The Mesoscopic Damage Mechanism of Jointed Sandstone Subjected to the Action of Dry–Wet Alternating Cycles

Abstract

1. Introduction

2. Experimental Principles and Method

2.1. Nuclear Magnetic Resonance Technology (NMR) and Small Angle X-Ray Scattering (SAXS)

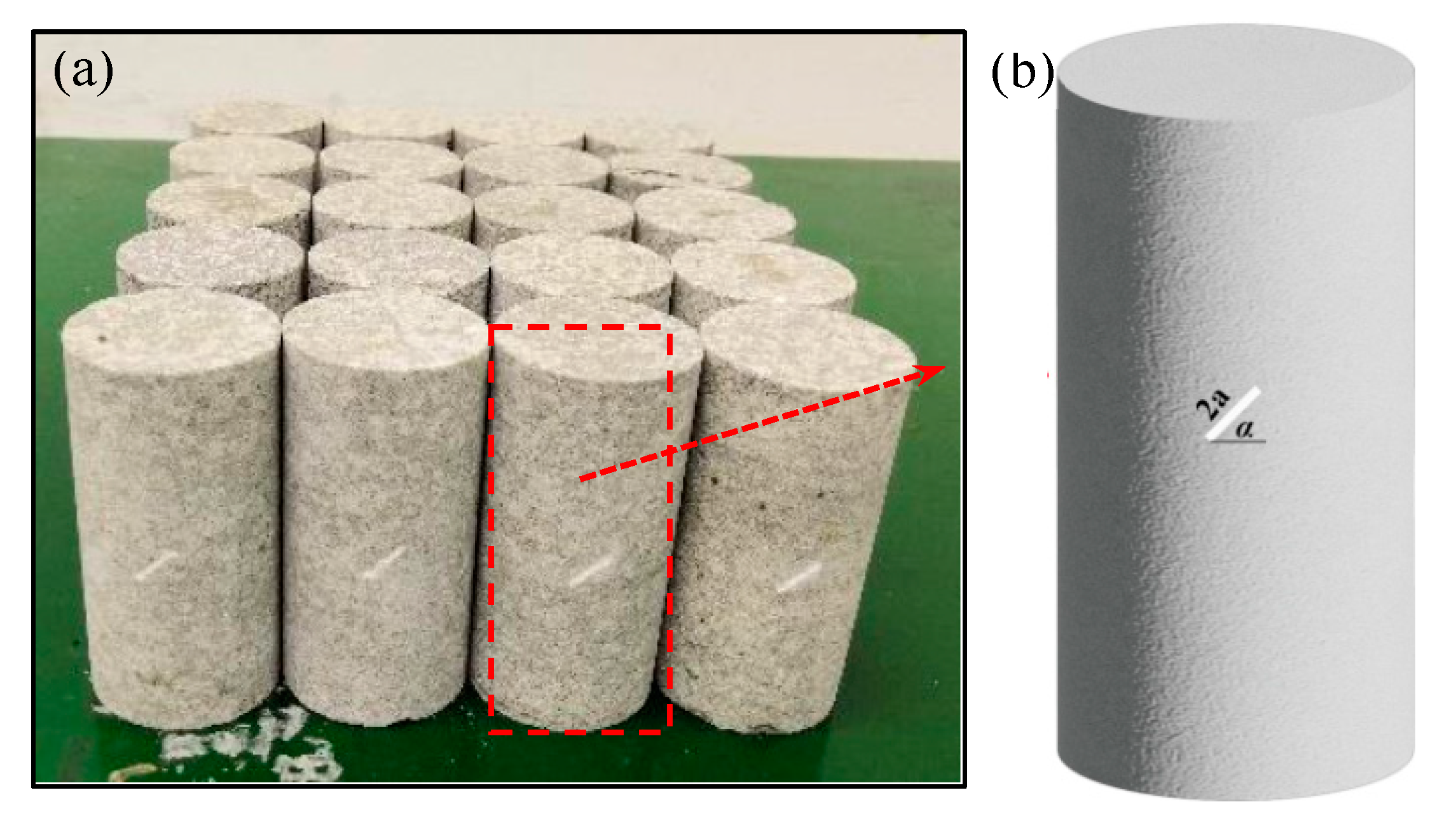

