A New Last Mile Delivery Approach for the Hybrid Truck Multi-Drone Problem Using a Genetic Algorithm

Abstract

1. Introduction

1.1. Motivation

1.2. Related Works

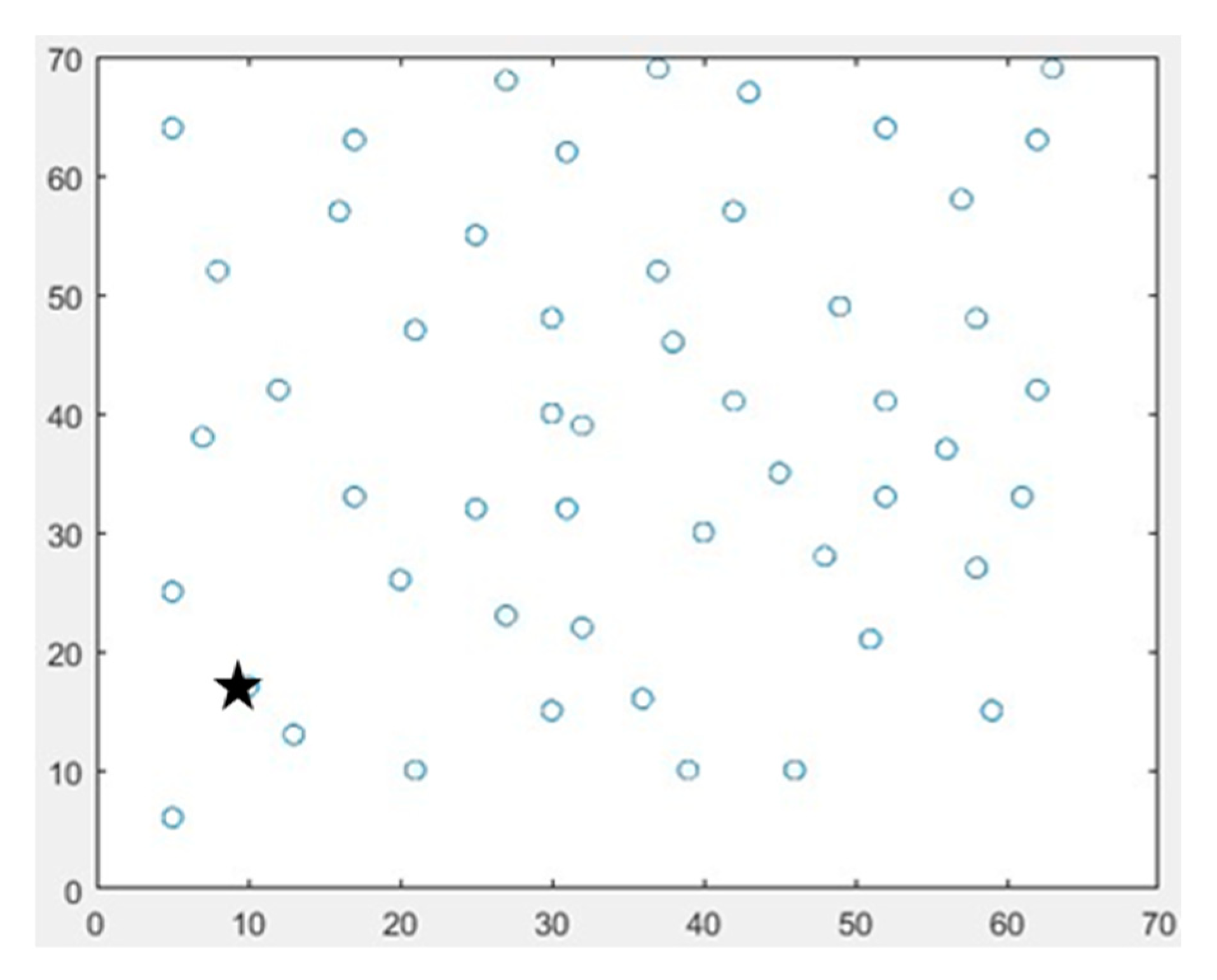

1.3. Hybrid Truck Multi-Drone Problem Description

- is a cluster of nodes on the graph.

- is a cluster of branches on the graph.

- is the cluster of the weights of the branches.

