Flexibility Assessment of Ternary Pumped Storage in Day-Ahead Optimization Scheduling of Power Systems

Abstract

:1. Introduction

2. Models for Various Types of Pumped Storage

2.1. Constraints on Pump Mode of Pumped Storage

2.2. Constraints on Turbine Mode of Pumped Storage

2.3. Constraints on the Operational State of Pumped Storage

2.4. Constraints on Reservoir Capacity of Pumped Storage

3. A Hierarchical Optimization Scheduling Model for the Wind-Thermal-Pumped Storage Bundled Transmission System

3.1. Upper-Level Scheduling Model

3.1.1. Upper-Level Objective Function

3.1.2. Upper-Level Constraints

3.2. Lower-Level Scheduling Model

3.2.1. Lower-Level Objective Function

3.2.2. Lower-Level Constraints

4. Definition of Evaluation Indicators

5. Case Study

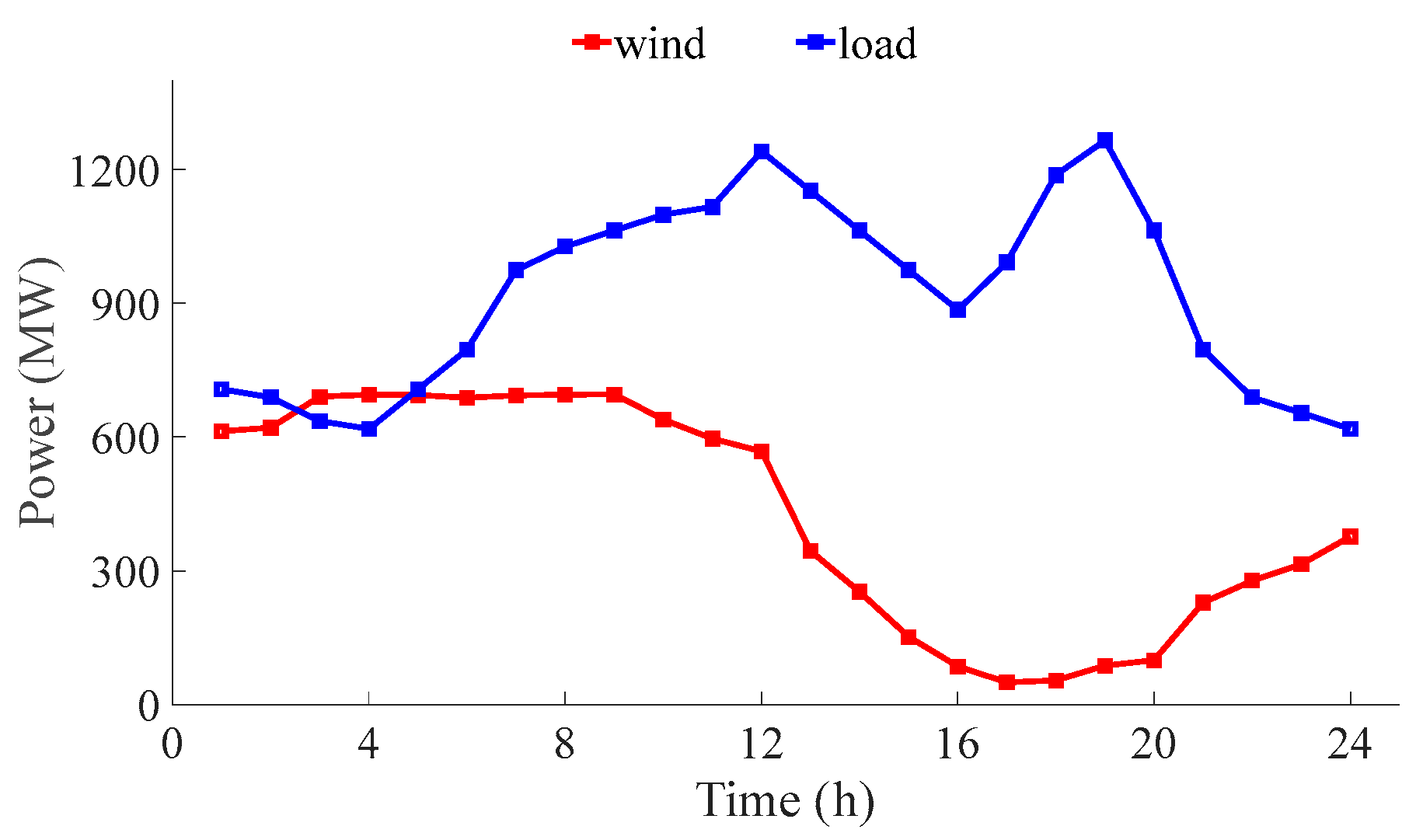

5.1. Basic Data