2.2. Preparation of Rock Samples

2.3. Experimental Procedure and Device

3. Mesostructural Evolution of Sandstone Under Dry–Wet Cycles

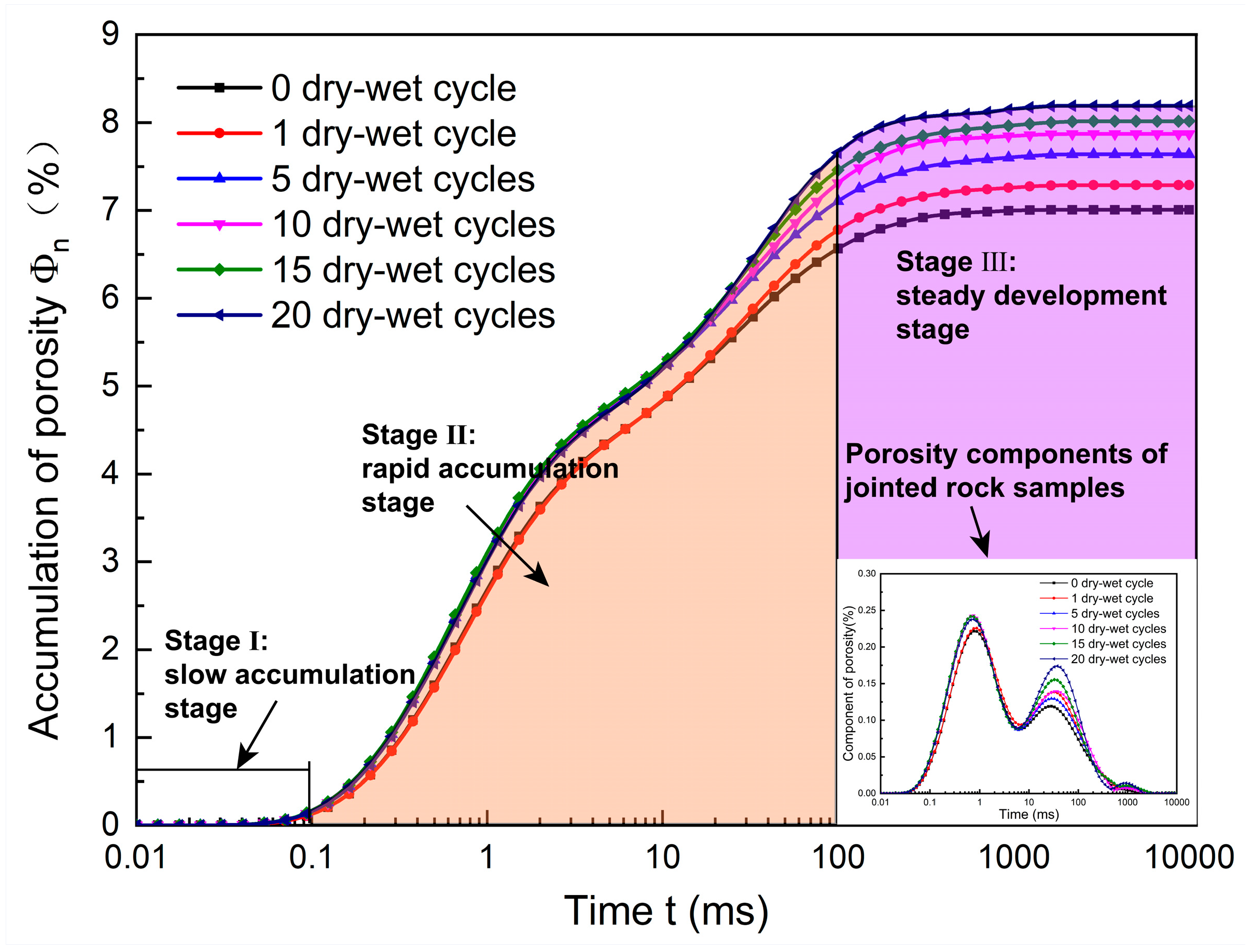

3.1. The Evolution of Porosity and Permeability of Jointed Sandstone

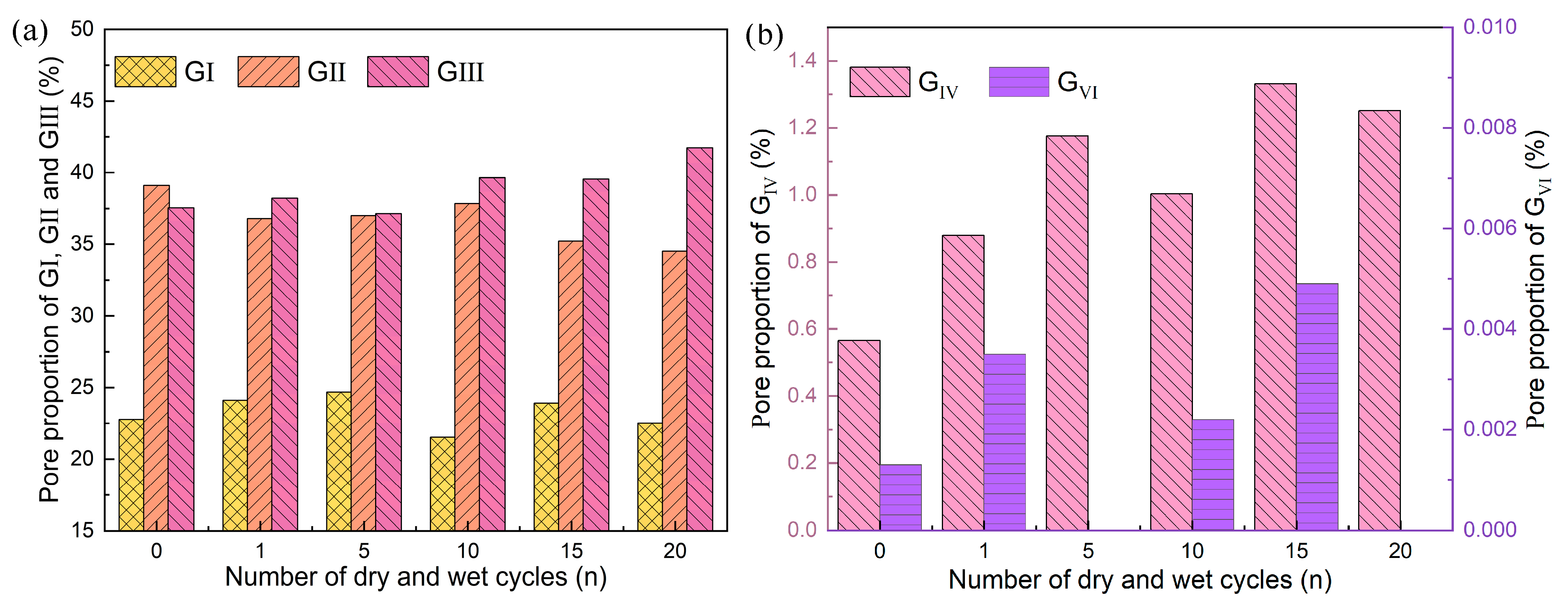

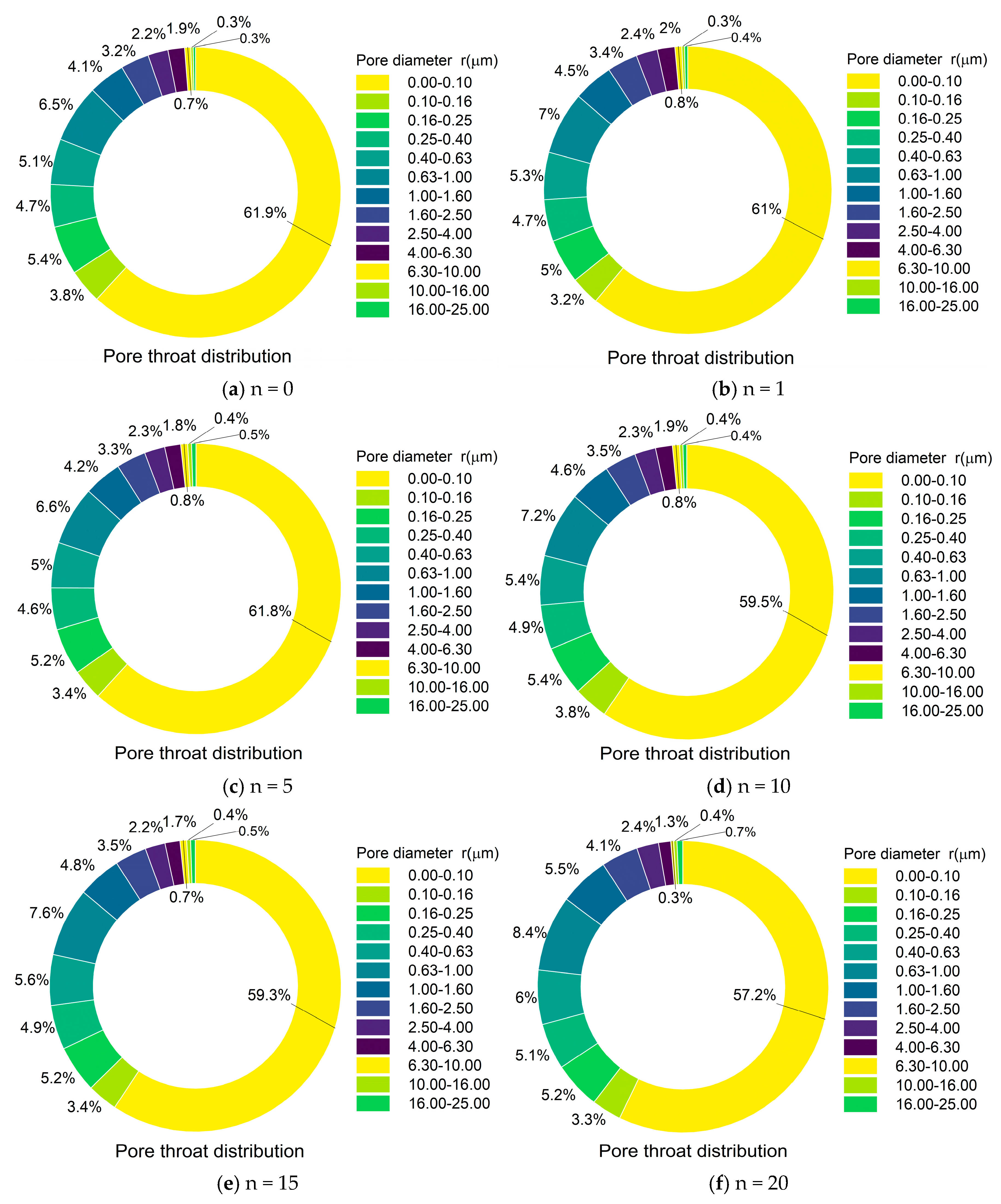

