Comprehensive Evaluation Method for High-Performance Milling of Inconel 718 Alloy

Abstract

1. Introduction

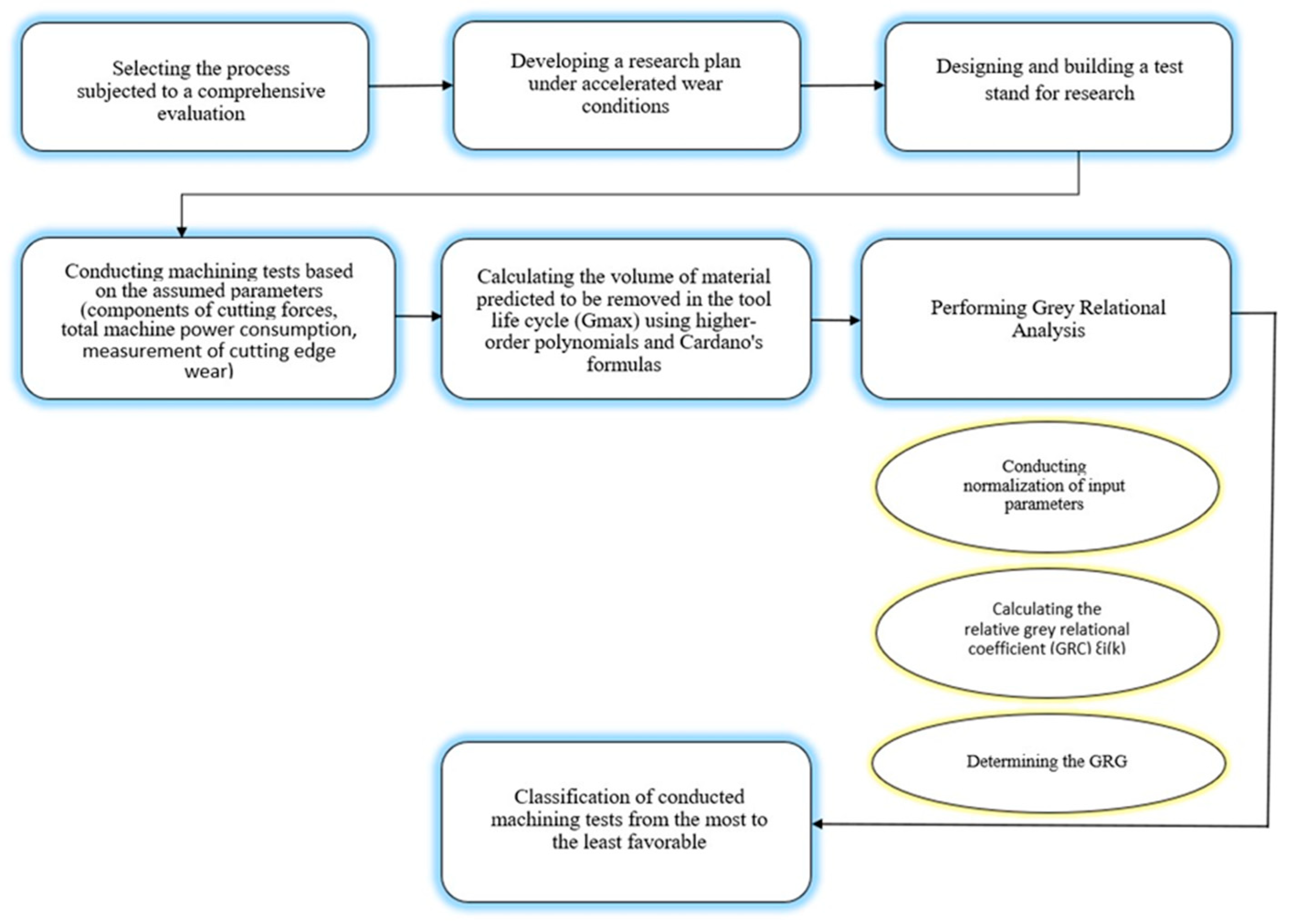

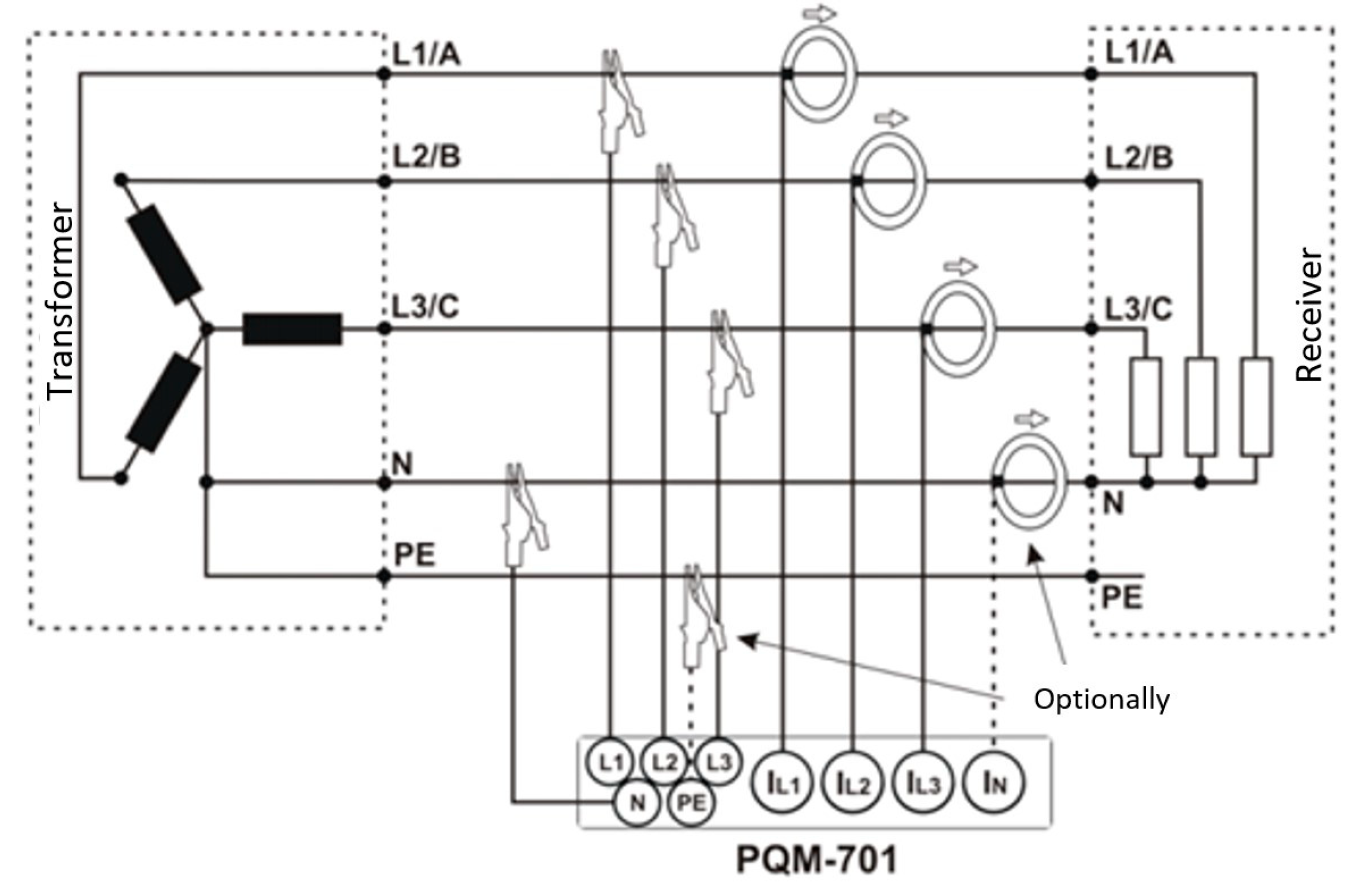

2. Materials and Methods

- the method pertains only to roughing operations;

