Advanced Micro/Nanocapsules for Self-Healing Coatings

Abstract

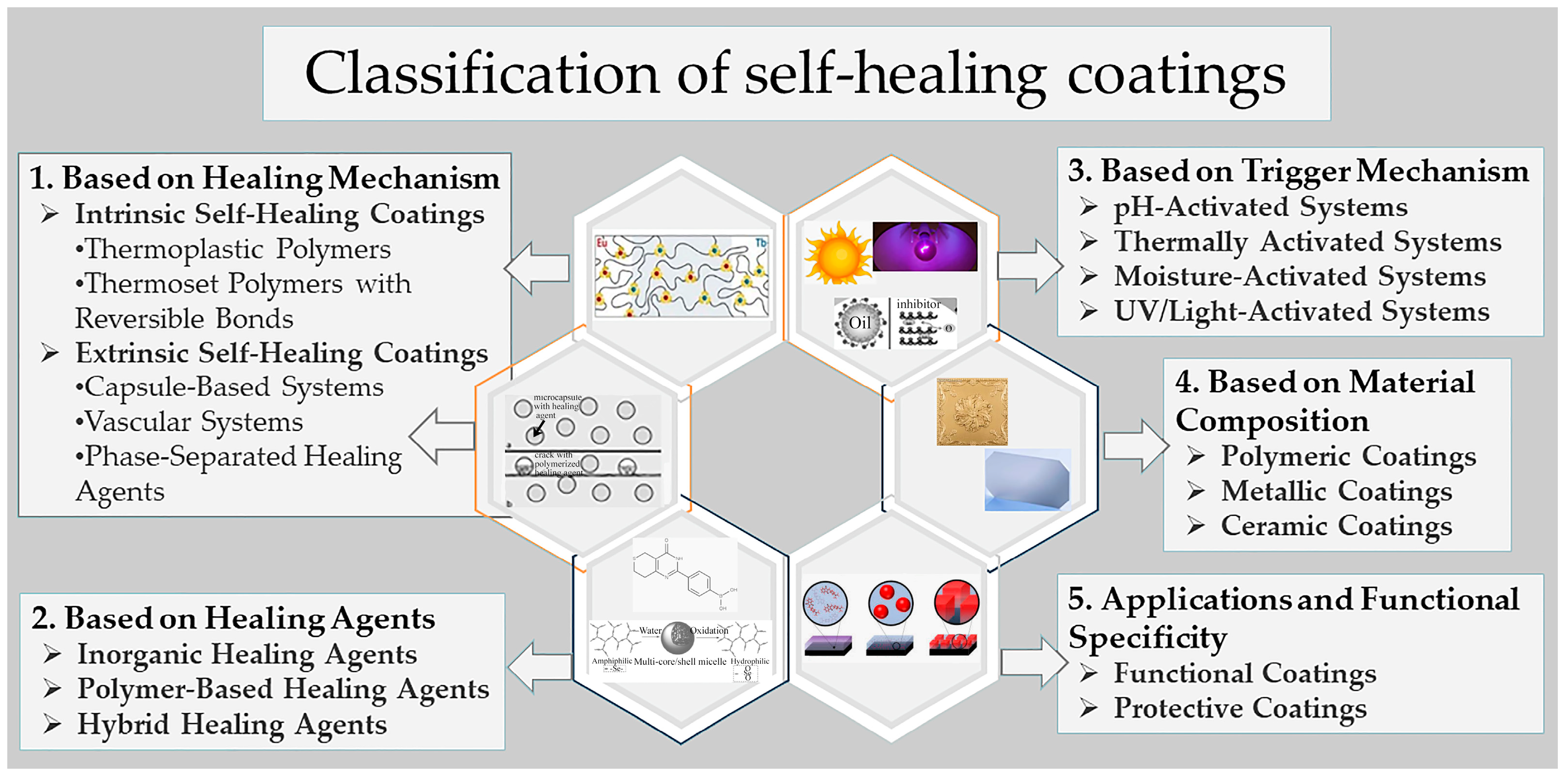

1. Introduction

2. Self-Healing Coatings Based on Additives Including Corrosion Inhibitors

3. Self-Healing Coatings Based on Additives Including Healing Agents

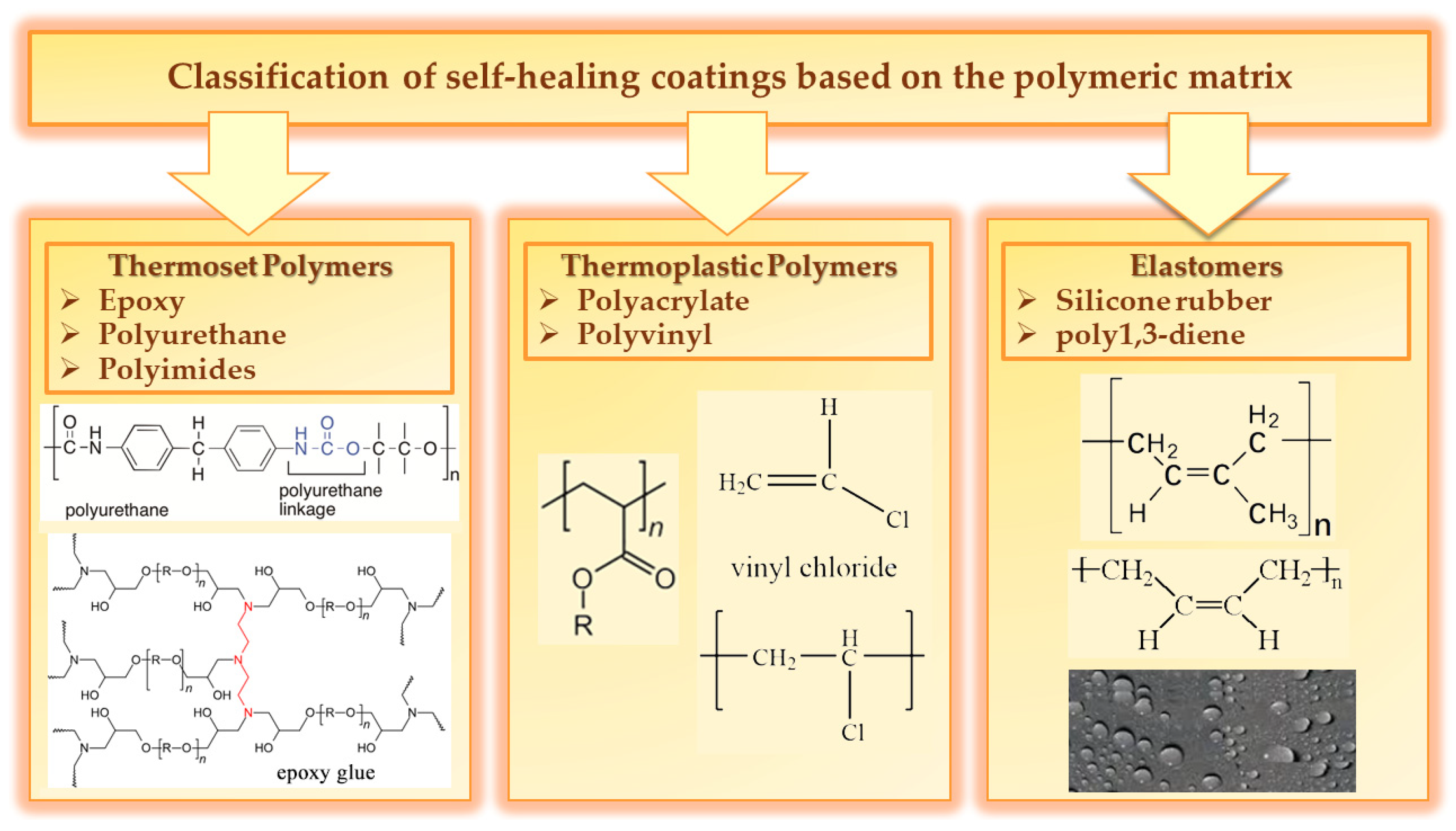

4. Classification of Self-Healing Coatings Based on the Polymeric Matrix

4.1. Thermoset Polymers

4.1.1. Epoxy-Based Self-Healing Coatings

4.1.2. Polyurethane-Based Self-Healing Coatings

4.1.3. Polyimide-Based Self-Healing Coatings

4.2. Thermoplastic Polymers

4.2.1. Polyacrylate-Based Self-Healing Coatings

4.2.2. Polyvinyl-Based Self-Healing Coatings

4.3. Elastomers

4.3.1. Silicone-Rubber-Based Self-Healing Coatings

4.3.2. Poly1,3-Diene-Based Self-Healing Coatings

5. Types of Self-Healing Capsules

5.1. Nanocapsules in Self-Healing Coatings

5.2. Mechanisms of Self-Healing Capsules

5.3. Application-Based Classification of Self-Healing Capsules

5.4. Optimization of Micro/Nanocapsule Design for Self-Healing Coatings

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmad, S.; Habib, S.; Nawaz, M.; Shakoor, R.A.; Kahraman, R.; Mohammed Al Tahtamouni, T. The role of polymeric matrices on the performance of smart self-healing coatings: A review. J. Ind. Eng. Chem. 2023, 124, 40–67. [Google Scholar] [CrossRef]

- Zehra, S.; Mobin, M.; Aslam, R.; Bhat, S.u.I. Nanocontainers: A comprehensive review on their application in the stimuli-responsive smart functional coatings. Prog. Org. Coat. 2023, 176, 107389. [Google Scholar] [CrossRef]

- Chen, Z.; Scharnagl, N.; Zheludkevich, M.L.; Ying, H.; Yang, W. Micro/nanocontainer-based intelligent coatings: Synthesis, performance and applications—A review. Chem. Eng. J. 2023, 451, 138582. [Google Scholar] [CrossRef]

