Field Trial and Performance Evaluation of Soybean-Based Bio-Fog Seals for Asphalt Rejuvenation

Abstract

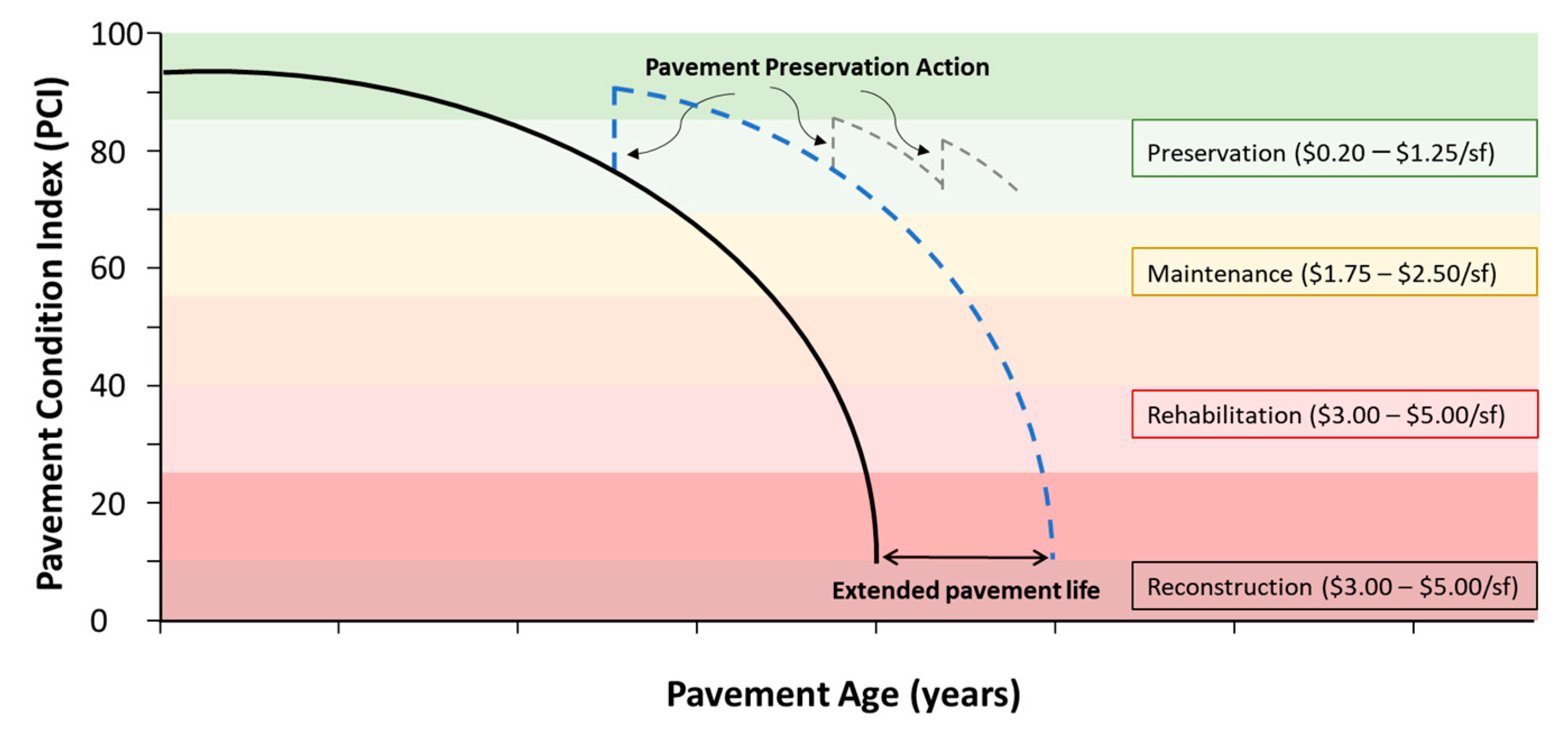

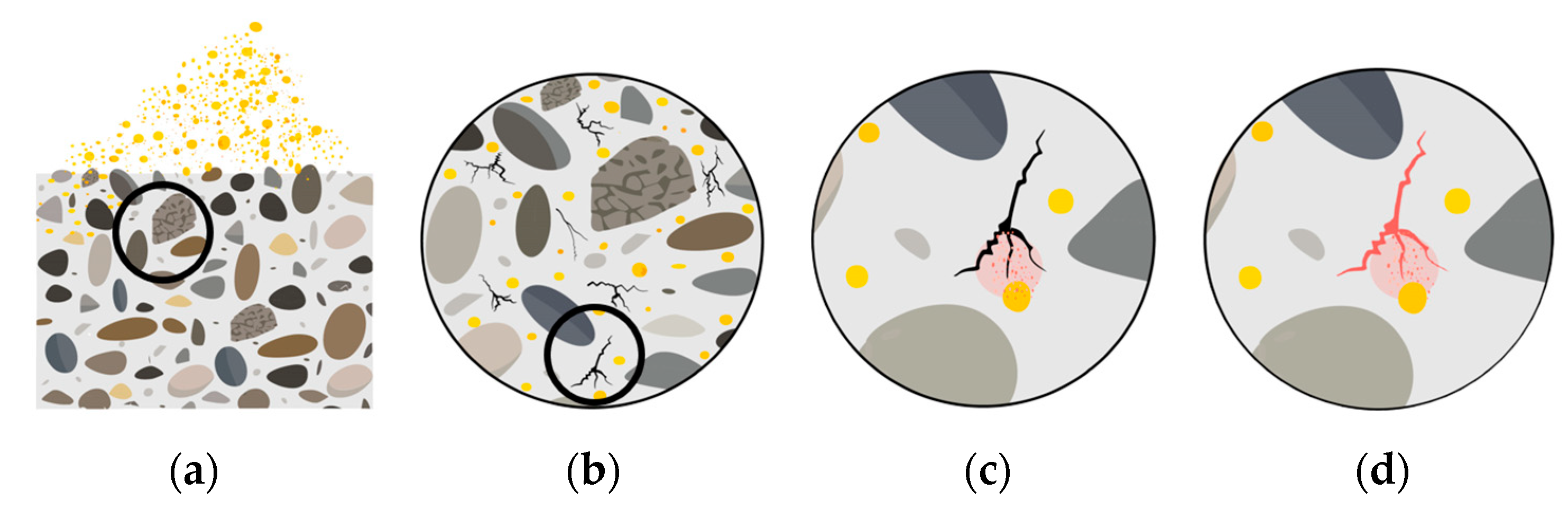

