Quality Enhancement of Torrefied Biopellets Prepared by Unused Forest Biomass and Wood Chip Residues in Pulp Mills

Abstract

1. Introduction

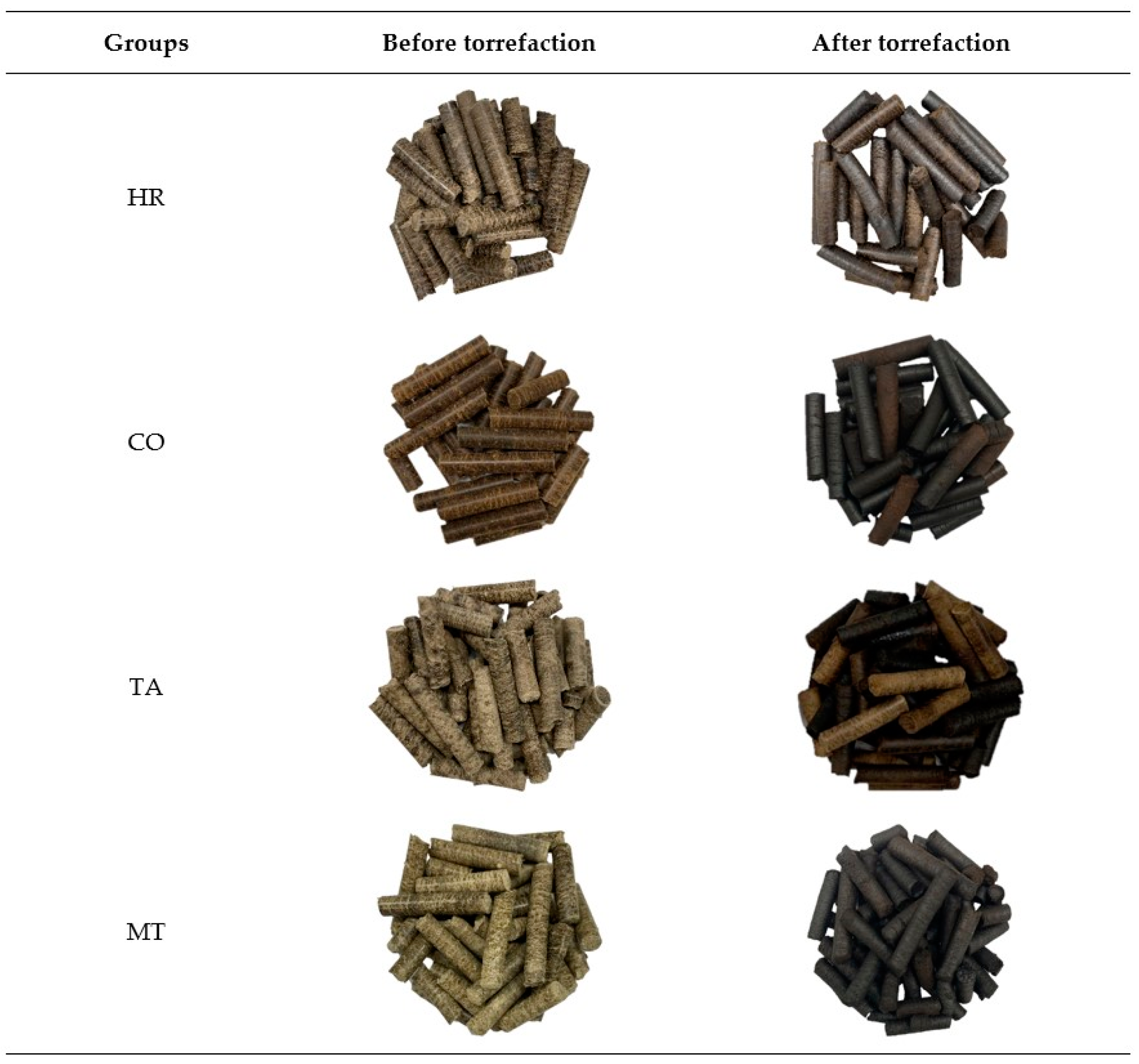

2. Materials and Methods

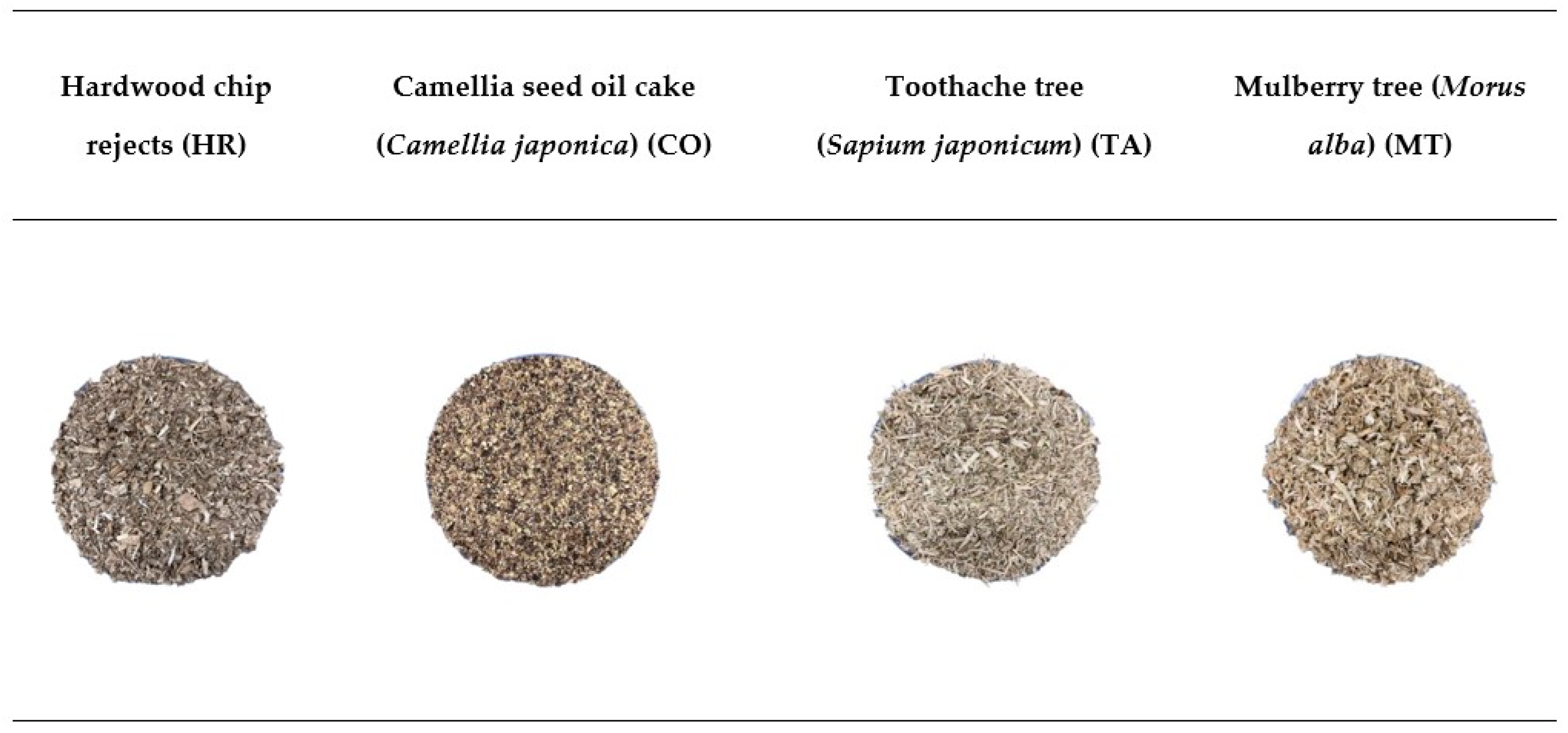

2.1. Materials

