Effect of Apple Puree as a Substitute for Fat and Sugar on the Texture and Physical Properties of Muffins

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Dosage of Pectin from Apple Puree

2.3. Determination of the Degree of Esterification of Pectin

2.4. Preparation of the Muffin Dough

2.5. Determination of Texture

2.6. Determination of Muffin Height

2.7. Determination of Muffin Volume

2.8. Loss of Weight during Baking

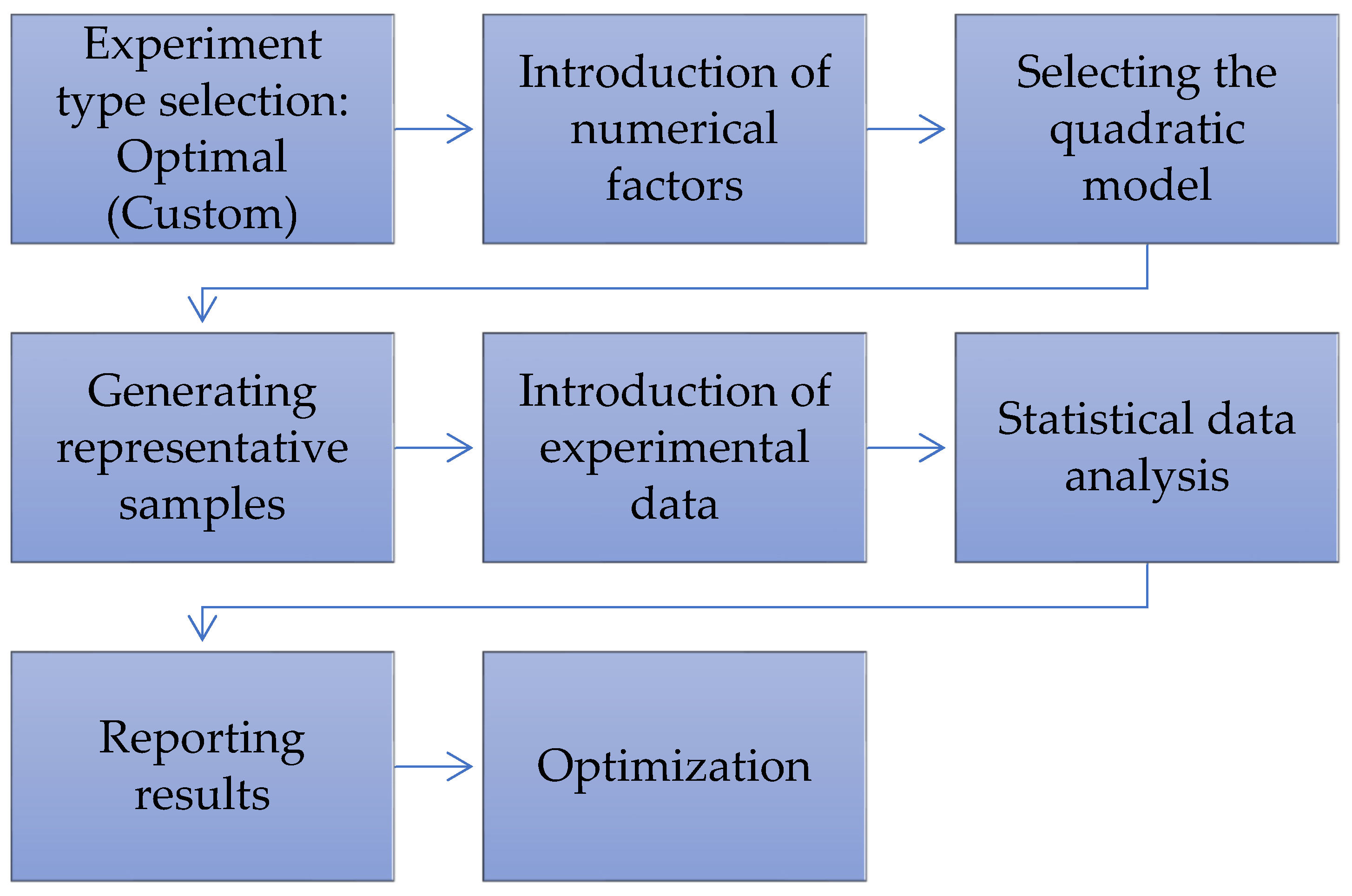

2.9. Experimental Design

2.10. Crumb Microstructure

3. Results

3.1. Determination of Pectin and Degree of Esterification of Pectin in Apple Puree

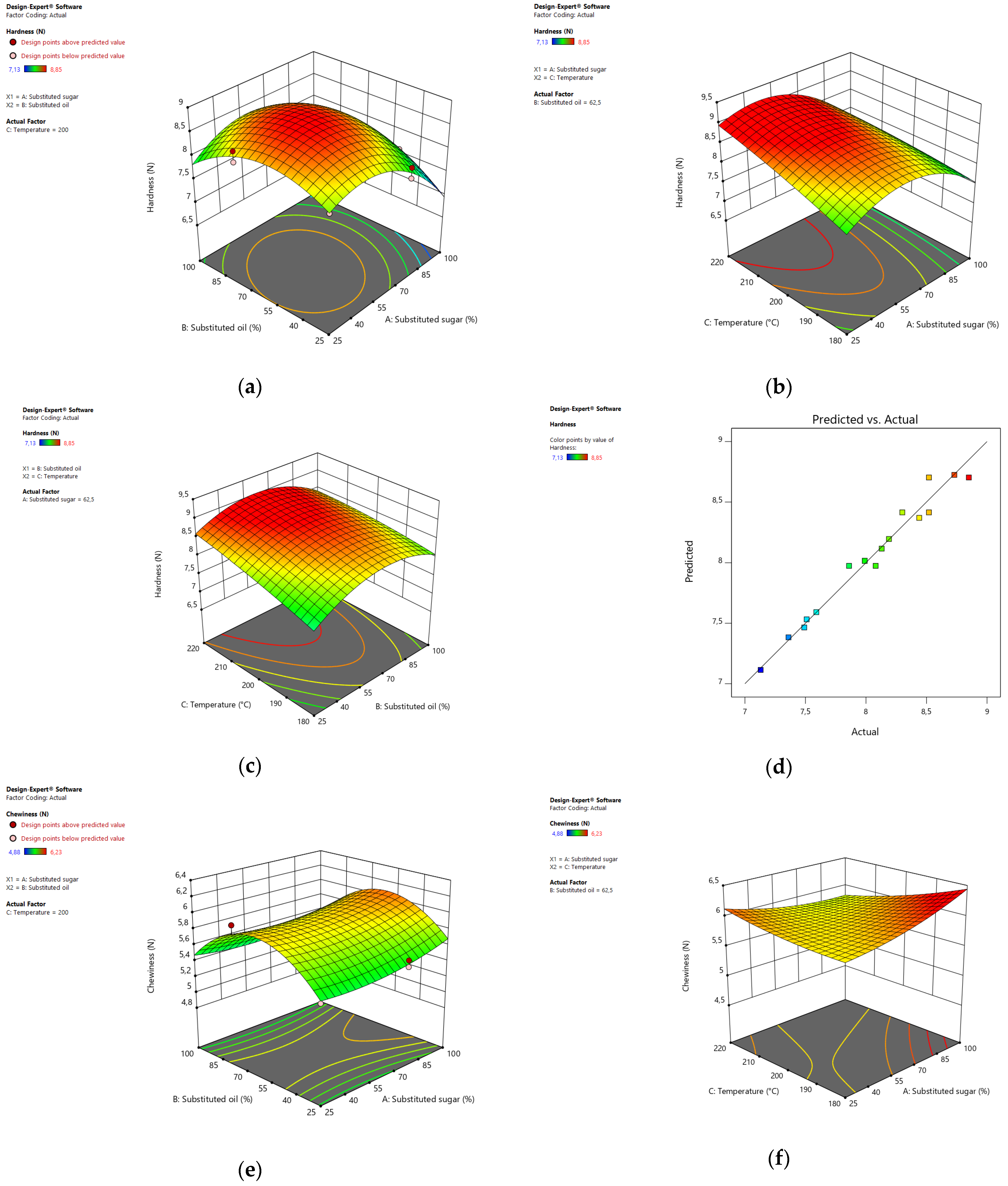

3.2. Determination of Muffin Texture

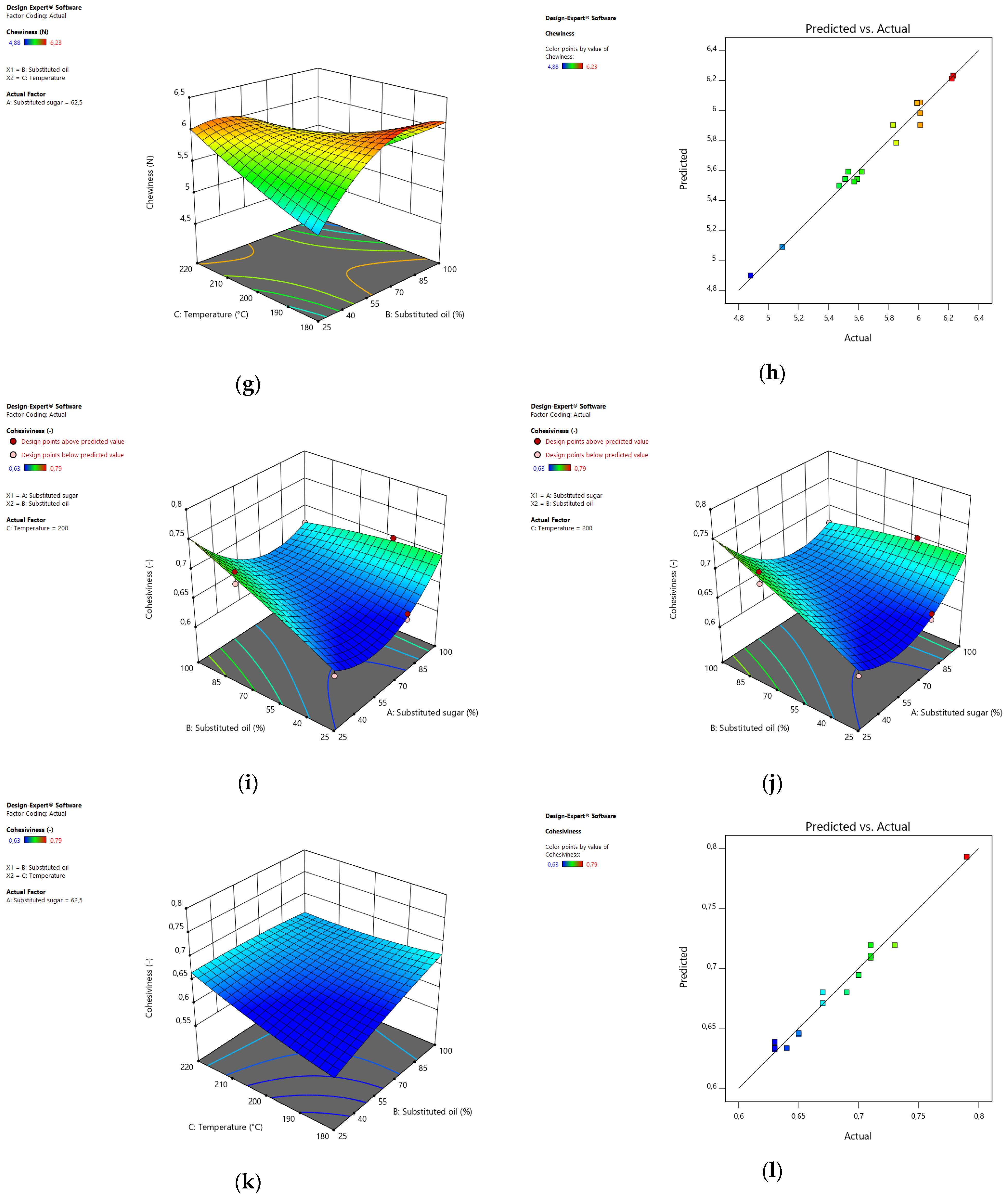

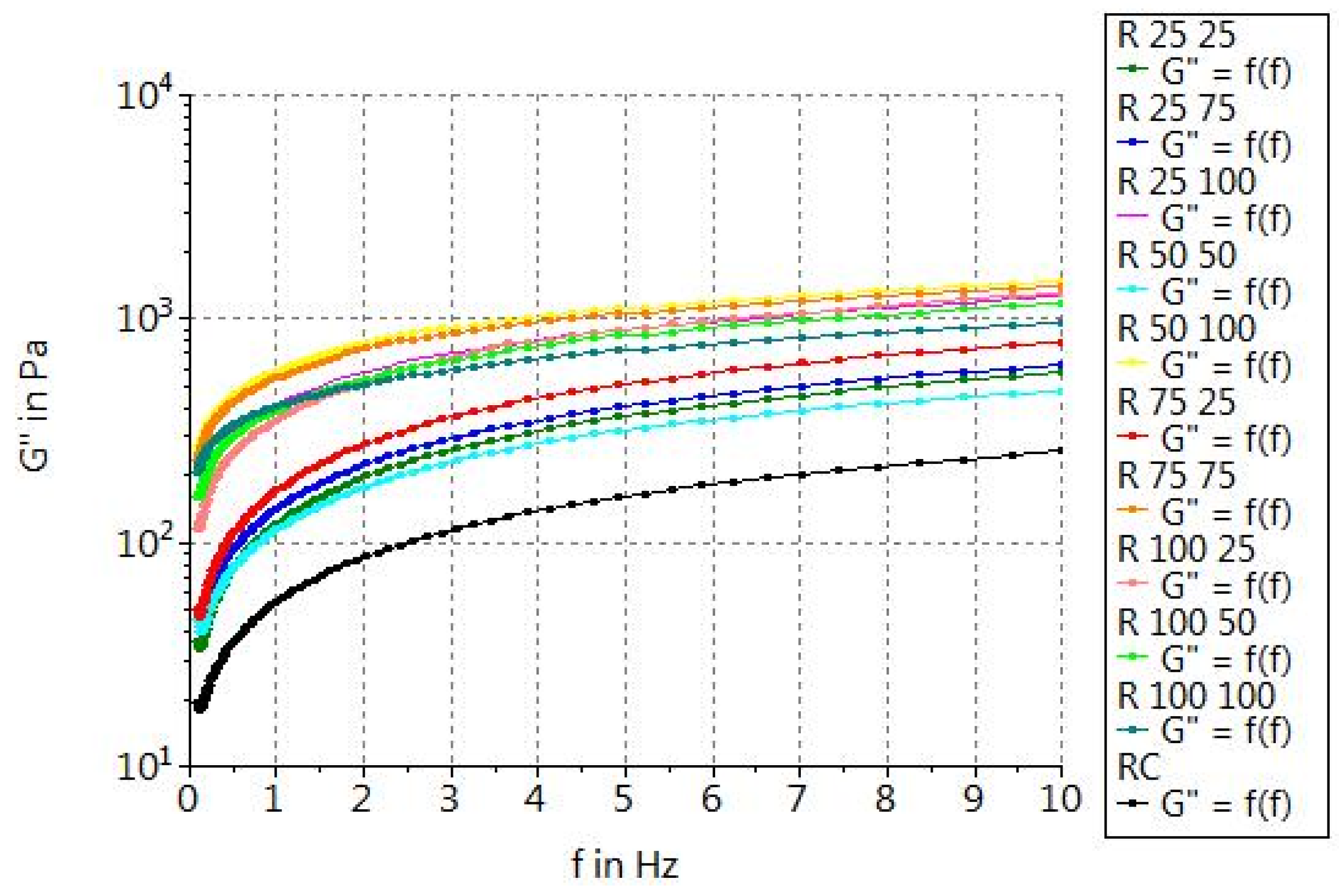

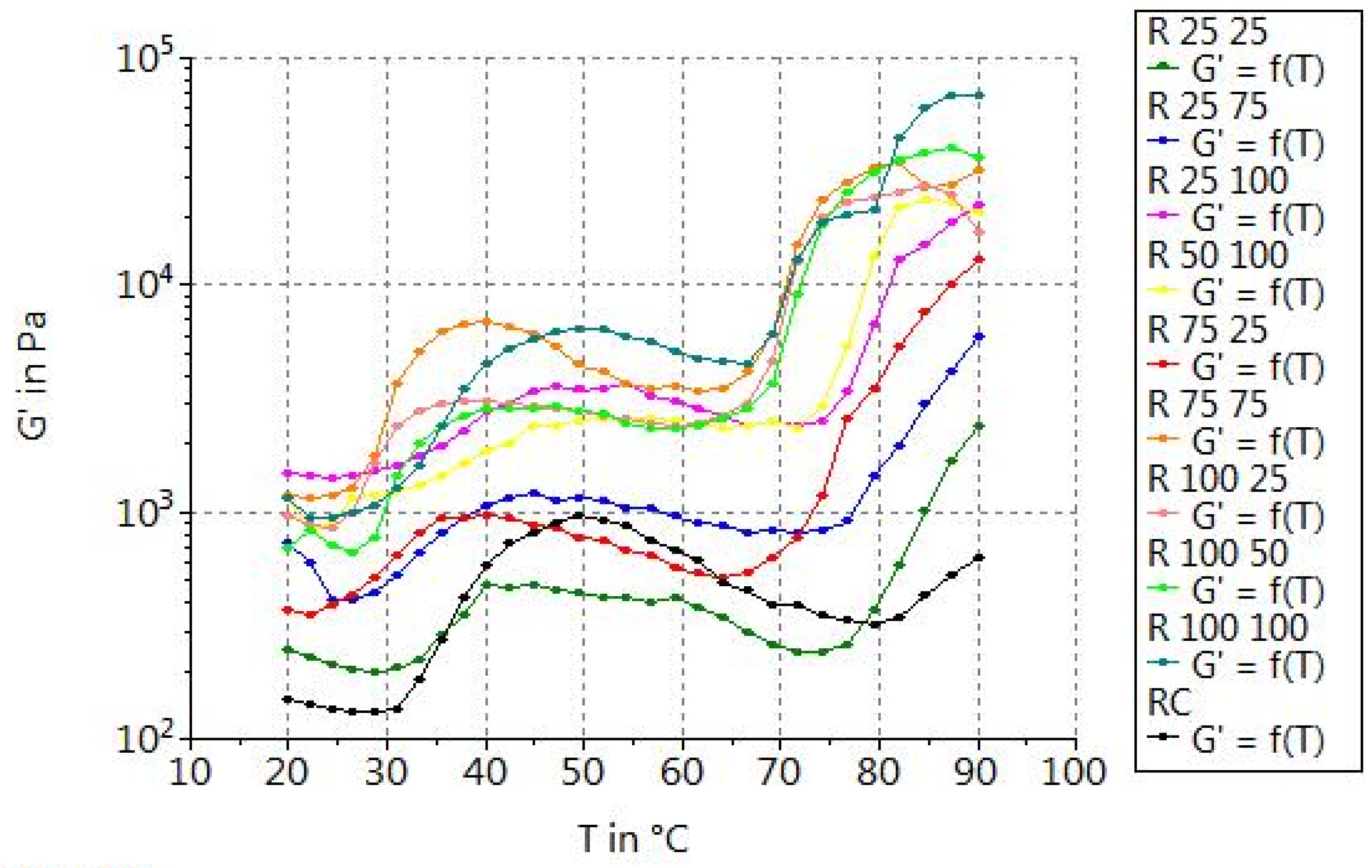

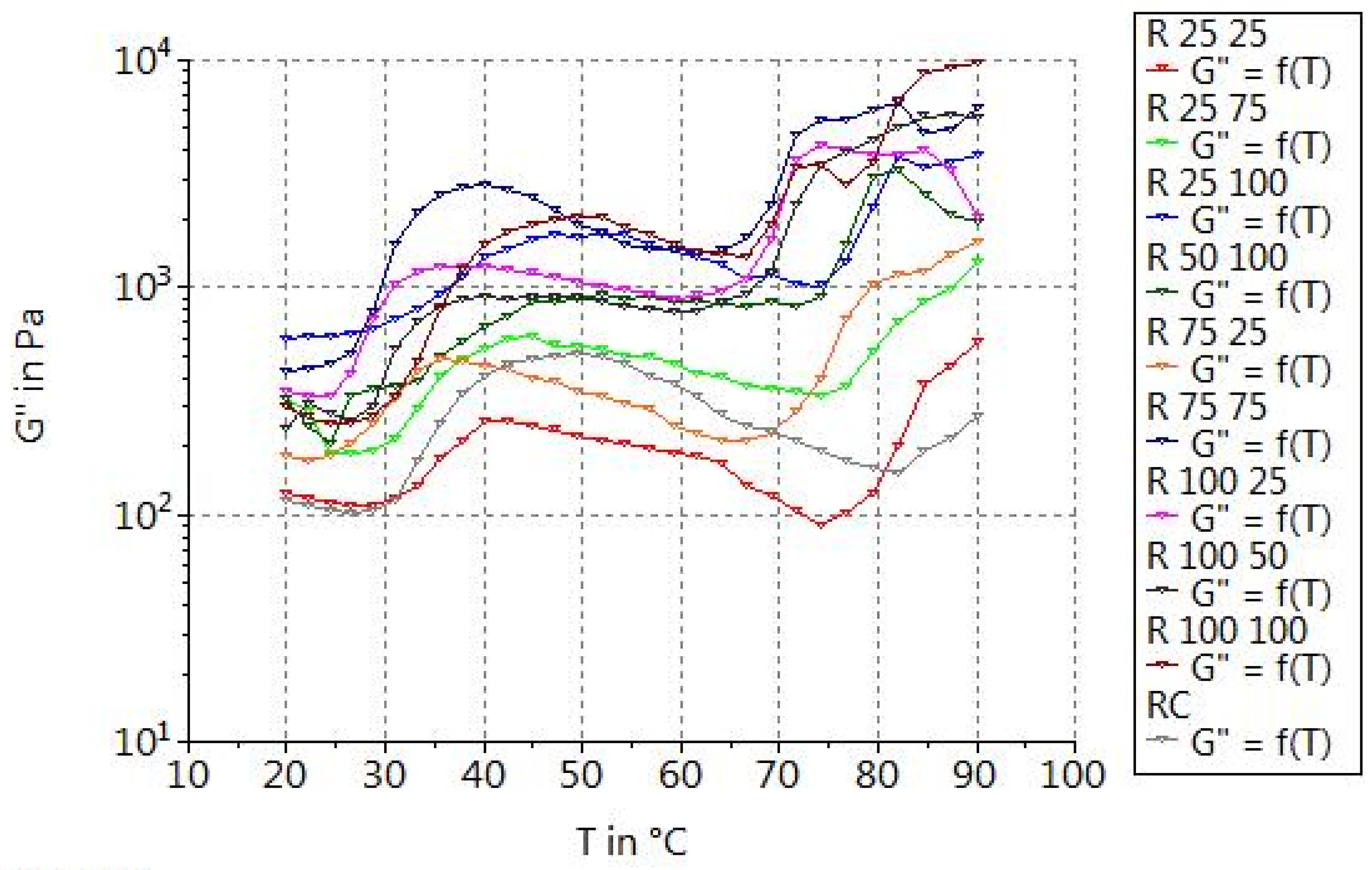

3.3. Study on the Effects of Replacing Sugar and Fat with Apple Puree on the Rheological Behavior of Muffin Dough

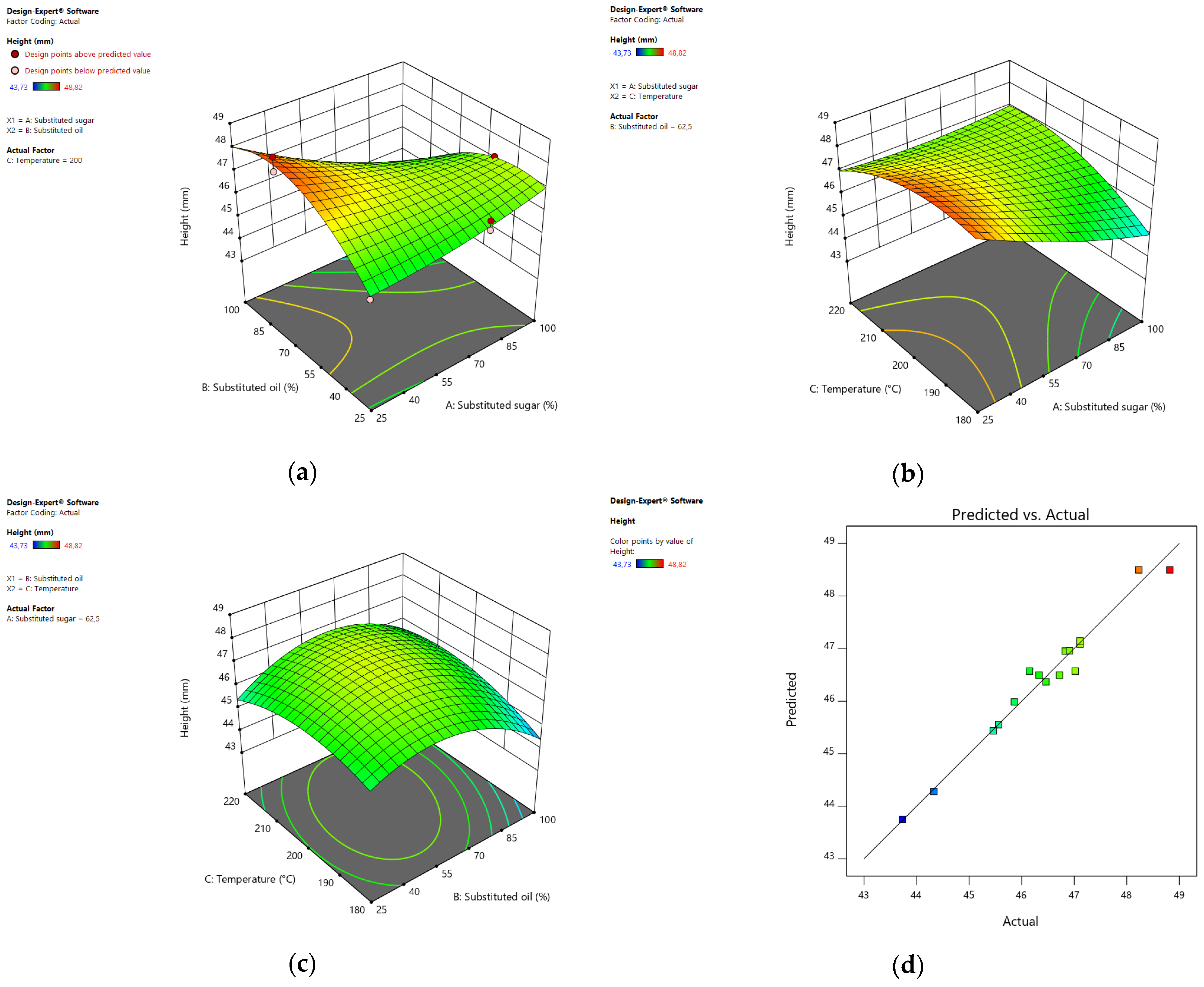