1.4. Proposed Approach

- There is only one warehouse, and its location is fixed;

- Initially, vehicles leave the warehouse and return to the warehouse after completing the delivery;

- Delivery vehicles include one truck and one or more drones;

- All drones are identical and can operate within a certain range;

- Drones start their movement from the truck and can only deliver to one point at a time, and after completing the delivery, they go to the appointment point and complete their movement when they reach the truck;

- The speeds of the vehicles are constant;

- All packages expected to be delivered can be delivered by both truck and drone (in terms of size, weight, etc.);

- The locations to be delivered to and the distances between these locations are known in advance and are fixed; they do not change after the delivery has started;

- Only one delivery should be made to all customers on the route.

1.5. Contribution and Outline

2. Materials and Methods

2.1. Creating the Initial Population

2.2. Calculation of Edge Costs on the Graph

2.3. Getting Road Condition Data via the Internet

2.4. Calculation of the Compatibility Score

- : Fitness function,

- : The value of the total transportation cost relative to the current individual.

2.5. Creating Sub-Routes and Examining How Vehicles Are Assigned on the Existing Route

- According to the scenario shown in Figure 4, there is one truck and one drone at point 1 that have made their deliveries. At this stage, it is necessary to decide how to deliver to the next delivery points. In the decision-making process, the total number of drones and drone range values are used. The algorithm first sets the truck’s movement from point 1 to point 2, and the distance that the truck will travel is set at ℓ12.

- The drone is then checked to see if it can deliver to the next delivery point. When the drone’s movement is from point 1 to point 3, which is the next delivery point, the point where it will make an appointment with the truck will be point 2. Accordingly, the expected distance to be covered by the drone will be ℓ13 + ℓ32.

- After calculating the distance that the drone will travel, there are two conditions for determining whether the drone can make this delivery. If the total number of drones is greater than the number of drones currently on duty, that is, if there are drones available for the mission and the drone range is greater than or equal to ℓ13 + ℓ32 distance, the drone is suitable for delivery.

- Assuming that these conditions are met in the current scenario, the drone will go from point 1 to point 3, and then from point 3 to point 2. It will also meet the truck at point 2.

- Afterward, the algorithm checks whether the next delivery point, point 4, is suitable for the drone to deliver. There is only one drone in the scenario, and since one of the conditions, the number of drones, cannot be met, the drone will not be assigned to delivery point number 4.

- If a drone could be sent to point 4, this drone would also meet with the truck at point 2. After it is understood that no drone will be sent to point 4, the truck starts to move toward point 2, and the drone starts to move toward point 3, as seen in Figure 4b. They come together again at point 2, as seen in Figure 4c.

2.6. Application of Genetic Operators

2.7. Stopping Condition of the Algorithm

2.8. Finding the Optimal Route

| Algorithm 1: The basic algorithmic structure of the genetic algorithm. |

| Genetic algorithm with dynamic operators ( ) { Initialize population randomly; Evaluate fitness of each individual in the population; While stopping condition met { Perform selection; Perform crossover and dynamic mutation; Evaluate fitness of each individual; Change selection, crossover and mutation operators. } } |

3. Results

3.1. Multi-Drone Results

- First of all, in simulations, comparisons were made with some optimization algorithms in the solution of the TSP problem with scenarios where drones are not used in order to measure the effectiveness of the proposed algorithm. As a result of these comparisons, the advantages and some disadvantages of GA were seen, and why it was preferred in this study was explained. In terms of the problem presented in the article, the genetic algorithm has advantages such as being able to provide optimum solutions in variable scenarios, not needing additional information, and being able to work with a large number of variables. Selecting parameters such as initial population size, mutation-crossover probability, and selection technique has partial effects and is useful in finding the global optimum. It has some disadvantages, such as sometimes experiencing convergence problems. However, in the hybrid truck and multi-drone distribution problem given in this article, these disadvantages are minimized, and an approach and results are presented.

- Then, new simulations were carried out on the same datasets using drones, and it was observed that the use of the drone had a positive effect on the result.

3.2. Results for Test Algorithm

3.3. Results for a Real-World Problem

- In terms of delivery, it is assumed that there are ten points on the map shown in Figure 25. The points on the figure are numbered for ease of identification, regardless of the order of delivery.

- In Figure 26, the traffic situation on the roads between these points is given.

- In this scenario, it is assumed that only one truck is used for delivery.

- The difference in the solutions obtained in cases where the number of drones changes and whether traffic data is taken into account is examined.

- The distances between the delivery points are shown in the distance matrix in Figure 27.

- In Figure 28, these points are seen as nodes of a representative graph.