:1. Introduction

2. Materials and Methods

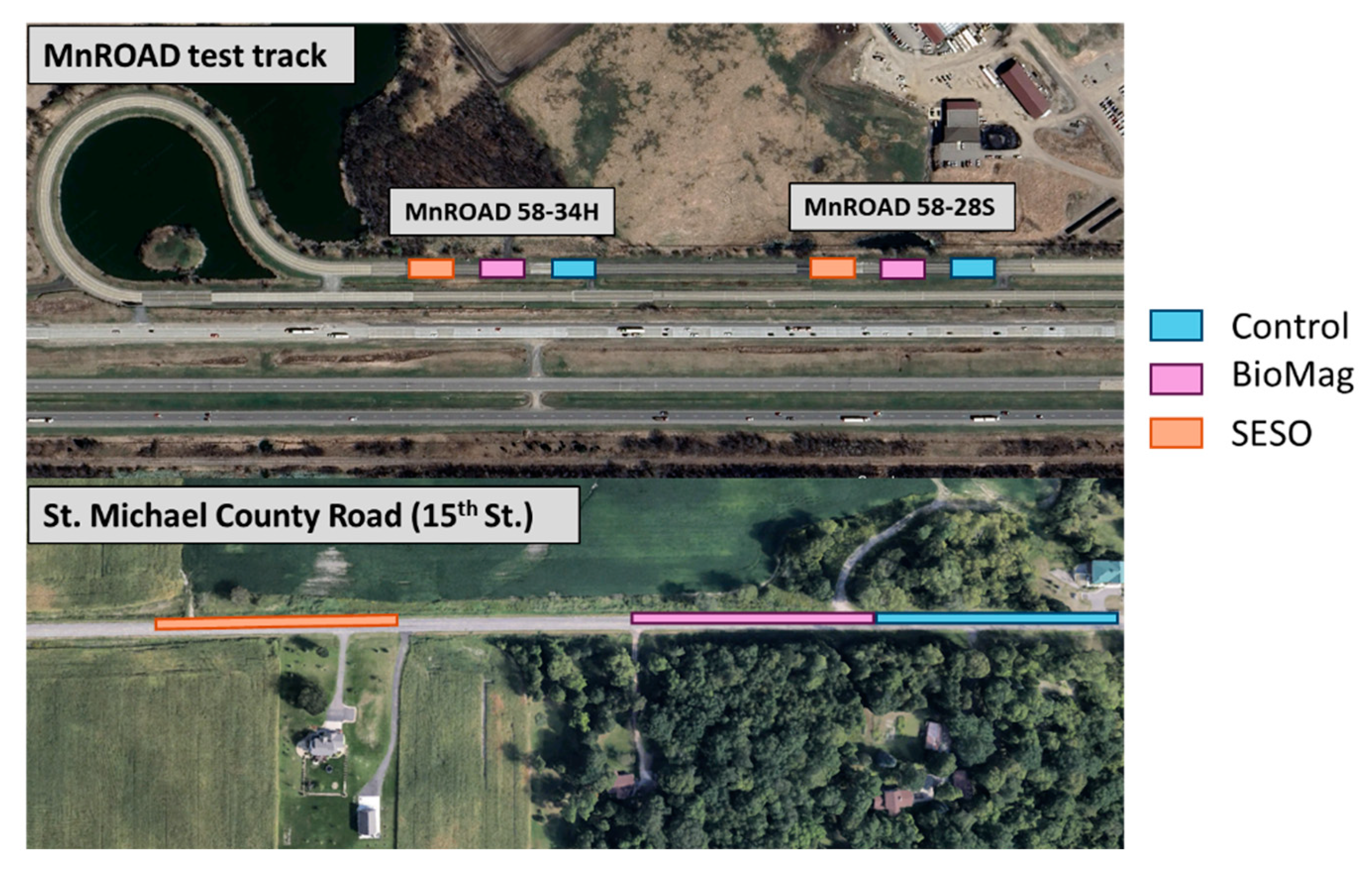

2.1. Field Testing Sites

2.2. Bio-Fog Seal Formulation

2.3. Application

