Physicochemical Properties and Nutritional Relevance of Rice Beverages Available on the Market

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Analysis of the Composition and Nutritional Value of Rice Drink

2.2.2. Physicochemical Properties of Rice Drinks

pH

Soluble Solids Content

Osmolality

Foaming Properties and Stability of the Foam Produced

2.2.3. Sensory Evaluation

2.2.4. L*a*b* Colour Measurements and White Index (WI)

2.2.5. Total Polyphenol Content

2.2.6. Antioxidant Activity

2.2.7. Statistical Methods

3. Results

3.1. Analysis of the Composition and Nutritional Value of the Tested Rice Drinks

3.2. Physico-Chemical Parameters of the Tested Rice Drinks

3.2.1. pH, Soluble Solids Content, and Osmolality

3.2.2. Foaming Properties and Foam Stability of the Studied Rice Drinks

3.2.3. Colour Parameters of the Studied Rice Drinks

3.3. Bioactive Properties of the Tested Rice Drinks

3.3.1. Polyphenol Content

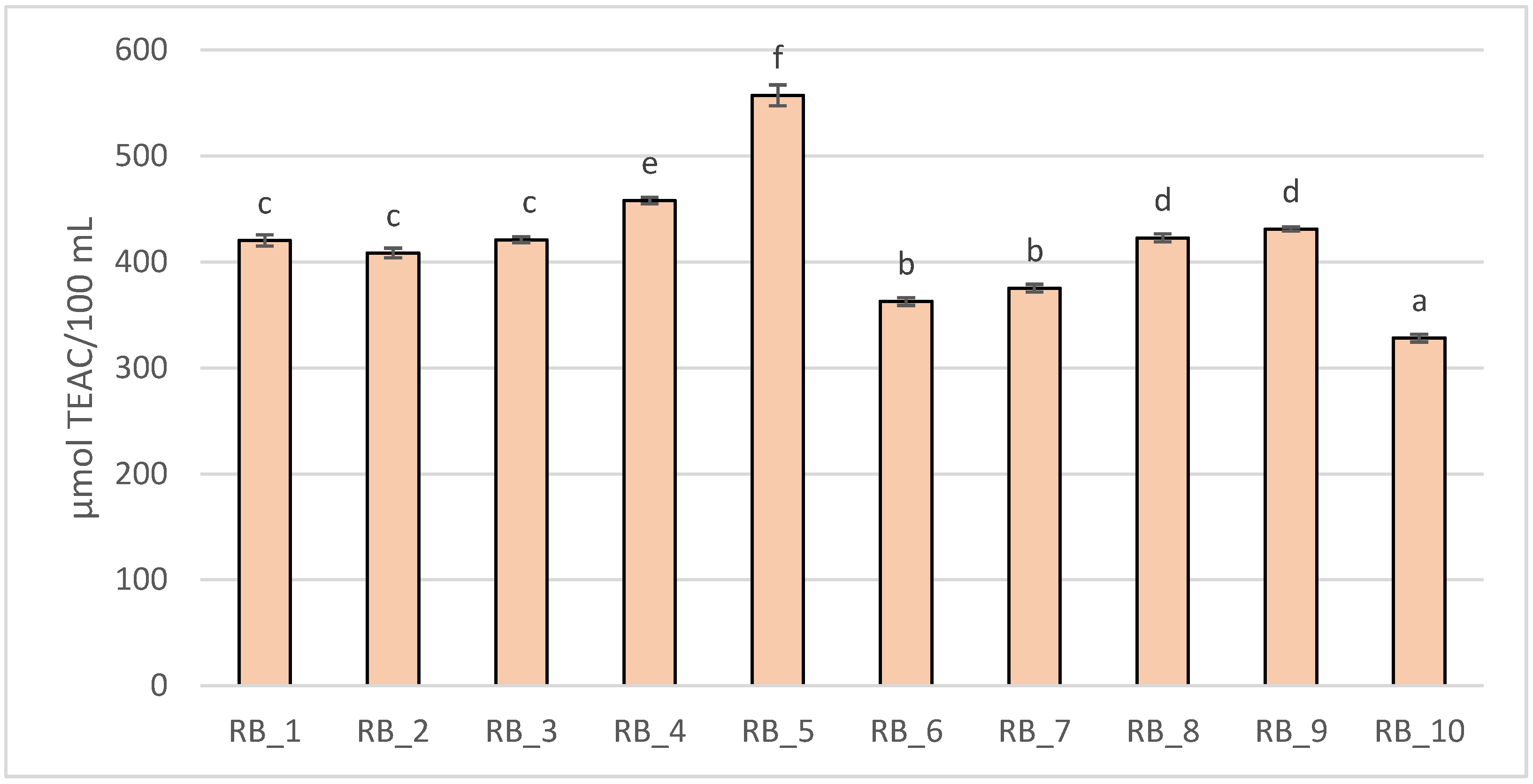

3.3.2. Antioxidant Properties

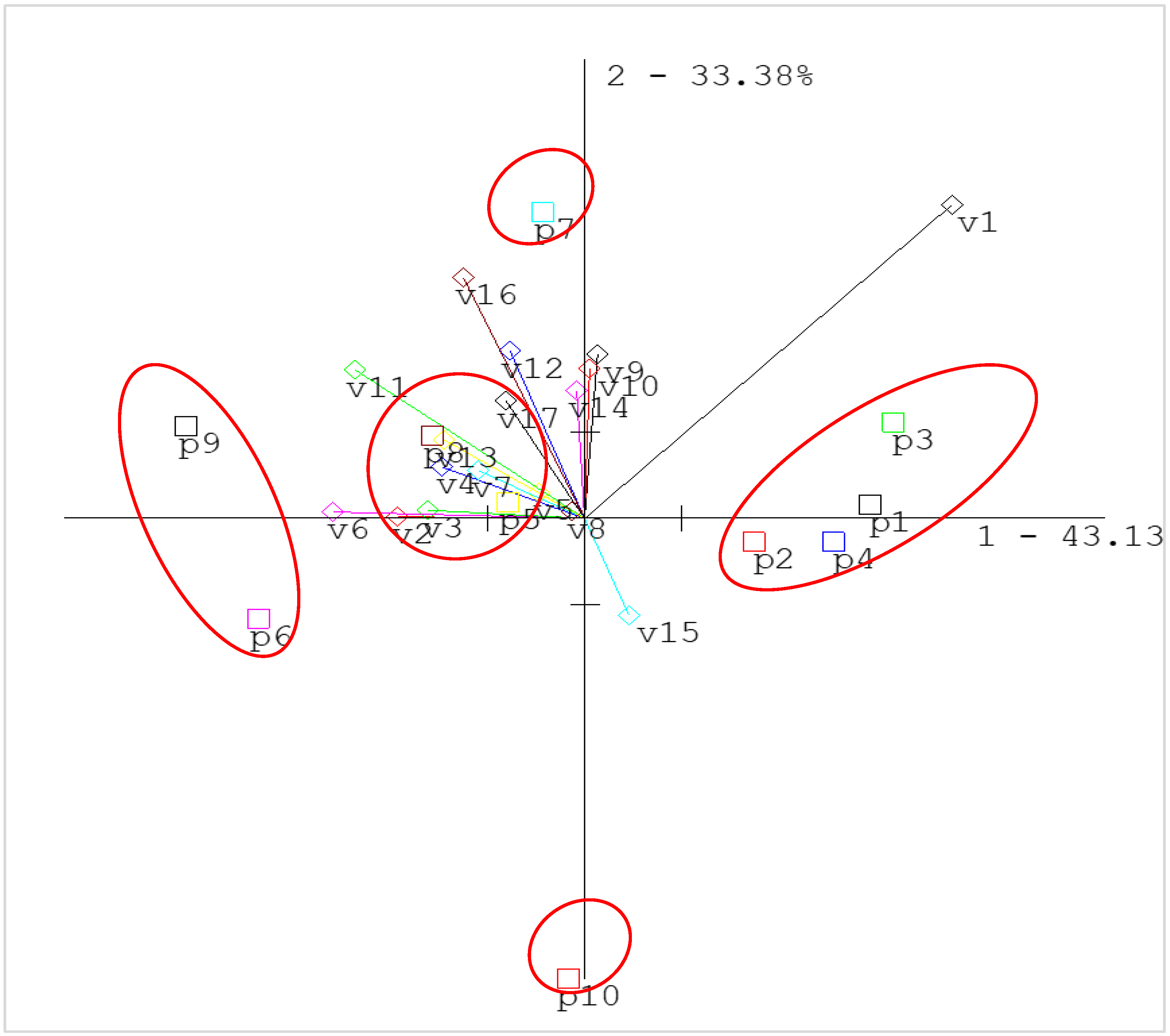

