Design of a Modular Energy Production–Storage System for a Sustainable Bicycle

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. User-Centred Design (UCD) Methodology

- Context-of-use understanding;

- User requirements specifications (design premises);

- Design solutions;

- Evaluation against requirements.

2.2. Context-of-Use Understanding

2.3. Design Premises

- Aesthetics—users would like maximum integration within the bike with the least visibility of the product;

- Battery capacity—users find this of vital importance to feed their electronic devices;

- Current output—one of the most important aspects as it will determine the amount of time necessary to charge the electronic devices plugged into the USB charger;

- Weight—users did not reach a consensus here, although most of them like to have light devices mounted on their frames;

- Easy battery replacement—users like to have easy access to batteries, so they can replace or repair them by themselves;

- Solar charging—users would like their devices to be charged not only when they are pedaling but also when they are stopped at traffic lights or resting during long rides;

- Drag force—users regret that drag force is variable when a dynamo is used. They would like the charging system to present a stable drag force for a wide range of speeds.

- Price—users want it as reduced as possible;

- Bluetooth/App—this is merely an informative aspect that some users would like the final model to include.

2.4. Design Solutions

2.5. Evaluation against Requirements

3. Results

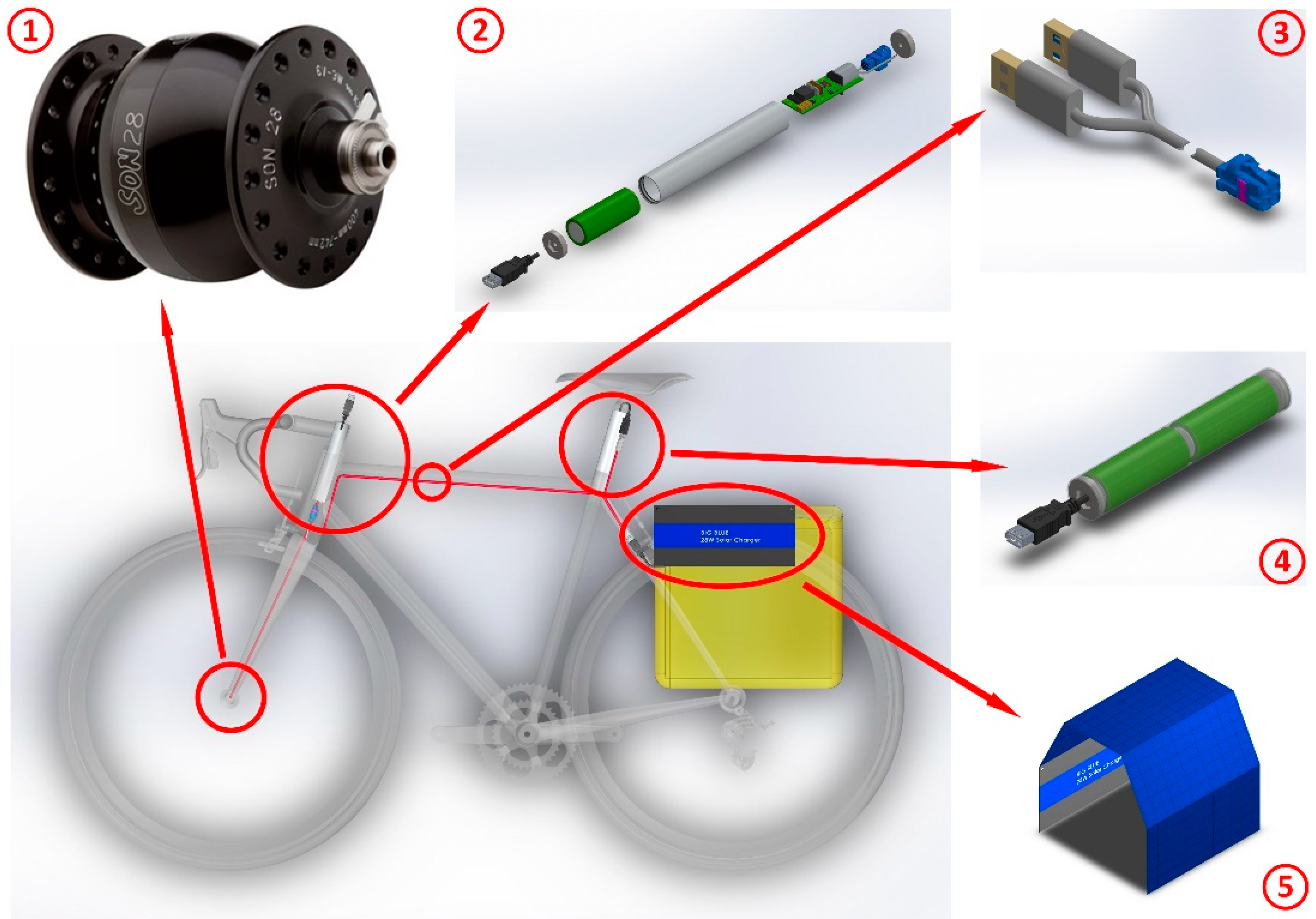

3.1. Description of the Modular Charge–Storage Scheme

3.1.1. The Hub Dynamo

3.1.2. Portable Battery Packs

3.1.3. Solar Panels

3.2. Electronic Design of the Integrated System

3.2.1. Electronics of the USB Charger Module

3.2.2. AC/DC Converter

3.2.3. DC/DC Converter

3.3. Batteries

3.4. Solar Panel Module

3.5. Interconnective Wiring