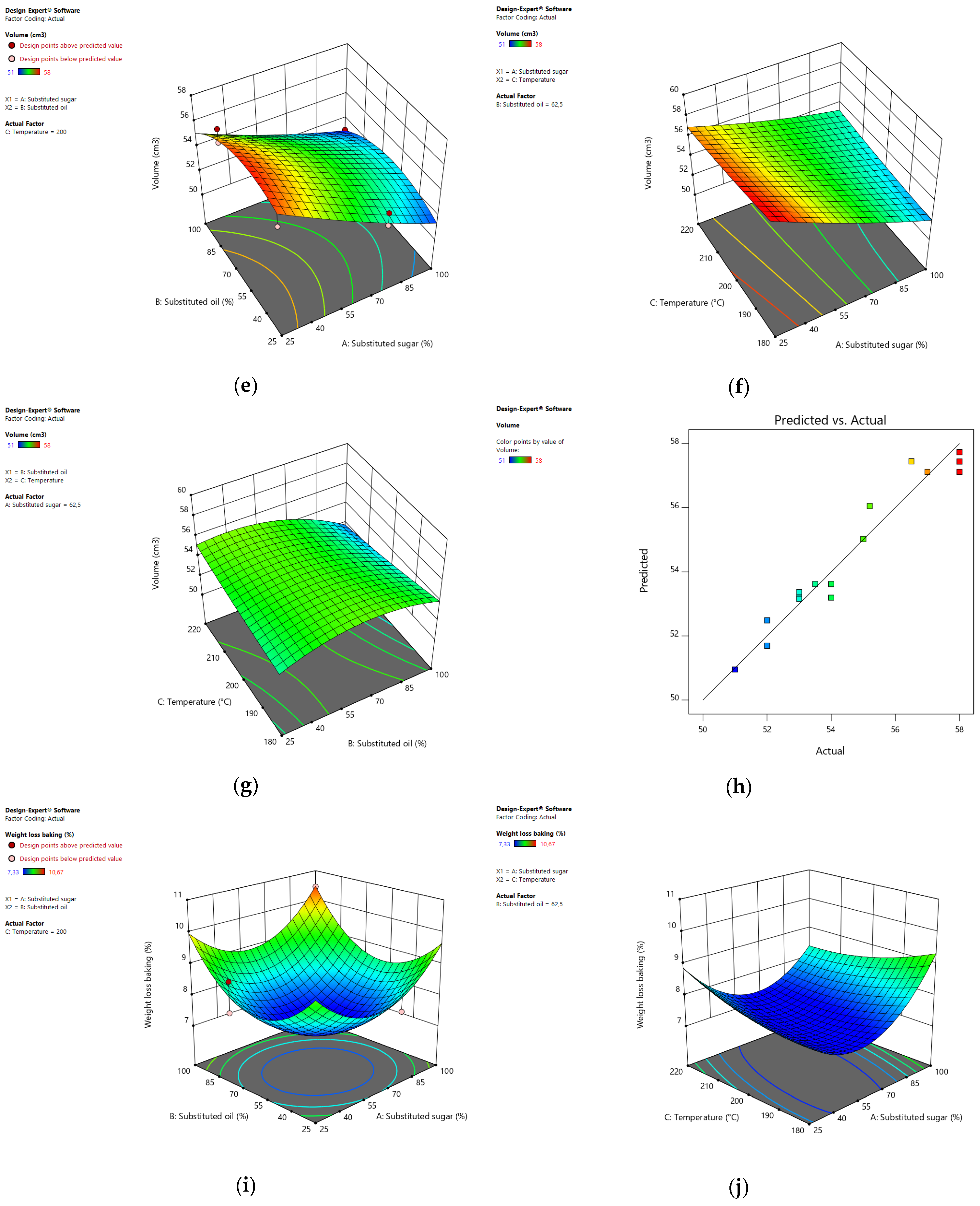

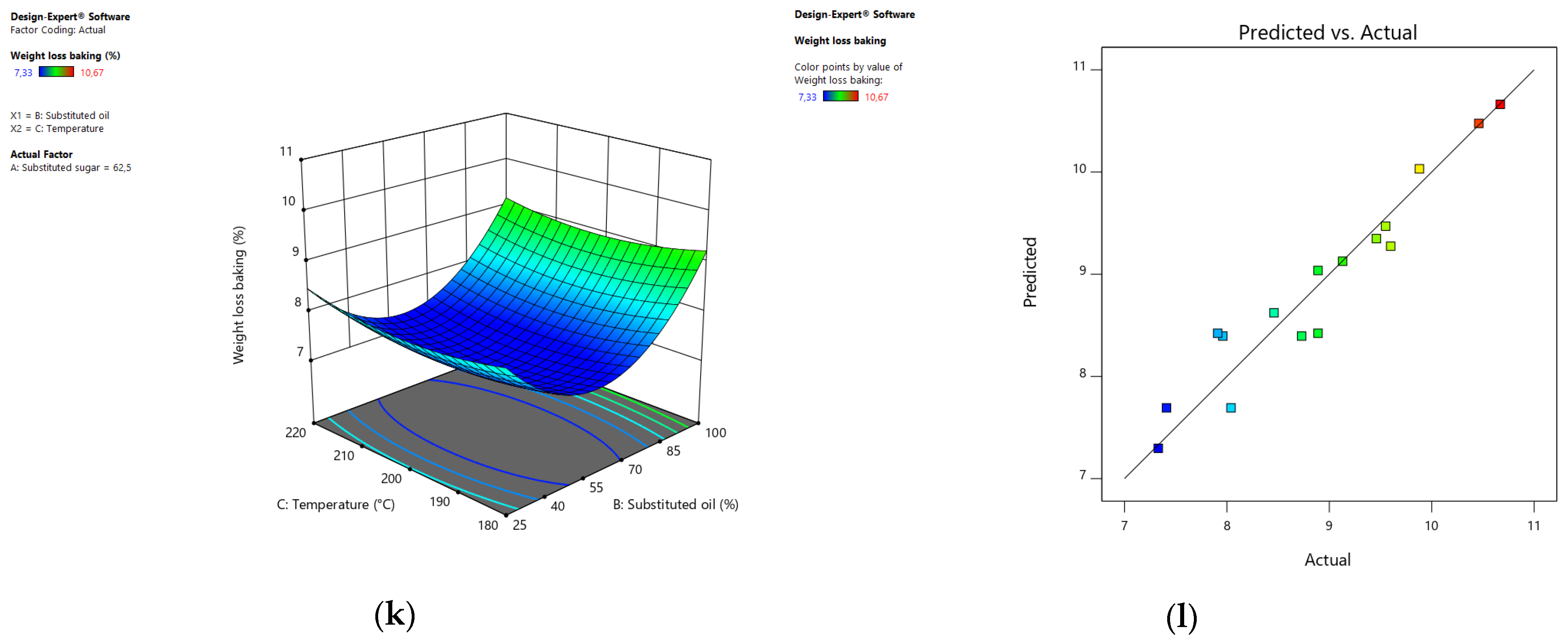

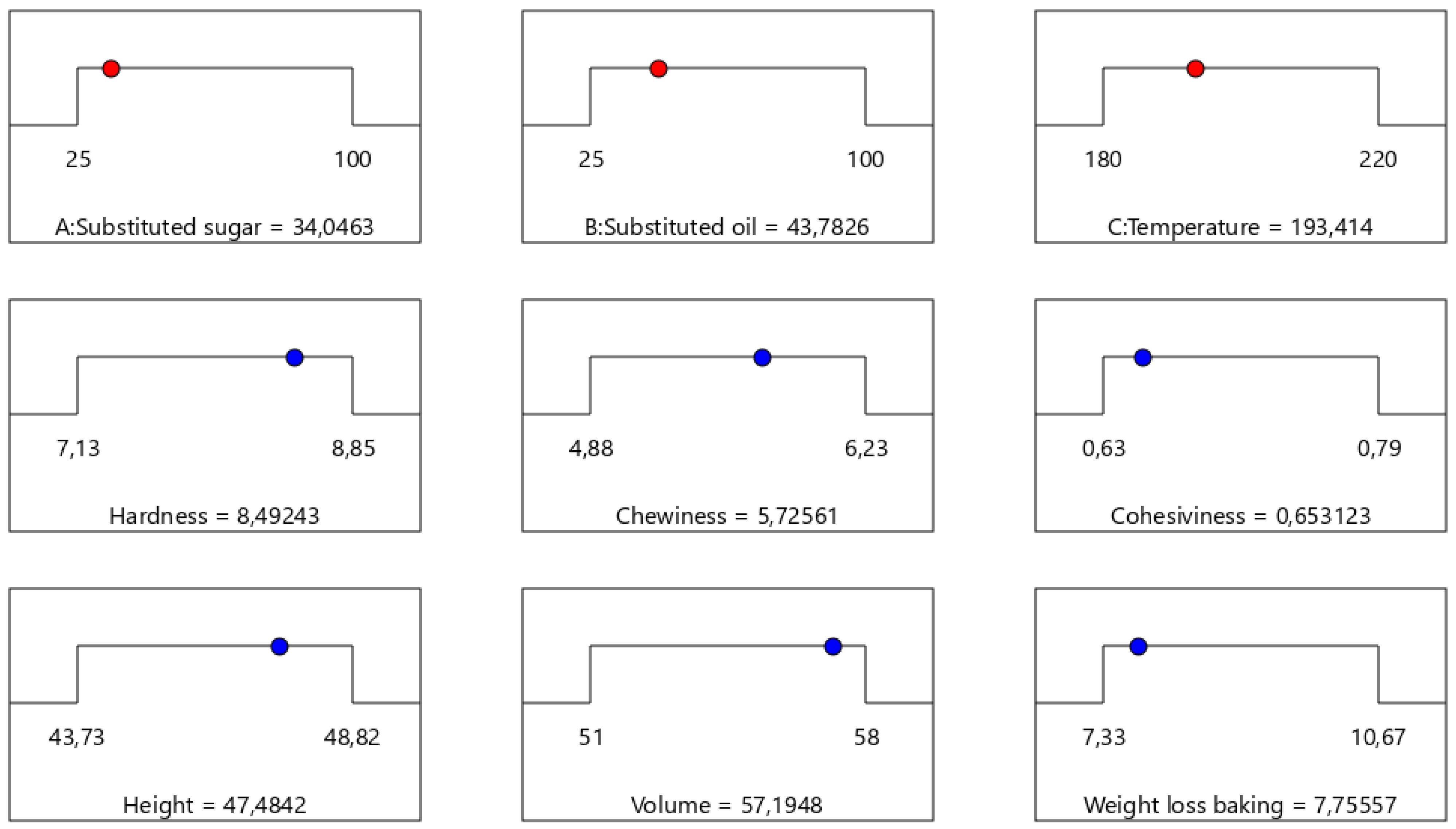

3.4. Optimization

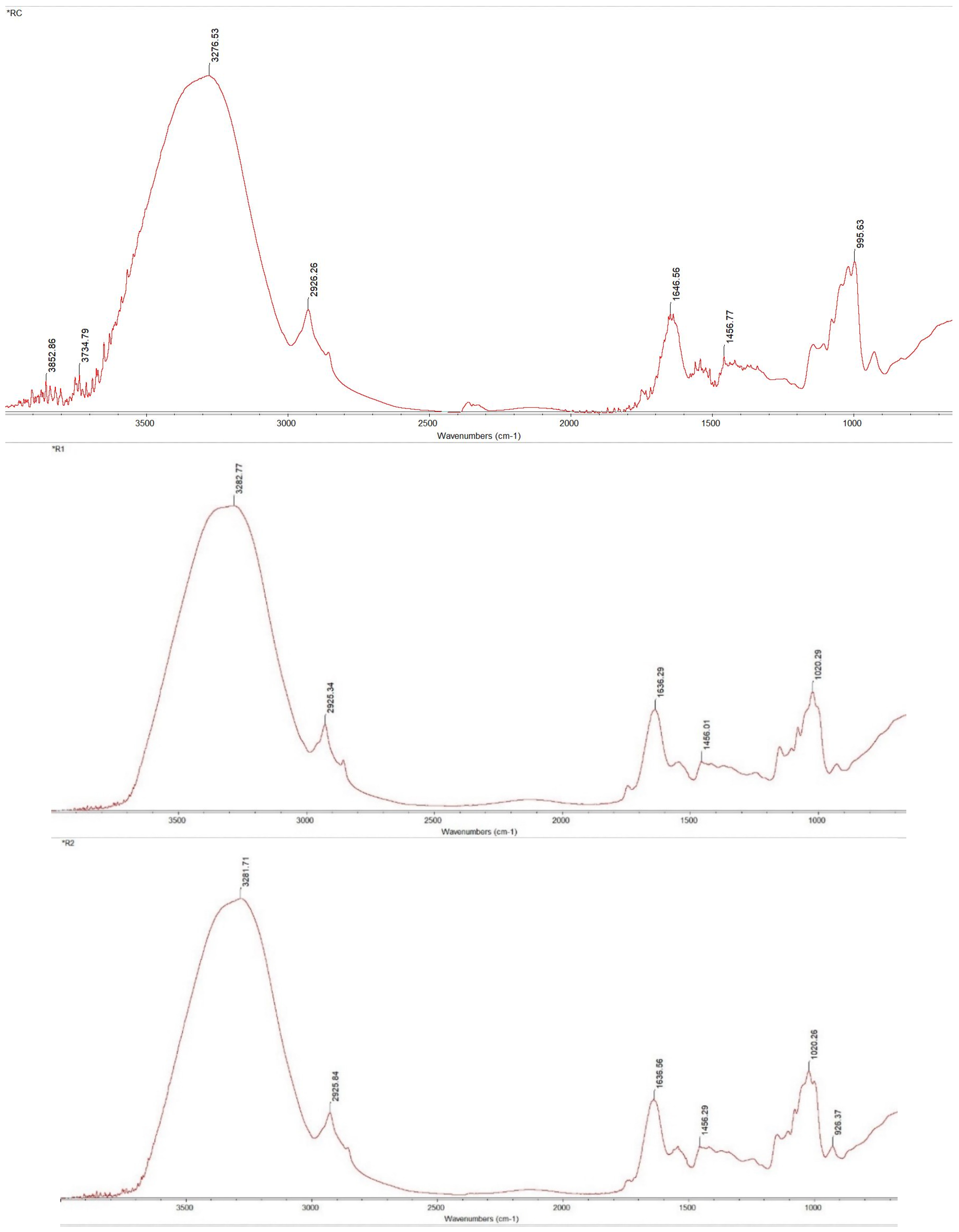

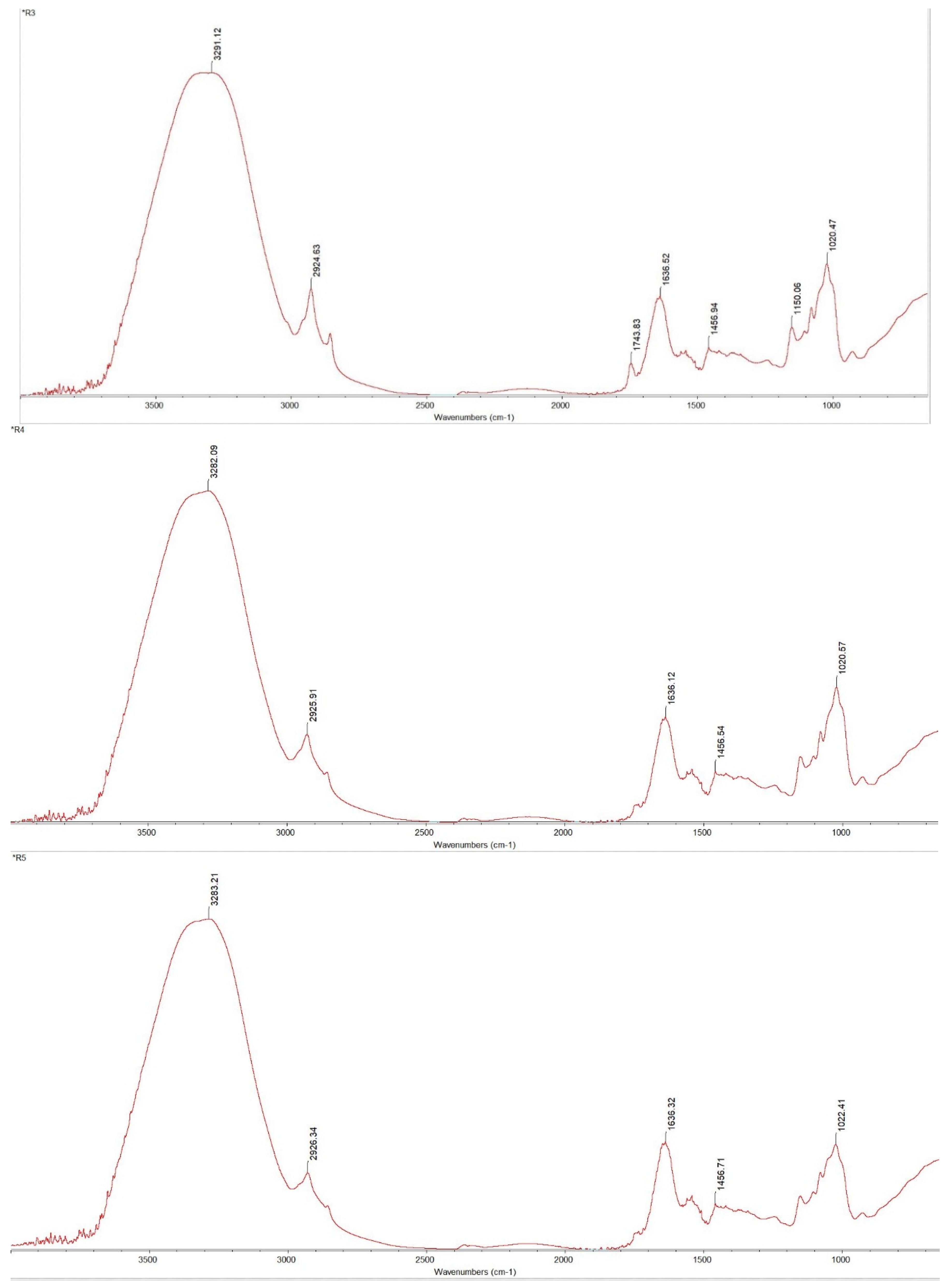

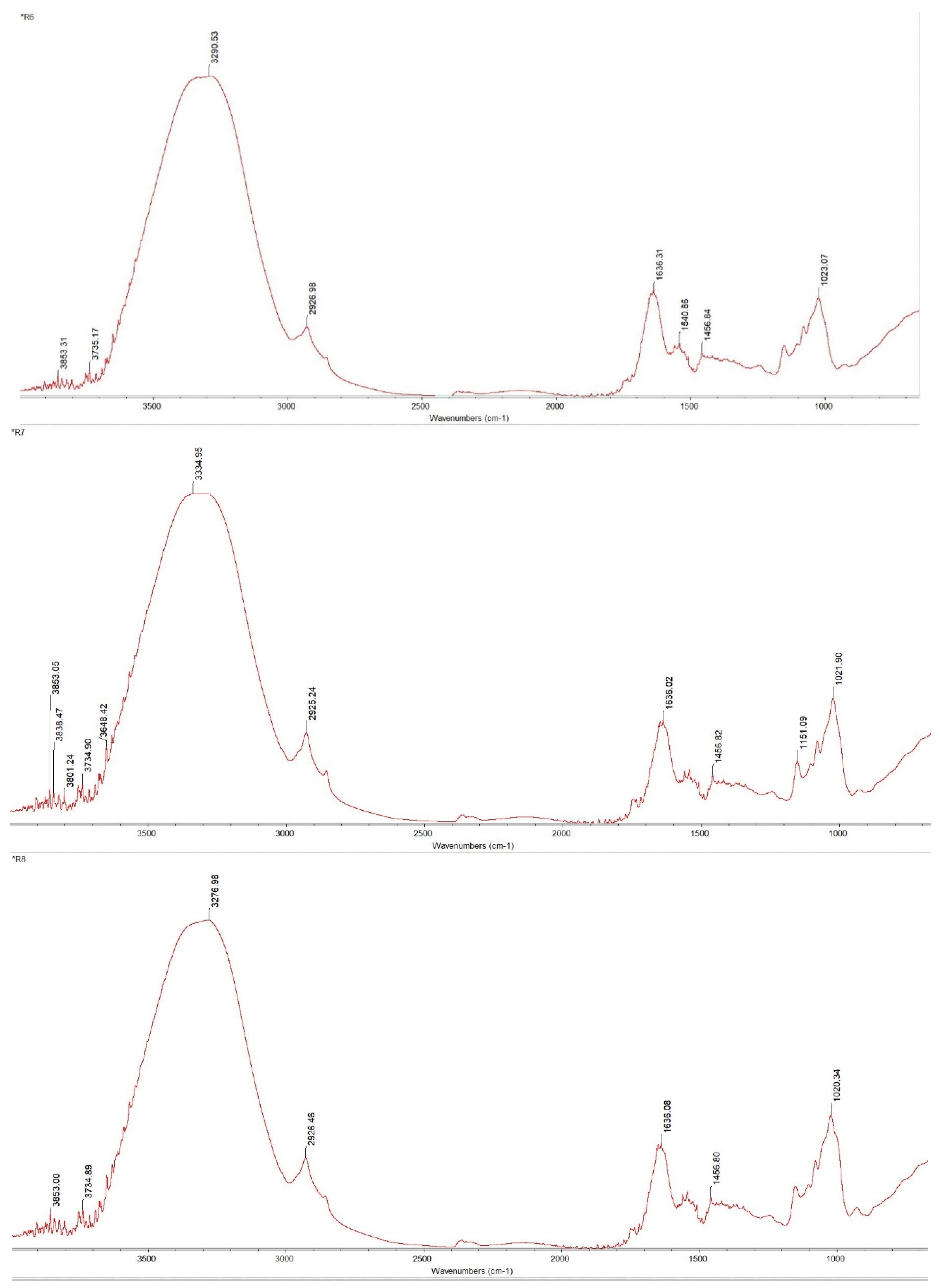

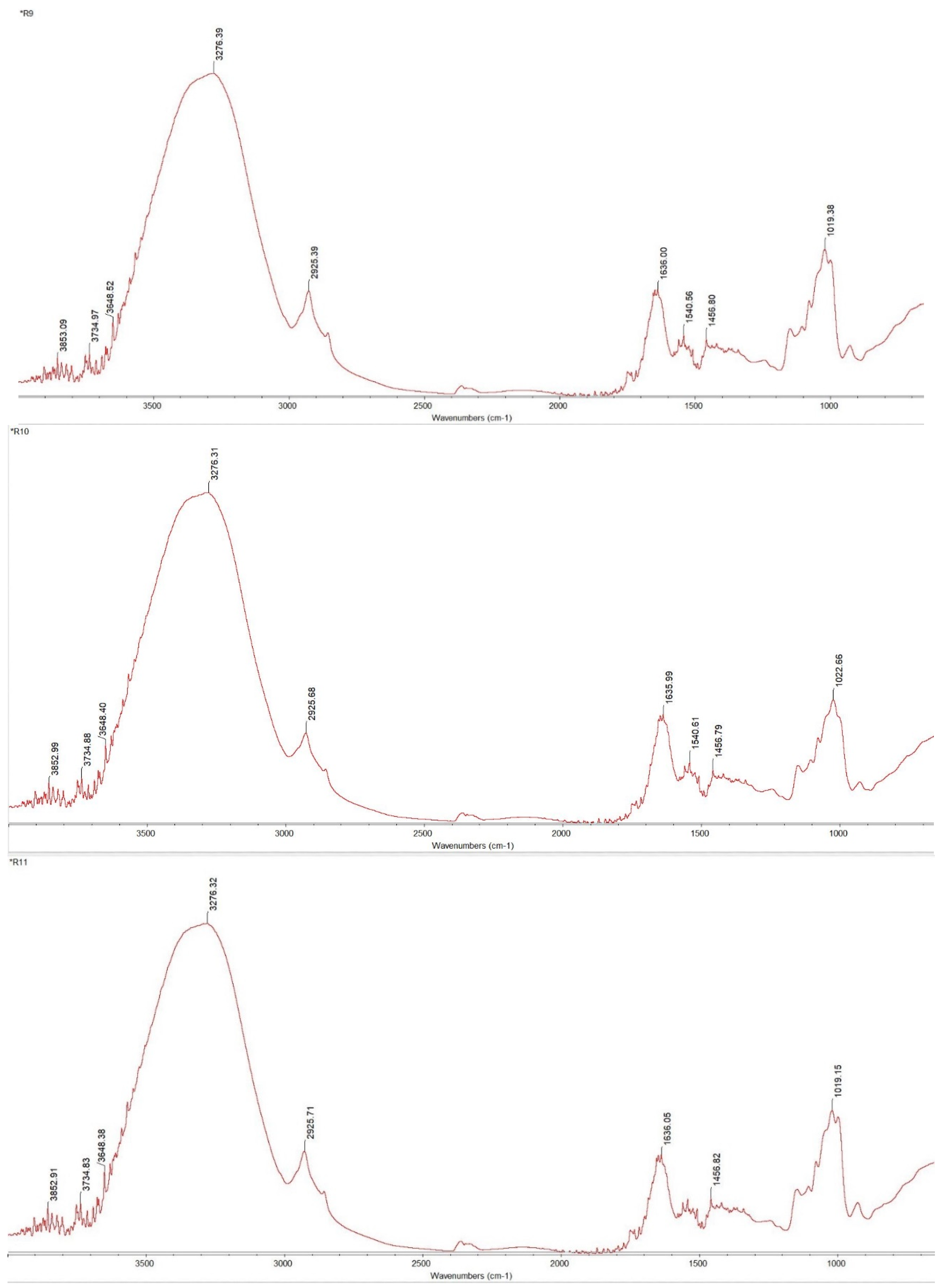

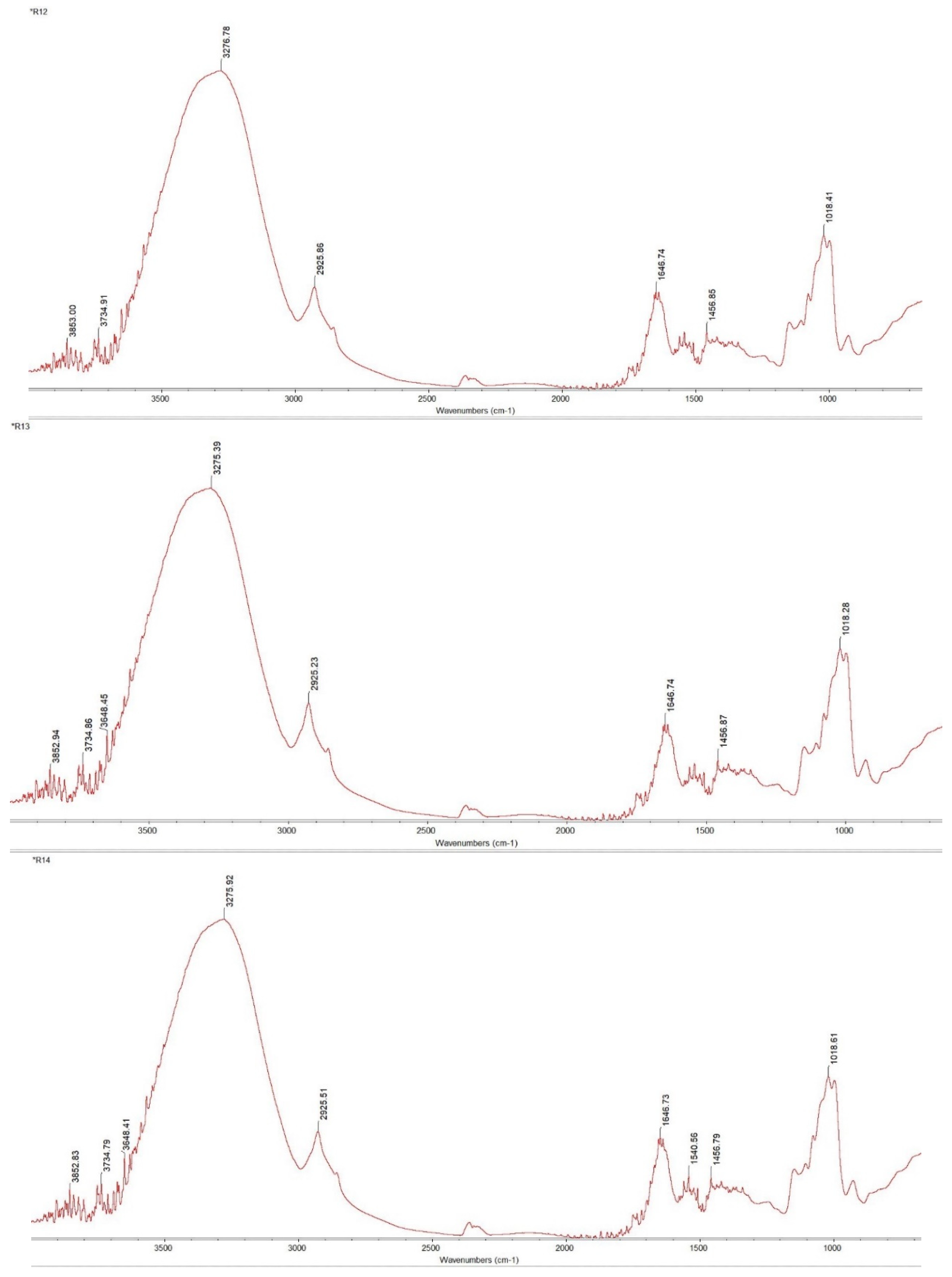

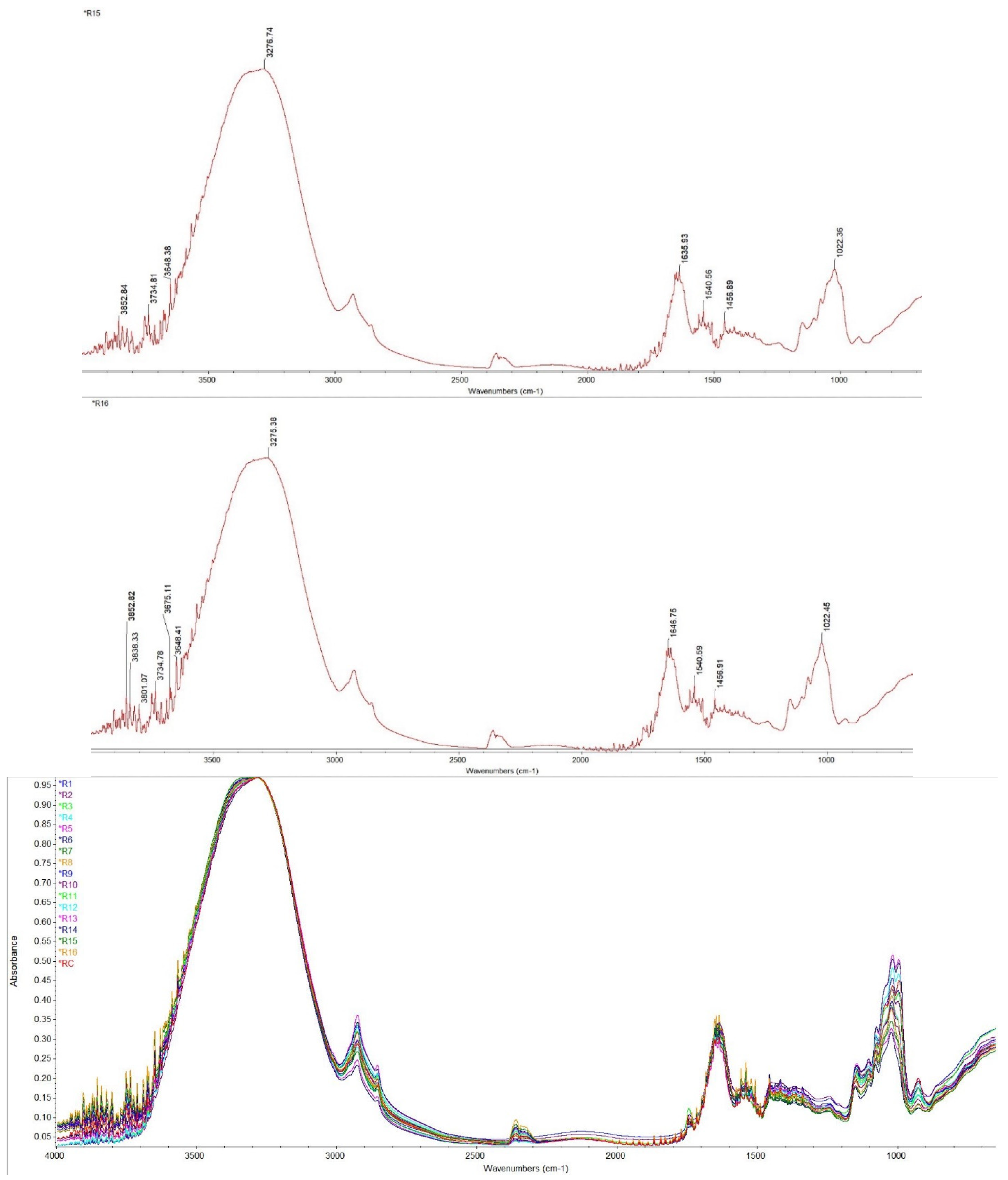

3.5. Analysis of Muffin Samples by Fourier Transform Infrared Spectroscopy (FTIR)

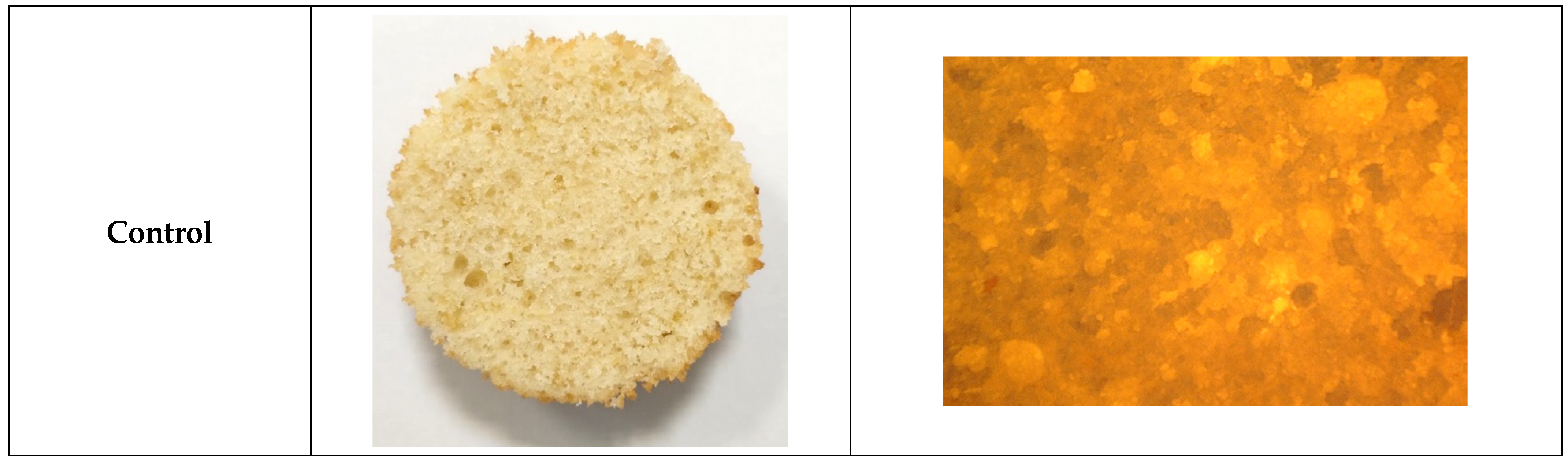

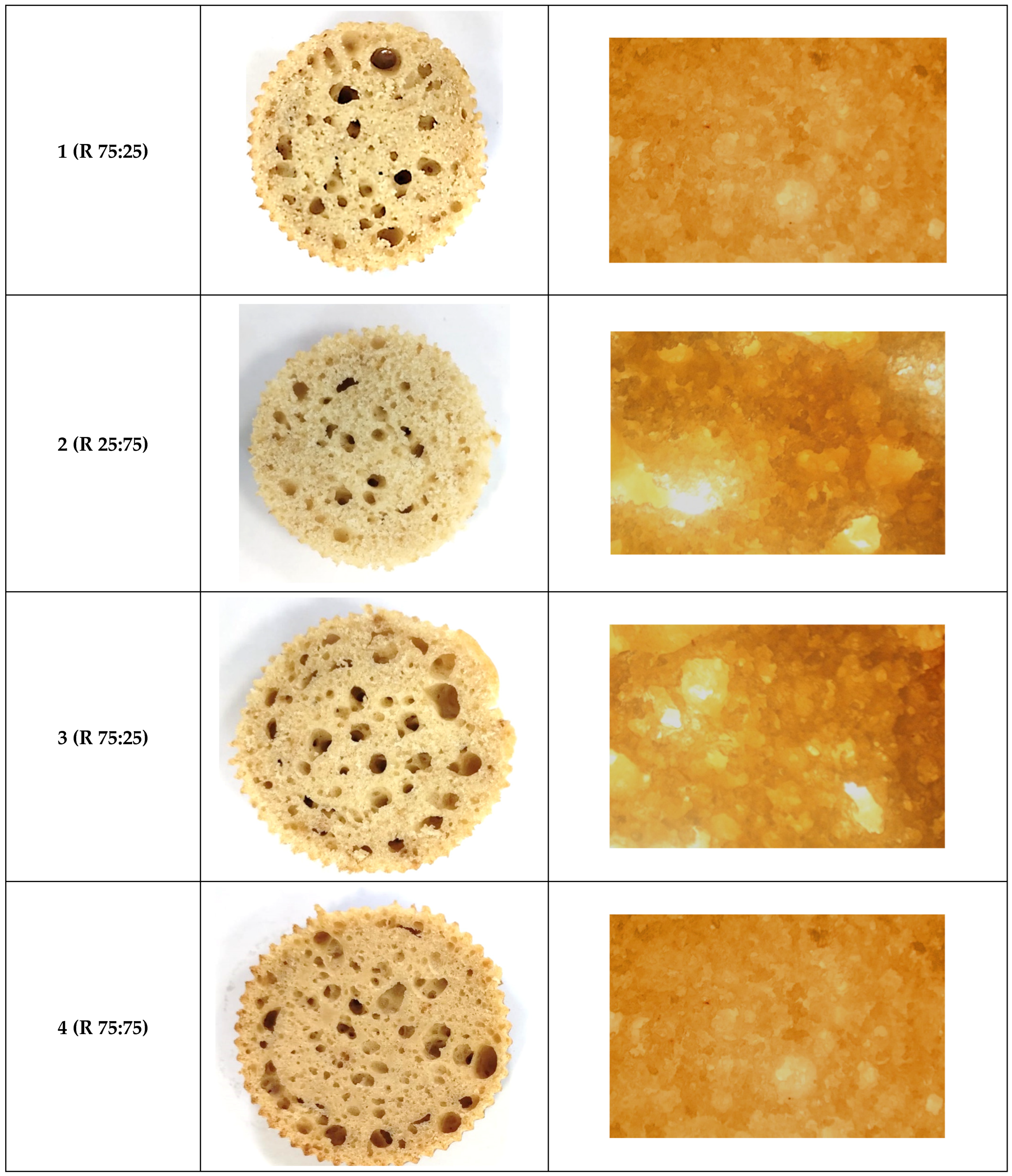

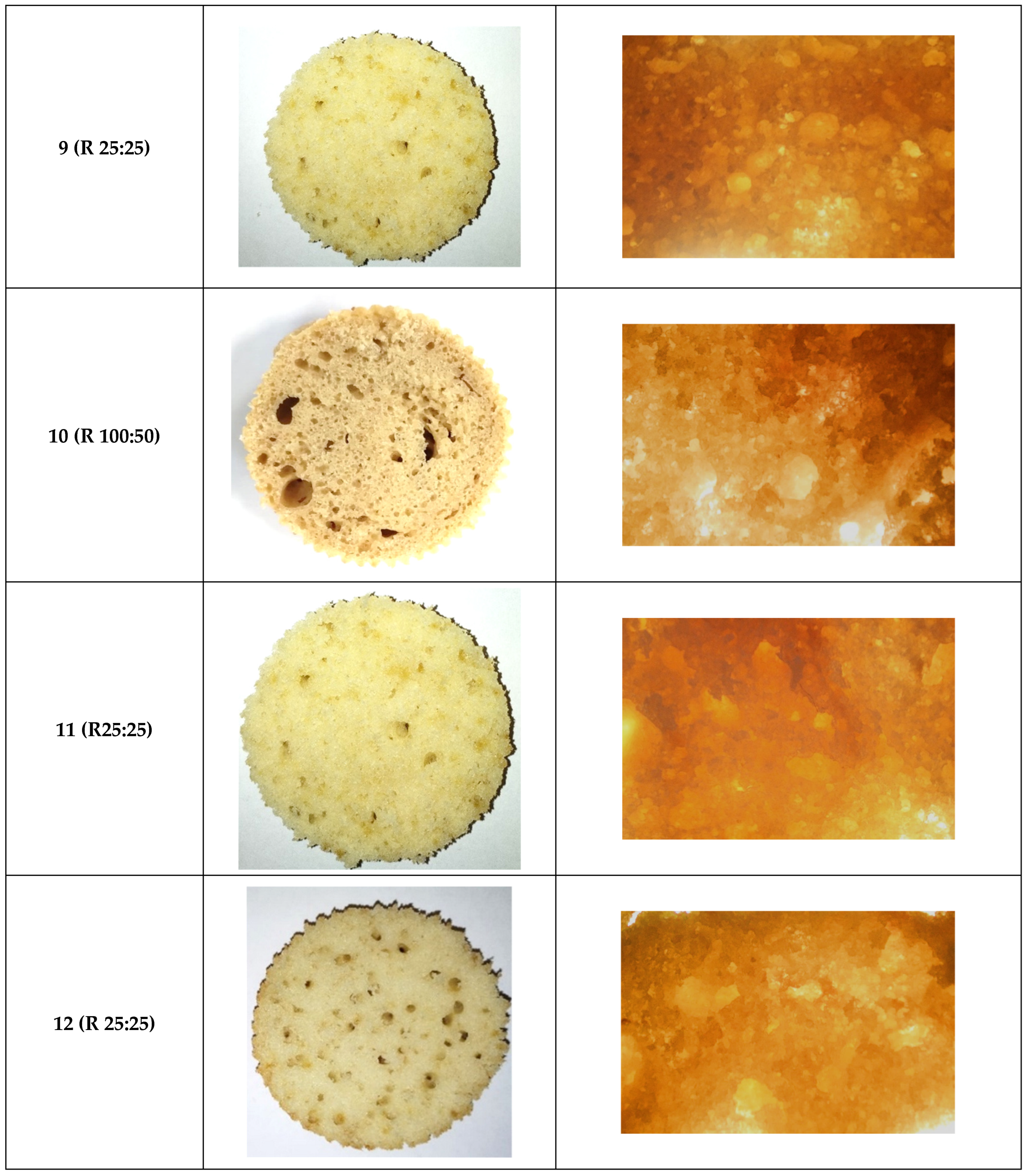

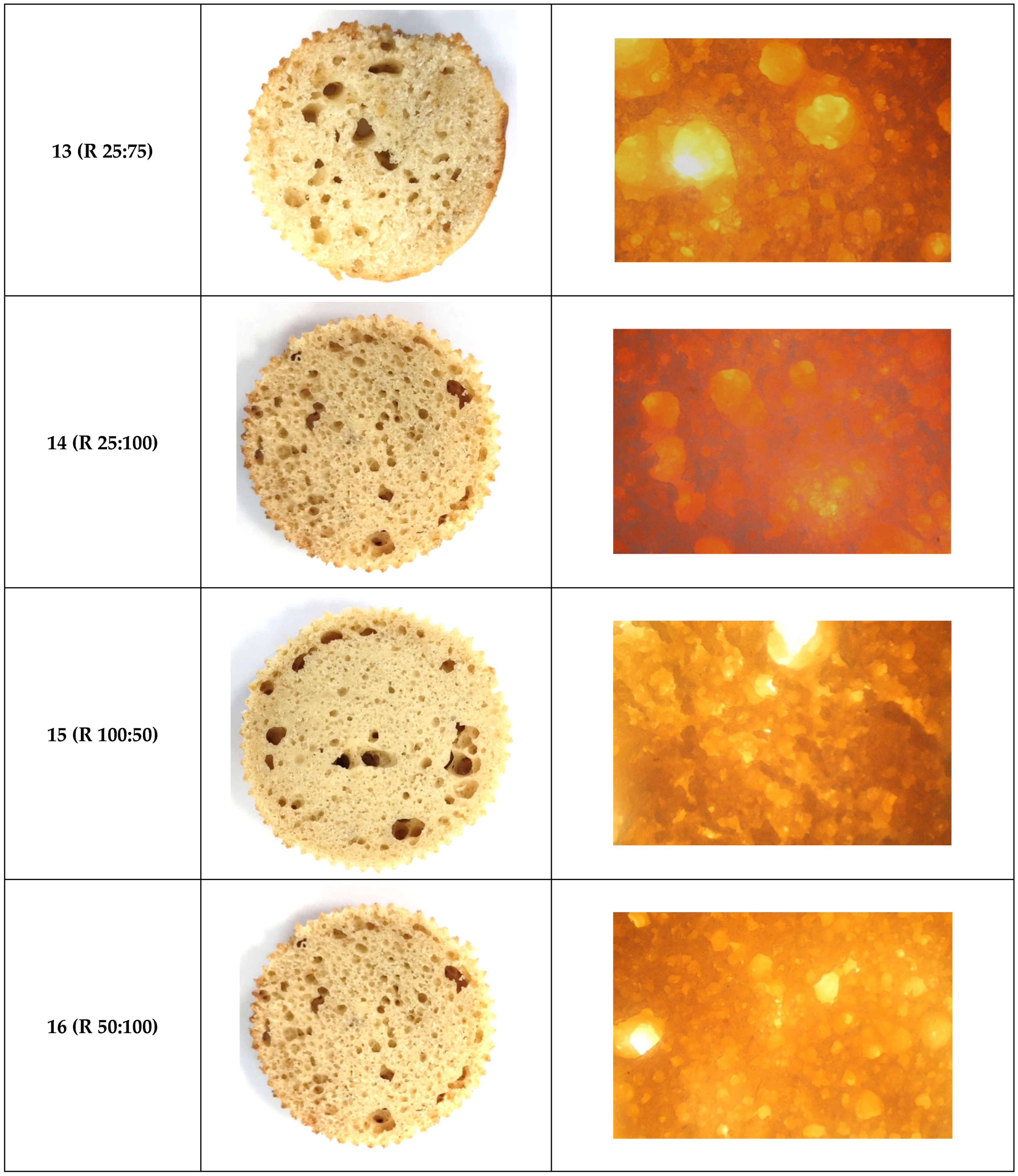

3.6. Muffin Crumb Microstructure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Estruch, R.; Vendrell, E.; Ruiz-León, A.M.; Casas, R.; Castro-Barquero, S.; Alvarez, X. Reformulation of Pastry Products to Improve Effects on Health. Nutrients 2020, 12, 1709. [Google Scholar] [CrossRef] [PubMed]