- Lee, K.; Cavazos, C.G.; Rouse, J.; Wei, X.; Li, M.; Wei, S. Advanced Micro/Nanocapsules for Self-healing Smart Anticorrosion Coatings; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Eduok, U.; Ohaeri, E.; Szpunar, J. Self-healing composite coatings with protective and anticorrosion potentials: Classification by healing mechanism. In Self-Healing Composite Materials; Woodhead Publishing: Sutton, UK, 2020; pp. 123–162. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, L.; Nie, Y.; Li, Y.; Wei, S.; Chen, X.; Zhao, W.; Yan, S. Advances and Challenges of Self-Healing Elastomers: A Mini Review. Materials 2022, 15, 5993. [Google Scholar] [CrossRef]

- Karaxi, E.K.; Kartsonakis, I.A.; Charitidis, C.A. Assessment of Self-Healing Epoxy-Based Coatings Containing Microcapsules Applied on Hot Dipped Galvanized Steel. Front. Mater. 2019, 6, 222. [Google Scholar] [CrossRef]

- Sadrabadi, T.E.; Allahkaram, S.R.; Staab, T.; Towhidi, N. Preparation and characterization of durable micro/nanocapsules for use in self-healing anticorrosive coatings. Polym. Sci. Ser. B 2017, 59, 281–291. [Google Scholar] [CrossRef]

- Shi, F.; Wu, J.; Zhao, B. Preparation and Investigation of Intelligent Polymeric Nanocapsule for Enhanced Oil Recovery. Materials 2019, 12, 1093. [Google Scholar] [CrossRef]

- Malekkhouyan, R.; Nouri Khorasani, S.; Esmaeely Neisiany, R.; Torkaman, R.; Koochaki, M.S.; Das, O. Preparation and Characterization of Electrosprayed Nanocapsules Containing Coconut-Oil-Based Alkyd Resin for the Fabrication of Self-Healing Epoxy Coatings. Appl. Sci. 2020, 10, 3171. [Google Scholar] [CrossRef]

- Habib, S.; Khan, A.; Nawaz, M.; Sliem, M.H.; Shakoor, R.A.; Kahraman, R.; Abdullah, A.M.; Zekri, A. Self-Healing Performance of Multifunctional Polymeric Smart Coatings. Polymers 2019, 11, 1519. [Google Scholar] [CrossRef]

- Shang, Z.; Zhu, J. Overview on plant extracts as green corrosion inhibitors in the oil and gas fields. J. Mater. Res. Technol. 2021, 15, 5078–5094. [Google Scholar] [CrossRef]

- Al-Amiery, A.A.; Isahak, W.N.R.W.; Al-Azzawi, W.K. Corrosion Inhibitors: Natural and Synthetic Organic Inhibitors. Lubricants 2023, 11, 174. [Google Scholar] [CrossRef]

- Al-Amiery, A.A.; Yousif, E.; Isahak, W.N.R.W.; Al-Azzawi, W.K. A Review of Inorganic Corrosion Inhibitors: Types, Mechanisms, and Applications. Tribol. Ind. 2023, 45, 313–339. [Google Scholar] [CrossRef]

- Rani, B.E.A.; Basu, B.B.J. Green Inhibitors for Corrosion Protection of Metals and Alloys: An Overview. Int. J. Corros. 2012, 2012, 1–15. [Google Scholar] [CrossRef]

- Zhou, X.; Dong, Q.; Wei, D.; Bai, J.; Xue, F.; Zhang, B.; Ba, Z.; Wang, Z. Smart corrosion inhibitors for controlled release: A review. Corros. Eng. Sci. Technol. 2022, 58, 190–204. [Google Scholar] [CrossRef]

- Yeganeh, M.; Omidi, M.; Rabizadeh, T. Anti-corrosion behavior of epoxy composite coatings containing molybdate-loaded mesoporous silica. Prog. Org. Coat. 2019, 126, 18–27. [Google Scholar] [CrossRef]

- Haddadi, S.A.; SA, A.R.; Mahdavian, M.; Arjmand, M. Epoxy nanocomposite coatings with enhanced dual active/barrier behavior containing graphene-based carbon hollow spheres as corrosion inhibitor nanoreservoirs. Corros. Sci. 2021, 185, 109428. [Google Scholar] [CrossRef]

- Attaei, M.; Calado, L.M.; Morozov, Y.; Taryba, M.G.; Shakoor, R.A.; Kahraman, R.; Marques, A.C.; Montemor, M.F. Smart epoxy coating modified with isophorone diisocyanate microcapsules and cerium organophosphate for multilevel corrosion protection of carbon steel. Prog. Org. Coat. 2020, 147, 105864. [Google Scholar] [CrossRef]

- Raj, R.; Morozov, Y.; Calado, L.M.; Taryba, M.G.; Kahraman, R.; Shakoor, A.; Montemor, M.F. Inhibitor loaded calcium carbonate microparticles for corrosion protection of epoxy-coated carbon steel. Electrochim. Acta 2019, 319, 801–812. [Google Scholar]

