Influence of Heat Treatment Parameters on the Microstructure of 17-4 PH Single Tracks Fabricated by Direct Energy Deposition

Abstract

1. Introduction

2. Materials and Methods

| Heat Treatment Route | Heating Ramp | Solution Treatment | Quenching | Aging at 480 °C (h) |

|---|---|---|---|---|

| HT1 | 10 °C/min | 1040 °C × 30 min | In water | 3 |

| HT2 | NO | 1040 °C × 30 min | In water | 3 |

| HT3 | NO | NO | NO | 3 |

| HT4 | 10 °C/min | 1040 °C × 30 min | In water | 100 |

| HT5 | NO | NO | NO | 100 |

3. Results and Discussion

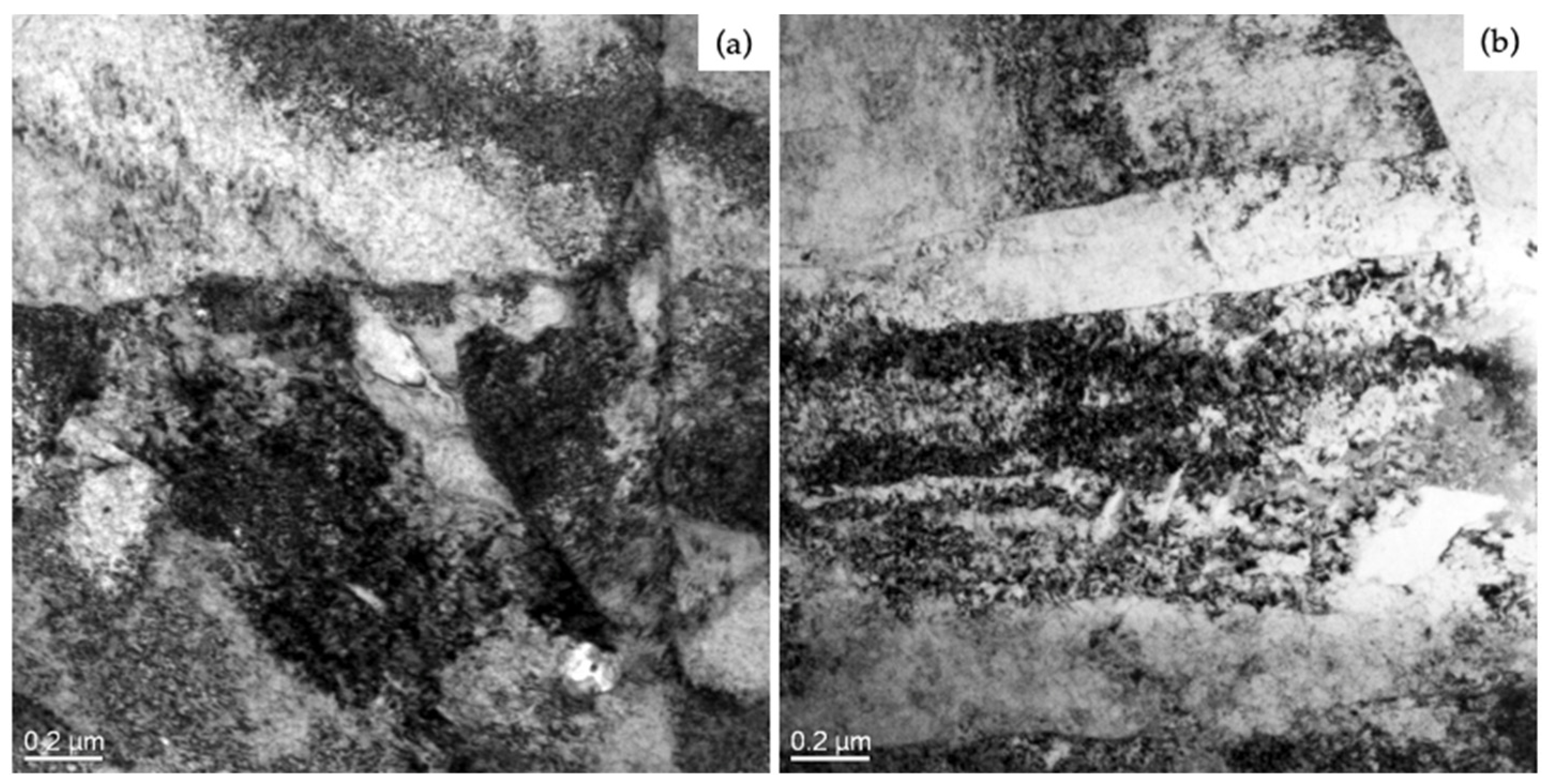

3.1. Microstructural Analysis of the Specimens in the as-Built Condition

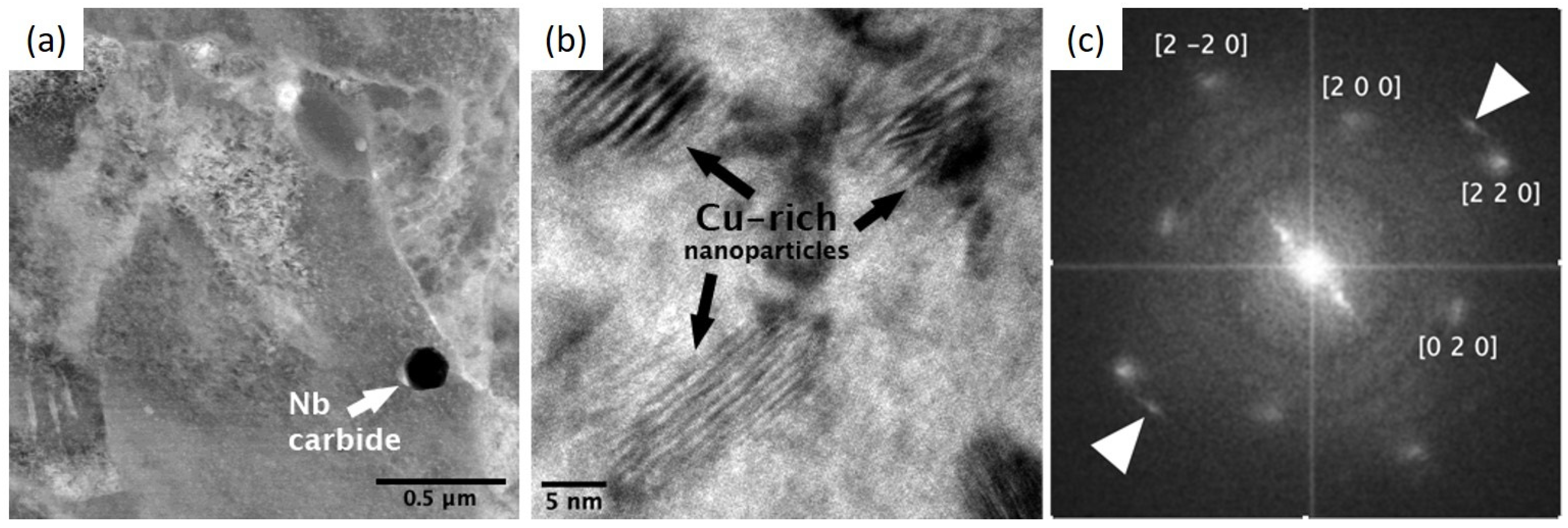

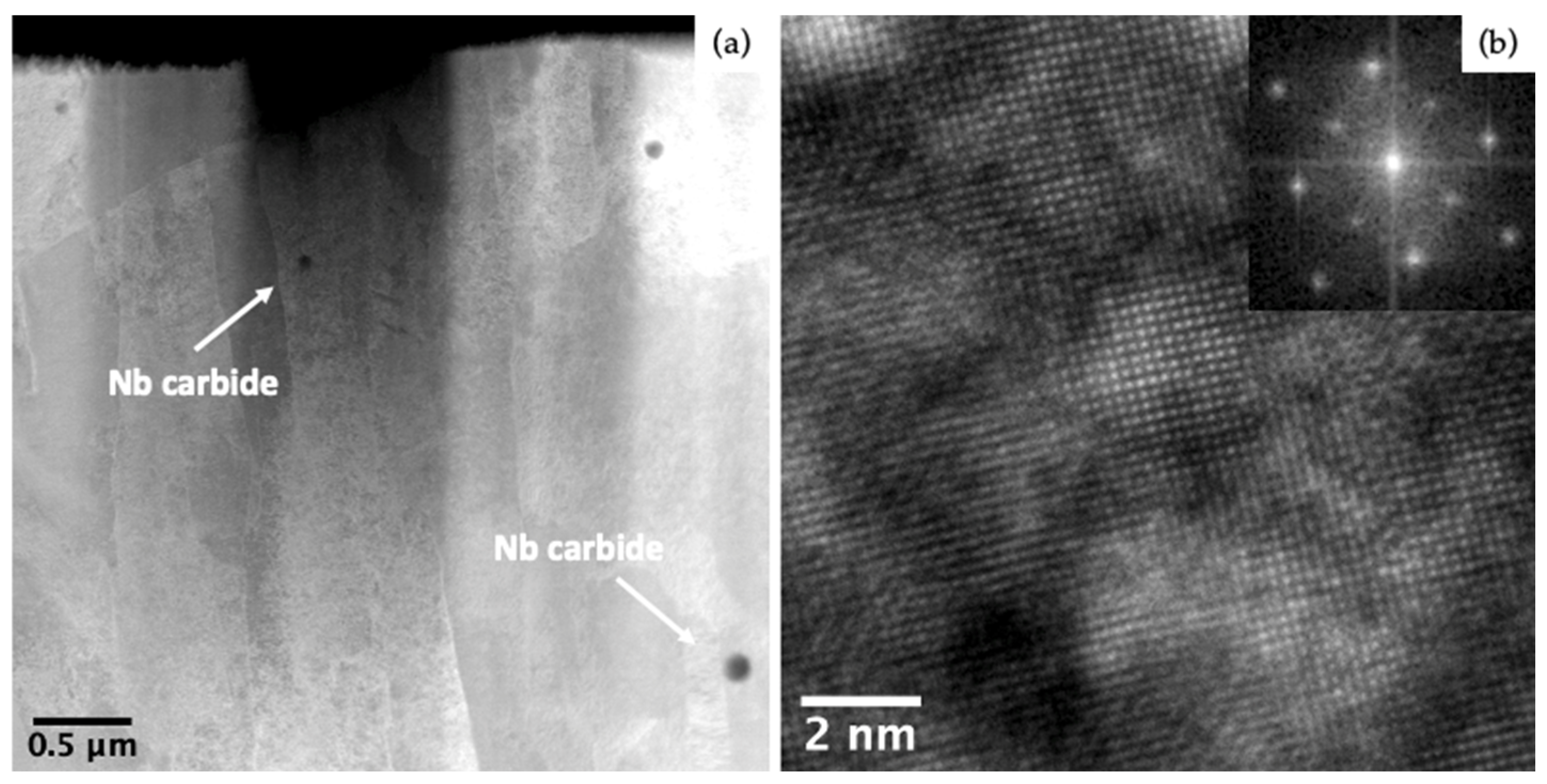

3.2. Microstructural Analysis of the Heat-Treated Specimens

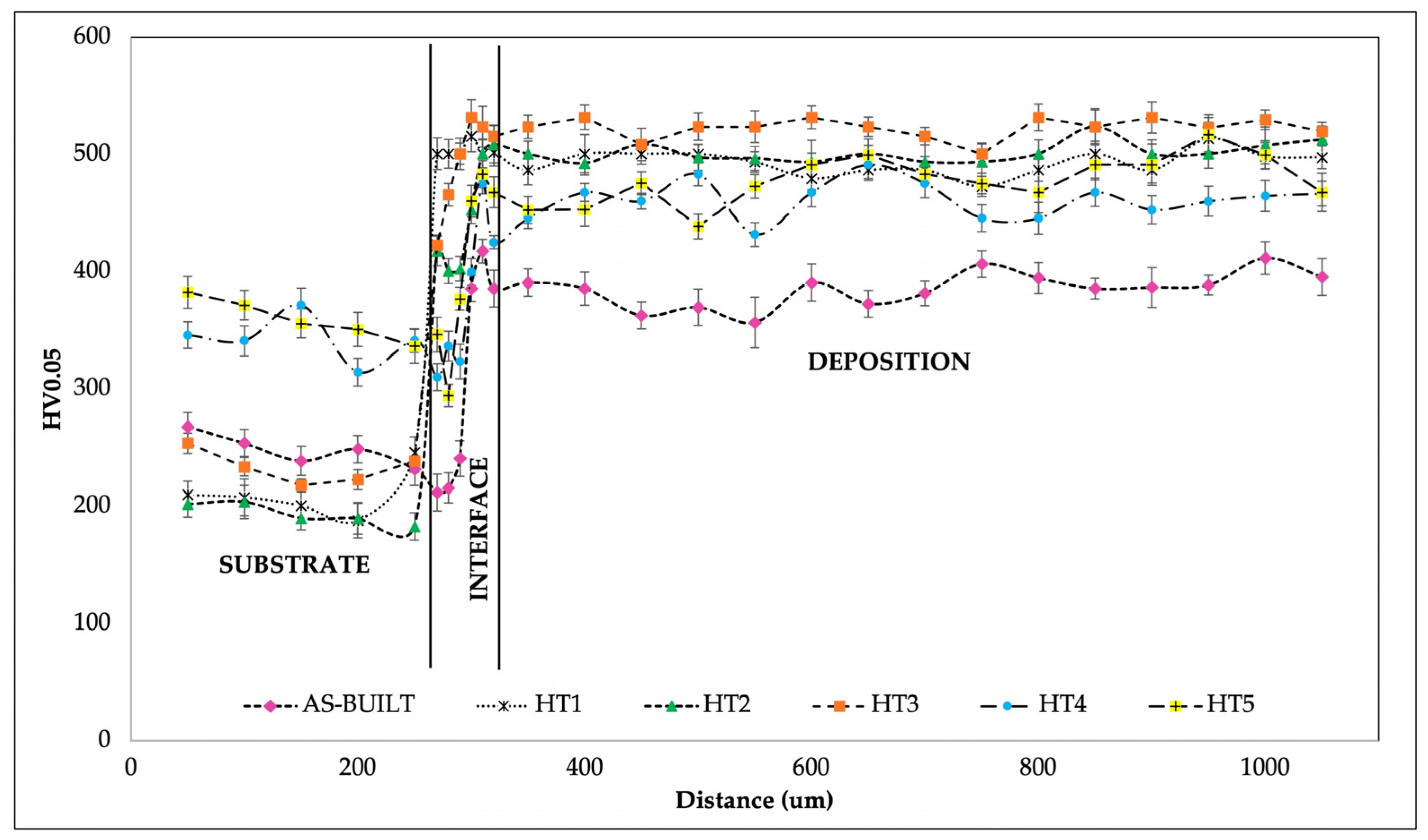