2.2. Pelletization

2.3. Torrefaction

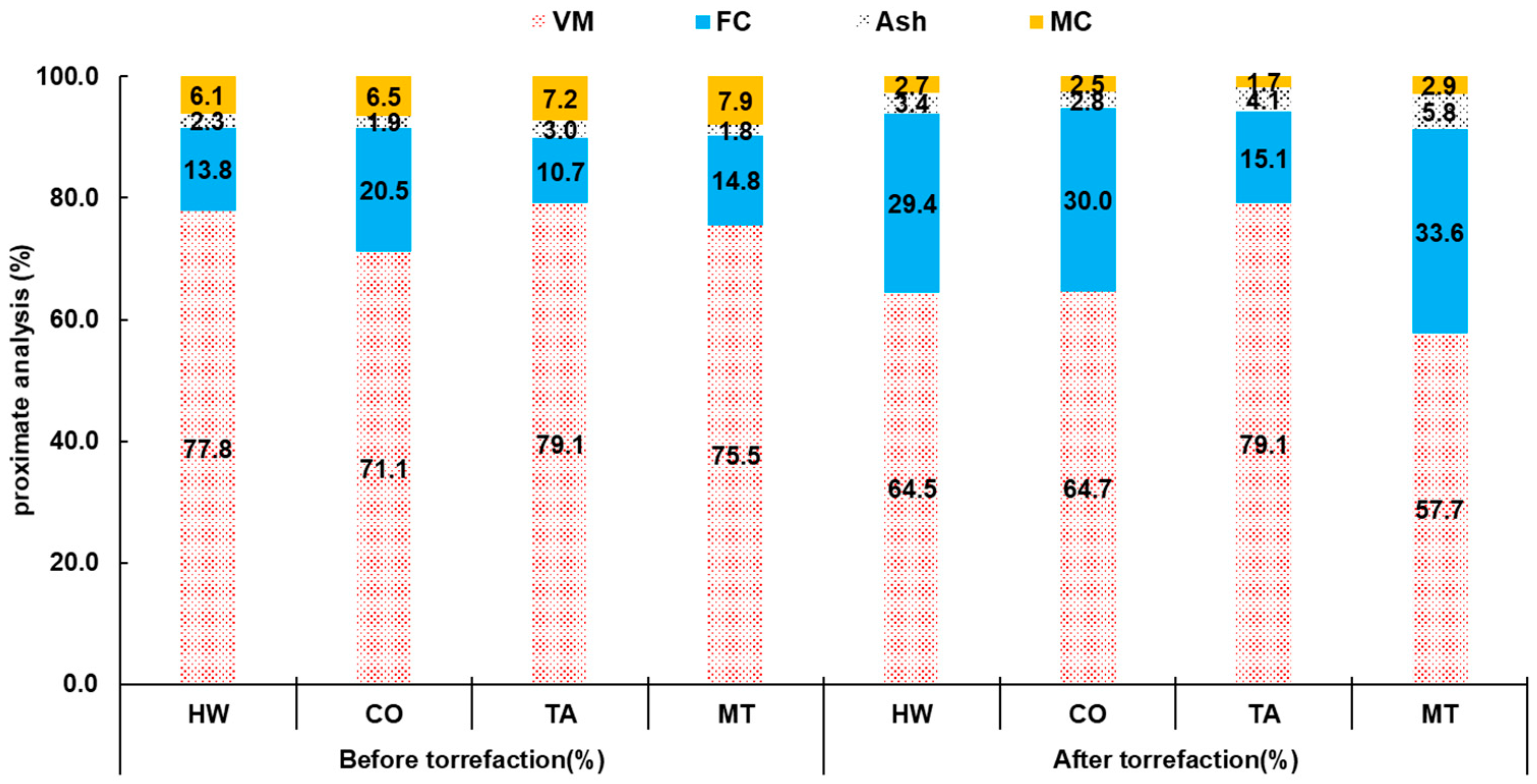

2.4. Proximate Analysis and Ultimate Analysis

2.5. Quality Analysis of the Biopellets

2.6. Mass Yield and Energy Yield

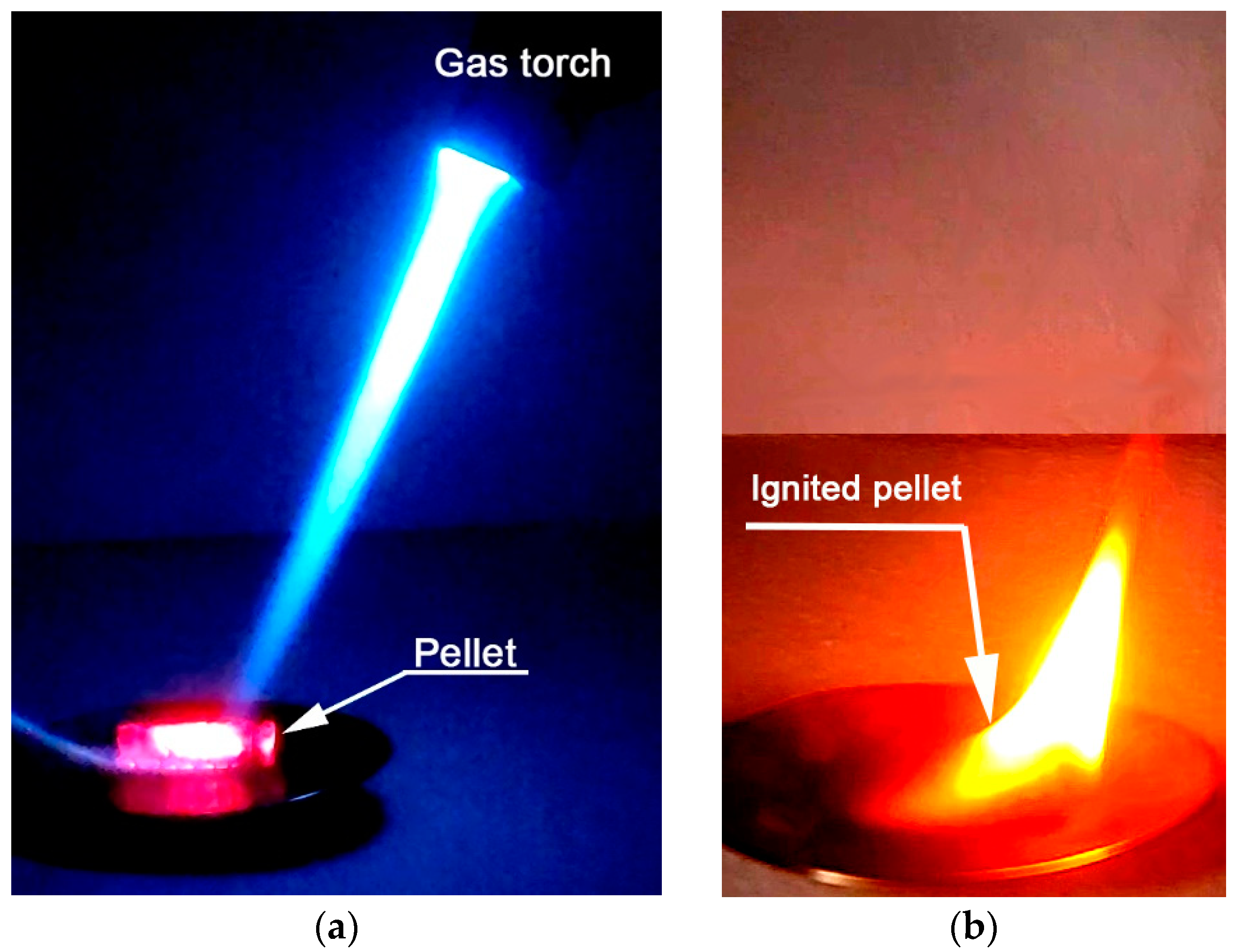