- the compared processes must use tools with the same geometry (i.e., the same diameter and number of cutting edges, or in the case of assembled tools with interchangeable inserts, the same tool body or the same number of cutting edges in the tool);

- the cutting speed must be the same in the compared processes;

- the cutting trials must be conducted on the same machine tool;

- The cutting trials must use material from the same heat of steel.

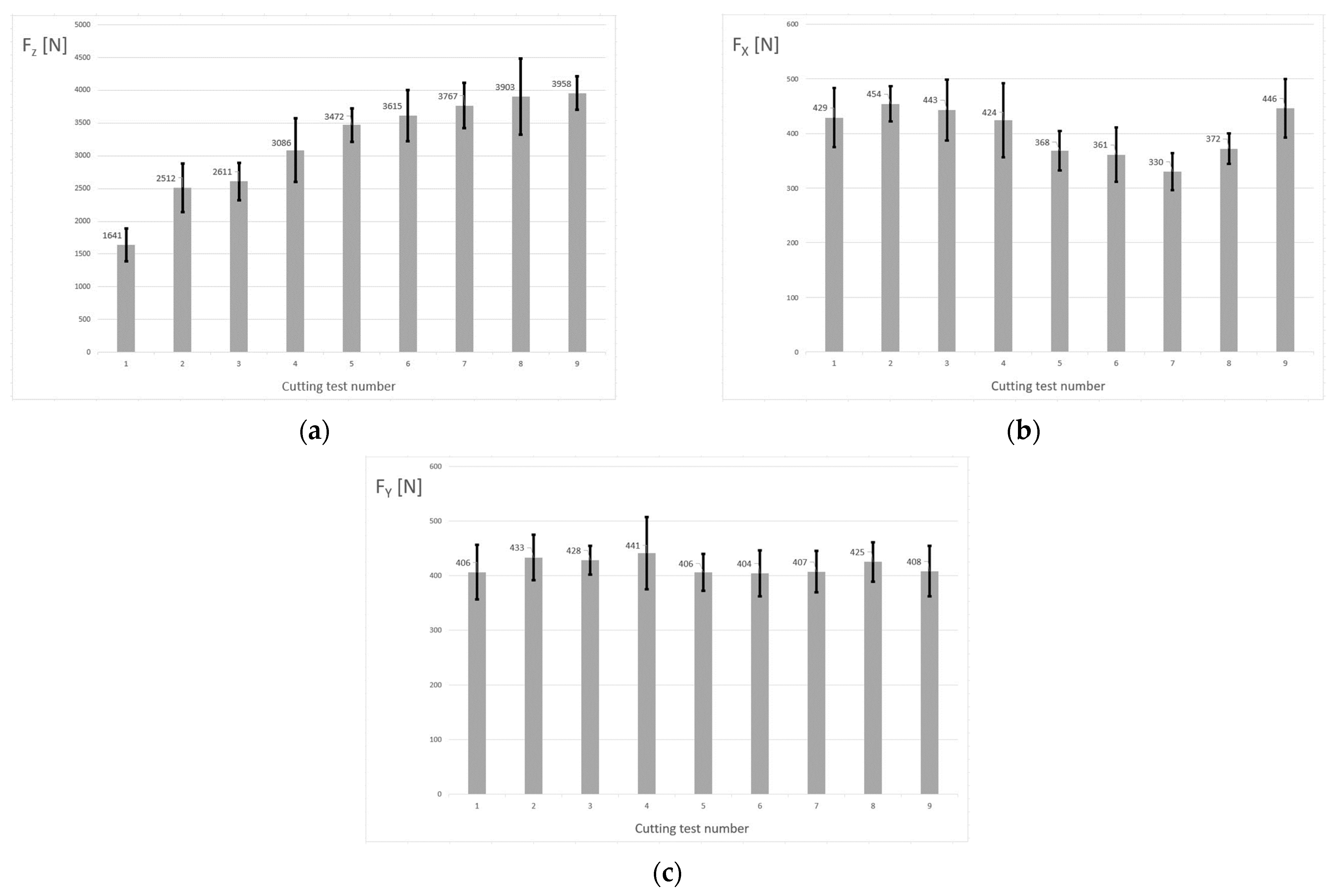

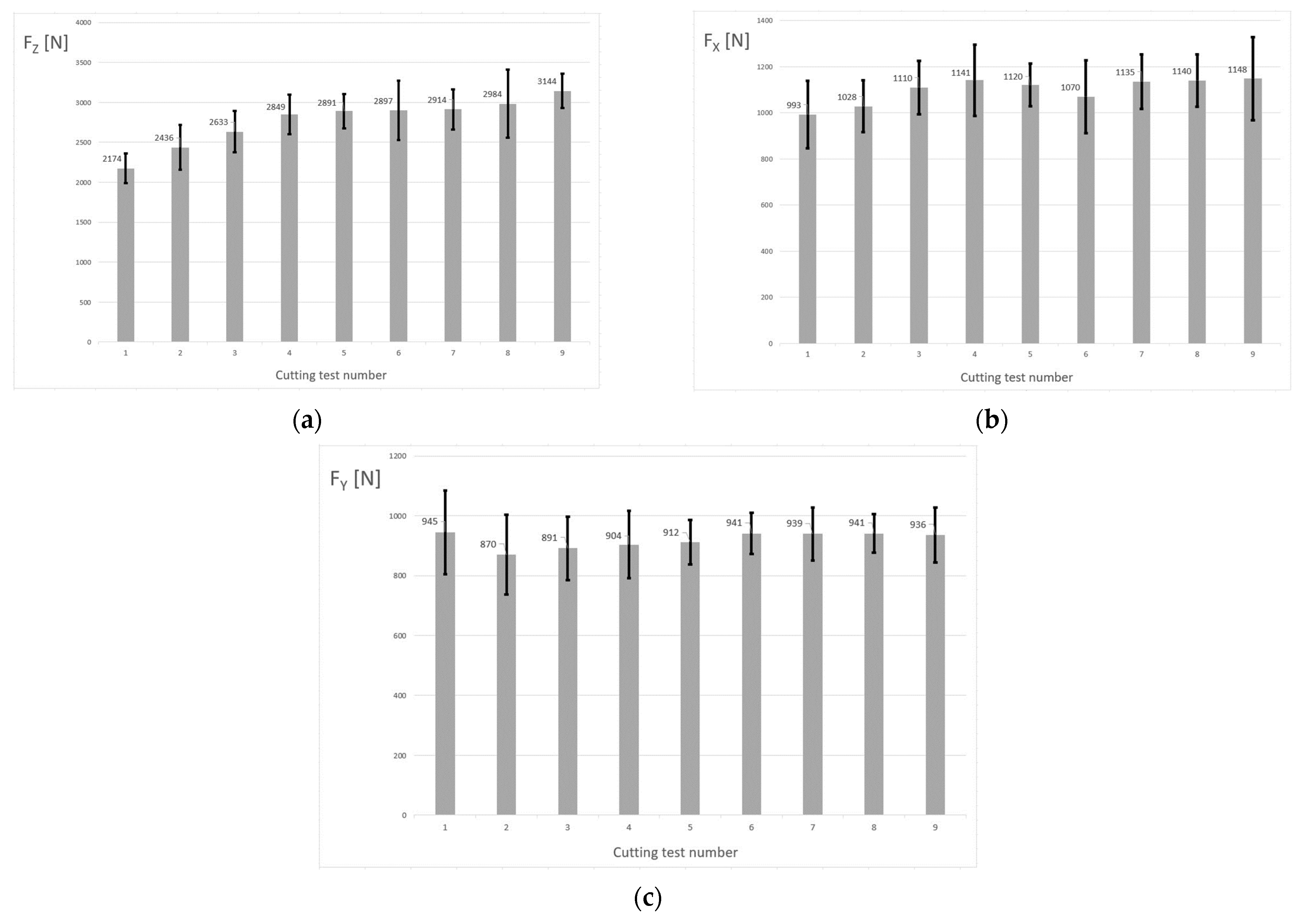

- components of cutting forces Fx, Fy, and Fz [N];

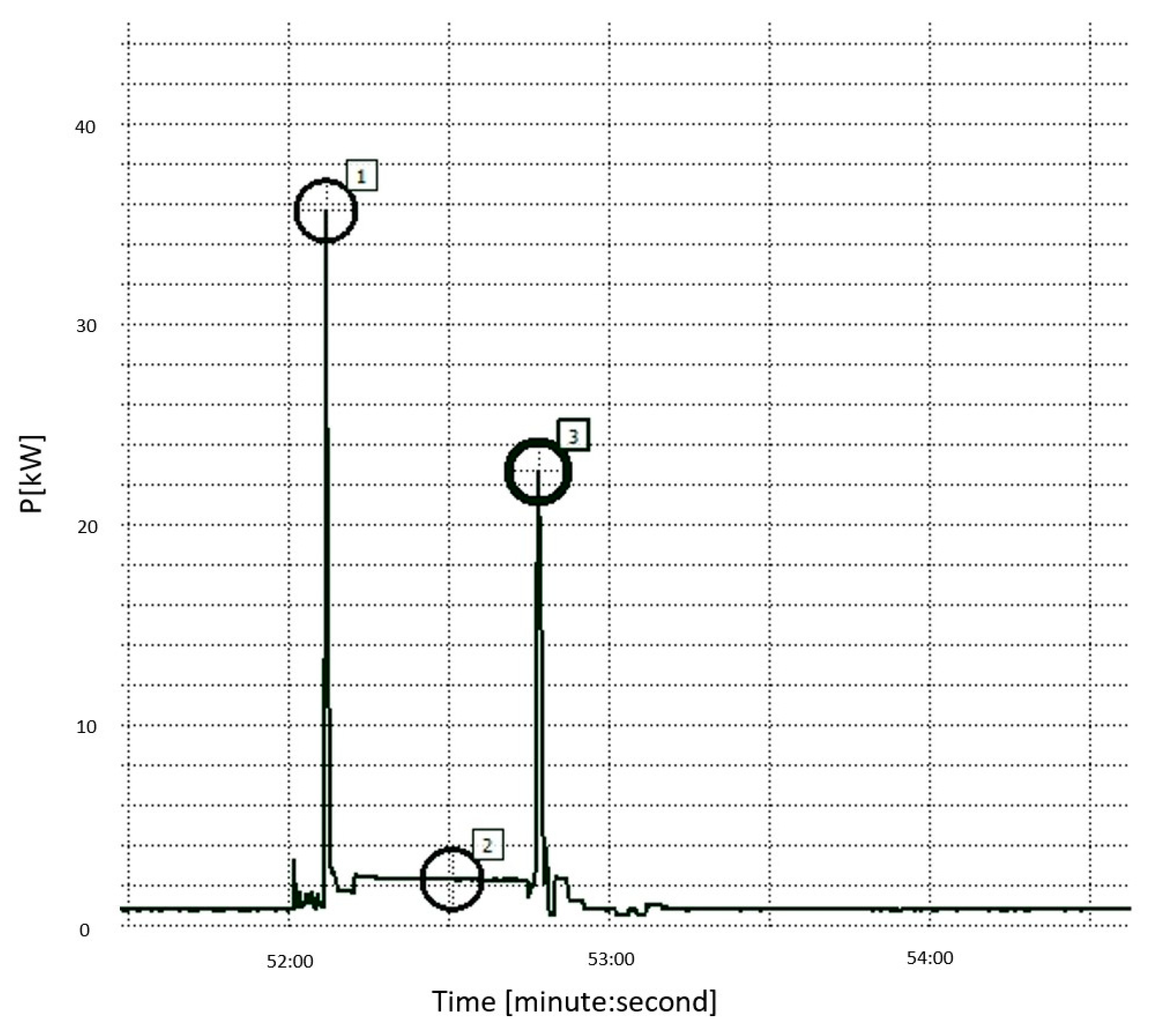

- total machine power consumption (Pc) [kW];