3.3. Hardness Behavior

4. Conclusions

- In the as-built condition, the single tracks exhibited a microstructure composed of a lathy martensitic matrix with a high amount of lathy δ-ferrite, mainly located at the interface between the substrate and the depositions, with an average microhardness value of 392 ± 17 HV0.05.

- Five different PFHTs were settled and successfully applied to the 17-4 PH single tracks. The direct aging strategy demonstrated its efficacy in improving the mechanical properties of the depositions, with increments up to 35% as compared to the as-built condition. The best results were obtained after direct aging conducted for 3 h at 480 °C.

- XRD analyses confirmed that distinguishing δ-ferrite peaks from α’-martensite ones in the diffraction pattern of 17-4 PH steel is challenging due to the low C concentration and their similar crystalline structures. Irrespective of the heat treatment route, the α’-martensite peaks may encompass both phases, namely either δ-ferrite or α’-martensite.

- TEM analyses performed on specimens subjected to long-time aging of 100 h were able to reveal the presence of Cu-rich nanometric particles and Nb carbides. In the directly aged specimens, the precipitation mechanism was different from that observed in the specimens subjected to solution heat treatment before aging. In the directly aged specimens, the Nb carbides were finer and closer to each other than those in the specimens solubilized prior to aging. These findings further justified the measured microhardness values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM A693-22; ASTM International Standard Specification for Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip. ASTM: West Conshohocken, PA, USA, 2022.

- Murthy, A.S. Role of Alloy Additions on Strengthening in 17-4 PH Stainless Steel. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2012. [Google Scholar]

- Steponaviciute, A.; Selskiene, A.; Stravinskas, K.; Borodinas, S.; Mordas, G. 17-4 PH Stainless-Steel as a Material for High Resolution Laser Metal Deposition. Mater. Today Proc. 2021, 52, 2268–2272. [Google Scholar] [CrossRef]

- ISO/ASTM 52900; Additive Manufacturing-General Principles. ASTM International Standard: West Conshohocken, PA, USA, 2015; pp. 1–28.

- ASTM F3187-16; Standard Guide for Directed Energy Deposition of Metals. ASTM International: West Conshohocken, PA, USA, 2016; pp. 1–22.

- ASTM F2792-12; ASTM Standard Terminology for Additive Manufacturing Technologies F2792. ASTM: West Conshohocken, PA, USA, 2012.