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roskilly, A.P.; Palacin, R.; Yan, J. Novel technologies and strategies for clean transport systems. Appl. Energy 2015, 100, 563–566. [Google Scholar] [CrossRef]

- Wolf, S.; Teitge, J.; Mielke, J.; Schütze, F.; Jaeger, C. The European Green Deal—More Than Climate Neutrality. Intereconomics 2021, 56, 99–107. [Google Scholar] [CrossRef] [PubMed]

- Siddi, M. The European Green Deal: Assessing Its Current State and Future Implementation; University of Cagliari: Cagliari, Italy, 2020. [Google Scholar]

- Mei, Z.; Wang, D.; Chen, J.; Wang, W. Investigation of bicycle travel time estimation using bluetooth sensors for low sampling rates. Promet-Traffic Transp. 2014, 26, 383–391. [Google Scholar] [CrossRef]

- Johansson, C.; Lövenheim, B.; Schantz, P.; Wahlgren, L.; Almström, P.; Markstedt, A.; Strömgren, M.; Forsberg, B.; Sommar, J.N. Impacts on air pollution and health by changing commuting from car to bicycle. Sci. Total Environ. 2017, 584–585, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-A.; Lee, H.-L. How to promote bike tourism globally. Tour. Hosp. Manag. 2017, 23, 1–16. [Google Scholar] [CrossRef]

- Alwyn, Y.W.S.; Faizal, M. Bicycle Powered Mobile Phone Charger. In Proceedings of the 14th EURECA 2020—International Engineering and Computing Research Conference “Shaping the Future through Multidisciplinary Research”, Subang Jaya, Malayasia, 25 November 2020; p. 03018. [Google Scholar]

- Kiefer, C.; Behrendt, F. Smart e-bike monitoring system: Real-time open source and open hardware GPS assistance and sensor data for electrically-assisted bicycles. IET Intell. Transp. Syst. 2016, 10, 79–88. [Google Scholar] [CrossRef]

- Fishman, E.; Cherry, C. E-bikes in the Mainstream: Reviewing a Decade of Research. Transp. Rev. 2016, 36, 72–91. [Google Scholar] [CrossRef]

- Shashank, R.; Akshay, V.; Ramesh, S.; Nithin, B.G.; Ravi, K.S.; Krishna, S.A.M. Design and fabrication of solar powered bicycle. J. Phys. Conf. Series 2021, 2070, 012208. [Google Scholar] [CrossRef]

