Recovered Foam Impact Absorption Systems

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Processing of the Foam Samples

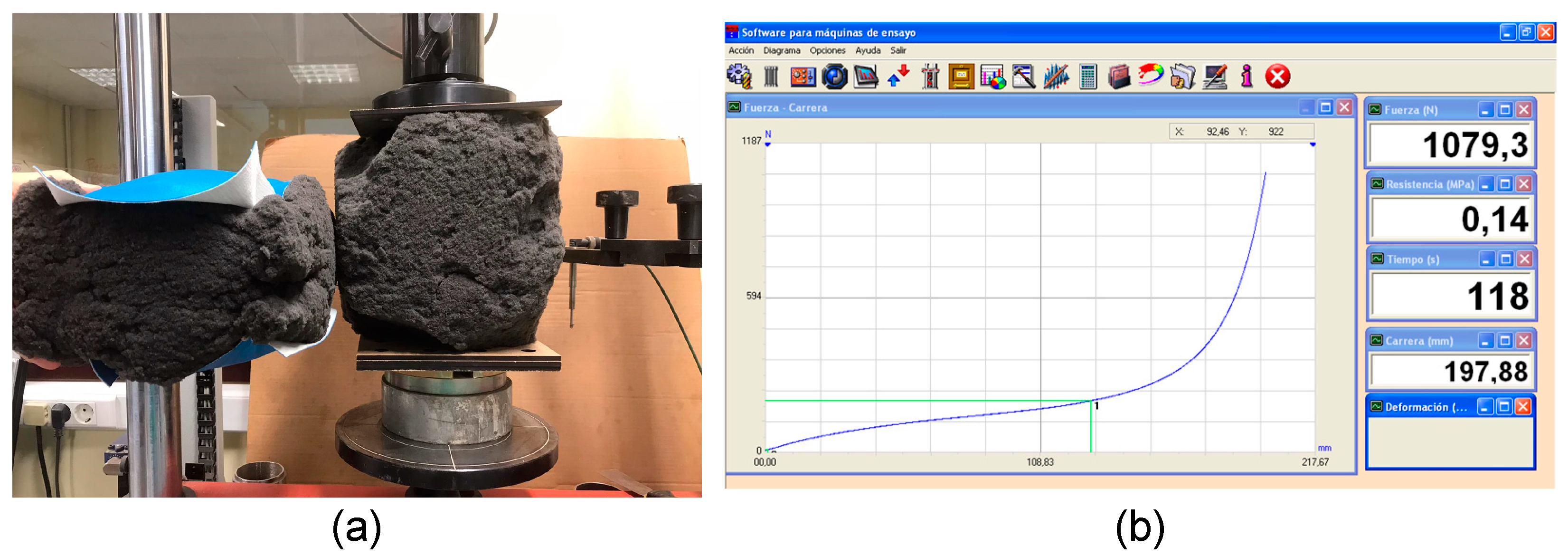