- Mathoho, I.; Akinlabi, E.T.; Arthur, N.; Tlotleng, M. Impact of DED Process Parameters on the Metallurgical Characteristics of 17-4 PH SS Deposited Using DED. CIRP J. Manuf. Sci. Technol. 2020, 31, 450–458. [Google Scholar] [CrossRef]

- Morales, C.; Merlin, M.; Fortini, A.; Fortunato, A. Direct Energy Depositions of a 17-4 PH Stainless Steel: Geometrical and Microstructural Characterizations. Coatings 2023, 13, 636. [Google Scholar] [CrossRef]

- Badi, L. Effect of Process Parameters on the Quality of 17-4 PH Samples Produced by Directed Energy Deposition. Master’s Thesis, Politecnico di Torino, Turin, Italy, 2021. [Google Scholar]

- Pan, L.; Kwok, C.T.; Niu, B.; Huang, X.; Cao, Y.; Zou, X.; Yi, J. Enhancement in Hardness and Corrosion Resistance of Directed Energy Deposited 17-4 PH Martensitic Stainless Steel via Heat Treatment. J. Mater. Res. Technol. 2023, 23, 1296–1311. [Google Scholar] [CrossRef]

- Tacq, Jeroen. L-PBF and Heat Treatment of 17-4PH Steel. 2021. Available online: https://static.fcomedia.be/user/11/images/inside_metal_am_3d_printing_with_steel.pdf (accessed on 25 May 2022).

- Hu, Z.; Zhu, H.; Zhang, H.; Zeng, X. Experimental Investigation on Selective Laser Melting of 17-4PH Stainless Steel. Opt. Laser Technol. 2017, 87, 17–25. [Google Scholar] [CrossRef]

- Bayode, A.; Pityana, S.; Akinlabi, E.T.; Shongwe, M.B. Effect of Scanning Speed on Laser Deposited 17-4PH Stainless Steel. In Proceedings of the 2017 8th International Conference on Mechanical and Intelligent Manufacturing Technologies, ICMIMT 2017, Cape Town, South Africa, 3–6 February 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Gu, H.; Gong, H.; Pal, D.; Rafi, K.; Starr, T.; Stucker, B. Influences of Energy Density on Porosity and Microstructure of Selective Laser Melted 17-4PH Stainless Steel. In Proceedings of the 24th International SFF Symposium-An Additive Manufacturing Conference, SFF 2013, Austin, TX, USA, 12–14 August 2013; pp. 474–489. [Google Scholar]

- Auguste, P.; Mauduit, A.; Fouquet, L.; Pillot, S. Study on 17-4 PH Stainless Steel Produced by Selective Laser Melting. UPB Sci. Bull. Ser. B Chem. Mater. Sci. 2018, 80, 197–210. [Google Scholar]

- Pham, L.; Lu, G.; Tran, P. Influences of Printing Pattern on Mechanical Performance of Three-Dimensional-Printed Fiber-Reinforced Concrete. 3D Print. Addit. Manuf. 2022, 9, 46–63. [Google Scholar] [CrossRef]

- Zhou, T.; Zheng, T.; Yildiz, A.B.; Spartacus, G.; Rolinska, M.; Cubitt, R.; Hedström, P. Microstructure Control during Deposition and Post-Treatment to Optimize Mechanical Properties of Wire-Arc Additively Manufactured 17-4 PH Stainless Steel. Addit. Manuf. 2022, 58, 103047. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Kong, C.; Adabifiroozjaei, E.; Li, S. Microstructure, Post Thermal Treatment Response, and Tribological Properties of 3D Printed 17-4 PH Stainless Steel. Wear 2020, 456–457, 203367. [Google Scholar] [CrossRef]

- Cheruvathur, S.; Lass, E.A.; Campbell, C.E. Additive Manufacturing of 17-4 PH Stainless Steel: Post-Processing Heat Treatment to Achieve Uniform Reproducible Microstructure. Miner. Met. Mater. Soc. ASM Int. 2016, 68, 930–942. [Google Scholar] [CrossRef]

- Stornelli, G.; Gaggia, D.; Rallini, M.; Di Schino, A. Heat Treatment Effect on Maraging Steel Manufactured by Laser Powder Bed Fusion Technology: Microstructure and Mechanical Properties. Acta Metall. Slovaca 2021, 27, 122–126. [Google Scholar] [CrossRef]

- Yeli, G.; Auger, M.A.; Wilford, K.; Smith, G.D.W.; Bagot, P.A.J.; Moody, M.P. Sequential Nucleation of Phases in a 17-4PH Steel: Microstructural Characterisation and Mechanical Properties. Acta Mater. 2017, 125, 38–49. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadeh, A. Aging Kinetics of 17-4 PH Stainless Steel. Mater. Chem. Phys. 2009, 116, 119–124. [Google Scholar] [CrossRef]

- ASM International Heat Treating. In ASM Handbook; ASM International: Novelty, OH, USA, 1991; Volume 4, pp. 1–2173.