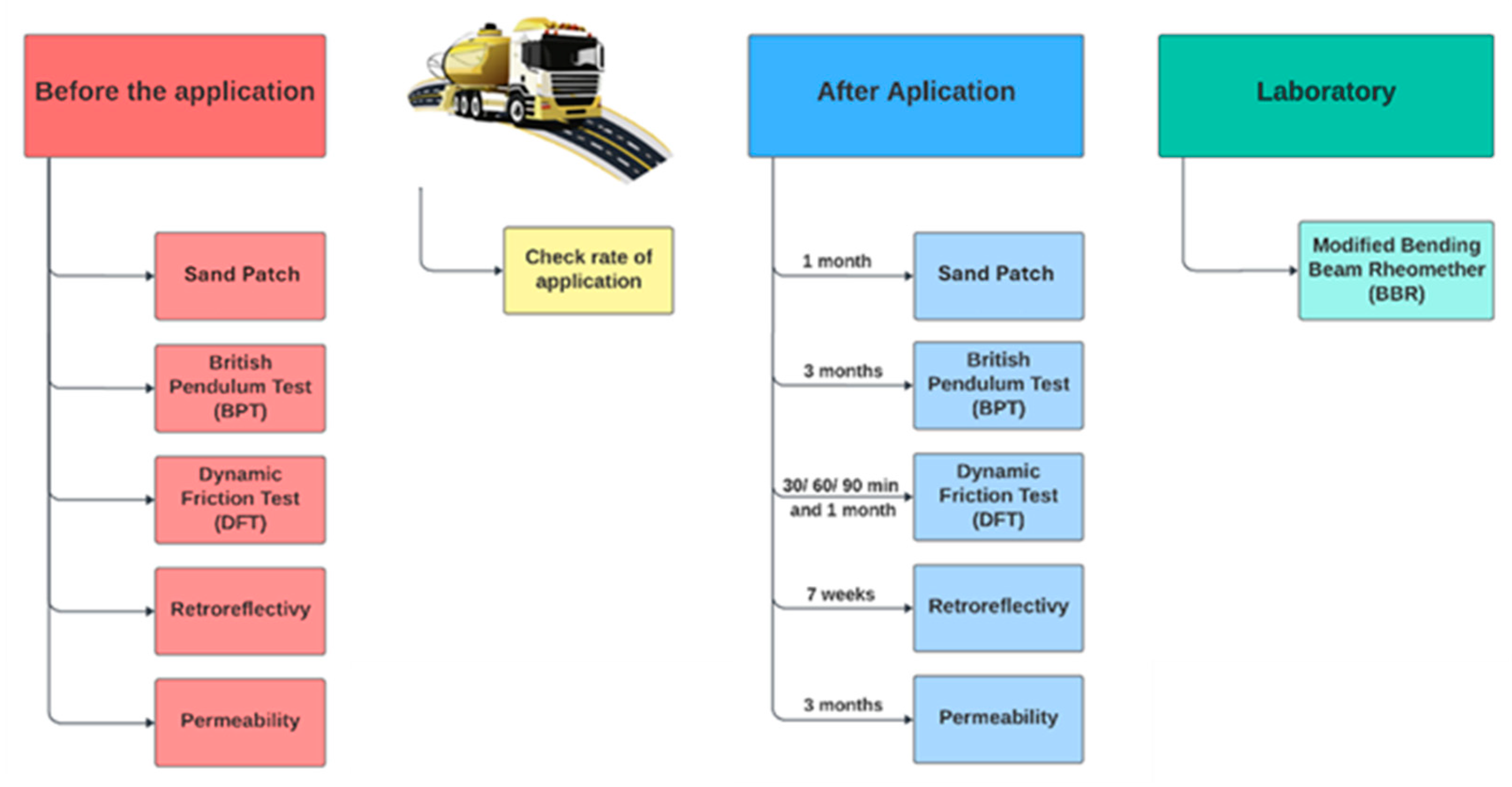

2.4. Experimental Plan

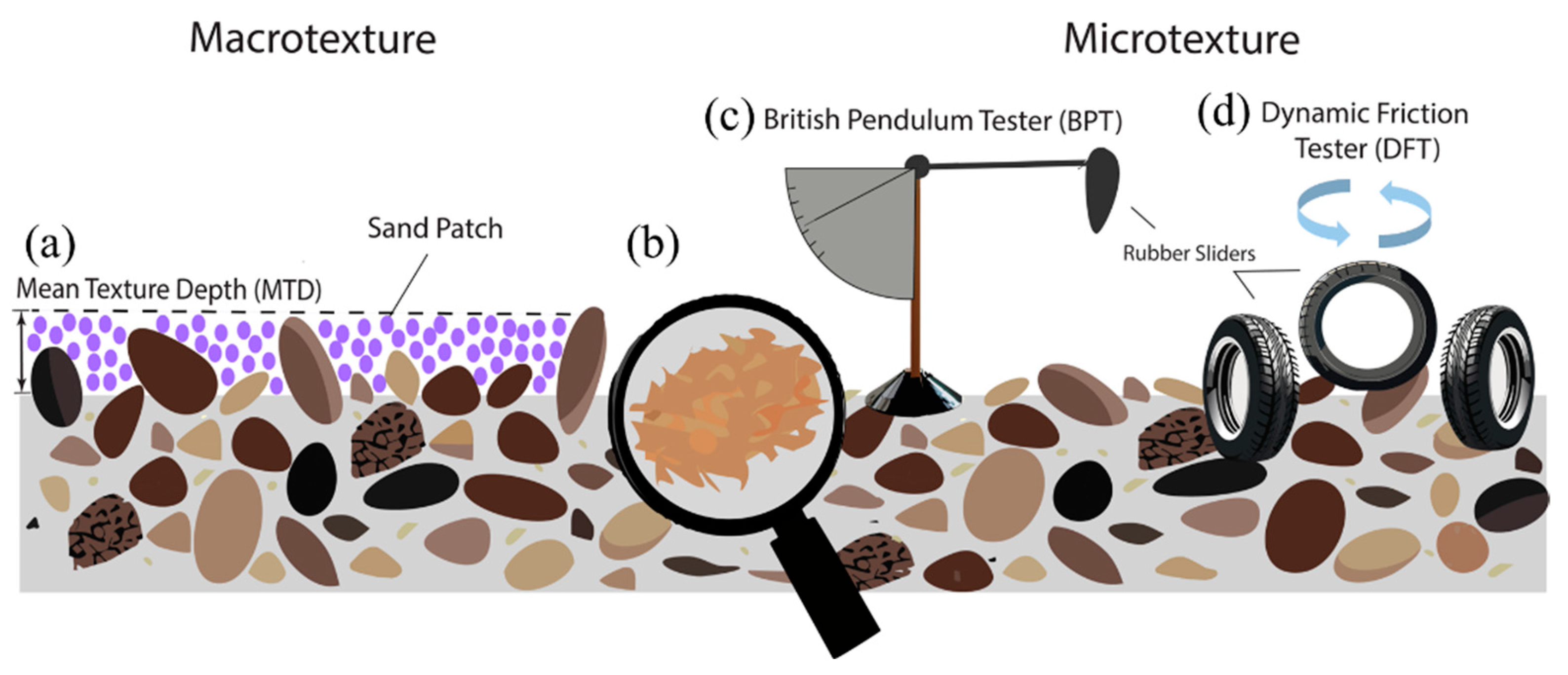

2.4.1. Pavement Friction

2.4.2. Retroreflectivity

2.4.3. Permeability

2.4.4. Stiffness and Relaxation