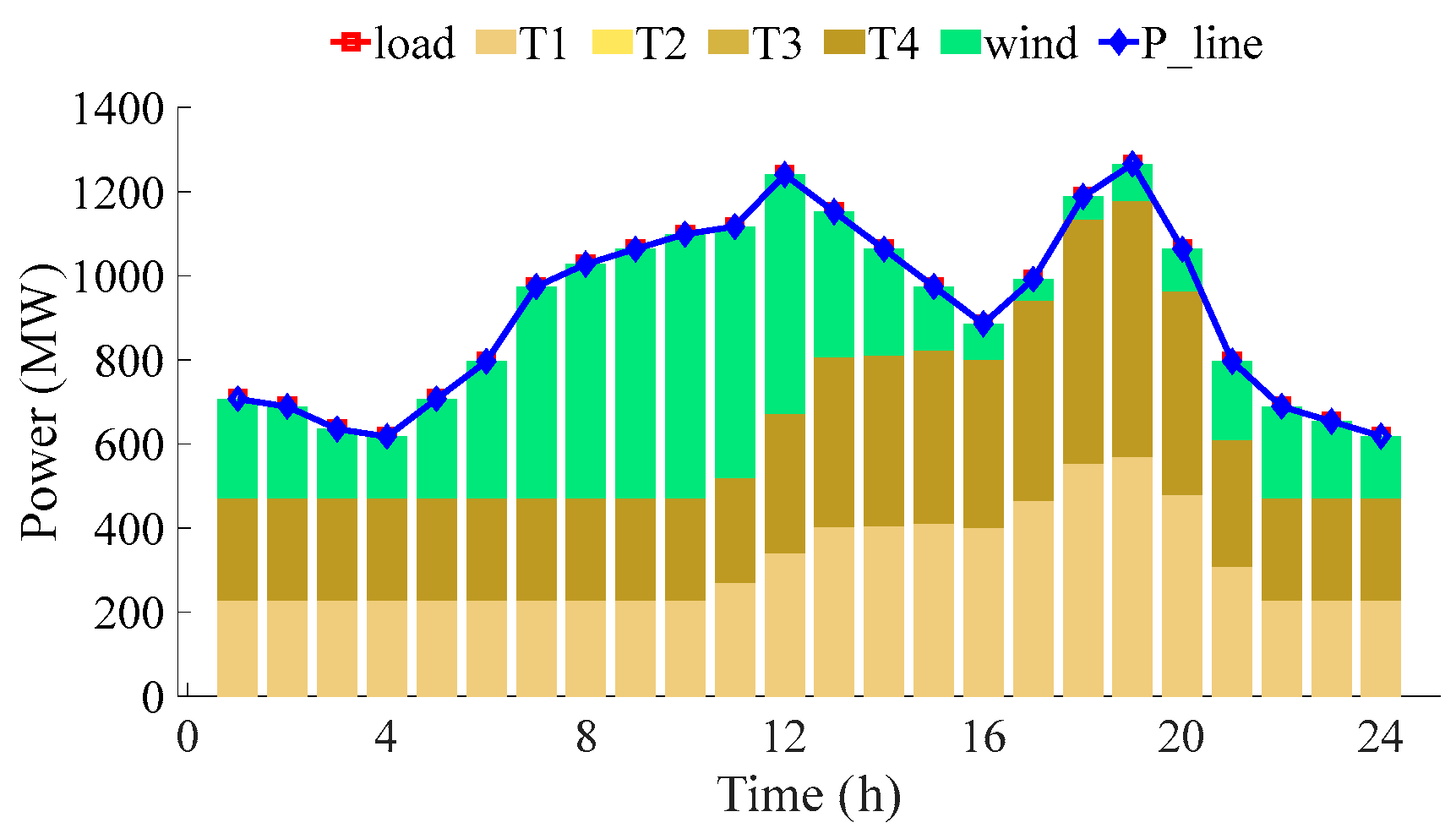

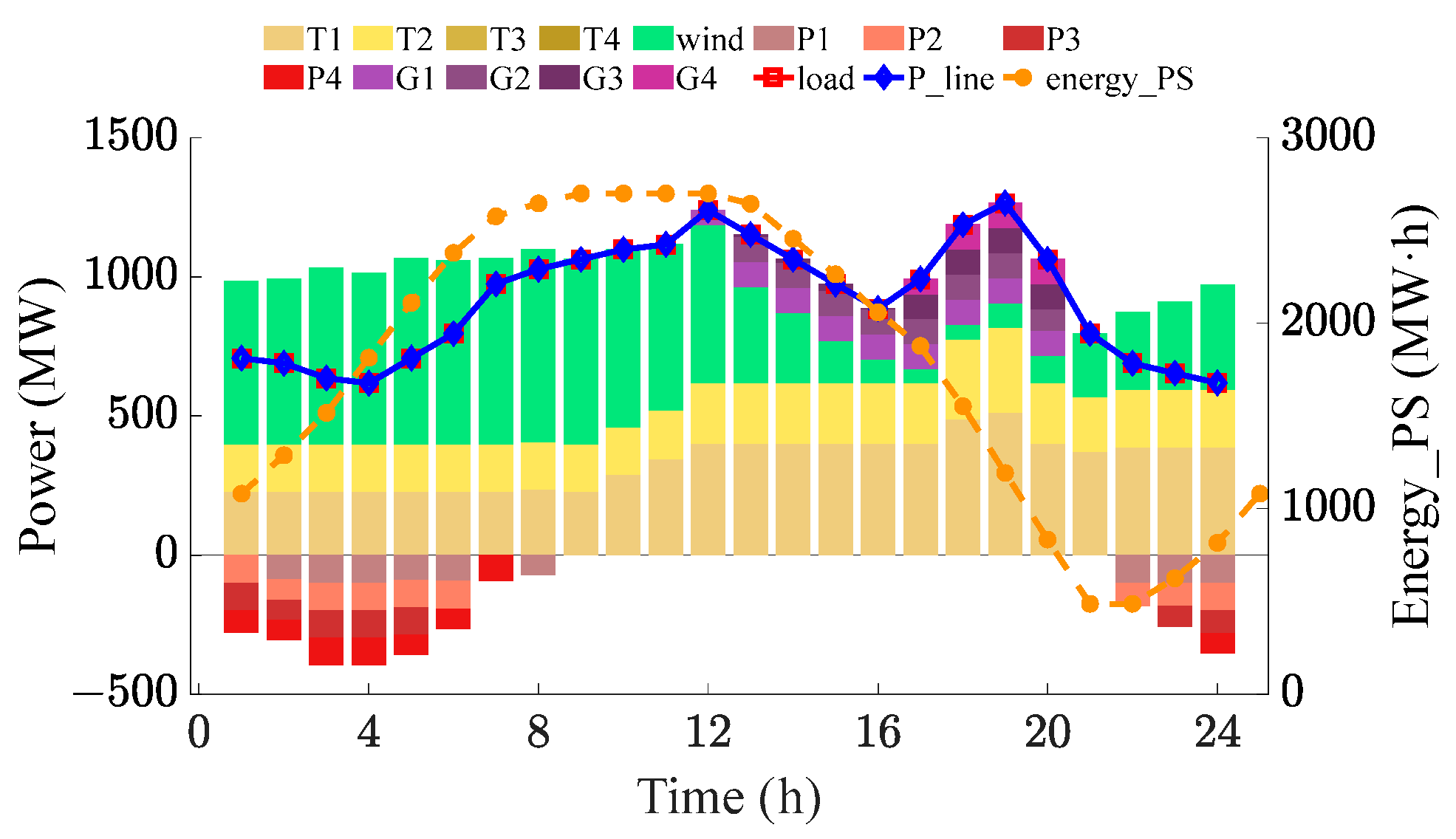

5.2. Analysis of Day-Ahead Optimization Scheduling Strategies for Different Types of Pumped Storage

5.3. Analysis of Optimization Scheduling Indicators for Different Types of Pumped Storage

5.3.1. Analysis of Net Load Curve Standard Deviation and Wind Power Curtailment Rate under Different Pumped Storage Configuration Schemes

