Influence of Deep Foundation Pit Excavation on Adjacent Pipelines: A Case Study in Nanjing, China

Abstract

:1. Introduction

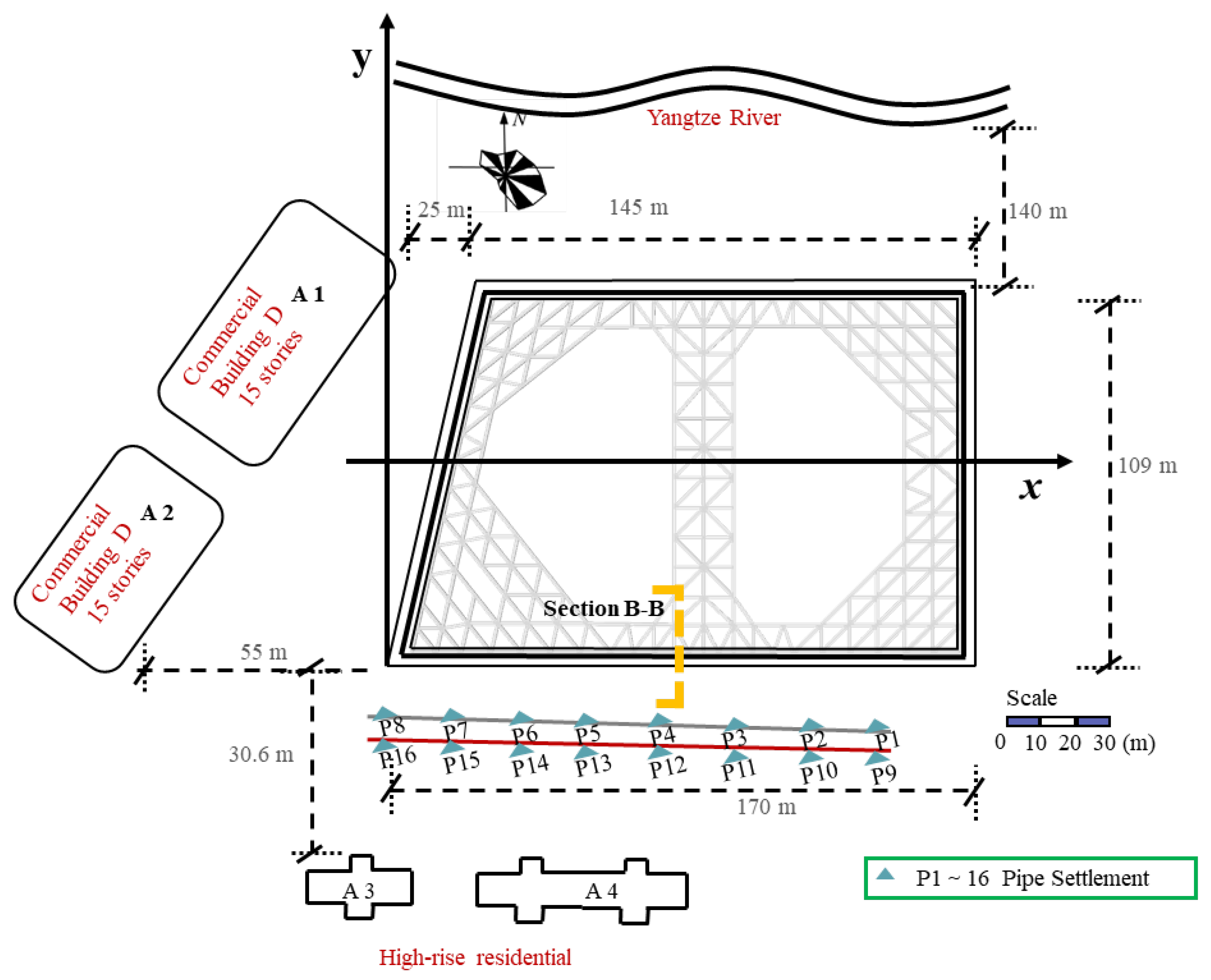

2. Case Study

2.1. Site Investigation and Data Collection

2.2. Geological Setting

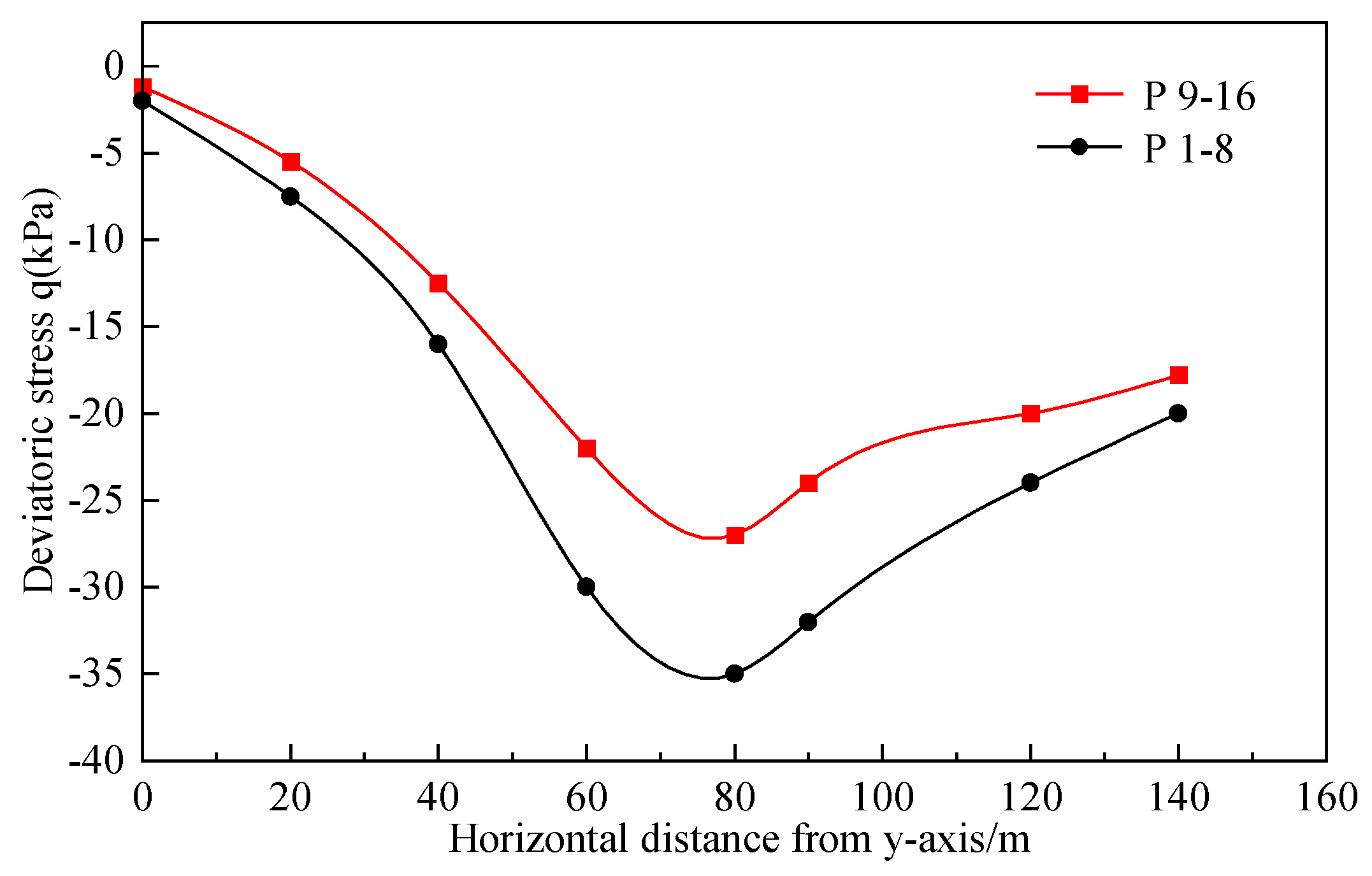

3. Analysis of Measured Data

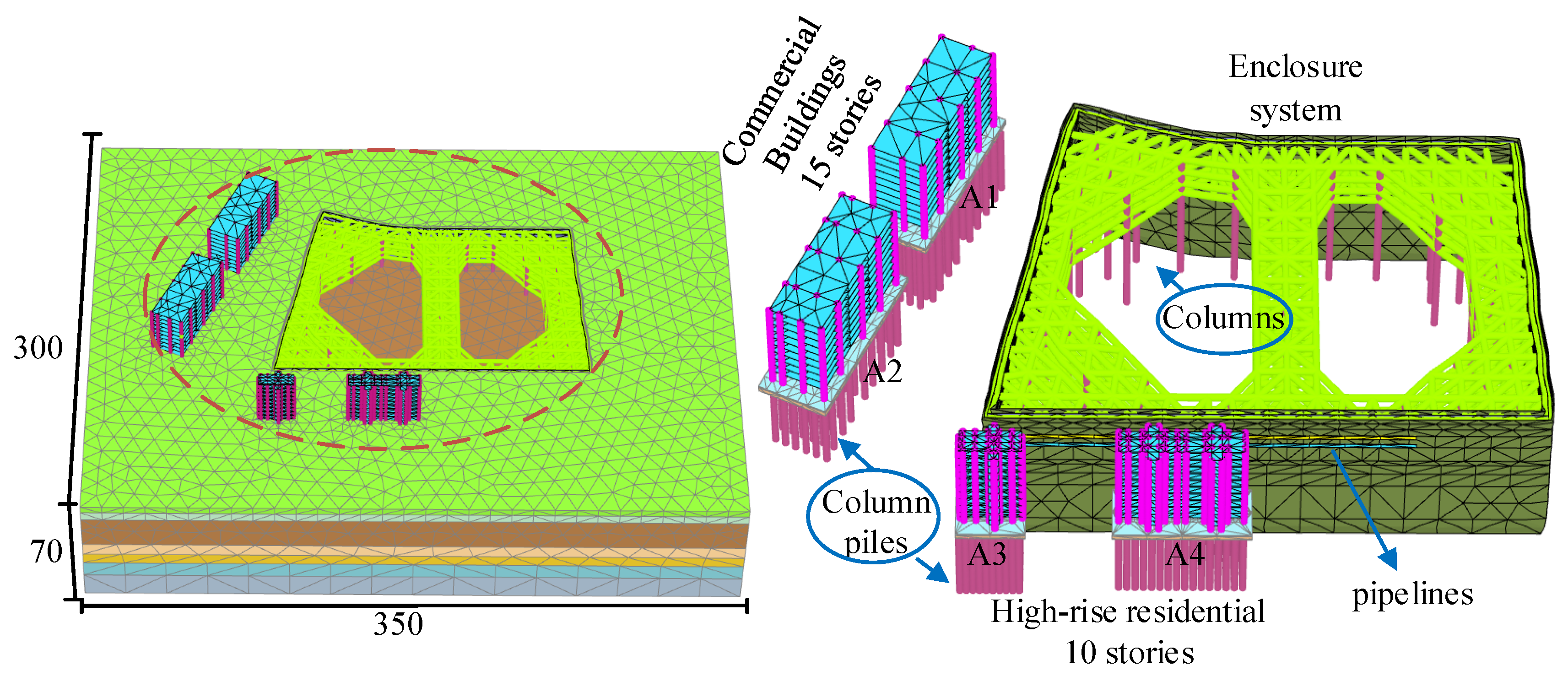

4. Numerical Simulations

4.1. Meshes and Boundary Conditions

4.2. Simulation Method

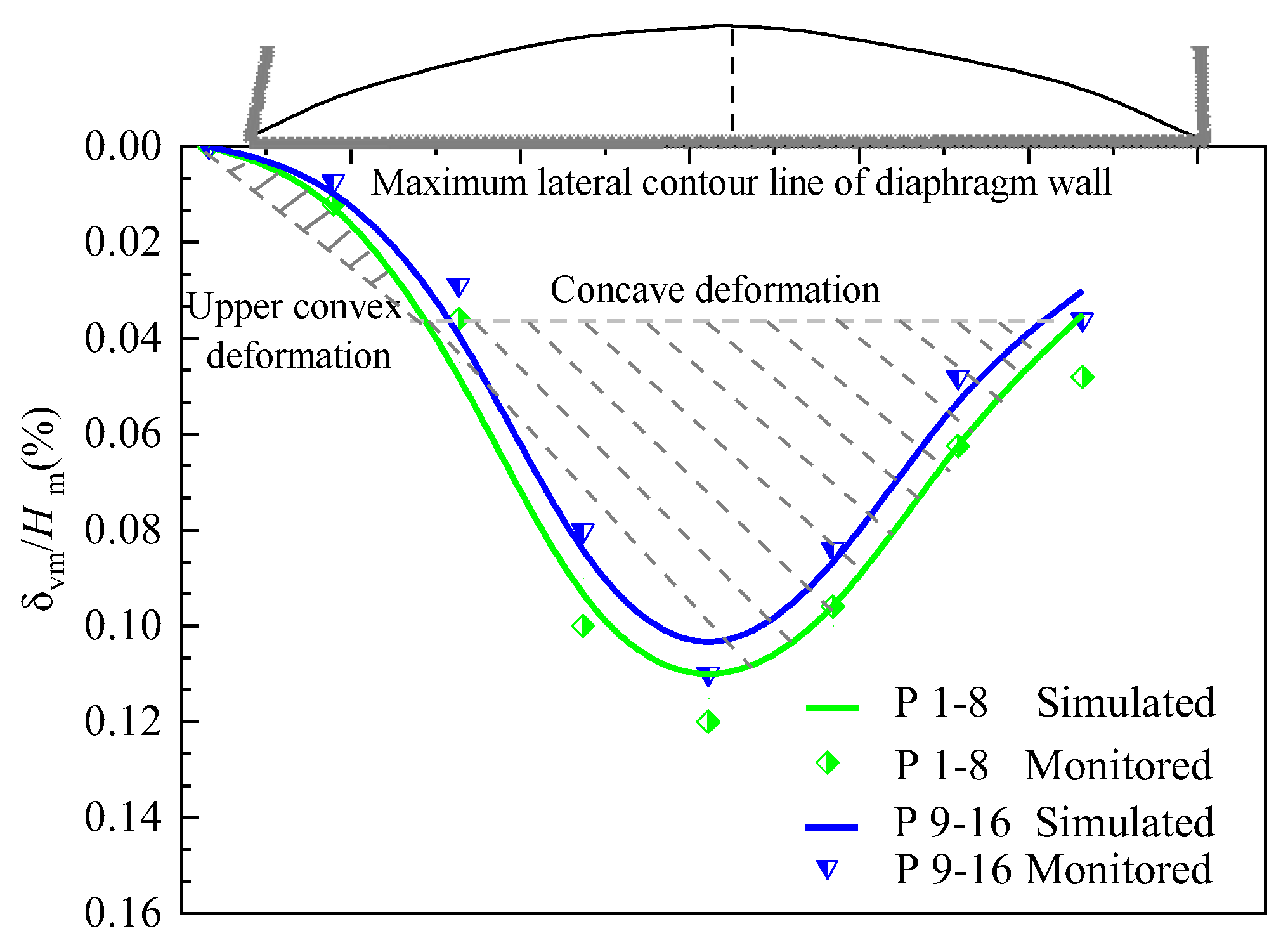

4.3. Validation of Numerical Simulation against Measured Results

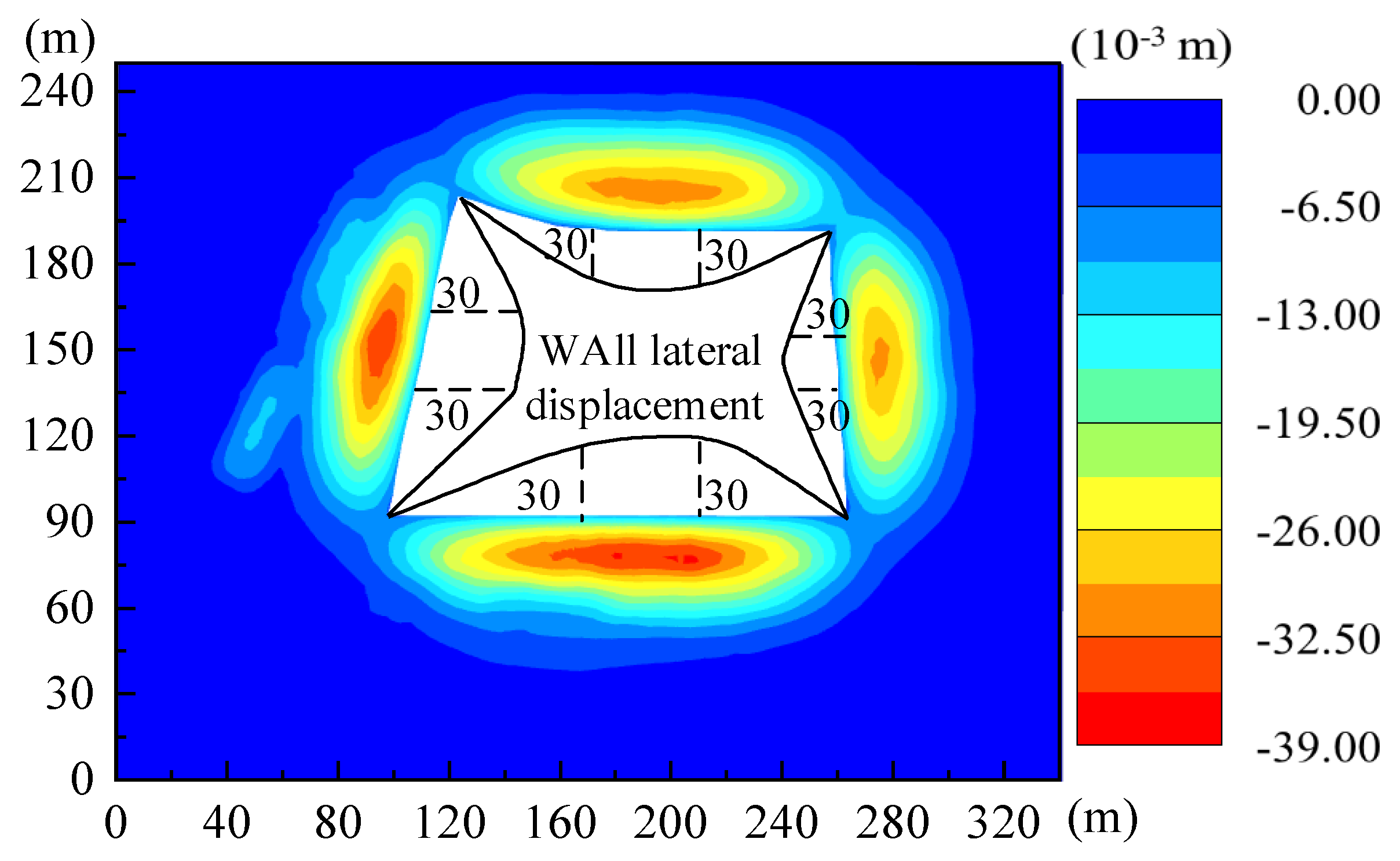

4.4. Single-Factor Numerical Simulation Analysis

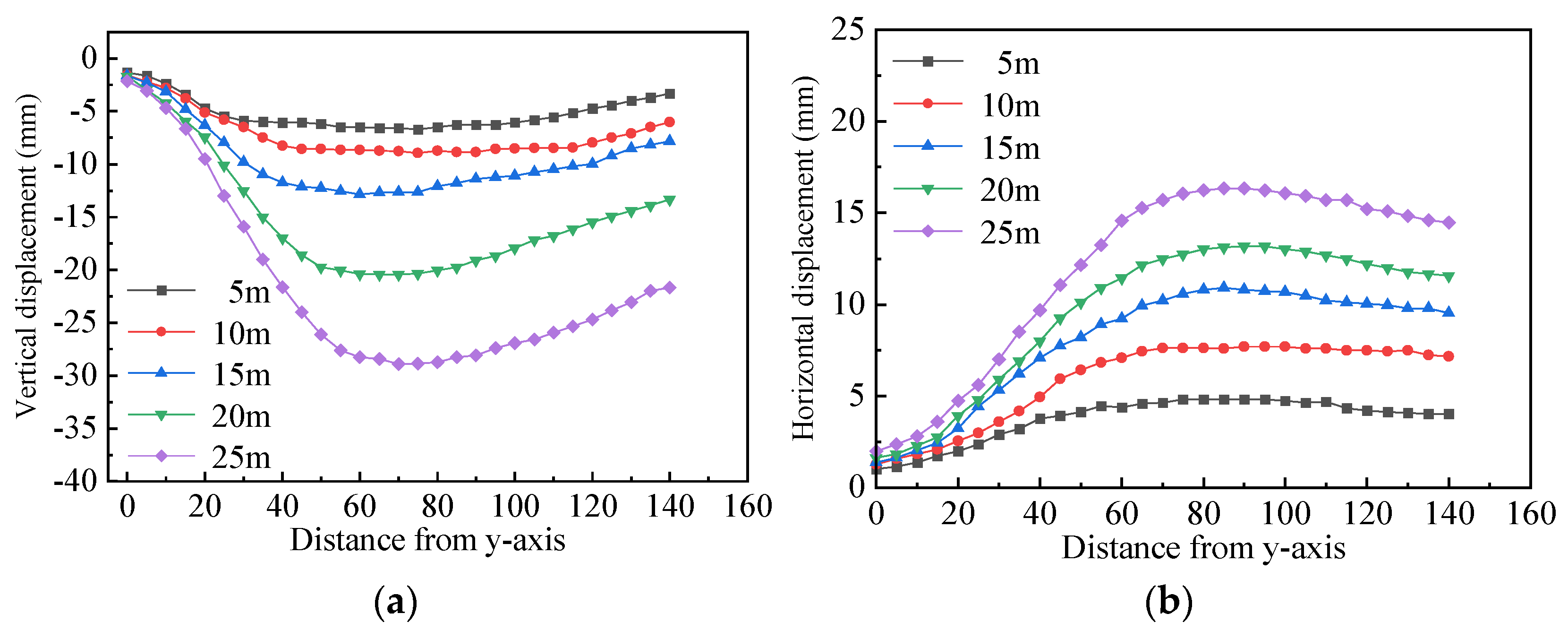

4.4.1. Depth of Pit Excavation

