Assessment of a Portable Air Cleaning Device Performance in Eliminating Indoor Air Contaminants by Considering Particle Transport Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Numerical Model

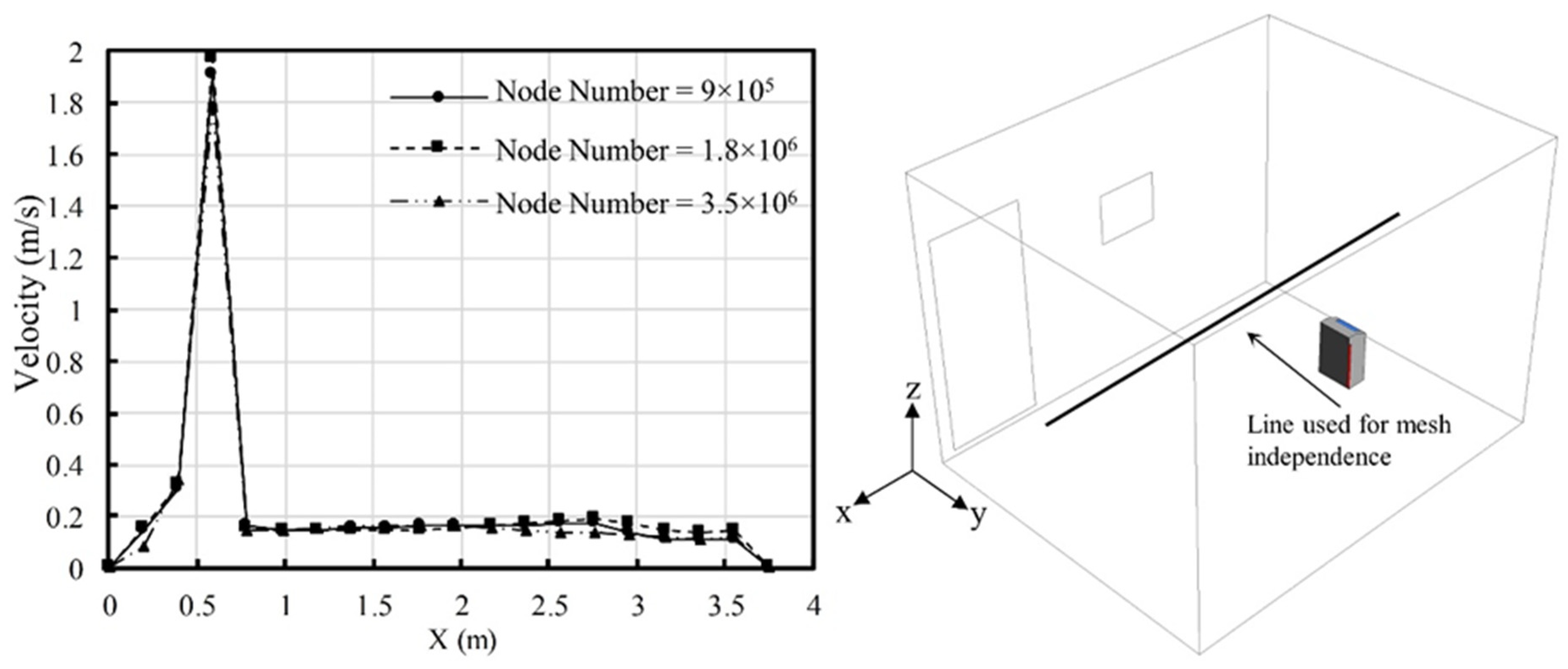

2.2. Solution Domain Model and Validation

2.3. Mean Age of Air

2.4. Particle Tracking

2.5. Clean Air Delivery Rate (CADR) Calculations

3. Results and Discussions

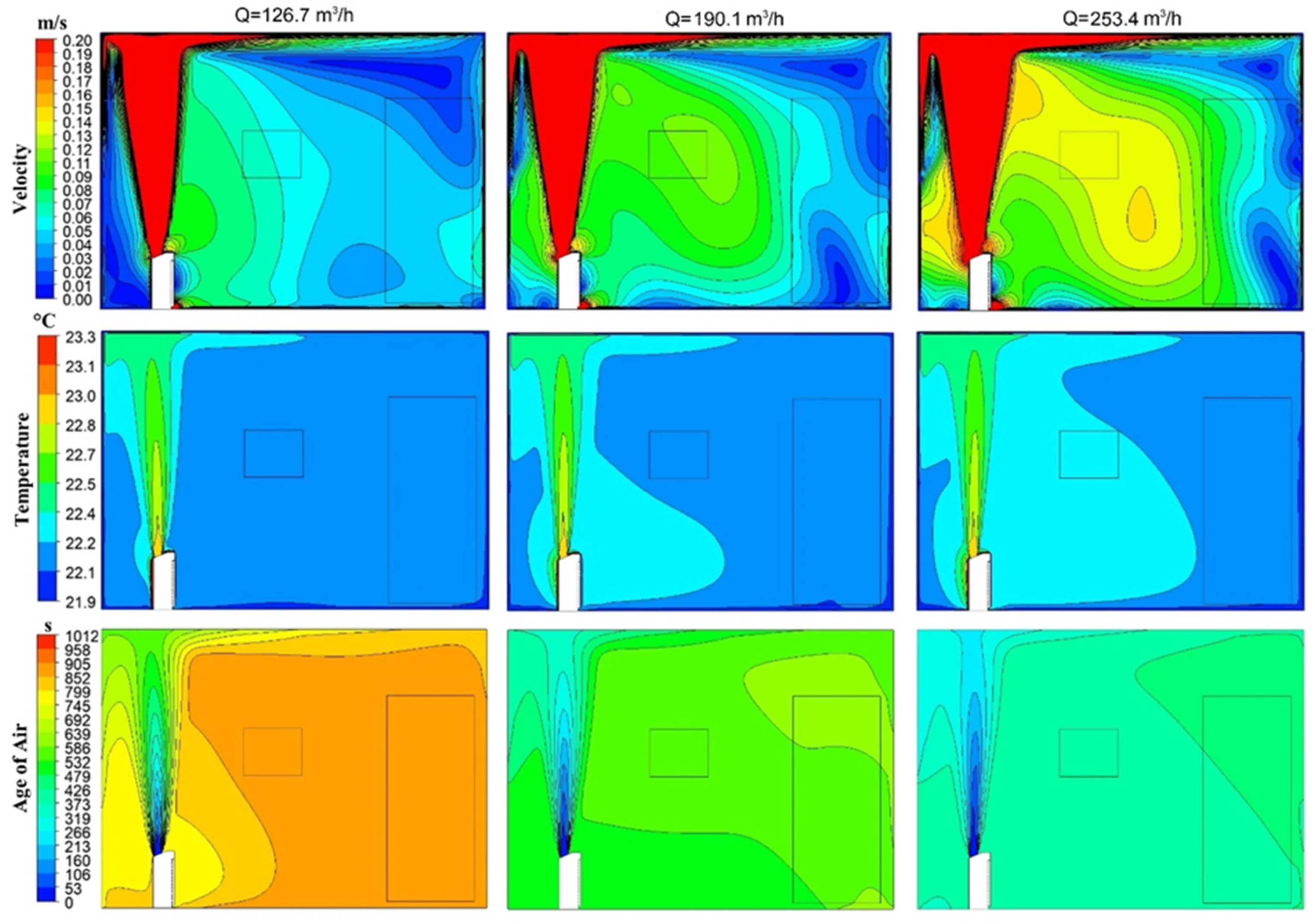

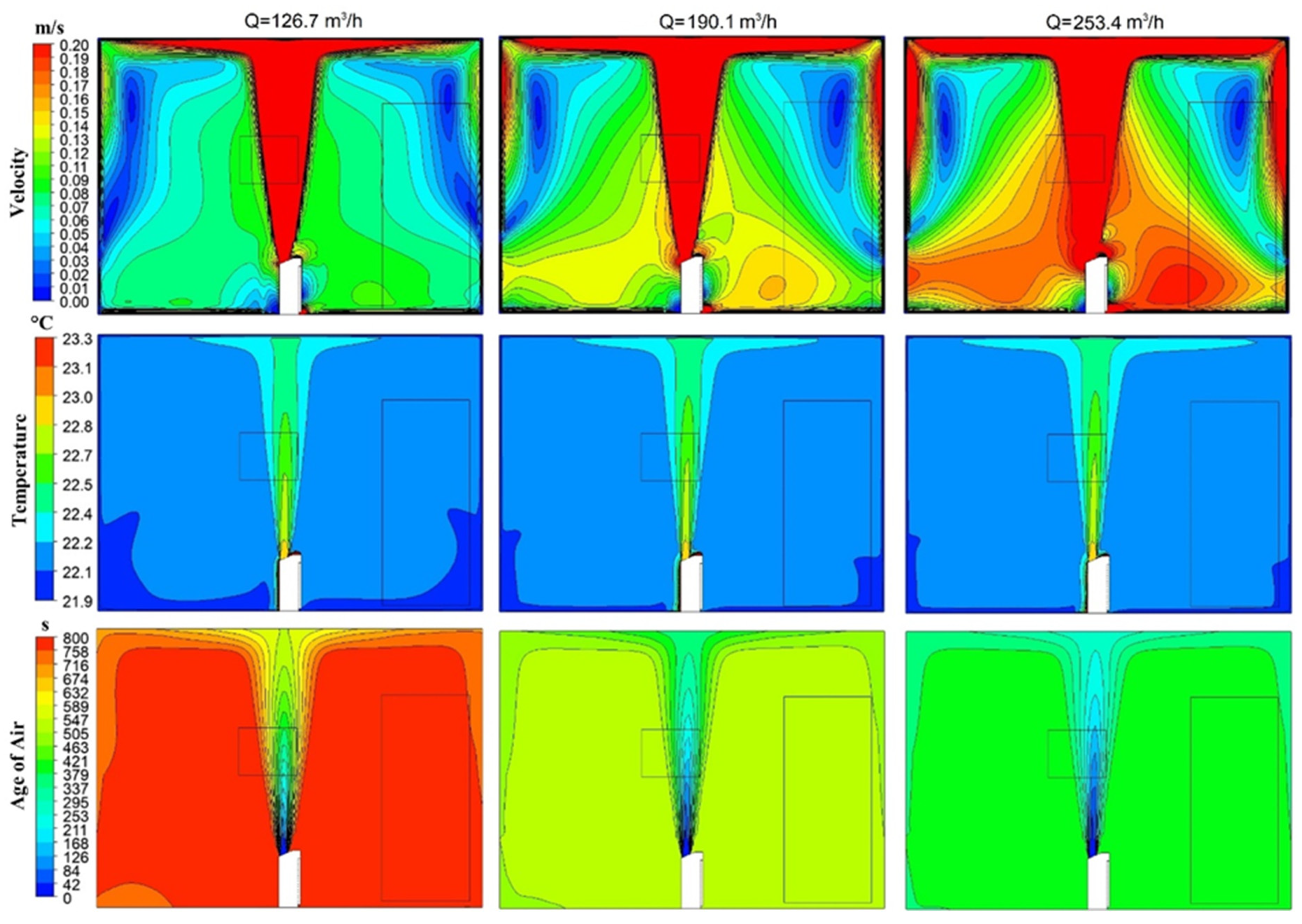

3.1. Velocity and Temperature Distributions

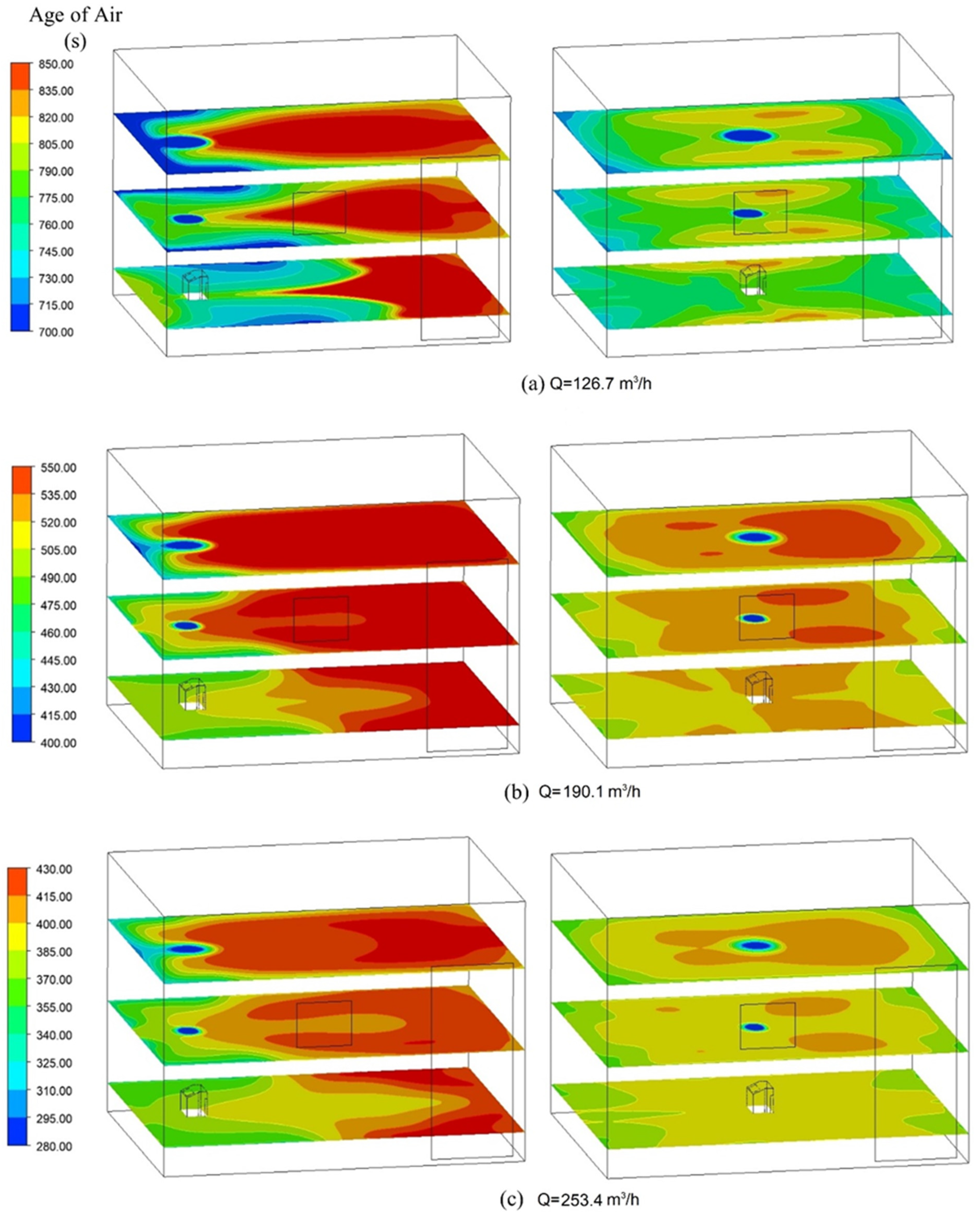

3.2. Age of Air Distributions

3.3. CADR Values

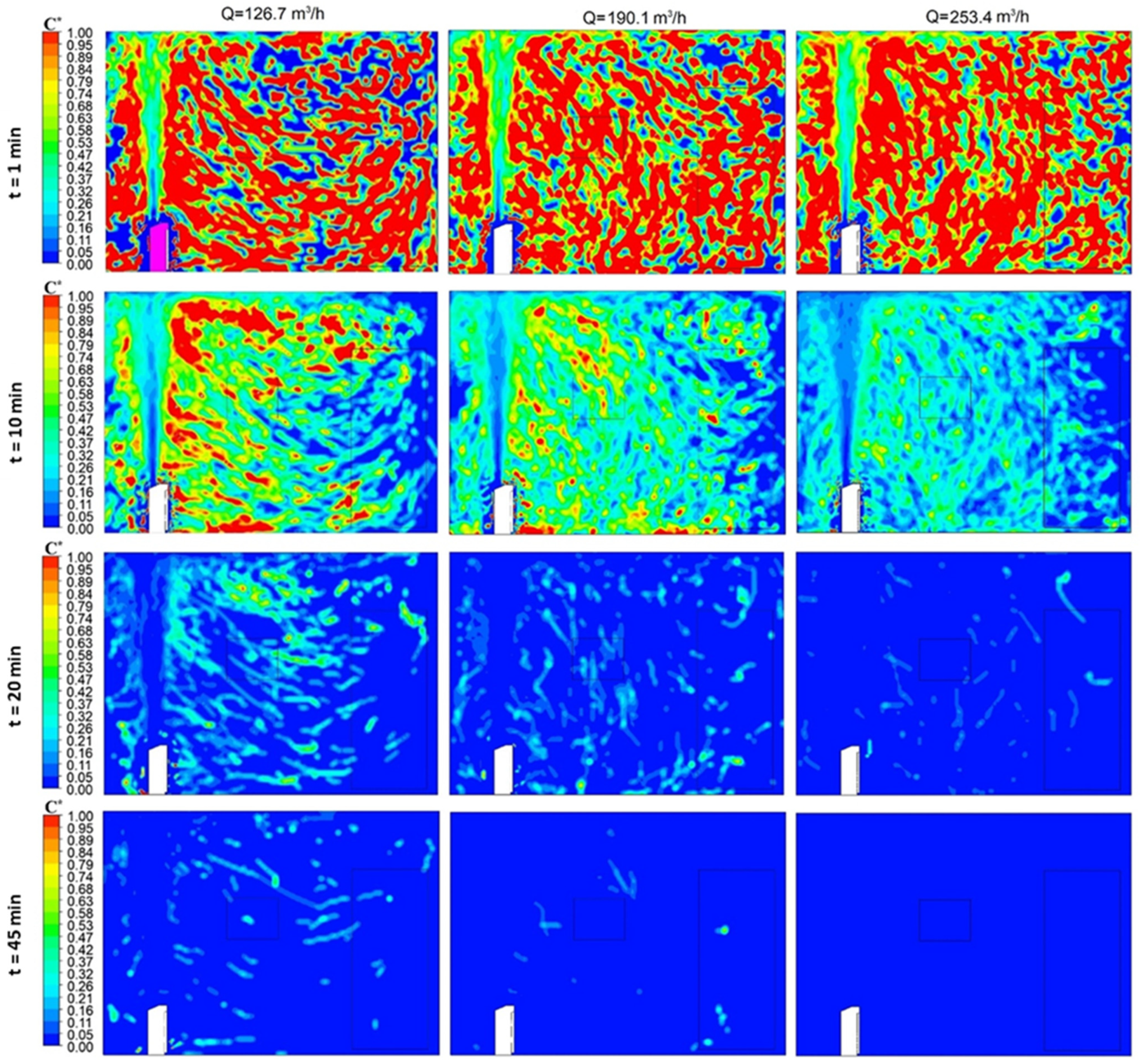

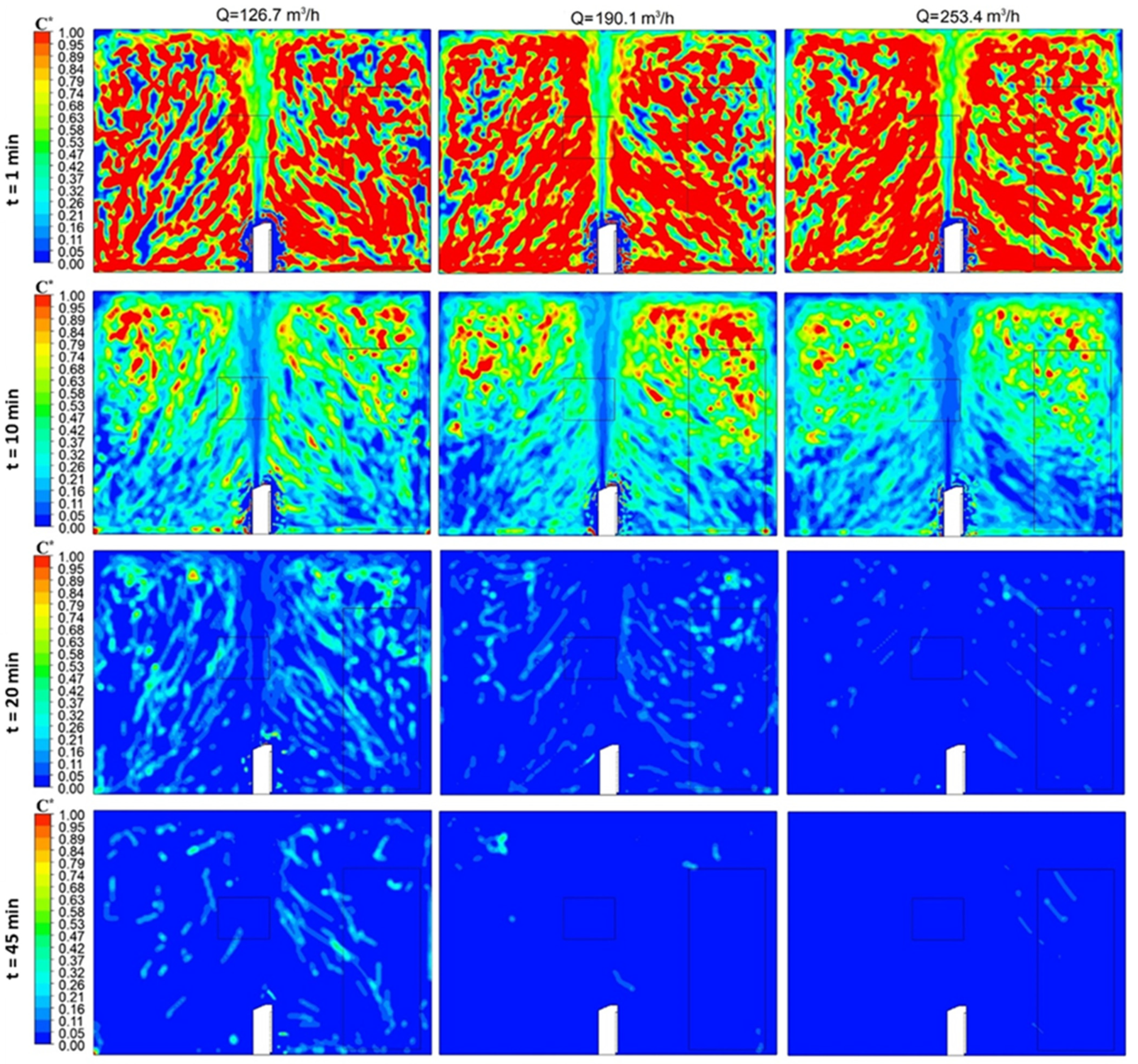

3.4. Particle Concentrations

3.5. Limitations of the Present Study

4. Conclusions