- Stoudt, M.R.; Ricker, R.E.; Lass, E.A.; Levine, L.E. Influence of Postbuild Microstructure on the Electrochemical Behavior of Additively Manufactured 17-4 PH Stainless Steel. JOM 2017, 69, 506–515. [Google Scholar] [CrossRef]

- LeBrun, T.; Nakamoto, T.; Horikawa, K.; Kobayashi, H. Effect of Retained Austenite on Subsequent Thermal Processing and Resultant Mechanical Properties of Selective Laser Melted 17–4 PH Stainless Steel. Mater. Des. 2015, 81, 44–53. [Google Scholar] [CrossRef]

- Hsu, T.-H.; Chang, Y.-J.; Huang, C.-Y.; Yen, H.-W.; Chen, C.-P.; Jen, K.-K.; Yeh, A.-C. Microstructure and Property of a Selective Laser Melting Process Induced Oxide Dispersion Strengthened 17-4 PH Stainless Steel. J. Alloys Compd. 2019, 803, 30–41. [Google Scholar] [CrossRef]

- Meredith, S.D.; Zuback, J.S.; Keist, J.S.; Palmer, T.A. Impact of Composition on the Heat Treatment Response of Additively Manufactured 17–4 PH Grade Stainless Steel. Mater. Sci. Eng. A 2018, 738, 44–56. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Elwany, A.; Yadollahi, A.; Thompson, S.M.; Bian, L.; Shamsaei, N. Mechanical Properties and Microstructural Characterization of Selective Laser Melted 17-4 PH Stainless Steel. Rapid Prototyp. J. 2017, 23, 280–294. [Google Scholar] [CrossRef]

- Pasebani, S.; Ghayoor, M.; Badwe, S.; Irrinki, H.; Atre, S. V Effects of Atomizing Media and Post Processing on Mechanical Properties of 17-4 PH Stainless Steel Manufactured via Selective Laser Melting. Addit. Manuf. 2018, 22, 127–137. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. Scanning Strategies for Texture and Anisotropy Tailoring during Selective Laser Melting of TiC/316L Stainless Steel Nanocomposites. J. Alloys Compd. 2017, 728, 424–435. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and Properties of 17-4 PH Stainless Steel Fabricated by Selective Laser Melting. J. Mater. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef]

- Rafi, H.K.; Pal, D.; Patil, N.; Starr, T.L.; Stucker, B.E. Microstructure and Mechanical Behavior of 17-4 Precipitation Hardenable Steel Processed by Selective Laser Melting. J. Mater. Eng. Perform. 2014, 23, 4421–4428. [Google Scholar] [CrossRef]

- Ziewiec, A.; Zielińska-Lipiec, A.; Kowalska, J.; Ziewiec, K. Microstructure Characterization of Welds in X5CrNiCuNb16-4 Steel in Overaged Condition. Adv. Mater. Sci. 2019, 19, 57–69. [Google Scholar] [CrossRef]

- Sowa, R.; Kowal, A.; Roga, E.; Arabasz, S.; Dziedzic, A.; Dul, I.; Parlinska-Wojtan, M. Influence of Double Solution Treatment on Hardness in 17-4 PH Steel. Zast. Mater. 2015, 56, 261–268. [Google Scholar] [CrossRef]

- Viswanathan, U.K.; Banerjee, S.; Krishnan, R. Effects of Aging on the Microstructure of 17-4 PH Stainless Steel. Mater. Sci. Eng. A 1988, 104, 181–189. [Google Scholar] [CrossRef]

- Murayama, M.; Katayama, Y.; Hono, K. Microstructural Evolution in a 17-4 PH Stainless Steel after Aging at 400 C. Metall. Mater. Trans. A 1999, 30, 345–353. [Google Scholar] [CrossRef]

- Sun, Y.; Hebert, R.J.; Aindow, M. Effect of Heat Treatments on Microstructural Evolution of Additively Manufactured and Wrought 17-4PH Stainless Steel. Mater. Des. 2018, 156, 429–440. [Google Scholar] [CrossRef]

- AlMangour, B.; Yang, J.-M. Understanding the Deformation Behavior of 17-4 Precipitate Hardenable Stainless Steel Produced by Direct Metal Laser Sintering Using Micropillar Compression and TEM. Int. J. Adv. Manuf. Technol. 2017, 90, 119–126. [Google Scholar] [CrossRef]

- Morales, C.; Merlin, M.; Debdoubi, F.; Fortini, A.; Ferrucci, P. La Metallurgia Italaina; SpiderWeb: Ferrara, Italy, 2023; pp. 42–47. [Google Scholar]

- UNI EN ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2018.