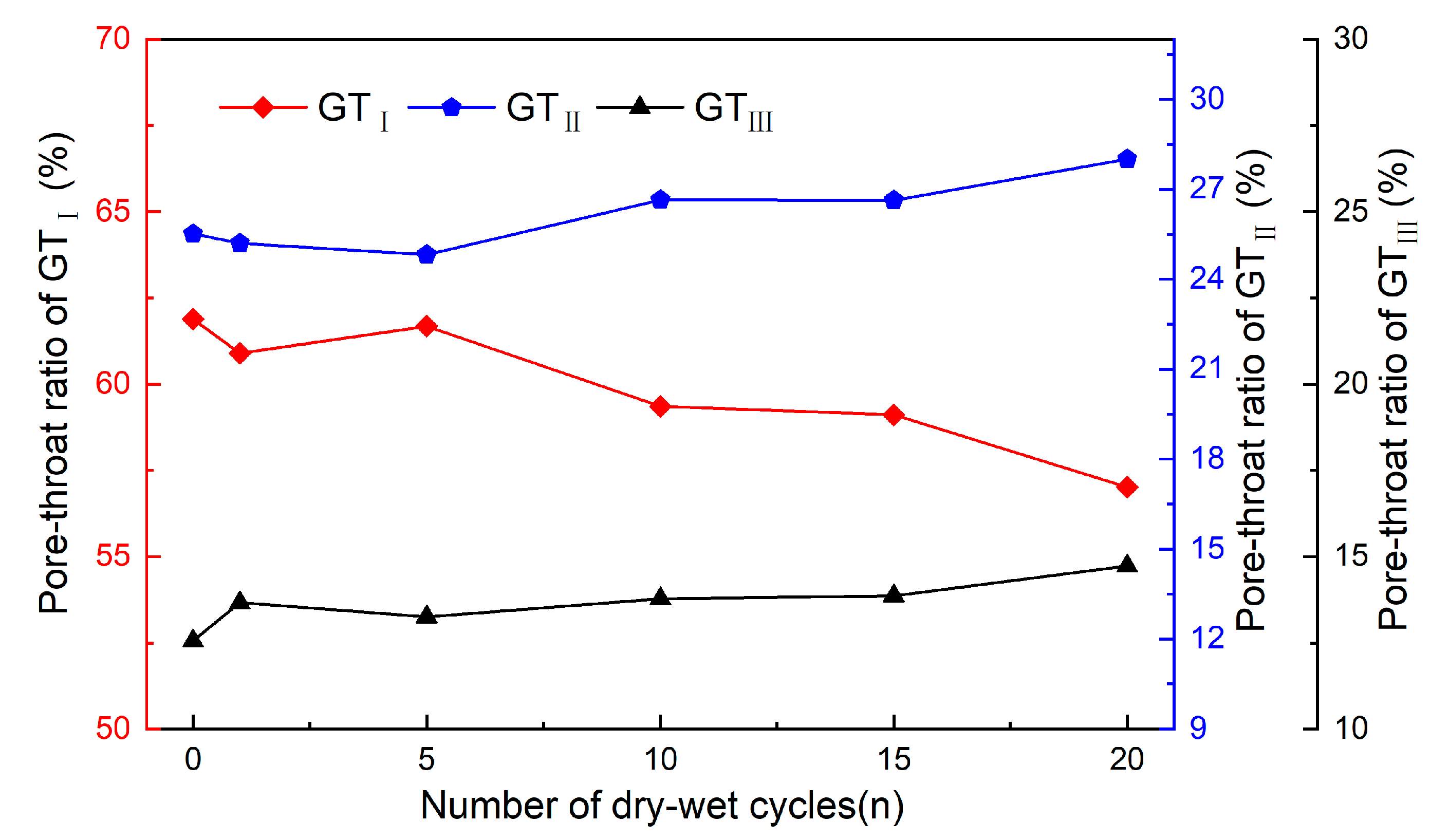

3.2. The Variation of Pore Size Distribution and Throats in Jointed Sandstone

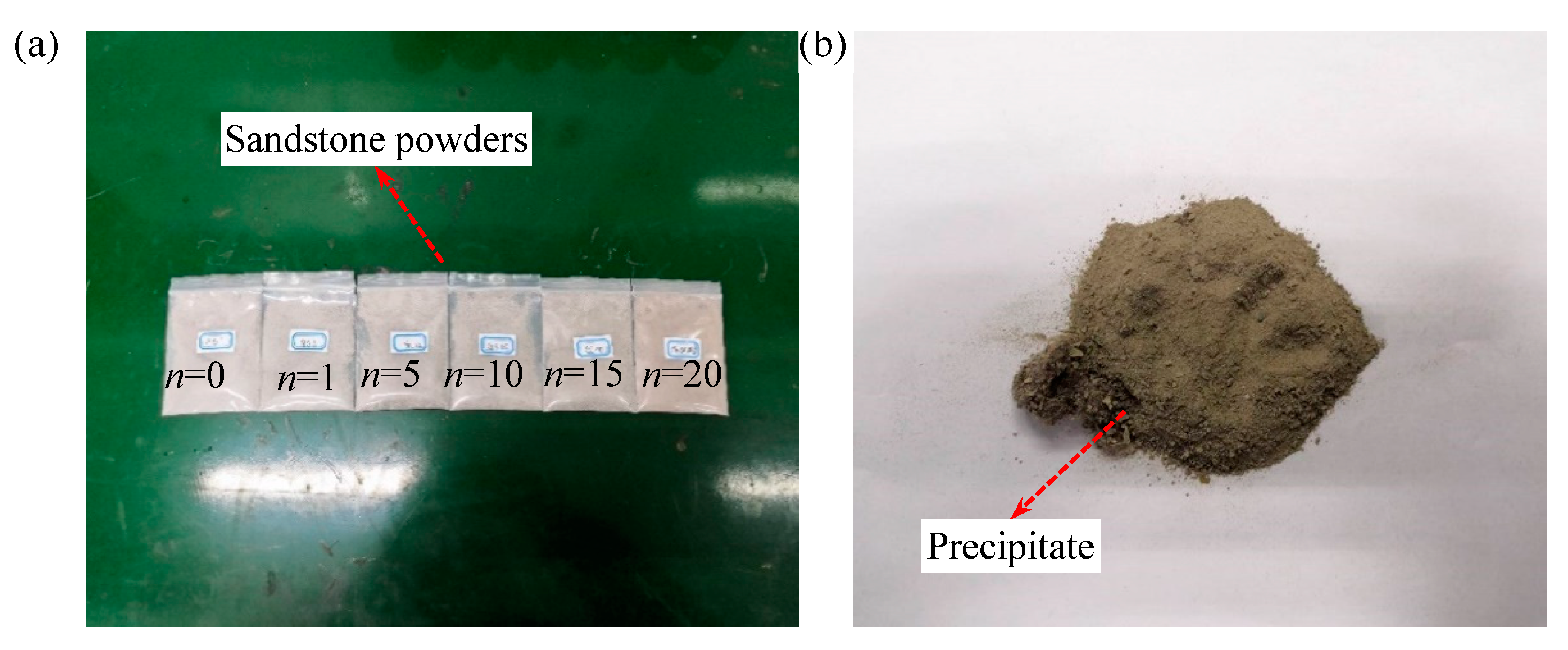

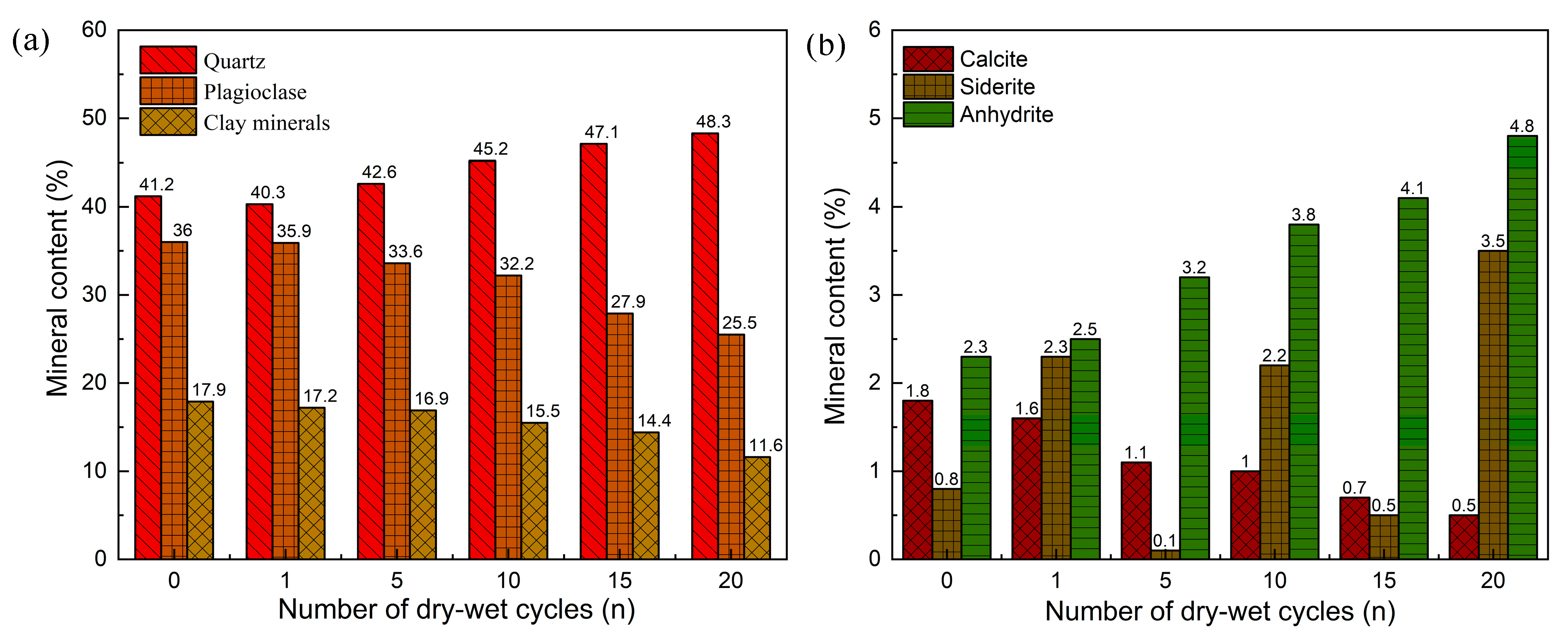

3.3. Variation of Mineral Composition of the Sandstone

4. Damage Mechanism of Mesostructure in Sandstone

- (i)