- An increase in the air flow rate of the ACD causes more substantial recirculation inside the room. The age of air values decrease when the flow rates increase at both locations. Also, the center placement of the ACD shortens the air age due to a smaller recirculation zone and a more homogeneous air distribution.

- An increase in the air flow rate results in an increase in the CADR values of the ACD, meaning a better cleaning performance. As a result, an increase in the air flow rate has positive effects on both CADR and age of air parameters. The center placement of the ACD has higher CADR values compared to the wall-side placement.

- To improve the air quality at a certain location, both an increase in blowing speed and a change of device position should be considered. Another important point is that the increase in blowing speed increases the difference in air age values between the two positions. In other words, the air age values in the room become more dependent on the device position as the distance of the location from the device and the blowing speeds increase.

- By comparing the two performance methods, it is observed that the mean age of air method shows a recirculation structure of the air in the room. Therefore, the best position, which gives the smallest mean air age in the room, can be determined. Meanwhile, the CADR method gives the best collection efficiency considering the particle diameters and the flow rate. In addition to that, the decay rate of the particles and the required cleaning time interval for an air cleaning device can be determined using the CADR method. Hence, both methods are useful to determine the performance of an air cleaner device.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Di Fiore, C.; Pandolfi, P.; Carriera, F.; Iannone, A.; Settimo, G.; Mattei, V.; Avino, P. The Presence of Aromatic Substances in Incense: Determining Indoor Air Quality and Its Impact on Human Health. Appl. Sci. 2023, 13, 7344. [Google Scholar] [CrossRef]

- Chirico, F.; Settimo, G.; Magnavita, N. Indoor Air Quality and Indoor Environmental Quality: The role of occupational health surveillance and the cooperation between public and occupational health stakeholders. J. Health Soc. Sci. 2023, 8, 262–269. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Zhang, S.; Ai, L.; Lv, H.; Zhu, C.; Wu, J.H.; Tan, W. Effects and interaction of air pollution and meteorological factors on pertussis incidence in PR China. Hyg. Environ. Health Adv. 2022, 4, 100036. [Google Scholar] [CrossRef]

- Aglan, A.; Synn, A.J.; Nurhussien, L.; Chen, K.; Scheerens, C.; Koutrakis, P.; Coull, B.; Rice, M.B. Personal and community-level exposure to air pollution and daily changes in respiratory symptoms and oxygen saturation among adults with COPD. Hyg. Environ. Health Adv. 2023, 6, 100052. [Google Scholar] [CrossRef] [PubMed]

- Gola, M.; Caggiano, G.; De Giglio, O.; Napoli, C.; Diella, G.; Carlucci, M.; Carpagnano, L.F.; D’Alessandro, D.; Joppolo, C.M.; Capolongo, S.; et al. SARS-CoV-2 indoor contamination: Considerations on anti-COVID-19 management of ventilation systems, and finishing materials in healthcare facilities. Ann. Ig. 2021, 33, 381–392. [Google Scholar] [CrossRef]

- Faulkner, W.B.; Mermarzadeh, F.; Riskowski, G.; Kalbasi, A.; Chang, A.C. Effects of Air Exchange Rate, Particle Size and Injection Place on Particle Concentrations within a Reduced-Scale Room. Build. Environ. 2015, 92, 246–255. [Google Scholar]