2.7. Ignition and Combustion

2.8. TGA (Thermogravimetric Analysis)

2.9. SEM Observation

3. Results and Discussion

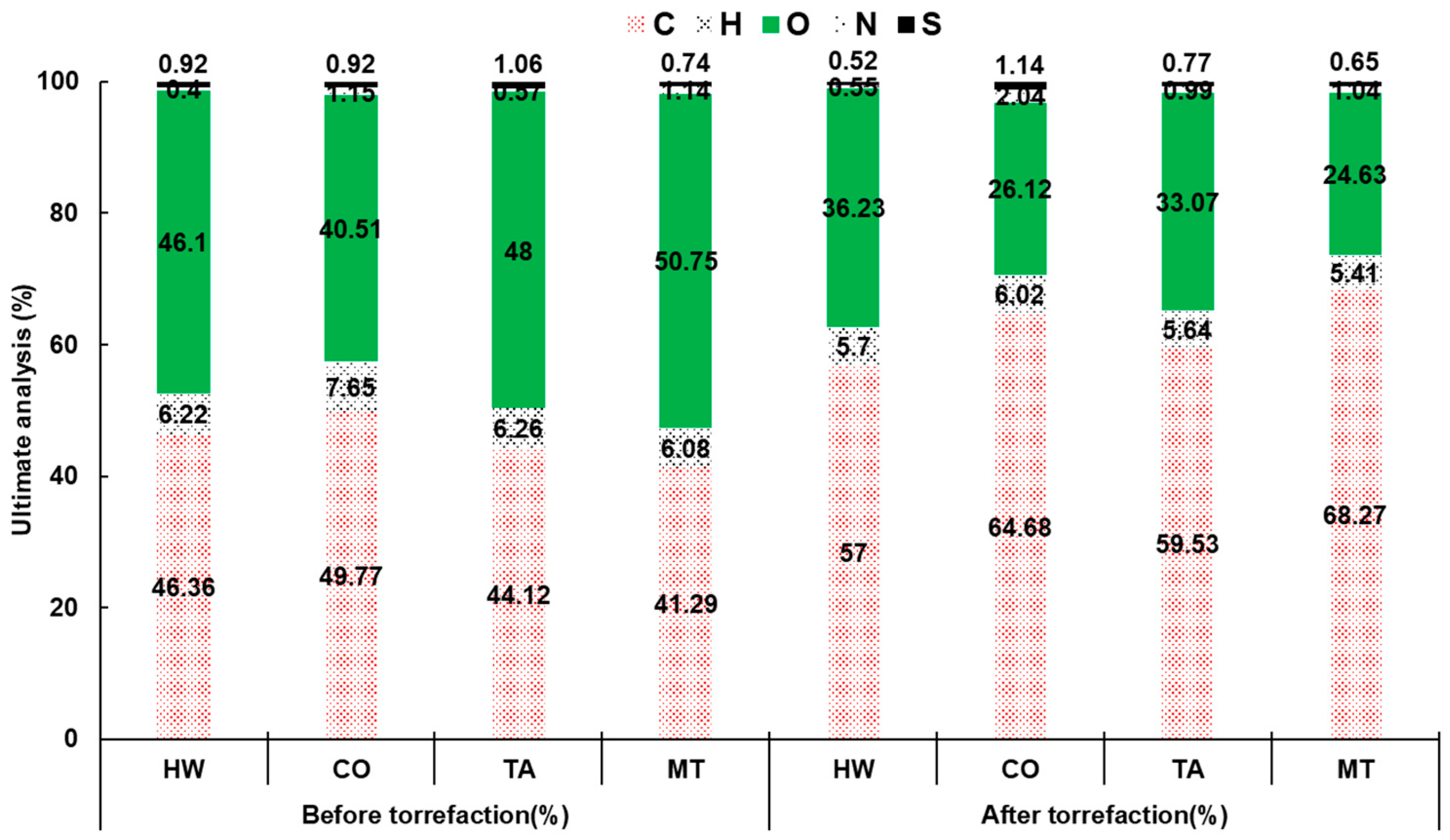

3.1. Ultimate and Proximate Analysis of Biopellets before and after Torrefaction

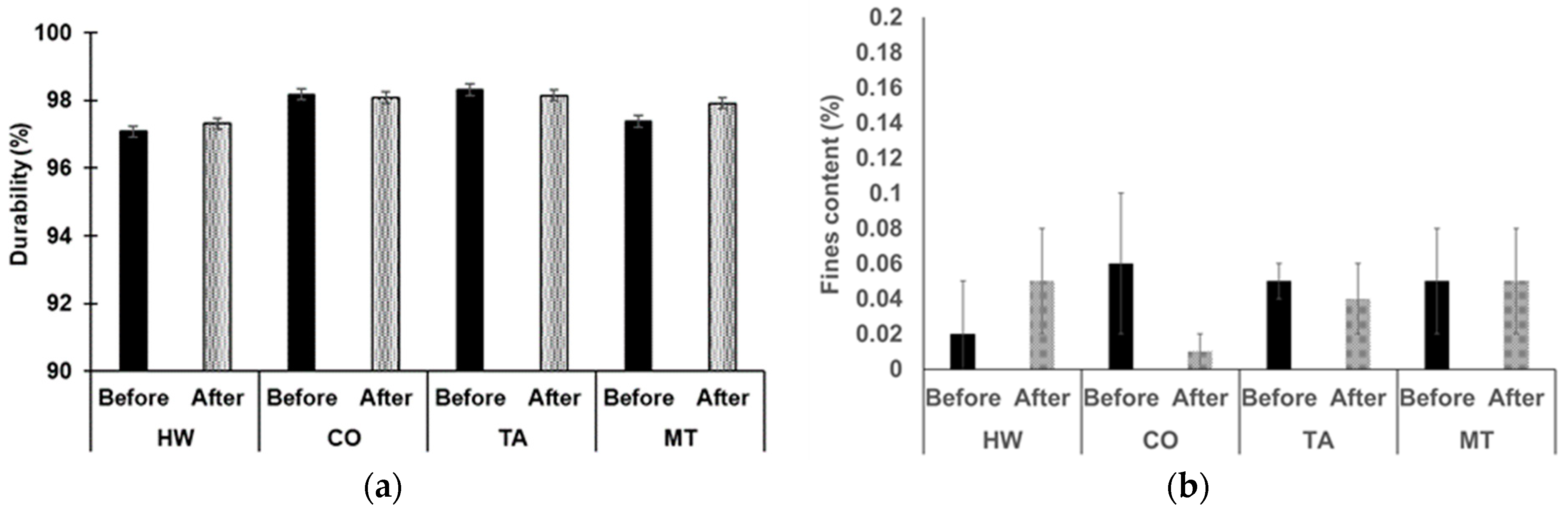

