | 580 | 0.20 | 1740 | 2.23 |

| Rockfill material | 0.75 | 1250 | 0.30 | 52.20 | 920 | 0.11 | 2500 | 2.20 |

| Extreme Values of Deformation Characteristics | Influence Factor | Relative Weight Contribution Value | |

|---|---|---|---|

| Completion Period | Storage Period | ||

| Internal settlement | F1 | 1.000 | 1.000 |

| F2 | 0.404 | 0.439 | |

| F3 | 0.014 | 0.014 | |

| F4 | 0.017 | 0.025 | |

| Displacement along the river | F1 | 1.000 | 1.000 |

| F2 | 0.644 | 0.756 | |

| F3 | 0.126 | 0.045 | |

| F4 | 0.129 | 0.086 | |

| Axial displacement | F1 | 1.000 | 1.000 |

| F2 | 0.472 | 0.440 | |

| F3 | 0.198 | 0.160 | |

| F4 | 0.201 | 0.239 | |

| Extreme Values of Stress Deformation Characteristics | Influence Factor | Relative Weight Contribution Value | |

|---|---|---|---|

| Completion Period | Storage Period | ||

| Deflection | F1 | 1.000 | 1.000 |

| F2 | 0.316 | 0.352 | |

| F3 | 0.183 | 0.154 | |

| F4 | 0.102 | 0.115 | |

| Axial displacement | F1 | 0.277 | 1.000 |

| F2 | 1.000 | 0.654 | |

| F3 | 0.283 | 0.120 | |

| F4 | 0.208 | 0.062 | |

| Tensile stress along the slope direction | F1 | 0.695 | 0.510 |

| F2 | 1.000 | 0.982 | |

| F3 | 0.919 | 0.324 | |

| F4 | 0.516 | 1.000 | |

| Compressive stress along the slope direction | F1 | 0.441 | 0.336 |

| F2 | 1.000 | 1.000 | |

| F3 | 0.838 | 0.309 | |

| F4 | 0.374 | 0.225 | |

| Axial tensile stress | F1 | 1.000 | 0.686 |

| F2 | 0.380 | 0.700 | |

| F3 | 0.303 | 0.251 | |

| F4 | 0.636 | 1.000 | |

| Axial compressive stress | F1 | 0.344 | 0.811 |

| F2 | 1.000 | 1.000 | |

| F3 | 0.601 | 0.502 | |

| F4 | 0.271 | 0.574 | |

| No. | Calculation Scheme | Dam Height/m | Bank Slope Gradient | Water Storage |

|---|---|---|---|---|

| 1 | 1-1 | 200 | 1:1.0 | 2 |

| 1-2 | 250 | |||

| 1-3 | 300 | |||

| 2 | 2-1 | 250 | 1:0.5 | 2 |

| 2-2 | 1:1.0 | |||

| 2-3 | 1:1.5 | |||

| 3 | 3-1 | 250 | 1:0.5 | 1 |

| 3-2 | 2 | |||

| 3-3 | 3 |

| Scheme | Dam Body | Panel | ||||||

|---|---|---|---|---|---|---|---|---|

| Internal Settlement/cm | Along the River Displacement/cm | Deflection/cm | Axial Displacement/cm | Along the Slope Direction | Along the Axial Direction | |||

| Compressive Stress/MPa | Tensile Stress/MPa | Compressive Stress/MPa | Tensile Stress/MPa | |||||

| 1-1 | 94.47 | 25.11 | 38.27 | 2.66 | 5.46 | 1.66 | 10.56 | 1.25 |

| 1-2 | 139.50 | 36.58 | 57.98 | 4.26 | 7.09 | 2.63 | 14.74 | 2.52 |

| 1-3 | 191.80 | 49.83 | 80.89 | 6.46 | 9.26 | 4.78 | 19.67 | 3.02 |

| 2-1 | 113.46 | 26.59 | 51.32 | 2.93 | 6.89 | 1.05 | 17.24 | 2.63 |

| 2-2 | 139.50 | 36.58 | 57.98 | 4.26 | 7.09 | 2.63 | 14.74 | 2.52 |

| 2-3 | 152.30 | 42.72 | 64.41 | 4.86 | 6.80 | 3.04 | 13.43 | 2.45 |

| 3-1 | 113.20 | 26.97 | 53.36 | 3.01 | 7.66 | 1.29 | 17.13 | 3.19 |

| 3-2 | 113.46 | 26.59 | 51.32 | 2.93 | 6.89 | 1.05 | 17.24 | 2.63 |

| 3-3 | 113.53 | 26.52 | 51.31 | 2.90 | 6.54 | 0.86 | 17.83 | 2.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, J.; Lv, Y.; Feng, C. Study on the Effects of Influence Factors on the Stress and Deformation Characteristics of Ultra-High CFRDs. Appl. Sci. 2024, 14, 8268. https://doi.org/10.3390/app14188268

Li H, Wang J, Lv Y, Feng C. Study on the Effects of Influence Factors on the Stress and Deformation Characteristics of Ultra-High CFRDs. Applied Sciences. 2024; 14(18):8268. https://doi.org/10.3390/app14188268

Chicago/Turabian StyleLi, Hongmei, Jianxin Wang, Yanyuan Lv, and Chengming Feng. 2024. "Study on the Effects of Influence Factors on the Stress and Deformation Characteristics of Ultra-High CFRDs" Applied Sciences 14, no. 18: 8268. https://doi.org/10.3390/app14188268