Artificial Intelligence in Maritime Transportation: A Comprehensive Review of Safety and Risk Management Applications

Abstract

1. Introduction

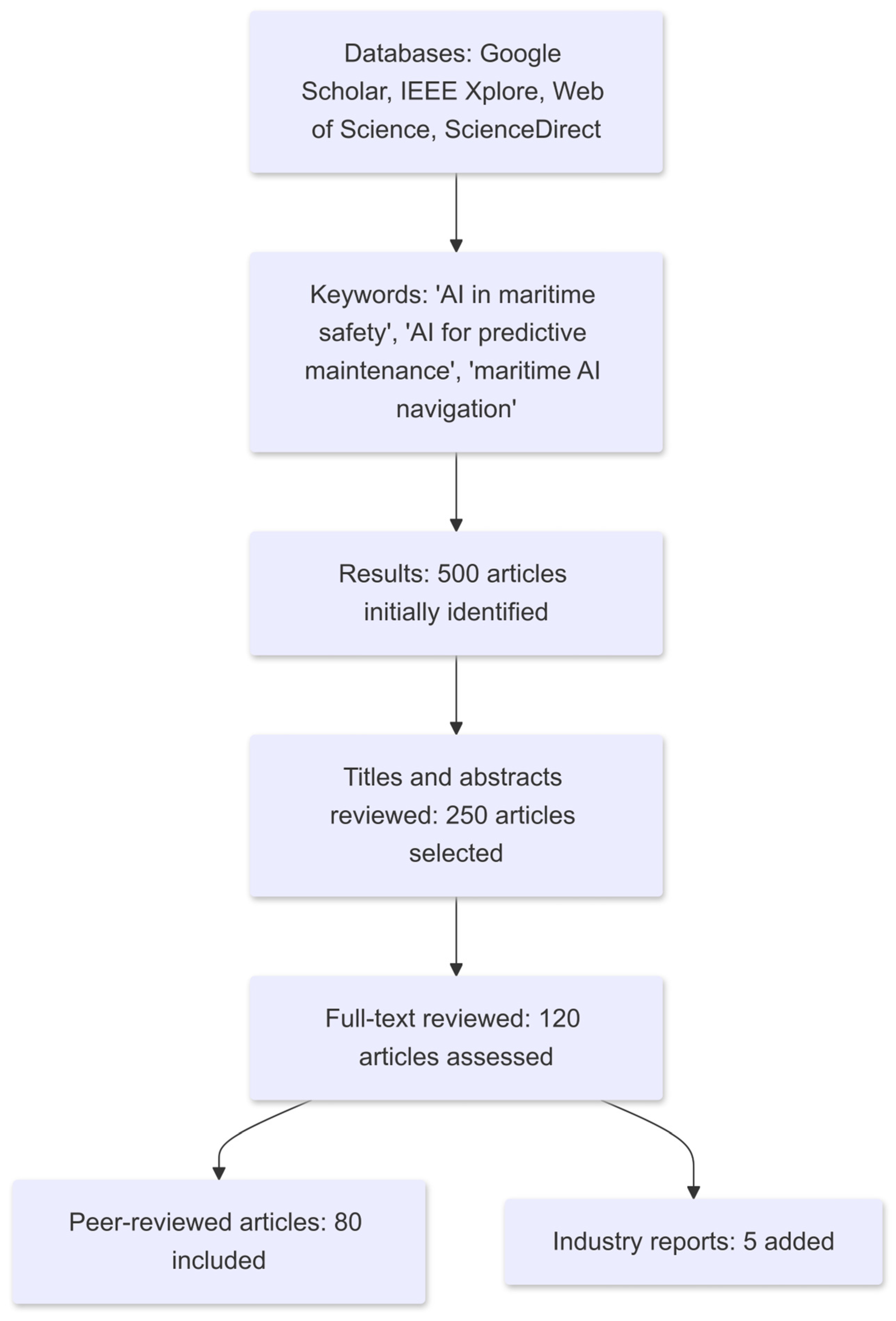

2. Methodology

2.1. Literature Review

2.2. Data Collection

- Identification of relevant studies based on the inclusion criteria.

- Extraction of key information from each study, including the AI technologies used, their applications, and outcomes.

- Categorization of the extracted data into thematic areas such as risk assessment, predictive maintenance, crew management, navigation, and hazardous material handling.

2.3. Case Study Analysis

- Maersk’s AI-powered risk management system.

- DNV GL’s Veracity platform for predictive maintenance and risk management.

- Wärtsilä’s SmartPredict system for enhanced navigation.

- Shell’s AI-enhanced navigational safety system.

- Description of the AI system and its components.

- Implementation process and integration with existing systems.

- Benefits and improvements observed.

- Challenges encountered and solutions implemented.

- Future prospects and scalability of the system.

- An introduction to the importance of maritime safety and the role of AI.

- Detailed descriptions of AI technologies and their specific applications.

- Analysis of case studies demonstrating successful implementations.

- Identification of benefits, challenges, and future prospects.

- Recommendations for effective AI integration in maritime operations.