3.4. Sensory Analysis of the Tested Rice Drinks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zaremba, A.; Jędrusek-Golińska, A.; Kobus-Cisowska, J.; Szymandera-Buszka, K. Zachowania konsumentów wobec napojów roślinnych jako alternatywy mleka. Zagadnienia Doradz. Rol. 2023, 111, 60–79. [Google Scholar]

- Tukker, A.; Goldbohm, R.A.; de Koning, A.; Verheijden, M.; Kleijn, R.; Wolf, O.; Pérez-Domínguez, I.; Rueda-Cantuche, J.M. Environmental Impacts of Changes to Healthier Diets in Europe. Ecol. Econ. 2011, 70, 1776–1788. [Google Scholar] [CrossRef]

- Hoffmann, M.; Kostyra, E. Jakość sensoryczna i wartość odżywcza wegańskich substytutów mleka krowiego. Postępy Tech. Przetwórstwa Spożywczego 2015, 1, 52–57. [Google Scholar]

- Fructuoso, I.; Romao, B.; Han, H.; Raposo, A.; Ariza-Montes, A.; Araya-Castillo, L.; Zandonadi, R.P. An overview on nutritional aspects of plant-based beverages used as substitutes for cow’s milk. Nutrients 2021, 13, 2650. [Google Scholar] [CrossRef]

- Bridgesm, M. Moo-ove over, cow’s milk: The rise of plant-based dairy lternatives. Nutr. Issues Gastroenterol. 2018, 171, 20–27. [Google Scholar]

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef]