5.3.2. Analysis of Pump Electricity and Thermal Power Electricity under Different Pumped Storage Configuration Schemes

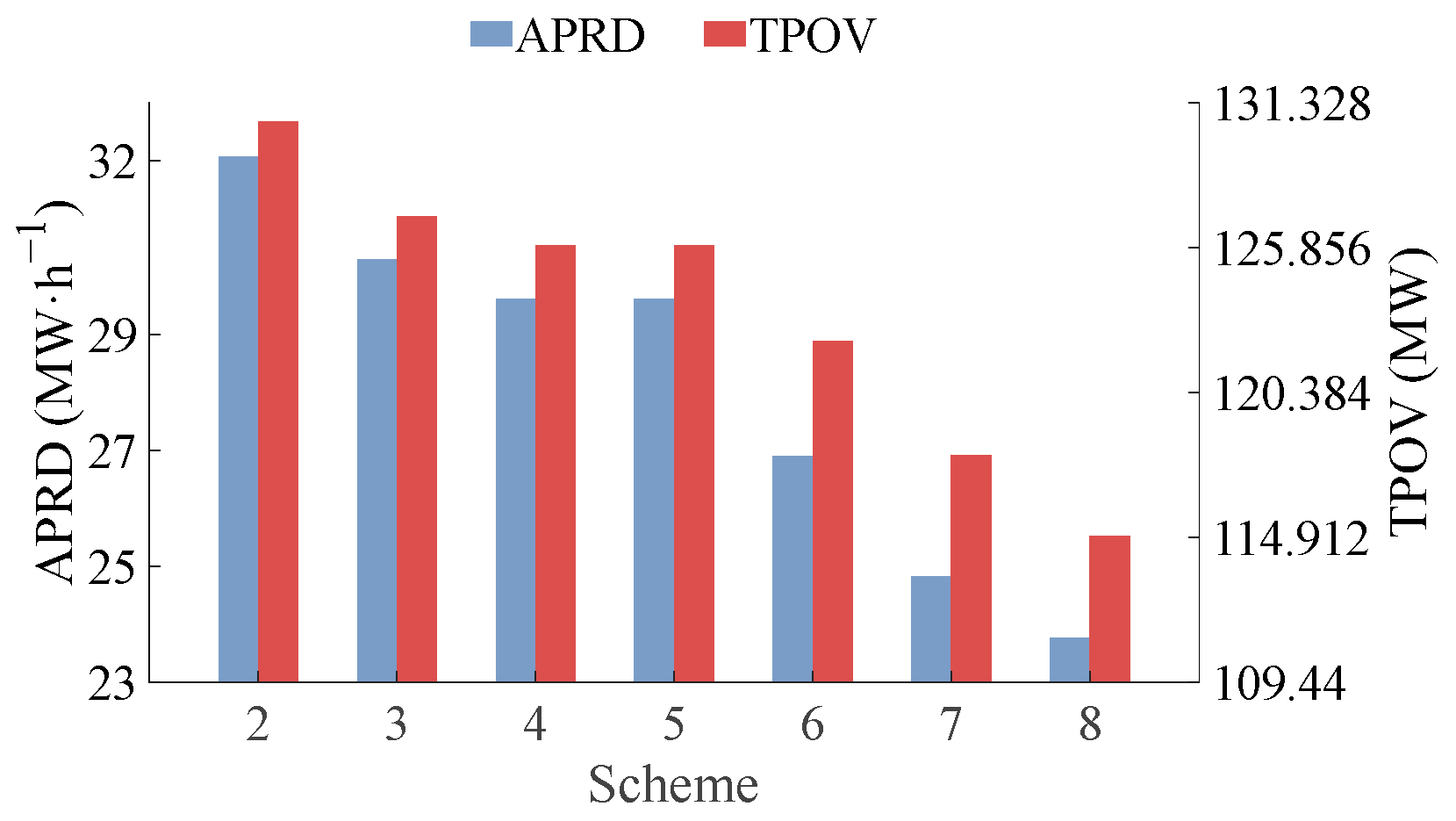

5.3.3. Analysis of APRD and TPOV under Different Pumped Storage Configuration Schemes

5.3.4. Analysis of Costs under Different Pumped Storage Configuration Schemes

5.4. Sensivity Analysis

5.4.1. Scenario Introduction

5.4.2. Sensitivity Analysis under Different Wind Power Capacities

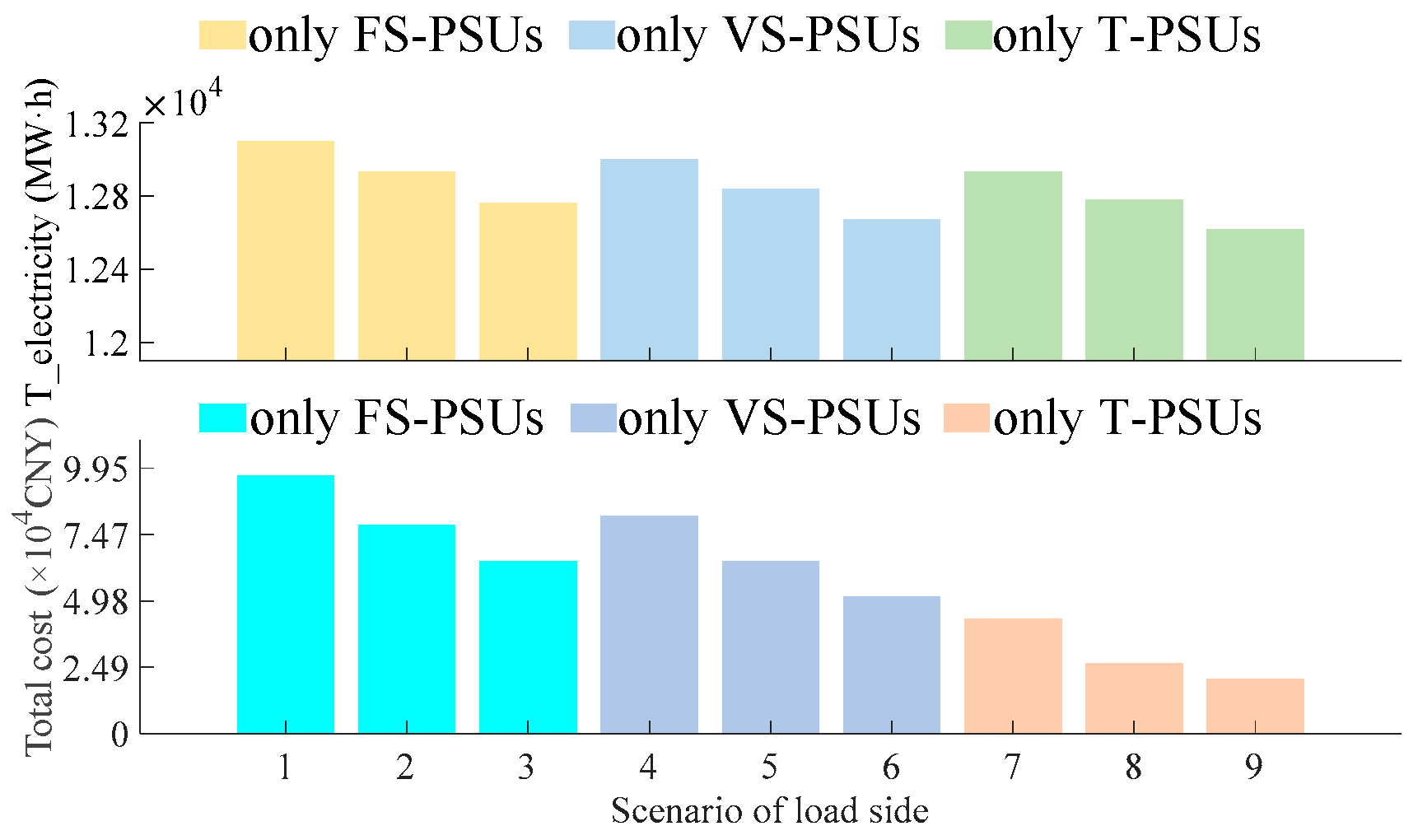

5.4.3. Sensitivity Analysis under Different Load Rates