2.2. Mechanical Tests

3. Results

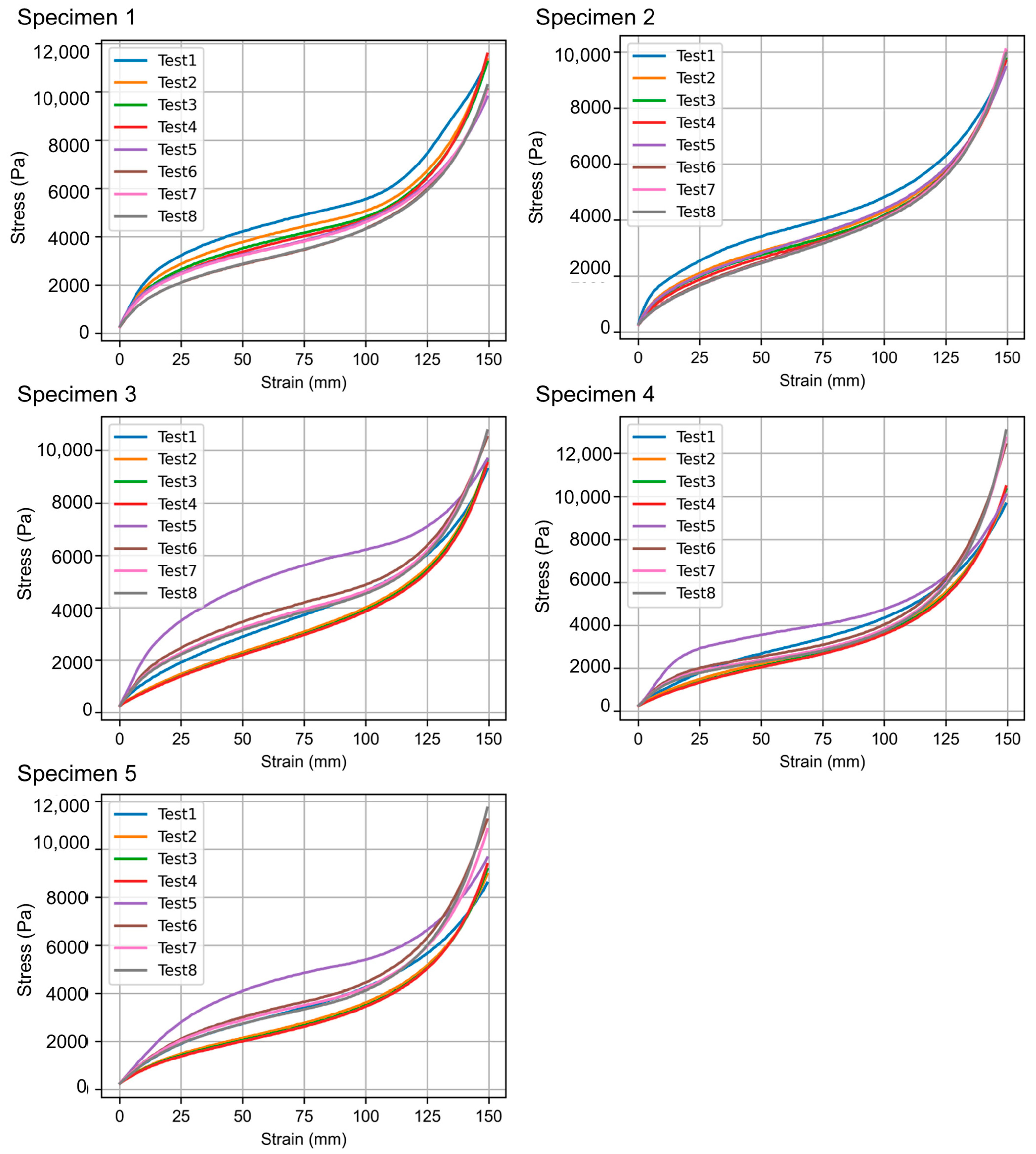

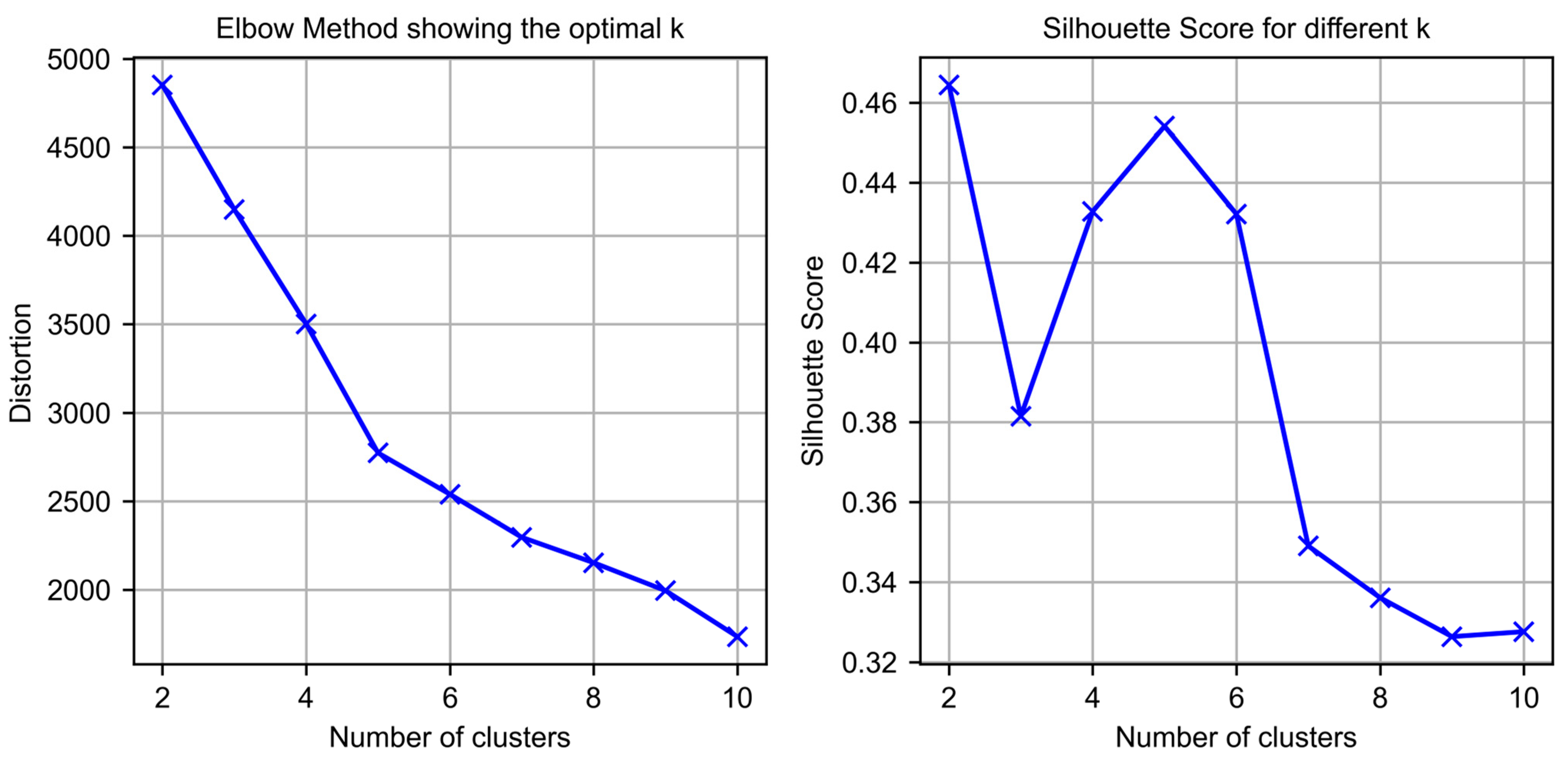

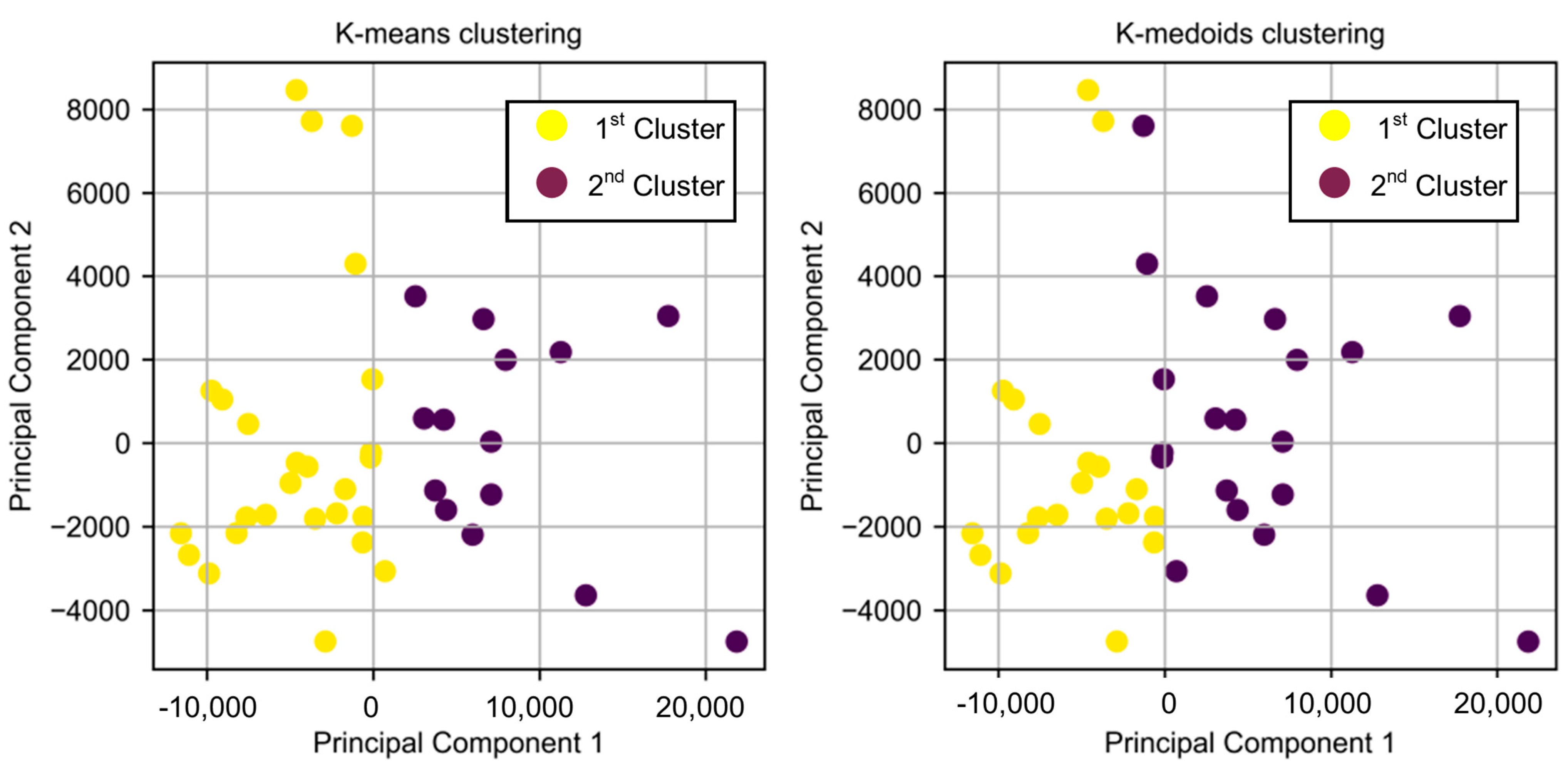