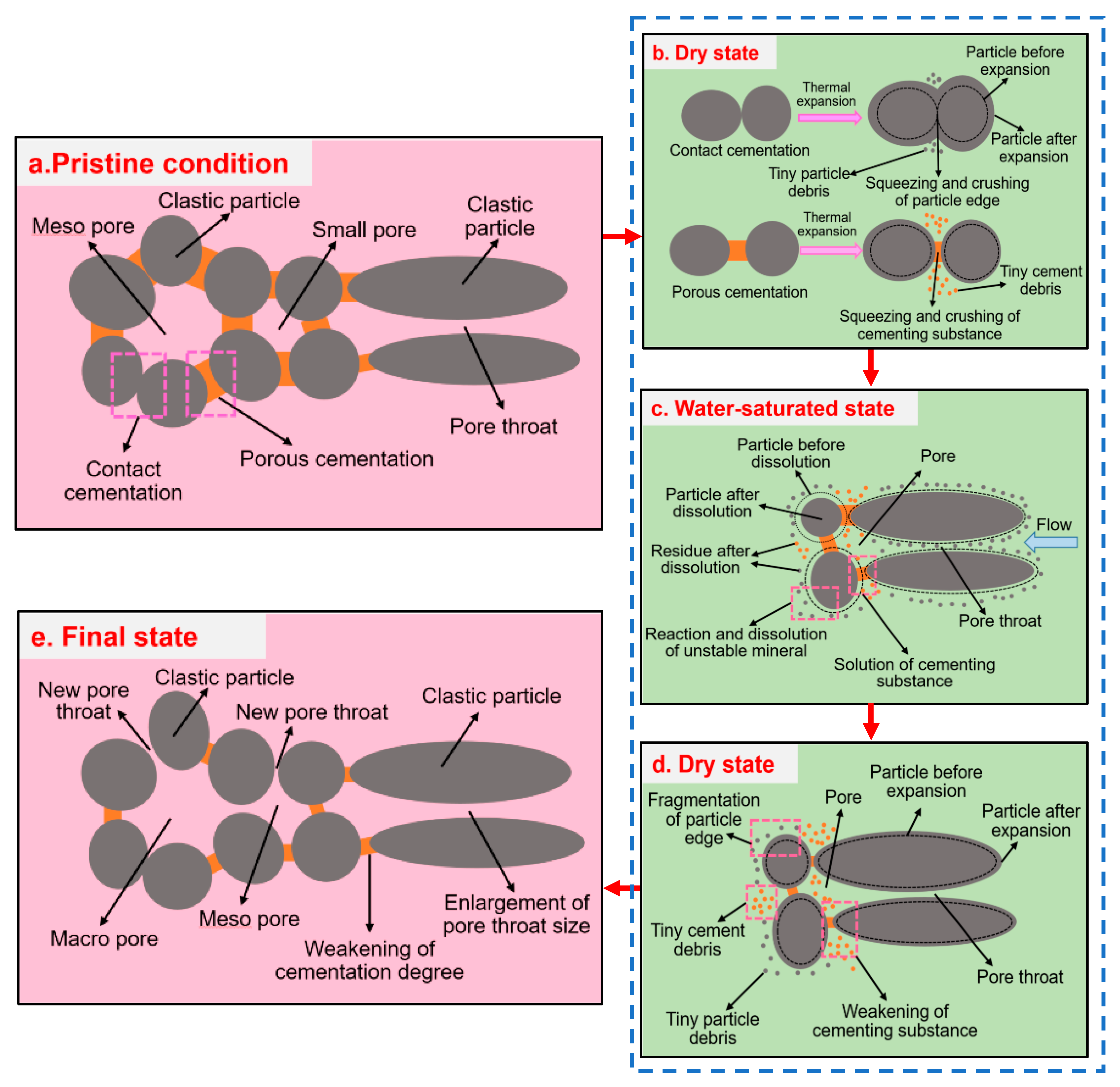

- Pristine condition (Figure 12a). The sandstone was formed by mechanical, chemical and biological deposition of ore-forming materials. In nature, the mineral particles inside the sandstone are usually connected with cementitious materials in the form of porosity and contact; i.e., porous connection and contact connection. Besides, the gap between the mineral particles divided into pores and pore throats (Figure 6 and Figure 8), and pore structure and throat features are all inner factors that affect and determine the mesoscopic damage evolution of rock samples under the dry–wet cycle.