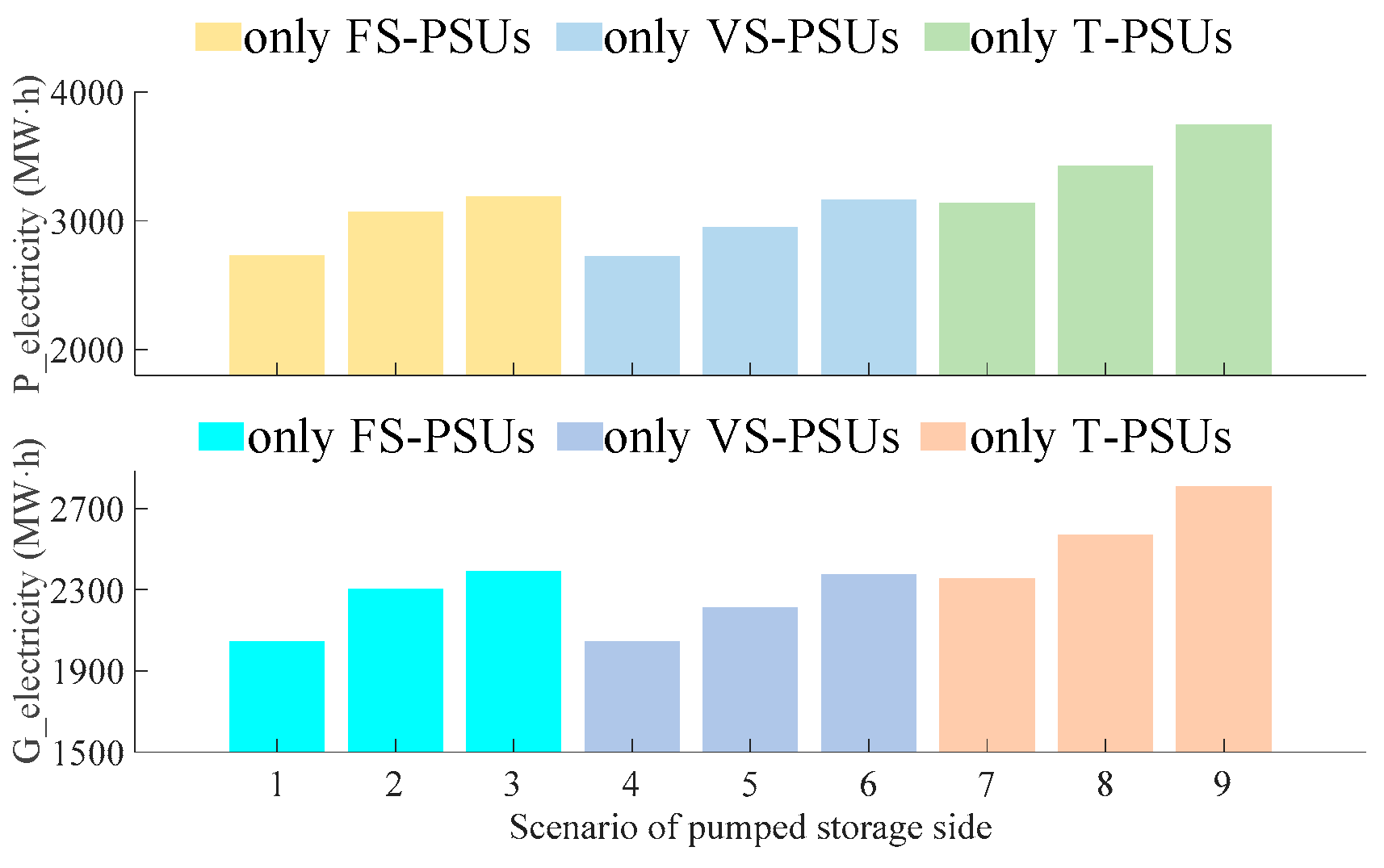

5.4.4. Sensitivity Analysis under Different Pumped Storage Capacities

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Xia, S.; Zhang, J.; Hu, Y.; Wu, M. Effect of the Digital Transformation of Power System on Renewable Energy Utilization in China. IEEE Access 2021, 9, 96201–96209. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Y.; Liu, C.; Fan, L. Two-stage Robust Optimal Scheduling of Wind Power-Photovoltaic-Thermal Power-Pumped Storage Combined System. IET Renew. Power Gener. 2022, 16, 2881–2891. [Google Scholar] [CrossRef]