- Habib, S.; Fayyed, E.; Shakoor, R.A.; Kahraman, R.; Abdullah, A. Improved self-healing performance of polymeric nanocomposites reinforced with talc nanoparticles (TNPs) and urea-formaldehyde microcapsules (UFMCs). Arab. J. Chem. 2021, 14, 102926. [Google Scholar] [CrossRef]

- Habib, S.; Fayyad, E.; Nawaz, M.; Khan, A.; Shakoor, R.A.; Kahraman, R.; Abdullah, A. Cerium Dioxide Nanoparticles as Smart Carriers for Self-Healing Coatings. Nanomaterials 2020, 10, 791. [Google Scholar] [CrossRef]

- Wen, J.; Lei, J.; Chen, J.; Gou, J.; Li, Y.; Li, L. An intelligent coating based on pH-sensitive hybrid hydrogel for corrosion protection of mild steel. Chem. Eng. J. 2020, 392, 123742. [Google Scholar] [CrossRef]

- Guo, Z.; Ma, T.; Yang, X.; Li, W.; Xu, Q.; Li, Y.; Li, J.; Vairis, A. Comprehensive investigation on linear friction welding a dissimilar material joint between Ti17(α+β) and Ti17(β): Microstructure evolution, failure mechanisms, with simultaneous optimization of tensile and fatigue properties. Mater. Sci. Eng. A 2024, 909, 146818. [Google Scholar] [CrossRef]

- Sanyal, S.; Park, S.; Chelliah, R.; Yeon, S.-J.; Barathikannan, K.; Vijayalakshmi, S.; Jeong, Y.-J.; Rubab, M.; Oh, D.H. Emerging Trends in Smart Self-Healing Coatings: A Focus on Micro/Nanocontainer Technologies for Enhanced Corrosion Protection. Coatings 2024, 14, 324. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Lee, J.K.Y.; Khorasani, S.N.; Ramakrishna, S. Towards the development of self-healing carbon/epoxy composites with improved potential provided by efficient encapsulation of healing agents in core-shell nanofibers. Polym. Test. 2017, 62, 79–87. [Google Scholar] [CrossRef]

- Li, H.; Li, S.; Li, F.; Li, Z.; Wang, H. Fabrication of SiO2 wrapped polystyrene microcapsules by Pickering polymerization for self-lubricating coatings. J. Colloid Interface Sci. 2018, 528, 92–99. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.; Yu, X.; Wu, G.; Lei, Y.; Sun, G.; You, B. Near infrared light responsive self-healing superhydrophobic coating based on solid wastes. J. Colloid Interface Sci. 2020, 560, 198–207. [Google Scholar] [CrossRef] [PubMed]

- Bolimowski, P.A.; Bond, I.P.; Wass, D.F. Robust synthesis of epoxy resin-filled microcapsules for application to self-healing materials. Philos. Trans. A Math. Phys. Eng. Sci. 2016, 374, 20150083. [Google Scholar] [CrossRef]

- Attaei, M.; Calado, L.M.; Taryba, M.G.; Morozov, Y.; Shakoor, R.A.; Kahraman, R.; Marques, A.C.; Montemor, M.F. Autonomous self-healing in epoxy coatings provided by high efficiency isophorone diisocyanate (IPDI) microcapsules for protection of carbon steel. Prog. Org. Coat. 2020, 139, 105445. [Google Scholar] [CrossRef]

- Chen, S.; Han, T.; Zhao, Y.; Luo, W.; Zhang, Z.; Su, H.; Tang, B.Z.; Yang, J. A Facile Strategy to Prepare Smart Coatings with Autonomous Self-Healing and Self-Reporting Functions. ACS Appl. Mater. Interfaces 2020, 12, 4870–4877. [Google Scholar] [CrossRef]

- Kouhi, M.; Mohebbi, A.; Mirzaei, M.; Peikari, M. Optimization of smart self-healing coatings based on micro/nanocapsules in heavy metals emission inhibition. Prog. Org. Coat. 2013, 76, 1006–1015. [Google Scholar] [CrossRef]

- Lei, Y.; Qiu, Z.; Tan, N.; Du, H.; Li, D.; Liu, J.; Liu, T.; Zhang, W.; Chang, X. Polyaniline/CeO2 nanocomposites as corrosion inhibitors for improving the corrosive performance of epoxy coating on carbon steel in 3.5% NaCl solution. Prog. Org. Coat. 2020, 139, 105430. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Liu, J.; Ge, Y.; Yan, X.; Sun, Y.; Wu, J.; Zhang, P. GO-modified double-walled polyurea microcapsules/epoxy composites for marine anticorrosive self-healing coating. Mater. Des. 2020, 189, 108547. [Google Scholar] [CrossRef]