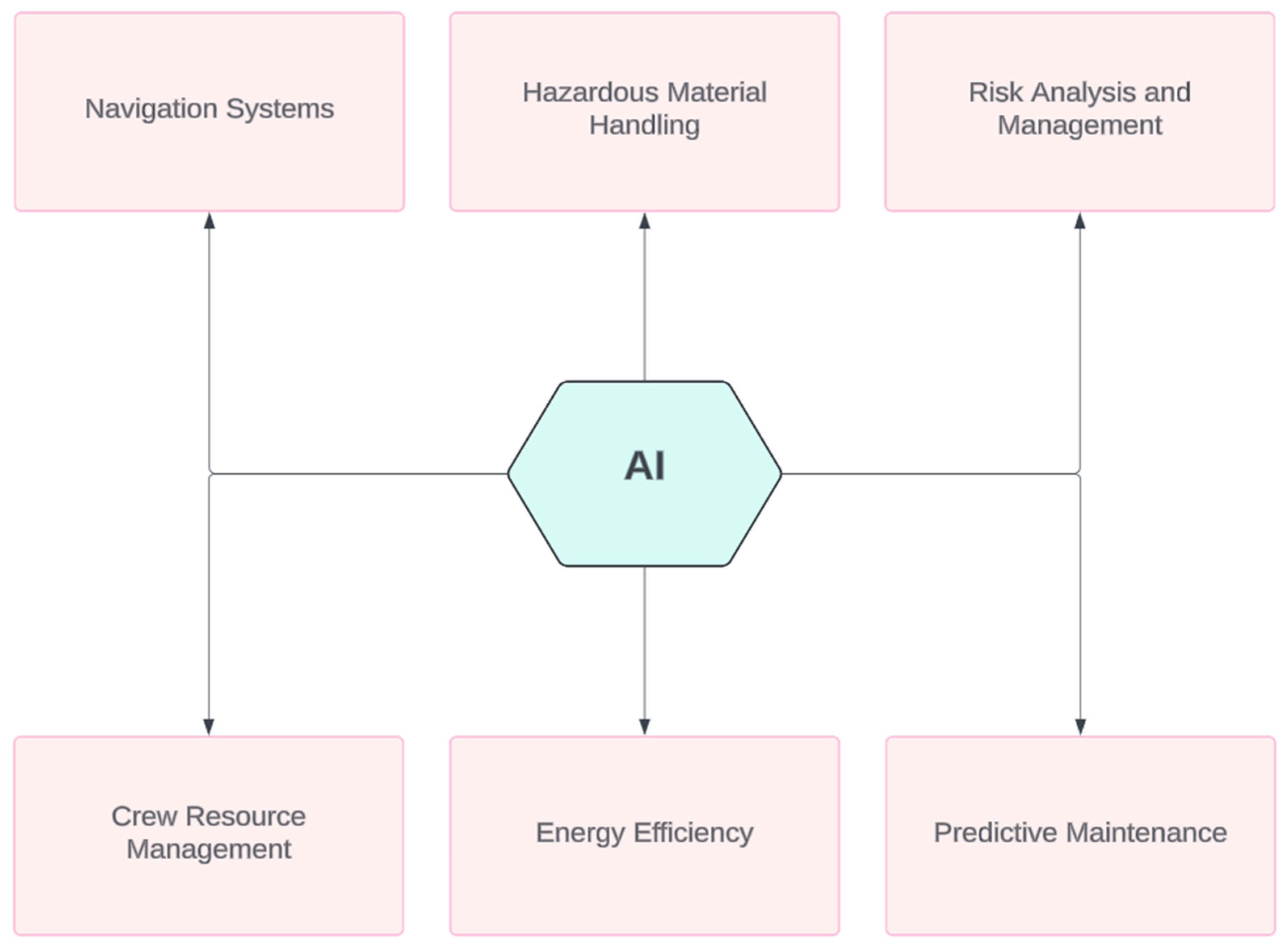

3. AI Implementations in Maritime Transport Systems

- Navigation Systems—AI algorithms assist in navigational decision-making to avoid collisions and enhance the accuracy of a ship’s navigational position, thereby increasing navigational safety;

- Hazardous Material Handling—AI-based tools that provide information on the rules for segregation and separation of hazardous cargo eliminate the possibility of human error, thereby preventing the risk of explosions, fires, and marine pollution;

- Risk Analysis and Management—AI algorithms enable risk management on ships during navigational tasks, mooring operations, technical inspections, regular operations, and shipyard repairs;

- Crew Resource Management—Tools that support the smooth operation of sea and port watches, as well as maintenance work on the ship, while ensuring compliance with rest time requirements for the crew in relation to working hours;

- Energy Efficiency—AI that supports route planning between ports and controls the use of the main engine and RPM (revolutions per minute) significantly reduces fuel costs and protects the marine environment by lowering exhaust emissions. Sustainable energy consumption should not be limited to the ship while it is at sea; it must also be considered during its time in port. The application of machine learning (ML), as a key subdomain of artificial intelligence (AI), can be viewed as a component of the digital transformation process aimed at advancing green practices in maritime port logistics. In the realm of environmental sustainability, emissions and energy consumption are the most commonly studied issues. Future research is distinguished by two broad directions: shifting focus to a greater diversity of machine learning approaches for promoting sustainability in ports and leveraging new perspectives to implement more environmentally friendly practices in port operations [1];

- Predictive Maintenance—Managing, controlling, and executing repair and maintenance work requires proper time management and planning according to the operating conditions of the ship. AI algorithms that analyze historical inspection and maintenance data improve the planning and management of upcoming inspections, eliminating the possibility of missing necessary repairs and periodic maintenance.

3.1. AI in Risk Analysis and Management

Case Studies

- Case Study 1: Maersk’s AI-Powered Risk Management

- Barriers:

- Integration with existing systems and data sources.

- Ensuring data quality and reliability from diverse sources.

- Overcoming resistance to change among crew members and stakeholders.

- Opportunities:

- Enhanced predictive capabilities with continuous data integration.

- Improved operational efficiency through proactive maintenance.

- Reduction in accidents and associated costs.

- Case Study 2: DNV GL’s Veracity Platform

- Barriers:

- Integration with legacy systems and varied equipment.

- Data security and privacy concerns.

- High initial investment costs for deployment.

- Opportunities:

- Enhanced real-time monitoring, leading to reduced downtime.

- Increased lifespan of equipment through timely maintenance.

- Potential for scalable solutions across the fleet.

- Case Study 3: Wärtsilä’s SmartPredict System

- Barriers:

- Ensuring data accuracy and real-time processing.

- Training crew to effectively use and trust the system.

- Integration with existing navigational tools and systems.

- Opportunities:

- Improved safety and efficiency during critical maneuvers.

- Reduction in collision and grounding incidents.

- Enhanced situational awareness and decision-making support.

- Case Study 4: Shell’s AI-Enhanced Navigational Safety

- Barriers:

- Ensuring reliable data transmission in remote areas.

- Integration with existing navigational and operational systems.

- Overcoming initial implementation costs and complexity.

- Opportunities:

- Enhanced route optimization, leading to fuel savings and reduced emissions.

- Increased safety and reduced risk of accidents in challenging environments.

- Improved decision support through real-time hazard prediction.

3.2. AI in Crew Resource Management

3.3. AI in Hazardous Material Handling

- Data Input Errors

- 2.

- Software Malfunctions

- 3.

- Algorithmic Errors

- 4.

- System Integration Issues

- 5.

- Cybersecurity Threats

- 6.

- Human Factors

Case Studies

- Case Study 1: Hapag-Lloyd’s Real-Time Hazardous Material Monitoring

- Barriers:

- Ensuring sensor accuracy and reliability under harsh maritime conditions.

