Corrosion Susceptibility and Microhardness of Al-Ni Alloys with Different Grain Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Directional Solidification Process and Metallographic Characterization

2.3. Electrochemical Tests

3. Results and Discussion

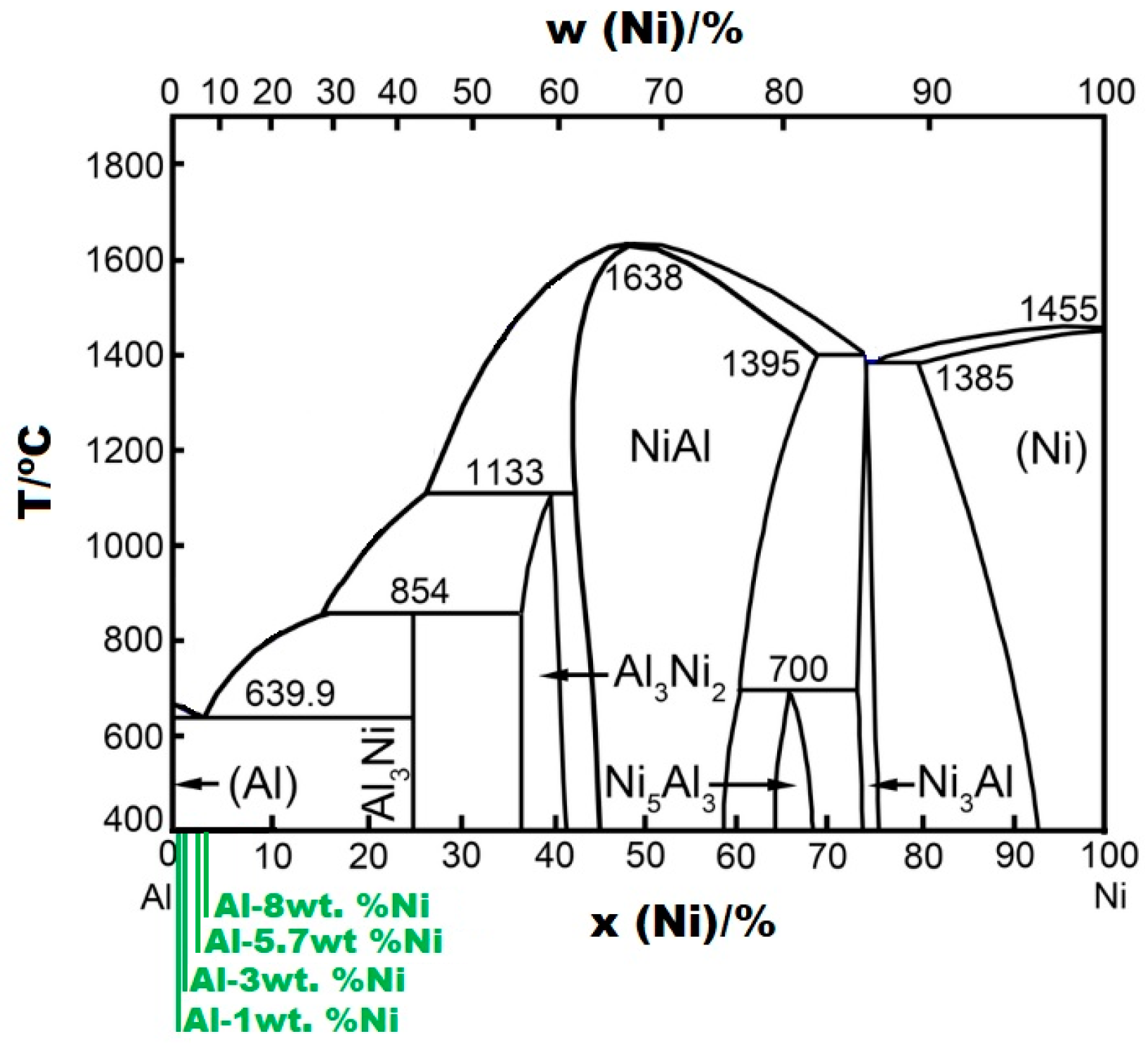

3.1. Solidification Process

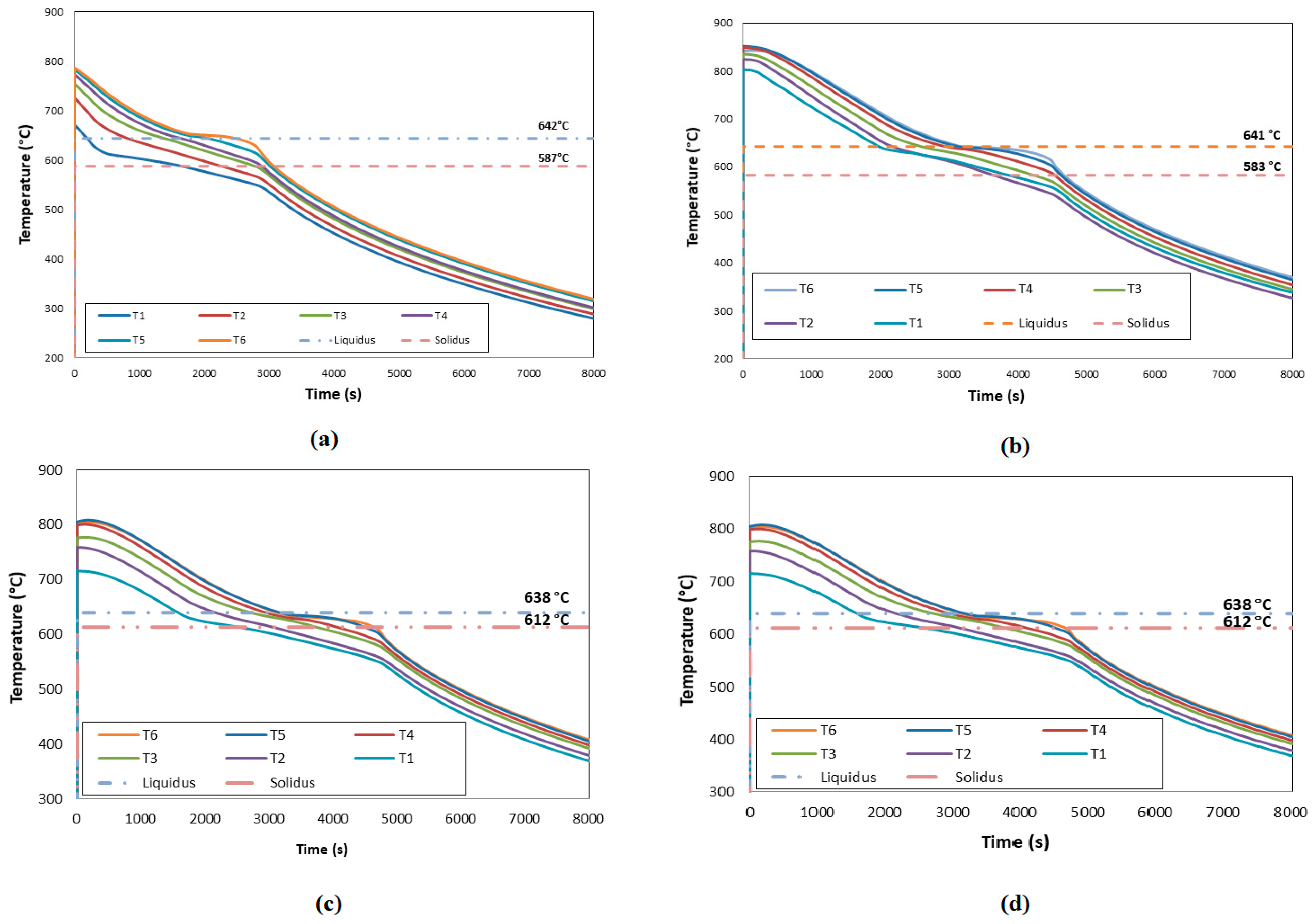

3.2. Thermal Gradients as a Function of Time

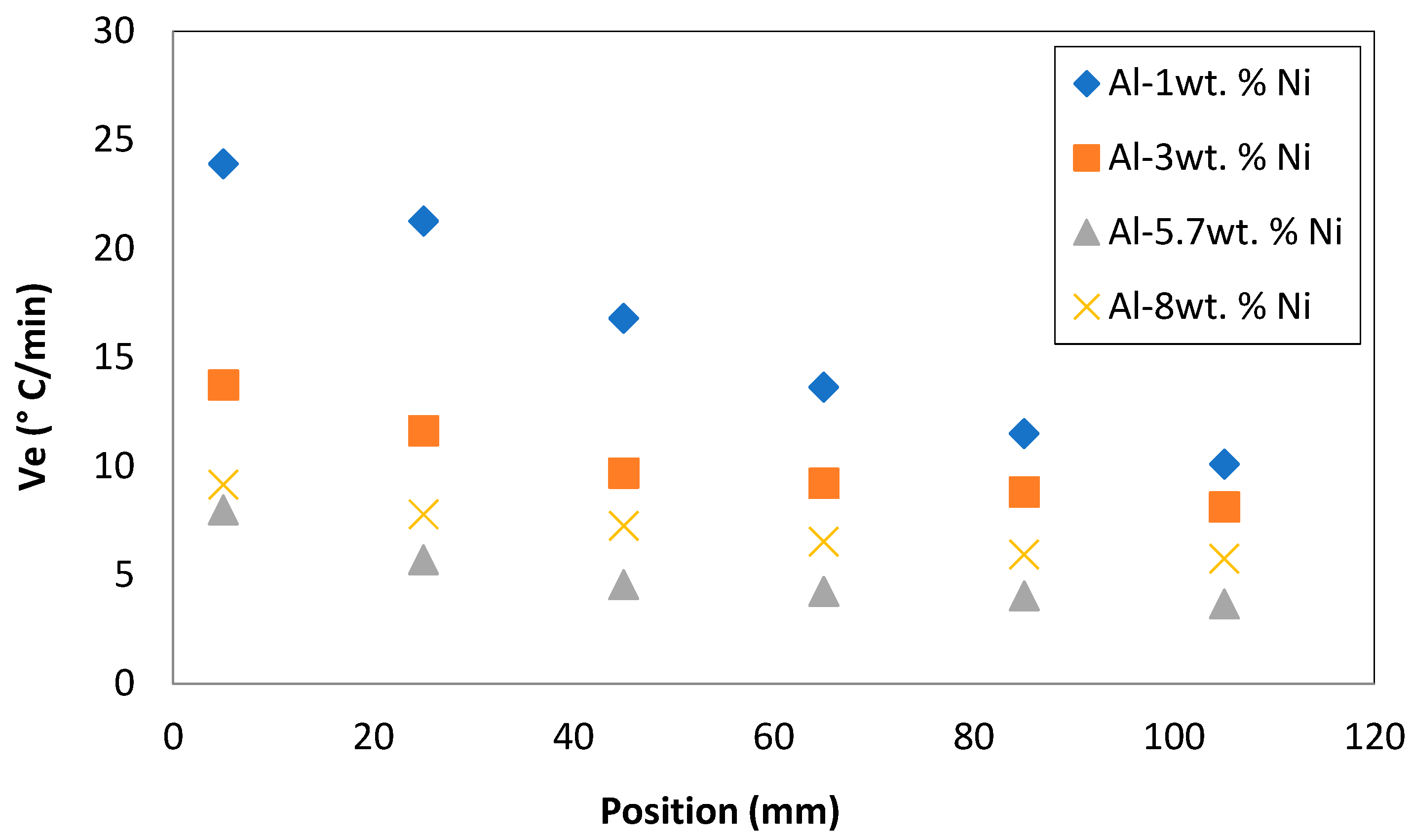

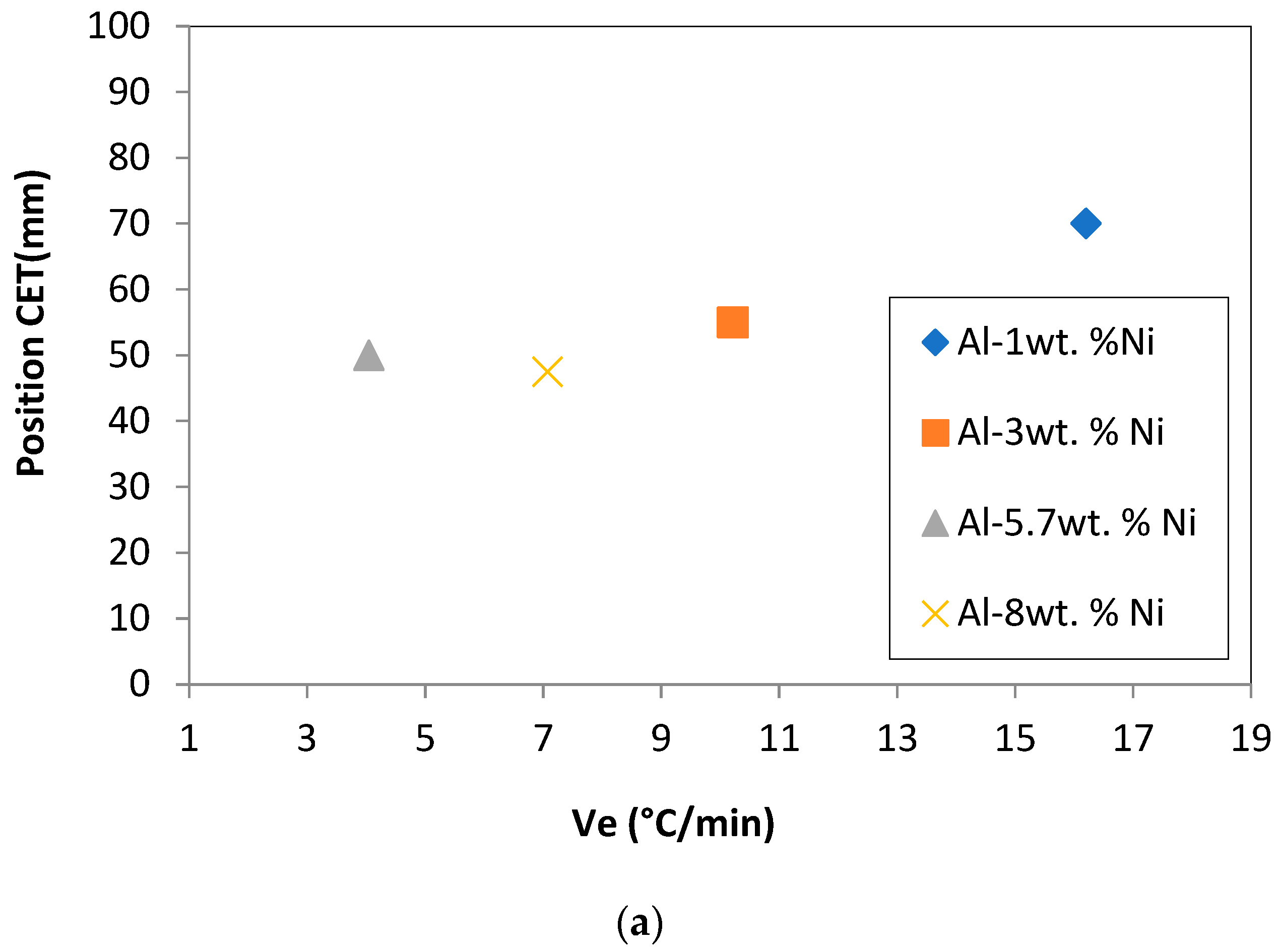

3.3. Cooling Rates and Macrostructure

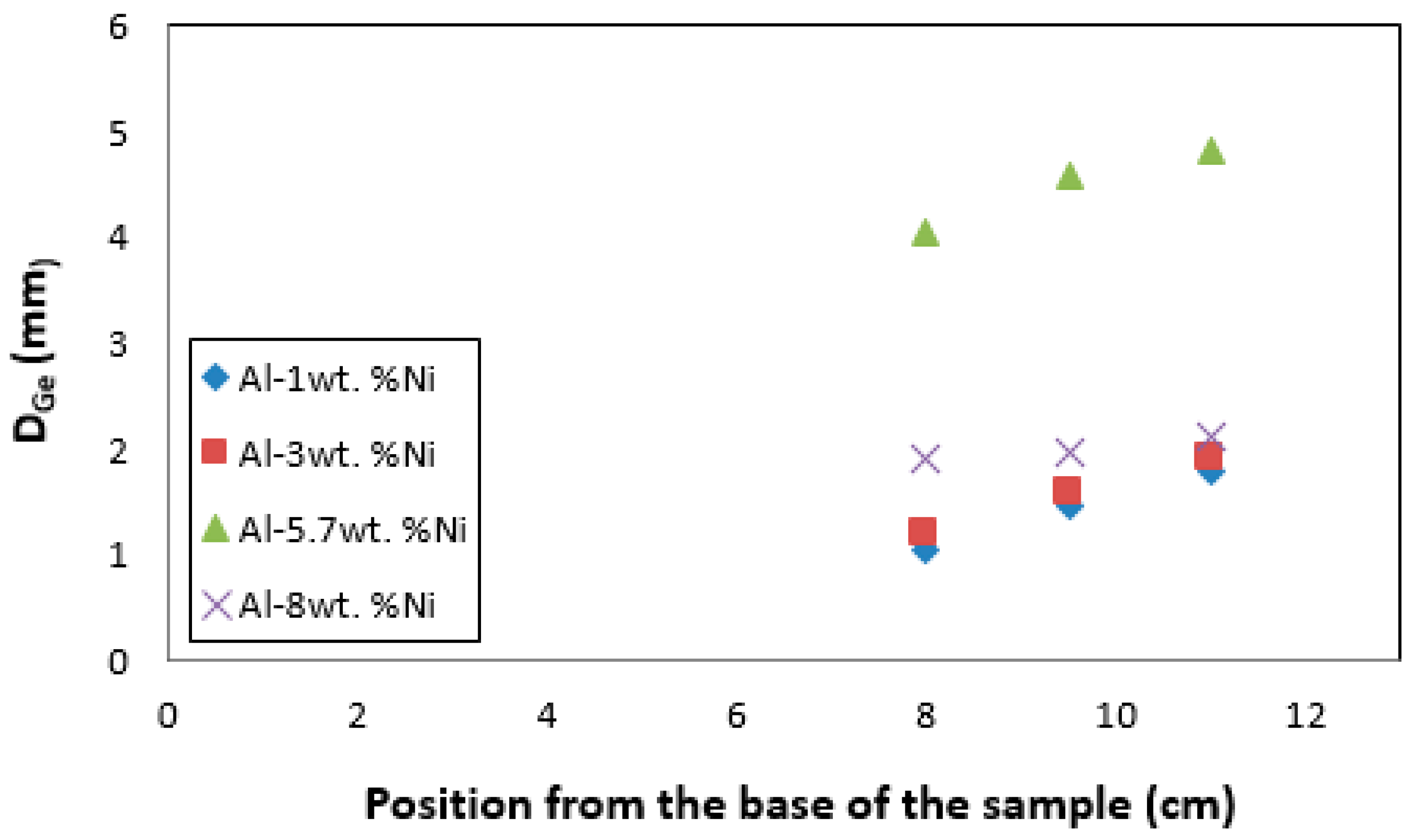

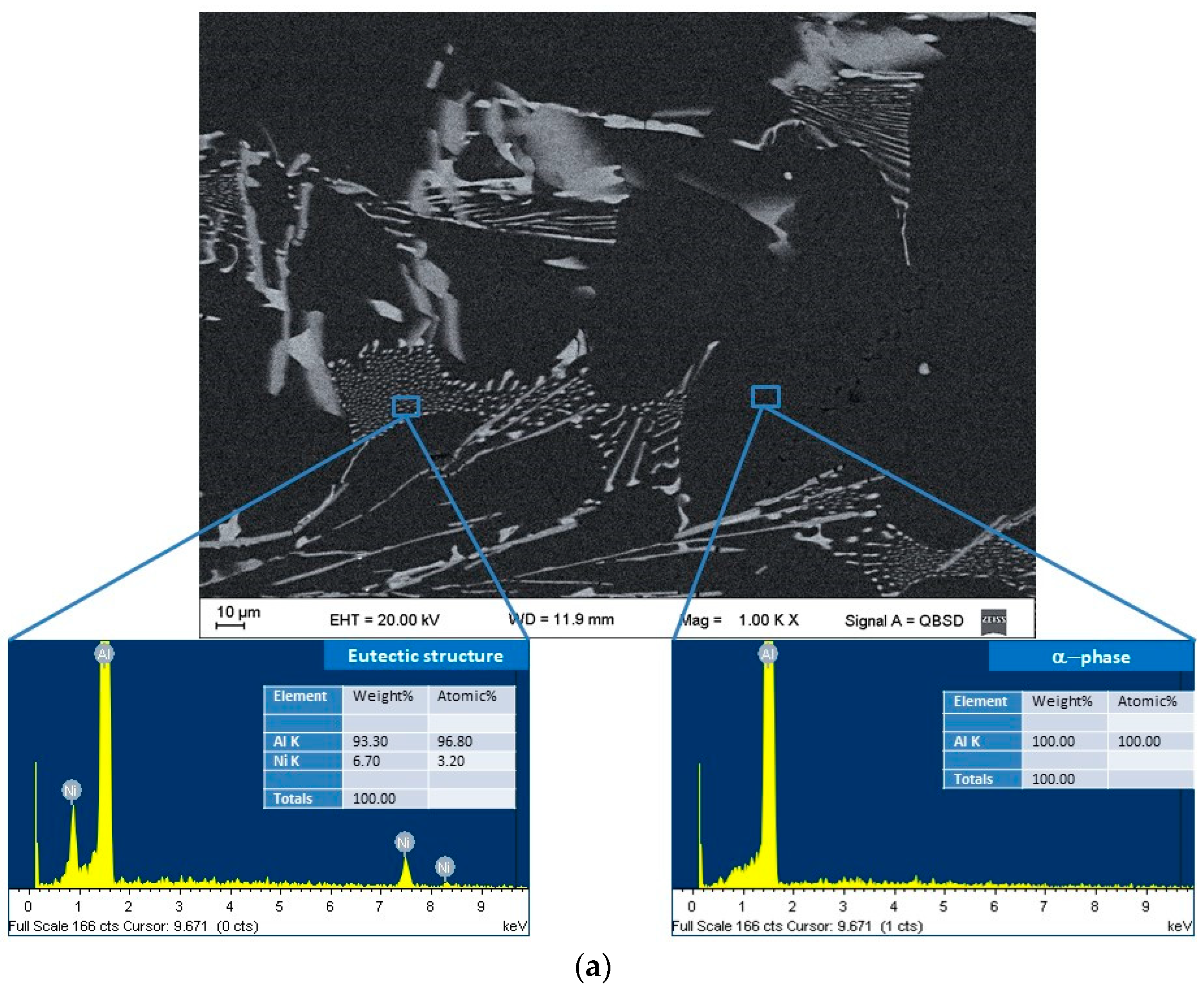

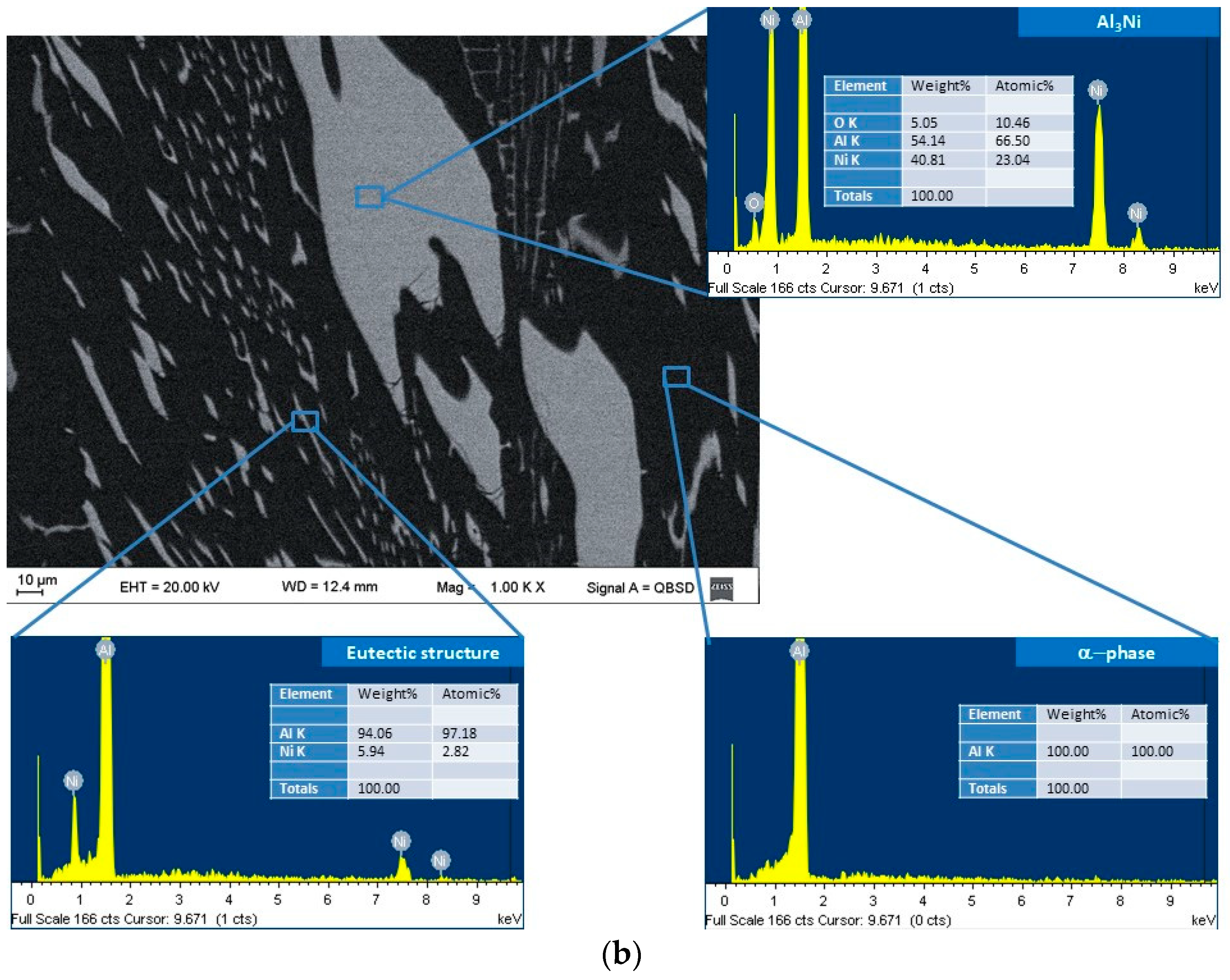

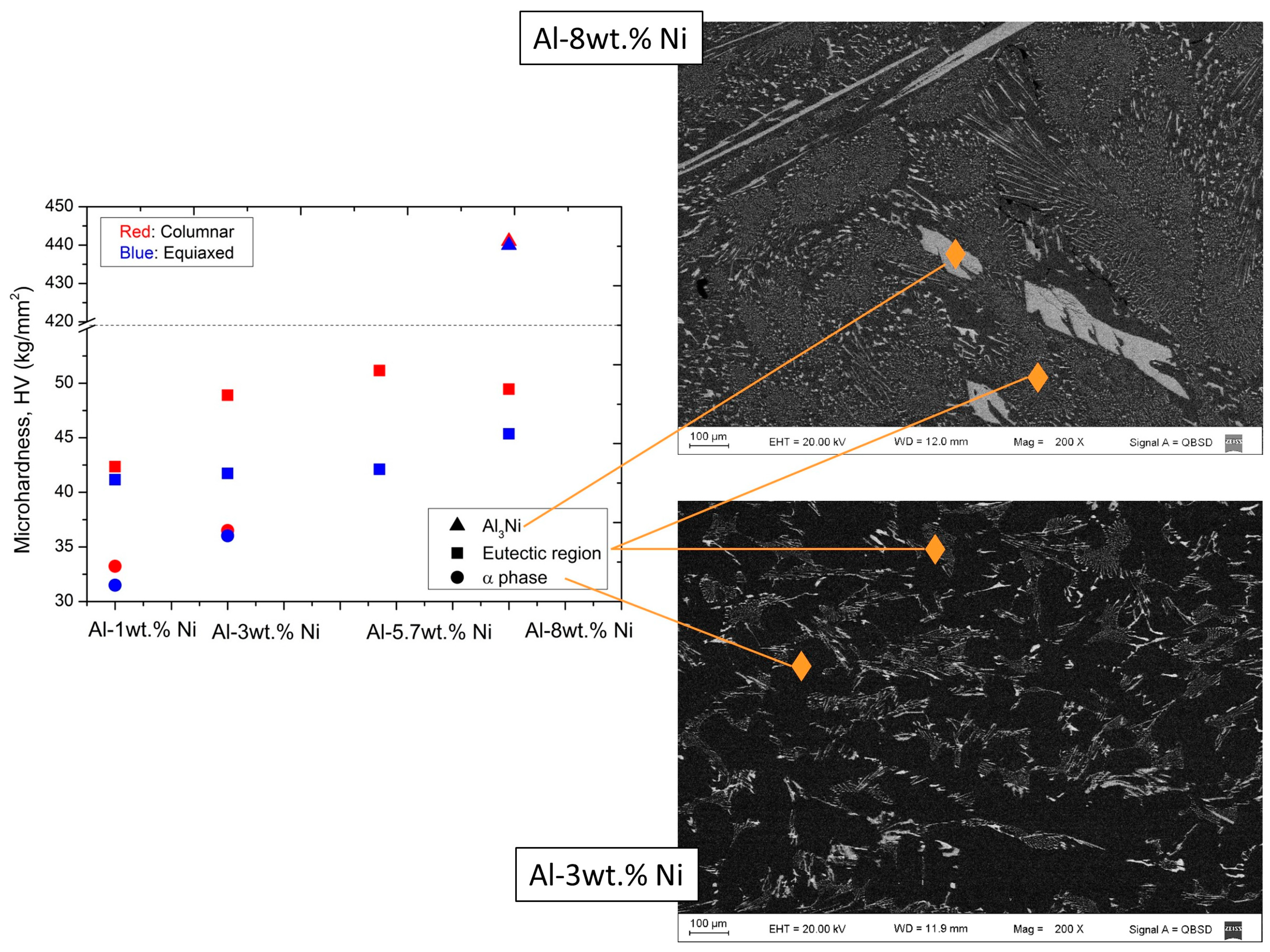

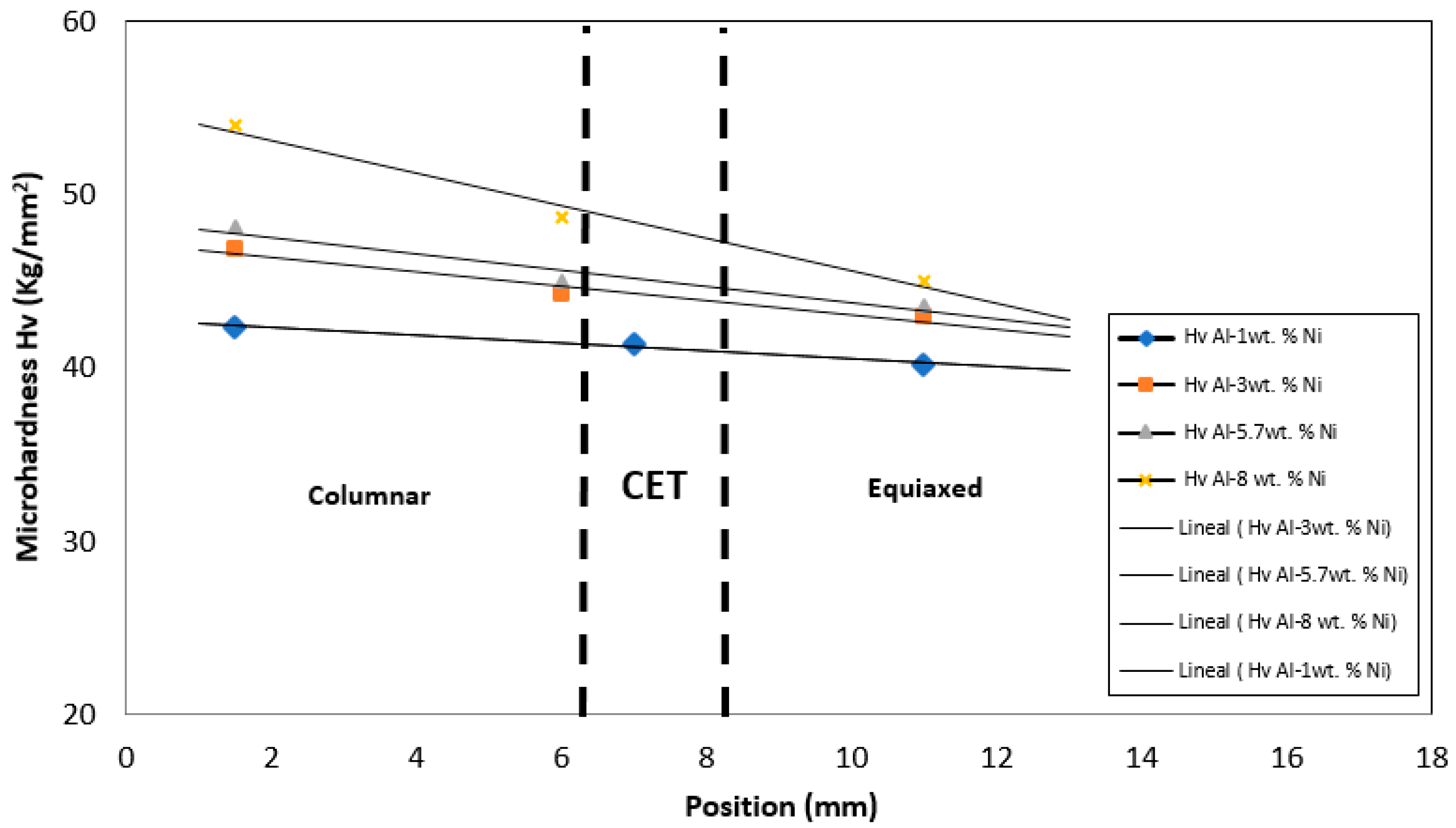

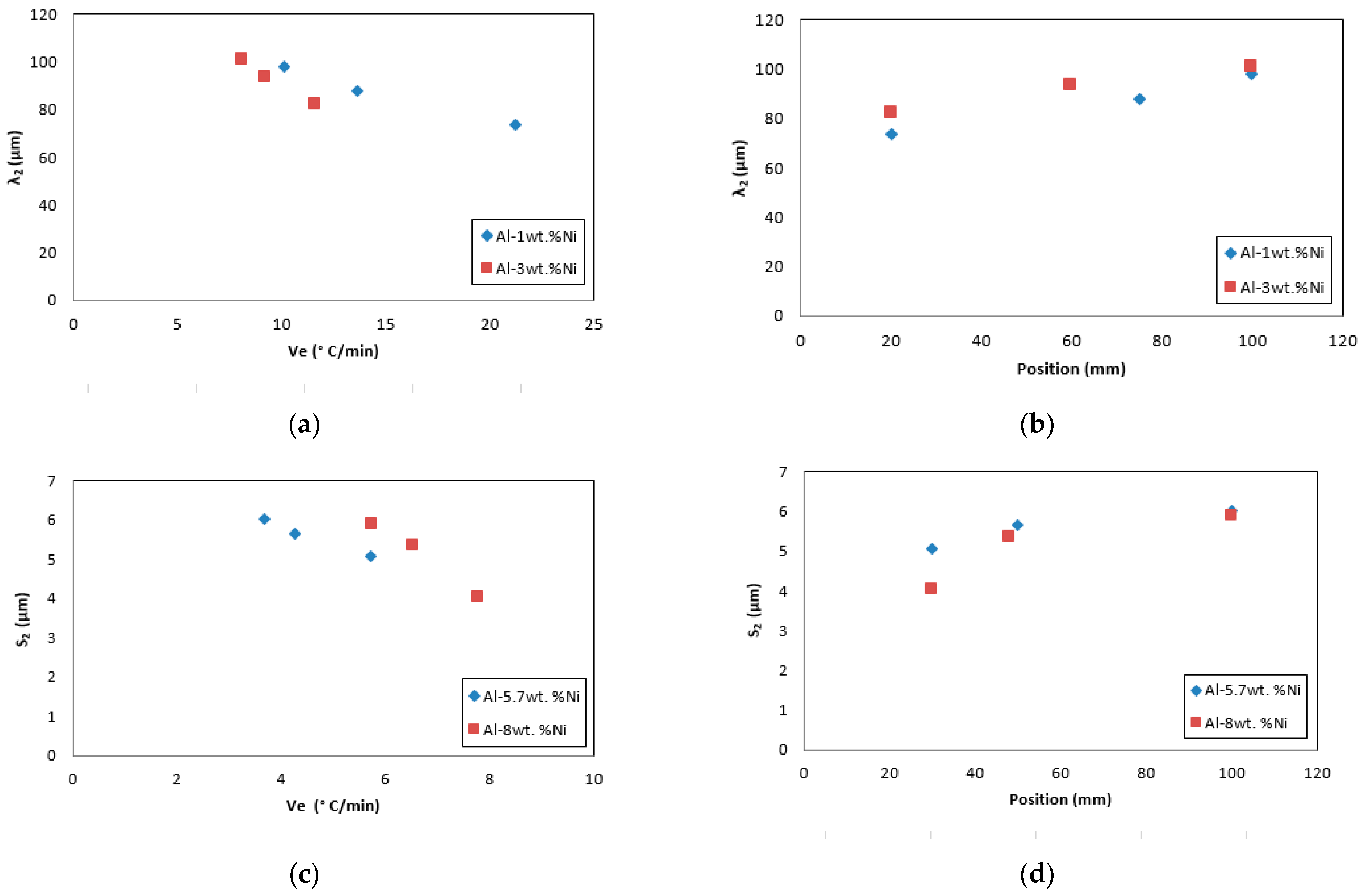

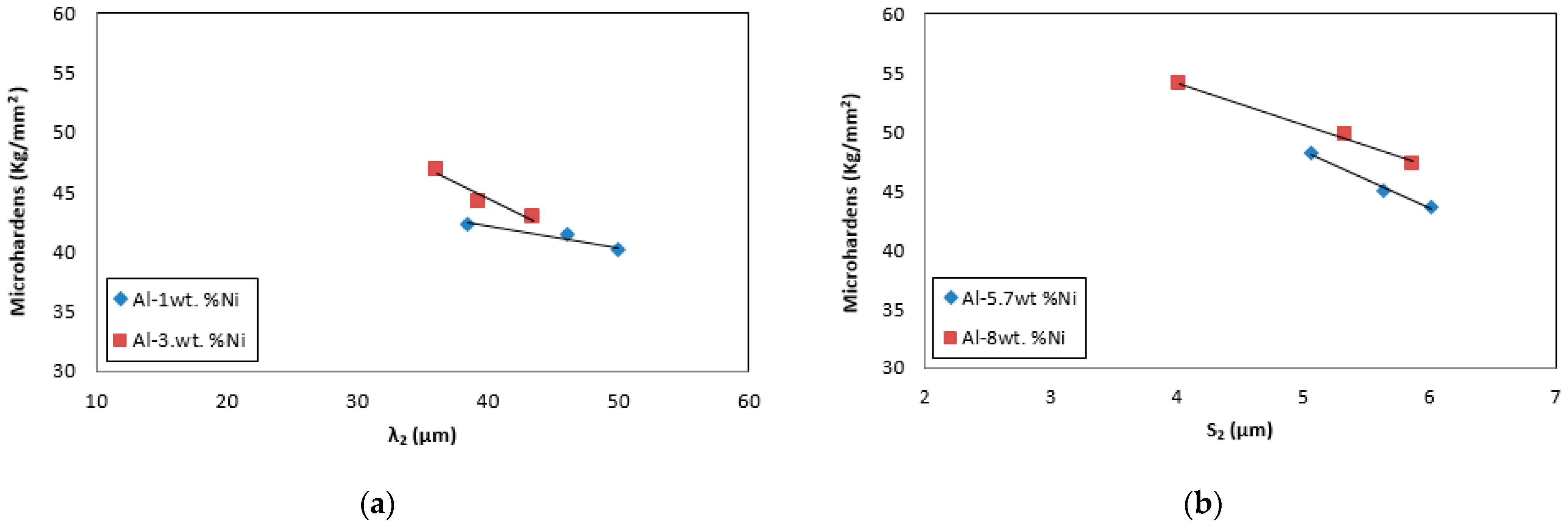

3.4. Microstructure and Microhardness

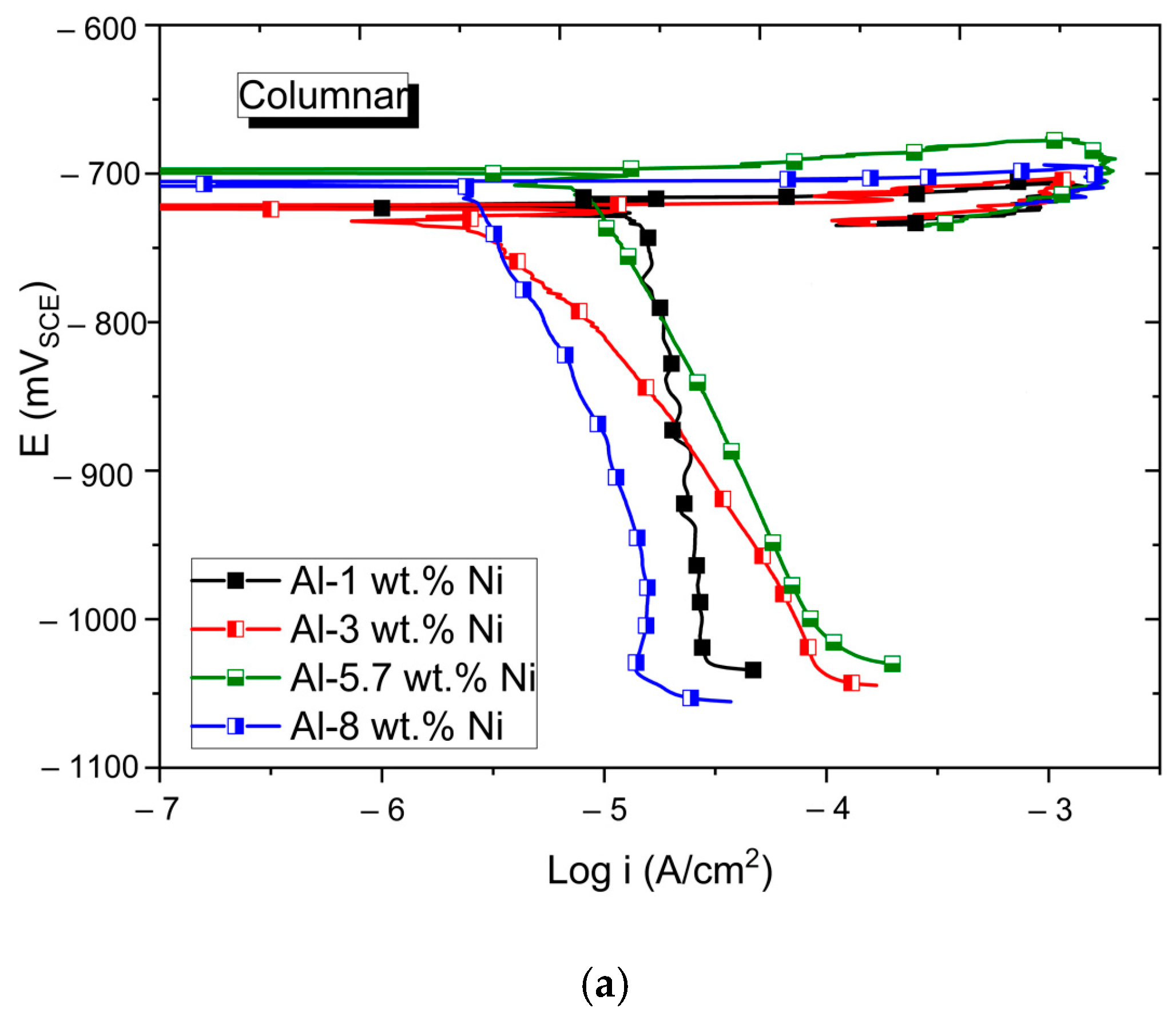

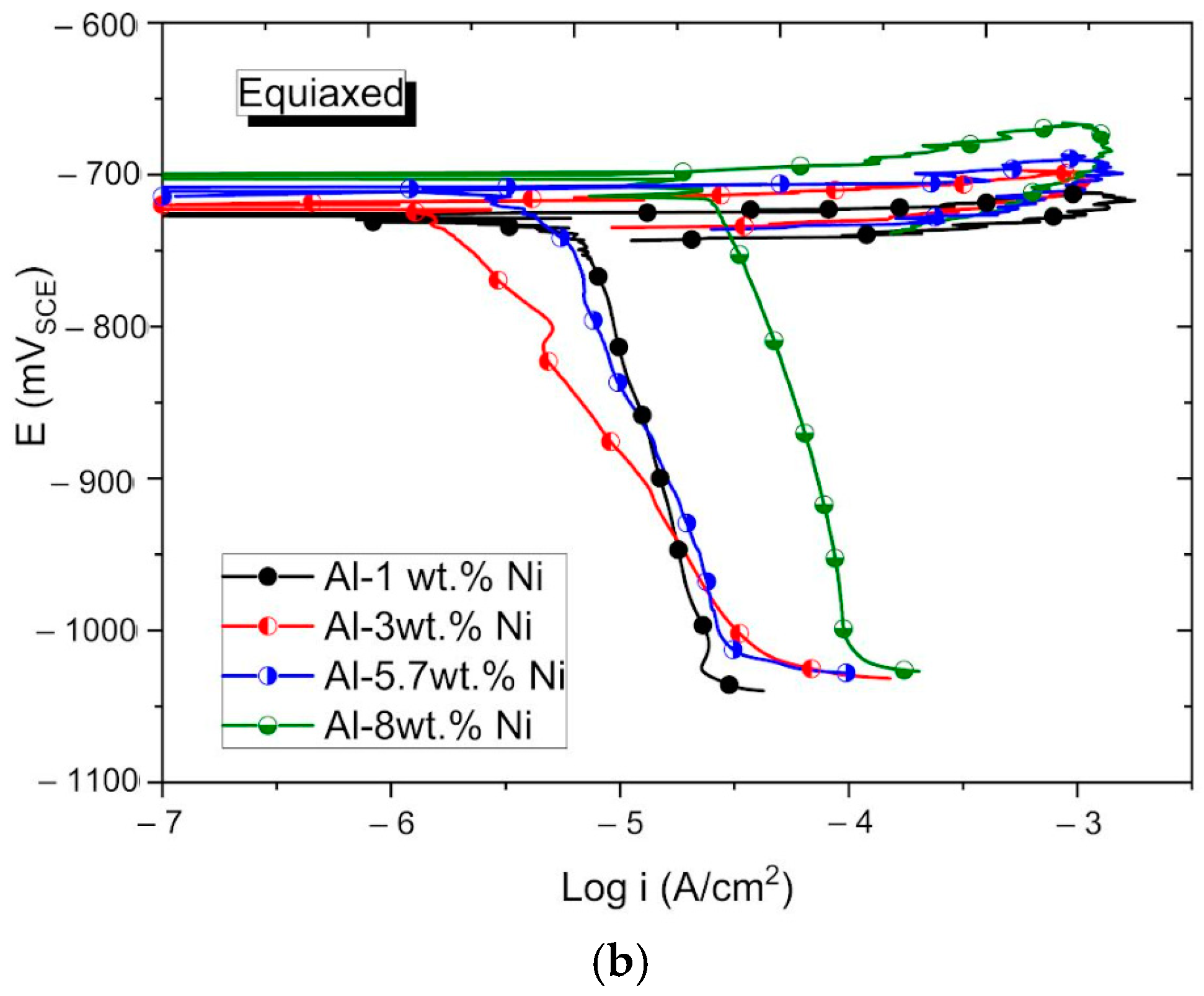

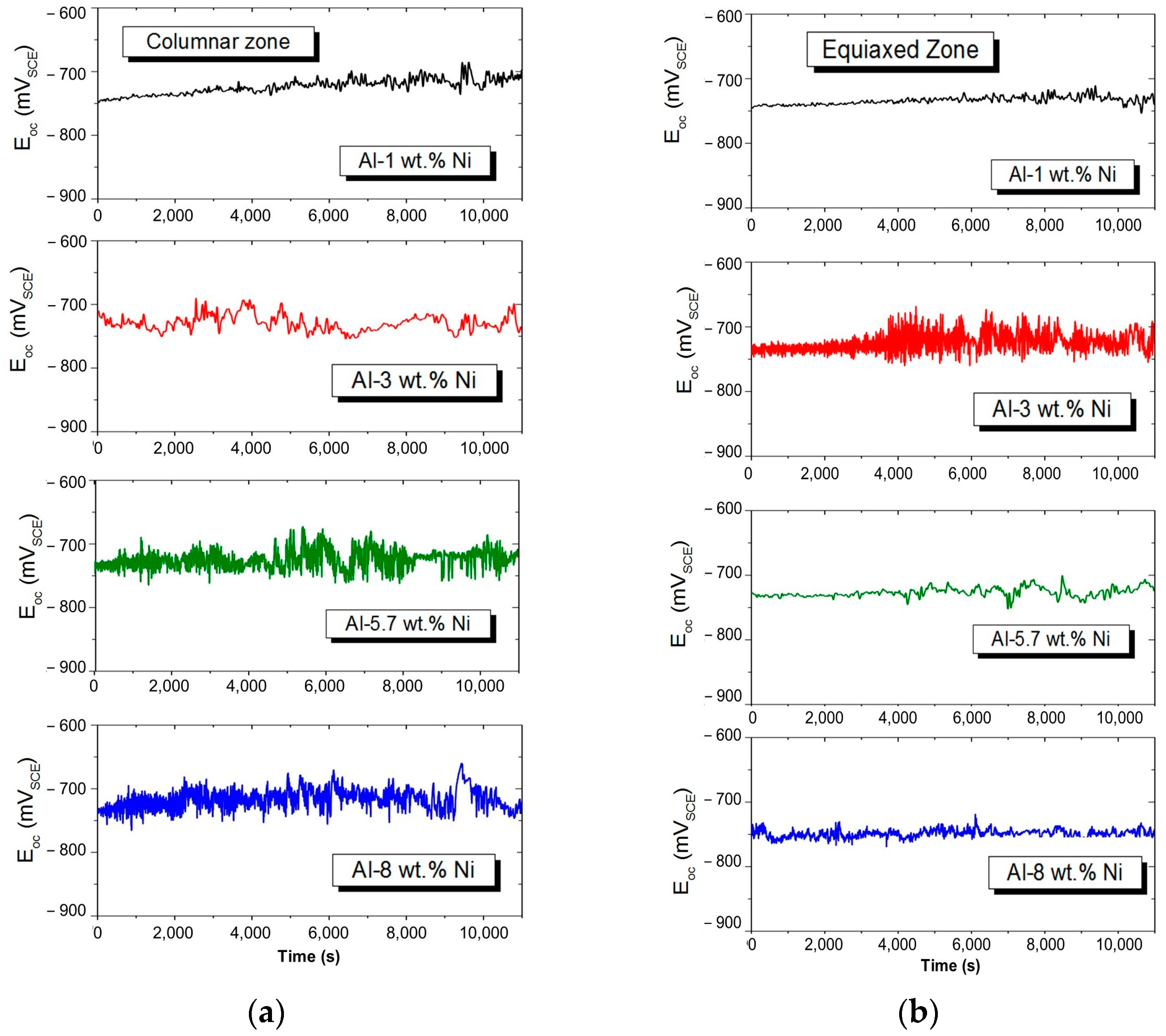

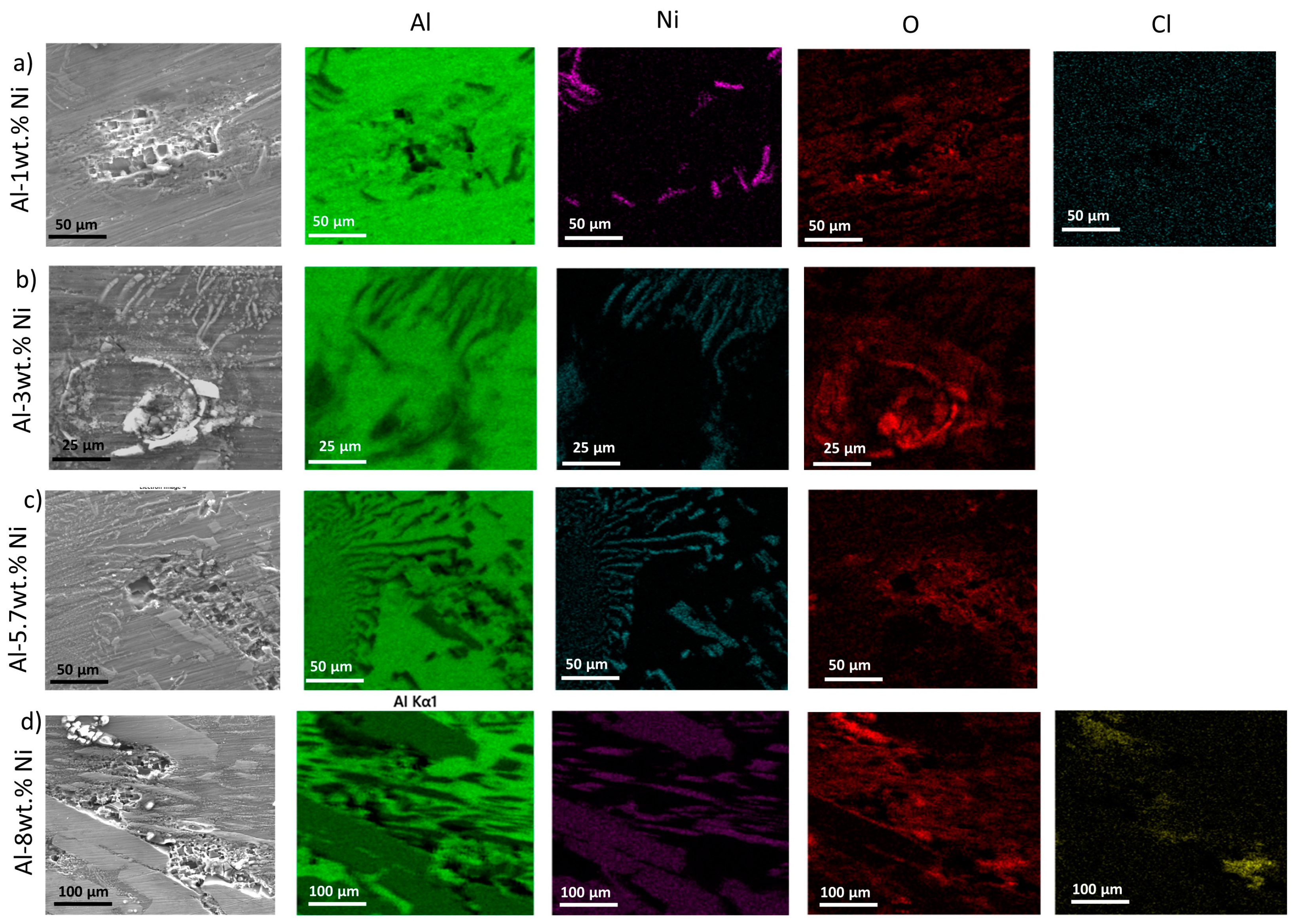

3.5. Potentiodynamic Polarization Curves

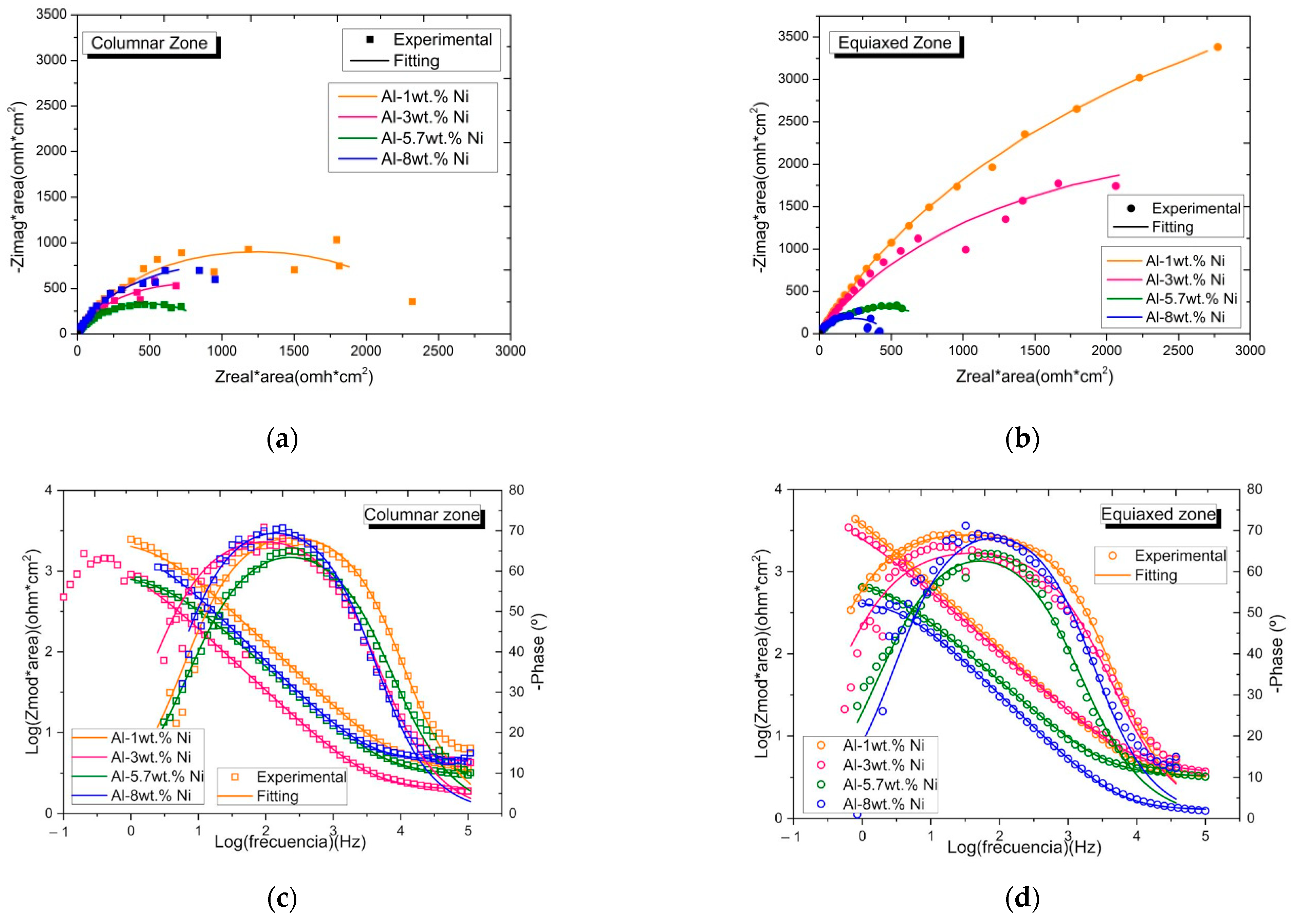

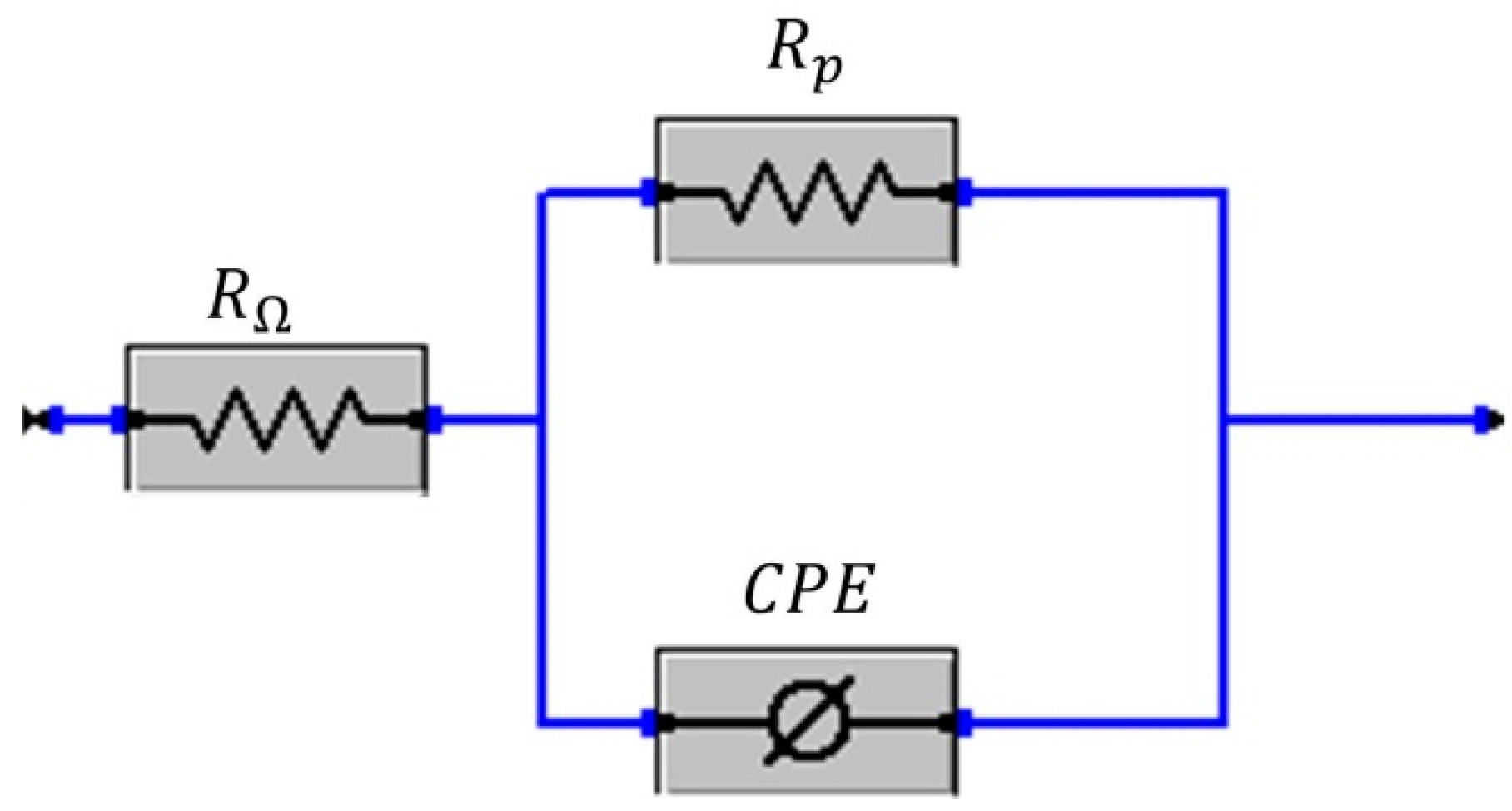