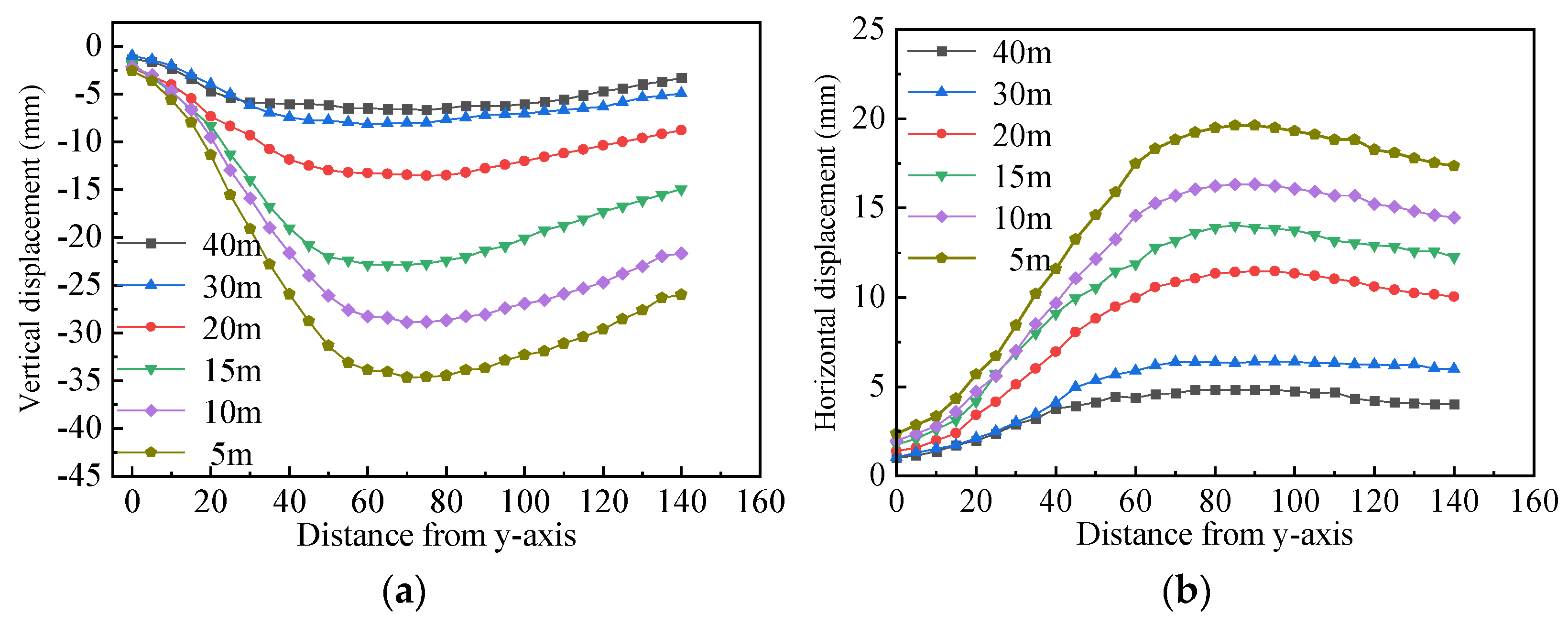

4.4.2. Distance between Pipeline and Pit

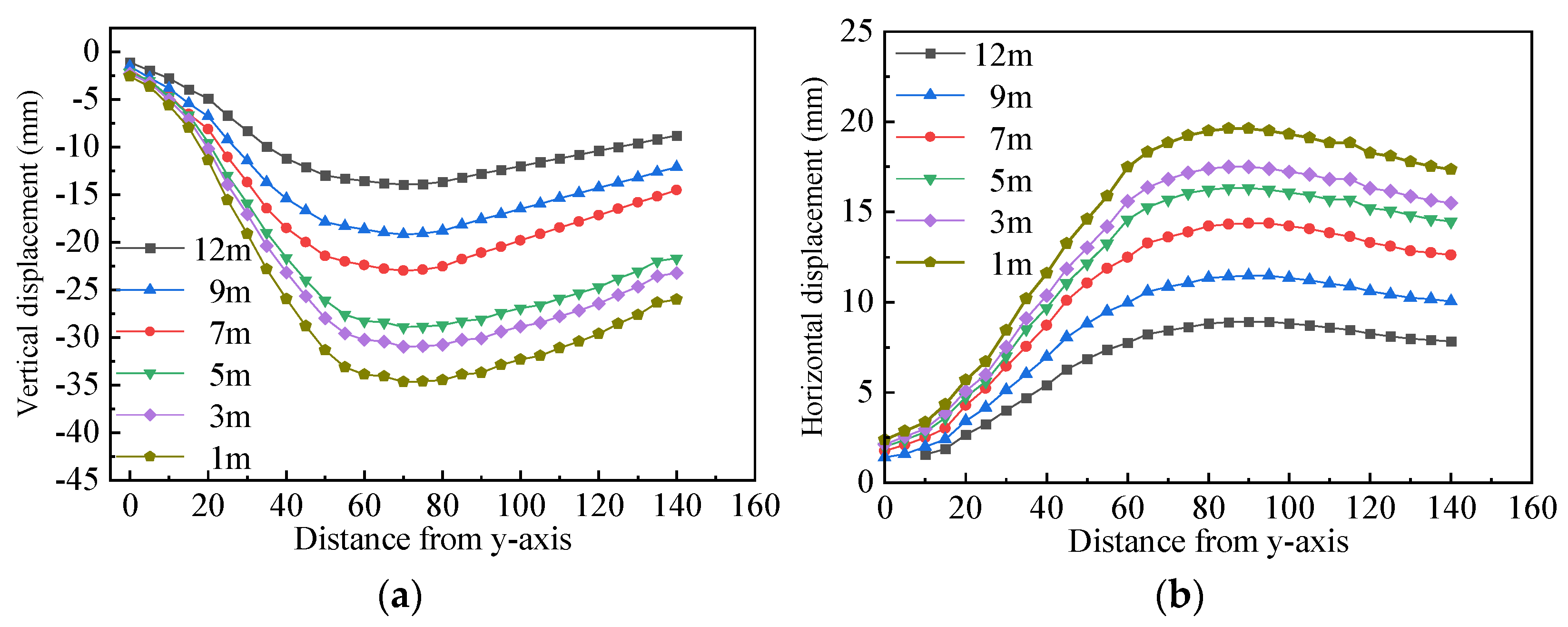

4.4.3. Depth of Buried Pipeline

5. Parameter Analysis

6. Conclusions

- (1)

- After the completion of foundation pit excavation, the pipeline typically exhibited a concave shape, with greater settlement in the middle and lesser settlement at the ends. Uneven displacement of the pipeline primarily occurred within 1.6 times the excavation length near the pit corners. It is recommended that the pipelines near the pit corners be specially protected prior to excavation to prevent uneven settlement, which could lead to tearing or rupture of the pipelines.

- (2)