- Asrori, A.; Rohman, F.; Faizal, E.; Karis, M. The design and Performance Investigation of Solar E-Bike using flexible solar panel by different battery charging controller. Int. J. Mech. Prod. Eng. Res. Dev. IJMPERD 2020, 10, 14431–14442. [Google Scholar]

- Apostolou, G.; Reinders, A.; Geurs, K. An overview of existing experiences with solar-powered e-bikes. Energies 2018, 11, 2129. [Google Scholar] [CrossRef]

- Reddy, P.R.; Gowda, K.S.S.; Charitha, S.; Mahalakshmi, R. Review and Redesign of Pedal Energy-Solar Power Augmented Hybrid Bicycle. In Proceedings of the 2020 Third International Conference on Smart Systems and Inventive Technology (ICSSIT), Tirunelveli, India, 20–22 August 2020; pp. 376–380. [Google Scholar]

- Brenna, M.; Falvo, M.C.; Foiadelli, F.; Martirano, L.; Massaro, F.; Poli, D.; Vaccaro, A. Challenges in energy systems for the smart-cities of the future. In Proceedings of the 2012 IEEE International Energy Conference and Exhibition (ENERGYCON), Florence, Italy, 9–12 September 2012; pp. 755–762. [Google Scholar]

- Cecconi, V.; Di Dio, V.; Di Tommaso, A.O.; La Cascia, D.; Miceli, R. Test bench realization and application of specific working cycles for the characterization of wheelchair electrical drives. In Proceedings of the 2006 IEEE International Symposium on Industrial Electronics, Montreal, QC, Canada, 9–13 July 2006; pp. 2188–2193. [Google Scholar]

- Tsai, C.-C.; Lin, W.-M.; Lin, C.-H.; Wu, M.-S. Designing a fast battery charger for electric bikes. In Proceedings of the 2010 International Conference on System Science and Engineering, Taipei, Taiwan, 1–3 July 2010; pp. 385–389. [Google Scholar]

- Boscaino, V.; Livreri, P.; Marino, F.; Minieri, M. Linear-non-linear digital control for dc/dc converters with fast transient response. Int. J. Power Energy Syst. 2009, 29, 38–47. [Google Scholar] [CrossRef]

- Yun, J.J.; Choe, H.J.; Hwang, Y.H.; Park, Y.K.; Kang, B. Improvement of Power-Conversion Efficiency of a DC–DC Boost Converter Using a Passive Snubber Circuit. IEEE Trans. Ind. Electron. 2012, 59, 1808–1814. [Google Scholar] [CrossRef]

- Dannier, A.; Rizzo, R. An overview of Power Electronic Transformer: Control strategies and topologies. In Proceedings of the International Symposium on Power Electronics Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 20–22 June 2012; pp. 1552–1557. [Google Scholar]

- ElMenshawy, M.; Massoud, A. Development of Modular DC-DC Converters for Low-Speed Electric Vehicles Fast Chargers. Alex. Eng. J. 2021, 60, 1067–1083. [Google Scholar] [CrossRef]

- Bani Ahmad, A.; Ooi, C.A.; Ishak, D.; Abdullah, M.N. Optimal cell utilisation with state-of-charge balancing control in a grid-scale three-phase battery energy storage system: An experimental validation. Alex. Eng. J. 2022, 61, 9043–9059. [Google Scholar] [CrossRef]

- Viswanatha, V. Microcontroller based bidirectional buck–boost converter for photo-voltaic power plant. J. Electr. Syst. Inf. Technol. 2018, 5, 745–758. [Google Scholar]

- Sudarshan, B.S.; Arunkumar, G. SiC switch-based isolated DC-DC converter for simultaneous charging of Li-ion batteries of different voltage ratings for low- and medium-power electric vehicle battery charging application. Int. J. Circuit Theory Appl. 2023, 51, 5348–5400. [Google Scholar] [CrossRef]