- Palazzo, I.; Raimondo, M.; Della Porta, G.; Guadagno, L.; Reverchon, E. Encapsulation of health-monitoring agent in poly-methyl-methacrylate microcapsules using supercritical emulsion extraction. J. Ind. Eng. Chem. 2020, 90, 287–299. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, H.; Koo, J.M.; Oh, D.X.; Park, J. Practical Applications of Self-Healing Polymers Beyond Mechanical and Electrical Recovery. Adv. Sci. 2024, 11, e2302463. [Google Scholar] [CrossRef] [PubMed]

- Beach, M.; Davey, T.; Subramanian, P.; Such, G. Self-healing organic coatings—Fundamental chemistry to commercial application. Prog. Org. Coat. 2023, 183, 107759. [Google Scholar] [CrossRef]

- Cappellesso, V.; di Summa, D.; Pourhaji, P.; Prabhu Kannikachalam, N.; Dabral, K.; Ferrara, L.; Cruz Alonso, M.; Camacho, E.; Gruyaert, E.; De Belie, N. A review of the efficiency of self-healing concrete technologies for durable and sustainable concrete under realistic conditions. Int. Mater. Rev. 2023, 68, 556–603. [Google Scholar] [CrossRef]

- Zhang, F.; Ju, P.; Pan, M.; Zhang, D.; Huang, Y.; Li, G.; Li, X. Self-healing mechanisms in smart protective coatings: A review. Corros. Sci. 2018, 144, 74–88. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Balaskas, A.C.; Koumoulos, E.P.; Charitidis, C.A.; Kordas, G. ORMOSIL-epoxy coatings with ceramic containers for corrosion protection of magnesium alloys ZK10. Prog. Org. Coat. 2013, 76, 459–470. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, L.; He, Y.; Chen, C.; Wu, Y.; Zhong, F.; Li, H.; Xie, P.; Guo, X. Designing a high-performance waterborne epoxy coating with passive/active dual self-healing properties by synergistic effect of V2O5@polyaniline-tannic acid inhibitors. Prog. Org. Coat. 2021, 151, 106036. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Athanasopoulou, E.; Snihirova, D.; Martins, B.; Koklioti, M.A.; Montemor, M.F.; Kordas, G.; Charitidis, C.A. Multifunctional epoxy coatings combining a mixture of traps and inhibitor loaded nanocontainers for corrosion protection of AA2024-T3. Corros. Sci. 2014, 85, 147–159. [Google Scholar] [CrossRef]

- Alizadegan, F.; Eivaz Mohammadloo, H.; Mirabedini, S.M.; Asemabadi, Z.; Sardari, A. Preparation of self-healing water-based epoxy coatings containing microcapsules, treated CeO2 particles and 8HQS corrosion inhibitor, and study of their anti-corrosion properties. Prog. Org. Coat. 2024, 195, 108660. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, S.; Sun, C.; Wu, Y.; Zhang, D. A novel epoxy-based self-healing robust superhydrophobic coatings for oil/water separation. Prog. Org. Coat. 2024, 194, 108574. [Google Scholar] [CrossRef]

- Henriques, R.R.; Carelo, J.C.; Soares, B.G. Anti-corrosive and self-healing properties of epoxy coatings loaded with montmorillonite modified with zinc-based ionic liquid. Prog. Org. Coat. 2024, 187, 108185. [Google Scholar] [CrossRef]

- Shan, Z.; Jia, X.; Li, S.; Li, Y.; Yang, J.; Fan, H.; Song, H. Self-lubricating and wear-resistant epoxy resin coatings based on the “soft-hard” synergistic mechanism for rapid self-healing under photo-thermal conditions. Chem. Eng. J. 2024, 481, 148664. [Google Scholar] [CrossRef]

- Wang, J.; Seidi, F.; Huang, Y.; Xiao, H. Smart lignin-based polyurethane conjugated with corrosion inhibitor as bio-based anticorrosive sublayer coating. Ind. Crops Prod. 2022, 188, 115719. [Google Scholar] [CrossRef]

- Kim, Y.N.; Lee, J.; Kim, Y.-O.; Kim, J.; Han, H.; Jung, Y.C. Colorless polyimides with excellent optical transparency and self-healing properties based on multi-exchange dynamic network. Appl. Mater. Today 2021, 25, 101226. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Chen, J.; Bai, W.; Zheng, X.; Lin, Q.; Lin, F.; Xu, Y. Two-dimensional lamellar polyimide/cardanol-based benzoxazine copper polymer composite coatings with excellent anti-corrosion performance. RSC Adv. 2022, 12, 10766–10777. [Google Scholar] [CrossRef]

- Lin, X.-Y.; Yu, Y.-H.; Tse, M.-M.; Cheng, S.-H.; Liu, Y.-H.; Lu, K.-L. Semiconductive (Cu–S)n metal–organic framework incorporated polyimide nanocomposite coatings forming an oxide barrier for durable anticorrosion effects. Prog. Org. Coat. 2023, 180, 107562. [Google Scholar] [CrossRef]

