Development of an Automatic Rock Mass Classification System Using Digital Tunnel Face Mapping

Abstract

:1. Introduction

| Classification Method | Researcher | Key Contents |

|---|---|---|

| Rock load | Terzaghi 1946 [2] |

|

| RQD (rock quality designation) | Deere 1988 [3] | RQD = core length greater than 10 cm/total core length five levels of rock quality (very poor–excellent) |

| RSR (rock structure rating) | Wickham 1972 [4] |

|

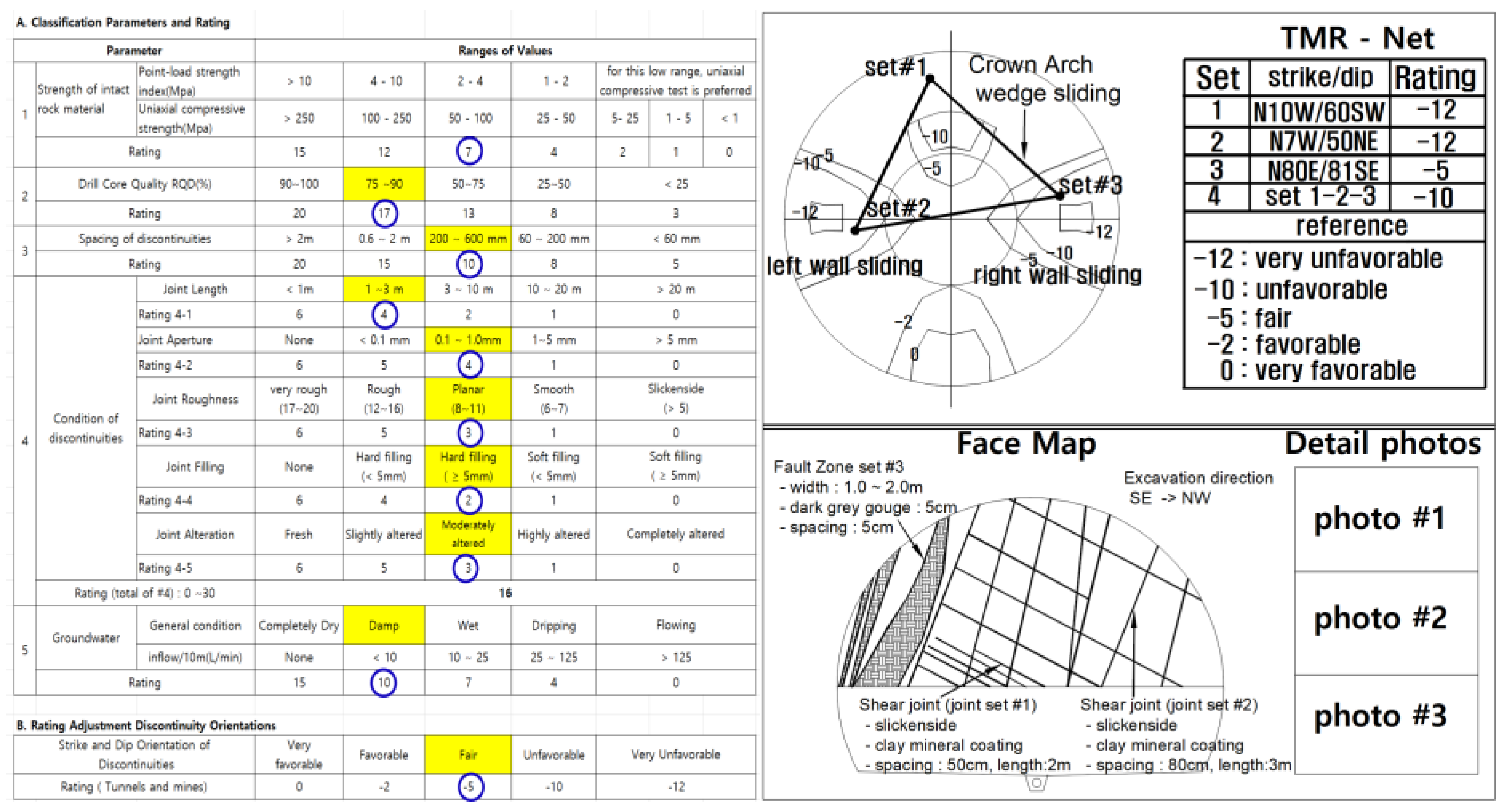

| RMR | Bieniawski 1973 [5] | Five parameters: rock strength, RQD, joint spacing, joint condition, groundwater inflow rate Rating score: 0~100 (very poor–very favourable) |

| Q-System | Barton 1974 [6] | Six parameters: RQD, No. of joints set, joint roughness, joint aperture, groundwater, insitu stress Rating score: 0~100 (very poor–very favourable) |

| SMR (slope mass rating) | Romana 2015 [7] | Basic RMR x three coefficients by joint orientation (F1–F3) + F4 (coefficient by excavation method) |

| GSI (Geological Strength Index) | Hoek 2019 [8] | Detailed classification of very poor rock masses with an RMR value of 23 or below |