3.6. Electrochemical Impedance Spectroscopy

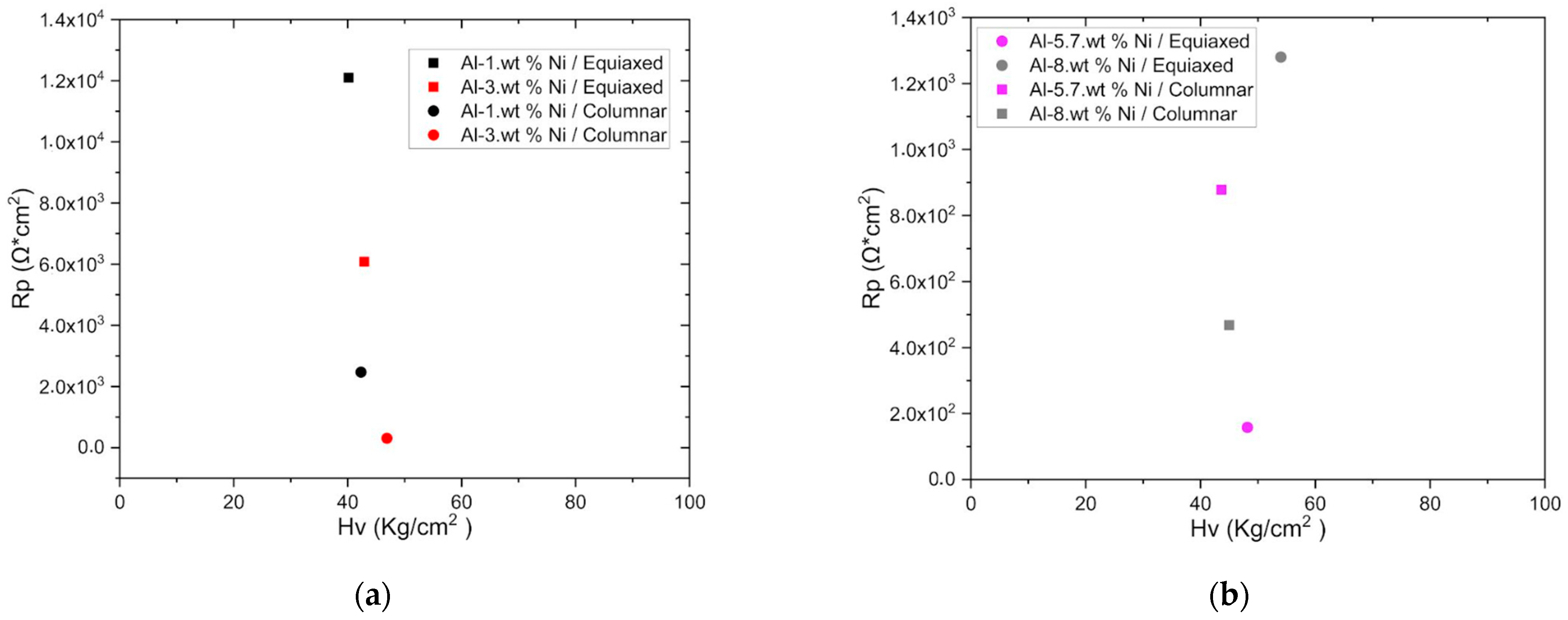

3.7. Correlation between Electrochemical Parameters and Microhardness

4. Conclusions

- The CET occurs in a zone where columnar and equiaxed grains coexist, and the position of the zone in the sample decreases as the Ni content in the alloy increases.

- The values of critical gradients (at the CET) were determined, and the values are 1.3 to 2.9 °C/cm.

- The eutectic region has greater microhardness than the α-phase, reasonably associated with the higher Ni-content.

- The microhardness values are smaller in the areas furthest from the base because, in further areas, the heat extraction rate is lower, and the grains are less refined.

- The highest cooling rate generates refinement in the secondary dendritic arm spacing and lamellar spacing, obtaining greater microstructural refinement in the zones of the samples close to the base.

- A small increase in the microhardness was observed as a function of the Ni content. For each concentration, as the cooling rate increases, the values of microhardness increase linearly.