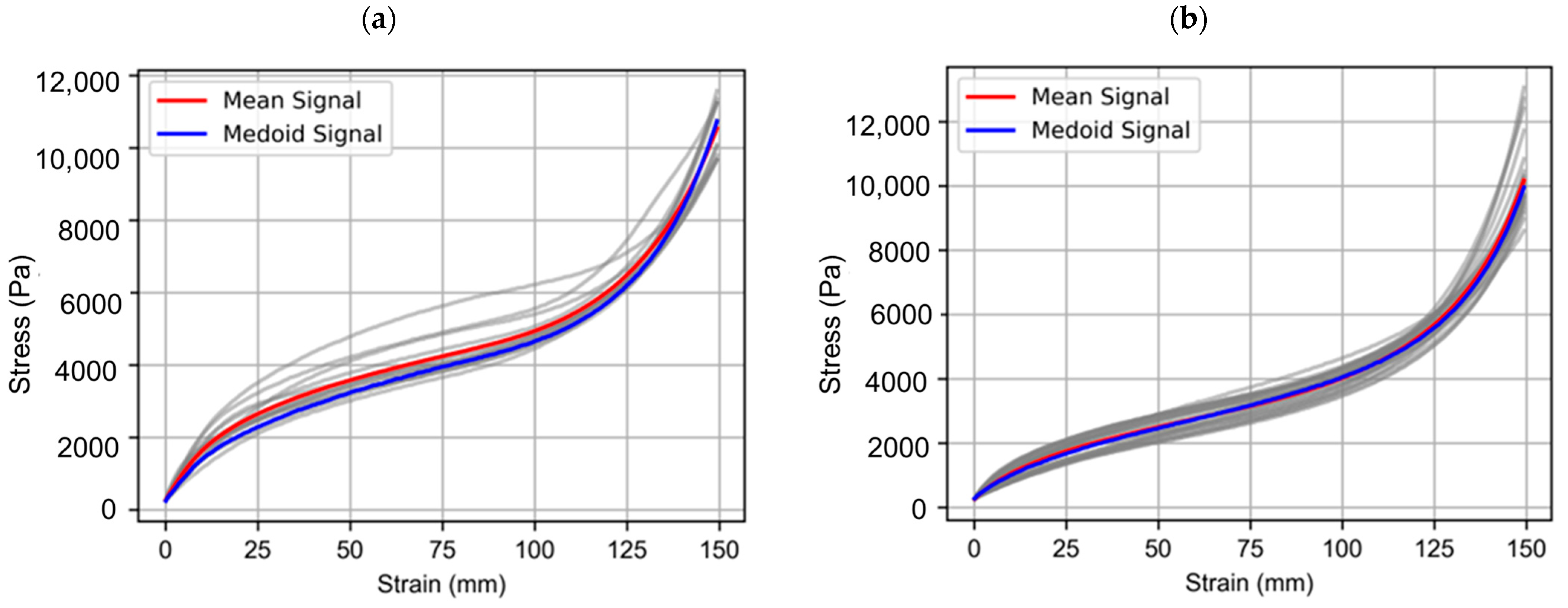

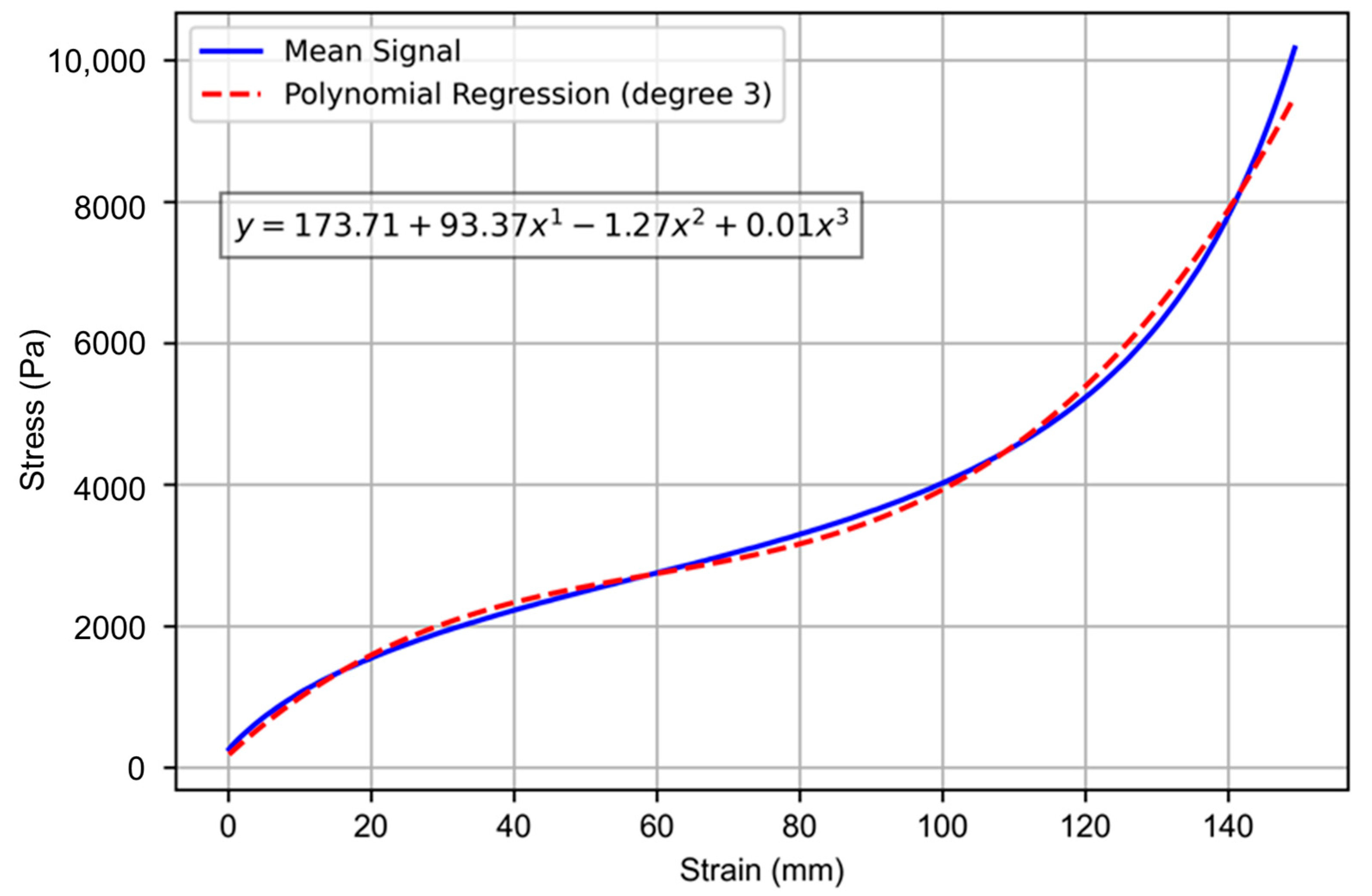

3.1. Characterization of Compressive Behavior in Foam: Analysis and Curve Fitting