- Integration with existing monitoring systems.

- Training crew to respond effectively to AI-generated alerts.

- Opportunities:

- Enhanced safety through real-time monitoring and early risk detection.

- Improved compliance with international safety regulations.

- Reduction in incidents involving hazardous materials.

- Case Study 2: Evergreen Marine’s AI-Powered Compliance Monitoring

- Barriers:

- Maintaining continuous and reliable data transmission.

- Integration with legacy compliance systems.

- Ensuring data security and privacy.

- Opportunities:

- Enhanced regulatory compliance through continuous monitoring.

- Prevention of incidents through early detection of non-compliance.

- Increased operational efficiency by reducing manual compliance checks.

3.4. AI in Predictive Maintenance

3.4.1. Data Collection

3.4.2. Algorithm Development

3.4.3. Implementation Challenges

3.4.4. Benefits and Opportunities

3.5. AI-Enhanced Navigation Systems

3.5.1. Implementation and Operationalization

3.5.2. Collision Detection and Avoidance

3.5.3. Monitoring Environmental Conditions

3.5.4. Critical Assessment of AI in Navigation

- Cybersecurity: with the digitalization of shipping and increased connectivity between ships, artificial intelligence systems, and autonomous machines, there is a greater risk associated with cybersecurity. Hackers can steal confidential information, cut off a vessel’s external communications, or tamper with navigation systems, potentially causing damage to the crew, ship, and entire company by:

- Changing vessel parameters—e.g., position, speed, name, cargo, and route information. This is an extremely dangerous phenomenon that can lead to chaos on shipping routes, causing loss of life and environmental disasters. The manipulation of the ship’s parameters and the possible negative consequences of this act can be used to commit a terrorist attack.

- Removal of existing vessels from radar—a very dangerous situation that may cause a collision between two or even more vessels, endangering human life and the environment. Particularly dangerous in conditions of restricted visibility, where ships rely mainly on radar data.

- Creating ‘ghost ships’—recognized by other ships as real but not existing in reality. This can force navigators to make unintended course and speed alterations, creating chaos on the fairway.

- Manipulating data and images in the Electronic Chart Display and Information System (ECDIS)—this is used for voyage planning and monitoring. This system displays digital nautical charts, which are the main source of information for modern navigators. As per IMO guidelines, the ECDIS replaces paper nautical charts, which are no longer required on board. This means that altering the data in this system robs navigators of crucial information about the ship’s position and its orientation relative to navigational and land hazards.

- Sending false weather information—causing vessels to alter course to avoid non-existent adverse weather conditions or deleting information about actual bad weather and deliberately steering the ship into a storm or cyclone, which could potentially lead to its sinking.

- Installing malware in a ship’s loading and stability software—this can have catastrophic consequences. A ship that is incorrectly loaded and does not meet stability requirements can capsize, break due to hull overload, or even sink. Improperly segregated and unseparated hazardous cargo can lead to explosions and fires, causing total loss of ship and crew and severe environmental contamination.

- Falsifying distress signals by imitating emergency Position-Indicating Radio Beacons (EPIRBs) and Search and Rescue Transponders (SARTs)—this can have serious consequences. False signals from emergency beacons would particularly impact Mission Rescue Coordination Centers (MRCCs) and Search and Rescue (SAR) centers, leading to costly rescue operations and dispatching units to a non-existent threat. False signals from radar transponders would result in other vessels searching for non-existent lifeboats with potential survivors.

- There are obviously privacy regulations that hold companies responsible for how they collect, store, and use sensitive data. On the other hand, companies often lack knowledge and certainty about how their use of AI-based solutions will affect compliance with these regulations.

- 2.

- Data integration.

- 3.

- Difficulty in demonstrating business benefits.

- 4.

- Concerns about employment security.

3.5.5. Auxiliary Infrastructure

3.5.6. Case Study

- Case Study: ABB Ability™ Marine Pilot Vision

3.6. AI in Energy Efficiency

4. Challenges and Limitations

4.1. Integration Challenges

- Cybersecurity Risks

- Cost and Scalability

4.2. Data Quality and Availability

4.3. Regulatory and Ethical Considerations

5. Future Prospects and Recommendations

Recommendations for Implementation

- Stakeholder Collaboration: Effective AI implementation requires collaboration among various stakeholders, including shipowners, technology providers, regulatory bodies, and crew members. Engaging all relevant parties ensures that AI solutions are designed and deployed in a manner that addresses the practical needs and regulatory requirements of the maritime industry.

- Comprehensive Training and Education: Ensuring that personnel are adequately trained to use and interact with AI systems is crucial. Training programs should focus on enhancing the digital literacy of the maritime workforce, equipping them with the skills needed to operate AI tools and interpret their outputs. Continuous education initiatives can help keep the workforce updated on the latest AI developments and best practices.

- Robust Data Management: The foundation of effective AI applications lies in high-quality data. Establishing robust data management practices, including standardized data collection methods, rigorous data validation processes, and secure data storage solutions, is essential. Investing in advanced sensor technologies and reliable data transmission systems can help overcome data quality and availability challenges.

- Incremental Integration: Rather than attempting a full-scale AI implementation all at once, a phased approach can be more effective. Starting with pilot projects and gradually scaling up allows organizations to identify and address potential issues early on in the process. This incremental integration can help build confidence in AI systems and ensure smoother adoption.

- Regulatory Compliance and Ethical Considerations: Adhering to regulatory requirements and addressing ethical considerations are paramount for sustainable AI deployment. Organizations should stay informed about evolving regulations and actively participate in industry efforts to develop international standards for AI use in maritime operations. Ethical guidelines should be established to ensure transparency, fairness, and accountability in AI systems.