- Chen, L.; Jin, X.; Yang, L.; Du, X.; Yang, Y. Particle transport characteristics in indoor environment with an air cleaner: The effect of nonuniform particle distributions. Build. Simul. 2017, 10, 123–133. [Google Scholar] [CrossRef]

- Zheng, W.; Hu, J.; Wang, Z.; Li, J.; Fu, Z.; Li, H.; Jurasz, J.; Chou, S.K.; Yan, J. COVID-19 Impact on Operation and Energy Consumption of Heating, Ventilation and Air-Conditioning (HVAC) Systems. Adv. Appl. Energy 2021, 3, 100040. [Google Scholar]

- Asadi, S.; Bouvier, N.; Wexler, A.S.; Ristenpart, W.D. The coronavirus pandemic and aerosols: Does COVID-19 transmit via expiratory particles? Aerosol Sci. Technol. 2020, 54, 635–638. [Google Scholar]

- Gralton, J.; Tovey, E.; McLaws, M.L.; Rawlinson, W.D. The role of particle size in aerosolised pathogen transmission: A review. J. Infect. 2011, 62, 1–13. [Google Scholar]

- Peng, S.; Chen, Q.; Liu, E. The role of computational fluid dynamics tools on investigation of pathogen transmission: Prevention and control. Sci. Total Environ. 2020, 746, 142090. [Google Scholar] [PubMed]

- Kähler, C.J.; Hain, R.; Fuchs, T. Assessment of Mobile Air Cleaners to Reduce the Concentration of Infectious Aerosol Particles Indoors. Atmosphere 2023, 14, 698. [Google Scholar] [CrossRef]

- Settimo, G.; Yu, Y.; Gola, M.; Buffoli, M.; Capolongo, S. Challenges in IAQ for Indoor Spaces: A Comparison of the Reference Guideline Values of Indoor Air Pollutants from the Governments and International Institutions. Atmosphere 2023, 14, 633. [Google Scholar] [CrossRef]

- Tobisch, A.; Springsklee, L.; Schäfer, L.F.; Sussmann, N.; Lehmann, M.J.; Weis, F.; Zöllner, R.; Niessner, J. Reducing indoor particle exposure using mobile air purifiers—Experimental and numerical analysis. AIP Adv. 2021, 11, 125114. [Google Scholar] [CrossRef]

- Mohamadi, F.; Fazeli, A. A Review on Applications of CFD Modeling in COVID-19 Pandemic. Arch. Comput. Methods Eng. 2022, 29, 3567–3586. [Google Scholar] [CrossRef]

- Kilic, M.; Sevilgen, G. Modelling airflow, heat transfer and moisture transport around a standing human body by computational fluid dynamics. Int. Commun. Heat Mass Transf. 2008, 35, 1159–1164. [Google Scholar]

- Sevilgen, G.; Kılıç, M. Transient Numerical Analysis of Airflow and Heat Transfer in a Vehicle Cabin during Heating Period. Int. J. Veh. Des. 2010, 52, 144–159. [Google Scholar]

- AHAM. Method for Measuring the Performance of Portable Household Electric Room Air Cleaners; AHAM: Quezon City, Philippines, 2013; pp. 1–4. [Google Scholar]

- Buratti, C.; Palladino, D. Mean Age of Air in Natural Ventilated Buildings: Experimental Evaluation and CO2 Prediction by Artificial Neural Networks. Appl. Sci. 2020, 10, 1730. [Google Scholar] [CrossRef]

- Kılıç, M.; Mutlu, İ.H.; Saldamlı, I. Numerical investigation of an air cleaning device performance. J. Fac. Eng. Arch. Gazi Univ. 2022, 37, 2077–2089. [Google Scholar]

- Zhang, T.; Wang, S.; Sun, G.; Xu, L.; Takaoka, D. Flow Impact of an Air Conditioner to Portable Air Cleaning. Build. Environ. 2010, 45, 2047–2056. [Google Scholar]

- Jin, X.; Yang, L.; Du, X.; Yang, Y. Particle Transport Characteristics in Indoor Environment with an Air Cleaner. Indoor Built Environ. 2016, 25, 987–996. [Google Scholar]

- Moradi Kashkooli, F.; Sefidgar, M.; Soltani, M.; Anbari, S.; Shahandashti, S.-A.; Zargar, B. Numerical Assessment of an Air Cleaner Device under Different Working Conditions in an Indoor Environment. Sustainability 2021, 13, 369. [Google Scholar] [CrossRef]

- Park, H.; Park, S.; Seo, J. Evaluation on Air Purifier’s Performance in Reducing the Concentration of Fine Particulate Matter for Occupants According to Its Operation Methods. Int. J. Environ. Res. Public Health 2020, 17, 5561. [Google Scholar] [CrossRef] [PubMed]

- Noh, K.C.; Oh, M. Variation of Clean Air Delivery Rate and Effective Air Cleaning Ratio of Room Air Cleaning Devices. Build. Environ. 2015, 84, 44–49. [Google Scholar]

- Ma, H.; Shen, H.; Shui, T.; Li, Q.; Zhou, L. Experimental Study on Ultrafine Particle Removal Performance of Portable Air Cleaners with Different Filters in an Office Room. Int. J. Environ. Res. Public Health 2016, 13, 102. [Google Scholar] [CrossRef]