- With an increase in the depth of the pit excavation, both vertical and horizontal displacements of the pipeline increased, with a relatively larger increase occurring in vertical displacement. Compared to excavation in a single-soil layer, excavation in composite soil–rock strata showed a relatively smaller impact on the settlement deformation of adjacent pipelines.

- (3)

- As the distance between the pipeline and the pit increased, both vertical and horizontal displacements of the pipeline gradually decreased. When the distance between the pipeline and the pit was less than 1.2 times the depth of excavation, larger uneven displacements of the pipeline were observed. This calls for careful planning and monitoring of pipeline integrity in close proximity to excavation sites.

- (4)

- Both vertical and horizontal displacements of the pipeline decreased with an increase in the depth of pipeline burial. To prevent significant uneven displacement and potential damage to pipelines due to pit excavation, the burial depth of the pipelines should be no less than 5 m.

- (5)

- The analysis indicated that the distance between the pipeline and the pit is the most critical factor influencing deformation, followed by burial depth. This underscores the need for the strategic planning and placement of pipelines in relation to excavation activities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ardakani, A.; Bayat, M.; Javanmard, M. Numerical modeling of soil nail walls considering Mohr Coulomb, hardening soil and hardening soil with small-strain stiffness effect models. Geomech. Eng. 2014, 6, 391–401. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Weng, X.L.; Song, Z.P.; Sun, Y.F. Modeling of Loess Soaking Induced Impacts on a Metro Tunnel Using a Water Soaking System in Centrifuge. Geofluids 2019, 2019, 5487952. [Google Scholar] [CrossRef]

- Cheng, W.C.; Song, Z.P.; Tian, W.; Wang, Z.F. Shield tunnel uplift and deformation characterisation: A case study from Zhengzhou metro. Tunn. Undergr. Space Technol. 2018, 79, 83–95. [Google Scholar] [CrossRef]

- Peck, R.B. Deep excavations and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 25–29 August 1969; State of the Art Volume. pp. 225–290. [Google Scholar]

- Yimsiri, S.; Soga, K.; Yoshizaki, K.; Dasari, G.R.; O’Rourke, T.D. Lateral and upward soil-pipe interactions in sand for deep embedment conditions. J. Geotech. Geoenviron. Eng. 2004, 130, 830–842. [Google Scholar] [CrossRef]

- Calvetti, F.; Di Prisco, C.; Nova, R. Experimental and numerical analysis of soil-pipe interaction. J. Geotech. Geoenviron. Eng. 2004, 130, 1292–1299. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, R.; Zhang, H. Mechanical Response Analysis of the Buried Pipeline Due to Adjacent Foundation Pit Excavation. Tunn. Undergr. Space Technol. 2018, 78, 135–145. [Google Scholar] [CrossRef]