- Tran, V.-L.; Tran, N.-T.; Yu, S.-H.; Park, Y.; Choi, W. Design of a nonisolated fuel cell boost charger for lithium polymer batteries with a low output ripple. IEEE Trans. Energy Convers. 2014, 30, 605–614. [Google Scholar] [CrossRef]

- Chandrasekaran, R.; Reddy, M.S.K.; Selvajyothi, K.; Raja, B. Design of bidirectional DC-DC converters and controllers for hybrid energy sources in electric vehicles. In Power Converters, Drives and Controls for Sustainable Operations; Wiley: Hoboken, NJ, USA, 2024; pp. 437–461. [Google Scholar] [CrossRef]

- Kushwaha, R.; Khadkikar, V.; Edpuganti, A. Electric Vehicle On-Board Fast Charging Through Converter Maximum Switch Utilization. IEEE Trans. Power Electron. 2024, 39, 998–1014. [Google Scholar] [CrossRef]

- Khan, S.; Awan, M.J. A generative design technique for exploring shape variations. Adv. Eng. Inform. 2018, 38, 712–724. [Google Scholar] [CrossRef]

- Volstad, N.L.; Boks, C. On the use of Biomimicry as a Useful Tool for the Industrial Designer. Sustain. Dev. 2012, 20, 189–199. [Google Scholar] [CrossRef]

- Feng, Y.; Zhao, Y.; Zheng, H.; Li, Z.; Tan, J. Data-driven product design toward intelligent manufacturing: A review. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420911257. [Google Scholar] [CrossRef]

- Stegall, N. Designing for sustainability: A philosophy for ecologically intentional design. Des. Issues 2006, 22, 56–63. [Google Scholar] [CrossRef]

- Kankainen, A. UCPCD: User-centered product concept design. In Proceedings of the 2003 Conference on Designing for User Experiences, San Francisco, CA, USA, 6–7 June 2003; pp. 1–13. [Google Scholar]

- Still, B.; Crane, K. Fundamentals of User-Centered Design: A Practical Approach; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Rubin, J.; Chisnell, D. Handbook of Usability Testing: How to Plan, Design, and Conduct Effective Tests; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Arntzen, C. The Bicycle-Powered Smartphone Charger; California Polytechnic State University: San Luis Obispo, CA, USA, 2013. [Google Scholar] [CrossRef]

- Affam, A.; Mohd-Mokhtar, R. Application of Three Independent Sources to Mobile Phone Charging During Emergencies. In Proceedings of the 10th International Conference on Robotics, Vision, Signal Processing and Power Applications, Penang, Malaysia, 2 April 2019; pp. 261–268. [Google Scholar]

- Schleyer, T.K.L.; Thyvalikakath, T.P.; Hong, J. What is user-centered design? J. Am. Dent. Assoc. 2007, 138, 1081–1082. [Google Scholar] [CrossRef] [PubMed]

- Brunner, J.; Chuang, E.; Goldzweig, C.; Cain, C.L.; Sugar, C.; Yano, E.M. User-centered design to improve clinical decision support in primary care. Int. J. Med. Inform. 2017, 104, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Lyon, A.R.; Koerner, K. User-centered design for psychosocial intervention development and implementation. Clin. Psychol. Sci. Pract. 2016, 23, 180. [Google Scholar] [CrossRef] [PubMed]

- Popescu, D.; Roibu, H.; Manta, F.L.; Unguritu, O.; Marian, M. Design of a Mobile Robot to Work in Special Environments. In Proceedings of the EPE 2020—Proceedings of the 2020 11th International Conference and Exposition on Electrical and Power Engineering, Iasi, Romania, 22–23 October 2020; pp. 226–231. [Google Scholar]

- Lowdermilk, T. User-Centered Design: A Developer’s Guide to Building User-Friendly Applications; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2013. [Google Scholar]

- Al Maghraoui, O.; Vallet, F.; Puchinger, J. Recommendations for a User-Centered Design of Mobility Solutions. In The Robomobility Revolution of Urban Public Transport: A Social Sciences Perspective; Springer: Berlin/Heidelberg, Germany, 2021; pp. 133–152. [Google Scholar]