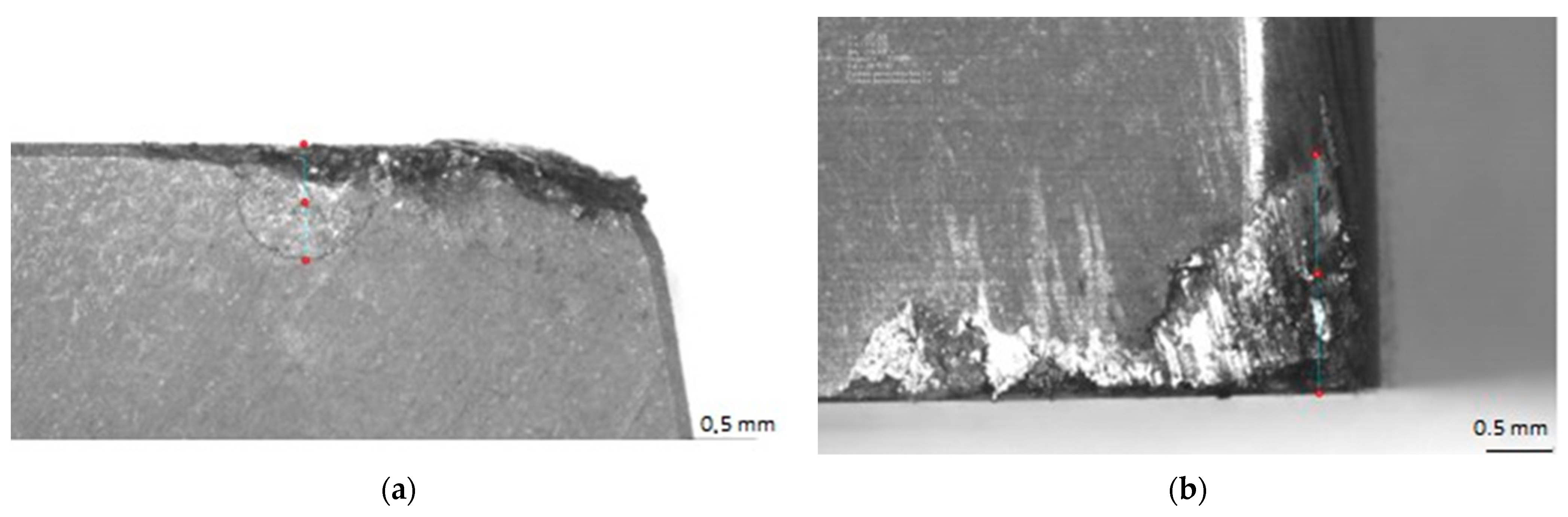

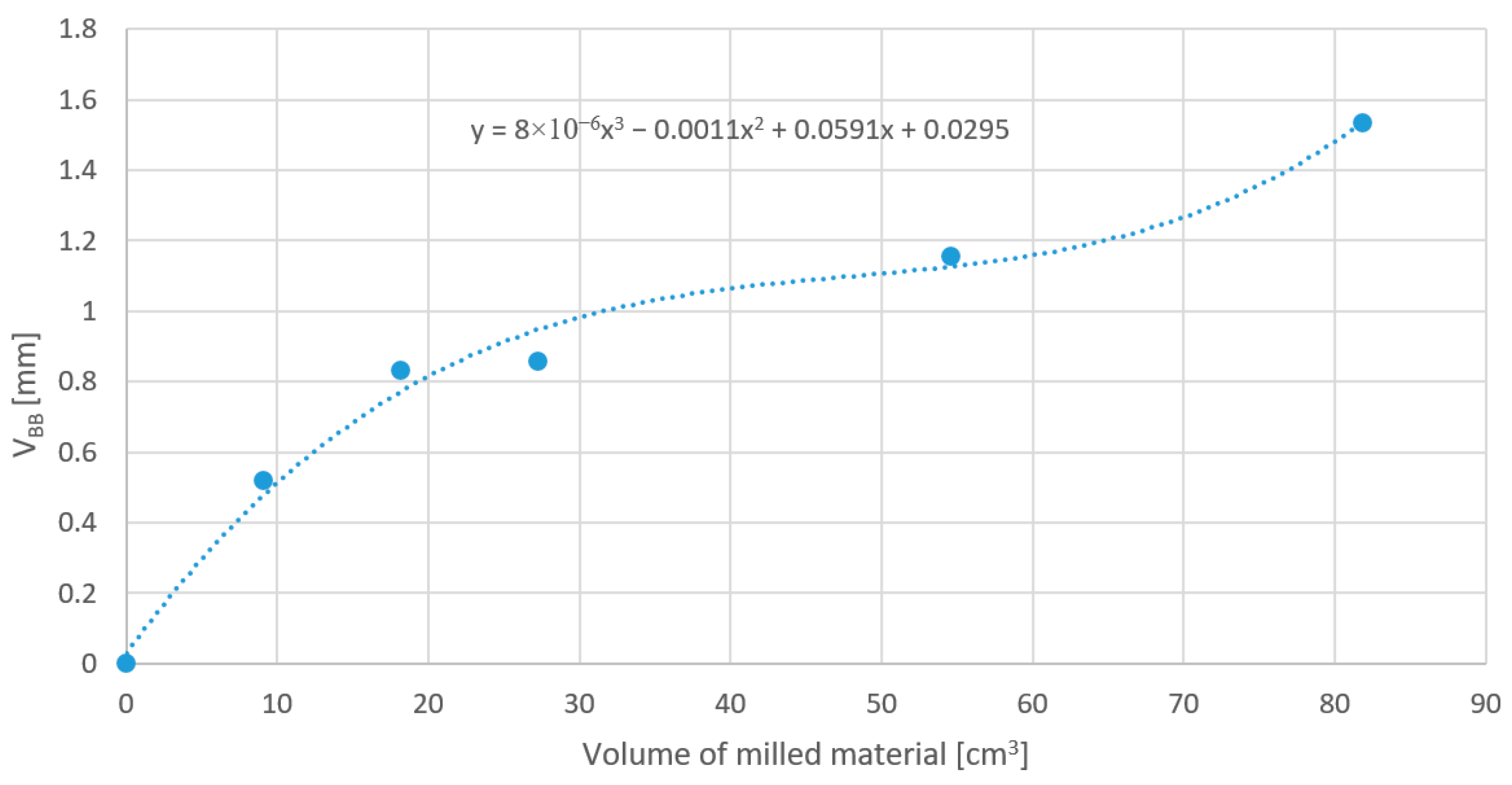

- cutting-edge wear (VBB) [mm];

- material removal rate (Q) [cm3/min].