- Continuous Monitoring and Improvement: AI systems should be continuously monitored to assess their performance and identify areas for improvement. Implementing feedback loops where insights from real-world operations are used to refine AI models can enhance their accuracy and reliability over time. Regular audits and evaluations can help ensure that AI systems remain aligned with safety standards and operational goals.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mansoursamaei, M.; Moradi, M.; González-Ramírez, R.; Lalla-Ruiz, E. Machine learning for promoting environmental sustainability in ports. J. Adv. Transp. 2023, 2023, 2144733. [Google Scholar] [CrossRef]

- Stanković, J.; Marjanović, I.; Papathanasiou, J.; Drezgić, S. Social, economic and environmental sustainability of port regions: Mcdm approach in composite index creation. J. Mar. Sci. Eng. 2021, 9, 74. [Google Scholar] [CrossRef]

- Mollaoğlu, M.; Altay, B.; Balin, A. Bibliometric review of route optimization in maritime transportation: Environmental sustainability and operational efficiency. Transp. Res. Rec. J. Transp. Res. Board 2023, 2677, 879–890. [Google Scholar] [CrossRef]

- Jović, M.; Tijan, E.; Žgaljić, D.; Aksentijević, S. Improving maritime transport sustainability using blockchain-based information exchange. Sustainability 2020, 12, 8866. [Google Scholar] [CrossRef]

- Batalden, B.; Sydnes, A. Maritime safety and the ism code: A study of investigated casualties and incidents. WMU J. Marit. Aff. 2013, 13, 3–25. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, Z.; Yin, J. Realising advanced risk-based port state control inspection using data-driven bayesian networks. Transp. Res. Part A Policy Pract. 2018, 110, 38–56. [Google Scholar] [CrossRef]

- Chen, J.; Bian, W.; Wan, Z.; Yang, Z.; Zheng, H.; Wang, P. Identifying factors influencing total-loss marine accidents in the world: Analysis and evaluation based on ship types and sea regions. Ocean Eng. 2019, 191, 106495. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Z. Bayesian network modelling and analysis of accident severity in waterborne transportation: A case study in china. Reliab. Eng. Syst. Saf. 2018, 180, 277–289. [Google Scholar] [CrossRef]

- Zhang, J.; Teixeira, A.; Soares, C.; Yan, X.; Liu, K. Maritime transportation risk assessment of tianjin port with bayesian belief networks. Risk Anal. 2016, 36, 1171–1187. [Google Scholar] [CrossRef]

- Sun, Y.; Ling, J.; Chen, X.; Kong, F.; Hu, Q.; Biancardo, S. Exploring maritime search and rescue resource allocation via an enhanced particle swarm optimization method. J. Mar. Sci. Eng. 2022, 10, 906. [Google Scholar] [CrossRef]

- Munim, Z.; Dushenko, M.; Jimenez, V.; Shakil, M.; Imset, M. Big data and artificial intelligence in the maritime industry: A bibliometric review and future research directions. Marit. Policy Manag. 2020, 47, 577–597. [Google Scholar] [CrossRef]

- Huang, D.; Hu, H.; Li, Y. Spatial analysis of maritime accidents using the geographic information system. Transp. Res. Rec. J. Transp. Res. Board 2013, 2326, 39–44. [Google Scholar] [CrossRef]

- Pallotta, G.; Vespe, M.; Bryan, K. Vessel pattern knowledge discovery from ais data: A framework for anomaly detection and route prediction. Entropy 2013, 15, 2218–2245. [Google Scholar] [CrossRef]

- Tu, E.; Zhang, G.; Rachmawati, L.; Rajabally, E.; Huang, G. Exploiting ais data for intelligent maritime navigation: A comprehensive survey from data to methodology. IEEE Trans. Intell. Transp. Syst. 2018, 19, 1559–1582. [Google Scholar] [CrossRef]

- Vu, V.V.; Le, T.; Mai, T.; Do, T.; Thuy, T.; Nguyen, H.; Bao, N.; Tran, M.; Paramasivam, P.; Le, T.T. An Insight into the Application of AI in Maritime and Logistics toward Sustainable Transportation. Int. J. Inform. Vis. 2024, 8, 158–174. [Google Scholar] [CrossRef]

- Yan, R.; Wang, S.; Peng, C. An Artificial Intelligence Model Considering Data Imbalance for Ship Selection in Port State Control Based on Detention Probabilities. J. Comput. Sci. 2021, 48, 101257. [Google Scholar] [CrossRef]

- Sharma, A.; Undheim, P.; Nazir, S. Design and implementation of ai chatbot for colregs training. WMU J. Marit. Aff. 2022, 22, 107–123. [Google Scholar] [CrossRef]

- Rong, Z.; Jin, Y.; Hu, Q.; Shao, Z.; Nikitakos, N. Maritime anomaly detection within coastal waters based on vessel trajectory clustering and naïve bayes classifier. J. Navig. 2017, 70, 648–670. [Google Scholar] [CrossRef]

- Hlongwa, L. Artificial intelligence and big data in the maritime silk road initiative: The road towards sea power 2.0. Sci. Mil. South Afr. J. Mil. Stud. 2022, 49, 113–131. [Google Scholar] [CrossRef]

- Chen, X. Application of artificial intelligence in maritime transportation. J. Mar. Sci. Eng. 2024, 12, 439. [Google Scholar] [CrossRef]

- Papi, F.; Tarchi, D.; Vespe, M.; Oliveri, F.; Borghese, F.; Aulicino, G.; Vollero, A. Radiolocation and tracking of automatic identification system signals for maritime situational awareness. IET Radar Sonar Navig. 2015, 9, 568–580. [Google Scholar] [CrossRef]

- Capobianco, S.; Forti, N.; Millefiori, L.; Braca, P.; Willett, P. Recurrent encoder-decoder networks for vessel trajectory prediction with uncertainty estimation. IEEE Trans. Aerosp. Electron. Syst. 2022, 59, 2554–2565. [Google Scholar] [CrossRef]

- Merrick, J.; Dorsey, C.; Wang, B.; Grabowski, M.; Harrald, J. Measuring prediction accuracy in a maritime accident warning system. Prod. Oper. Manag. 2022, 31, 819–827. [Google Scholar] [CrossRef]

- Weng, S.; Reps, J.; Kai, J.; Garibaldi, J.M.; Qureshi, N. Can machine-learning improve cardiovascular risk prediction using routine clinical data? PLoS ONE 2017, 12, e0174944. [Google Scholar] [CrossRef] [PubMed]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Hoffmann, M.W.; Wildermuth, S.; Gitzel, R.; Boyaci, A.; Gebhardt, J.; Kaul, H.; Amihai, I.; Forg, B.; Suriyah, M.; Leibfried, T.; et al. Integration of novel sensors and machine learning for predictive maintenance in medium voltage switchgear to enable the energy and mobility revolutions. Sensors 2020, 20, 2099. [Google Scholar] [CrossRef]