- Singh, B.P.; Yadav, D.; Vij, S. Soybean Bioactive Molecules: Current Trend and Future Prospective. In Bioactive Molecules in Food: Reference Series in Phytochemistry; Mérillon, J.M., Ramawat, K., Eds.; Springer: Cham, Switzerland, 2017; pp. 1–29. [Google Scholar] [CrossRef]

- Wolever, T.M.S.; Rahn, M.; Dioum, E.; Spruill, S.E.; Ezatagha, A.; Campbell, J.E.; Jenkins, A.L.; Chu, Y. An Oat β-Glucan Beverage Reduces LDL Cholesterol and Cardiovascular Disease Risk in Men and Women with Borderline High Cholesterol: A Double-Blind, Randomized, Controlled Clinical Trial. J. Nutr. 2021, 151, 2655–2666. [Google Scholar] [CrossRef] [PubMed]

- Balbino, S.; Cvitković, D.; Skendrović, H.; Dragović-Uzelac, V. Optimisation of Almond-Based Dairy-Free Milk Alternative Formulation Fortified with Myrtle, Bay Leaf and Fennel Extracts. Food Technol. Biotechnol. 2023, 61, 378–388. [Google Scholar] [CrossRef]

- Siriphanich, J.; Saradhuldhat, P.; Romphophak, T.; Krisanapook, K.; Pathaveerat, S.; Tongchitpakdee, S. Coconut (Cocos nucifera L.). In Woodhead Publishing Series in Food Science, Technology and Nutrition, Postharvest Biology and Technology of Tropical and Subtropical Fruits; Yahia, E.M., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 8–35. [Google Scholar] [CrossRef]