- Noh, K.C.; Yook, S.J. Evaluation of Clean Air Delivery Rates and Operating Cost Effectiveness for Room Air Cleaner and Ventilation System in a Small Lecture Room. Energy Build. 2016, 119, 111–118. [Google Scholar]

- Tran, P.T.M.; Adam, M.G.; Balasubramanian, R. Mitigation of Indoor Human Exposure to Airborne Particles of Outdoor Origin in an Urban Environment during Haze and Non-Haze Periods. J. Hazard. Mater. 2021, 403, 123555. [Google Scholar]

- Pei, J.; Dai, W.; Li, H.; Liu, J. Laboratory and Field Investigation of Portable Air Cleaners’ Long-Term Performance for Particle Removal to Be Published in: Building and Environment. Build. Environ. 2020, 181, 107100. [Google Scholar]

- Siegel, J.A. Primary and Secondary Consequences of Indoor Air Cleaners. Indoor Air 2016, 26, 88–96. [Google Scholar]

- Sabanskis, A.; Vidulejs, D.D.; Teličko, J.; Virbulis, J.; Jakovičs, A. Numerical Evaluation of the Efficiency of an Indoor Air Cleaner under Different Heating Conditions. Atmosphere 2023, 14, 1706. [Google Scholar] [CrossRef]

- Saidi, M.S.; Rismanian, M.; Monjezi, M.; Zendehbad, M.; Fatehiboroujeni, S. Comparison between Lagrangian and Eulerian approaches in predicting motion of micron-sized particles in laminar flows. Atmos. Environ. 2014, 89, 199–206. [Google Scholar]

- Wang, M.; Lin, C.H.; Chen, Q. Advanced turbulence models for predicting particle transport in enclosed environments. Build. Environ. 2012, 47, 40–49. [Google Scholar]

- ANSYS. AnsysFluent 19.0 Theory Guide; Release 19.0; ANSYS Inc.: Canonsburg, PA, USA, 2021. [Google Scholar]

- Sevilgen, G.; Kılıç, M. Three Dimensional Numerical Analysis of Temperature Distribution in an Automobile Cabin. Therm. Sci. 2012, 16, 321–326. [Google Scholar]

- Sevilgen, G.; Kılıç, M. Investigation of Transient Cooling of an Automobile Cabin with a Virtual Manikin under Solar Radiation. Therm. Sci. 2013, 17, 397–406. [Google Scholar]

- Sevilgen, G.; Kılıç, M. Numerical analysis of air flow, heat transfer, moisture transport and thermal comfort in a room heated by two-panel radiators. Energy Build. 2011, 43, 137–146. [Google Scholar] [CrossRef]

- Choudhury, D. Introduction to the Renormalization Group Method and Turbulence Modelling; Fluent Inc.: New York, NY, USA, 1993; Volume 107. [Google Scholar]

- Hinds, W.C. Aerosol Technology, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Mutlu, M. Numerical Investigation of Indoor Air Quality in a Floor Heated Room with Different Air Change Rates. Build. Simul. 2020, 13, 1063–1075. [Google Scholar] [CrossRef]

- Mutlu, M. Particle Concentration Comparison of Radiator and Floor Heating Systems under Zero Air Change Rate Condition. Aerosol Air Qual. Res. 2021, 21, 210148. [Google Scholar] [CrossRef]

- Joppolo, C.M.; Bertolina, D.; Palazzo, M.; Marocco, L. Preserving Leonardo’s Last Supper: A CFD case study. J. Cult. Herit. 2021, 51, 194–200. [Google Scholar] [CrossRef]

- Kılıç, M.; Mutlu, M.; Altun, A.F. Numerical Simulation and Analytical Evaluation of the Collection Efficiency of the Particles in a Gas by the Wire-Plate Electrostatic Precipitators. Appl. Sci. 2022, 12, 6401. [Google Scholar] [CrossRef]

- Bake, B.; Larsson, P.; Ljungkvist, G.; Ljungström, E.; Olin, A.C. Exhaled particles and small airways. Respir. Res. 2019, 20, 8. [Google Scholar] [CrossRef]

- Nicas, M.; Nazaroff, W.W.; Hubbard, A. Toward understanding the risk of secondary airborne infection: Emission of respirable pathogens. J. Occup. Environ. Hyg. 2005, 2, 143–154. [Google Scholar] [CrossRef] [PubMed]

- Johnson, G.R.; Morawska, L.; Ristovski, Z.D.; Hargreaves, M.; Mengersen, K.; Chao, C.Y.H.; Wan, M.P.; Li, Y.; Xie, X.; Katoshevski, D.; et al. Modality of human expired aerosol size distributions. J. Aerosol Sci. 2011, 42, 839–851. [Google Scholar] [CrossRef]

- Morawska, L.; Johnson, G.R.; Ristovski, Z.D.; Hargreaves, M.; Mengersen, K.; Corbett, S.; Chao, C.Y.H.; Li, Y.; Katoshevski, D. Size distribution and sites of origin of droplets expelled from the human respiratory tract during expiratory activities. J. Aerosol Sci. 2009, 40, 256–269. [Google Scholar] [CrossRef]

- Allen, M.D.; Raabe, O.G. Re-evaluation of millikan’s oil drop data for the motion of small particles in air. J. Aerosol Sci. 1982, 13, 537–547. [Google Scholar]