- Li, J.; Cheng, L.; Zhang, P.; Wang, L.; Li, H. Effect of Delta Ferrites on the Anisotropy of Impact Toughness in Martensitic Heat-Resistant Steel. J. Mater. Res. Technol. 2019, 8, 1781–1788. [Google Scholar] [CrossRef]

- Bahrami Balajaddeh, M.; Naffakh-Moosavy, H. Pulsed Nd:YAG Laser Welding of 17-4 PH Stainless Steel: Microstructure, Mechanical Properties, and Weldability Investigation. Opt. Laser Technol. 2019, 119, 105651. [Google Scholar] [CrossRef]

- Garcia-Cabezon, C.; Castro-Sastre, M.A.; Fernandez-Abia, A.I.; Rodriguez-Mendez, M.L.; Martin-Pedrosa, F. Microstructure–Hardness–Corrosion Performance of 17–4 Precipitation Hardening Stainless Steels Processed by Selective Laser Melting in Comparison with Commercial Alloy. Met. Mater. Int. 2022, 28, 2652–2667. [Google Scholar] [CrossRef]

- Nezhadfar, P.D.; Burford, E.; Anderson-Wedge, K.; Zhang, B.; Shao, S.; Daniewicz, S.R.; Shamsaei, N. Fatigue Crack Growth Behavior of Additively Manufactured 17-4 PH Stainless Steel: Effects of Build Orientation and Microstructure. Int. J. Fatigue 2019, 123, 168–179. [Google Scholar] [CrossRef]

- Feng, Z. The Lattice Parameter of Gamma Iron and Iron-Chromium Alloys. Master’s Thesis, Case Western Reserve University, Cleveland, OH, USA, 2015. [Google Scholar]

- Li, K.; Sridar, S.; Tan, S.; Xiong, W. Effect of Homogenization on Precipitation Behavior and Strengthening of 17-4PH Stainless Steel Fabricated Using Laser Powder Bed Fusion. arXiv 2021, arXiv:2112.06289. [Google Scholar]

- Ščetinec, A.; Klobčar, D.; Nagode, A.; Vuherer, T.; Bračun, D.; Trdan, U. Optimisation of Precipitation Hardening for 15-5 PH Martensitic Stainless Steel Produced by Wire Arc Directed Energy Deposition. Sci. Technol. Weld. Join. 2023, 28, 558–568. [Google Scholar] [CrossRef]

- Rowolt, C.; Milkereit, B.; Springer, A.; Kreyenschulte, C.; Kessler, O. Dissolution and Precipitation of Copper-Rich Phases during Heating and Cooling of Precipitation-Hardening Steel X5CrNiCuNb16-4 (17-4 PH). J. Mater. Sci. 2020, 55, 13244–13257. [Google Scholar] [CrossRef]

- Villa, M.; Grumsen, F.B.; Niessen, F.; Dahmen, T.; Cao, L.; Reich, M.; Kessler, O.; Huang, X.; Somers, M.A.J. Aging 17-4 PH Martensitic Stainless Steel Prior to Hardening: Effects on Martensitic Transformation, Microstructure and Properties. Materialia 2023, 32, 101882. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Shen, Q.; Liu, W.; Wang, Z. Nano-Precipitates Evolution and Their Effects on Mechanical Properties of 17-4 Precipitation-Hardening Stainless Steel. Acta Mater. 2018, 156, 158–171. [Google Scholar] [CrossRef]

- Wang, J.; Zou, H.; Li, C.; Qiu, S.; Shen, B. The Spinodal Decomposition in 17-4PH Stainless Steel Subjected to Long-Term Aging at 350 °C. Mater. Charact. 2008, 59, 587–591. [Google Scholar] [CrossRef]

- Yan, S.; Wang, Z.; Li, T.; Chen, Z.; Du, X.; Liu, Y.; Chen, D.; Sun, K.; Liu, R.; Bai, B.; et al. In Situ Characterization of 17-4PH Stainless Steel by Small-Angle Neutron Scattering. Materials 2023, 16, 5583. [Google Scholar] [CrossRef]

- Cuppari, M.G.d.V.; Santos, S.F. Physical Properties of the NbC Carbide. Metals 2016, 6, 250. [Google Scholar] [CrossRef]

- Materials Explorer. Available online: https://next-gen.materialsproject.org/materials/mp-1184054?formula=CuNi3 (accessed on 29 December 2023).