- The Al-5.7wt. %Ni alloy, which corresponds to the eutectic composition, presents the noblest pitting potential values, followed by the Al-8wt. %Ni alloy, with a hypereutectic composition. Hypoeutectic alloys have the least noble potential values that are very close to each other.

- For the same alloy composition, the zone of columnar grains presents nobler pitting potential values than the zone of equiaxed grains. However, these differences between values are less than 5 mV, so they are not considered significant differences.

- When the Ni content increases, the resistance to polarization decreases for samples with equiaxed grain structure throughout the range of compositions studied. Furthermore, the equiaxed grain structure presents higher resistance to polarization values than the columnar grain zone for alloys with a composition equal to or lower than the eutectic composition. For the hypereutectic alloy, Al-8wt. % Ni, the trend is modified, with the area of columnar grains being the one with the highest resistance to polarization.

- With respect to the correlation between resistance to polarization and microhardness for Al-Ni alloys studied, when microhardness increases, the resistance to polarization decreases for hypoeutectic (Al-1wt. %Ni and Al-3wt. %Ni) and eutectic (Al-5.7wt. %Ni) alloys. The trend for the hypereutectic (Al-8wt. %Ni) alloy changes. The different behavior can be justified because the Al3Ni intermetallic could play a dual role in the corrosion of an Al-Ni alloy. It can act as a barrier against corrosion or as a galvanic cathode that accelerates the corrosion process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pandey, P.; Kumar, S.; Gault, B. On the origin of a remarkable increase in the strength and stability of an Al rich Al-Ni eutectic alloy by Zr addition. Acta Mater. 2019, 170, 205–217. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Pandee, P.; Patakham, U.; Limmaneevichitr, C. New generation of eutectic Al-Ni casting alloys for elevated temperature services. Mater. Sci. Eng. A 2018, 709, 46–54. [Google Scholar] [CrossRef]

- Fan, Y.; Makhlouf, M.M. Castable aluminium alloys for high temperature applications. Mater. Sci. Forum. 2013, 765, 8–12. [Google Scholar] [CrossRef]