- Chen, X.; Wang, S.; Shi, C.; Wu, H.; Zhao, J.; Fu, J. Robust ship tracking via multi-view learning and sparse representation. J. Navig. 2018, 72, 176–192. [Google Scholar] [CrossRef]

- Li, H.; Liu, J.; Liu, R.; Xiong, N.; Wu, K.; Kim, T. A dimensionality reduction-based multi-step clustering method for robust vessel trajectory analysis. Sensors 2017, 17, 1792. [Google Scholar] [CrossRef]

- Eyring, V. Emissions from international shipping: 2. impact of future technologies on scenarios until 2050. J. Geophys. Res. Atmos. 2005, 110. [Google Scholar] [CrossRef]

- Bakdi, A.; Glad, I.K.; Vanem, E.; Engelhardtsen, Ø. AIS-based multiple vessel collision and grounding risk identification based on adaptive safety domain. J. Mar. Sci. Eng. 2019, 8, 5. [Google Scholar] [CrossRef]

- Aylward, K.A.; Weber, R.; Lundh, M.; MacKinnon, S.; Dahlman, J. Navigators’ views of a collision avoidance decision support system for maritime navigation. J. Navig. 2022, 75, 1035–1048. [Google Scholar] [CrossRef]

- Salas, E.; Tannenbaum, S.I.; Kraiger, K.; Smith-Jentsch, K.A. The science of training and development in organizations. Psychol. Sci. Public Interest 2012, 13, 74–101. [Google Scholar] [CrossRef] [PubMed]

- Atik, O. Eye tracking for assessment of situational awareness in bridge resource management training. J. Eye Mov. Res. 2020, 12. [Google Scholar] [CrossRef] [PubMed]

- Cavaleiro, S.C.; Gomes, C.; Lopes, M.P. Bridge resource management: Training for the minimisation of human error in the military naval context. J. Navig. 2020, 73, 1146–1158. [Google Scholar] [CrossRef]

- Atik, O.; Arslan, Ö. Use of eye tracking for assessment of electronic navigation competency in maritime training. J. Eye Mov. Res. 2019, 12. [Google Scholar] [CrossRef]

- Abdelsalam, H.E.B.; Elnabawi, M.N. The transformative potential of artificial intelligence in the maritime transport and its impact on port industry. Marit. Res. Technol. 2024, 3, 19. [Google Scholar] [CrossRef]

- Vagale, A.; Osen, O.; Brandsæter, A.; Tannum, M.; Hovden, C.; Bye, R. On the use of maritime training simulators with humans in the loop for understanding and evaluating algorithms for autonomous vessels. J. Phys. Conf. Ser. 2022, 2311, 012026. [Google Scholar] [CrossRef]

- Vukša, S.; Vidan, P.; Bukljaš, M.; Pavić, S. Research on ship collision probability model based on monte carlo simulation and bi-lstm. J. Mar. Sci. Eng. 2022, 10, 1124. [Google Scholar] [CrossRef]

- Gouareb, R.; Can, F.; Ferdowsi, S.; Teodoro, D. Vessel destination prediction using a graph-based machine learning model. In Network Science, Proceedings of the 7th International Winter Conference, NetSci-X 2022, Porto, Portugal, 8–11 February 2022; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Wahl, A.; Kongsvik, T. Crew resource management training in the maritime industry: A literature review. WMU J. Marit. Aff. 2018, 17, 377–396. [Google Scholar] [CrossRef]

- Chen, L.; Chen, P.; Lin, Z. Artificial intelligence in education: A review. IEEE Access 2020, 8, 75264–75278. [Google Scholar] [CrossRef]

- Mallam, S.; Nazir, S.; Renganayagalu, S.K. Rethinking maritime education, training, and operations in the digital era: Applications for emerging immersive technologies. J. Mar. Sci. Eng. 2019, 7, 428. [Google Scholar] [CrossRef]

- Sam, O.; Le, D.; Ang, G.; Liu, Y.; Zhang, D. Objective and intelligent training assessment package for maritime training in simulator. J. Phys. Conf. Ser. 2022, 2311, 012014. [Google Scholar] [CrossRef]

- Statheros, T.; Howells, G.; McDonald-Maier, K. Autonomous ship collision avoidance navigation concepts, technologies and techniques. J. Navig. 2007, 61, 129–142. [Google Scholar] [CrossRef]

- Zhang, C.; Xiong, Z.; Lin, C. Fusing xgboost and shap models for maritime accident prediction and causality interpretability analysis. J. Mar. Sci. Eng. 2022, 10, 1154. [Google Scholar] [CrossRef]

- Fung, M.L.; Chen, M.Z.Q.; Chen, Y.H. Sensor fusion: A review of methods and applications. In Proceedings of the 2017 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017. [Google Scholar] [CrossRef]

- Ahmad, B.; Mishra, B.K.; Ghufran, M.; Pervez, Z.; Ramzan, N. Intelligent predictive maintenance model for rolling components of a machine based on speed and vibration. In Proceedings of the 2021 International Conference on Artificial Intelligence in Information and Communication (ICAIIC), Jeju Island, Republic of Korea, 13–16 April 2021. [Google Scholar] [CrossRef]

- Baraeinejad, B.; Shayan, M.F.; Vazifeh, A.R.; Rashidi, D.; Hamedani, M.S.; Tavolinejad, H.; Gorji, P.; Razmara, P.; Vaziri, K.; Vashaee, D.; et al. Design and implementation of an ultralow-power ecg patch and smart cloud-based platform. IEEE Trans. Instrum. Meas. 2022, 71, 2506811. [Google Scholar] [CrossRef]

- Vijay, G. Revolutionizing network management with an ai-driven intrusion detection system. Multidiscip. Sci. J. 2023, 5, 2023ss0313. [Google Scholar] [CrossRef]

- Harada, Y.; Katsukura, S.; Kawamura, R.; Shimizu, T. Efficacy of artificial-intelligence-driven differential-diagnosis list on the diagnostic accuracy of physicians: An open-label randomized controlled study. Int. J. Environ. Res. Public Health 2021, 18, 2086. [Google Scholar] [CrossRef]

- Burley, J.; Eisikovits, N. Workplace automation and political replacement: A valid analogy? AI Ethics 2022, 3, 1361–1370. [Google Scholar] [CrossRef]