- (ii)

- Dry state (Figure 12b). In the dry state, due to the thermal expansion caused by changes in temperature, the compression and fragmentation of the inter-particles occurs in contact cementation, resulting in the formation of mineral particle debris. Meanwhile, the expansion of particles causes compression and fragmentation of the cementitious material between the clastic particles, inducing the generation of tiny amounts of cement debris. The combined effect of the two kinds of fragmentation mechanisms leads to microscopic structure changes in sandstone.

- (iii)

- Water-saturated state (Figure 12c). On the one hand, when the water permeates the rock specimens, the particle debris, cement debris and unstable mineral particles inside the rock (such as feldspar, calcite, etc.) are dissolved. The cohesion between the mineral particles will be weakened. This was demonstrated by the mineral analysis experiment in Section 3.3. On the other hand, the mineral particles will shrink slightly when the rock is cooled by water. The compression between particles will become tension, leading to microcracks in the contact cementation structure. Finally, the micropores continue to expand and new throats are produced, which further enhances the permeability of the rock sample.

- (iv)

- The second dry state (Figure 12d). When the water-saturated rock sample is dried again, the contact and porous cementation are squeezed again due to thermal expansion. The force between clastic particles changes from tension to compression, resulting in the formation of mineral particle debris and cement debris. The mineral particles in the rock sample go through tension-compression transformation under alternating dry–wet cycles, leading to the continuous fragmentation and dissolution of soluble minerals and cements. Besides, some closed pores are transformed into open pores due to the formation of new cracks in the inter-particle structure [52]. Therefore, with an increasing dry–wet alternation number, the proportion of small pores and pore throats decreases, while the proportion of medium and large pores and pore throats increases (Figure 7 and Figure 8).

- (v)

- Final state (Figure 12e). During the dry–wet alternation action, the size of pores and pore throats continues to expand due to the weakening of the cements between mineral particles. The proportion of mesopores and medium pore throats is significantly increased. Besides, the content of soluble minerals and cements in the pores of rock samples decreases continuously due to the erosion of water, so new pores and pore throats are gradually generated under the action of dry–wet alternation [44]. Meanwhile, the cementation effect on the inter-particles gradually decreases during the dry–wet cycle. Ultimately, the micropore morphology and structure change significantly (Figure 4 and Figure 5), resulting in the irreversible cumulative damage of jointed sandstone during dry–wet alternation action.

5. Conclusions

- (1)

- The dry–wet alternation action can cause the development of the porosity channel, leading to cumulative damage in sandstone. Therefore, the accumulated porosity and permeability of sandstone increase as the wet–dry cycle goes on, and the cumulative porosity goes through the slow accumulation stage, the rapid accumulation stage and the steady development stage.

- (2)

- During the dry–wet alternation process, the dissolution soluble minerals, hydration reaction and uneven shrink increase the size of pores and pore throats. In detail, micropores transform to medium and macropores, while medium pores transform to macropores gradually. The more micropores exist in the sandstone, the more obvious is the transformation from micropores to medium pores. Besides, the proportion of small pore throats decreases gradually, while the proportion of medium and large pore throats increases gradually.

- (3)

- The contents of feldspar (potassium feldspar and albite), calcite and clay minerals (TCCM) in the test rock samples decreased as the dry–wet cycle went on, which led to the continuous development of pores and pore throats.

- (4)

- In the alternating dry–wet environment, the combined effects of extrusion crush, tensile fracture, chemical reaction and dissolution action, etc., of clastic particles inside the jointed sandstone led to the continual development of mesoscopic pore structures, which ultimately caused the porosity and permeability to increase. The damage process was the essential reason for the weakening of rock strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duda, M.; Renner, J. The weakening effect of water on the brittle failure strength of sandstone. Geophys. J. Int. 2013, 192, 1091–1108. [Google Scholar] [CrossRef]

- Momeni, A.; Hashemi, S.S.; Khanlari, G.R.; Heidari, M. The effect of weathering on durability and deformability properties of granitoid rocks. Bull. Eng. Geol. Environ. 2017, 76, 1037–1049. [Google Scholar] [CrossRef]

- Eang, K.E.; Igarashi, T.; Kondo, M.; Nakatani, T.; Tabelin, C.B.; Fujinaga, R. Groundwater monitoring of an open-pit limestone quarry: Water-rock interaction and mixing estimation within the rock layers by geochemical and statistical analyses. Int. J. Min. Sci. Technol. 2018, 28, 849–857. [Google Scholar] [CrossRef]

- Li, Y.; Tang, D.Z.; Elsworth, D.; Xu, H. Characterization of coalbed methane reservoirs at multiple length scales: A cross-section from Southeastern Ordos Basin, China. Energy Fuels 2014, 28, 5587–5595. [Google Scholar] [CrossRef]

- Wu, Q.; Jiang, Y.; Tang, H.; Luo, H.; Wang, X.; Kang, J.; Zhang, S.; Yi, X.; Fan, L. Experimental and numerical studies on the evolution of shear behaviour and damage of natural discontinuities at the interface between different rock types. Rock Mech. Rock Eng. 2020, 53, 3721–3744. [Google Scholar] [CrossRef]

- Özbek, A. Investigation of the effects of wetting–drying and freezing–thawing cycles on some physical and mechanical properties of selected ignimbrites. Bull. Eng. Geol. Environ. 2014, 73, 595–609. [Google Scholar] [CrossRef]

- Ramandi, H.L.; Mostaghimi, P.; Armstrong, R.T.; Saadatfar, M.; Pinczewski, W.V. Porosity and permeability characterization of coal: A micro-computed tomography study. Int. J. Coal Geol. 2016, 154–155, 57–68. [Google Scholar] [CrossRef]

- Khanlari, G.; Abdilor, Y. Influence of wet–dry, freeze–thaw, and heat–cool cycles on the physical and mechanical properties of upper red sandstones in central Iran. Bull. Eng. Geol. Environ. 2015, 74, 1287–1300. [Google Scholar] [CrossRef]

- Liu, X.X.; Li, Y.; Wang, W.W. Study on mechanical properties and energy characteristics of carbonaceous shale with different fissure angles under dry–wet cycles. Bull. Eng. Geol. Environ. 2022, 81, 319. [Google Scholar] [CrossRef]