3.2. Quality Analysis of Biopellets before and after Torrefaction

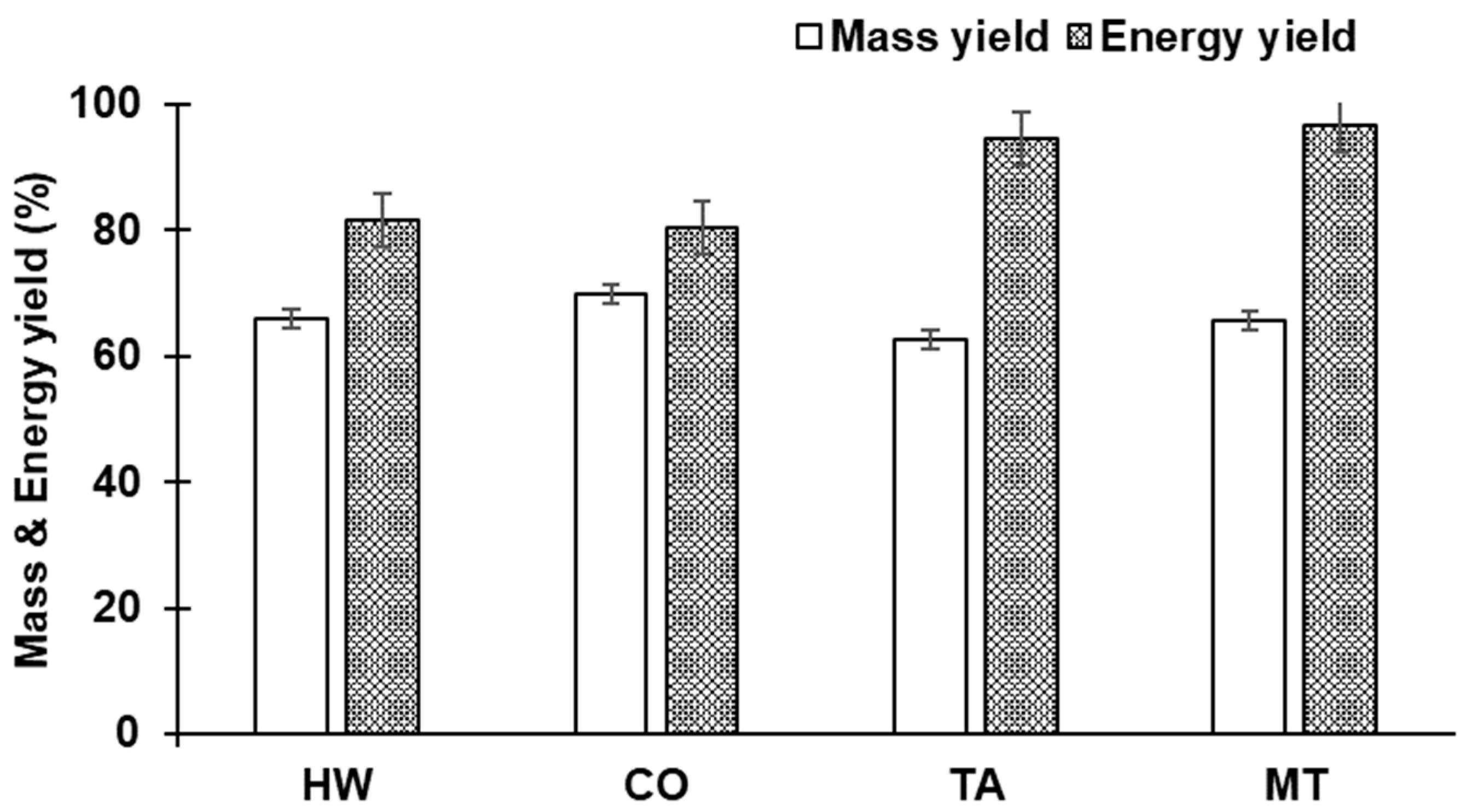

3.3. Mass and Energy Yield of the Biopellets by Torrefaction

3.4. Ignition and Combustion of the Biopellets before and after Torrefaction