- Yang, M.; Dai, B.; Wang, J.; Chen, X.; Sun, Y.; Li, B. Day-ahead Wind Power Combination Forecasting Based on Corrected Numerical Weather Prediction and Entropy Method. IET Renew. Power Gener. 2021, 15, 1358–1368. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Ye, L.; Fang, J. A Coordinated Dispatch Method with Pumped-Storage and Battery-Storage for Compensating the Variation of Wind Power. Prot. Control Mod. Power Syst. 2018, 3, 2. [Google Scholar] [CrossRef]

- Ren, G.; Liu, J.; Wan, J.; Wang, W.; Fang, F.; Hong, F.; Yu, D. Investigating the Complementarity Characteristics of Wind and Solar Power for Load Matching Based on the Typical Load Demand in China. IEEE Trans. Sustain. Energy 2022, 13, 778–790. [Google Scholar] [CrossRef]

- Wang, R.; Yang, W.; Ji, L.; Li, X.; Zhang, S.; Jing, X. Regulation Intensity Assessment of Pumped Storage Units in Daily Scheduling for Renewable Energy Consumption. Sustain. Energy Technol. Assess 2023, 56, 103027. [Google Scholar] [CrossRef]

- Yang, B.; Cao, X.; Cai, Z.; Yang, T.; Chen, D.; Gao, X.; Zhang, J. Unit Commitment Comprehensive Optimal Model Considering the Cost of Wind Power Curtailment and Deep Peak Regulation of Thermal Unit. IEEE Access 2020, 8, 71318–71325. [Google Scholar] [CrossRef]

- Wu, W.; Zhu, J.; Chen, Y.; Luo, T.; Shi, P.; Guo, W.; Shi, P.; Jiang, C. Modified Shapley Value-Based Profit Allocation Method for Wind Power Accommodation and Deep Peak Regulation of Thermal Power. IEEE Trans. Ind. Appl. 2023, 59, 276–288. [Google Scholar] [CrossRef]

- Cao, M.; Hu, Z.; Cai, J. Optimal Scheduling of Pumped Storage Hydropower Plants with Multi-Type of Units in Day-Ahead Electricity Market Considering Water Head Effects. Front. Energy Res. 2023, 11, 1326068. [Google Scholar] [CrossRef]

- Nag, S.; Lee, K.Y.; Suchitra, D. A Comparison of the Dynamic Performance of Conventional and Ternary Pumped Storage Hydro. Energies 2019, 12, 3513. [Google Scholar] [CrossRef]

- Dong, Z.; Tan, J.; St-Hilaire, A.; Muljadi, E.; Corbus, D.; Nelms, R.; Jacobson, M. Modelling and Simulation of Ternary Pumped Storage Hydropower for Power System Studies. IET Gener. Transm. Distrib. 2019, 13, 4382–4390. [Google Scholar] [CrossRef]

- Li, Y.; Li, O.; Wu, F.; Ma, S.; Shi, L.; Hong, F. Multi-Objective Capacity Optimization of Grid-Connected Wind–Pumped Hydro Storage Hybrid Systems Considering Variable-Speed Operation. Energies 2023, 16, 8113. [Google Scholar] [CrossRef]

- Yao, W.; Li, W.; Liu, R.; Sun, Y. Optimal Capacity of Variable-Speed Pumped Storage for Wind Power Consumption Based on Double-Layer Stochastic Programming. J. Renew. Sustain. Energy 2023, 15, 024103. [Google Scholar] [CrossRef]

- Feng, C.; Zheng, Y.; Li, C.; Mai, Z.; Wu, W.; Chen, H. Cost Advantage of Adjustable-Speed Pumped Storage Unit for Daily Operation in Distributed Hybrid System. Renew. Energy 2021, 176, 1–10. [Google Scholar] [CrossRef]

- Bruninx, K.; Dvorkin, Y.; Delarue, E.; Pandžić, H.; D’haeseleer, W.; Kirschen, D.S. Coupling Pumped Hydro Energy Storage With Unit Commitment. IEEE Trans. Sustain. Energy 2016, 7, 786–796. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, W.; Liu, Y.; Bao, Z.; Mao, Z.; Rashad, E.M. Modeling and Transient Response Analysis of Doubly-Fed Variable Speed Pumped Storage Unit in Pumping Mode. IEEE Trans. Ind. Electron. 2023, 70, 9935–9947. [Google Scholar] [CrossRef]

- Hu, K.; Deng, Y.; Chen, D. Advantages of Variable-Speed Pumped Storage Plants in Generating Phase-Modulation Mode: Rapidity and Stability. IET Renew. Power Gener. 2020, 14, 3732–3740. [Google Scholar] [CrossRef]