- Galenko, P.K.; Toropova, L.V.; Alexandrov, D.V.; Phanikumar, G.; Assadi, H.; Reinartz, M.; Paul, P.; Fang, Y.; Lippmann, S. Anomalous kinetics, patterns formation in recalescence, and final microstructure of rapidly solidified Al-rich Al-Ni alloys. Acta Mater. 2022, 241, 118384. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Frederick, A.; Wang, Y.; Wang, Y.; Allard, L., Jr.; Koehler, M.; Shin, S.; Hu, A.; Feng, Z. In-situ formation of Al3Ni nano particles in synthesis of Al 7075 alloy by friction stir processing with Ni powder addition. J. Mater. Process. Technol. 2023, 311, 117803. [Google Scholar] [CrossRef]

- Cosan, K.A.; Gunduz, K.O.; Tarakcı, M.; Gencer, Y. Plasma electrolytic oxidation of as-cast and heat-treated binary Al-Ni alloys. Surf. Coat. Technol. 2022, 450, 128998. [Google Scholar] [CrossRef]

- Ding, R.; Deng, J.; Liu, X.; Wu, Y.; Geng, Z.; Li, D.; Zhang, T.; Chen, C.; Zhou, K. Enhanced mechanical properties and thermal stability in additively manufactured Al-Ni alloy by Sc addition. J. Alloys Compd. 2023, 934, 167894. [Google Scholar] [CrossRef]

- Morando, C.; Fornaro, O. Morphology and phase formation during the solidification of Al-Cu-Si and Al-Ag-Cu ternary eutectic system. Mater. Res. 2018, 21, 1–11. [Google Scholar] [CrossRef]