3.2. New Recovered Foam Impact Absorption System Modelization

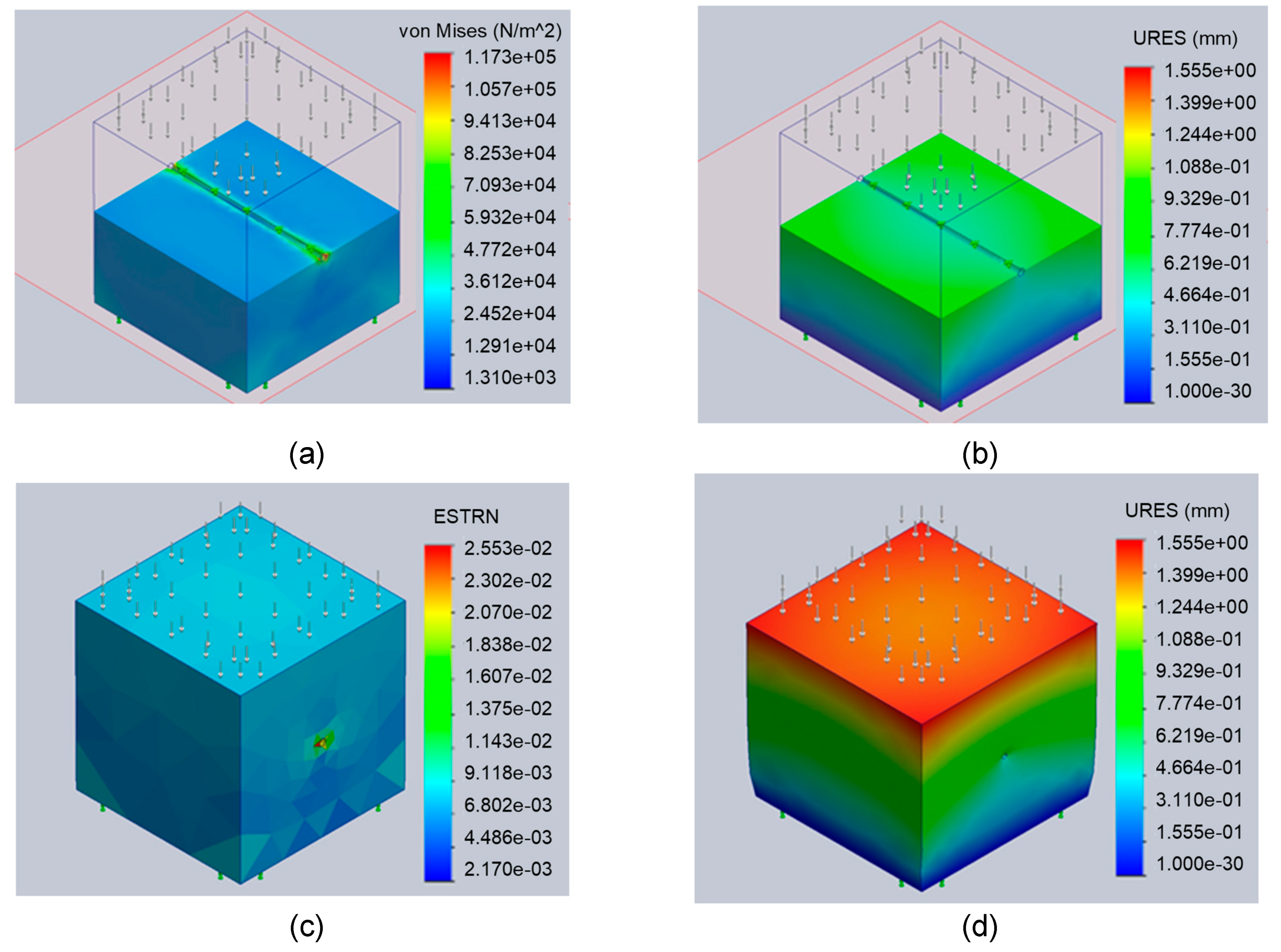

3.2.1. Cube Modelization

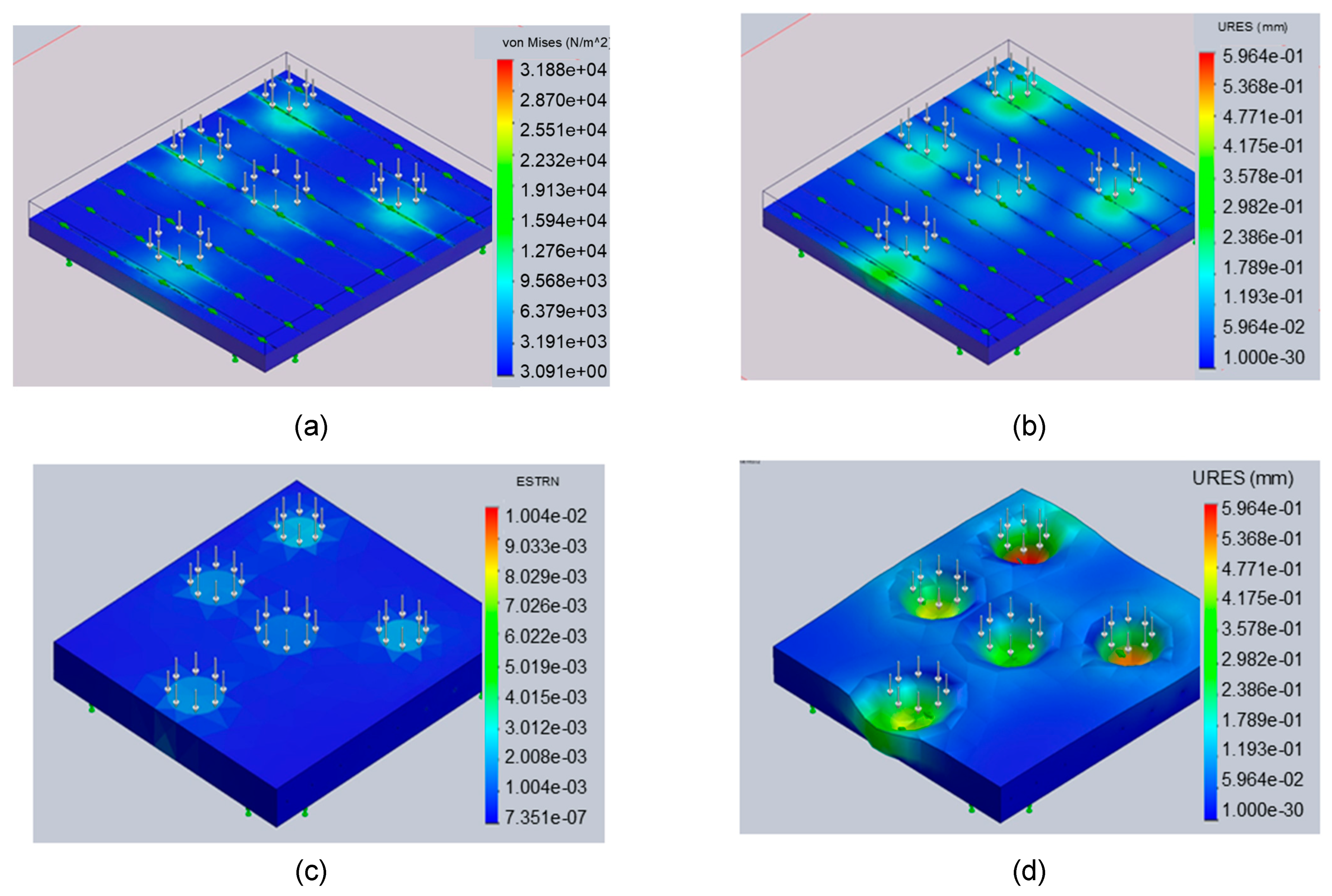