2. Literature Review and Case Study

2.1. Traditional Rock Mass Classification

2.2. New Techniques of Rock Masses Classification

2.3. New Technologies Related to Digital Mapping of the Tunnel Face

3. Automated Rock Quality Classification Using Digital Tunnel Face Mapping

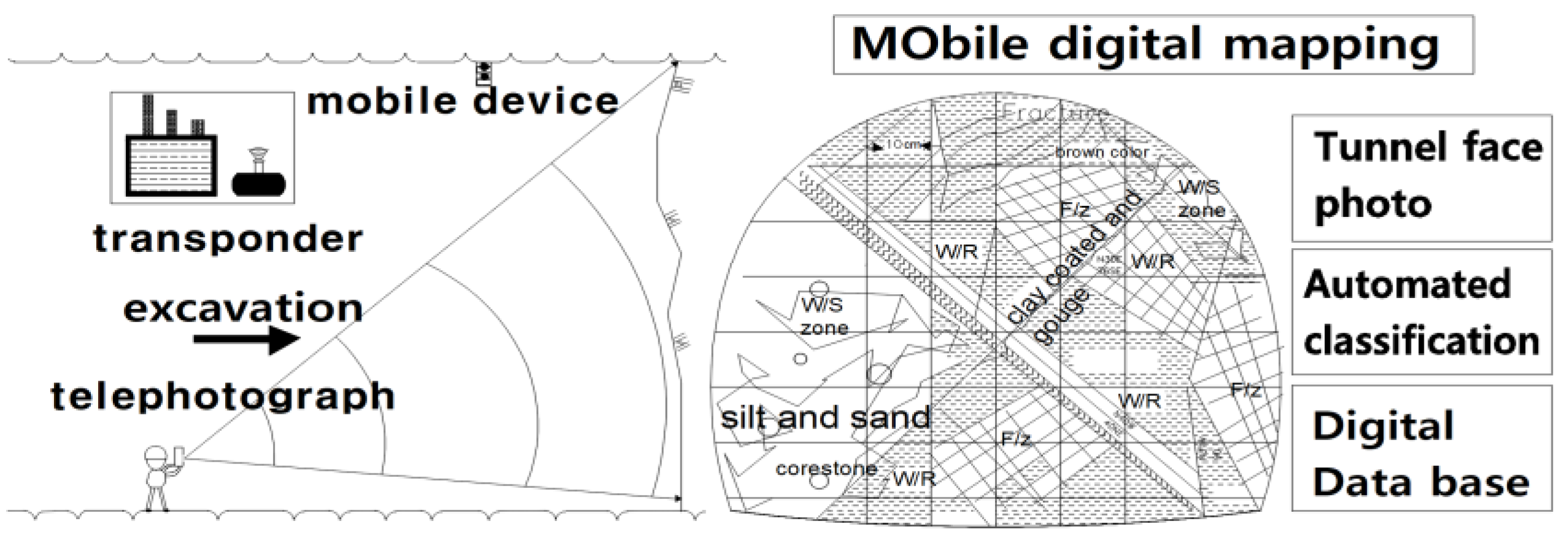

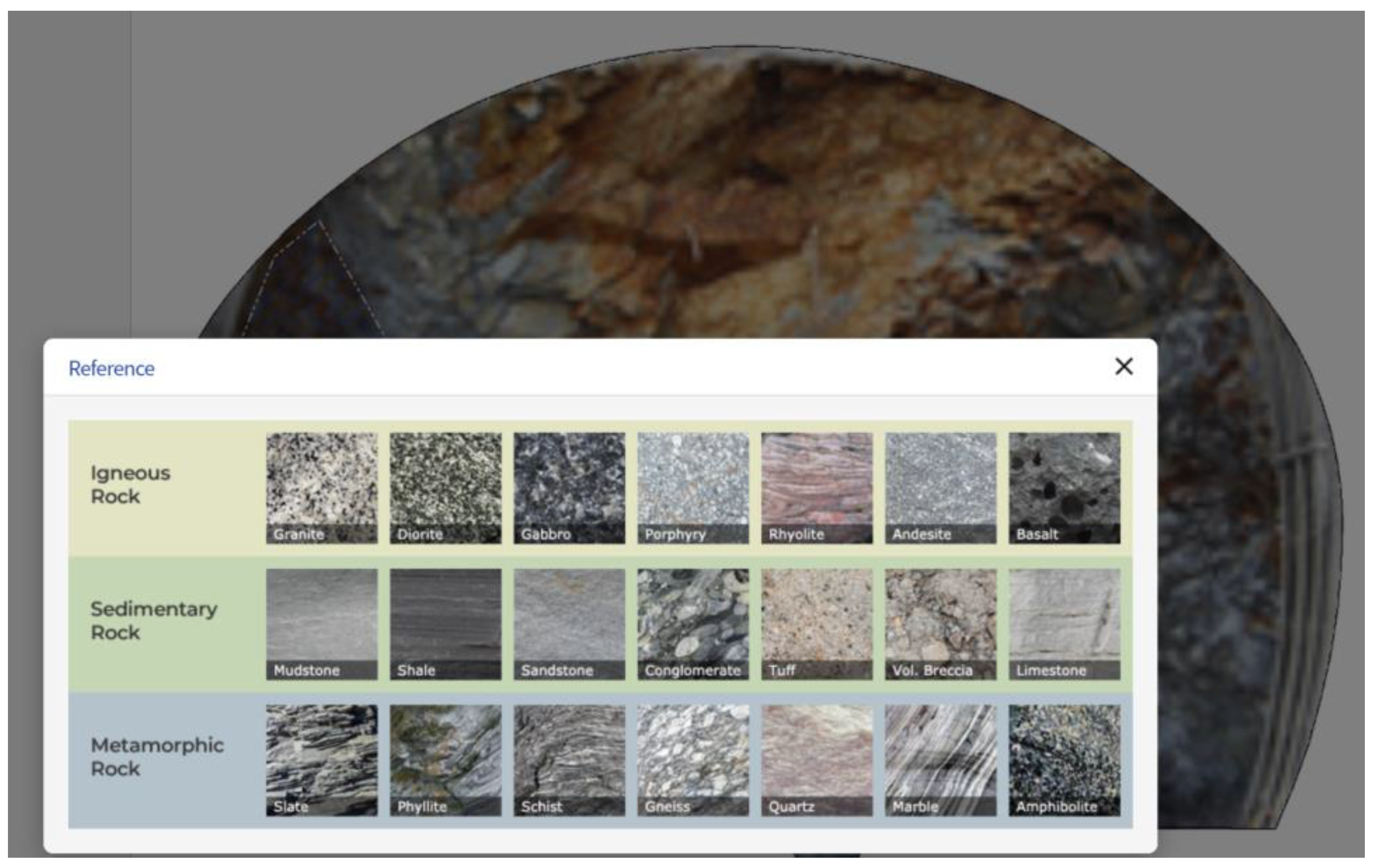

3.1. Digital Tunnel Face Mapping

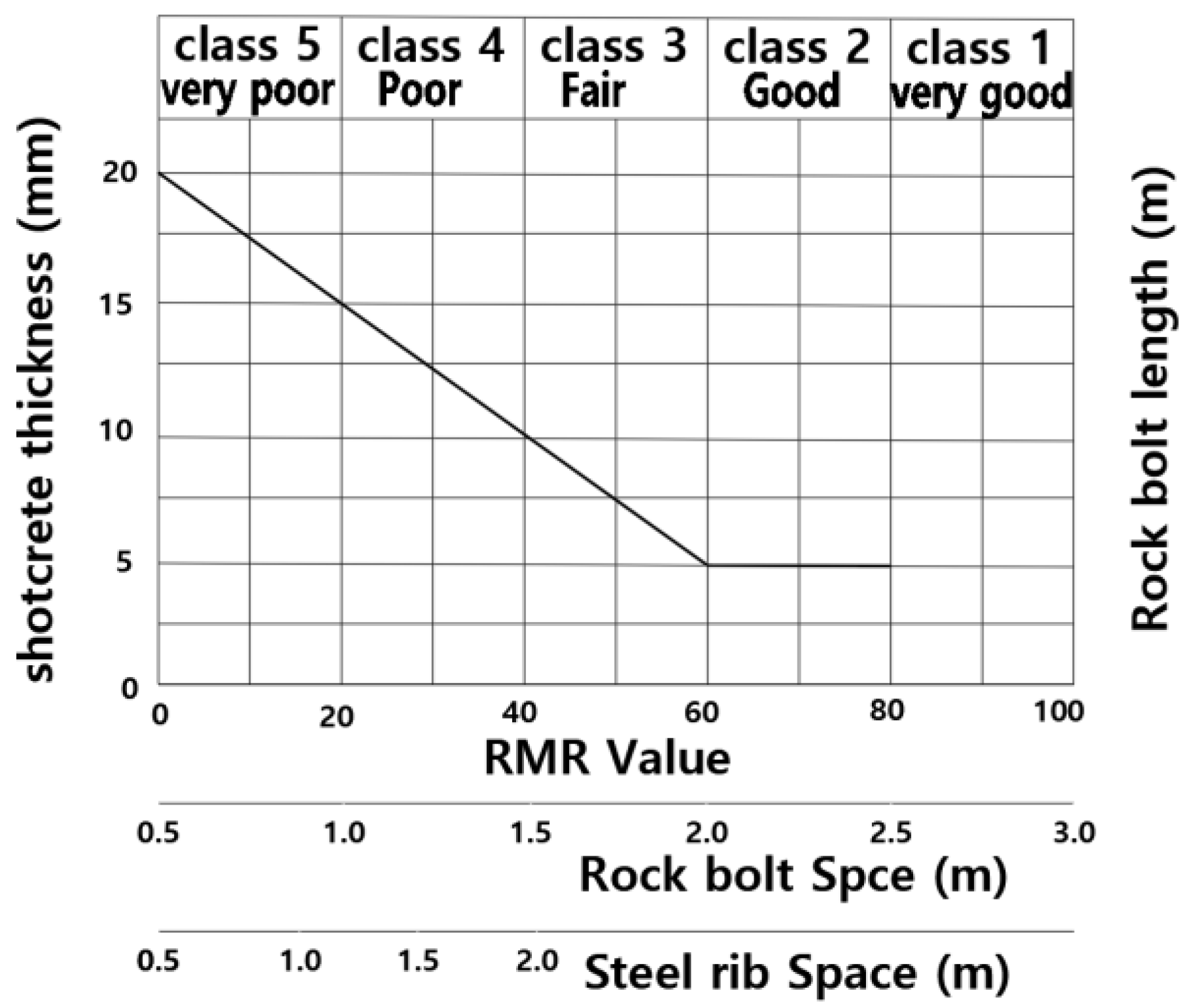

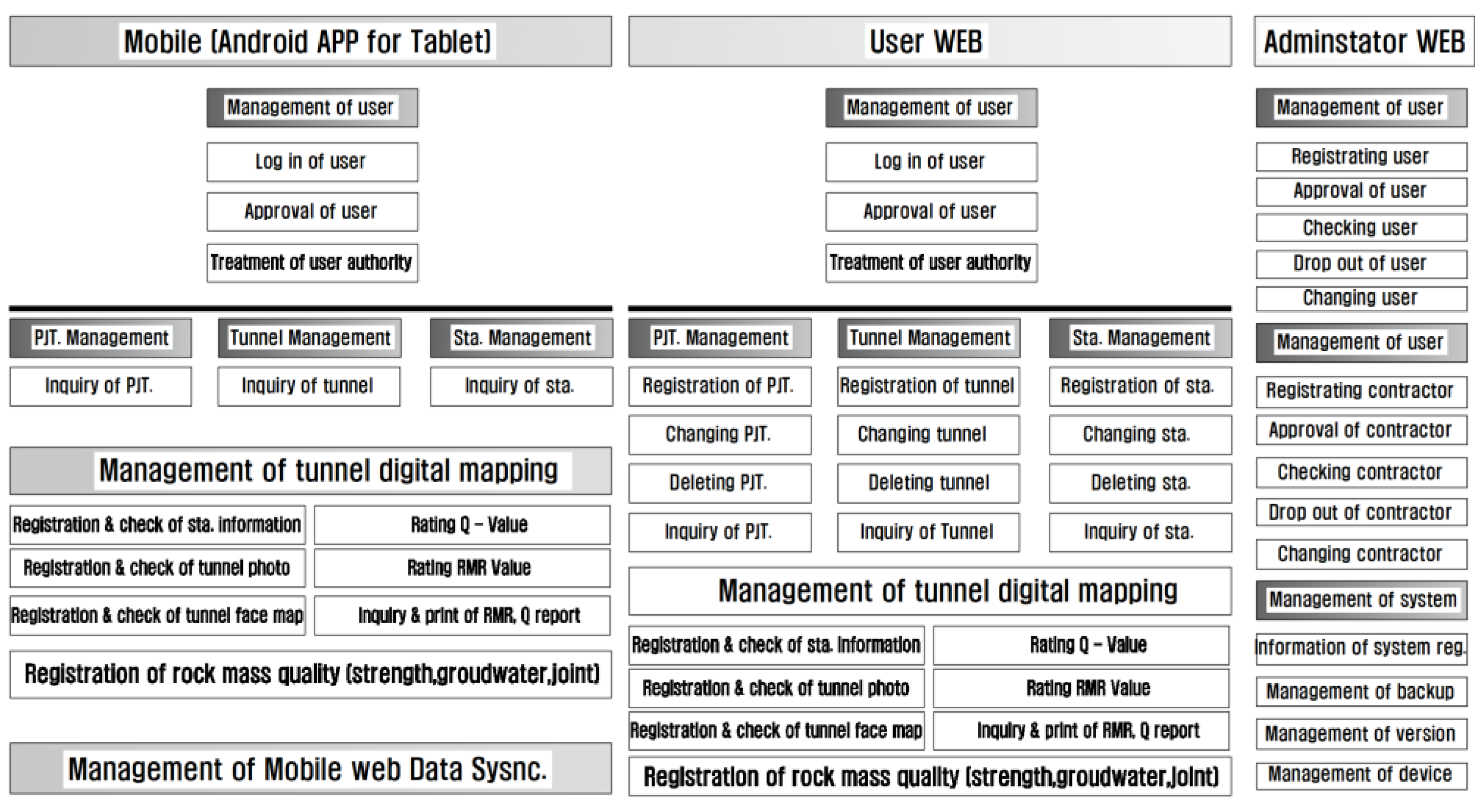

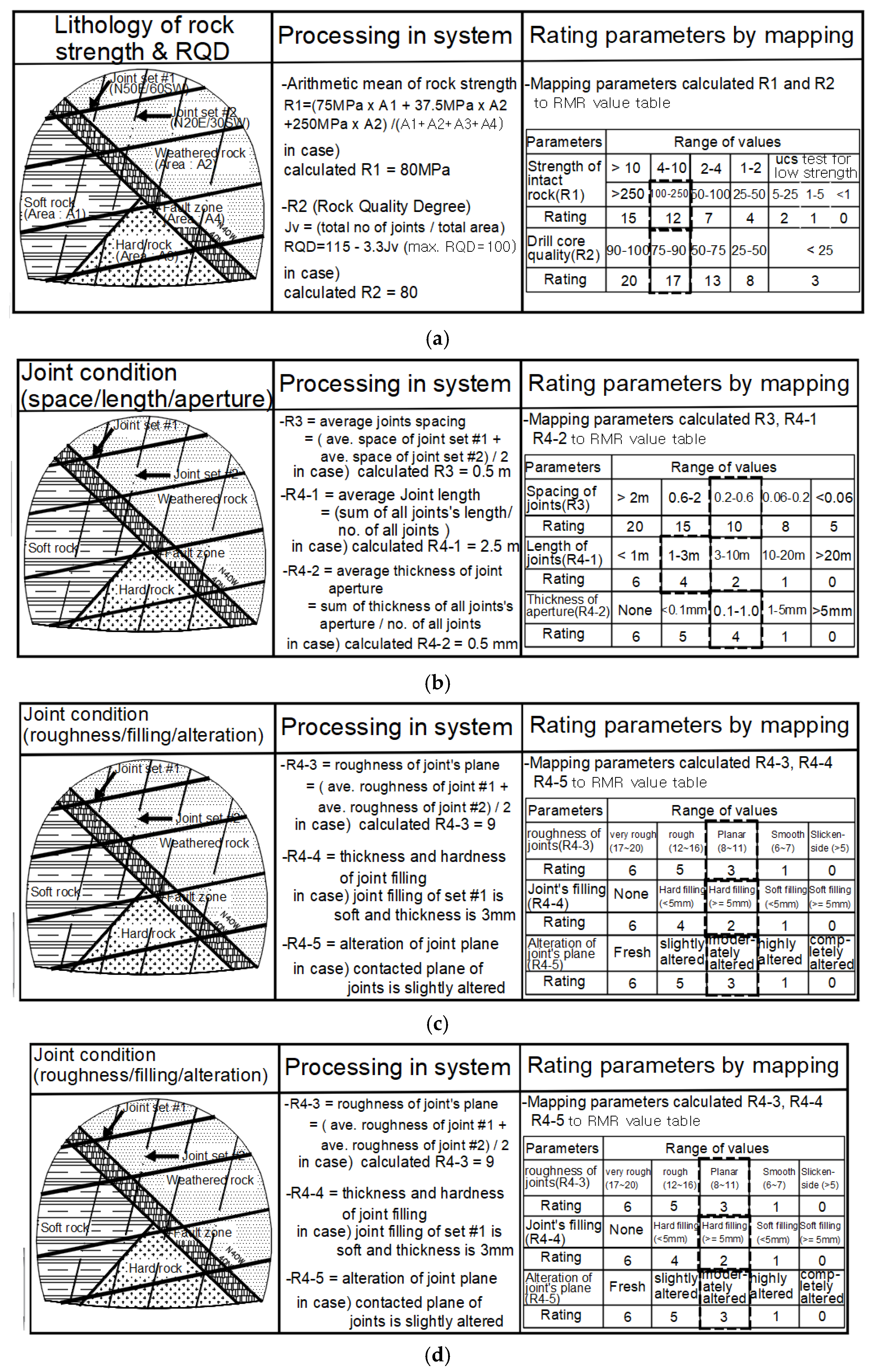

3.2. Automated Rock Mass Classification System

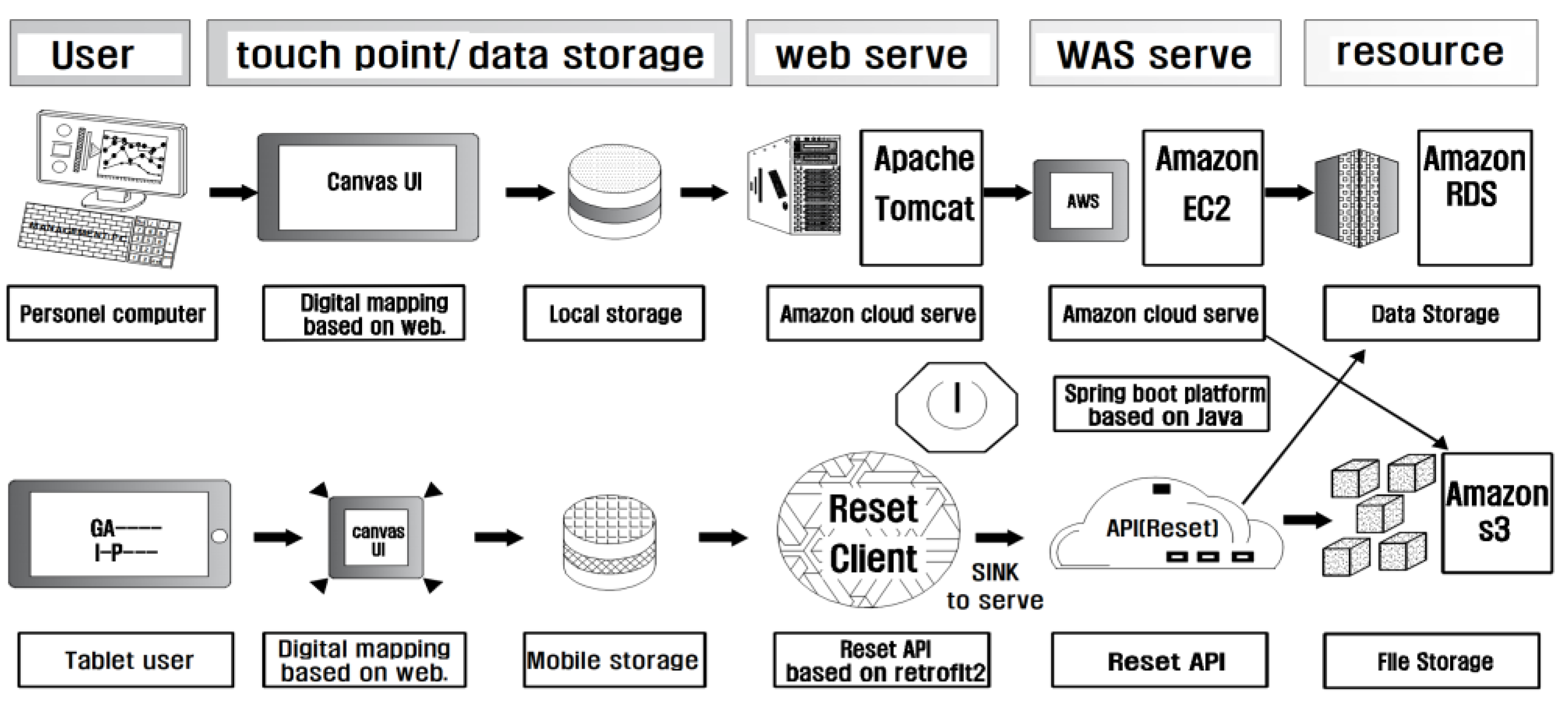

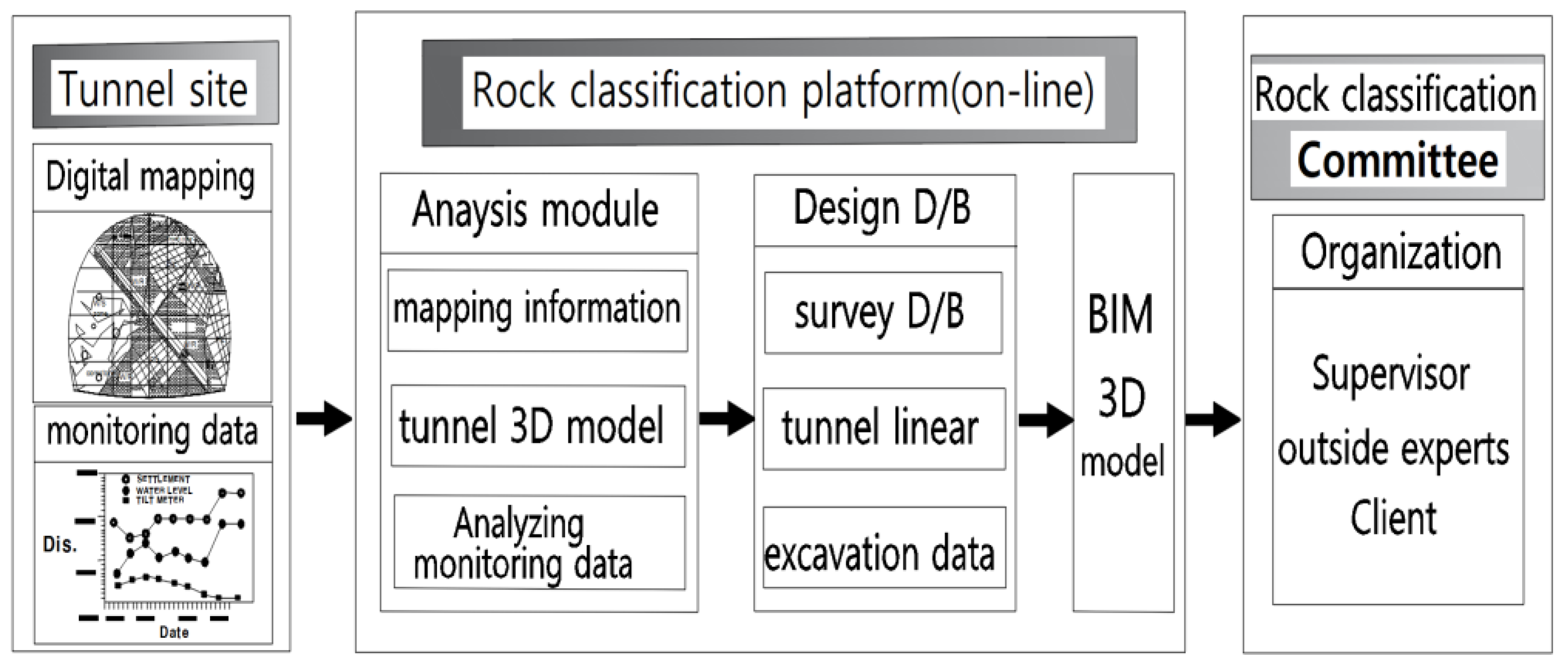

4. Tunnel Digital-Mapping-Based Online Rock Mass Evaluation