3. Results and Discussion

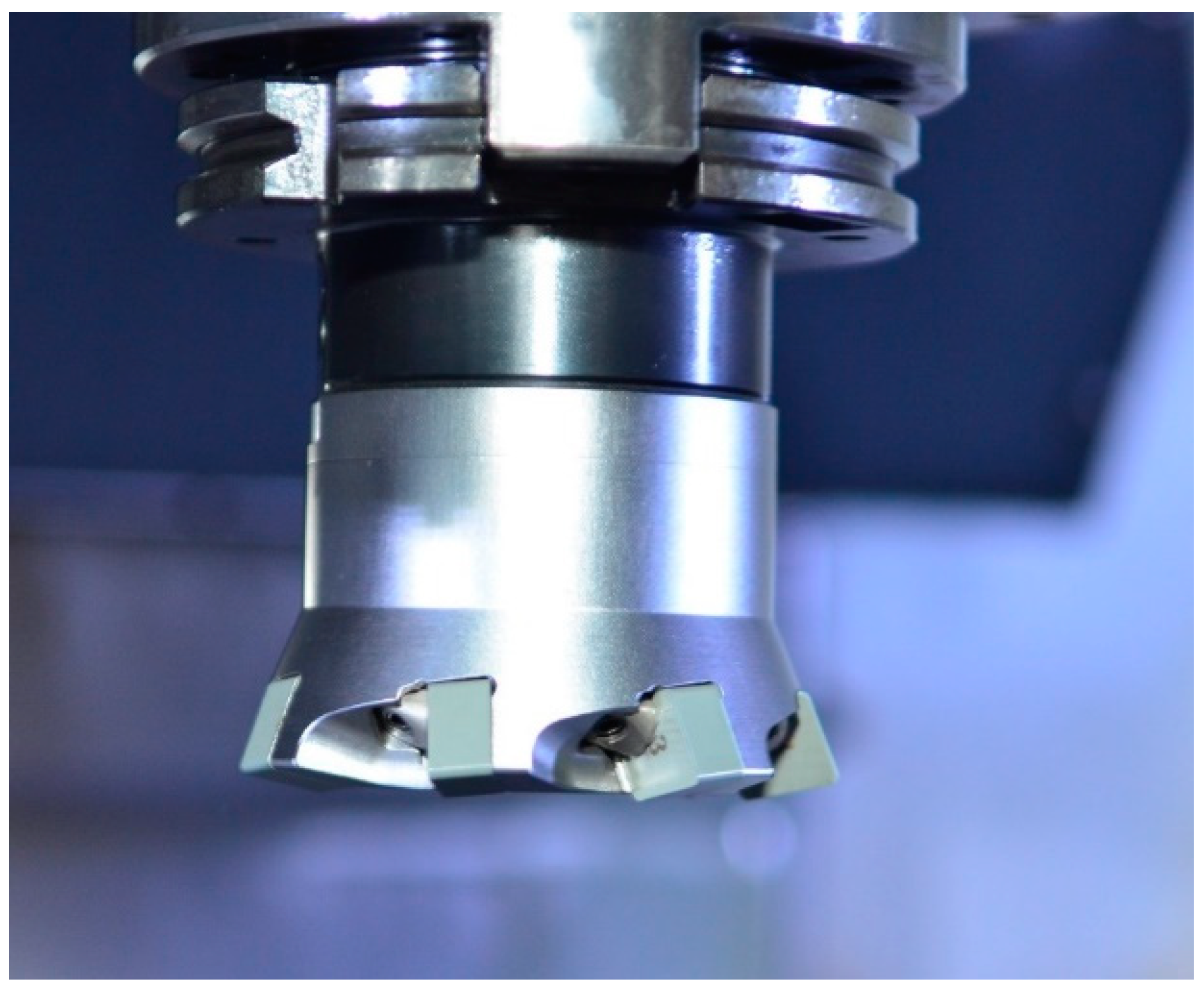

3.1. High-Feed Milling

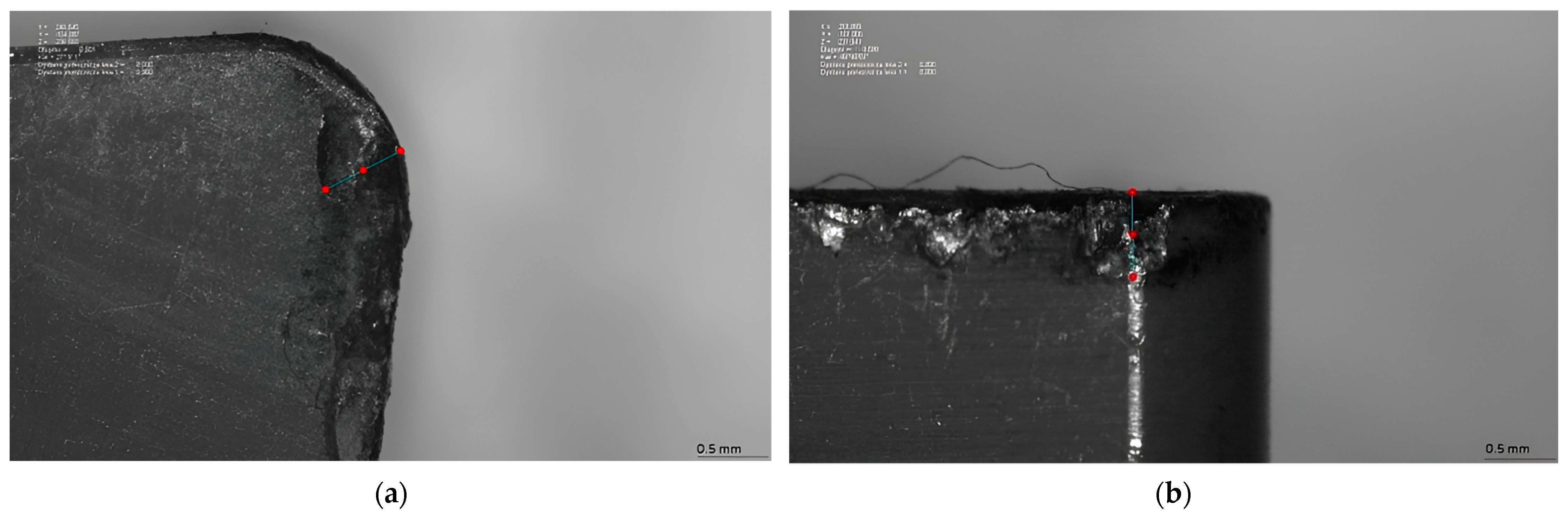

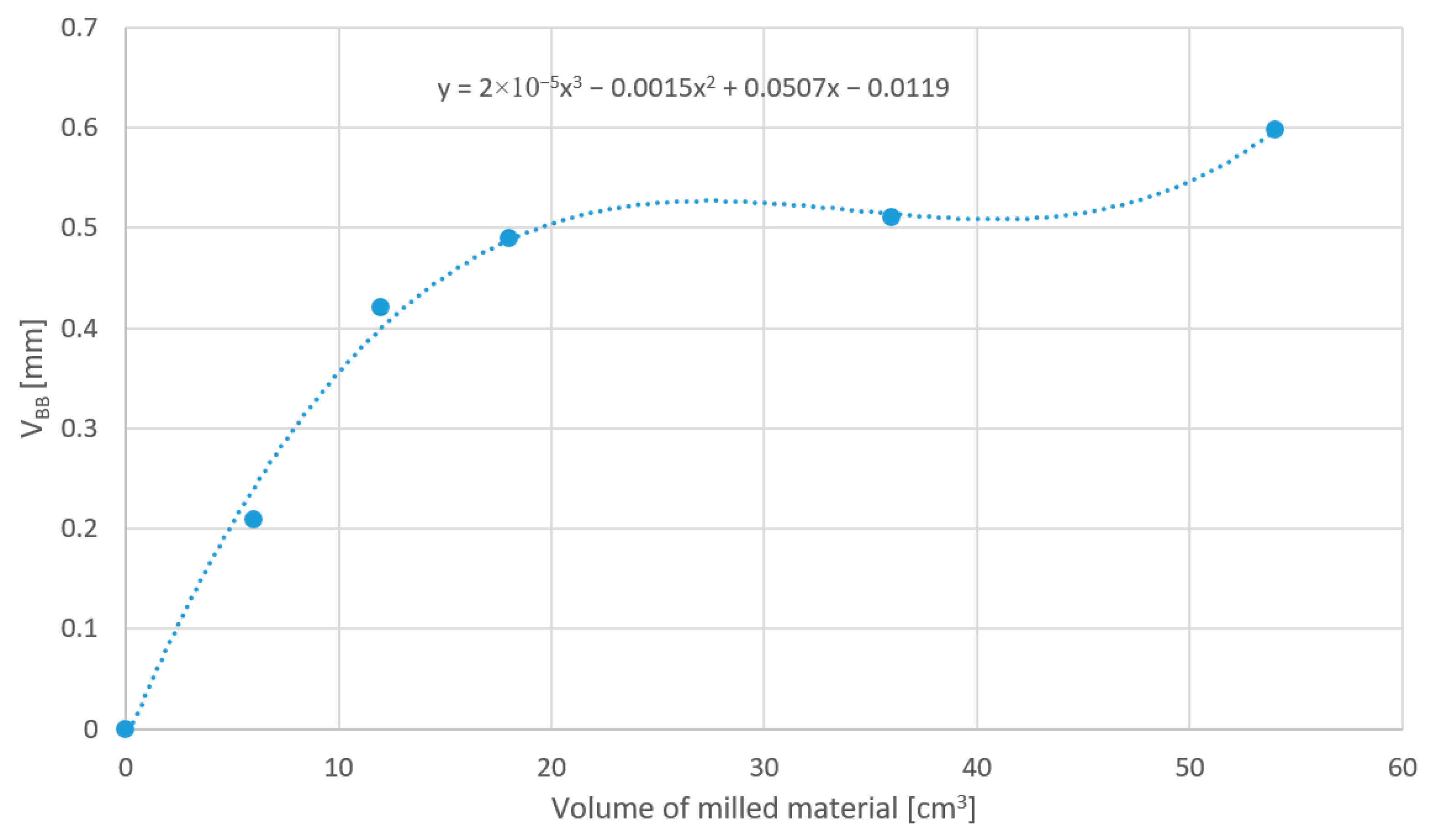

3.2. Plunge Milling

3.3. Evaluation Method Results

4. Conclusions

- The method has been verified for two different Inconel milling processes, allowing for the assessment of its effectiveness and applicability in real machining conditions;

- The research results showed that high-feed milling ensures higher material removal rates and lower tool wear, making it more efficient for roughing operations;

- Plunge milling was characterized by a lower axial force component (Fz), which can positively influence machining accuracy and process stability;

- The use of accelerated tool wear allows for a detailed analysis and comparison of different milling techniques and tools used in the machining process;

- Appropriate cutting parameters, such as spindle speed, feed rate, and depth of cut, significantly affect tool life and the quality of the machined surface;

- The proposed evaluation method is universal and can also be applied to other hard-to-machine materials, not just Inconel alloys;

- Optimization of process parameters, such as cutting forces and power consumption, is crucial for increasing efficiency and reducing the machining costs of high-strength alloys like Inconel 718;

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choudhury, I.A.; El-Baradie, M.A. Machinability of Nickel-Base Super Alloys: A General Review. J. Mater. Process. Technol. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Dogra, M.; Pruncu, C.I. Evaluation of Tool Wear, Energy Consumption, and Surface Roughness During Turning of Inconel 718 Using Sustainable Machining Technique. J. Mater. Res. Technol. 2020, 9, 5794–5804. [Google Scholar] [CrossRef]

- Singh, T.; Dureja, J.S.; Dogra, M.; Bhatti, M.S. Environment Friendly Machining of Inconel 625 under Nano-Fluid Minimum Quantity Lubrication (NMQL). Int. J. Precis. Eng. Manuf. 2018, 19, 1689–1697. [Google Scholar] [CrossRef]

- Hsiao, T.-C.; Vu, N.-C.; Tsai, M.-C.; Dang, X.-P.; Huang, S.-C. Modeling and Optimization of Machining Parameters in Milling of Inconel 800 Super Alloy Considering Energy, Productivity, and Quality Using Nanoparticle Suspended Lubrication. Meas. Control 2021, 54, 880–894. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; Polvorosa, R.; Artaza, T.; Holmberg, J.; López de Lacalle, L.N.; Wretland, A. Surface integrity and fatigue of non-conventional machined Alloy 718. J. Manuf. Process. 2019, 48, 44–50. [Google Scholar] [CrossRef]