3.2.2. New Recovered Foam Impact Absorption System Modelization

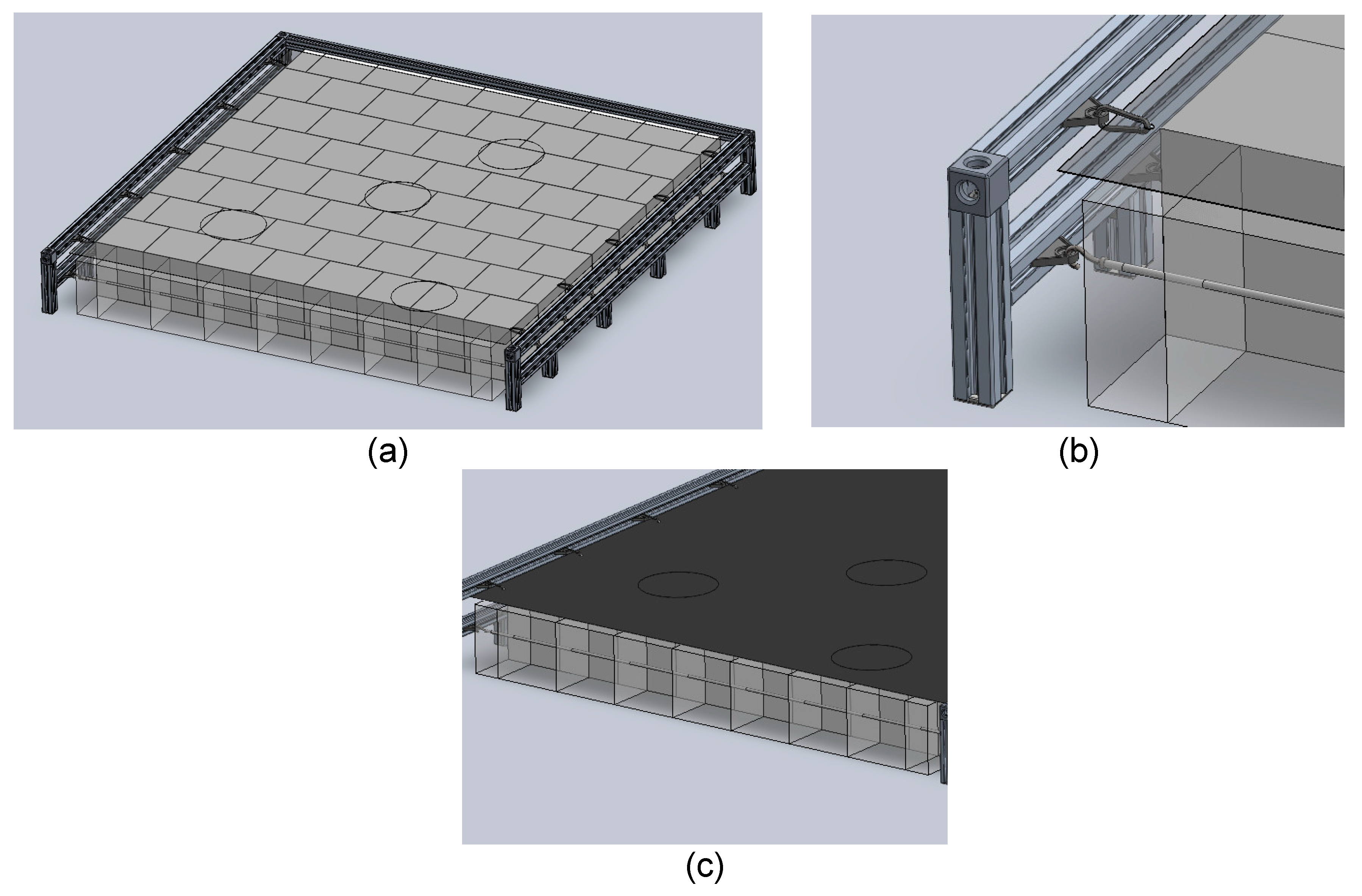

3.3. New Recovered Foam Impact Absorption System Design and Manufacture

- Maximizing the use of recycled materials: The system prioritizes the reuse of available materials, especially the buckets, to minimize environmental impact.