- Gutierrez-Estevez, D.M.; Wang, Y.; Gramaglia, M.; De Domenico, A.; Dandachi, G.; Khatibi, S.; Tsolkas, D.; Balan, I.; Garcia-Saavedra, A.; Elzur, U. Artificial intelligence for elastic management and orchestration of 5g networks. IEEE Wirel. Commun. 2019, 26, 134–141. [Google Scholar] [CrossRef]

- Zhang, B.; Hirayama, K.; Ren, H.; Wang, D.; Li, H. Ship anomalous behavior detection using clustering and deep recurrent neural network. J. Mar. Sci. Eng. 2023, 11, 763. [Google Scholar] [CrossRef]

- Wu, X.; Han, Y.; Zhang, X.; Zhou, Z.; Lu, C. Large-area compliant, low-cost, and versatile pressure-sensing platform based on microcrack-designed carbon black@polyurethane sponge for human–machine interfacing. Adv. Funct. Mater. 2016, 26, 6246–6256. [Google Scholar] [CrossRef]

- Snyder, E.G.; Watkins, T.H.; Solomon, P.A.; Thoma, E.D.; Williams, R.W.; Hagler, G.S.W.; Shelow, D.; Hindin, D.A.; Kilaru, V.J.; Preuss, P.W. The changing paradigm of air pollution monitoring. Environ. Sci. Technol. 2013, 47, 11369–11377. [Google Scholar] [CrossRef] [PubMed]

- Kwon, D.; Lee, T.-I.; Shim, J.; Ryu, S.; Kim, M.S.; Kim, S.; Kim, T.-S.; Park, I. Highly sensitive, flexible, and wearable pressure sensor based on a giant piezocapacitive effect of three-dimensional microporous elastomeric dielectric layer. ACS Appl. Mater. Interfaces 2016, 8, 16922–16931. [Google Scholar] [CrossRef] [PubMed]

- Bag, A.; Lee, N. Recent advancements in development of wearable gas sensors. Adv. Mater. Technol. 2021, 6, 2000883. [Google Scholar] [CrossRef]

- Namuduri, S.; Narayanan, B.; Davuluru, V.; Burton, L.; Bhansali, S. Review—Deep learning methods for sensor based predictive maintenance and future perspectives for electrochemical sensors. J. Electrochem. Soc. 2020, 167, 037552. [Google Scholar] [CrossRef]

- Susto, G.; Schirru, A.; Pampuri, S.; McLoone, S.; Beghi, A. Machine learning for predictive maintenance: A multiple classifier approach. IEEE Trans. Ind. Inform. 2015, 11, 812–820. [Google Scholar] [CrossRef]

- Halvorsen-Weare, E. Maritime logistics optimisation for predictive maintenance at offshore wind farms. J. Phys. Conf. Ser. 2023, 2626, 012040. [Google Scholar] [CrossRef]

- Venegas, P.; Ivorra, E.; Ortega, M.; Ocáriz, I. Towards the automation of infrared thermography inspections for industrial maintenance applications. Sensors 2022, 22, 613. [Google Scholar] [CrossRef]

- Meddaoui, A.; Hachmoud, A.; Hain, M. Advanced ml for predictive maintenance: Case study on remaining useful life prediction and reliability enhancement. Int. J. Adv. Manuf. Technol. 2024, 132, 323–335. [Google Scholar] [CrossRef]

- Bousdekis, A.; Lepenioti, K.; Apostolou, D.; Mentzas, G. A review of data-driven decision-making methods for industry 4.0 maintenance applications. Electronics 2021, 10, 828. [Google Scholar] [CrossRef]

- Gashi, M.; Gursch, H.; Hinterbichler, H.; Pichler, S.; Lindstaedt, S.; Thalmann, S. Medep: Maintenance event detection for multivariate time series based on the pelt approach. Sensors 2022, 22, 2837. [Google Scholar] [CrossRef] [PubMed]

- Mistry, P.; Hughes, P.; Gunasekaran, A.; Tucker, G.; Bevan, A. Using event data to build predictive engine failure models. Machines 2023, 11, 704. [Google Scholar] [CrossRef]

- Xiao, F.; Ligteringen, H.; Gulijk, C.; Ale, B. Comparison study on ais data of ship traffic behavior. Ocean Eng. 2015, 95, 84–93. [Google Scholar] [CrossRef]

- Zhao, L.; Shi, G. Maritime anomaly detection using density-based clustering and recurrent neural network. J. Navig. 2019, 72, 894–916. [Google Scholar] [CrossRef]

- Pan, S.; Yin, J. Extracting shipping route patterns by trajectory clustering model based on automatic identification system data. Sustainability 2018, 10, 2327. [Google Scholar] [CrossRef]

- Robards; Silber, G.; Adams, J.; Arroyo, J.; Lorenzini, D.; Schwehr, K.; Amos, J. Conservation science and policy applications of the marine vessel automatic identification system (ais)—A review. Bull. Mar. Sci. 2016, 92, 75–103. [Google Scholar] [CrossRef]

- Zhang, X.; Fu, X.; Xiao, Z.; Xu, H.; Qin, Z. Vessel Trajectory Prediction in Maritime Transportation: Current Approaches and Beyond. IEEE Trans. Intell. Transp. Syst. 2022, 23, 19980–19998. [Google Scholar] [CrossRef]

- Yu, H.; Murray, A.T.; Fang, Z.; Liu, J.; Peng, G.; Solgi, M.; Zhang, W. Ship Path Optimization That Accounts for Geographical Traffic Characteristics to Increase Maritime Port Safety. IEEE Trans. Intell. Transp. Syst. 2022, 23, 5765–5776. [Google Scholar] [CrossRef]

- Yang, X.; Han, Q. Improved Reinforcement Learning for Collision-Free Local Path Planning of Dynamic Obstacle. Ocean Eng. 2023, 283, 115040. [Google Scholar] [CrossRef]

- Hu, X.; Wang, J.; Li, G. Contrastive Learning-Based Haze Visibility Enhancement in Intelligent Maritime Transportation System. J. Adv. Transp. 2022, 2022, 2160044. [Google Scholar] [CrossRef]

- Ibáñez, J.; Zeadally, S.; Contreras-Castillo, J. Sensor technologies for intelligent transportation systems. Sensors 2018, 18, 1212. [Google Scholar] [CrossRef] [PubMed]