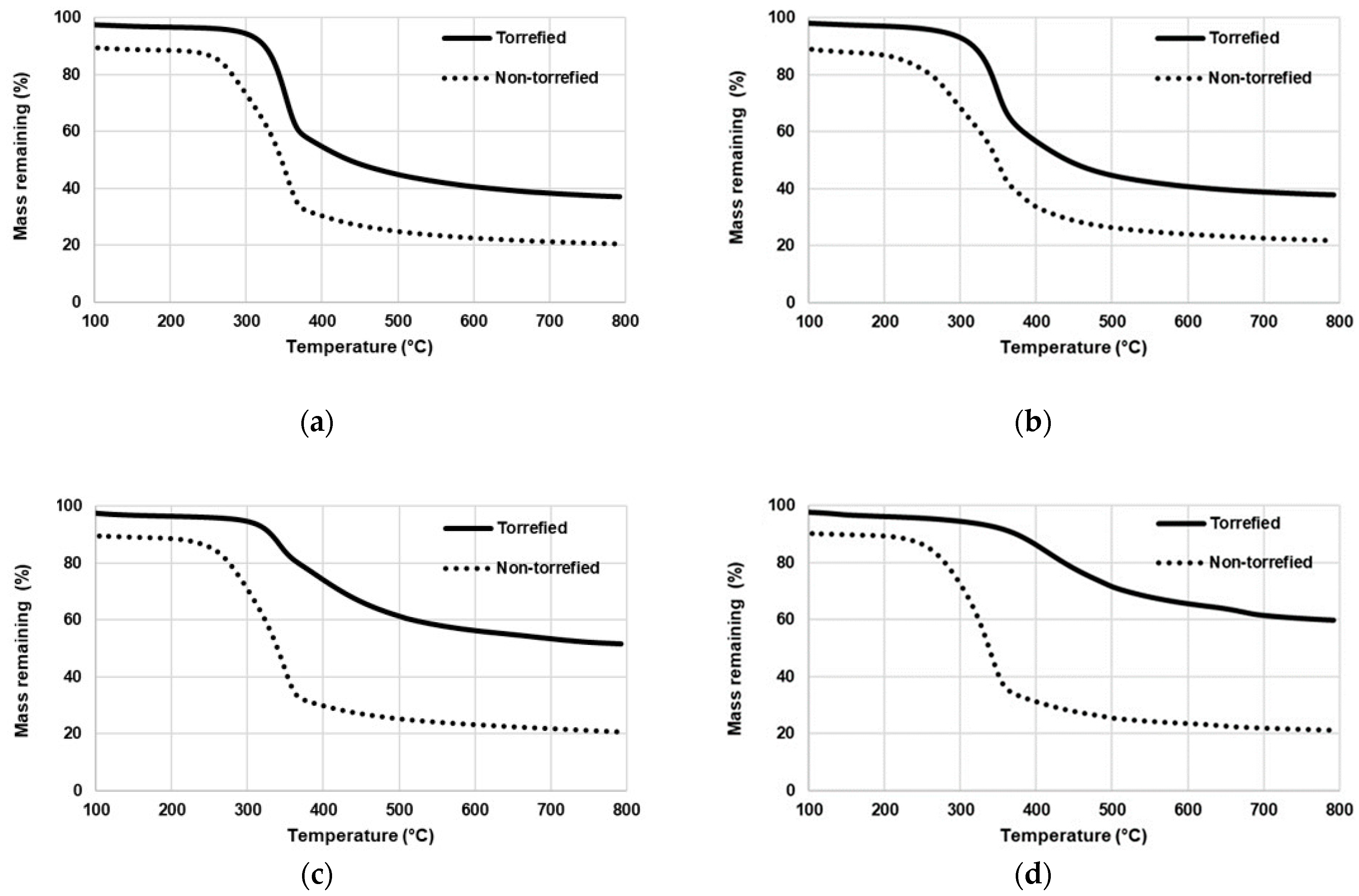

3.5. TGA Analysis of the Biopellets before and after Torrefaction

3.6. Morphological Comparison of Biopellets before and after Torrefaction

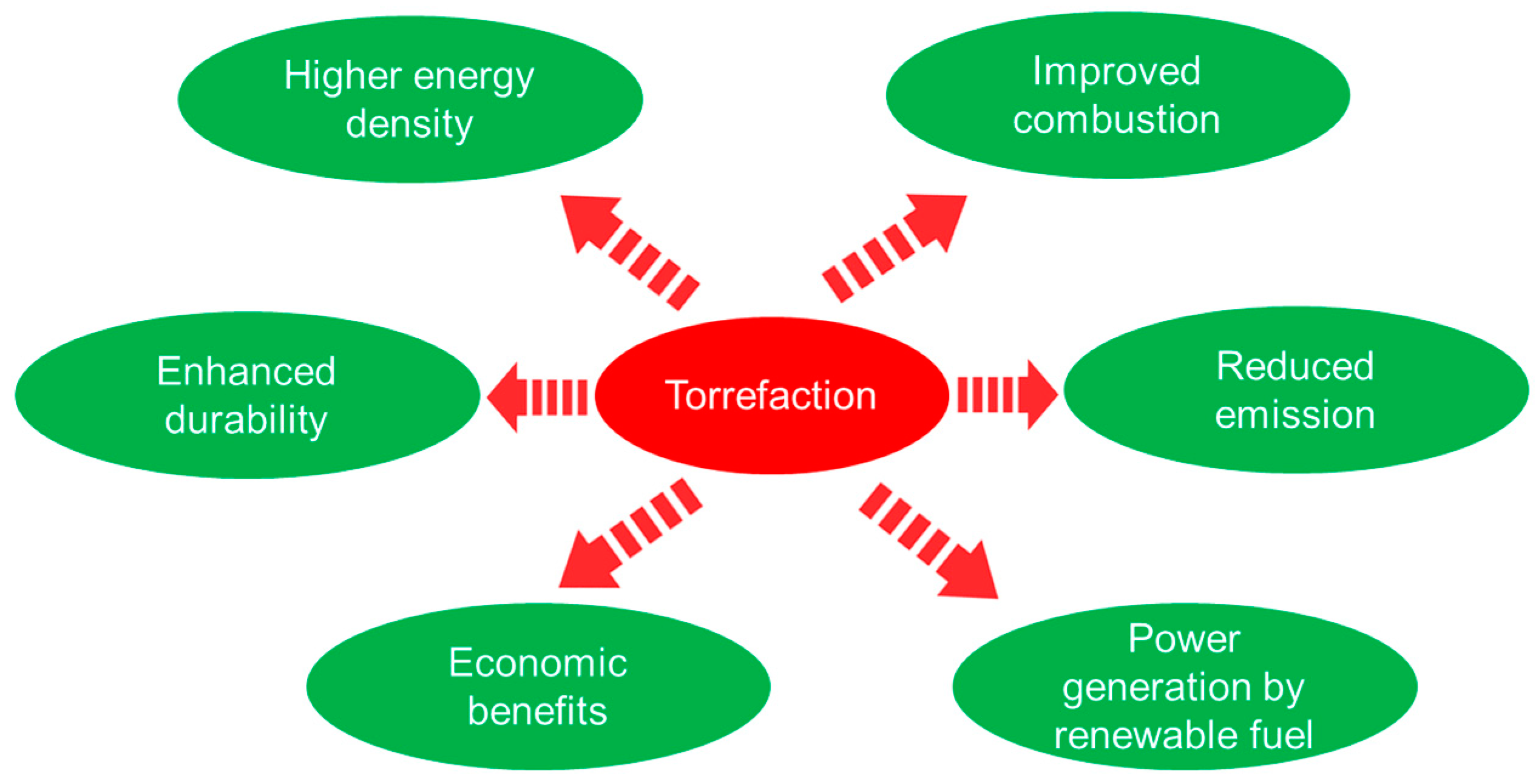

3.7. Importance of Torrefied Biopellets

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pulles, T.; Gillenwater, M.; Radunsky, K. CO2 emissions from biomass combustion: Accounting of CO2 emissions from biomass under the UNFCCC. Carbon Manag. 2021, 13, 181–189. [Google Scholar] [CrossRef]