- Xu, Z.H.; Feng, G.L.; Sun, Q.C.; Zhang, G.D.; He, Y.M. A modified model for predicting the strength of drying-wetting cycled sandstone based on the P-wave velocity. Sustainability 2020, 12, 5655. [Google Scholar] [CrossRef]

- Vasarhelyi, B. Some observations regarding the strength and deformability of sandstones in dry and saturated conditions. Bull. Eng. Geol. Environ. 2003, 62, 245–249. [Google Scholar] [CrossRef]

- Hua, W.; Dong, S.M.; Peng, F.; Li, K.Y.; Wang, Q.Y. Experimental investigation on the effect of wetting-drying cycles on mixed mode fracture toughness of sandstone. Int. J. Rock Mech. Min. 2017, 93, 242–249. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Wild, K.M.; Walter, P.; Amann, F. The response of Opalinus Clay when exposed to cyclic relative humidity variations. Solid Earth 2017, 8, 351–360. [Google Scholar] [CrossRef]

- Song, Z.Y.; Sun, L.H.; Cheng, S.Y.; Liu, Z.Q.; Tan, J.; Ning, F.B. Experimental study on the property degradation and failure mechanism of weakly cemented sandstone under dry-wet cycles. Adv. Mater. Sci. Eng. 2022, 2022, 9431349. [Google Scholar] [CrossRef]

- Shi, Z.M.; Li, J.T.; Zhao, Y. Study on damage evolution and constitutive model of sandstone under the coupled effects of wetting-drying cycles and cyclic loading. Eng. Fract. Mech. 2021, 253, 107883. [Google Scholar] [CrossRef]

- Meng, Y.Y.; Jing, H.W.; Yin, Q.; Gu, X.W. Investigation on mechanical and AE characteristics of yellow sandstone undergoing wetting-drying cycles. KSCE J. Civ. Eng. 2020, 24, 3267–3278. [Google Scholar] [CrossRef]

- Zhao, B.Y.; Li, Y.F.; Huang, W.; Yang, J.S.; Sun, J.C.; Li, W.C.; Zhang, L.Y.; Zhang, L. Mechanical characteristics of red sandstone under cyclic wetting and drying. Environ. Earth Sci. 2021, 80, 738. [Google Scholar] [CrossRef]

- Liu, X.W.; Liu, Q.S.; Huang, S.B.; Liu, B.; Liu, J. Effects of cyclic wetting-drying on the mechanical behavior and improved damage model for sandstone. Mar. Georesour. Geotechnol. 2021, 39, 1244–1254. [Google Scholar] [CrossRef]

- Colas, E.; Klopries, E.M.; Tian, D.Y.; Kroll, M.; Selzner, M.; Bruecker, C.; Khaledi, K.; Kukla, P.; Preuße, A.; Sabarny, C.; et al. Overview of converting abandoned coal mines to underground pumped storage systems: Focus on the underground reservoir. J. Energy Storage 2023, 73, 109153. [Google Scholar] [CrossRef]

- Yuan, P.; Zheng, X.B.; Wei, N.N.; Li, A.B. Characterization of the mechanical behavior and constitutive modeling of sandstone under acidic dry-wet cycles and dynamic loading. Mech. Time-Depend. Mater. 2024. [Google Scholar] [CrossRef]

- De Kock, T.; Boone, M.A.; De Schryver, T.; Van Stappen, J.; Derluyn, H.; Masschaele, B.; De Schutter, G.; Cnudde, V. A pore-scale study of fracture dynamics in rock using X-ray micro-CT under ambient freeze-thaw cycling. Environ. Sci. Technol. 2015, 49, 2867–2874. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Huang, L.S.; Lv, X.Q.; Ren, Y.J. Variation features of unfrozen water content of water-saturated coal under low freezing temperature. Sci. Rep. 2021, 11, 15398. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Cui, S. A review on theory and application of plastic meso-damage mechanics. Theor. Appl. Fract. Mech. 2020, 109, 102686. [Google Scholar] [CrossRef]

- Shan, L.Q.; Liu, C.Q.; Liu, Y.C.; Kong, W.F.; Hei, X.L. Rock CT image super-resolution using residual dual-channel atention generative adversarial network. Energies 2022, 15, 5115. [Google Scholar] [CrossRef]

- Zhou, H.W.; Zhong, J.C.; Ren, W.G.; Wang, X.Y.; Yi, H.Y. Characterization of pore-fracture networks and their evolution at various measurement scales in coal samples using X-ray μ CT and a fractal method. Int. J. Coal Geol. 2018, 189, 35–49. [Google Scholar] [CrossRef]

- Wang, R.Q.; Wang, G.L.; Zhang, L.; Sun, F.; Cao, T.C.; Li, B.Y.; Xu, H. Coupled macro–meso damage constitutive model for fractured rocks based on logistic growth theory. Eng. Fract. Mech. 2023, 281, 109132. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.F.; Wang, S.H.; Wang, Q.Z.; Ding, J.L. Shear strength and mesoscopic character of undisturbed loess with sodium sulfate after dry-wet cycling. Bull. Eng. Geol. Environ. 2020, 79, 1523–1541. [Google Scholar] [CrossRef]

- Guo, P.Y.; Gu, J.; Su, Y.; Wang, J.; Ding, Z. Effect of cyclic wetting-drying on tensile mechanical behavior and microstructure of clay-bearing sandstone. Int. J. Coal Sci. Technol. 2021, 8, 956–968. [Google Scholar] [CrossRef]

- Ma, D.H.; Yao, H.Y.; Xiong, J.; Zhu, D.; Lu, J. Experimental Study on the Deterioration Mechanism of Sandstone under the Condition of Wet-Dry Cycles. KSCE J. Civ. Eng. 2022, 26, 2685–2694. [Google Scholar] [CrossRef]