- Svitlana, K. Institute of Hospitality Management in Prague. 2012. Available online: https://is.ucp.cz/th/z0x8r/Company_Business_plan_lhkoidkw.pdf (accessed on 3 October 2024).

- Rios, R.V.; Pessanha, M.D.F.; de Almeida, P.F.; Viana, C.L.; Lannes, S.C. da S. Application of Fats in Some Food Products. Food Sci. Technol. 2014, 34, 3–15. [Google Scholar] [CrossRef]

- Mahmood, A.; Napi, N.N.M.; Mohamad, N.J. The Effect of Inulin Substitution as A Fat Replacer on Physicochemical and Sensory Properties of Muffins. Pertanika J. Trop. Agric. Sci. 2024, 47, 495–508. [Google Scholar] [CrossRef]

- Hussien, H.A. Using Vegetable Puree as a Fat Substitute in Cakes. Int. J. Nutr. Food Sci. 2016, 5, 284. [Google Scholar] [CrossRef]

- Colla, K.; Costanzo, A.; Gamlath, S. Fat Replacers in Baked Food Products. Foods 2018, 7, 192. [Google Scholar] [CrossRef]

- Kim, S.H.; Jo, Y.J.; Lee, S.H.; Park, S.H. Development of Oleogel-Based Fat Replacer and Its Application in Pan Bread Making. Foods 2024, 13, 1678. [Google Scholar] [CrossRef]