4. Discussion and Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Camisón-Haba, S.; Clemente-Almendros, J.A. A global model for the Estimation of Transport Costs. Econ. Res. 2020, 33, 2075–2100. [Google Scholar] [CrossRef]

- Izadi, A.; Nabipour, M.; Titidezh, O. Cost Models and Cost Factors of Road Freight Transportation: A Literature Review and Model Structure. Fuzzy Inf. Eng. 2020, 11, 257–278. [Google Scholar] [CrossRef]

- Onstein, T.C.; Tavasszy, L.A.; van Damme, D.A. Factors Determining Distribution Structure Decisions in Logistics: A Literature Review and Research Agenda. Transp. Rev. 2019, 39, 243–260. [Google Scholar] [CrossRef]

- Yan, G.J. Discussion on The Method of Logistics Cost Control in Foreign Trade Enterprises, Advances in Social Science, Education and Humanities Research. In Proceedings of the 4th International Conference on Humanities Science, Management and Education Technology (HSMET 2019), Singapore, 21–23 June 2019; Volume 334, pp. 649–652. [Google Scholar]

- Majercak, P. Saving Logistics Transportation Costs in The Era of Globalization for Firms. SHS Web Conf. 2020, 74, 04014. [Google Scholar] [CrossRef][Green Version]

- Victoria, V.P.; Oksana, N.K.; Alyona, I.N.; Nickolay, A.S.; Pavel, G.V. Logistics Management as a Tool to Achieve Competitive Advantages of the Enterprise Trade. Int. Rev. Manag. Mark. 2016, 6 (Suppl. S6), 32–37. [Google Scholar]

- Engblom, J.; Solakivi, T.; Töyli, J.; Ojala, L. Multiple-Method Analysis of Logistics Costs. Int. J. Prod. Econ. 2012, 137, 29–35. [Google Scholar] [CrossRef]

- Kitjacharoenchai, P.; Lee, S. Vehicle Routing Problem with Drones for Last Mile Delivery. Procedia Manuf. 2019, 39, 314–324. [Google Scholar] [CrossRef]

- Ozel, A. Optimization of Last-Mile Deliveries with Synchronous Truck and Drones. Master’s Thesis, The Graduate School of Engineering and Science of Bilkent University, Ankara, Turkey, 2020. [Google Scholar]

- Roberti, R.; Ruthmair, M. Exact Methods for the Traveling Salesman Problem with Drone. Transp. Sci. 2020, 55, 315–335. [Google Scholar] [CrossRef]

- Liu, W.; Lin, C.; Chiu, C.; Tsao, Y.; Wang, Q. Minimizing the Carbon Footprint for the Time-Dependent Heterogeneous-Fleet Vehicle Routing Problem with Alternative Paths. Sustainability 2014, 6, 4658–4684. [Google Scholar] [CrossRef]

- Kitjacharoenchai, P.; Ventresca, M.; Moshref-Javadi, M.; Lee, S.; Tanchoco, J.M.A.; Brunese, P.A. Multiple Traveling Salesman Problem with Drones: Mathematical Model and Heuristic Approach. Comput. Ind. Eng. 2019, 129, 14–30. [Google Scholar] [CrossRef]

- Iwata, K.; Matsubara, K.; Kawasaki, K.; Matsumoto, O. Turbojet Engine for Aerial Cargo Robot (ACR). J. Robot. Mechatron. 2012, 24, 1040–1045. [Google Scholar] [CrossRef]

- Karaköse, E. Coordination of Multi UAV’s Equipped with IoT. In Proceedings of the 7th International Conference on Advanced Technologies (ICAT’18), Antalya, Turkey, 28 April–1 May 2018; Volume 1, pp. 169–172. [Google Scholar]

- Karaköse, E. A Comparative Study for Cooperative Mission Planning of UAV Swarm. In Proceedings of the 5th International Conference on Advanced Technology (ICAT’17), Istanbul, Turkey, 9–12 May 2017; Volume 1, pp. 540–544. [Google Scholar]

- Karaköse, E.; Karaköse, M.; Yılmazer, M. Multi-Package Delivery Optimization with Drone. In Proceedings of the 2021 International Conference on Data Analytics for Business and Industry (ICDABI), Sakheer, Bahrain, 25–26 October 2021; pp. 65–69. [Google Scholar]

- Amazon. “Amazon Prime Air”. 2021. Available online: https://www.amazon.com/Amazon-PrimeAir/b?ie=UTF8&node=8037720011 (accessed on 1 December 2023).