- Ye, S.H.; Zhao, Z.F.; Wang, D.Q. Deformation analysis and safety assessment of existing metro tunnels affected by excavation of a foundation pit. Undergound Space 2021, 6, 421–431. [Google Scholar] [CrossRef]

- Jin, W.; Ke, L.; Hu, F.J.; Yang, K.F.; Xu, C.J. Influence of deep foundation pit excavation on adjacent large-diameter pipeline. Sci. Technol. Eng. 2020, 20, 790–796. (In Chinese) [Google Scholar] [CrossRef]

- Shi, Y.Z.; Ge, X.R.; Li, X.F.; Lin, S.Z. Numerical analysis of the influence of metro deep foundation pit construction on surrounding pipelines. J. Sun Yat-Sen Univ. (Nat. Sci. Ed.) 2017, 56, 83–93. [Google Scholar]

- Mohammed, A.K.; Sai, K.V.; Won, T.O. Numerical investigation of Soil–pipeline System Behavior Nearby Unsupported Excavation in Saturated and Unsaturated Glacial Till. Can. Geotech. J. 2019, 56, 69–88. [Google Scholar]

- Miliziano, S.; Caponi, S.; Carlaccini, D.; de Lillis, A. Prediction of tunnelling-induced effects on a historic building in Rome. Tunn. Undergr. Space Technol. 2021, 119, 104212. [Google Scholar] [CrossRef]

- Song, Z.; Wu, Y.; Zhang, Y.; Wang, K.; Tian, J.; Tian, X. Deformation Response of a Pipeline to Nearby Deep Foundation Pit Excavation: Numerical Simulations and Field Tests. Appl. Sci. 2023, 13, 6597. [Google Scholar] [CrossRef]

- Tan, Y.; Lu, Y. Responses of Shallowly Buried Pipelines to Adjacent Deep Excavations in Shanghai Soft Ground. J. Pipeline Syst. Eng. Pract. 2018, 9, 05018002. [Google Scholar] [CrossRef]

- Jiang, N.; Gao, T.; Zhou, C.; Luo, X. Effect of Excavation Blasting Vibration on Adjacent Buried Gas Pipeline in a Metro Tunnel. Tunn. Undergr. Space Technol. 2018, 81, 590–601. [Google Scholar] [CrossRef]

- Jiang, N.; Zhu, B.; He, X.; Zhou, C.; Luo, X.; Wu, T. Safety Assessment of Buried Pressurized Gas Pipelines Subject to Blasting Vibrations Induced by Metro Foundation Pit Excavation. Tunn. Underground Space Technol. 2020, 102, 103448. [Google Scholar] [CrossRef]

- Jiao, N.; Ding, J.W.; Ji, F.; Guo, K.; Liao, Z.S. Analysis on Influence of Deep Foundation Pit Excavation in Soil-Rock Composite Stratum on Deformation of Adjacent Pipelines. J. Southeast Univ. (Nat. Sci. Ed.) 2022, 52, 229–236. [Google Scholar] [CrossRef]

- Chen, Z.B. Monitoring and Numerical Analysis of Deformation of Complex Pipelines Adjacent to the Deep Foundation Pit Excavation of the Silihe Road Station of Hefei Metro. Master’s Thesis, Hefei University of Technology, Hefei, China, 2018. (In Chinese). [Google Scholar]

- Cheng, K.; Xu, R.; Ying, H.; Gan, X.; Zhang, L.; Liu, S. Observed performance of a 30.2 m deep-large basement excavation in Hangzhou soft clay. Tunn. Underground Space Technol. 2021, 111, 103872. [Google Scholar] [CrossRef]

- Brinkgreve, R.B.J.; Engin, E.; Swolfs, W.M. PLAXIS 3D 2013 User Manual; Plaxis B.V.: Delft, The Netherlands, 2013. [Google Scholar]

- Benz, T. Small-Strain Stiffness of Soils and its Numerical Consequences. Ph.D. Thesis, Universitat Stuttgart, Stuttgart, Germany, 2007. [Google Scholar]

- Shi, Y.Z.; Ge, X.R.; Li, X.F.; Lin, S.Z. Numerical Analysis of the Impact of Subway Deep Foundation Pit Construction on Surrounding Pipelines. Acta Sci. Nat. Univ. Sunyatseni 2017, 56, 84–91. [Google Scholar] [CrossRef]

| Parameter | Definition | Unit |

|---|---|---|

| Reference secant modulus | MPa | |

| Reference tangent modulus | MPa | |

| Reference loading and unloading modulus | MPa | |

| m | Stiffness stress level related power exponent | / |

| Effective cohesion | kPa | |

| Effective internal friction angle | ° | |

| Dilatancy angle | ° | |

| damage ratio | / | |

| ur | Load–unload Poisson’s ratio | / |

| Initial shear modulus under reference confining pressure | MPa | |

| Static side pressure coefficient | ||

| Shear strain threshold | / |

| Soil Layer | C (kPa) | φ (°) | K0 | (°) | (kPa) | (MPa) | (MPa) | (MPa) | (MPa) | (10−4) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ① Miscellaneous fill | 25.0 | 15.0 | 0.74 | 0 | 100 | 0.65 | 0.42 | 5.5 | 29.2 | 4.9 | 0.84 | 28.1 | 1.5 |

| ② Plain fill | 27.3 | 20.5 | 0.65 | 0 | 100 | 0.75 | 0.39 | 6.1 | 32.0 | 5.6 | 0.79 | 30.2 | 2.3 |