- Nosov, P.; Zinchenko, S.; Ben, A.; Prokopchuk, Y.; Mamenko, P.; Popovych, I.; Moiseienko, V.; Kruglyj, D. Navigation safety control system development through navigator action prediction by data mining means. East. Eur. J. Enterp. Technol. 2021, 2, 55–68. [Google Scholar] [CrossRef]

- Zis, T.P.V.; Psaraftis, H.N.; Ding, L. Ship Weather Routing: A Taxonomy and Survey. Ocean Eng. 2020, 213, 107697. [Google Scholar] [CrossRef]

- Kuroda, M.; Sugimoto, Y. Evaluation of Ship Performance in Terms of Shipping Route and Weather Condition. Ocean Eng. 2022, 254, 111335. [Google Scholar] [CrossRef]

- Fan, A.; Yang, J.; Yang, L.; Liu, W.; Vladimir, N. Joint Optimisation for Improving Ship Energy Efficiency Considering Speed and Trim Control. Transp. Res. D Transp. Env. 2022, 113, 103527. [Google Scholar] [CrossRef]

- You, J.; Jo, Y. Formulating cybersecurity requirements for autonomous ships using the square methodology. Sensors 2023, 23, 5033. [Google Scholar] [CrossRef]

- Leite, W.; Moraes, C.; Albuquerque, C.; Machado, R.; Sá, A. A triggering mechanism for cyber-attacks in naval sensors and systems. Sensors 2021, 21, 3195. [Google Scholar] [CrossRef]

- Petković, M. Every vessel counts: Neural network based maritime traffic counting system. Sensors 2023, 23, 6777. [Google Scholar] [CrossRef]

- Valero, C.; Ivancos, E.; Vaño, R.; Garro, E.; Boronat, F.; Palau, C. Design and development of an aiot architecture for introducing a vessel eta cognitive service in a legacy port management solution. Sensors 2021, 21, 8133. [Google Scholar] [CrossRef]

- Liu, H.; Jurdana, I.; Lopac, N.; Wakabayashi, N. Bluenavi: A microservices architecture-styled platform providing maritime information. Sustainability 2022, 14, 2173. [Google Scholar] [CrossRef]

- Nguyen, H.P.; Nguyen, C.T.U.; Tran, T.M.; Dang, Q.H.; Pham, N.D.K. Artificial Intelligence and Machine Learning for Green Shipping: Navigating towards Sustainable Maritime Practices. Int. J. Inform. Vis. 2024, 8, 1–17. [Google Scholar] [CrossRef]

- Ji, Q.; Zhu, Z.; Lan, P. Real-time nonintrusive monitoring and prediction of driver fatigue. IEEE Trans. Veh. Technol. 2004, 53, 1052–1068. [Google Scholar] [CrossRef]

- Thombre, S.; Zhao, Z.; Ramm-Schmidt, H.; Garcia, J.M.V.; Malkamaki, T.; Nikolskiy, S.; Hammarberg, T.; Nuortie, H.; Bhuiyan, M.Z.H.; Sarkka, S.; et al. Sensors and ai techniques for situational awareness in autonomous ships: A review. IEEE Trans. Intell. Transp. Syst. 2022, 23, 64–83. [Google Scholar] [CrossRef]

- Ilias, L.; Tsapelas, G.; Kapsalis, P.; Michalakopoulos, V.; Kormpakis, G.; Mouzakitis, S.; Askounis, D. Leveraging extreme scale analytics, ai and digital twins for maritime digitalization: The vesselai architecture. Front. Big Data 2023, 6, 1220348. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Qi, L.; Yang, Y.; Luo, Q.; Postolache, O.; Tang, J.; Wu, H. Video-based detection infrastructure enhancement for automated ship recognition and behavior analysis. J. Adv. Transp. 2020, 2020, 7194342. [Google Scholar] [CrossRef]

- Wu, J. The application of 5g wireless communication in maritime environment. J. Phys. Conf. Ser. 2023, 2618, 012003. [Google Scholar] [CrossRef]

- Kim, H.; Sewaiwar, A.; Chung, Y. High-performance time-code diversity scheme for shore-to-sea maritime visible-light communication. J. Opt. Soc. Korea 2015, 19, 514–520. [Google Scholar] [CrossRef]

- Pavur, J.; Moser, D.; Strohmeier, M.; Lenders, V.; Martinovic, I. A tale of sea and sky on the security of maritime vsat communications. In Proceedings of the 2020 IEEE Symposium on Security and Privacy, San Francisco, CA, USA, 18–21 May 2020. [Google Scholar] [CrossRef]

- Chen, X.; Ling, J.; Yang, Y.; Zheng, H.; Xiong, P.; Postolache, O. Ship trajectory reconstruction from ais sensory data via data quality control and prediction. Math. Probl. Eng. 2020, 2020, 7191296. [Google Scholar] [CrossRef]

- Lv, T.; Tang, P.; Zhang, J. A real-time ais data cleaning and indicator analysis algorithm based on stream computing. Sci. Program. 2023, 2023, 8345603. [Google Scholar] [CrossRef]

- Kastrisios, C.; Dyer, N.; Nada, T.; Contarinis, S.; Cordero, J. Increasing efficiency of nautical chart production and accessibility to marine environment data through an open-science compilation workflow. ISPRS Int. J. Geo-Inf. 2023, 12, 116. [Google Scholar] [CrossRef]

- Duan, Y.; Edwards, J.; Dwivedi, Y. Artificial intelligence for decision making in the era of big data–evolution, challenges and research agenda. Int. J. Inf. Manag. 2019, 48, 63–71. [Google Scholar] [CrossRef]

- Liao, F.; Adelaine, S.; Afshar, M.; Patterson, B. Governance of clinical ai applications to facilitate safe and equitable deployment in a large health system: Key elements and early successes. Front. Digit. Health 2022, 4, 931439. [Google Scholar] [CrossRef] [PubMed]

- Thenral, M.; Annamalai, A. Challenges of building, deploying, and using ai-enabled telepsychiatry platforms for clinical practice among urban indians: A qualitative study. Indian J. Psychol. Med. 2020, 43, 336–342. [Google Scholar] [CrossRef] [PubMed]

- biznesalert.pl. Available online: https://biznesalert.pl/maersk-zaatakowany-przez-petya-strata-300-mln-dol/ (accessed on 1 September 2024).