- Landis, W.; Altman, L. Efficacy of Fruit-Purees as Partial Fat-Replacements in a Chocolate Cake and Cookie Recipe. J. Nutr. Recipe Menu Dev. 1996, 2, 13–28. [Google Scholar] [CrossRef]

- Majzoobi, M.; Mohammadi, M.; Farahnaky, A. Simultaneous Reduction of Fat and Sugar in Cake Production; Effects of Changing Sucrose, Oil, Water, Inulin, and Rebaudioside A on Cake Batter Properties. J. Food Process. Preserv. 2020, 44, e14733. [Google Scholar] [CrossRef]

- Lim, J.; Ko, S.; Lee, S. Use of Yuja (Citrus Junos) Pectin as a Fat Replacer in Baked Foods. Food Sci. Biotechnol. 2014, 23, 1837–1841. [Google Scholar] [CrossRef]

- Rodríguez-García, J.; Puig, A.; Salvador, A.; Hernando, I. Optimization of a Sponge Cake Formulation with Inulin as Fat Replacer: Structure, Physicochemical, and Sensory Properties. J. Food Sci. 2012, 77, C189–C197. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Osama, K.; Gaur, V.K.; Farooqui, A.; Varjani, S.; Younis, K. Sustainable Utilization of Citrus Limetta Peel for Obtaining Pectin and Its Application in Cookies as a Fat Replacer. J. Food Sci. Technol. 2023, 60, 975–986. [Google Scholar] [CrossRef]