| ③ Silty powdery clay | 18.3 | 30.2 | 0.5 | 0.2 | 100 | 0.64 | 0.33 | 3.8 | 37.5 | 3.5 | 0.90 | 47.4 | 2.9 |

| ④ Powdery fine sand | 1.6 | 35.4 | 0.42 | 5.4 | 100 | 0.56 | 0.30 | 8.9 | 42.8 | 6.9 | 0.64 | 90.5 | 3.5 |

| ⑤ Fine medium sand | 0.8 | 33.3 | 0.46 | 3.3 | 100 | 0.73 | 0.32 | 12.6 | 56.2 | 10.7 | 0.72 | 108.2 | 3.2 |

| Soil Layer | Ontogenetic Relations | Thickness (m) | Young’s Modulus, E (MPa) | Unit Weight (kN·m−3) | Cohesion, c (kPa) | Friction Angle, φ (°) |

|---|---|---|---|---|---|---|

| ⑥ Strongly weathered tuff | MC | 2.1 | 35.0 | 21.0 | 43.0 | 35 |

| ⑦ Medium weathered tuff | MC | — | 15,000.0 | 23.0 | 83.0 | 35 |

| Support Elements | Cross-Section (mm) | Unit Weight (kN·m−3) | Elastic Modulus, E (GPa) | Poisson’s Ratio |

|---|---|---|---|---|

| Diaphragm walls | 1200 | 26 | 30 | 0.15 |

| Inner support | 1000 × 1000 | 26 | 30 | 0.15 |

| Column pile | R = 500 | 24 | 30 | 0.22 |

| floor slab | 500 | 26 | 30 | 0.15 |

| Superstructure beams and columns | (300 × 400) and (350 × 350) | 24 | 30 | 0.22 |

| Lower pile of building | 1000 × 1000 | 24 | 30 | 0.22 |

| Gas pipeline | R = 600 | 75 | 206 | 0.2 |

| Water supply pipeline | R = 500 | 9.5 | 0.8 | 0.4 |

| Stage | Simulation Step | Construction Sequence | Construction Date |

|---|---|---|---|

| 1 | Generate the initial stress field | ||

| 2 | Create an adjacent building model | ||

| 3 | Clear displacement; create the enclosure structure and column piles | Construction of diaphragm walls and column piles | 2020.12.28–2021.3.14 |

| 4 | Dewatering to BGS 2.5 m (level 1), and excavating to BGS 1.5 m | Dewatering to BGS 2.5 m (level 1), and excavating to BGS 1.5 m | 2021.3.15–2021.3.27 |

| 5 | Activate the first level of horizontal support at BGS 1.5 m | First floor support set up | 2021.3.31–2021.4.11 |

| 6 | Dewatering to BGS 8 m (level 2), and excavating to BGS 7 m | Dewatering to BGS 8 m (level 2), and excavating to BGS 7 m | 2021.4.22–2021.5.20 |

| 7 | Activate the second level of horizontal support at BGS 7 m | 2nd level support set up | 2021.5.22–2021.6.1 |

| 8 | Dewatering to BGS 14.5 m (level 3), and excavating to BGS 13.5 m | Dewatering to BGS 14.5 m (level 3), and excavating to BGS 13.5 m | 2021.6.2–2021.6.10 |

| 9 | Activate the third level support at BGS 13.5 m | 3rd-level support set up | 2021.6.11–2021.6.22 |

| 10 | Dewatering to BGS 19.5 m (level 4), and excavating to BGS 18.5 m | Dewatering to BGS 19.5 m (level 4), and excavating to BGS 18.5 m | 2021.6.25–2021.7.12 |

| 11 | Activate the fourth level support at BGS 18.5 m | 4th-level support set up | 2021.7.14–2021.7.25 |

| 12 | Dewatering to BGS 26 m (level 5), and excavating to BGS 25 m | Dewatering to BGS 26 m (level 5), and excavating to BGS 25 m | 2021.7.27–2021.8.16 |

| 13 | Activate the bottom plate | Pouring bottom plate | 2021.8.16–2021.8.30 |

| Influencing Factors | Vertical Displacement Sensitivity | Horizontal Displacement Sensitivity |

|---|---|---|

| Depth of pit excavation | 0.198 | 0.156 |

| Distance between pipeline and pit | 0.455 | 0.655 |

| Depth of buried pipeline | 0.412 | 0.325 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B.; Ge, C.; Li, P.; Yang, M.; Li, L. Influence of Deep Foundation Pit Excavation on Adjacent Pipelines: A Case Study in Nanjing, China. Appl. Sci. 2024, 14, 572. https://doi.org/10.3390/app14020572

Wu B, Ge C, Li P, Yang M, Li L. Influence of Deep Foundation Pit Excavation on Adjacent Pipelines: A Case Study in Nanjing, China. Applied Sciences. 2024; 14(2):572. https://doi.org/10.3390/app14020572

Chicago/Turabian StyleWu, Bin, Chenhe Ge, Pengfei Li, Meng Yang, and Liulian Li. 2024. "Influence of Deep Foundation Pit Excavation on Adjacent Pipelines: A Case Study in Nanjing, China" Applied Sciences 14, no. 2: 572. https://doi.org/10.3390/app14020572

APA StyleWu, B., Ge, C., Li, P., Yang, M., & Li, L. (2024). Influence of Deep Foundation Pit Excavation on Adjacent Pipelines: A Case Study in Nanjing, China. Applied Sciences, 14(2), 572. https://doi.org/10.3390/app14020572