- United Nations. Framework Convention on Climate Change. In Adoption of the Paris Agreement; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Klass, D.L. Biomass for Renewable Energy, Fuels, and Chemicals; Elsevier: Amsterdam, Netherlands, 1998; pp. 1–672. [Google Scholar]

- Manikandan, S.; Vickram, S.; Sirohi, R.; Subbaiya, R.; Krishnan, R.Y.; Karmegam, N.; Awasthi, M.K. Critical review of biochemical pathways to transformation of waste and biomass into bioenergy. Bioresour. Technol. 2023, 372, 128679. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Zamiri, M.A.; Dafchahi, M.N.; Ebadian, M.; Acharya, B. Optimizing production conditions of innovative bio-pellets developed from flax straw. Ind. Crops Prod. 2024, 218, 118950. [Google Scholar] [CrossRef]

- Mouzakitis, Y.; Neilas, K.; Adamides, E.D. A feasibility study toward circular bioeconomy: The case of a wood-chipping plant in Greece. Acad. Eng. 2024, 1. [Google Scholar] [CrossRef]

- Sang, C.S.; Samad, N.A.F.A.; Saleh, S.B. Enhancing biofuel pellet quality using combined torrefaction and co-pelletization processes of palm kernel shell and empty fruit bunch. Res. Sq. 2024. [Google Scholar] [CrossRef]

- Liu, W.; Yu, Z.; Xie, X.; Von Gadow, K.; Peng, C. A critical analysis of the carbon neutrality assumption in life cycle assessment of forest bioenergy systems. Environ. Rev. 2018, 26, 93–101. [Google Scholar] [CrossRef]

- Mandley, S.; Wicke, B.; Junginger, H.; van Vuuren, D.; Daioglou, V. Integrated assessment of the role of bioenergy within the EU energy transition targets to 2050. GCB Bioenergy 2022, 14, 157–172. [Google Scholar] [CrossRef]

- Wieruszewski, M.; Mydlarz, K. The potential of the bioenergy market in the European Union—An overview of energy biomass resources. Energies 2022, 15, 9601. [Google Scholar] [CrossRef]

- Moon, J.H.; Lee, J.W.; Lee, U.D. Economic analysis of biomass power generation schemes under renewable energy initiative with Renewable Portfolio Standards (RPS) in Korea. Bioresour. Technol. 2011, 102, 9550–9557. [Google Scholar] [CrossRef]

- Yun, H.; Clift, R.; Bi, X. Environmental and economic assessment of torrefied wood pellets from British Columbia. Energy Convers. Manag. 2020, 208, 112513. [Google Scholar] [CrossRef]

- Jölli, D.; Giljum, S. Unused biomass extraction in agriculture, forestry and fishery. SERI Stud. 2005, 3, 1–42. [Google Scholar]

- Yun, S.; Choi, S.M.; Lee, J.W.; Park, S.M. Estimation of unused forest biomass potential resource amount in Korea. Korean J. Agric. Sci. 2022, 49, 317–330. [Google Scholar] [CrossRef]

- Lee, B.H. Estimation of the production potential of domestic wood pellets using unused forest biomass by analyzing the potential volume of forest biomass and the growth of forest trees. J. Korean Appl. Sci. Technol. 2018, 35, 247–253. [Google Scholar]

- Holt, E.A.; Wiser, R.; Bolinger, M. Who Owns Renewable Energy Certificates? An Exploration of Policy Options and Practice; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2006. [Google Scholar]

- Jo, B.K.; Jang, G. An evaluation of the effect on the expansion of photovoltaic power generation according to renewable energy certificates on energy storage systems: A case study of the Korean renewable energy market. Sustainability 2019, 11, 4337. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vladut, V.; Voicu, G.; Dinca, M.N.; Zabava, B.S. Influence of biomass moisture content on pellet properties–Review. Eng. Rural. Dev. 2018, 17, 1876–1883. [Google Scholar]

- Lee, J.Y.; Kim, C.H.; Kwon, S.; Park, H.H. Effect of composting of paper mill sludge for land spreading. Nord. Pulp Paper Res. J. 2017, 32, 691–698. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; Cho, L.; Kim, M.J.; Jeong, I.S.; Kim, D. Investigation of agro-byproduct pellet properties and improvement in pellet quality through mixing. Energy 2020, 190, 116380. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J. Torrefaction of wood: Part 1. Weight loss kinetics. J. Anal. Appl. Pyrolysis 2006, 77, 28–34. [Google Scholar] [CrossRef]

- Sadaka, S.; Negi, S. Improvements of biomass physical and thermochemical characteristics via torrefaction process. Environ. Prog. Sustain. Energy 2009, 28, 427–434. [Google Scholar] [CrossRef]

- Shankar Tumuluru, J.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kothari, R.; Tyagi, V.V. Thermochemical conversion of biomass–Eco-friendly energy routes. Renew. Sustain. Energy Rev. 2012, 16, 1801–1816. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.S.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.S.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Pimchuai, A.; Dutta, A.; Basu, P. Torrefaction of agriculture residue to enhance combustible properties. Energy Fuels 2010, 24, 4638–4645. [Google Scholar] [CrossRef]

- Liang, H.; Hao, B.Q.; Chen, G.C.; Ye, H.; Ma, J. Camellia as an oilseed crop. HortScience 2017, 52, 488–497. [Google Scholar] [CrossRef]

- Saini, P.; Rohela, G.K.; Kumar, J.S.; Shabnam, A.A.; Kumar, A. Cultivation, utilization, and economic benefits of mulberry. In The Mulberry Genome; Saini, P., Ed.; Springer: Cham, Switzerland, 2023; pp. 13–56. [Google Scholar]

- Sharma, S.; Barman, K.; Siddiqui, M.W.; Nath, V. Training and pruning for improved postharvest fruit quality. In Preharvest Modulation of Postharvest Fruit and Vegetable Quality; Siddiqui, M.W., Ed.; Academic Press: London, UK, 2018; pp. 257–276. [Google Scholar]

- ISO 16948:2015; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. International Organization for Standardization: Geneva, Switzerland, 2016.