- Fernández-Lucio, P.; Pereira Neto, O.; Gómez-Escudero, G.; Amigo Fuertes, F.J.; Fernández Valdivielso, A.; López de Lacalle Marcaide, L.N. Roughing Milling with Ceramic Tools in Comparison with Sintered Carbide on Nickel-Based Alloys. Coatings 2021, 11, 734. [Google Scholar] [CrossRef]

- Zimmermann, R.; Welling, D.; Venek, T.; Ganser, P.; Bergs, T. Tool Wear Progression of SiAlON Ceramic End Mills in Five-Axis High-Feed Rough Machining of an Inconel 718 BLISK. Procedia CIRP 2021, 101, 13–16. [Google Scholar] [CrossRef]

- Holmberg, J.; Wretland, A.; Berglund, J.; Beno, T. A Detailed Investigation of Residual Stresses After Milling Inconel 718 Using Typical Production Parameters for Assessment of Affected Depth. Mater. Today Commun. 2020, 24, 100958. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, W.; Chen, J. Tool Wear Mechanisms in Laser-Assisted Milling of Nickel-Based Superalloys. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 151. [Google Scholar] [CrossRef]

- Vasudevan, H.; Rajguru, R.; Dave, G.; Alva, A.; Punjani, V.; Bhurke, D. Experimental Investigation and Optimization of End-Milling Parameters in the Machining of Inconel 825 Using Carbide-Coated Tool. In Proceedings of International Conference on Intelligent Manufacturing and Automation; Springer: Singapore, 2019; pp. 401–412. [Google Scholar] [CrossRef]

- Altin, A.; Nalbant, M.; Taskesen, A. The Effects of Cutting Speed on Tool Wear and Tool Life When Machining Inconel 718 with Ceramic Tools. Mater. Des. 2007, 28, 2518–2522. [Google Scholar] [CrossRef]

- Molaiekiya, F.; Aliakbari Khoei, A.; Aramesh, M.; Veldhuis, S.C. Machined surface integrity of inconel 718 in high-speed dry milling using SiAlON ceramic tools. Int. J. Adv. Manuf. Technol. 2021, 112, 1941–1950. [Google Scholar] [CrossRef]

- Molaiekiya, F.; Stolf, P.; Paiva, J.M.; Bose, B.; Goldsmith, J.; Gey, C.; Engin, S.; Fox-Rabinovich, G.; Veldhuis, S.C. Influence of Process Parameters on the Cutting Performance of SiAlON Ceramic Tools During High-Speed Dry Face Milling of Hardened Inconel 718. Int. J. Adv. Manuf. Technol. 2019, 105, 1083–1098. [Google Scholar] [CrossRef]