- Mäkinen, O.E.; Wanhalinna, V.; Zannini, E.; Arendt, E.K. Foods for Special Dietary Needs: Non-dairy Plant-based Milk Substitutes and Fermented Dairy-type Products. Crit. Rev. Food Sci. Nutr. 2016, 56, 339–349. [Google Scholar] [CrossRef]

- Silva, A.R.A.; Silva, M.M.N.; Ribeiro, B.D. Health issues and technological aspects of plant-based alternative milk. Food Res. Int. 2020, 131, 108972. [Google Scholar] [CrossRef]

- McClements, D.J.; Newman, E.; McClements, I.F. Plant-based milks: A review of the science underpinning their design, fabrication and performance. Compr. Rev. Food Sci. Food Saf. 2019, 18, 2047–2067. [Google Scholar] [CrossRef] [PubMed]

- Scholz-Ahrens, K.E.; Ahrens, F.; Barth, C.A. Nutritional and health attributes of milk and milk imitations. Eur. J. Nutr. 2020, 59, 1436–6215. [Google Scholar] [CrossRef] [PubMed]

- Grossmann, L.; Kinchla, A.J.; Nolden, A.; Mc Clements, D.J. Standardized methods for testing the quality attributes of plant-based foods: Milk and cream alternatives. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2206–2233. [Google Scholar] [CrossRef] [PubMed]

- Verduci, E.; D’Elios, S.; Cerrato, L.; Comberiati, P.; Calvani, M.; Palazzo, S.; Martelli, A.; Landi, M.; Trikamjee, T.; Peroni, D.G. Cow’s milk substitutes for children: Nutritional aspects of milk from different mammalian species, special formula and plant-based beverages. Nutrients 2019, 11, 2072–6643. [Google Scholar] [CrossRef]

- Atwaa, E.H.; Elmaadawy, A.A.; Awaad, E.A. Production of Fruit Flavored Probiotic Rice Milk Beverage. J. Food Dairy Sci. 2019, 10, 453–458. [Google Scholar] [CrossRef]

- Vanga, S.K.; Raghavan, V. How well do plant based alternatives fare nutritionally compared to cow’s milk? J. Food Sci. Tech. 2018, 55, 10–20. [Google Scholar] [CrossRef]

- Esa, N.M.; Ling, T.B.; Peng, L.S. By-products of rice processing: An overview of health benefits and applications. Rice Res. 2013, 1, 1. [Google Scholar]

- Aydar, E.F.; Tutuncu, S.; Ozcelik, B. Plant-based milk substitutes: Bioactive compounds, conventional and novel processes, bioavailability studies, and health effects. J. Funct. Foods 2020, 70, 103975. [Google Scholar] [CrossRef]

- Lamothe, M.; Rivero-Mendoza, D.; Wendy, J.D. Plant-based milks: Rice. Food Sci. Hum. Nutr. 2020, 5, 1–4. [Google Scholar] [CrossRef]

- Polska Norma PN-EN 12143:2000; Oznaczanie zawartości substancji rozpuszczalnych—Metoda refraktometryczna. Polski Komitet Normalizacyjny. Wydział Wydawnictw Normalizacyjnych: Warsaw, Poland, 2000.

- Stone, H.; Sidel, J.L. Sensory Evaluation Practices; Academic Press: Orlando, FL, USA, 1985. [Google Scholar]

- Polska Norma PN-EN ISO 13299:2016-05; Analiza sensoryczna—Metodyka—Ogólne wytyczne ustalania profilu sensorycznego. Analiza Żywności. Polski Komitet Normalizacyjny. Wydział Wydawnictw Normalizacyjnych: Warsaw, Poland, 2016.

- Polska Norma PN-EN ISO 8586:2014-03; Analiza sensoryczna—Ogólne wytyczne wyboru, szkolenia i monitorowania wybranych oceniających i ekspertów oceny sensorycznej. Analiza Żywności. Polski Komitet Normalizacyjny. Wydział Wydawnictw Normalizacyjnych: Warsaw, Poland, 2014.