- Mao, J.-Y.; Vredenburg, K.; Smith, P.W.; Carey, T. The state of user-centered design practice. Commun. ACM 2005, 48, 105–109. [Google Scholar] [CrossRef]

- Mathur, S.; Janaudis-Ferreira, T.; Hemphill, J.; Cafazzo, J.A.; Hart, D.; Holdsworth, S.; Lovas, M.; Wickerson, L. User-centered design features for digital health applications to support physical activity behaviors in solid organ transplant recipients: A qualitative study. Clin. Transplant. 2021, 35, e14472. [Google Scholar] [CrossRef]

- Gray, C.S.; Khan, A.I.; Kuluski, K.; McKillop, I.; Sharpe, S.; Bierman, A.S.; Lyons, R.F.; Cott, C. Improving patient experience and primary care quality for patients with complex chronic disease using the electronic patient-reported outcomes tool: Adopting qualitative methods into a user-centered design approach. JMIR Res. Protoc. 2016, 5, e5204. [Google Scholar]

- Jokela, T.; Iivari, N.; Matero, J.; Karukka, M. The standard of user-centered design and the standard definition of usability: Analyzing ISO 13407 against ISO 9241-11. In Proceedings of the Latin American Conference on Human-Computer Interaction, Rio de Janeiro, Brazil, 17–20 August 2003; pp. 53–60. [Google Scholar]

- Arbour, M. New Cinq Plug5 Pure: Dynamo Power Perfected. 2020. Available online: https://bikepacking.com/news/cinq-plug5-pure/ (accessed on 6 January 2024).

- NC-17 Connect. NC-17 Connect AppCon 3000. NC-17 Connect. Available online: https://www.appcon3000.de/products/nc-17-connect-appcon-3000 (accessed on 6 January 2024).

- Lumi-Con-Bike Energy Harvester. Available online: https://www.lumi-con.de/prod_USB_eng.html (accessed on 6 January 2024).

- Automatiklader V5: Forumslader. Available online: https://www.bumm.de/en/products/stromversorgung/parent/3610/produkt/361bw.html (accessed on 6 January 2024).

- USB-WERK-Busch + Müller EN. Available online: https://www.forumslader.de/aeltere-versionen/automatiklader-v5/ (accessed on 6 January 2024).

- Majeau-Bettez, G.; Hawkins, T.R.; Strømman, A.H. Life Cycle Environmental Assessment of Lithium-Ion and Nickel Metal Hydride Batteries for Plug-In Hybrid and Battery Electric Vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef]

- Takahashi, M.; Ohtsuka, H.; Akuto, K.; Sakurai, Y. Confirmation of Long-Term Cyclability and High Thermal Stability of LiFePO[sub 4] in Prismatic Lithium-Ion Cells. J. Electrochem. Soc. 2005, 152, A899. [Google Scholar] [CrossRef]

| Model | Battery Type | Capacity [mAh] Voltage [V] | Temperature Range [°C] | Lifetime | Price [EUR] |

|---|---|---|---|---|---|

| Plug5 Plus [46] | LiFePO3 | 1100 3.2 | −15–60 | >2000 cycles | 259 |

| Appcon3000 [47] | Li-ion: LG INR18650 | 3000 3.63 | 0–45 | >300 cycles | 229 |

| USB-P5 [48] | Li-ion: Samsung INR18650-25R | 2 × 2500 3.6 | 0–60 | >250 cycles | 95 |

| Forumslader V5 Ahead [49] | LiMn: Efest IMR18350 | 3 × 700 3.7 | 0–60 | >250 cycles | 227 |

| USB-Werk [50] | LiFePO3 | 2 × 150 3.2 | −15–60 | >2000 cycles | 80–95 |

| Model | Aesthetics | Capacity | Current Output | Weight | Battery Replacement | Solar Charging | Stable Drag Force | Bluetooth/App | Price | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Plug5 Plus [46] | 3 | 1 1100 mAh | 1 1.2 A | 1 195 g | 0 | 0 | 0 | 1 | 0 EUR 259 | 7 |