- Wen, Z.; Zhao, Y.; Hou, H.; Tian, J.; Han, P. First-principles study of Ni-Al intermetallic compounds under various temperature and pressure. Superlattices Microstruct. 2017, 103, 9–18. [Google Scholar] [CrossRef]

- Babilas, R.; Młynarek, K.; Łoński, W.; Lis, M.; Łukowiec, D.; Kądziołka-Gaweł, M.; Warski, T.; Radoń, A. Analysis of thermodynamic parameters for designing quasicrystalline Al-Ni-Fe alloys with enhanced corrosion resistance. J. Alloys Compd. 2021, 868, 159241. [Google Scholar] [CrossRef]

- Miyajima, Y.; Homma, T.; Takenaka, S.; Watanabe, C.; Adachi, H.; Ishikawa, K. High strength and low electrical resistivity of Al-0.1 at%Ni alloys produced by accumulative roll bonding. Mater. Today Commun. 2022, 33, 104587. [Google Scholar] [CrossRef]

- Esquivel, J.; Murdoch, H.A.; Darling, K.A.; Gupta, R.K. Excellent corrosion resistance and hardness in Al alloys by extended solid solubility and nanocrystalline structure. Mater. Res. Lett. 2017, 6, 79–83. [Google Scholar] [CrossRef]

- Hu, S.S.Q.; Ding, W.L.Z.; Xia, M.X.M. In situ study on the growth behavior of primary Al3Ni phase in solidifying Al–Ni alloy by synchrotron radiography. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 668–672. [Google Scholar]