- Küpper, M.; Asbach, C.; Schneiderwind, U.; Finger, H.; Spiegelhoff, D.; Schumacher, S. Testing of an Indoor Air Cleaner for Particulate Pollutants under Realistic Conditions in an Office Room. Aerosol Air Qual. Res. 2019, 19, 1655–1665. [Google Scholar] [CrossRef]

- Shiue, A.; Hu, S.C.; Tseng, C.H.; Kuo, E.H.; Liu, C.Y.; Hou, C.T.; Yu, T. Verification of Air Cleaner On-Site Modeling for PM2.5 and TVOC Purification in a Full-Scale Indoor Air Quality Laboratory. Atmos. Pollut. Res. 2019, 10, 209–218. [Google Scholar] [CrossRef]

- Gunschera, J.; Markewitz, D.; Bansen, B.; Salthammer, T.; Ding, H. Portable Photocatalytic Air Cleaners: Efficiencies and by-Product Generation. Environ. Sci. Pollut. Res. 2016, 23, 7482–7493. [Google Scholar] [CrossRef]

| Points | X (m) | Y (m) | Z (m) | Measured Velocity (m/s) | Predicted Velocity (m/s) | Diff. % |

|---|---|---|---|---|---|---|

| P1 | 1.875 | 1.5 | 1.0 | 0.06 | 0.059 | 1.7 |

| P2 | 0.9375 | 1.5 | 1.0 | 1.00 | 0.990 | 1.0 |

| P3 | 2.8125 | 1.5 | 1.0 | 0.05 | 0.048 | 4.0 |

| P4 | 0.9375 | 2.25 | 1.0 | 0.06 | 0.059 | 1.7 |

| P5 | 1.875 | 2.25 | 1.0 | 0.06 | 0.061 | 1.7 |

| P6 | 2.8125 | 2.25 | 1.0 | 0.08 | 0.075 | 6.3 |

| P7 | 1.875 | 1.5 | 0.5 | 0.11 | 0.105 | 4.5 |

| P8 | 0.9375 | 1.5 | 0.5 | 0.09 | 0.090 | 0 |

| P9 | 2.8125 | 1.5 | 0.5 | 0.05 | 0.052 | 4 |

| P10 | 0.9375 | 2.25 | 0.5 | 0.08 | 0.078 | 2.5 |

| P11 | 1.875 | 2.25 | 0.5 | 0.07 | 0.067 | 4.3 |

| P12 | 2.8125 | 2.25 | 0.5 | 0.06 | 0.057 | 5.0 |

| Flow rate | 126.7 (m3/h) | 190.1 (m3/h) | 253.4 (m3/h) | |||

| Mean Age of Air (s) | ||||||

| Location | Mean | Max | Mean | Max | Mean | Max |

| Wall Side (Pos. 1) | 802.2 | 1012.8 | 539.4 | 607.5 | 401.6 | 444.1 |

| Center (Pos. 2) | 774.3 | 827.8 | 516.2 | 545.6 | 387.2 | 409.5 |

| Position | Wall Side Placement (Position 1) | ||||||

|---|---|---|---|---|---|---|---|

| Flow Rate | m3/h | 126.7 | 126.7 | 190.1 | 190.1 | 253.4 | 253.4 |

| dp | μm | 1 | 10 | 1 | 10 | 1 | 10 |

| CADR | m3/h | 89.4 | 93.0 | 134.4 | 145.2 | 179.4 | 186.6 |

| η | % | 71 | 73 | 71 | 76 | 71 | 74 |

| ke | min−1 | 0.055 | 0.057 | 0.08 | 0.086 | 0.105 | 0.109 |

| Δt10% | min | 41.86 | 40.39 | 28.78 | 26.77 | 21.93 | 21.12 |

| Δt1% | min | 83.73 | 80.79 | 57.56 | 53.55 | 43.86 | 42.25 |

| Position | Center Placement (Position 2) | ||||||

| Flow Rate | m3/h | 126.7 | 126.7 | 190.1 | 190.1 | 253.4 | 253.4 |

| dp | μm | 1 | 10 | 1 | 10 | 1 | 10 |

| CADR | m3/h | 100.2 | 109.2 | 154.2 | 165.0 | 204.6 | 217.2 |

| η | % | 79 | 86 | 81 | 87 | 81 | 86 |

| ke | min−1 | 0.061 | 0.066 | 0.091 | 0.097 | 0.119 | 0.126 |

| Δt10% | min | 37.7 | 34.9 | 25.3 | 23.7 | 19.3 | 18.3 |

| Δt1% | min | 75.5 | 69.8 | 50.6 | 47.5 | 38.7 | 36.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gür, M.; Kılıç, M. Assessment of a Portable Air Cleaning Device Performance in Eliminating Indoor Air Contaminants by Considering Particle Transport Characteristics. Appl. Sci. 2024, 14, 8362. https://doi.org/10.3390/app14188362

Gür M, Kılıç M. Assessment of a Portable Air Cleaning Device Performance in Eliminating Indoor Air Contaminants by Considering Particle Transport Characteristics. Applied Sciences. 2024; 14(18):8362. https://doi.org/10.3390/app14188362

Chicago/Turabian StyleGür, Miray, and Muhsin Kılıç. 2024. "Assessment of a Portable Air Cleaning Device Performance in Eliminating Indoor Air Contaminants by Considering Particle Transport Characteristics" Applied Sciences 14, no. 18: 8362. https://doi.org/10.3390/app14188362