3. Results

3.1. Application

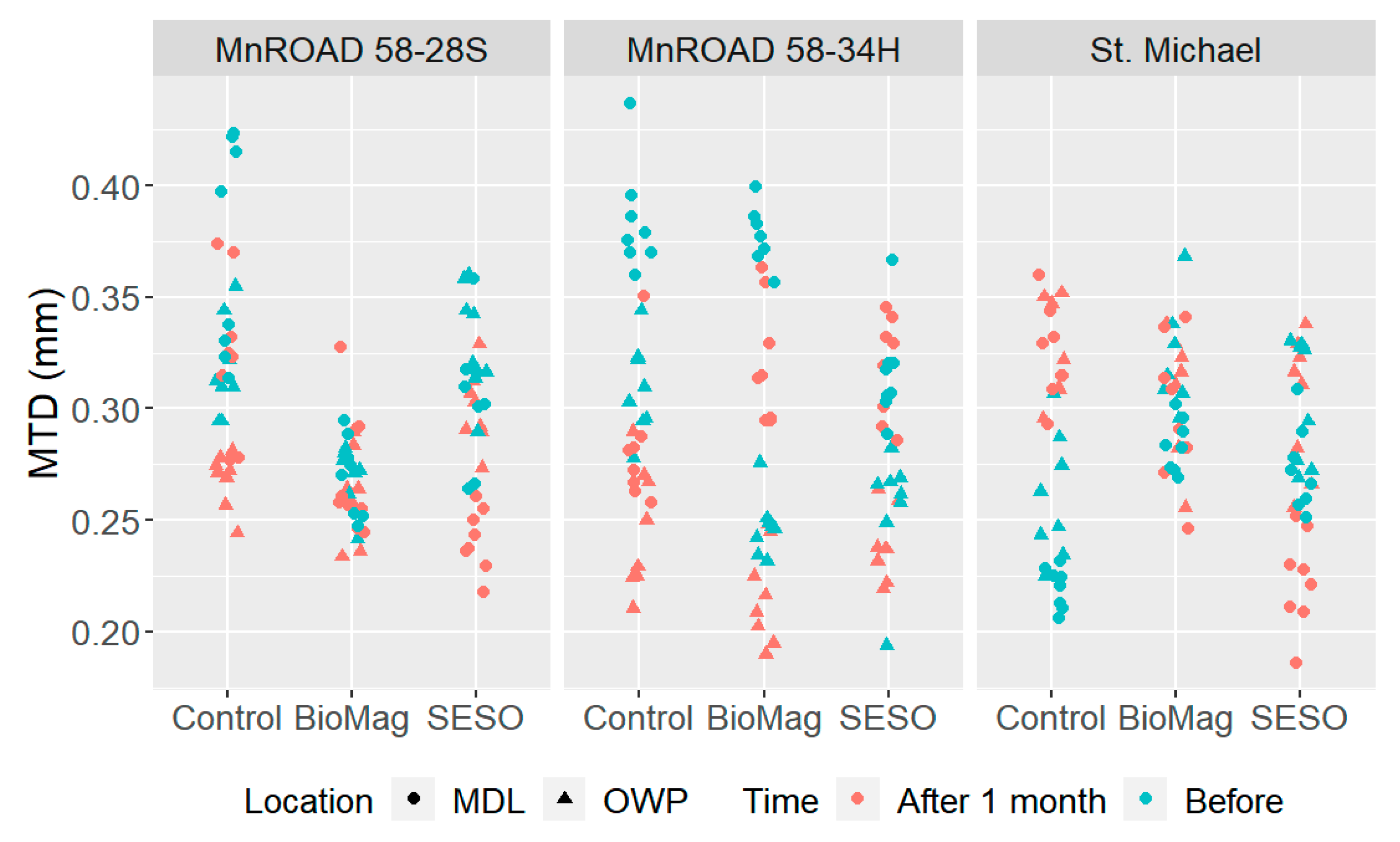

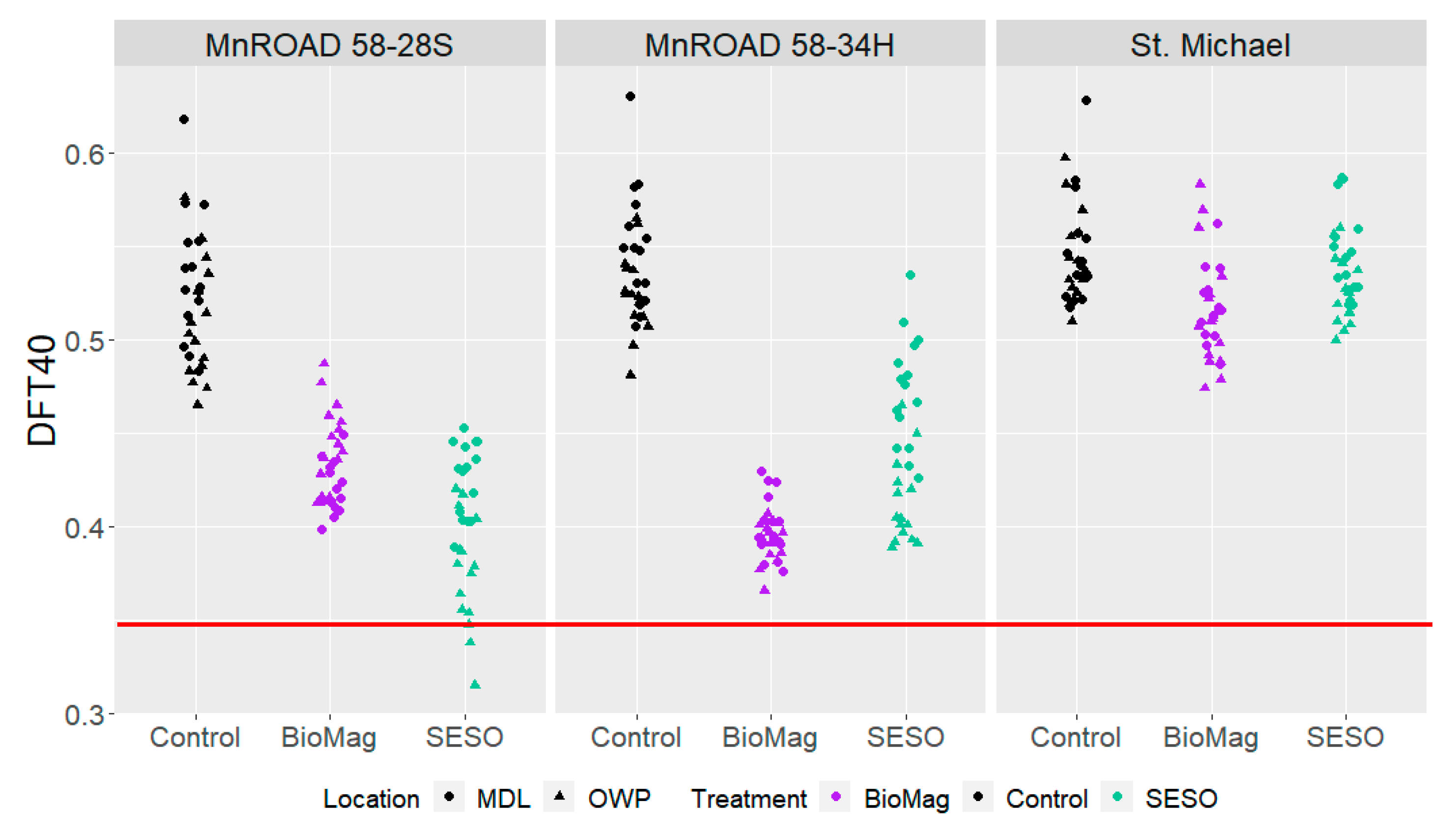

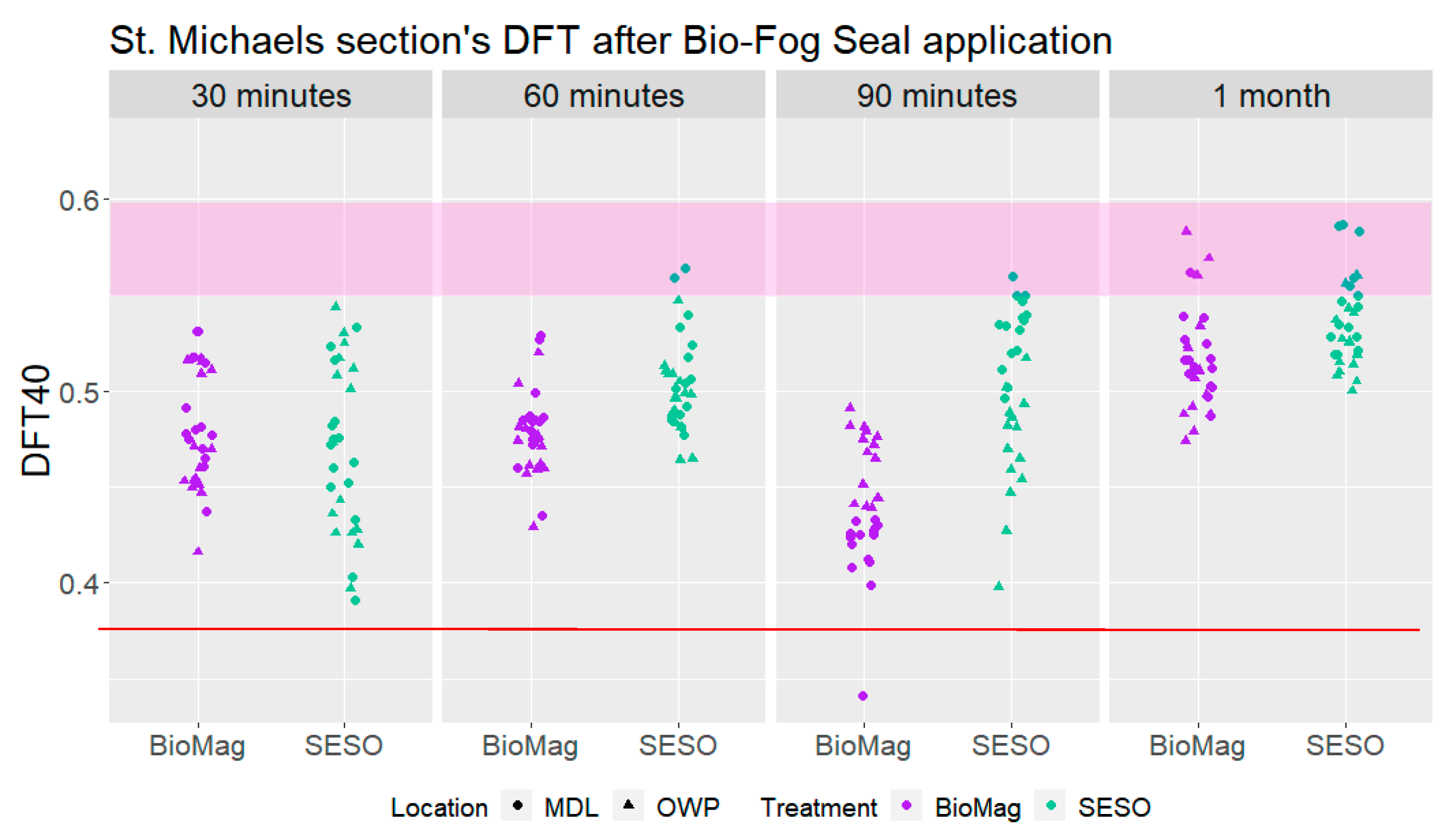