- Akopyan, T.K.; Belov, N.A.; Naumova, E.A.; Letyagin, N.V. New in-situ Al matrix composites based on Al-Ni-La eutectic. Mater. Lett. 2019, 245, 110–113. [Google Scholar] [CrossRef]

- Osório, W.R.; Peixoto, L.C.; Canté, M.V.; Garcia, A. Microstructure features affecting mechanical properties and corrosion behavior of a hypoeutectic Al-Ni alloy. Mater. Des. 2010, 31, 4485–4489. [Google Scholar] [CrossRef]

- Osório, W.R.; Peixoto, L.C.; Canté, M.V.; Garcia, A. Electrochemical corrosion characterization of Al-Ni alloys in a dilute sodium chloride solution. Electrochim. Acta 2010, 55, 4078–4085. [Google Scholar] [CrossRef]

- Zhang, Z.; Akiyama, E.; Watanabe, Y. Effect of α-Al/Al3Ni microstructure on the corrosion behaviour of Al–5.4wt % Ni alloy fabricated by equal-channel angular pressing. Corros. Sci. 2007, 49, 2962–2972. [Google Scholar] [CrossRef]

- Román, A.S.; Ibañez, E.R.; Méndez, C.M.; Pedrozo, M.; Kramer, G.R.; Zadorozne, N.S.; Alonso, P.R.; Ares, A.E. Electrochemical Properties of Diluted Al-Mg Alloys with Columnar-To-Equiaxed Transition. Front. Mater. 2022, 9, 1–15. [Google Scholar] [CrossRef]