- Modularity of the design: The system is designed to be modular, allowing for easy adaptation to different spaces and requirements. This modularity also facilitates installation and maintenance.

- Ease of maintenance and bucket replacement: The system is designed so that buckets can be easily replaced or maintained without needing to disassemble the entire structure. This design ensures greater durability and long-term functionality.

- Modular metal structure that serves as a resistant frame and allows the use of standard joining elements, allowing the goal of ease of assembly and maintenance and adaptability to various spaces to be achieved.

- A unifying canvas from textile waste in the manufacture of other protection elements of the same leisure center. This canvas provides uniformity, limits the movements of the unitary foam elements, and allows the hygiene of the system to be maintained.

- A set of unitary foam elements reused from the previous activity of the leisure facility and that were previously eliminated by sending them to landfill, joined together by central wire ropes that make them work as a single protective element.

- Some union elements of the protective canvas and foam elements to the structure for easy maintenance and installation.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A Review on Textile Recycling Practices and Challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Zamani, B.; Svanström, M.; Peters, G.; Rydberg, T. A Carbon Footprint of Textile Recycling. A Case Study in Sweden. J. Ind. Ecol. 2008, 19, 676–687. [Google Scholar] [CrossRef]

- Hawley, J.M. Textile Recycling as a System: A Micro/Macro Analysis. J. Fam. Consum. Sci. 2000, 92, 40. [Google Scholar]

- Navone, L.; Moffitt, K.; Hansen, K.-A.; Blinco, J.; Payne, A.; Speight, R. Closing the Textile Loop: Enzymatic Fibre Separation and Recycling of Wool/Polyester Fabric Blends. J. Waste Manag. 2020, 102, 149–160. [Google Scholar] [CrossRef]

- Koszewska, M. Challenges for the Textile and Clothing Industry. Autex Res. J. 2018, 18, 337–347. [Google Scholar] [CrossRef]

- Valverde, I.C.; Castilla, L.H.; Nuñez, D.F.; Rodriguez-Senıín, E.; de la Mano Ferreira, R. Development of New Insulation Panels Based on Textile Recycled Fibers. Waste Biomass Valor. 2013, 4, 139–146. [Google Scholar] [CrossRef]

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.-S. Possibility Routes for Textile Recycling Technology. Polymers 2021, 13, 3834. [Google Scholar] [CrossRef]

- Pensupa, N.; Leu, S.-Y.; Hu, Y.; Du, C.; Liu, H.; Jing, H.; Wang, H.; Lin, C.S.K. Recent Trends in Sustainable Textile Waste Recycling. Methods: Current Situation and Future Prospects. In Chemistry and Chemical Technologies in Waste Valorization. Topics in Current Chemistry Collections; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Chavan, J. Environmental Sustainability through Textile Recycling. Text. Sci. Eng. 2014, S2. [Google Scholar] [CrossRef]

- Khan, W.S.; Asmatulu, E.; Uddin, M.N.; Asmatulu, R. Recycling and Reusing of Engineering Materials: Recycling for Sustainable Developments; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 978-0-12-822462-5. [Google Scholar]

- Banik, J.; Chakraborty, D.; Rizwan, M.; Shaik, A.H.; Chandan, M.R. Review on Disposal, Recycling and Management of Waste Polyurethane Foams: A Way Ahead. Waste Manag. Res. 2023, 41, 1063–1080. [Google Scholar] [CrossRef]

- Dounis, D.V.; Wilkes, G.L. Structure-Property Relationships of Flexible Polyurethane Foams. Polymer 1997, 38, 2819–2828. [Google Scholar] [CrossRef]

- Ates, M.; Karadag, S.; Eker, A.A.; Eker, B. Polyurethane Foam Materials and Their Industrial Applications. Polym. Int. 2022, 71, 1157–1163. [Google Scholar] [CrossRef]

- Somarathna, H.M.C.C.; Raman, S.N.; Mohotti, D.; Mutalib, A.A.; Badri, K.H. The Use of Polyurethane for Structural and Infrastructural Engineering Applications: A State-of-the-Art Review. Constr. Build. Mater. 2018, 190, 995–1014. [Google Scholar] [CrossRef]

- Kylili, A.; Seduikyte, L.; Fokaides, P.A. 9—Life Cycle Analysis of Polyurethane Foam Wastes. In Recycling of Polyurethane Foams; Thomas, S., Rane, A.V., Kanny, K., V.K., A., Thomas, M.G., Eds.; Plastics Design Library; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 97–113. ISBN 978-0-323-51133-9. [Google Scholar]

- Liberati, G.; Biagi, F.; Nanni, A.; Parisi, M.F.; Barbaresi, L.; Querci, L.; Ceccarelli, S.; Regazzi, M.; Bonoli, A.; Colonna, M. Mechanical Recycling of Foam from End-of-Life Mattresses by AIR-LAY Process for the Production of New Mattresses with a Fully Circular Approach. Clean. Mater. 2024, 12, 100249. [Google Scholar] [CrossRef]

- Miltz, J.; Ramon, O. Energy Absorption Characteristics of Polymeric Foams Used as Cushioning Materials. Polym. Eng. Sci. 1990, 30, 129–133. [Google Scholar] [CrossRef]

- de Souza, F.M.; Kahol, P.K.; Gupta, R.K. Introduction to Polyurethane Chemistry. In Polyurethane Chemistry: Renewable Polyols and Isocyanates; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2021; Volume 1380, pp. 1–24. ISBN 978-0-8412-9840-8. [Google Scholar]