- Jena, C.; Guerrero, J.M.; Abusorrah, A.; Al-Turki, Y.; Khan, B. Multi-Objective Generation Scheduling of Hydro-Thermal System Incorporating Energy Storage with Demand Side Management Considering Renewable Energy Uncertainties. IEEE Access 2022, 10, 52343–52357. [Google Scholar] [CrossRef]

- Chen, L.; Wang, J.; Sun, Z.; Huang, T.; Wu, F. Smoothing Photovoltaic Power Fluctuations for Cascade Hydro-PV-Pumped Storage Generation System Based on a Fuzzy CEEMDAN. IEEE Access 2019, 7, 172718–172727. [Google Scholar] [CrossRef]

- Lan, Z.; Gu, J.; Liu, J.; Hu, J.; Liu, S.; Xie, H. Benefits of Variable Speed Pumped Hydro Storage Technology for Increasing Renewable Integration in Regional Power Grids. In Proceedings of the 2021 IEEE 5th Conference on Energy Internet and Energy System Integration (EI2), Taiyuan, China, 22–24 October 2021; pp. 660–664. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, D.; Li, J.; Wei, S.; Sun, H. Flexibility Assessment of Regional Energy Systems Considering Five Types of Pumped Storage with Different Operational Characteristics. Proc. Chin. Soc. Electr. Eng. 2023, 43, 7103–7114. [Google Scholar] [CrossRef]

- Nag, S.; Lee, K.Y. Neural Network-Based Control for Hybrid PV and Ternary Pumped-Storage Hydro Plants. Energies 2021, 14, 4397. [Google Scholar] [CrossRef]

- Yokoyama, Y.; Yamamoto, K.; Tani, K. Renovation of the Pumped-Storage System from Fixed Speed to Adjustable Speed at Okutataragi Power Station. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 082004. [Google Scholar] [CrossRef]

- Cao, M.; Hu, Z.; Meng, Y.; Cai, F.; Duan, X. Day-Ahead Optimal Dispatch Method for Flexible DC System with Pumped Storage Hydropower Plant and New Energy Power Generation. Autom. Electr. Power Syst. 2021, 45, 36–44. [Google Scholar] [CrossRef]

- Li, N.; Hedman, K.W. Evaluation of the Adjustable-Speed Pumped Hydro Storage in Systems with Renewable Resources. In Proceedings of the 2016 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Dallas, TX, USA, 3–5 May 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Fernández-Muñoz, D.; Pérez-Díaz, J.I. Unit Commitment in a Hybrid Diesel/Wind/Pumped-Storage Isolated Power System Considering the Net Demand Intra-Hourly Variability. IET Renew. Power Gener. 2021, 15, 30–42. [Google Scholar] [CrossRef]

- Koritarov, V.; Veselka, T.D.; Gasper, J.; Bethke, B.M.; Botterud, A.; Wang, J.; Mahalik, M.; Zhou, Z.; Milostan, C.; Feltes, J.; et al. Modeling and Analysis of Value of Advanced Pumped Storage Hydropower in the United States; Argonne National Laboratory (ANL): Oak Ridge, TN, USA, 2014. [Google Scholar] [CrossRef]

- Li, X.; Yang, W.; Zhao, Z.; Wang, R.; Yin, X. Advantage of Priority Regulation of Pumped Storage for Carbon-Emission-Oriented Co-Scheduling of Hybrid Energy System. J. Energy Storage 2023, 58, 106400. [Google Scholar] [CrossRef]

- Lin, L.; Yue, X.; Xu, B.; Sun, Y.; Wei, M. Sequence and Strategy of Pumped Storage-Thermal Combined Peak Shaving Considering Benefits of Pumped Storage and Deep Regulation of Thermal Power. Power Syst. Technol. 2021, 45, 20–29. [Google Scholar] [CrossRef]

- Guo, J.; Xue, X.; Li, L.; Cheng, Y.; Li, Y. Peak-Valley Time Division Model Based on Net Load Curve. IOP Conf. Ser. Earth Environ. Sci. 2020, 467, 012037. [Google Scholar] [CrossRef]

- Qiao, Y.; Liu, Y.; Chen, Y.; Han, S.; Wang, L. Power Generation Performance Indicators of Wind Farms Including the Influence of Wind Energy Resource Differences. Energies 2022, 15, 1797. [Google Scholar] [CrossRef]

- Gurobi Optimization, LLC. Gurobi Optimizer Reference Manual. 2023. Available online: https://www.gurobi.com (accessed on 25 August 2024).