- DHL—Deutsche Post DHL Group. Rapid Response from the Air: Medicines Successfully Delivered Using a Parcel Drone in East Africa. 2021. Available online: https://www.dpdhl.com/en/media-relations/press-releases/2018/rapid-response-from-the-air-medicines-successfully-delivered-using-a-parcel-drone-in-east-africa.html (accessed on 1 December 2023).

- Swiss Post. Drones: A Vision Has Become Reality. 2021. Available online: https://www.post.ch/en/about-us/innovation/innovations-in-development/drones (accessed on 1 December 2023).

- Leon-Blanco, J.M.; Gonzalez, R.P.L.; Andrade-Pineda, J.L.; Canca, D.; Calle, M. A Multi-Agent Approach to The Truck Multi-Drone Routing Problem. Expert Syst. Appl. 2022, 195, 116604. [Google Scholar] [CrossRef]

- Salama, M.R.; Srinivas, S. Collaborative truck multi-drone routing and scheduling problem: Package Delivery with Flexible Launch and Recovery Sites. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102788. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Z.; Kou, G.; Xiao, F.; Zhou, X.; Fan, L. A Collaborative Truck Multi-Drone Routing Problem with Flexible Launch and Recovery Operations. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Liang, C.Y.; Luo, X.; Chen, X.D.; Han, B. Route Planning of Truck and Multi-Drone Rendezvous with Available Time Window Constraints of Drones. Sci. China Technol. Sci. 2022, 65, 2190–2204. [Google Scholar] [CrossRef]

- Zeng, F.; Chen, Z.; Clarke, J.-P.; Goldsman, D. Nested Vehicle Routing Problem: Optimizing Drone-Truck Surveillance Operations. Transp. Res. Part C: Emerg. Technol. 2022, 139, 103645. [Google Scholar] [CrossRef]

- Yasar, S.N.; Karaköse, E. Trajectory Control of Quadcopter in Matlab Simulation Environment. In Proceedings of the 2022 International Conference on Decision Aid Sciences and Applications (DASA), Chiangrai, Thailand, 23–25 March 2022; pp. 1127–1131. [Google Scholar]

- Gomez-Lagos, J.; Candia-Véjar, A.; Encina, F. A New Truck-Drone Routing Problem for Parcel Delivery Services Aided by Parking Lots. IEEE Access 2021, 9, 11091–11108. [Google Scholar] [CrossRef]

- Alam, T.; Qamar, S.; Dixit, A.; Benaida, M. Genetic Algorithm: Reviews, Implementations, and Applications. Int. J. Eng. Pedagog. (IJEP) 2020. [Google Scholar] [CrossRef]

- Beasley, D.; Bull, D.R.; Martin, R. An Overview of Genetic Algorithms: Part 1, Fundamentals. Univ. Comput. Arch. 1993, 15, 58–69. [Google Scholar]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A Review on genetic Algorithm: Past, Present, and Future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Altundoğan, T.G.; Yıldız, A.; Karaköse, E. Genetic Algorithm Approach based on Graph Theory for Location Optimization of Electric Vehicle Charging Stations. In Proceedings of the 2021 Innovations in Intelligent Systems and Applications Conference (ASYU), Elazig, Turkey, 6–8 October 2021. [Google Scholar]

- Murray, C.C.; Chu, A.G. The Flying Sidekick Traveling Salesman Problem: Optimization of Drone-Assisted Parcel Delivery. Transp. Res. Part C Emerg. Technol. 2015, 54, 86–109. [Google Scholar] [CrossRef]

- Kim, S.; Moon, I. Traveling Salesman Problem with a Drone Station. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 42–52. [Google Scholar] [CrossRef]

- Agatz, N.; Bouman, P.; Schmidt, M. Optimization Approaches for the Traveling Salesman Problem with Drone. Transp. Sci. 2018, 52, 965–981. [Google Scholar] [CrossRef]

- Oberlin, P.; Rathinam, S.; Darbha, S. A Transformation for a Heterogenous, Multiple Depot, Multiple Traveling Salesman Problem. In Proceedings of the American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 1292–1297. [Google Scholar]

- Boone, N.; Sathyan, A.; Cohen, K. Enhanced Approaches to Solving the Multiple Traveling Salesman Problem. In Proceedings of the AIAA Infotech at Aerospace, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Ali, K.B.; Telmoudi, A.J.; Gattoufi, S. Improved Genetic Algorithm Approach Based on New Virtual Crossover Operators for Dynamic Job Shop Scheduling. IEEE Access 2020, 8, 213318–213329. [Google Scholar] [CrossRef]

- ZIB, Zuse Institute Berlin, “TSPLIB” Access: 13 September 2021. Available online: https://elib.zib.de/pub/mp-testdata/tsp/tsplib/tsp/index.html (accessed on 1 December 2023).