| AI Application Area | Description | Key Benefits | Examples |

|---|---|---|---|

| Risk Analysis and Management | Identifying potential hazards and predicting risks using data analysis and machine learning. | Enhanced risk prediction and mitigation | Maersk’s AI-Powered Risk Management, DNV GL’s Veracity Platform |

| Crew Resource Management | Enhancing crew training and decision-making through AI-powered simulations and real-time support. | Improved training effectiveness and decision support | Wärtsilä’s SmartPredict System |

| Hazardous Material Handling | Monitoring and managing hazardous materials using AI systems for compliance and safety. | Increased safety and compliance | ABB Ability™ Marine Pilot Vision |

| Predictive Maintenance | Analyzing equipment data to predict and prevent failures, reducing downtime and costs. | Reduced downtime and maintenance costs | Kongsberg’s Kognifai Maritime Ecosystem |

| Navigation Systems | Optimizing routes, avoiding collisions, and monitoring environmental conditions with AI. | Enhanced navigation safety and efficiency | Wärtsilä’s Fleet Operations Solution, ABB Ability™ Marine Pilot Vision |

| Case Study | AI Application | Implementation Details | Outcome/Impact |

|---|---|---|---|

| Wärtsilä’s Fleet Operations Solution | Navigation Systems | Integration of route optimization, collision avoidance, and environmental monitoring in a single platform. | Safer and more efficient voyages through dynamic route adjustments |

| ABB Ability™ Marine Pilot Vision | Situational Awareness and Collision Avoidance | AI-driven system using sensors to create a 3D model of surroundings and provide real-time guidance. | Enhanced navigation safety during complex maneuvers |

| Kongsberg’s Kognifai Maritime Ecosystem | Navigation and Environmental Monitoring | Continuous monitoring of environmental conditions and vessel performance for optimized navigation. | Reduced transit time and fuel consumption in congested areas |

| Maersk’s AI-Powered Risk Management | Risk Analysis and Management | AI algorithms for risk identification and mitigation in maritime operations. | Improved risk prediction and proactive risk management |

| DNV GL’s Veracity Platform | Risk Analysis and Compliance | Platform for integrating data from various sources to enhance risk management and regulatory compliance. | Enhanced safety and regulatory compliance through data integration |

| Aspect | Description | Benefits | Examples |

|---|---|---|---|

| Real-Time Monitoring | AI systems continuously monitor hazardous materials, ensuring compliance with safety protocols and detecting anomalies. | Enhanced safety, early detection of potential hazards | Real-time monitoring systems in chemical tankers [53,54,55] |

| Automated Response Systems | AI-driven automated systems that can initiate immediate response actions in case of hazardous material incidents. | Quick and efficient response, minimized human exposure | Automated fire suppression systems [56,57] |

| Data Analytics and Prediction | AI analyzes historical data to predict potential hazardous material incidents and optimize handling processes. | Proactive risk management, reduced incidents | Predictive analytics in cargo handling [54,55,56] |

| Regulatory Compliance | AI systems help ensure adherence to international and local regulations regarding hazardous materials. | Improved compliance, avoidance of fines and legal issues | Compliance management systems [55,56,57] |

| Incident Management | AI supports the management of hazardous material incidents by providing real-time data and response recommendations. | Efficient incident resolution, reduced impact on operations | Incident management platforms [54,56,57] |

| Challenge | Description | Potential Solutions |

|---|---|---|

| Integration with Legacy Systems | Compatibility issues between advanced AI technologies and existing maritime infrastructure. | Gradual upgrades, modular AI systems, and training for seamless integration [79,80] |

| Data Quality and Availability | Difficulty in collecting consistent and high-quality data due to harsh maritime environments and sensor malfunctions. | Standardizing data collection methods, improving sensor technology, and robust data management practices [84,86] |

| Regulatory Compliance | Navigating complex and varied maritime regulations that may not be up-to-date with AI advancements. | Developing international standards and guidelines, staying informed about evolving regulations, and participating in industry efforts for regulatory alignment [94,95,96] |

| Ethical Considerations | Addressing the impact of AI on employment, ensuring transparency and fairness in AI decision-making, and mitigating biases in AI systems. | Implementing retraining programs, fostering explainable AI, and establishing ethical guidelines to ensure fair and unbiased AI operations [95,96,97,98] |

| Future Development | Description | Potential Impact |

|---|---|---|

| Enhanced Machine Learning Algorithms | Development of more sophisticated AI models capable of deeper analysis and more accurate predictions. | Improved decision-making and operational efficiency [62,63] |

| Integration with IoT and Blockchain | Combining AI with IoT for real-time data collection and blockchain for secure data transactions. | Increased data reliability and operational transparency [66,67,68] |

| Autonomous Vessels | AI-driven autonomous ships capable of operating with minimal human intervention. | Significant reduction in human error, enhanced safety, and operational efficiency [79,80] |

| Advanced Predictive Maintenance | Improved predictive maintenance systems using advanced AI and sensor technologies. | Reduced maintenance costs and downtime, extended equipment lifespan [85,86] |

| Real-Time Environmental Monitoring | AI systems providing real-time analysis of environmental conditions for better navigation and operational decisions. | Enhanced safety and reduced environmental impact [74,75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durlik, I.; Miller, T.; Kostecka, E.; Tuński, T. Artificial Intelligence in Maritime Transportation: A Comprehensive Review of Safety and Risk Management Applications. Appl. Sci. 2024, 14, 8420. https://doi.org/10.3390/app14188420

Durlik I, Miller T, Kostecka E, Tuński T. Artificial Intelligence in Maritime Transportation: A Comprehensive Review of Safety and Risk Management Applications. Applied Sciences. 2024; 14(18):8420. https://doi.org/10.3390/app14188420

Chicago/Turabian StyleDurlik, Irmina, Tymoteusz Miller, Ewelina Kostecka, and Tomasz Tuński. 2024. "Artificial Intelligence in Maritime Transportation: A Comprehensive Review of Safety and Risk Management Applications" Applied Sciences 14, no. 18: 8420. https://doi.org/10.3390/app14188420

APA StyleDurlik, I., Miller, T., Kostecka, E., & Tuński, T. (2024). Artificial Intelligence in Maritime Transportation: A Comprehensive Review of Safety and Risk Management Applications. Applied Sciences, 14(18), 8420. https://doi.org/10.3390/app14188420