- Chandrasekaran, A.; Ramachandran, S.; Subbiah, S. Determination of kinetic parameters in the pyrolysis operation and thermal behavior of Prosopis juliflora using thermogravimetric analysis. Bioresour. Technol. 2017, 233, 413–422. [Google Scholar] [CrossRef]

- Poddar, S.; Kamruzzaman, M.; Sujan, S.M.A.; Hossain, M.; Jamal, M.S.; Gafur, M.A.; Khanam, M. Effect of compression pressure on lignocellulosic biomass pellet to improve fuel properties: Higher heating value. Fuel 2014, 131, 43–48. [Google Scholar] [CrossRef]

- ISO 18134-1:2022; Solid Biofuels—Determination of Moisture Content. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 18122:2022; Solid Biofuels—Determination of Ash Content. International Organization for Standardization: Geneva, Switzerland, 2022.

- ASTM D3175-20:2020; Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2020.

- ISO 17831-1:2015; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 17828:2015; Solid Biofuels—Determination of Bulk Density. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 5370:2023; Solid Biofuels—Determination of Fines Content in Pellets. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 11358-1:2022; Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2022.

- Bushnell, D.J.; Haluzok, C.; Dadkhah-Nikoo, A. Biomass Fuel Characterization: Testing and Evaluating the Combustion Characteristics of Selected Biomass Fuels: Final Report May 1, 1988–July, 1989; USDOE Bonneville Power Administration: Portland, OR, USA, 1990; Report No. DOE/BP-1363. [Google Scholar]

- Wahyono, Y.; Hadiyanto, H.; Pratiwi, W.Z.; Dianratri, I. “Biopellet” as One of Future Promising Biomassbased Renewable Energy: A Review. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 317, p. 04029. [Google Scholar]

- Wannapeera, J.; Fungtammasan, B.; Worasuwannarak, N. Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass. J. Anal. Appl. Pyrolysis 2011, 92, 99–105. [Google Scholar] [CrossRef]

- Kim, S.; Kramer, R.W.; Hatcher, P.G. Graphical method for analysis of ultrahigh-resolution broadband mass spectra of natural organic matter: The van Krevelen diagram. Anal. Chem. 2003, 75, 5336–5344. [Google Scholar] [CrossRef] [PubMed]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Lim, C.J.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Bates, R.B.; Ghoniem, A.F. Biomass torrefaction: Modeling of volatile and solid product evolution kinetics. Bioresour. Technol. 2012, 124, 460–469. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Chen, W.H.; Du, S.W.; Tsai, C.H.; Wang, Z.Y. Torrefied biomasses in a drop tube furnace to evaluate their utility in blast furnaces. Bioresour. Technol. 2012, 111, 433–438. [Google Scholar] [CrossRef]

| Raw Materials | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Extractive (%) | Ash (%) |

|---|---|---|---|---|---|

| Hardwood chip rejects (HR) | 44.3 ± 0.04 | 25.7 ± 0.09 | 23.1 ± 0.03 | 4.4 ± 0.01 | 2.5 ± 0.01 |

| Camellia oilseed cake (CO) | 24.8 ± 0.02 | 32.9 ± 0.08 | 29.7 ± 0.04 | 10.7 ± 0.05 | 1.9 ± 0.01 |

| Toothache tree (TA) | 45.5 ± 0.05 | 26.3 ± 0.07 | 21.1 ± 0.02 | 5.4 ± 0.02 | 1.7 ± 0.01 |

| Mulberry tree (MT) | 44.7 ± 0.07 | 24.8 ± 0.06 | 21.9 ± 0.04 | 6.7 ± 0.02 | 1.9 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, T.-G.; Kim, C.-H.; Park, H.-H.; Park, J.-H.; Park, M.-S.; Lee, J.-S. Quality Enhancement of Torrefied Biopellets Prepared by Unused Forest Biomass and Wood Chip Residues in Pulp Mills. Appl. Sci. 2024, 14, 9398. https://doi.org/10.3390/app14209398

Lee T-G, Kim C-H, Park H-H, Park J-H, Park M-S, Lee J-S. Quality Enhancement of Torrefied Biopellets Prepared by Unused Forest Biomass and Wood Chip Residues in Pulp Mills. Applied Sciences. 2024; 14(20):9398. https://doi.org/10.3390/app14209398

Chicago/Turabian StyleLee, Tae-Gyeong, Chul-Hwan Kim, Hyeong-Hun Park, Ju-Hyun Park, Min-Sik Park, and Jae-Sang Lee. 2024. "Quality Enhancement of Torrefied Biopellets Prepared by Unused Forest Biomass and Wood Chip Residues in Pulp Mills" Applied Sciences 14, no. 20: 9398. https://doi.org/10.3390/app14209398

APA StyleLee, T.-G., Kim, C.-H., Park, H.-H., Park, J.-H., Park, M.-S., & Lee, J.-S. (2024). Quality Enhancement of Torrefied Biopellets Prepared by Unused Forest Biomass and Wood Chip Residues in Pulp Mills. Applied Sciences, 14(20), 9398. https://doi.org/10.3390/app14209398