3.2. Pavement Friction

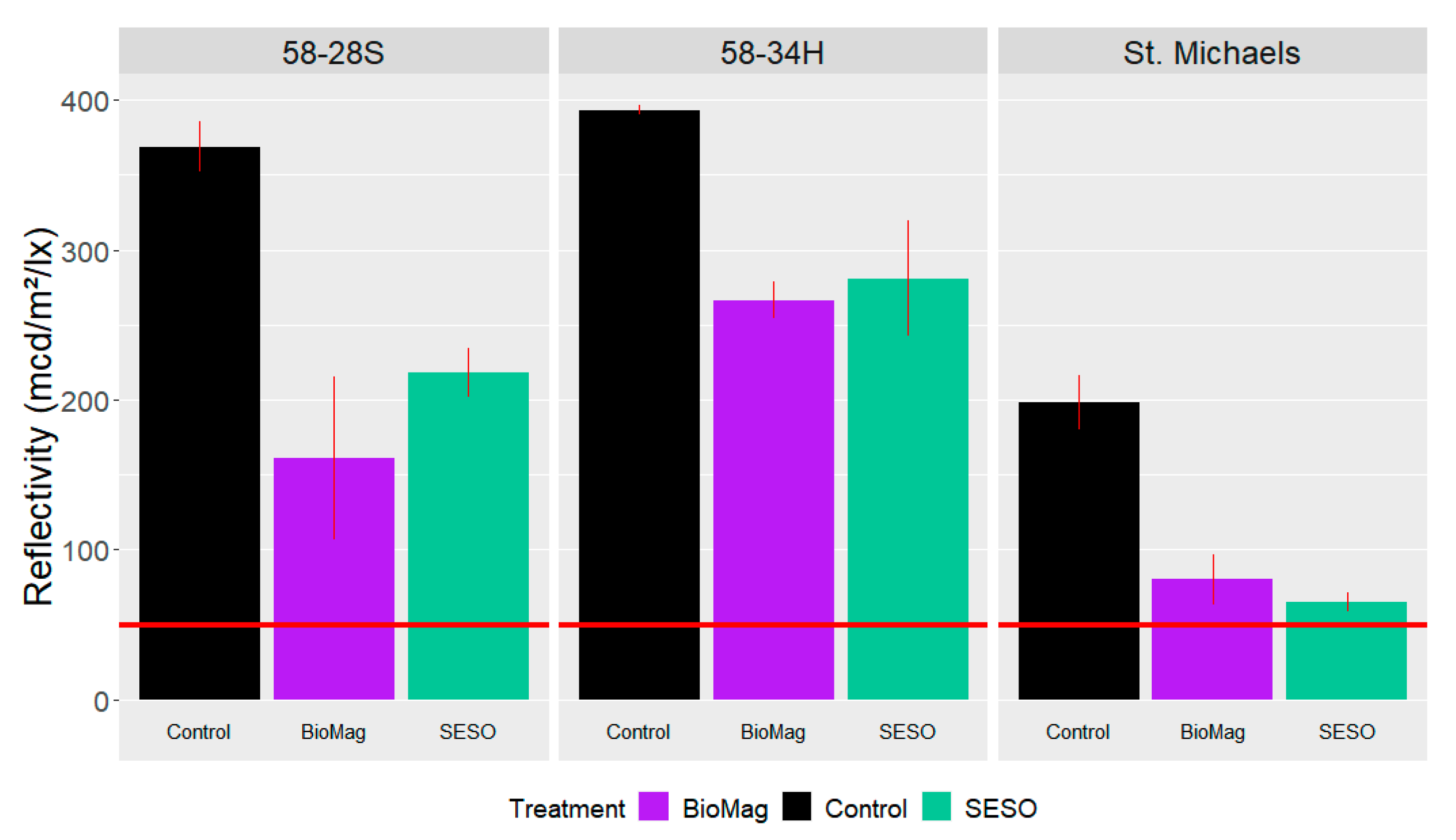

3.3. Retroreflecticity

3.4. Permeability

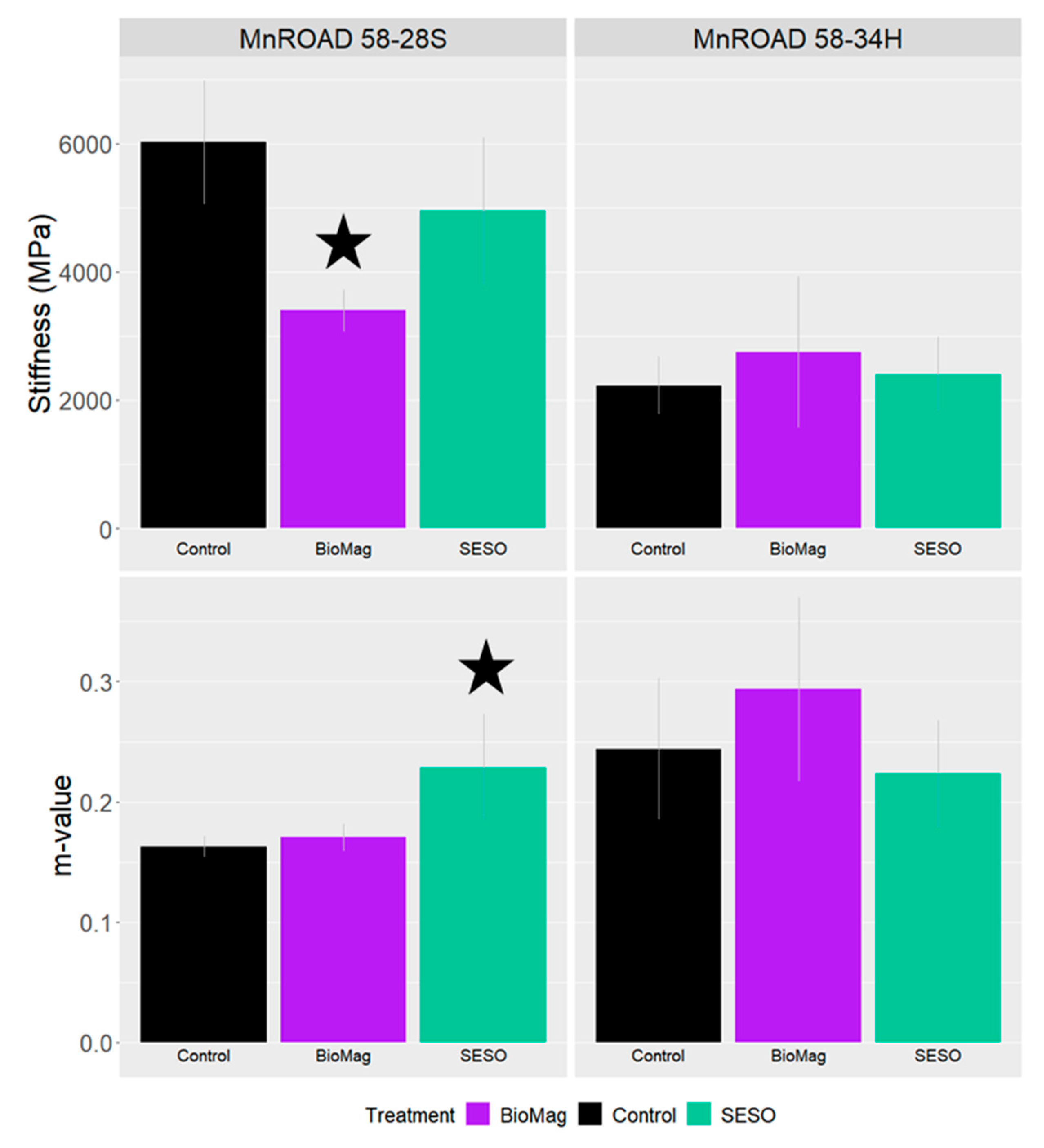

3.5. Stiffness and Relaxation

4. Conclusions and Recommendations

- The one-pass, no-heat application process offers significant advantages over traditional methods, which allows rapid drying and minimal traffic disruption.