- Dobrzańska, A.; Cais-Sokolińska, D. Ocena przydatności systemów pomiaru barwy do badań preparatów białek mleka i serwatki. Apar. Badaw. Dydakt. 2014, 3, 267–272. [Google Scholar]

- Singleton, V.L.; Rossi, J.A., Jr. Colorimetry of total phenolics with phosphomolybdic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Rodríguez, M.L.; Serrano-Carretero, A.; García-Herrera, P.; Cámara-Hurtado, M.; Sánchez-Mata, M.C. Plant-based beverages as milk alternatives? Nutritional and functional approach through food labelling. Int. Food Res. 2023, 173, 113244. [Google Scholar] [CrossRef] [PubMed]

- Giugliano, R.; Musolino, N.; Ciccotelli, V.; Ferraris, C.; Savio, V.; Vivaldi, B.; Ercolini Bianchi, D.M.; Decastelli, L. Soy, Rice and oat drinks: Investigating chemical and biological safety in plant-based milk alternatives. Nutrients 2023, 15, 2258. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, L.R.; Velasco, J.I.; Matta Fakhouri, F.M. Use of rice on the development of plant-based milk with antioxidant properties: From raw material to residue. LWT-Food Sci. Technol. 2023, 173, 114271. [Google Scholar] [CrossRef]

- Chalupa-Krebzdak, S.; Long, C.J.; Bohrer, B.M. Nutrient density and nutritional value of milk and plant-based milk alternatives. Int. Dairy J. 2018, 87, 84–92. [Google Scholar] [CrossRef]

- Sakkas, H.; Bozidis, P.; Touzios, C.; Kolios, D.; Athanasiou, G.; Athanasopoulou, E.; Gerou, I.; Gartzonika, C. Nutritional status and the influence of the vegan diet on the gut microbiota and human health. Medicina 2020, 56, 88. [Google Scholar] [CrossRef]

- Tulashie, S.K.; Amenakpor, J.; Atisey, S.; Odai, R.; Akpari, E.E.A. Production of coconut milk: A sustainable alternative plant based milk. Case Stud. Chem. Environ. Eng. 2022, 6, 100206. [Google Scholar] [CrossRef]

- Rincon, L.; Botelho, R.B.A.; de Alencar, E.R. Development of novel plant-based milk based on chickpea and coconut. LWT 2020, 128, 109479. [Google Scholar] [CrossRef]

- Pérez-Castillo, Í.M.; Williams, J.A.; López-Chicharro, J.; Mihic, N.; Rueda, R.; Bouzamondo, H.; Horswill, C.A. Compositional aspects of beverages designed to promote hydration before, during, and after exercise: Concepts revisited. Nutrients 2024, 16, 17. [Google Scholar] [CrossRef]

- Sadowska, A.; Świderski, F.; Rakowska, R.; Waszkiewicz-Robak, B.; Żebrowska-Krasuska, M.; Dybkowska, E. Beverage osmolality as a marker for maintaining appropriate body hydration. Rocz. Państwowego Zakładu Hig. 2017, 68, 167–173. [Google Scholar]

- Faria, D.K.; Mendes, M.E.; Sumita, N.M. The measurement of serum osmolality and its application to clinical practice and laboratory: Literature Review. J. Bras. Patol. Med. Lab. 2017, 53, 38–45. [Google Scholar] [CrossRef]

- Amaglianim, L.; Silva, J.V.C.; Saffon, M.; Dombrowski, J. On the foaming properties of plant proteins: Current status and future opportunities. Trends Food Sci. Tech. 2021, 118 Pt A, 261–272. [Google Scholar] [CrossRef]

- Hayashi, S.; Yanase, E. A study on the color deepening in red rice during storage. Food Chem. 2016, 199, 457–462. [Google Scholar] [CrossRef] [PubMed]

- Jeske, S.; Bez, J.; Arendt, E.K.; Zannini, E. Formation, stability and sensory characteristics af a lentil-based milk substitute as affected by homogenisation and pasteurisation. Eur. Food Res. Technol. 2019, 245, 1519–1531. [Google Scholar] [CrossRef]