4.1. Challenges

4.2. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clegg, P.; Bruciatelli, L.; Domingos, F.; Jones, R.R.; De Donatis, M.; Wilson, R.W. Digital geological mapping with tablet PC and PDA: A comparison. Comput. Geosci. 2006, 32, 1682–1698. [Google Scholar] [CrossRef]

- Terzaghi, K. Rock defects and loads on tunnel supports. In Rock Tunneling with Steel Supports; Proctor, R.V., White, T.L., Eds.; Commercial Shearing and Stamping Company: Youngstown, OH, USA, 1946; Volume 1, pp. 17–99. [Google Scholar]

- Deere, D.U.; Deere, D.W. The rock quality designation (RQD) index in practice. In Rock Classification Systems for Engineering Purposes; Kirkaldie, L., Ed.; ASTM Special Publication: West Conshohocken, PA, USA, 1988; Volume 984, pp. 91–101. [Google Scholar]

- Wickham, G.E.; Tiedemann, H.R.; Skinner, E.H. Support determination based on geologic predictions. In Proceedings of the North American Rapid Excavation and Tunneling Conference, Chicago, IL, USA, 5–7 June 1972; Lane, K.S., Garfield, L.A., Eds.; American Institute of Mining, Metallurgical, and Petroleum Engineers: New York, NY, USA, 1972; pp. 43–64. [Google Scholar]

- Bieniawski, Z.T. Engineering classification of jointed rock masses. Trans. S. Afr. Inst. Civ. Eng. 1973, 15, 335–344. [Google Scholar]