- The bio-fog seals effectively reduced pavement permeability, potentially enhancing long-term durability by sealing cracks and preventing water infiltration.

- Pavement marking reflectivity remained acceptable, eliminating the need for immediate restriping.

- The soybean-based treatments showed promise for improving anti-cracking properties.

- The study focused on samples collected after a short period (less than 2 months).

- Bio-fog seals caused a slight decrease in pavement friction and marking reflectivity. Careful selection of roads for application is necessary, potentially excluding older pavements with low initial friction.

- The lack of understanding regarding bio-fog seal diffusion leads to application rates based on experience. Optimizing these rates could lead to more substantial pavement rejuvenation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, X.; Ma, X.; Wang, Z.; Song, S.; Sheng, Y. Investigation of changing SARA and fatigue properties of asphalt bi-tumen under ageing and analysis of their relation based upon the BP neural network. Constr. Build. Mater. 2023, 394, 132163. [Google Scholar] [CrossRef]

- Airey, G. State of the Art Report on Ageing Test Methods for Bituminous Pavement Materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Zhang, R.; Sias, J.E.; Dave, E.V. Evaluation of the cracking and aging susceptibility of asphalt mixtures using viscoelastic properties and master curve parameters. J. Traffic Transp. Eng. 2022, 9, 106–119. [Google Scholar] [CrossRef]

- Hu, Y.; Si, W.; Kang, X.; Xue, Y.; Wang, H.; Parry, T.; Airey, G.D. State of the art: Multiscale evaluation of bitumen ageing behaviour. Fuel 2022, 326, 125045. [Google Scholar] [CrossRef]

- Hu, Y.; Allanson, M.; Sreeram, A.; Ryan, J.; Wang, H.; Zhou, L.; Airey, G.D. Characterisation of bitumen through multiple ageing-rejuvenation cycles. Int. J. Pavement Eng. 2024, 25, 2365350. [Google Scholar] [CrossRef]

- Ong, G.; Nantung, T.E.; Sinha, K.C. Indiana Pavement Preservation Program; Publication FHWA/IN/2010/14; Purdue University: West Lafayette, IN, USA, 2010. [Google Scholar]

- Babashamsi, P.; Khahro, S.H.; Omar, H.A.; Al-Sabaeei, A.M.; Memon, A.M.; Milad, A.; Khan, M.I.; Sutanto, M.H.; Yusoff, N.I.M. Perspective of Life-Cycle Cost Analysis and Risk Assessment for Airport Pavement in Delaying Preventive Maintenance. Sustainability 2022, 14, 2905. [Google Scholar] [CrossRef]

- Los Angeles County Department of Public Works. Pavement Management System—LA County Public Works. Los Angeles County Department of Public Works. Available online: https://pw.lacounty.gov/gmed/lacroads/Pm.aspx (accessed on 10 May 2024).

- You, L.; Dai, Q.; You, Z.; Zhou, X.; Washko, S. Stability and rheology of asphalt-emulsion under varying acidic and alkaline levels. J. Clean. Prod. 2020, 256, 120417. [Google Scholar] [CrossRef]

- Kiihnl, L.; Braham, A. Exploring the influence of pavement preservation, maintenance, and rehabilitation on Arkansas’ highway network: An education case study. Int. J. Pavement Eng. 2019, 22, 570–581. [Google Scholar] [CrossRef]

- Jiang, Y.; Yi, Y.; Tian, T.; Fan, J.; Yuan, K.; Deng, C.; Xue, J. Development and application of skid resistance fog seal for pavements. Coatings 2020, 10, 867. [Google Scholar] [CrossRef]

- Prapaitrakul, N.; Freeman, T.; Glover, C. Analyze Existing Fog Seal Asphalts and Additives: Literature Review; Report No. FHWA/TX, 06/0-5091-1; Texas Department of Transportation: Austin, TX, USA, 2005. [Google Scholar]

- Li, S. Evaluation of Pavement Surface Treatments; Joint Transpiration Research Program—Indiana Department of Transportation; Purdue University: West Lafayette, Indiana, 2012. [Google Scholar]

- Praticò, F.G.; Vaiana, R.; Iuele, T. Macrotexture modeling and experimental validation for pavement surface treatments. Constr. Build. Mater. 2015, 95, 658–666. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, Z.; Li, X.; Yuan, J.; Zhou, Q.; Xiao, F. Cracking investigation on fog seal technology with waterborne acrylate and polyurethane as a clean modification approach. J. Clean. Prod. 2021, 329, 129751. [Google Scholar] [CrossRef]

- Herrington, P.R. Diffusion and reaction of oxygen in bitumen films. Fuel 2012, 94, 86–92. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, H.; Hui, B.; Jelagin, D.; You, Z.; Feng, P. Optimal design of fresh sand fog seal mortar using response surface methodology (RSM): Towards to its workability and rheological properties. Constr. Build. Mater. 2022, 340, 127638. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Ye, M.; Yap, Y.; Si, C. The impact of bio-oil as rejuvenator for aged asphalt binder. Constr. Build. Mater. 2019, 196, 134–143. [Google Scholar] [CrossRef]

- Kim, Y.R.; Im, J.H. Fog Seal Effectiveness for Bituminous Surface Treatments; Report No. HWY 2010-02.16; North Carolina Department of Transportation: Raleigh, NC, USA, 2012. [Google Scholar]

- Gayle, G.; King, H. Spray Applied Polymer Surface Seals. In Proceedings of the Southeast Pavement Preservation Partnership (SEPPP) Meeting, Foundation for Pavement Preservation/FHWA, Atlanta, GA, USA, 6–8 May 2008. [Google Scholar]