- Das, A.; Mahanwar, P. A Brief Discussion on Advances in Polyurethane Applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Uttaravalli, A.N.; Dinda, S.; Gidla, B.R. Scientific and Engineering Aspects of Potential Applications of Post-Consumer (Waste) Expanded Polystyrene: A Review. Process Saf. Environ. Prot. 2020, 137, 140–148. [Google Scholar] [CrossRef]

- Iwuozor, K.O.; Emenike, E.C.; Ighalo, J.O.; Adeniyi, A.G. Expanded Polyethylene Circularity Potentials: A Comprehensive Overview of Production Process, Applications, and Recycling Techniques. Chem. Afr. 2024, 1–12. [Google Scholar] [CrossRef]

- Urtekin, G.; Ullah, M.S.; Yildirim, R.; Ozkoc, G.; Kodal, M. A Comprehensive Review of the Recent Developments in Thermoplastics and Rubber Blends-Based Composites and Nanocomposites. Polym. Compos. 2023, 44, 8303–8329. [Google Scholar] [CrossRef]

- Rostami-Tapeh-Esmaeil, E.; Vahidifar, A.; Esmizadeh, E.; Rodrigue, D. Chemistry, Processing, Properties, and Applications of Rubber Foams. Polymers 2021, 13, 1565. [Google Scholar] [CrossRef]

- Backes, E.H.; Harb, S.V.; Pinto, L.A.; de Moura, N.K.; de Melo Morgado, G.F.; Marini, J.; Passador, F.R.; Pessan, L.A. Thermoplastic Polyurethanes: Synthesis, Fabrication Techniques, Blends, Composites, and Applications. J. Mater. Sci. 2024, 59, 1123–1152. [Google Scholar] [CrossRef]

- Chruściel, J.J. Modifications of Textile Materials with Functional Silanes, Liquid Silicone Softeners, and Silicone Rubbers—A Review. Polymers 2022, 14, 4382. [Google Scholar] [CrossRef] [PubMed]

- Adetunji, C.O.; Olaniyan, O.T.; Anani, O.A.; Inobeme, A.; Mathew, J.T. Environmental Impact of Polyurethane Chemistry. In Polyurethane Chemistry: Renewable Polyols and Isocyanates; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2021; Volume 1380, pp. 393–411. ISBN 978-0-8412-9840-8. [Google Scholar]

- Eaves, D. Handbook of Polymer Foams; Rapra Technology Limited: Shrewsbury, UK, 2004; ISBN 978-1-84735-054-1. [Google Scholar]

- Diez-Olivan, A.; Penalva, M.; Veiga, F.; Deitert, L.; Sanz, R.; Sierra, B. Kernel Density-Based Pattern Classification in Blind Fasteners Installation. In Hybrid Artificial Intelligent Systems; Martínez de Pisón, F.J., Urraca, R., Quintián, H., Corchado, E., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 195–206. [Google Scholar]

- Ortego, P.; Diez-Olivan, A.; Del Ser, J.; Veiga, F.; Penalva, M.; Sierra, B. Evolutionary LSTM-FCN Networks for Pattern Classification in Industrial Processes. Swarm Evol. Comput. 2020, 54, 100650. [Google Scholar] [CrossRef]

- Kauvaka, P.; Smeets, M.; Koohbor, B.; Youssef, G. Impact Response of Polyurea Elastomeric Foams. J. Dyn. Behav. Mater. 2024, 10, 210–222. [Google Scholar] [CrossRef]

| Material Type | Common Applications | Key Properties for Impact Absorption |

|---|---|---|

| Polyurethane (PU) Foam | Automotive interiors, packaging, leisure facilities, sports equipment | Lightweight, flexible, excellent energy absorption, customizable densities [19] |

| Expanded Polystyrene (EPS) | Helmets, packaging, construction insulation | Rigid, good energy dissipation, low density, brittle under repeated impact [20] |

| Polyethylene (PE) Foam | Sports mats, automotive, protective packaging | Lightweight, resilient, durable, excellent cushioning, closed-cell structure [21] |

| Neoprene Rubber | Wetsuits, sports equipment, industrial padding | Elastic, good impact resistance, high durability, moisture resistance [22] |

| Ethylene Vinyl Acetate (EVA) Foam | Footwear, sports equipment, protective padding | Soft, flexible, shock-absorbing, good recovery after compression [23] |

| Thermoplastic Polyurethane (TPU) | Footwear, mobile device protection, automotive components | Highly elastic, excellent impact resistance, good wear and abrasion resistance [24] |

| Silicone Rubber | Medical devices, electronic protection, sports equipment | Flexible, temperature resistant, good shock absorption, durable [25] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcelino-Sádaba, S.; Benito, P.; Martin-Antunes, M.Á.; Roldán, P.V.; Veiga, F. Recovered Foam Impact Absorption Systems. Appl. Sci. 2024, 14, 9549. https://doi.org/10.3390/app14209549

Marcelino-Sádaba S, Benito P, Martin-Antunes MÁ, Roldán PV, Veiga F. Recovered Foam Impact Absorption Systems. Applied Sciences. 2024; 14(20):9549. https://doi.org/10.3390/app14209549

Chicago/Turabian StyleMarcelino-Sádaba, Sara, Pablo Benito, Miguel Ángel Martin-Antunes, Pedro Villanueva Roldán, and Fernando Veiga. 2024. "Recovered Foam Impact Absorption Systems" Applied Sciences 14, no. 20: 9549. https://doi.org/10.3390/app14209549

APA StyleMarcelino-Sádaba, S., Benito, P., Martin-Antunes, M. Á., Roldán, P. V., & Veiga, F. (2024). Recovered Foam Impact Absorption Systems. Applied Sciences, 14(20), 9549. https://doi.org/10.3390/app14209549