- Barton, N.R.; Lien, R.; Lunde, J. Engineering classification of rock masses for the design of tunnel support. Rock Mech. 1974, 6, 189–239. [Google Scholar] [CrossRef]

- Romana, M.; Tomás, R.; Serón, J.B. Slope Mass Rating (SMR) geomechanics classification: Thirty years review. In Proceedings of the ISRM Congress 2015 Proceedings—International Symposium on Rock Mechanics, Montreal, QC, Canada, 10–13 May 2015; 10p. ISBN 978-1-926872-25-4. [Google Scholar]

- Hoek, E.; Brown, E.T. The Hoek—Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. Eng. 2019, 11, 445e463. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. (Ed.) Rock mass classification in rock engineering. In Exploration for Rock Engineering, Proceedings of the Symposium; Balkema: Cape Town, South Africa, 1976; Volume 1, pp. 97–106. [Google Scholar]

- Barton, N.; Choubey, V. The shear strength of rock joints in theory and practice. Rock Mech. 1977, 10, 1–54. [Google Scholar] [CrossRef]

- Doohwan, J. A management plan for rock tunnel sites considering geological characteristics. J. Korean Geotech. Soc. 2020, 36, 333–340. [Google Scholar]

- Fernando, O.; Olalla, C.; Jiménez, R. Relationship between RMRb and GSI based on in situ data. In Proceedings of the Ceballos EUROCK Vigo 2014, ISRM European Rock Mechanics Symposium, Vigo, Spain, 26–28 May 2014. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, X.; Zhu, H.; Li, J. Quantitative assessments of the correlations between rock mass rating (RMR) and geological strength index (GSI). Tunn. Undergr. Space Technol. 2019, 83, 73–81. [Google Scholar] [CrossRef]

- Gaich, A.; Pischinger, G. 3D images for digital geological mapping. Geomech. Tunn. 2016, 9, 45–51. [Google Scholar] [CrossRef]

- Fekete, S.; Diederichs, M. Integration of three-dimensional laser scanning with discontinuum modelling for stability analysis of tunnels in blocky rock masses. Int. J. Rock Mech. Min. Sci. 2013, 57, 11–23. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, H.G.; Bae, S.W.; Kim, C.Y.; Yoo, W.K.; Lee, J.D. Development of Mobile System Based on Android for Tunnel Face Mapping. J. Eng. Geol. 2014, 24, 343–351. [Google Scholar] [CrossRef]