- Li, X.; Al-Ostaz, A.; Jaradat, M.; Rahmani, F.; Nouranian, S.; Rushing, G.; Manasrah, A.; Alkhateb, H.; Finckenor, M.; Lichtenhan, J. Substantially enhanced durability of polyhedral oligomeric silsequioxane-polyimide nanocomposites against atomic oxygen erosion. Eur. Polym. J. 2017, 92, 233–249. [Google Scholar] [CrossRef]

- Burattini, S.; Greenland, B.W.; Merino, D.H.; Weng, W.; Seppala, J.; Colquhoun, H.M.; Hayes, W.; Mackay, M.E.; Hamley, I.W.; Rowan, S.J. A healable supramolecular polymer blend based on aromatic pi-pi stacking and hydrogen-bonding interactions. J. Am. Chem. Soc. 2010, 132, 12051–12058. [Google Scholar] [CrossRef]

- Das, A.; Sallat, A.; Bohme, F.; Suckow, M.; Basu, D.; Wiessner, S.; Stockelhuber, K.W.; Voit, B.; Heinrich, G. Ionic Modification Turns Commercial Rubber into a Self-Healing Material. ACS Appl. Mater. Interfaces 2015, 7, 20623–20630. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Zhang, Z.; Hu, J.; Feng, X.; Xu, J.; Wu, Y.; Yan, S. Robust and ultra-fast self-healing elastomers with hierarchically anisotropic structures and used for wearable sensors. Chem. Eng. J. 2022, 446, 137305. [Google Scholar] [CrossRef]

- Jang, D.-H.; Park, B.-M.; Kwon, K.H.; Ree, M.; Han, K.-Y. Nanoscratch self-healing characteristics of polyvinyl polymer thin films embedded with Al2O3 nanoparticles with thermal and UV energy reactivity. Mater. Today Commun. 2020, 25, 101375. [Google Scholar] [CrossRef]

- Luo, S.; Qiao, X.; Wang, Q.-Y.; Zhang, Y.-F.; Fu, P.; Lin, Z.-D.; Du, F.-P.; Cheng, C. Excellent self-healing and antifogging coatings based on polyvinyl alcohol/hydrolyzed poly(styrene-co-maleic anhydride). J. Mater. Sci. 2019, 54, 5961–5970. [Google Scholar] [CrossRef]

- Qian, X.; Mu, N.; Zhao, X.; Shi, C.; Jiang, S.; Wan, M.; Yu, B. Novel self-healing and recyclable fire-retardant polyvinyl alcohol/borax hydrogel coatings for the fire safety of rigid polyurethane foam. Soft Matter 2023, 19, 6097–6107. [Google Scholar] [CrossRef]

- Niratiwongkorn, T.; Luckachan, G.E.; Mittal, V. Self-healing protective coatings of polyvinyl butyral/polypyrrole-carbon black composite on carbon steel. RSC Adv. 2016, 6, 43237–43249. [Google Scholar] [CrossRef]

- Abd El-Lateef, H.M.; Alnajjar, A.O.; Khalaf, M.M. Advanced self-healing coatings based on ZnO, TiO2, and ZnO-TiO2/polyvinyl chloride nanocomposite systems for corrosion protection of carbon steel in acidic solutions containing chloride. J. Taiwan Inst. Chem. Eng. 2020, 116, 286–302. [Google Scholar] [CrossRef]

- Deriabin, K.V.; Ignatova, N.A.; Kirichenko, S.O.; Novikov, A.S.; Islamova, R.M. Nickel(II)-pyridinedicarboxamide-co-polydimethylsiloxane complexes as elastic self-healing silicone materials with reversible coordination. Polymer 2021, 212, 123119. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, K.; Sun, J.; Yuan, J.; Yang, Z.; Gao, C.; Wu, Y. A Type of Hydrogen Bond Cross-Linked Silicone Rubber with the Thermal-Induced Self-Healing Properties Based on the Nonisocyanate Reaction. Ind. Eng. Chem. Res. 2019, 58, 21452–21458. [Google Scholar] [CrossRef]

- Liu, C.; Ma, C.; Xie, Q.; Zhang, G. Self-repairing silicone coatings for marine anti-biofouling. J. Mater. Chem. A 2017, 5, 15855–15861. [Google Scholar] [CrossRef]

- Xiong, J.; Thangavel, G.; Wang, J.; Zhou, X.; Lee, P.S. Self-healable sticky porous elastomer for gas-solid interacted power generation. Sci. Adv. 2020, 6, eabb4246. [Google Scholar] [CrossRef] [PubMed]

- Rao, Y.L.; Chortos, A.; Pfattner, R.; Lissel, F.; Chiu, Y.C.; Feig, V.; Xu, J.; Kurosawa, T.; Gu, X.; Wang, C.; et al. Stretchable Self-Healing Polymeric Dielectrics Cross-Linked Through Metal-Ligand Coordination. J. Am. Chem. Soc. 2016, 138, 6020–6027. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Tang, Z.; Huang, J.; Guo, B.; Huang, G. Promoted strain-induced-crystallization in synthetic cis-1,4-polyisoprene via constructing sacrificial bonds. Polymer 2016, 97, 580–588. [Google Scholar] [CrossRef]