- Saleem, M.Q.; Mumtaz, S. Face Milling of Inconel 625 via Wiper Inserts: Evaluation of Tool Life and Workpiece Surface Integrity. J. Manuf. Process. 2020, 56, 322–336. [Google Scholar] [CrossRef]

- Iç, Y.T.; Adıgüzel, Z.A.; Azizoğlu, A.B.; Keskin, A.E.; Köksal, M.; Özbek, B.S. Optimization of Machined Product Quality in the Milling Process of Inconel High-Tech Material. Prod. Manag. Process Control. 2023, 104, 71–79. [Google Scholar] [CrossRef]

- Zhang, H.-J.; Sun, C.; Liu, M.; Gao, F. Analysis of the Optimization of Tool Geometric Parameters for Milling of Inconel718. IOP Conference Series: Mater. Sci. Eng. 2018, 423, 012030. [Google Scholar] [CrossRef]

- Faraz, M.I.; Petru, J. Evaluation of Machining Variables on Machinability of Nickel Alloy Inconel 718 Using Coated Carbide Tools. Machines 2024, 12, 4. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, F.; Li, Z.; Hu, W.; Sun, T.; Zhang, J. Investigation of Laser-Assisted Micro-Milling Process of Inconel 718. J. Manuf. Mater. Process. 2023, 7, 149. [Google Scholar] [CrossRef]

- Kim, E.J.; Lee, C.M. A Study on the Optimal Machining Parameters of the Induction Assisted Milling with Inconel 718. Materials 2019, 12, 233. [Google Scholar] [CrossRef] [PubMed]

- Finkeldei, I.; Stenzel, T.; Denkena, B. End milling of Inconel 718 using solid Si3N4 ceramic cutting tools. Procedia CIRP 2019, 81, 1131–1135. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Miao, L.; Zhang, W. Deformation Analysis of Continuous Milling of Inconel718 Nickel-Based Superalloy. Micromachines 2022, 13, 683. [Google Scholar] [CrossRef]

- Nalbant, M.; Altın, A.; Gökkaya, H. The Effect of Cutting Speed and Cutting Tool Geometry on Machinability Properties of Nickel-Base Inconel 718 Super Alloys. Mater. Des. 2007, 28, 1334–1338. [Google Scholar] [CrossRef]

- Zębala, W.; Gaweł, A. Additive and Subtractive Manufacturing of Inconel 718 Components–Estimation of Time, Costs and Carbon Dioxide Emission–Case Study. Adv. Sci. Technol. Res. J. 2024, 18, 98–109. [Google Scholar] [CrossRef] [PubMed]

- Thakur, A.; Gangopadhyay, S. State-of-the-Art in Surface Integrity in Machining of Nickel-Based Super Alloys. Int. J. Mach. Tools Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Mahesh, K.; Philip, J.T.; Joshi, S.N.; Kuriachen, B. Machinability of Inconel 718: A Critical Review on the Impact of Cutting Temperatures. Mater. Manuf. Process. 2021, 36, 753–791. [Google Scholar] [CrossRef]

- Pawade, R.S.; Joshi, S.S.; Brahmankar, P.K.; Rahman, M. An Investigation of Cutting Forces and Surface Damage in High-Speed Turning of Inconel 718. J. Mater. Process. Technol. 2007, 192–193, 139–146. [Google Scholar] [CrossRef]

- Amini, S.; Fatemi, M.H.; Atefi, R.K.H. High Speed Turning of Inconel 718 Using Ceramic and Carbide Cutting Tools. Arab. J. Sci. Eng. 2014, 39, 2271–2280. [Google Scholar] [CrossRef]

- Taşlıyan, A.; Acarer, M.; Şeker, U.; Gökkaya, H.; Demir, B. The Effect of Cutting Parameters on Cutting Force During the Processing of Inconel 718 Super Alloy. J. Fac. Eng. Archit. Gazi Univ. 2007, 22, 1–5. [Google Scholar]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Machinability Investigation of Inconel 718 in High-Speed Turning. Int. J. Adv. Manuf. Technol. 2009, 45, 421–429. [Google Scholar] [CrossRef]

- Vinod, A.R.; Srinivasa, C.K.; Keshavamurthy, R.; Shashikumar, P.V. A Novel Technique for Reducing Lead-Time and Energy Consumption in Fabrication of Inconel-625 Parts by Laser-Based Metal Deposition Process. Rapid Prototyp. J. 2016, 22, 162–171. [Google Scholar] [CrossRef]

- Thirumalai, R.; Seenivasan, M.; Panneerselvam, K. Experimental Investigation and Multi Response Optimization of Turning Process Parameters for Inconel 718 Using TOPSIS Approach. Mater. Today Proc. 2020, 45, 467–472. [Google Scholar] [CrossRef]

- Sanghvi, N.; Vora, D.; Patel, J.; Malik, A. Optimization of End Milling of Inconel 825 with Coated Tool: A Mathematical Comparison Between GRA, TOPSIS and Fuzzy Logic Methods. Mater. Today Proc. 2020, 38, 2301–2309. [Google Scholar] [CrossRef]

- Karolczak, P.; Adamczak, M. Evaluation of the Influence of Tool Coatings on the Machinability of the Ti6Al4V Alloy Using Gray Relational Analysis. Adv. Sci. Technol. Res. J. 2024, 18, 13–28. [Google Scholar] [CrossRef] [PubMed]

- Pereira, O.; Urbikain, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Calleja, A.; Ayesta, I.; López de Lacalle, L.N. Internal cryolubrication approach for Inconel 718 milling. Procedia Manuf. 2017, 13, 89–93. [Google Scholar] [CrossRef]

- Piórkowski, P.; Borkowski, W.; Bartoszuk, M.; Miko, E.; Skoczyński, W. Investigation of Cutting Tool Wear in the Milling Process of the Inconel 718 Alloy. Adv. Sci. Technol. Res. J. 2024, 18, 26–35. [Google Scholar] [CrossRef]

- Pérez-Ruiz, D.J.; Marin, F.; Martínez, S.; Lamikiz, A.; Urbikain, G.; López de Lacalle, L.N. Stiffening near-net-shape functional parts of Inconel 718 LPBF considering material anisotropy and subsequent machining issues. Mech. Syst. Signal Process. 2022, 168, 108675. [Google Scholar] [CrossRef]

- PQM-701 Power Quality Analyser. User’s Manual. 2014, 22.

- ISO 13399-1:2006; Cutting tool data representation and exchange. Part 1: Overview, fundamental principles and general information model. ISO: Geneva, Switzerland, 2006.