| Appcon3000 [47] | 2 | 3 3000 mAh | 2 2.0 A | 3 102 g | 0 | 0 | 0 | 1 | 1 EUR 229 | 12 |

| USB-P5 [48] | 1 | 4 5000 mAh | 1 1.5 A | 2 150 g | 1 | 0 | 0 | 0 | 3 EUR 95 | 12 |

| Forumslader V5 Ahead [49] | 3 | 2 2100 mAh | 3 2.9 A | 1 210 g | 1 | 0 | 0 | 1 | 1 EUR 227 | 12 |

| USB-Werk [50] | 1 | 0 300 mAh | 0 0.5 A | 4 53 g | 1 | 0 | 0 | 0 | 4 EUR 80 | 10 |

| Best Comparable Market Model | User Desirable | Designed Product | |

|---|---|---|---|

| USB charger | |||

| Working above 12 km/h | Working above 10 km/h | Working above 9 km/h |

| As provided by manufacturer | Modular and interchangeable | Modular and interchangeable |

| Fixed outside the frame | Fixed inside the frame | Fixed inside the frame |

| 1 (hub dynamo) | 2 (hub dynamo/solar) | 2 (hub dynamo/solar) |

| Variable | Stable at any speed | Stable from 10 to 25 km per h |

| Battery pack | |||

| As provided by manufacturer | Modular with replaceable parts | Modular with replaceable parts |

| Must dismount carcass/not sold separately | Easy to replace by user/sold separately | Easy to replace by user/sold separately |

| Fixed outside the frame | Fixed inside the frame | Fixed inside the shank’s tube |

| 1 (USB charger OR solar panel) | 2 (USB charger AND solar panel) | 2 (USB charger AND solar panel) |

| 300 cycles/150 g | Above 300 cycles/less than 150 g | 500 cycles/around 200 g |

| Around 5000 mAh | Around 8000 mAh | Around 10,500 mAh |

| Solar charging system | |||

| Single USB-A output | Double USB-A output | Double USB-A output |

| Above 28 W | Above 20 W | Above 28 W |

| 21.5–23.5% | Above 20% | 21.5–23.5% |

| Small and low | Small and low | Small and low |

| Interconnect wiring | |||

| Does not exist | Universal and sturdy No tools needed to connect | USB (universal) and MATE-AX (sturdy) |

| Pricing | |||

| EUR 80–260 | Around EUR 80 | Around EUR 45 (100 units) |

| Model | Aesthetics | Capacity | Current Output | Weight | Battery Replacement | Solar Charging | Stable Drag Force | Bluetooth/App | Price | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Final Design | 2 | 4 10,500 mAh | 2 2.0 A | 1 200 g | 1 | 1 | 1 | 0 | 4 EUR 45 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velázquez, J.S.; Cavas, F.; Valverde-Martínez, J.A.; Ignacio Mulero-Martínez, J. Design of a Modular Energy Production–Storage System for a Sustainable Bicycle. Appl. Sci. 2024, 14, 523. https://doi.org/10.3390/app14020523

Velázquez JS, Cavas F, Valverde-Martínez JA, Ignacio Mulero-Martínez J. Design of a Modular Energy Production–Storage System for a Sustainable Bicycle. Applied Sciences. 2024; 14(2):523. https://doi.org/10.3390/app14020523

Chicago/Turabian StyleVelázquez, José S., Francisco Cavas, Juan A. Valverde-Martínez, and Juan Ignacio Mulero-Martínez. 2024. "Design of a Modular Energy Production–Storage System for a Sustainable Bicycle" Applied Sciences 14, no. 2: 523. https://doi.org/10.3390/app14020523

APA StyleVelázquez, J. S., Cavas, F., Valverde-Martínez, J. A., & Ignacio Mulero-Martínez, J. (2024). Design of a Modular Energy Production–Storage System for a Sustainable Bicycle. Applied Sciences, 14(2), 523. https://doi.org/10.3390/app14020523