- Lofberg, J. YALMIP: A Toolbox for Modeling and Optimization in MATLAB. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation (IEEE Cat. No.04CH37508), Taipei, Taiwan, 2–4 September 2004; pp. 284–289. [Google Scholar] [CrossRef]

| Parameters | T1 | T2 | T3 | T4 |

|---|---|---|---|---|

| PCoalmin,m/MW | 228 | 170 | 280 | 244 |

| PCoalmax,m/MW | 570 | 425 | 700 | 610 |

| am/(CNY/MW2·h) | 0.000176 | 0.00023 | 0.000117 | 0.000151 |

| bm/(CNY/MW·h) | 0.1106 | 0.1509 | 0.0704 | 0.1308 |

| cm/(CNY/h) | 3.02 | 5.03 | 7.04 | 3.01 |

| Upward/downward ramp rates/MW | 171 | 128 | 210 | 183 |

| Minimum start–stop time/h | 2 | 2 | 2 | 2 |

| PStorage,n/MW | N | μ | α | β | ηPump,n | TGenmax/h | Emin/MW·h |

|---|---|---|---|---|---|---|---|

| 90 | 4 | 1.1 | 0.8 | 0.4 | 0.75 | 7.5 | 1080 |

| Periods | Intervals | Price/(CNY/kW·h) |

|---|---|---|

| Peak period | 10:00–15:00, 18:00–21:00 | 1.2893 |

| Flat period | 7:00–10:00, 15:00–18:00, 21:00–23:00 | 0.8731 |

| Valley period | 23:00–7:00 | 0.4570 |

| Configuration Schemes | Combination Approach | Capacity of FS-PSUs/MW | Capacity of VS-PSUs/MW | Capacity of T-PSUs/MW |

|---|---|---|---|---|

| 1 | No PS | - | - | - |

| 2 | PS with only FS-PSUs | 4 × 90 | - | - |

| 3 | Hybrid PS with FS-PSUs and VS-PSUs | 3 × 90 | 1 × 90 | - |

| 4 | Hybrid PS with FS-PSUs and VS-PSUs | 2 × 90 | 2 × 90 | - |

| 5 | PS with only VS-PSUs | - | 4 × 90 | - |

| 6 | Hybrid PS with FS-PSUs and T-PSUs | 3 × 90 | - | 1 × 90 |

| 7 | Hybrid PS with FS-PSUs and T-PSUs | 2 × 90 | - | 2 × 90 |

| 8 | PS with only T-PSUs | - | - | 4 × 90 |

| Schemes | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

| Indicators | |||||||||

| Thermal power cost/CNY | 3202 | 2805 | 2787 | 2785 | 2785 | 2776 | 2769 | 2764 | |

| Total System cost/(×104 CNY) | 75.75 | 7.82 | 6.58 | 6.46 | 6.46 | 3.88 | 3.12 | 2.65 | |

| Scenarios | Wind Power Side | Load Side | Pumped Storage Side | ||

|---|---|---|---|---|---|

| Wind Power Capacity/MW | Capacity of PS When Wind Changes/MW | Load Rate | Capacity of PS When Load Changes/MW | Capacity of PS When PS Changes/MW | |

| 1 | 950 | 4 × 90 FS-PSUs | 0.5 | 4 × 90 FS-PSUs | 4 × 90 FS-PSUs |

| 2 | 1000 | 4 × 90 FS-PSUs | 0.6 | 4 × 90 FS-PSUs | 4 × 100 FS-PSUs |

| 3 | 1050 | 4 × 90 FS-PSUs | 0.7 | 4 × 90 FS-PSUs | 4 × 110 FS-PSUs |

| 4 | 950 | 4 × 90 VS-PSUs | 0.5 | 4 × 90 VS-PSUs | 4 × 90 VS-PSUs |

| 5 | 1000 | 4 × 90 VS-PSUs | 0.6 | 4 × 90 VS-PSUs | 4 × 100 VS-PSUs |

| 6 | 1050 | 4 × 90 VS-PSUs | 0.7 | 4 × 90 VS-PSUs | 4 × 110 VS-PSUs |

| 7 | 950 | 4 × 90 T-PSUs | 0.5 | 4 × 90 T-PSUs | 4 × 90 T-PSUs |

| 8 | 1000 | 4 × 90 T-PSUs | 0.6 | 4 × 90 T-PSUs | 4 × 100 T-PSUs |

| 9 | 1050 | 4 × 90 T-PSUs | 0.7 | 4 × 90 T-PSUs | 4 × 110 T-PSUs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Wang, J.; Peng, S.; Zhang, Y.; Pan, W.; Tang, J. Flexibility Assessment of Ternary Pumped Storage in Day-Ahead Optimization Scheduling of Power Systems. Appl. Sci. 2024, 14, 8820. https://doi.org/10.3390/app14198820

Wu Z, Wang J, Peng S, Zhang Y, Pan W, Tang J. Flexibility Assessment of Ternary Pumped Storage in Day-Ahead Optimization Scheduling of Power Systems. Applied Sciences. 2024; 14(19):8820. https://doi.org/10.3390/app14198820

Chicago/Turabian StyleWu, Zhiyu, Junzhou Wang, Sui Peng, Yining Zhang, Wenxuan Pan, and Junjie Tang. 2024. "Flexibility Assessment of Ternary Pumped Storage in Day-Ahead Optimization Scheduling of Power Systems" Applied Sciences 14, no. 19: 8820. https://doi.org/10.3390/app14198820