- Garcia, A.; Jelfs, J.; Austin, C.J. Internal asphalt mixture rejuvenation using capsules. Constr. Build. Mater. 2015, 101, 309–316. [Google Scholar] [CrossRef]

- Chen, C.; Podolsky, J.H.; Hernández, N.B.; Hohmann, A.D.; Williams, R.C.; Cochran, E.W. Preliminary investigation of bioadvantaged polymers as sustainable alternatives to petroleum-derived polymers for asphalt modification. Mater. Struct. 2017, 50, 225. [Google Scholar] [CrossRef]

- Cochran, E.; Hernandez, N.; Hohmann, A.; Williams, R.; Forrester, M.; Podolsky, J.; Ledtje, P.; Chen, C. Biosolvents Useful for Improved Asphalt Products Utilizing Recycled Asphalt Pavement or Other Brittle Asphalt Binders such as Vacuum Tower Bottoms. U.S. Patent US20210079224A1, 18 March 2021. [Google Scholar]

- Cochran, E.; Williams, R.; Hernandez, N.; Cascione, A. Thermoplastic Elastomers via Atom Transfer Radical Polymerization of Plant oil. U.S. Patent No. 9,932,435, 2018. [Google Scholar]

- Catalá, J.; Caballero, M.P.; de la Cruz-Martínez, F.; Tejeda, J.; Castro-Osma, J.A.; Lara-Sánchez, A.; García-Vargas, J.M.; García, M.T.; Ramos, M.J.; Gracia, I.; et al. Carbonation of epoxidized soybean oil in supercritical CO2 assisted by imidazole-based organocatalysts. J. CO2 Util. 2022, 61, 102060. [Google Scholar] [CrossRef]

- Yu, J.; Quan, H.; Huang, Z.; Li, P.; Chang, S. Synthesis of a Heavy-Oil Viscosity Reducer Containing a Benzene Ring and Its Viscosity Reduction Mechanism. ChemistrySelect 2022, 7, e202102694. [Google Scholar] [CrossRef]

- Liu, S.; Qi, X.; Shan, L. Effect of molecular structure on low-temperature properties of bitumen based on molecular dynamics. Constr. Build. Mater. 2022, 319, 126029. [Google Scholar] [CrossRef]

- Podolsky, J.H.; Saw, B.; Sotoodeh-Nia, Z.; Hernandez, N.; Empric, B.; Lin, F. Changes in the chemical composition of virgin asphalt and RAP extracted binder used for a high volume high RAP mix design due to the addition of a soybean derived chemical additive. In Proceedings of the 55th Petersen Asphalt Research Conference, Laramie, Wyoming, 11–14 July 2018. [Google Scholar]

- Hernández, N.; Williams, R.C.; Cochran, E.W. The battle for the “green” polymer. Different approaches for biopolymer synthesis: Bioadvantaged vs. bioreplacement. Org. Biomol. Chem. 2014, 12, 2834–2849. [Google Scholar] [CrossRef]

- ASTM E965-15; Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM E303-18; Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- Road Research Laboratory. Instructions for Using the Portable Skid-Resistance Tester, 2nd ed.; [Road Note 27]; HM Stationery Office: London, UK, 1969.

- ASTM E1911-19; Standard Test Method for Measuring Surface Frictional Properties Using the Dynamic Friction Tester. ASTM International: West Conshohocken, PA, USA, 2019.

- Heitzman, M.; Turner, P.; Greer, M. High Friction Surface Treatment Alternative Aggregates Study; NCAT Report 15-04; National Center for Asphalt Technology: Auburn, AL, USA, 2015. [Google Scholar]

- Henry, J.J. Evaluation of Pavement Friction Characteristics; NCHRP Synthesis of Highway Practice 291; TRB, National Research Council: Washington, DC, USA, 2000. [Google Scholar]

- ASTM E1710-18; Standard Test Method for Measurement of Retroreflective Pavement Marking Materials with CEN-Prescribed Geometry Using a Portable Retroreflectometer. ASTM International: West Conshohocken, PA, USA, 2018.

- Pike, A.M.; Satterfield, C.; Schertz, G.; Cheung, J.; Falk, K.W. Methods for Maintaining Pavement Marking Retroreflectivity; FHWA-SA-22-028; United States Federal Highway Administration Office of Safety: Washington, DC, USA, 2022. [Google Scholar]

- Cooley, A.J. Permeability of Superpave Mixtures: Evaluation of Field Permeameters; NCAT Report 99-1; National Center for Asphalt Technology: Auburn, AL, USA, 1999. [Google Scholar]

- Velasquez, R.A.; Marasteanu, M.; Labuz, J.F.; Turos, M. Evaluation of Bending Beam Rheometer for Characterization of Asphalt Mixtures. J. Assoc. Asph. Paving Technol. 2010, 79, 295–324. [Google Scholar]

- Ghosh, D.; Turos, M.; Marasteanu, M. Evaluation of Bio-Fog Sealants for Pavement Preservation; Report No. MN/RC 2016-20; University of Minnesota: St. Paul, MN, USA, 2016. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, A.L.; Falcao, C.; Staver, M.; Pinto, I.; Becker, A.; Forrester, M.; Hohmann, A.; Kuehl, B.; Hernandez, N.; Buss, A.; et al. Field Trial and Performance Evaluation of Soybean-Based Bio-Fog Seals for Asphalt Rejuvenation. Appl. Sci. 2024, 14, 9168. https://doi.org/10.3390/app14209168

Rodrigues AL, Falcao C, Staver M, Pinto I, Becker A, Forrester M, Hohmann A, Kuehl B, Hernandez N, Buss A, et al. Field Trial and Performance Evaluation of Soybean-Based Bio-Fog Seals for Asphalt Rejuvenation. Applied Sciences. 2024; 14(20):9168. https://doi.org/10.3390/app14209168

Chicago/Turabian StyleRodrigues, Ana Luiza, Caio Falcao, Maxwell Staver, Irvin Pinto, Andrew Becker, Michael Forrester, Austin Hohmann, Baker Kuehl, Nacu Hernandez, Ashley Buss, and et al. 2024. "Field Trial and Performance Evaluation of Soybean-Based Bio-Fog Seals for Asphalt Rejuvenation" Applied Sciences 14, no. 20: 9168. https://doi.org/10.3390/app14209168