- Ahmed, O.M.A.; Kahramanlı, H. Meta-Heuristic Solution Approaches for Traveling Salesperson Problem. Int. J. Appl. Math. Electron. Comput. 2018, 6, 21–26. [Google Scholar]

- Seifried, K. The Traveling Salesman Problem with One Truck and Multiple Drones. 2019. Available online: https://ssrn.com/abstract=3389306; http://dx.doi.org/10.2139/ssrn.3389306 (accessed on 1 December 2023).

- Thomas, T.; Srinivas, S.; Rajendran, C. Collaborative Truck Multi-Drone Delivery System Considering Drone Scheduling and En-Route Operations. 2022. Available online: https://ssrn.com/abstract=4080821 (accessed on 1 December 2023).

| Parameters | Values |

|---|---|

| Crossover probability | 0.79–0.99 |

| Mutation probability | 0.01–0.2 |

| Crossover operator | Mean/Min–Max 2 point crossover |

| Mutation operator | Dynamic mutation |

| Selection procedure | The roulette wheel selection |

| Number of iteration | 100 |

| Population size | 30–120 |

| (a) Parameters for Numerical Example | |||

|---|---|---|---|

| Parameter | Numerical value | ||

| N: Number of nodes (a, b, c, d, e, f) | 6 | ||

| D: Number of drones | 2 | ||

| C: Number of customers | 3 | ||

| t: The amount of time a drone can stay at the node for deployment | 4 min | ||

| b: Battery capacity of the drones | 1.8 kWh | ||

| w: Weight capacities of drones | 5 kg and 10 kg | ||

| (b) Numerical results | |||

| Route | Arrival time (minutes) | Leaving time (minutes) | |

| Truck | a–c–a | 99 (for a)–11 (for c) | 0–88 |

| Drone 1 | c–e–c | 11 (for c)–42 (for e) | 88–45 |

| Drone 2 | c–d–f–c | 11 (for c)–23 (for d)–60 (for f) | 76–26–63 |

| Sample | Calculated Parameter | PSO | GWO | GA |

|---|---|---|---|---|

| Oliver30 (423) | Best Result | 500.20 | 449.86 | 423.74 |

| Worst Result | 592.66 | 601.78 | 424.69 | |

| Average Result | 542.08 | 522.74 | 423.93 | |

| Error Rate (%) | 0.29 | 0.24 | 0.003 | |

| Runtime (s) | 1289.25 | 108.17 | 38.60 | |

| Best Result | 723.41 | 532.20 | 439.31 | |

| Worst Result | 776.43 | 827.32 | 448.14 | |

| Eil51 (429) | Average Result | 745.65 | 666.53 | 442.89 |

| Error Rate (%) | 0.75 | 0.58 | 0.03 | |

| Runtime (s) | 2385.41 | 208.86 | 72.88 | |

| Best Result | 12,489.38 | 10,981.60 | 7762.72 | |

| Worst Result | 13,731.19 | 13,539.54 | 8316.30 | |

| Berlin52 (7542) | Average Result | 13,103.28 | 12,447.52 | 8021.78 |

| Error Rate (%) | 0.74 | 0.63 | 0.07 | |

| Runtime (s) | 2506.23 | 239.16 | 80.05 | |

| Best Result | 1572.10 | 1194.62 | 695.40 | |

| Worst Result | 1883.93 | 1616.17 | 715.87 | |

| st70 (675) | Average Result | 1686.88 | 1373.35 | 704.52 |

| Error Rate (%) | 1.56 | 1.08 | 0.05 | |

| Runtime (s) | 3896.87 | 274.51 | 121.83 | |

| Best Result | 1212.12 | 927.09 | 578.22 | |

| Worst Result | 1416.46 | 1115.37 | 592.97 | |

| Eil76 (538) | Average Result | 1287.18 | 997.37 | 588.04 |

| Error Rate (%) | 1.44 | 0.90 | 0.09 | |

| Runtime (s) | 4036.43 | 282.94 | 103.94 | |

| Best Result | 73,889.32 | 46,057.62 | 23,961.88 | |

| Worst Result | 83,672.94 | 123,953.40 | 27,348.95 | |