- Struck, S.; Gundel, L.; Zahn, S.; Rohm, H. Fiber Enriched Reduced Sugar Muffins Made from Iso-Viscous Batters. LWT Food Sci. Technol. 2016, 65, 32–38. [Google Scholar] [CrossRef]

- Rohm, H.; Brennan, C.; Turner, C.; Günther, E.; Campbell, G.; Hernando, I.; Struck, S.; Kontogiorgos, V. Adding Value to Fruit Processing Waste: Innovative Ways to Incorporate Fibers from Berry Pomace in Baked and Extruded Cereal-Based Foods—A Susfood Project. Foods 2015, 4, 690–697. [Google Scholar] [CrossRef]

- Park, W.-H.; Park, S.-B.; Cha, S.-H.; Han, I.-B.; Bak, S.-L.; Hyun, T.K.; Jang, K.-I. Quality and Antioxidant Characteristics of Apple Puree Containing Peel and Added Vitamin C. J. Korean Soc. Food Sci. Nutr. 2021, 50, 992–1000. [Google Scholar] [CrossRef]

- Dana, H.; Sonia, A. Physicochemical Properties of Apple Purees and Peel Extract for Potential Use in Pastry Products. Appl. Sci. 2024, 14, 2011. [Google Scholar] [CrossRef]