- Roman, A.S.; Mendez, C.M.; Gervasi, C.A.; Rebak, R.B.; Ares, A.E. Corrosion resistance of aluminum-copper alloys with different grain structures. J. Mater. Eng. Perform. 2020, 30, 131–144. [Google Scholar] [CrossRef]

- Okamoto, H.; Schlesinger, M.E.; Mueller, E.M. Alloy Phase Diagrams; ASM Handbook; ASM International, ASM Headquarters and Geodesic Dome, Materials Park campus, Russell Township: Geauga County, OH, USA, 2016; Volume 8, pp. 108–146. [Google Scholar]

- Petzow, G. Metallographic Etching, 2nd ed.; American Society for Metals: Metals Park, OH, USA, 2008. [Google Scholar]

- Vander Voort, G. Metallography and Microstructures; ASM Handbook; ASM International: Metals Park, OH, USA, 2004; Volume 9, #06044G. [Google Scholar]

- Gueijman, S.F.; Schvezov, C.E.; Ares, A.E. Vertical and horizontal directional solidification of Zn-Al and Zn-Ag diluted alloys. Mater. Trans. 2010, 51, 1861–1870. [Google Scholar] [CrossRef]

- Ares, A.E.; Gueijman, S.F.; Schvezov, C.E. Semi-empirical modeling for columnar and equiaxed growth of alloys. J. Cryst. Growth 2002, 241, 235–240. [Google Scholar] [CrossRef]

- Ares, A.E.; Schvezov, C.E. Influence of solidification thermal parameters on the columnar-to-equiaxed transition of aluminum-zinc and zinc-aluminum alloys. Metall. Mater. Trans. A 2007, 38, 1485–1499. [Google Scholar] [CrossRef]

- Ares, A.E.; Schvezov, C.E. Solidification parameters during the columnar-to-equiaxed transition in lead-tin alloys. Metall. Mater. Trans. A 2000, 31, 1611–1625. [Google Scholar] [CrossRef]

- Kociubzyk, A.I.; Rozicki, R.S.; Ares, A.E. Movement of the interphases during the horizontal solidification of tin-zinc alloys. Rev. Mater. 2018, 23, e-11993. [Google Scholar]

- Ares, A.E.; Gassa, L.M. Corrosion susceptibility of Zn–Al alloys with different grains and dendritic microstructures in Nacl solutions. Corros. Sci. 2012, 59, 290–306. [Google Scholar] [CrossRef]

- ASTM E 112—96e3; Standard Test Methods for Determining Average Grain Size. ASTM: West Conshohocken, PA, USA, 2004.

- Kaya, H.; Böyük, U.; Çadırlı, E.; Maras, N. Measurements of the microhardness, electrical and thermal properties of the Al–Ni eutectic alloy. Mater. Des. 2012, 34, 707–712. [Google Scholar] [CrossRef]

- ASTM G5-14; Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements. ASTM: West Conshohocken, PA, USA, 2021.

- Martínez Villalobos, M.A.; Figueroa, I.A.; Suarez, M.A.; Angel, G.; Rodríguez, L.; Peralta, O.N.; González Reyes, G.; López, I.A.; Verduzco Martínez, J.; Trujillo, C.D. Microstructural Evolution of Rapid Solidified Al-Ni Alloys. J. Mex. Chem. Soc. 2016, 60, 67–72. [Google Scholar] [CrossRef]

- Zaid, B.; Saidi, D.; Benzaid, A.; Hadji, S. Effects of pH and chloride concentration on pitting corrosion of AA6061 aluminum alloy. Corros. Sci. 2008, 50, 1841–1847. [Google Scholar] [CrossRef]

- Palcut, M.; Priputen, P.; Kusy, M.; Janovec, J. Corrosion behaviour of Al–29at%Co alloy in aqueous NaCl. Corros. Sci. 2013, 75, 461–466. [Google Scholar] [CrossRef]

- Lekatou, A.; Sfikas, A.K.; Karantzalis, A.E.; Sioulas, D. Microstructure and corrosion performance of Al-32%Co alloys. Corros. Sci. 2012, 63, 193–209. [Google Scholar] [CrossRef]

- Palcut, M.; Ďuriška, L.; Špoták, M.; Vrbovský, M.; Gerhátová, Z.; Černičková, I.; Janovec, J. Electrochemical Corrosion of Al-Pd alloys in HCl and NaOH solutions. J. Min. Metall. Sect. B-Metall. 2017, 53, 333–340. [Google Scholar] [CrossRef]

- Duriška, L.; Cernicková, I.; Priputen, P.; Palcut, M. Aqueous Corrosion of Aluminum-Transition Metal Alloys Composed of Structurally Complex Phases: A Review. Materials 2021, 14, 5418. [Google Scholar] [CrossRef] [PubMed]

- Frankel, G.S. Electrochemical Techniques in Corrosion: Status, Limitations, and Needs. Electrochem. Tech. Corros. 2008, 5, 1–27. [Google Scholar] [CrossRef]

- Ralston, K.D.; Fabijanic, D.; Birbilis, N. Effect of grain size on corrosion of high purity aluminium. Electrochim. Acta 2011, 56, 1729–1736. [Google Scholar] [CrossRef]

- Soltis, J. Passivity breakdown, pit initiation and propagation of pits in metallic materials. Corros. Sci. 2015, 90, 5–22. [Google Scholar] [CrossRef]

- Natishan, P.M.; O’Grady, W.E. Chloride Ion Interactions with Oxide-Covered Aluminum Leading to Pitting Corrosion: A Review. J. Electrochem. Soc. 2014, 161, C421–C432. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Wang, M. Microstructures and corrosion resistances of hypoeutectic Al-6.5Si-0.45Mg casting alloy with addition of Sc and Zr. Mater. Chem. Phys. 2022, 276, 125321. [Google Scholar] [CrossRef]

- Kelly, R.G.; Scully, J.R.; Shoesmith, D.W.; Buchheit, R.G. Electrochemical Techniques in Corrosion Science and Engineering; Routledge, Taylor and Francis Group: London, UK, 2003. [Google Scholar]

- Fernandes Gomes, L.; Kugelmeier, C.L.; Garcia, A.; Della Rovere, C.A.; Spinelli, J.E. Influences of alloying elements and dendritic spacing on the corrosion behavior of Al-Si-Ag alloys. J. Mater. Res. Technol. 2021, 15, 5880–58930. [Google Scholar] [CrossRef]

- Osório, W.R.; Spinelli, J.E.; Afonso, C.R.M.; Peixoto, L.C.; Garcia, A. Electrochemical corrosion behavior of gas atomized Al-Ni alloy powders. Electrochim. Acta 2012, 69, 371–378. [Google Scholar] [CrossRef]

| Alloy | Ve Liq. (°C/min) | VS (mm/s) | Gc (°C/cm) | Solidification Time (s) | CETMin (mm) | CETMax (mm) | Columnar Grain Width (mm) | DGe (mm) |

|---|---|---|---|---|---|---|---|---|

| Al-1wt. %Ni | 16.20 | 1.25 | 1.9 | 743 | 65 | 75 | 2 | 1.45 |

| Al-3wt. %Ni | 10.26 | 0.79 | 1.3 | 814 | 50 | 60 | 3 | 1.60 |

| Al-5.7wt. %Ni | 5.04 | 0.67 | 2.9 | 905 | 45 | 55 | 5.5 | 6.86 |

| Al-8wt. %Ni | 6.52 | 1.18 | 2.5 | 864 | 43 | 52 | 4.6 | 1.99 |

| Ecorr | icorr | ||

|---|---|---|---|

| (mV) | mA/cm2 | ||

| Al-1wt. %Ni | Columnar zone | −722 | 0.0144 |

| Equiaxed zone | −726 | 0.0068 | |

| Al-3wt. %Ni | Columnar zone | −721 | 0.0029 |

| Equiaxed zone | −725 | 0.0014 | |

| Al-5.7wt. %Ni | Columnar zone | −698 | 0.0083 |

| Equiaxed zone | −701 | 0.0242 | |

| Al-8wt. %Ni | Columnar zone | −707 | 0.0026 |

| Equiaxed zone | −710 | 0.0046 |

| RΩ | Rp | CPE | n | Ceff | ||

|---|---|---|---|---|---|---|

| Ω*cm2 | Ω*cm2 | Ω−1s-n*cm−2 | F.cm−2 | |||

| Al-1wt. % Ni | Columnar zone | 3.6 | 2.47 × 103 | 4.32 × 10−5 | 0.81 | 3.03 × 10−6 |

| Equiaxed zone | 3 | 1.21 × 104 | 5.45 × 10−5 | 0.79 | 2.99 × 10−6 | |

| Al-3wt. % Ni | Columnar zone | 0.39 | 3.08 × 102 | 9.40 × 10−4 | 0.79 | 1.89 × 10−4 |

| Equiaxed zone | 3.56 | 6.08 × 103 | 7.87 × 10−5 | 0.74 | 1.82 × 10−6 | |

| Al-5.7wt. % Ni | Columnar zone | 2.67 | 1.58 × 102 | 6.94 × 10−4 | 0.7 | 2.03 × 10−5 |

| Equiaxed zone | 3.2 | 8.78 × 102 | 1.55 × 10−4 | 0.77 | 7.98 × 10−6 | |

| Al-8wt. % Ni | Columnar zone | 4.62 | 1.28 × 103 | 5.43 × 10−5 | 0.85 | 7.33 × 10−6 |

| Equiaxed zone | 1.26 | 4.68 × 102 | 1.57 × 10−4 | 0.82 | 2.18 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Román, A.S.; Ibañez, E.R.; Zadorozne, N.S.; Méndez, C.M.; Ares, A.E. Corrosion Susceptibility and Microhardness of Al-Ni Alloys with Different Grain Structures. Appl. Sci. 2024, 14, 8862. https://doi.org/10.3390/app14198862

Román AS, Ibañez ER, Zadorozne NS, Méndez CM, Ares AE. Corrosion Susceptibility and Microhardness of Al-Ni Alloys with Different Grain Structures. Applied Sciences. 2024; 14(19):8862. https://doi.org/10.3390/app14198862

Chicago/Turabian StyleRomán, Alejandra Silvina, Edgar Rolando Ibañez, Natalia Silvina Zadorozne, Claudia Marcela Méndez, and Alicia Esther Ares. 2024. "Corrosion Susceptibility and Microhardness of Al-Ni Alloys with Different Grain Structures" Applied Sciences 14, no. 19: 8862. https://doi.org/10.3390/app14198862

APA StyleRomán, A. S., Ibañez, E. R., Zadorozne, N. S., Méndez, C. M., & Ares, A. E. (2024). Corrosion Susceptibility and Microhardness of Al-Ni Alloys with Different Grain Structures. Applied Sciences, 14(19), 8862. https://doi.org/10.3390/app14198862