- Walther, A.; Göldel, A.; Müller, A.H.E. Controlled crosslinking of polybutadiene containing block terpolymer bulk structures: A facile way towards complex and functional nanostructures. Polymer 2008, 49, 3217–3227. [Google Scholar] [CrossRef]

- Tang, F.; Gong, D. Polymerization of butadiene, isoprene and 1-substituted dienes using cobalt catalysts. Inorganica Chim. Acta 2022, 539, 121011. [Google Scholar] [CrossRef]

- Dallaev, R. Advances in Materials with Self-Healing Properties: A Brief Review. Materials 2024, 17, 2464. [Google Scholar] [CrossRef]

- Msomi, V.; Srivastava, A.; Usha, P.; Al-Alawachi, S.F.A.; Kansal, L.; K, A.; Arora, D.; Ngonda, T. Self-Healing Materials: Mechanisms, Characterization, and Applications: A detailed Review. E3S Web Conf. 2024, 505, 01019. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Charitidis, C.A. Corrosion Protection Evaluation of Mild Steel: The Role of Hybrid Materials Loaded with Inhibitors. Appl. Sci. 2020, 10, 6594. [Google Scholar] [CrossRef]

- Wei, H.; Wang, Y.; Guo, J.; Shen, N.Z.; Jiang, D.; Zhang, X.; Yan, X.; Zhu, J.; Wang, Q.; Shao, L.; et al. Advanced micro/nanocapsules for self-healing smart anticorrosion coatings. J. Mater. Chem. A 2015, 3, 469–480. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Sottos, N.R.; White, S.R. Nanocapsules for self-healing materials. Compos. Sci. Technol. 2008, 68, 978–986. [Google Scholar] [CrossRef]

- Sadabadi, H.; Allahkaram, S.R.; Kordijazi, A.; Rohatgi, P.K. Self-healing Coatings Loaded by Nano/microcapsules: A Review. Prot. Met. Phys. Chem. Surf. 2022, 58, 287–307. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, H.W.; Lee, J.S.; An, H.S.; Chung, C.M. Microcapsule-Type Self-Healing Protective Coating That Can Maintain Its Healed State upon Crack Expansion. Materials 2021, 14, 6198. [Google Scholar] [CrossRef] [PubMed]

- Stephenson, A.K.a.L.D. Self Healing Coatings Using Microcapsules and Nanocapsules; NACE: Bethlehem, PA, USA, 2002. [Google Scholar]

- Samadzadeh, M.; Boura, S.H.; Peikari, M.; Kasiriha, S.M.; Ashrafi, A. A review on self-healing coatings based on micro/nanocapsules. Prog. Org. Coat. 2010, 68, 159–164. [Google Scholar] [CrossRef]

- Krzak, M.; Tabor, Z.; Nowak, P.; Warszyński, P.; Karatzas, A.; Kartsonakis, I.A.; Kordas, G.C. Water diffusion in polymer coatings containing water-trapping particles. Part 2. Experimental verification of the mathematical model. Prog. Org. Coat. 2012, 75, 207–214. [Google Scholar] [CrossRef]

- Lv, Z.; Chen, H. Analytical models for determining the dosage of capsules embedded in self-healing materials. Comput. Mater. Sci. 2013, 68, 81–89. [Google Scholar] [CrossRef]

- Lv, Z.; Li, S.; Chen, H. Analytical model for effects of capsule shape on the healing efficiency in self-healing materials. PLoS ONE 2017, 12, e0187299. [Google Scholar] [CrossRef]

- Nesterova, T.; Dam-Johansen, K.; Pedersen, L.T.; Kiil, S. Microcapsule-based self-healing anticorrosive coatings: Capsule size, coating formulation, and exposure testing. Prog. Org. Coat. 2012, 75, 309–318. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-Healing in Cementitious Materials-A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Yan, X.; Wu, Z. Application and prospect of self-healing microcapsules in surface coating of wood. Colloid Interface Sci. Commun. 2023, 56, 100736. [Google Scholar] [CrossRef]

- Liu, B.; Wu, M.; Du, W.; Jiang, L.; Li, H.; Wang, L.; Li, J.; Zuo, D.; Ding, Q. The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect. Polymers 2023, 15, 2718. [Google Scholar] [CrossRef]

- Wang, Y.; Pham, D.T.; Ji, C. Nanocomposites for Extrinsic Self-Healing Polymer Materials; Springer: Berlin/Heidelberg, Germany, 2017; pp. 243–279. [Google Scholar] [CrossRef]

- Mohonee, V.K.; Lim Goh, K.; Mishnaevsky, L.; Pasbakhsh, P. Capsule based self-healing composites: New insights on mechanical behaviour based on finite element analysis. Comput. Mater. Sci. 2021, 192, 110203. [Google Scholar] [CrossRef]