- Şirin, P. Physico-Chemical and Sensory Properties of Low Sugar Apple. Master’s Thesis, Izmir Institute of Technology, Urla, Turkey, 2019. [Google Scholar]

- Xu, X.; Zhang, H.; Li, L.; Sun, L.; Jia, B.; Yang, H.; Zuo, F. Preparation of Fat Substitute Based on the High-Methoxyl Pectin of Citrus and Application in Moon-Cake Skin. Food Sci. Technol. 2022, 42, e92121. [Google Scholar] [CrossRef]

- Syan, V.; Kaur, J.; Sharma, K.; Patni, M.; Rasane, P.; Singh, J.; Bhadariya, V. An Overview on the Types, Applications and Health Implications of Fat Replacers. J. Food Sci. Technol. 2024, 61, 27–38. [Google Scholar] [CrossRef] [PubMed]

- Chandel, V.; Biswas, D.; Roy, S.; Vaidya, D.; Verma, A.; Gupta, A. Current Advancements in Pectin: Extraction, Properties and Multifunctional Applications. Foods 2022, 11, 2683. [Google Scholar] [CrossRef] [PubMed]

- Qi, K.; Cao, S.; Li, C. Possible Interaction between Pectin and Gluten Alters the Starch Digestibility and Texture of Wheat Bread. Int. J. Biol. Macromol. 2024, 269, 131907. [Google Scholar] [CrossRef] [PubMed]