| KroA100 (21282) | Average Result | 78,544.64 | 79,129.14 | 25,371.21 |

| Error Rate (%) | 2.70 | 2.99 | 0.21 | |

| Runtime (s) | 4951.84 | 389.70 | 132.78 |

| Sample | Parameter | n = 1 | n = 2 | n = 3 |

|---|---|---|---|---|

| Shortest Time | 268.57 | 225.53 | 199.22 | |

| Oliver30 | Average Time | 286.17 | 230.7 | 203.11 |

| Longest Time | 298.89 | 237.55 | 204.34 | |

| Shortest Time | 275.86 | 228.95 | 197.79 | |

| Eil51 | Average Time | 293.42 | 233.6 | 205.43 |

| Longest Time | 301.79 | 236.37 | 213.24 | |

| Shortest Time | 5464.90 | 4547.6 | 3851.57 | |

| Berlin52 | Average Time | 5769.94 | 4676.11 | 3992.83 |

| Longest Time | 5970.97 | 4817.53 | 4094.61 | |

| Shortest Time | 485.96 | 403.75 | 345.95 | |

| st70 | Average Time | 497.2 | 411.49 | 360.44 |

| Longest Time | 517.53 | 427.88 | 378.7 | |

| Shortest Time | 395.67 | 309.23 | 260.54 | |

| Eil76 | Average Time | 412.61 | 316.04 | 265.98 |

| Longest Time | 430.79 | 329.88 | 272.2 | |

| Shortest Time | 19,788.83 | 16,207.64 | 13,718.63 | |

| KroA100 | Average Time | 20,593.88 | 16,786.1 | 14,017.2 |

| Longest Time | 21,083.2 | 17,577.64 | 14,755.49 |

| Parameter | k = 0 | k = 1 | k = 2 | k = 3 |

|---|---|---|---|---|

| Shortest Time | 260.42 | 191.47 | 143.71 | 131.16 |

| Average Time | 299.11 | 226.33 | 161.46 | 153.62 |

| Longest Time | 336.23 | 251.89 | 178.17 | 181.70 |

| Delivery Time Savings for Scenario 1 20 Instances and Low Flight Ranges | ||||||

|---|---|---|---|---|---|---|

| Distribution types and Number of drones | ||||||

| Ref. | RD-2 | RD-3 | RD-4 | CD-2 | CD-3 | CD-4 |

| [23] | 3.3% | 5.2% | 8.7% | 4.1% | 7.1% | 7.9% |

| [21] | 7.5% | 10.1% | 12.6% | 6.0% | 9.9% | 11.2% |

| [40] | 7.2% | 9.1% | 13.6% | 6.4% | 10.1% | 14.4% |

| This paper | 8.1% | 12.9% | 15.2% | 9.0% | 11.1% | 17.4% |

| Delivery Time Savings for Scenario 2 50 Instances and High Flight Ranges | ||||||

| Distribution types and Number of drones | ||||||

| Ref. | RD-2 | RD-3 | RD-4 | CD-2 | CD-3 | CD-4 |

| [23] | % 4.6 | % 6.8 | % 7.9 | % 5.1 | % 7.5 | % 8.6 |

| [21] | % 7.2 | % 11.7 | % 14.3 | % 8.7 | % 12.1 | % 13.9 |

| [40] | % 7.2 | % 12.2 | % 10.2 | % 6.3 | % 11.0 | % 12.9 |

| This paper | % 8.9 | % 13.1 | % 16.3 | % 9.7 | % 12.6 | % 16.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karaköse, E. A New Last Mile Delivery Approach for the Hybrid Truck Multi-Drone Problem Using a Genetic Algorithm. Appl. Sci. 2024, 14, 616. https://doi.org/10.3390/app14020616

Karaköse E. A New Last Mile Delivery Approach for the Hybrid Truck Multi-Drone Problem Using a Genetic Algorithm. Applied Sciences. 2024; 14(2):616. https://doi.org/10.3390/app14020616

Chicago/Turabian StyleKaraköse, Ebru. 2024. "A New Last Mile Delivery Approach for the Hybrid Truck Multi-Drone Problem Using a Genetic Algorithm" Applied Sciences 14, no. 2: 616. https://doi.org/10.3390/app14020616

APA StyleKaraköse, E. (2024). A New Last Mile Delivery Approach for the Hybrid Truck Multi-Drone Problem Using a Genetic Algorithm. Applied Sciences, 14(2), 616. https://doi.org/10.3390/app14020616