- Wang, J.; Zou, H.; Li, C.; Peng, Y.; Qiu, S.; Shen, B. The Microstructure Evolution of Type 17-4PH Stainless Steel during Long-Term Aging at 350 °C. Nucl. Eng. Des. 2006, 236, 2531–2536. [Google Scholar] [CrossRef]

- Sun, Y.; Hebert, R.J.; Aindow, M. Effect of Laser Scan Length on the Microstructure of Additively Manufactured 17-4PH Stainless Steel Thin-Walled Parts. Addit. Manuf. 2020, 35, 101302. [Google Scholar] [CrossRef]

- Haines, M.P.; Moyle, M.S.; Rielli, V.V.; Luzin, V.; Haghdadi, N.; Primig, S. Experimental and Computational Analysis of Site-Specific Formation of Phases in Laser Powder Bed Fusion 17–4 Precipitate Hardened Stainless Steel. Addit. Manuf. 2023, 73, 103686. [Google Scholar] [CrossRef]

- Alkan, G.; Chae, D.; Kim, S.J. Effect of δ Ferrite on Impact Property of Hot-Rolled 12Cr-Ni Steel. Mater. Sci. Eng. A 2013, 585, 39–46. [Google Scholar] [CrossRef]

- Benoit, M.J.; Tabaie, S.; Waqar, T.; Ganton, T.; Amirkhiz, B.S.; Hadadzadeh, A.; Nasiri, A. Effects of Additive Manufacturing Processes and Isothermal Aging on the Microstructure and Properties of 13-8 Mo Precipitation Hardening Martensitic Stainless Steel. Addit. Manuf. 2023, 72, 103615. [Google Scholar] [CrossRef]

- Fang, K.; Luo, K.; Wang, L. Effect of Microstructure on Mechanical Properties of 316 LN Austenitic Stainless Steel. Coatings 2022, 12, 1461. [Google Scholar] [CrossRef]

- Chae, H.; Luo, M.Y.; Huang, E.W.; Shin, E.; Do, C.; Hong, S.K.; Woo, W.; Lee, S.Y. Unearthing Principal Strengthening Factors Tuning the Additive Manufactured 15-5 PH Stainless Steel. Mater. Charact. 2022, 184, 111645. [Google Scholar] [CrossRef]

| Element | Si | Cr | Ni | Cu | Nb | Mn | P | S | C | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Chemical composition (wt. %) | 0.43 | 15.28 | 4.49 | 3.39 | 0.27 | 0.50 | 0.019 | 0.0003 | 0.039 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merlin, M.; Morales, C.; Ferroni, M.; Fortini, A.; Soffritti, C. Influence of Heat Treatment Parameters on the Microstructure of 17-4 PH Single Tracks Fabricated by Direct Energy Deposition. Appl. Sci. 2024, 14, 700. https://doi.org/10.3390/app14020700

Merlin M, Morales C, Ferroni M, Fortini A, Soffritti C. Influence of Heat Treatment Parameters on the Microstructure of 17-4 PH Single Tracks Fabricated by Direct Energy Deposition. Applied Sciences. 2024; 14(2):700. https://doi.org/10.3390/app14020700

Chicago/Turabian StyleMerlin, Mattia, Cindy Morales, Matteo Ferroni, Annalisa Fortini, and Chiara Soffritti. 2024. "Influence of Heat Treatment Parameters on the Microstructure of 17-4 PH Single Tracks Fabricated by Direct Energy Deposition" Applied Sciences 14, no. 2: 700. https://doi.org/10.3390/app14020700

APA StyleMerlin, M., Morales, C., Ferroni, M., Fortini, A., & Soffritti, C. (2024). Influence of Heat Treatment Parameters on the Microstructure of 17-4 PH Single Tracks Fabricated by Direct Energy Deposition. Applied Sciences, 14(2), 700. https://doi.org/10.3390/app14020700