- Djordjević, M.; Šoronja-Simović, D.; Nikolić, I.; Djordjević, M.; Šereš, Z.; Milašinović-Šeremešić, M. Sugar Beet and Apple Fibres Coupled with Hydroxypropylmethylcellulose as Functional Ingredients in Gluten-Free Formulations: Rheological, Technological and Sensory Aspects. Food Chem. 2019, 295, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Cervera, S.; Salvador, A.; Sanz, T. Comparison of Different Polyols as Total Sucrose Replacers in Muffins: Thermal, Rheological, Texture and Acceptability Properties. Food Hydrocoll. 2014, 35, 1–8. [Google Scholar] [CrossRef]

- Santos, E.; Rosell, C.M.; Collar, C. Gelatinization and Retrogradation Kinetics of High-Fiber Wheat Flour Blends: A Calorimetric Approach. Cereal Chem. 2008, 85, 455–463. [Google Scholar] [CrossRef]

- Cui, Y.; Chen, J.; Zhang, S. The Effect of Degree of Esterification of Pectin on the Interaction between Pectin and Wheat Gluten Protein. Food Hydrocoll. 2023, 136, 108272. [Google Scholar] [CrossRef]

- Li, J.; Yadav, M.P.; Li, J. Effect of Different Hydrocolloids on Gluten Proteins, Starch and Dough Microstructure. J. Cereal Sci. 2019, 87, 85–90. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Zhao, J.; Mu, M.; Jia, F.; Wang, Q.; Liang, Y.; Wang, J. Aggregative and Structural Properties of Wheat Gluten Induced by Pectin. J. Cereal Sci. 2021, 100, 103247. [Google Scholar] [CrossRef]

- Correa, M.J.; Ferrer, E.; Añón, M.C.; Ferrero, C. Interaction of Modified Celluloses and Pectins with Gluten Proteins. Food Hydrocoll. 2014, 35, 91–99. [Google Scholar] [CrossRef]

- Chen, J.; Cui, Y.; Shi, W.; Ma, Y.; Zhang, S. The Interaction between Wheat Starch and Pectin with Different Esterification Degree and Its Influence on the Properties of Wheat Starch-Pectin Gel. Food Hydrocoll. 2023, 145, 2018–2021. [Google Scholar] [CrossRef]

- Ishwarya, S.P.; Nisha, P. Advances and Prospects in the Food Applications of Pectin Hydrogels. Crit. Rev. Food Sci. Nutr. 2021, 62, 4393–4417. [Google Scholar] [CrossRef] [PubMed]

- Mao, G.; Wu, D.; Wei, C.; Tao, W.; Ye, X.; Linhardt, R.J.; Orfila, C.; Chen, S. Reconsidering Conventional and Innovative Methods for Pectin Extraction from Fruit and Vegetable Waste: Targeting Rhamnogalacturonan I. Trends Food Sci. Technol. 2019, 94, 65–78. [Google Scholar] [CrossRef]

- Freitas de Oliveira, C.; Giordani, D.; Lutckemier, R.; Gurak, P.D.; Cladera-Olivera, F.; Ferreira Marczak, L.D. Extraction of Pectin from Passion Fruit Peel Assisted by Ultrasound. Lwt 2016, 71, 110–115. [Google Scholar] [CrossRef]

- Luisa Franchi, M. Evaluation of Enzymatic Pectin Extraction by a Recombinant Polygalacturonase (PGI) From Apples and Pears Pomace of Argentinean Production and Characterization of the Extracted Pectin. J. Food Process. Technol. 2014, 5, 1–4. [Google Scholar] [CrossRef]

- Baixauli, R.; Salvador, A.; Fiszman, S.M. Textural and Colour Changes during Storage and Sensory Shelf Life of Muffins Containing Resistant Starch. Eur. Food Res. Technol. 2008, 226, 523–530. [Google Scholar] [CrossRef]

- Harastani, R.; James, L.J.; Ghosh, S.; Rosenthal, A.J.; Woolley, E. Reformulation of Muffins Using Inulin and Green Banana Flour: Physical, Sensory, Nutritional and Shelf-Life Properties. Foods 2021, 10, 1883. [Google Scholar] [CrossRef]

- Majzoobi, M.; Mohammadi, M.; Mesbahi, G.; Farahnaky, A. Feasibility Study of Sucrose and Fat Replacement Using Inulin and Rebaudioside A in Cake Formulations. J. Texture Stud. 2018, 49, 468–475. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Cervera, S.; de la Hera, E.; Sanz, T.; Gómez, M.; Salvador, A. Effect of Using Erythritol as a Sucrose Replacer in Making Spanish Muffins Incorporating Xanthan Gum. Food Bioprocess Technol. 2012, 5, 3203–3216. [Google Scholar] [CrossRef]

- Kupiec, M.; Szymanska, I.; Osytek, K.; Zbikowska, A.; Kowalska, M.; Marciniak-lukasiak, K.; Rutkowska, J. Microbial β -Glucan Incorporated into Mu Ffi Ns: Impact on Quality of the Batter and Baked Products. Agriculture 2020, 10, 126. [Google Scholar]

- Bianchi, F.; Cervini, M.; Giuberti, G.; Simonato, B.; Rocchetti, G.; Lucini, L. Distilled Grape Pomace as a Functional Ingredient in Vegan Muffins: Effect on Physicochemical, Nutritional, Rheological and Sensory Aspects. Int. J. Food Sci. Technol. 2022, 57, 4847–4858. [Google Scholar] [CrossRef]

- Ren, Y.; Yookyung, K.S. Physicochemical and Retrogradation Properties of Low-Fat Muffins with Inulin and Hydroxypropyl Methylcellulose as Fat Replacers. J. Food Process. Preserv. 2020, 44, e14816. [Google Scholar] [CrossRef]

- Fiszman, S.M. Evaluation of Four Types of Resistant Starch in Muffins. II. Effects in Texture, Colour and Consumer Response; Springer: Berlin/Heidelberg, Germany, 2009; pp. 197–204. [Google Scholar] [CrossRef]

- Gao, J.; Guo, X.; Brennan, M.A.; Mason, S.L.; Zeng, X.A.; Brennan, C.S. The Potential of Modulating the Reducing Sugar Released (and the Potential Glycemic Response) of Muffins Using a Combination of a Stevia Sweetener and Cocoa Powder. Foods 2019, 8, 644. [Google Scholar] [CrossRef]

- Grasso, S.; Liu, S.; Methven, L. Quality of Muffins Enriched with Upcycled Defatted Sunflower Seed Flour. Lwt 2020, 119, 108893. [Google Scholar] [CrossRef]

- Belorio, M.; Sahagún, M.; Gómez, M. Psyllium as a Fat Replacer in Layer Cakes: Batter Characteristics and Cake Quality. Food Bioprocess Technol. 2019, 12, 2085–2092. [Google Scholar] [CrossRef]

- Bakare, A.H.; Osundahunsi, O.F.; Olusanya, J.O. Rheological, Baking, and Sensory Properties of Composite Bread Dough with Breadfruit (Artocarpus Communis Forst) and Wheat Flours. Food Sci. Nutr. 2016, 4, 573–587. [Google Scholar] [CrossRef] [PubMed]

- Nieto-Mazzocco, E.; Saldaña-Robles, A.; Franco-Robles, E.; Mireles-Arriaga, A.I.; Mares-Mares, E.; Ozuna, C. Optimization of Gluten-Free Muffin Formulation with Agavin-Type Fructans as Fat and Sucrose Replacer Using Response Surface Methodology. Futur. Foods 2022, 5, 100112. [Google Scholar] [CrossRef]

- Kurek, M.A.; Moczkowska-Wyrwisz, M.; Wyrwisz, J.; Karp, S. Development of Gluten-Free Muffins with β-Glucan and Pomegranate Powder Using Response Surface Methodology. Foods 2021, 10, 2551. [Google Scholar] [CrossRef]

- Marak, S.; Kaushik, N.; Dikiy, A.; Shumilina, E.; Falch, E. Nutritionally Enriched Muffins from Roselle Calyx Extract Using Response Surface Methodology. Foods 2022, 11, 3982. [Google Scholar] [CrossRef]

- Ahsan, M.; Ashraf, H.; Iahtisham-Ul-Haq; Liaquat, A.; Nayik, G.A.; Ramniwas, S.; Alfarraj, S.; Ansari, M.J.; Gere, A. Exploring Pectin from Ripe and Unripe Banana Peel: A Novel Functional Fat Replacers in Muffins. Food Chem. X 2024, 23, 101539. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.Z.; Hu, X.F.; Jia, Y.J.; Pan, L.H.; Zheng, Z.; Zhao, Y.Y.; Mu, D.D.; Zhong, X.Y.; Jiang, S.T. Camellia Oil-Based Oleogels Structuring with Tea Polyphenol-Palmitate Particles and Citrus Pectin by Emulsion-Templated Method: Preparation, Characterization and Potential Application. Food Hydrocoll. 2019, 95, 76–87. [Google Scholar] [CrossRef]

- Psimouli, V.; Oreopoulou, V. The Effect of Fat Replacers on Batter and Cake Properties. J. Food Sci. 2013, 78, 1495–1502. [Google Scholar] [CrossRef]

- Arifin, N.; Siti Nur Izyan, M.A.; Huda-Faujan, N. Physical Properties and Consumer Acceptability of Basic Muffin Made from Pumpkin Puree as Butter Replacer. Food Res. 2019, 3, 840–845. [Google Scholar] [CrossRef]

- Eslava-Zomeño, C.; Quiles, A.; Hernando, I. Designing a Clean Label Sponge Cake with Reduced Fat Content. J. Food Sci. 2016, 81, C2352–C2359. [Google Scholar] [CrossRef] [PubMed]

- Zahn, S.; Pepke, F.; Rohm, H. Effect of Inulin as a Fat Replacer on Texture and Sensory Properties of Muffins. Int. J. Food Sci. Technol. 2010, 45, 2531–2537. [Google Scholar] [CrossRef]

- 53Bala, M.; Arun Kumar, T.V.; Tushir, S.; Nanda, S.K.; Gupta, R.K. Quality Protein Maize Based Muffins: Influence of Non-Gluten Proteins on Batter and Muffin Characteristics. J. Food Sci. Technol. 2019, 56, 713–723. [Google Scholar] [CrossRef]

- Aydogdu, A.; Sumnu, G.; Sahin, S. Effects of Addition of Different Fibers on Rheological Characteristics of Cake Batter and Quality of Cakes. J. Food Sci. Technol. 2018, 55, 667–677. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.P.; Kaur, A.; Singh, N. Development of Eggless Gluten-Free Rice Muffins Utilizing Black Carrot Dietary Fibre Concentrate and Xanthan Gum. J. Food Sci. Technol. 2016, 53, 1269–1278. [Google Scholar] [CrossRef]

- GÓmez, M.; Ruiz-ParÍs, E.; Oliete, B.; Pando, V. Modeling of Texture Evolution of Cakes during Storage. J. Texture Stud. 2010, 41, 17–33. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; Sanz, T.; Salvador, A.; Fiszman, S.M. Rheological, Textural and Sensorial Properties of Low-Sucrose Muffins Reformulated with Sucralose/Polydextrose. Lwt 2012, 45, 213–220. [Google Scholar] [CrossRef]

- Kaur, A.; Singh, B.; Kaur, A.; Singh, N. Chemical, Thermal, Rheological and FTIR Studies of Vegetable Oils and Their Effect on Eggless Muffin Characteristics. J. Food Process. Preserv. 2019, 43, e13978. [Google Scholar] [CrossRef]