- Jeske, S.; Zannini, E.; Arendt, E.K. Evaluation of physicochemical and glycaemic properties of commercial plant-based milk substitutes. Plant Foods Hum. Nutr. 2017, 72, 26–33. [Google Scholar] [CrossRef]

- McClements, D.J. Colloidal basis of emulsion color. Curr. Opin. Colloid Interface Sci. 2002, 7, 451–455. [Google Scholar] [CrossRef]

- McClements, D.J. Theoretical prediction of emulsion color. Adv. Colloid Interface Sci. 2002, 97, 63–89. [Google Scholar] [CrossRef]

- Alasalvar, C.; Bolling, B.W. Review of nut phytochemicals, fat-soluble bioactives, antioxidant components and health effects. Br. J. Nutr. 2015, 113, 68–78. [Google Scholar] [CrossRef]

- Fitrotin, U.; Utami, T.; Hastuti, P.; Santoso, U. Antioxidant properties of fermented sesame milk using Lactobacillus plantarum Dad 13. Int. J. Biol. Sci. 2015, 4, 56–61. [Google Scholar]

- Grajek, W. Zmiany potencjału przeciwutleniającego surowców roślinnych w procesach przetwórczych i w czasie trawienia. Żywność 2003, 4, 26–35. [Google Scholar]

| Beverage Code | Beverage Ingredients |

|---|---|

| RB_1 | water, rice (12%), sunflower oil, tricalcium phosphate, maltodextrin, sea salt, stabiliser (gellan gum), vitamins (B12, D2), and acidity regulator (potassium phosphates) |

| RB_2 | water, rice (14%), sunflower oil, and sea salt |

| RB_3 | water, rice (14%), sunflower oil, and sea salt |

| RB_4 | water, rice (11%), sunflower oil, calcium carbonate, and salt |

| RB_5 | water, rice (12.5%), sunflower oil, calcium carbonate, vegetable fibre, stabilisers: gellan gum, sea salt, and vitamins (D, B12) |

| RB_6 | water, rice, sunflower oil, sea salt, and an acidity regulator: calcium carbonate |

| RB_7 | water, rice (17%), sunflower oil, and sea salt |

| RB_8 | water, rice (15%), sunflower oil, and sea salt |

| RB_9 | water, rice (14.4%), sunflower oil, sea salt, and natural vanilla flavouring |

| RB_10 | water, rice (12%), cold-pressed sunflower oil, and sea salt |

| Energy and Nutritional Value | RB_1 | RB_2 | RB_3 | RB_4 | RB_5 | RB_6 | RB_7 | RB_8 | RB_9 | RB_10 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy value | kcal/100 mL | 47 | 50 | 55 | 54 | 50 | 50 | 54 | 54 | 52 | 37 |

| kJ/100 mL | 200 | 212 | 229 | 230 | 209 | 211 | 229 | 228 | 221 | 158 | |

| Fat | g/100 mL | 1.0 | 1.1 | 1.0 | 1.0 | 1.3 | 1.3 | 1.0 | 1.0 | 0.9 | 0.6 |

| of which s. f. a.* | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.1 | 0.1 | 0.0 | <0.1 | |

| Carbohydrates | g/100 mL | 9.5 | 9.9 | 11.0 | 11.0 | 9.2 | 9.6 | 11.0 | 11.0 | 11.0 | 8.0 |

| of which sugars | 3.3 | 7.1 | 7.5 | 6.0 | 4.3 | 3.5 | 5.0 | 5.0 | 7.8 | 4.0 | |

| Protein | g/100 mL | 0.1 | <0.5 | <0.5 | 0.2 | 0.1 | <0.1 | <0.5 | 0.3 | 0.0 | <0.5 |

| Salt | g/100 mL | 0.09 | 0.08 | 0.1 | 0.1 | 0.12 | 0.06 | 0.1 | 0.07 | 0.1 | 0.08 |