- Sagong, M.; Lee, J.S.; You, K.; Kim, J.G. Digitalized tunnel face mapping system (DiTFAMS) using PDA and wireless network. Tunn. Undergr. Space Technol. 2006, 21, 390. [Google Scholar] [CrossRef]

- Lee, H.W.; Kim, B.R.; Choi, S.O. Technical Development for Extraction of Discontinuities in Rock Mass Using LiDAR. Tunn. Undergr. Space 2021, 31, 10–24. [Google Scholar] [CrossRef]

- Kim, C.-H.; Kemeny, J. Measurement of Joint Roughness in Large-Scale Rock Fracture Using LiDAR. Tunn. Undergr. Space Technol. 2009, 19, 52–63. [Google Scholar]

- Kim, H.; Cho, L.; Kim, K.S. Rock Classification Prediction in Tunnel Excavation Using CNN. J. Korean Geotech. Soc. 2019, 35, 37–45. [Google Scholar]

- Chen, J.; Zhou, M.; Huang, H.; Zhang, D.; Peng, Z. Automated extraction and evaluation of fracture trace maps from rock tunnel face images via deep learning. Int. J. Rock Mech. Min. Sci. 2021, 142, 104745. [Google Scholar] [CrossRef]

| Division | RMRb (1989) | GSI | Remark |

|---|---|---|---|

| Uniaxial Strength | 15 | 0 | |

| Mechanical Structure | 40 | 50 | RQD Joint space |

| Discontinuities Condition | 30 | 50 | |

| Groundwater Condition | 15 | 0 |

| System | Country (Company) | Main Function |

|---|---|---|

| Four-dimensional super NATM measurement system | Japan (Toda corp.) | A tunnel displacement prediction technique using a 3D laser scanner. |

| Shape-Matrix 3D program | Austria (3GSM GmbH) [14] | Three-dimensional tunnel modelling and geological digital tunnel mapping using several types of image data and a laser scanner. |

| Tunnel program by 3D laser | Greece (Seraphim Amvrazis) [15] | Tunnel projection mapping (tunnel face mapping using a laser scanner). Forecasting the progress of excavation. |

| Tunnel digital mapping system | Korea (KICT) [16] | Digital mapping of the tunnel face on a tunnel photo image. |

| Extraction of discontinuities | Korea (Seoul University) [17,18,19] | Extracting joint sets using a laser scanner and deep learning. |

| Rock classification prediction in tunnel excavation using CNN | Korea (Samsung E&C) [20] | Rock quality classification using a convolutional neural network (CNN). |

| Automated extraction fracture trace maps from tunnel face images | China (Jiayao Chen, Tongji University) [21] | Extracting fracture and analysing rock structures using a CNN. |

| Division | Serve | Cloud | OS | Version | TPMC/Core | Core | MEM | DISC | SW_WAS |

|---|---|---|---|---|---|---|---|---|---|

| Operation | Web Serve | AWS | Linux/ UNIX | Amazon Linux 2/4.2.17 | 35,490.93 (t2.large) | 2 | Virtualization Management | Virtualization Management | Tomcat 8.5 |

| WAS | AWS | Linux/ UNIX | Amazon Linux 2/4.2.17 | 35,490.93 (t2.large) | 2 | Virtualization Management | Virtualization Management | Tomcat 8.5 | |

| DB Serve | AWS | Linux/ UNIX | Amazon Linux 2/4.2.17 | 35,490.93 (t2.large) | 2 | Virtualization Management | Virtualization Management | Mysql5.6 | |

| Development | Web Serve | - | Linux/ UNIX | Ubuntu 20.04 | - | 4 | 32G | IT | Tomcat 8.5 |

| WAS | - | Linux/ UNIX | Ubuntu 20.04 | - | 4 | 32G | IT | Tomcat 8.5 | |

| DB Serve | - | Linux/ UNIX | Ubuntu 20.04 | - | 4 | 32G | IT | Mysql5.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-K.; Song, M.-K.; Jeong, Y.-O.; Lee, S.S.-W. Development of an Automatic Rock Mass Classification System Using Digital Tunnel Face Mapping. Appl. Sci. 2024, 14, 9024. https://doi.org/10.3390/app14199024

Lee H-K, Song M-K, Jeong Y-O, Lee SS-W. Development of an Automatic Rock Mass Classification System Using Digital Tunnel Face Mapping. Applied Sciences. 2024; 14(19):9024. https://doi.org/10.3390/app14199024

Chicago/Turabian StyleLee, Hyun-Koo, Myung-Kyu Song, Young-Oh Jeong, and Sean Seung-Won Lee. 2024. "Development of an Automatic Rock Mass Classification System Using Digital Tunnel Face Mapping" Applied Sciences 14, no. 19: 9024. https://doi.org/10.3390/app14199024

APA StyleLee, H.-K., Song, M.-K., Jeong, Y.-O., & Lee, S. S.-W. (2024). Development of an Automatic Rock Mass Classification System Using Digital Tunnel Face Mapping. Applied Sciences, 14(19), 9024. https://doi.org/10.3390/app14199024