- Shukla, D.; Tewari, B.N.; Trivedi, S.P.; Dwivedi, S.; Kumar, V.; Tiwari, V. Quality and Functional Attributes of Muffins with Incorporation of Fruit, Vegetable, and Grain Substitutes: A Review. J. Appl. Nat. Sci. 2024, 16, 344–355. [Google Scholar] [CrossRef]

| Variable | −1 | −0.33 | 0 | 0.33 | 1 |

|---|---|---|---|---|---|

| Percentage of substituted sugar, % | 25 | 50 | - | 75 | 100 |

| Percentage of substituted oil, % | 25 | 50 | - | 75 | 100 |

| Temperature, °C | 180 | - | 200 | - | 220 |

| Run | Actual Values | ||

|---|---|---|---|

| Percentage of Substituted Sugar (%) | Percentage of Substituted Oil (%) | Temperature (°C) | |

| 1 (R 75 25) | 75 | 25 | 200 |

| 2 (R 25 75) | 25 | 75 | 200 |

| 3 (R 75 25) | 75 | 25 | 200 |

| 4 (R 75 75) | 75 | 75 | 220 |

| 5 (R 75 75) | 75 | 75 | 220 |

| 6 (R100 25) | 100 | 25 | 220 |

| 7 (R 100 100) | 100 | 100 | 200 |

| 8 (R 50 50) | 50 | 50 | 180 |

| 9 (R 25 25) | 25 | 25 | 180 |

| 10 (R 100 50) | 100 | 50 | 180 |

| 11 (R 25 25) | 25 | 25 | 200 |

| 12 (R 25 25) | 25 | 25 | 220 |

| 13 (R 25 75) | 25 | 75 | 200 |

| 14 (R 25 100) | 25 | 100 | 220 |

| 15 (R 100 50) | 100 | 50 | 200 |

| 16 (R 50 100) | 50 | 100 | 180 |

| Sample | Pectin, % | DE, % |

|---|---|---|

| Raw puree | 0.64 ± 0.03 a | 79 ± 0.2 a |

| Cooked puree | 0.57 ± 0.02 a | 68 ± 0.1 b |

| Run | Ingredients (g) | |||||||

|---|---|---|---|---|---|---|---|---|

| Eggs | Sugar | Oil | Milk | Wheat Flour | Baking Powder | Salt | Apple Puree (0.57% Pectin) | |

| 1 | 75 | 25 | 75 | 35 | 125 | 3.5 | 1.5 | 100 |

| 2 | 75 | 75 | 25 | 35 | 125 | 3.5 | 1.5 | 100 |

| 3 | 75 | 25 | 75 | 35 | 125 | 3.5 | 1.5 | 100 |

| 4 | 75 | 25 | 25 | 35 | 125 | 3.5 | 1.5 | 150 |

| 5 | 75 | 25 | 25 | 35 | 125 | 3.5 | 1.5 | 150 |

| 6 | 75 | - | 75 | 35 | 125 | 3.5 | 1.5 | 125 |

| 7 | 75 | - | - | 35 | 125 | 3.5 | 1.5 | 200 |

| 8 | 75 | 50 | 50 | 35 | 125 | 3.5 | 1.5 | 100 |

| 9 | 75 | 75 | 75 | 35 | 125 | 3.5 | 1.5 | 150 |

| 10 | 75 | - | 50 | 35 | 125 | 3.5 | 1.5 | 150 |

| 11 | 75 | 75 | 75 | 35 | 125 | 3.5 | 1.5 | 150 |

| 12 | 75 | 75 | 75 | 35 | 125 | 3.5 | 1.5 | 150 |

| 13 | 75 | 75 | 25 | 35 | 125 | 3.5 | 1.5 | 100 |

| 14 | 75 | 75 | - | 35 | 125 | 3.5 | 1.5 | 125 |

| 15 | 75 | - | 50 | 35 | 125 | 3.5 | 1.5 | 150 |

| 16 | 75 | 50 | - | 35 | 125 | 3.5 | 1.5 | 150 |

| Hardness (N) | |||||

|---|---|---|---|---|---|

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

| Model | 3.85 | 9 | 0.4281 | 23.05 | 0.0006 |

| A—Subtituted sugar | 1.45 | 1 | 1.45 | 78.00 | 0.0001 |

| B—Substituted oil | 0.0099 | 1 | 0.0099 | 0.5314 | 0.4935 |

| C—Temperature | 0.6833 | 1 | 0.6833 | 36.80 | 0.0009 |

| AB | 0.2764 | 1 | 0.2764 | 14.89 | 0.0084 |

| AC | 0.1647 | 1 | 0.1647 | 8.87 | 0.0247 |

| BC | 0.0690 | 1 | 0.0690 | 3.72 | 0.1021 |

| A2 | 1.18 | 1 | 1.18 | 63.41 | 0.0002 |

| B2 | 0.7080 | 1 | 0.7080 | 38.13 | 0.0008 |

| C2 | 0.0165 | 1 | 0.0165 | 0.8880 | 0.3824 |

| R2 | 0.971 | ||||

| Chewiness (N) | |||||

| Model | 2.12 | 9 | 0.2355 | 36.75 | 0.0001 |

| A—Subtituted sugar | 0.0312 | 1 | 0.0312 | 4.88 | 0.0693 |

| B—Substituted oil | 0.0164 | 1 | 0.0164 | 2.56 | 0.1604 |

| C—Temperature | 0.0834 | 1 | 0.0834 | 13.01 | 0.0113 |

| AB | 0.0066 | 1 | 0.0066 | 1.03 | 0.3500 |

| AC | 0.2034 | 1 | 0.2034 | 31.74 | 0.0013 |

| BC | 1.43 | 1 | 1.43 | 223.10 | <0.0001 |

| A2 | 0.0197 | 1 | 0.0197 | 3.08 | 0.1297 |

| B2 | 0.5772 | 1 | 0.5772 | 90.06 | <0.0001 |

| C2 | 0.0123 | 1 | 0.0123 | 1.92 | 0.2156 |

| R2 | 0.982 | ||||

| Cohesiveness (/) | |||||

| Model | 0.0307 | 9 | 0.0034 | 32.15 | 0.0002 |

| A—Sugar | 0.0003 | 1 | 0.0003 | 2.44 | 0.1691 |

| B—Oil | 0.0037 | 1 | 0.0037 | 35.29 | 0.0010 |

| C—Temperature | 0.0026 | 1 | 0.0026 | 24.38 | 0.0026 |

| AB | 0.0076 | 1 | 0.0076 | 71.78 | 0.0001 |

| AC | 0.0086 | 1 | 0.0086 | 80.99 | 0.0001 |

| BC | 0.0030 | 1 | 0.0030 | 28.76 | 0.0017 |

| A2 | 0.0069 | 1 | 0.0069 | 65.29 | 0.0002 |

| B2 | 0.0000 | 1 | 0.0000 | 0.4502 | 0.5272 |

| C2 | 0.0002 | 1 | 0.0002 | 1.64 | 0.2474 |

| R2 | 0.9679 | ||||

| Run | Independent Variables | Measured Response | Predicted Response | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SS, % | SO, % | T, °C | Hardness, N | Chewiness, N | Cohesiveness, - | Hardness, N | Chewiness, N | Cohesiveness, - | |

| 1 | 75 | 25 | 200 | 7.86 | 5.51 | 0.63 | 7.97 | 5.54 | 0.63 |

| 2 | 25 | 75 | 200 | 8.3 | 6.01 | 0.71 | 8.41 | 5.90 | 0.71 |

| 3 | 75 | 25 | 200 | 8.08 | 5.59 | 0.64 | 7.97 | 5.54 | 0.63 |

| 4 | 75 | 75 | 220 | 8.85 | 5.62 | 0.69 | 8.70 | 5.59 | 0.68 |

| 5 | 75 | 75 | 220 | 8.52 | 5.53 | 0.67 | 8.70 | 5.59 | 0.68 |

| 6 | 100 | 25 | 220 | 7.13 | 6.01 | 0.79 | 7.11 | 5.98 | 0.79 |

| 7 | 100 | 100 | 200 | 7.49 | 5.57 | 0.67 | 7.46 | 5.52 | 0.67 |

| 8 | 50 | 50 | 180 | 8.44 | 5.85 | 0.63 | 8.36 | 5.78 | 0.63 |

| 9 | 25 | 25 | 180 | 7.51 | 4.88 | 0.65 | 7.53 | 4.89 | 0.64 |

| 10 | 100 | 50 | 180 | 7.36 | 6.23 | 0.63 | 7.38 | 6.23 | 0.63 |

| 11 | 25 | 25 | 200 | 8.19 | 5.47 | 0.63 | 8.19 | 5.49 | 0.63 |

| 12 | 25 | 25 | 220 | 8.73 | 6.22 | 0.65 | 8.72 | 6.21 | 0.4 |

| 13 | 25 | 75 | 200 | 8.52 | 5.83 | 0.73 | 8.41 | 5.90 | 0.71 |

| 14 | 25 | 100 | 220 | 8.13 | 5.09 | 0.71 | 8.11 | 5.08 | 0.71 |

| 15 | 100 | 50 | 200 | 7.59 | 5.99 | 0.7 | 7.59 | 6.05 | 0.69 |

| 16 | 50 | 100 | 180 | 7.99 | 6.01 | 0.71 | 8.01 | 6.05 | 0.70 |

| Height (mm) | |||||

|---|---|---|---|---|---|

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

| Model | 23.83 | 9 | 2.65 | 23.41 | 0.0005 |

| A—Subtituted sugar | 5.96 | 1 | 5.96 | 52.71 | 0.0003 |

| B—Substituted oil | 0.7707 | 1 | 0.7707 | 6.82 | 0.0401 |

| C—Temperature | 0.2758 | 1 | 0.2758 | 2.44 | 0.1694 |

| AB | 10.22 | 1 | 10.22 | 90.38 | <0.0001 |

| AC | 3.16 | 1 | 3.16 | 27.98 | 0.0018 |

| BC | 0.7924 | 1 | 0.7924 | 7.01 | 0.0382 |

| A2 | 0.1122 | 1 | 0.1122 | 0.9926 | 0.3576 |

| B2 | 4.31 | 1 | 4.31 | 38.16 | 0.0008 |

| C2 | 1.64 | 1 | 1.64 | 14.54 | 0.0088 |

| R2 | 0.972 | ||||

| Volume (cm3) | |||||

| Model | 76.51 | 9 | 8.50 | 12.33 | 0.0032 |

| A—Subtituted sugar | 58.77 | 1 | 58.77 | 85.25 | <0.0001 |

| B—Substituted oil | 3.97 | 1 | 3.97 | 5.75 | 0.0534 |

| C—Temperature | 0.1427 | 1 | 0.1427 | 0.2069 | 0.6652 |

| AB | 1.29 | 1 | 1.29 | 1.87 | 0.2203 |

| AC | 2.52 | 1 | 2.52 | 3.65 | 0.1045 |

| BC | 4.80 | 1 | 4.80 | 6.97 | 0.0386 |

| A2 | 0.1615 | 1 | 0.1615 | 0.2343 | 0.6455 |

| B2 | 4.97 | 1 | 4.97 | 7.21 | 0.0363 |

| C2 | 0.0751 | 1 | 0.0751 | 0.1089 | 0.7526 |

| R2 | 0.948 | ||||

| Weight Loss during Baking (%) | |||||

| Model | 29.95 | 9 | 3.33 | 13.51 | 0.0012 |

| A—Substituted sugar | 14.14 | 9 | 1.57 | 7.98 | 0.0100 |

| B—Subtituted oil | 0.4596 | 1 | 0.4596 | 2.34 | 0.1772 |

| C—Temperature | 1.14 | 1 | 1.14 | 5.82 | 0.0524 |

| AB | 0.0000 | 1 | 0.0000 | 0.0002 | 0.9880 |

| AC | 0.0063 | 1 | 0.0063 | 0.0320 | 0.8640 |

| BC | 1.06 | 1 | 1.06 | 5.37 | 0.0597 |

| A2 | 0.0035 | 1 | 0.0035 | 0.0176 | 0.8987 |

| B2 | 4.15 | 1 | 4.15 | 21.11 | 0.0037 |

| C2 | 5.61 | 1 | 5.61 | 28.50 | 0.0018 |

| R2 | 0.922 | ||||

| Run | Independent Variables | Measured Response | Predicted Response | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SS, % | SO, % | T, °C | Height, mm | Volume, cm3 | Weight Loss Baking, % | Height, mm | Volume, cm3 | Weight Loss Baking, % | |

| 1 | 75 | 25 | 200 | 46.72 | 54.00 | 7.96 | 46.49 | 53.19 | 8.40 |

| 2 | 25 | 75 | 200 | 48.82 | 58.00 | 7.91 | 48.50 | 57.11 | 8.42 |

| 3 | 75 | 25 | 200 | 46.33 | 53.00 | 8.73 | 46.49 | 53.19 | 8.40 |

| 4 | 75 | 75 | 220 | 47.02 | 54.00 | 7.41 | 46.57 | 53.62 | 7.69 |

| 5 | 75 | 75 | 220 | 46.15 | 53.00 | 8.04 | 46.57 | 53.62 | 7.69 |

| 6 | 100 | 25 | 220 | 46.91 | 53.00 | 9.55 | 46.96 | 53.15 | 9.47 |

| 7 | 100 | 100 | 200 | 43.73 | 51.00 | 10.46 | 43.75 | 50.95 | 10.48 |

| 8 | 50 | 50 | 180 | 46.83 | 55.20 | 7.33 | 46.95 | 56.05 | 7.30 |

| 9 | 25 | 25 | 180 | 46.46 | 58.00 | 8.89 | 46.37 | 57.44 | 9.04 |

| 10 | 100 | 50 | 180 | 45.56 | 52.00 | 9.46 | 45.55 | 51.69 | 9.35 |

| 11 | 25 | 25 | 200 | 45.86 | 56.50 | 9.6 | 45.99 | 57.44 | 9.27 |

| 12 | 25 | 25 | 220 | 44.33 | 58.00 | 9.88 | 44.28 | 57.73 | 10.03 |

| 13 | 25 | 75 | 200 | 48.23 | 57.00 | 8.89 | 48.50 | 57.11 | 8.42 |

| 14 | 25 | 100 | 220 | 47.11 | 53.00 | 10.67 | 47.14 | 53.37 | 10.66 |

| 15 | 100 | 50 | 200 | 47.11 | 52.00 | 8.46 | 47.08 | 52.49 | 8.62 |

| 16 | 50 | 100 | 180 | 45.46 | 55.00 | 9.13 | 45.44 | 55.02 | 9.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dana, H.; Sonia, A. Effect of Apple Puree as a Substitute for Fat and Sugar on the Texture and Physical Properties of Muffins. Appl. Sci. 2024, 14, 9009. https://doi.org/10.3390/app14199009

Dana H, Sonia A. Effect of Apple Puree as a Substitute for Fat and Sugar on the Texture and Physical Properties of Muffins. Applied Sciences. 2024; 14(19):9009. https://doi.org/10.3390/app14199009

Chicago/Turabian StyleDana, Huțu, and Amariei Sonia. 2024. "Effect of Apple Puree as a Substitute for Fat and Sugar on the Texture and Physical Properties of Muffins" Applied Sciences 14, no. 19: 9009. https://doi.org/10.3390/app14199009