| Fiber | g/100 mL | 0.0 | <0.5 | <0.5 | 0.3 | 0.3 | 0.0 | <0.5 | 0.1 | 0.0 | <0.5 |

| Vitamin B12 | μg/100 mL | 0.38 | - | - | - | 0.38 | - | - | - | - | - |

| Vitamin D | μg/100 mL | 0.75 | - | - | - | 0.75 | - | - | - | - | - |

| Calcium | mg/100 mL | 120 | - | - | 120 | - | 120 | - | - | - | - |

| Beverage Code | pH | Soluble Solids [%] | Osmolality mOsm/kg H2O |

|---|---|---|---|

| RB_1 | 7.43 ± 0.01 h | 10.67 ± 0.29 b | 260.67 ± 1.53 b |

| RB_2 | 6.70 ± 0.03 d | 12.17 ± 0.29 d | 306.00 ± 1.00 c |

| RB_3 | 6.97 ± 0.01 f | 12.33 ± 0.29 d | 326.00 ± 1.00 c |

| RB_4 | 7.26 ± 0.01 g | 11.33 ± 0.29 c | 360.67 ± 1.53 d |

| RB_5 | 6.93 ± 0.01 e | 10.17 ± 0.29 b | 267.33 ± 2.52 b |

| RB_6 | 6.66 ± 0.01 c | 10.17 ± 0.29 b | 427.67 ± 6.51 e |

| RB_7 | 6.96 ± 0.01 f | 12.33 ± 0.29 d | 364.00 ± 1.00 d |

| RB_8 | 6.59 ± 0.01 b | 12.67 ± 0.29 d | 420.00 ± 4.36 e |

| RB_9 | 6.66 ± 0.01 c | 11.17 ± 0.29 c | 321.67 ± 3.51 c |

| RB_10 | 6.32 ± 0.01 a | 8.67 ± 0.29 a | 193.33 ± 1.53 a |

| Beverage Code | L* | a* | b* | White Index (WI) |

|---|---|---|---|---|

| RB_1 | 80.29 ± 0.02 f | 3.14 ± 0.03 a | 17.46 ± 0.49 d | 82.23 ± 0.09 e |

| RB_2 | 83.39 ± 0.01 h | 5.89 ± 0.01 e | 13.87 ± 0.26 a | 84.74 ± 0.04 f |

| RB_3 | 78.41 ± 0.06 c | 5.94 ± 0.04 e | 17.35 ± 0.18 d | 80.53 ± 0.09 c |

| RB_4 | 75.14 ± 0.10 a | 3.72 ± 0.01 b | 19.89 ± 0.12 f | 77.82 ± 0.06 a |

| RB_5 | 76.26 ± 0.15 b | 6.34 ± 0.04 f | 19.84 ± 0.57 f | 79.06 ± 0.29 b |

| RB_6 | 79.79 ± 0.20 e | 3.89 ± 0.01 c | 17.57 ± 0.42 d | 81.80 ± 0.29 d |

| RB_7 | 78.99 ± 0.41 d | 5.30 ± 0.06 d | 18.58 ± 0.47 e | 81.32 ± 0.50 d |

| RB_8 | 82.47 ± 0.47 g | 6.25 ± 0.09 f | 15.86 ± 0.20 c | 84.22 ± 0.50 f |

| RB_9 | 84.87 ± 0.12 i | 3.89 ± 0.10 c | 14.59 ± 0.40 b | 86.20 ± 0.18 g |

| RB_10 | 78.11 ± 0.11 c | 6.87 ± 0.06 g | 16.06 ± 0.09 c | 80.03 ± 0.12 c |

| Sensory Distinctions | RB_1 | RB_2 | RB_3 | RB_4 | RB_5 | RB_6 | RB_7 | RB_8 | RB_9 | RB_10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Colour | 4.65 | 2.24 | 4.76 | 5.30 | 6.54 | 3.53 | 4.78 | 3.39 | 1.91 | 1.16 |

| S.* sweet | 1.29 | 2.69 | 1.98 | 2.53 | 1.87 | 2.51 | 1.65 | 2.00 | 3.34 | 2.43 |