- Osmond, L.; Cook, I.; Curtis, D.; Slatter, T. Tool Life and Wear Mechanisms of CVD Coated and Uncoated SiAlON Ceramic Milling Inserts When Machining Aged Inconel 718. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 1069–1083. [Google Scholar] [CrossRef]

- Jankowski, T.; Borkowski, W.; Piórkowski, P.; Roszkowski, A.; Skoczyński, W. Comparison of vertical milling centers geometric errors with different time of machining. Mechanik 2018, 91, 650–652. [Google Scholar] [CrossRef]

| Parameter Set | Machining Type | fz [mm/tooth] | ae [%D] or [mm] | ap [mm] | Q [cm3/min] | Theoretical Diameter D [mm] | Spindle Speed n [rpm] | Feed Rate vf [mm/min] |

|---|---|---|---|---|---|---|---|---|

| 1 | High feed | 0.3 | 100% | 0.5 | 267.39 | 70.54 | 3610 | 7581 |

| 2 | High feed | 0.4 | 100% | 0.5 | 356.52 | 70.54 | 3610 | 10,108 |

| 3 | High feed | 0.5 | 100% | 0.5 | 445.65 | 70.54 | 3610 | 12,635 |

| 4 | High feed | 0.3 | 100% | 1 | 534.78 | 72.8 | 3498 | 7346 |

| 5 | Plunging | 0.08 | 1 | - | 142.61 | 80 | 3183 | 1783 |

| 6 | Plunging | 0.08 | 1.5 mm | - | 213.91 | 80 | 3183 | 1783 |

| 7 | Plunging | 0.08 | 3 mm | - | 427.82 | 80 | 3183 | 1783 |

| Volume of Milled Material [cm3] | VBB [mm] |

|---|---|

| 0 | 0 |

| 9.1 | 0.517 |

| 18.2 | 0.832 |

| 27.3 | 0.858 |

| 54.6 | 1.154 |

| 81.9 | 1.532 |

| Parameter Set | Feed per Tooth fz [mm/tooth] | Width of Cut ae [%D] | Depth of Cut ap [mm] | Volumetric Material Removal Rate Q [cm3/min] | Predicted Material Volume to be Removed in Tool Life Cycle Gmax [cm3] | Average Maximum Power Consumption Pc [kW] | Average Maximum Cutting-Force Component Fz [N] |

|---|---|---|---|---|---|---|---|

| 1 | 0.3 | 70.54 | 0.5 | 267.39 | 57.32 | 22.36 | 1935 |

| 2 | 0.4 | 70.54 | 0.5 | 356.52 | 54.042 | 27.28 | 2524 |

| 3 | 0.5 | 70.54 | 0.5 | 445.65 | 57.89 | 27.96 | 3174 |

| 4 | 0.3 | 72.8 | 1 | 534.78 | 106.39 | 38.87 | 3096 |

| Volume of Milled Material [cm3] | VBB [mm] |

|---|---|

| 0 | 0 |

| 6 | 0.209 |

| 12 | 0.42 |

| 18 | 0.49 |

| 36 | 0.51 |

| 54 | 0.598 |

| Parameter Set | Feed per Tooth fz [mm/tooth] | Width of Cut ae [%D] | Depth of Cut ap [mm] | Volumetric Material Removal Rate Q [cm3/min] | Predicted Material Volume to be Removed in Tool Life Cycle Gmax [cm3] | Average Maximum Power Consumption Pc [kW] | Average Maximum Cutting-Force Component Fz [N] |

|---|---|---|---|---|---|---|---|

| 5 | 0.08 | 1 | 25 | 142.61 | 33.61 | 15.41 | 2078 |

| 6 | 0.08 | 1.5 | 25 | 213.91 | 50.58 | 21.91 | 2769 |

| 7 | 0.08 | 3 | 25 | 427.82 | 73.16 | 31.08 | 3638 |

| Parameter Set | Normalized Volumetric Material Removal Rate Q [-] | Normalized Volume of Material Predicted to be Removed in Tool Life Cycle Gmax [-] | Normalized Average Maximum Power Consumption Pc [-] | Normalized Average Maximum Cutting-Force Component Fz [-] |

|---|---|---|---|---|

| 1 | 0.318 | 0.326 | 0.704 | 0.770 |

| 2 | 0.545 | 0.281 | 0.494 | 1.000 |

| 3 | 0.773 | 0.334 | 0.465 | 0.517 |

| 4 | 1.000 | 1.000 | 0.000 | 0.547 |

| 5 | 0.000 | 0.000 | 1.000 | 0.944 |

| 6 | 0.182 | 0.233 | 0.723 | 0.675 |

| 7 | 0.727 | 0.543 | 0.332 | 0.000 |

| Parameter Set | GRC for Volumetric Material Removal Rate ξi(Q) [-] | GRC for Volume of Material Predicted to be Removed in Tool Life Cycle ξi(Gmax) [-] | GRC for Average Maximum Power Consumption ξi(Pc) [-] | GRC for Average Maximum Cutting-Force Component ξi(Fz) [-] |

|---|---|---|---|---|

| 1 | 0.423 | 0.426 | 0.628 | 0.685 |

| 2 | 0.524 | 0.410 | 0.497 | 1.000 |

| 3 | 0.688 | 0.429 | 0.483 | 0.509 |

| 4 | 1.000 | 1.000 | 0.333 | 0.525 |

| 5 | 0.333 | 0.333 | 1.000 | 0.900 |

| 6 | 0.379 | 0.395 | 0.643 | 0.606 |

| 7 | 0.647 | 0.523 | 0.428 | 0.430 |

| Parameter Set | Machining Type | fz [mm/ tooth] | ae [mm] | ap [mm] | Q [cm3/min] | Grey Relational Grade (GRG) | Ranking Based on the Applied Evaluation Method |

|---|---|---|---|---|---|---|---|

| 1 | High feed | 0.3 | 70.54 | 0.5 | 267.39 | 0.541 | 4 |

| 2 | High feed | 0.4 | 70.54 | 0.5 | 356.52 | 0.608 | 3 |

| 3 | High feed | 0.5 | 70.54 | 0.5 | 445.65 | 0.527 | 5 |

| 4 | High feed | 0.3 | 72.8 | 1 | 534.78 | 0.715 | 1 |

| 5 | Plunging | 0.08 | 1 | 25 | 142.61 | 0.642 | 2 |

| 6 | Plunging | 0.08 | 1.5 | 25 | 213.91 | 0.506 | 7 |

| 7 | Plunging | 0.08 | 3 | 25 | 427.82 | 0.507 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piorkowski, P.; Borkowski, W.; Skoczynski, W. Comprehensive Evaluation Method for High-Performance Milling of Inconel 718 Alloy. Appl. Sci. 2024, 14, 9023. https://doi.org/10.3390/app14199023

Piorkowski P, Borkowski W, Skoczynski W. Comprehensive Evaluation Method for High-Performance Milling of Inconel 718 Alloy. Applied Sciences. 2024; 14(19):9023. https://doi.org/10.3390/app14199023

Chicago/Turabian StylePiorkowski, Paweł, Wojciech Borkowski, and Waclaw Skoczynski. 2024. "Comprehensive Evaluation Method for High-Performance Milling of Inconel 718 Alloy" Applied Sciences 14, no. 19: 9023. https://doi.org/10.3390/app14199023

APA StylePiorkowski, P., Borkowski, W., & Skoczynski, W. (2024). Comprehensive Evaluation Method for High-Performance Milling of Inconel 718 Alloy. Applied Sciences, 14(19), 9023. https://doi.org/10.3390/app14199023