- Li, J.; Guan, X.; Zhang, C. Inorganic capsule based on expansive mineral for self-healing concrete. Cem. Concr. Compos. 2023, 144, 105305. [Google Scholar] [CrossRef]

| Types of Self-Healing Capsules | Description | Self-Healing Mechanisms | Applications |

|---|---|---|---|

| Single-walled capsules | These capsules consist of a single shell that encases the healing agent. | When the material cracks, the capsule breaks, releasing the healing agent directly into the damaged area. | Used in polymers, coatings, and composite materials |

| Double-walled capsules | These capsules have two shells, with the healing agent contained within the inner shell and an activator or a secondary component within the outer shell. | Damage causes both shells to rupture, allowing the healing agent and the activator to mix and initiate the healing process. | Used in applications requiring delayed healing response or a more controlled response, such as in aerospace materials. |

| Core–shell microcapsules | These capsules have a core that contains the healing agent, surrounded by a protective shell. | Upon shell rupture, the core releases the agent to fill cracks or gaps. | Used in structural materials, protective coatings, and smart textiles. |

| Multicore capsules | These capsules contain multiple cores within a single shell, each filled with different healing agents or components. | Upon damage, multiple healing agents are released sequentially or simultaneously to enhance the repair process or to address different types of damage. | Used in complex systems where multiple types of damage might occur. |

| Encapsulated liquid metals | These capsules are filled with liquid metals, which can flow and solidify to repair damage. | When a crack forms, the liquid metal flows into the damaged area, filling the voids, and solidifies to restore the material’s integrity. | Used in batteries, electronic circuits, and advanced materials requiring rapid and robust healing. |

| Temperature-responsive capsules | These capsules are triggered by changes in temperature. | When the material is exposed to a certain temperature range, the capsule releases its healing agent to address thermal damage. | Used in high-temperature environments, such as in automotive or aerospace applications. |

| pH-responsive capsules | These capsules are designed to release their healing agent in response to changes in pH levels. | When the material’s environment becomes more acidic or basic due to corrosion or damage, the capsules respond by releasing the healing agent. | Used in materials exposed in harsh environments and corrosion-resistant coatings. |

| Polymer capsules | These capsules contain polymer precursors that can form a solid polymer when released. | Upon capsule rupture, the polymer precursors are released, and through chemical reactions, a solid polymer is created that heals the crack. | Used in adhesives, coatings, and structural polymers. |

| Emulsion-based capsules | These capsules contain emulsions that can release healing agents when triggered. | The emulsion can release the healing agent either through a gradual diffusion process or by capsule rupture. | Used in paints and self-healing coatings, where gradual healing over time is desired. |

| Time-delayed capsules | These capsules are designed to release their healing agent after a specific time delay. | The capsule slowly degrades or reacts over time, eventually releasing the healing agent. | Used in systems where immediate repair is not necessary or where gradual healing is needed. |

| Types of Self-Healing Capsules | Description | Self-Healing Mechanisms | Advantages | Disadvantages |

|---|---|---|---|---|

| Microcapsules | Tiny capsules embedded in the material, typically filled with liquid healing agents like adhesives or resins. | When a crack propagates, it ruptures the capsules, releasing the healing agent. | Localized healing, simple manufacturing, broad application. | Finite healing capacity, potential weakness, limited control. |

| Vascular networks | This system mimics biological vascular networks, where channels or hollow fibers filled with healing agents are embedded in the material. | When damage occurs, the healing agent flows from the network to the damaged area. | Extended healing capability, controlled release, self-refilling. | Complex manufacturing, potential for leakage, bulkier systems. |

| Nanocapsules | These capsules contain healing agents at the nanoscale, allowing them to be embedded in materials without significantly affecting their properties. | When a crack propagates, it ruptures the capsules, releasing the healing agent. | Minimal impact on material properties, versatility, and cost-effective ease of incorporation. | Slow healing process. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kartsonakis, I.A.; Kontiza, A.; Kanellopoulou, I.A. Advanced Micro/Nanocapsules for Self-Healing Coatings. Appl. Sci. 2024, 14, 8396. https://doi.org/10.3390/app14188396

Kartsonakis IA, Kontiza A, Kanellopoulou IA. Advanced Micro/Nanocapsules for Self-Healing Coatings. Applied Sciences. 2024; 14(18):8396. https://doi.org/10.3390/app14188396

Chicago/Turabian StyleKartsonakis, Ioannis A., Artemis Kontiza, and Irene A. Kanellopoulou. 2024. "Advanced Micro/Nanocapsules for Self-Healing Coatings" Applied Sciences 14, no. 18: 8396. https://doi.org/10.3390/app14188396

APA StyleKartsonakis, I. A., Kontiza, A., & Kanellopoulou, I. A. (2024). Advanced Micro/Nanocapsules for Self-Healing Coatings. Applied Sciences, 14(18), 8396. https://doi.org/10.3390/app14188396