| S. milky | 0.99 | 2.10 | 1.7 | 2.80 | 1.22 | 2.03 | 0.76 | 1.62 | 2.41 | 1.81 |

| S. vanilla | 0.81 | 1.84 | 1.67 | 1.96 | 2.15 | 1.31 | 0.63 | 0.98 | 1.76 | 1.56 |

| S. rice | 1.87 | 4.56 | 2.16 | 2.71 | 2.25 | 3.36 | 1.84 | 2.97 | 3.99 | 2.56 |

| S. fatty | 1.17 | 2.37 | 1.37 | 2.36 | 1.55 | 2.01 | 1.16 | 1.22 | 2.14 | 1.50 |

| S. other (caramel) | 0.00 | 0.40 | 0.00 | 0.00 | 0.38 | 0.27 | 0.44 | 0.85 | 0.21 | 0.00 |

| Overall smell intensity | 2.74 | 4.73 | 2.63 | 3.73 | 3.65 | 3.96 | 2.71 | 3.38 | 4.60 | 3.76 |

| Density | 2.57 | 1.54 | 1.78 | 3.09 | 2.46 | 2.23 | 2.01 | 1.63 | 2.71 | 1.01 |

| Viscosity | 2.61 | 1.81 | 1.73 | 2.90 | 2.51 | 2.40 | 2.46 | 2.31 | 2.79 | 1.07 |

| T.* sweetness | 2.82 | 5.74 | 4.55 | 4.99 | 3.44 | 5.86 | 4.52 | 5.82 | 5.13 | 2.79 |

| F.* milky | 3.3 | 2.81 | 3.47 | 4.24 | 2.53 | 3.24 | 2.43 | 3.47 | 4.01 | 1.89 |

| F. rice | 3.17 | 4.69 | 3.66 | 4.36 | 3.98 | 3.53 | 3.11 | 3.94 | 5.00 | 3.23 |

| F. fatty | 2.87 | 2.84 | 2.42 | 3.16 | 3.05 | 2.97 | 2.47 | 2.51 | 2.80 | 1.50 |

| F. other (caramel) | 0.69 | 1.71 | 2.16 | 1.27 | 1.95 | 1.53 | 1.61 | 0.48 | 0.77 | 2.40 |

| “Body” | 4.13 | 3.74 | 3.5 | 5.79 | 3.88 | 5.06 | 4.00 | 4.38 | 5.71 | 2.70 |

| Overall sensory quality | 4.92 | 4.83 | 4.75 | 5.54 | 4.38 | 5.37 | 4.53 | 4.74 | 5.60 | 3.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najman, K.; Ponikowska, P.; Sadowska, A.; Hallmann, E.; Wasiak-Zys, G.; Świderski, F.; Buczak, K. Physicochemical Properties and Nutritional Relevance of Rice Beverages Available on the Market. Appl. Sci. 2024, 14, 9150. https://doi.org/10.3390/app14199150

Najman K, Ponikowska P, Sadowska A, Hallmann E, Wasiak-Zys G, Świderski F, Buczak K. Physicochemical Properties and Nutritional Relevance of Rice Beverages Available on the Market. Applied Sciences. 2024; 14(19):9150. https://doi.org/10.3390/app14199150

Chicago/Turabian StyleNajman, Katarzyna, Paulina Ponikowska, Anna Sadowska, Ewelina Hallmann, Grażyna Wasiak-Zys, Franciszek Świderski, and Krzysztof Buczak. 2024. "Physicochemical Properties and Nutritional Relevance of Rice Beverages Available on the Market" Applied Sciences 14, no. 19: 9150. https://doi.org/10.3390/app14199150

APA StyleNajman, K., Ponikowska, P., Sadowska, A., Hallmann, E., Wasiak-Zys, G., Świderski, F., & Buczak, K. (2024). Physicochemical Properties and Nutritional Relevance of Rice Beverages Available on the Market. Applied Sciences, 14(19), 9150. https://doi.org/10.3390/app14199150