- Zhang, H.X.; Lu, K.P.; Zhang, W.Z.; Li, D.; Yang, G. Quantification and acoustic emission characteristics of sandstone damage evolution under dry-wet cycles. J. Build. Eng. 2022, 48, 103996. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, W.; Zhang, H.; Zhang, J.B.; Hu, Z.J. Damage characteristics and new constitutive model of sandstone under wet-dry cycles. J. Mt. Sci. 2022, 19, 2111–2125. [Google Scholar] [CrossRef]

- Pu, H.; Yi, Q.Y.; Jivkov, A.P.; Bian, Z.F.; Chen, W.Q.; Wu, J.Y. Effect of dry-wet cycles on dynamic properties and microstructures of sandstone: Experiments and modelling. Int. J. Min. Sci. Technol. 2024, 34, 655–679. [Google Scholar] [CrossRef]

- Ge, X.M.; Xiao, Y.F.; Fan, Y.R.; Liu, J.Y.; Zhang, Y.H. Laboratory investigation of the relationship between static rock elastic parameters and low field nuclear magnetic resonance data. Int. J. Rock Mech. Min. 2020, 127, 104207. [Google Scholar] [CrossRef]

- Xu, L.; Li, Q.; Myers, M.; Chen, Q.; Li, X.C. Application of nuclear magnetic resonance technology to carbon capture, utilization and storage: A review. J. Rock Mech. Geotech. 2019, 11, 892–908. [Google Scholar] [CrossRef]

- Anovitz, L.M.; Cole, D.R. Characterization and analysis of porosity and pore structures. Rev. Miner. Geochem. 2015, 80, 61–164. [Google Scholar] [CrossRef]

- Kikhney, A.G.; Svergun, D.I. A practical guide to small angle X-ray scattering (SAXS) of flexible and intrinsically disordered proteins. FEBS Lett. 2015, 589, 2570–2577. [Google Scholar] [CrossRef] [PubMed]

- Mertens, H.D.; Svergun, D.I. Structural characterization of proteins and complexes using small-angle X-ray solution scattering. J. Struct. Biol. 2010, 172, 128–141. [Google Scholar] [CrossRef]

- Chai, S.B.; Wang, H.; Yu, L.Y.; Shi, J.H.; Abi, E. Experimental study on static and dynamic compression mechanical properties of filled rock joints. Lat. Am. J. Solids Struct. 2020, 17, 1–15. [Google Scholar] [CrossRef]

- Yu, J.; Chen, X.; Cai, Y.Y.; Li, H. Triaxial test research on mechanical properties and permeability of sandstone with a single joint filled with gypsum. KSCE J. Civ. Eng. 2016, 20, 2243–2252. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, X.R.; Fu, Y. Study on deterioration of strength parameters of sandstone under the action of dry-wet cycles in acid and alkaline environment. Arab. J. Sci. Eng. 2018, 43, 335–348. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, X.Y.; Fu, Y. Chemical thermodynamics and chemical kinetics analysis of sandstone dissolution under the action of dry-wet cycles in acid and alkaline environment. Bull. Eng. Geol. Environ. 2019, 78, 793–801. [Google Scholar] [CrossRef]

- Fan, Z.Y.; Hou, J.G.; Xing, D.H.; Ge, X.M.; Zhang, F.S. Core NMR experiments for low permeability reservoir and its field application. J. China Univ. Pet. 2019, 43, 53–59. [Google Scholar] [CrossRef]

- Tan, H.; Li, J.T.; Shi, Z.M.; Wang, M.X.; Wang, J.; Li, J. Damage evolution and failure characteristics of red sandstone with prefabricated crack under coupled dry-wet cycle-fatigue loading. Int. J. Fatigue 2023, 175, 107751. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, G.L.; Liu, B.L.; Sun, F.; Wang, R.Q. Experimental investigation of the fracture evolution and fracture criterion of jointed sandstone subject to dry-wet cycling. Bull. Eng. Geol. Environ. 2023, 82, 101. [Google Scholar] [CrossRef]

- Fang, J.C.; Deng, H.F.; Li, J.L.; Assefa, E. Study on the seepage characteristics and degradation mechanism of a single-jointed sandstone under the cyclic dry–wet process in the Three Gorges reservoir. Bull. Eng. Geol. Environ. 2021, 80, 8123–8136. [Google Scholar] [CrossRef]

- Li, M.R.; Li, C.C.; Xing, J.T.; Sun, X.T.; Yuan, G.H.; Cao, Y.C. An experimental study on dynamic coupling process of alkaline feldspar dissolution and secondary mineral precipitation. Acta Geochim. 2019, 38, 872–882. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Xie, Q.; Saeedi, A. Role of ion exchange, surface complexation, and albite dissolution in low salinity water flooding in sandstone. J. Petrol. Sci. Eng. 2019, 176, 126–131. [Google Scholar] [CrossRef]

- Zhu, C.; Rimstidt, J.D.; Zhang, Y.L.; Kang, J.T.; Schott, J.; Yuan, H.L. Decoupling feldspar dissolution and precipitation rates at near-equilibrium with Si isotope tracers: Implications for modeling silicate weathering. Geochim. Et Cosmochim. Acta 2020, 271, 132–153. [Google Scholar] [CrossRef]

- Wang, M.Q.; Xie, J.; Guo, F.J.; Zhou, Y.W.; Yang, X.D.; Meng, Z. Determination of NMR T2 cutoff and CT scanning for pore structure evaluation in mixed siliciclastic–carbonate rocks before and after acidification. Energies 2020, 13, 1338. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, W.; Han, L.; Chen, X.C.; Cui, Q.; Yao, H.Y.; Wang, Z.L. Disintegration behavior of strongly weathered purple mudstone in drawdown area of three gorges reservoir, China. Geomorphology 2018, 315, 68–79. [Google Scholar] [CrossRef]

- Chen, L.L.; Chen, X.Z.; Gong, S.; Li, Z.H.; Su, Z.K. Experimental Study on Pore Structure Evolution of Unloaded Rock Mass during Excavation of Reservoir Slope under Dry–Wet Cycle. Appl. Sci. 2024, 14, 4716. [Google Scholar] [CrossRef]

| System Parameters | Value | System Parameters | Value |

|---|---|---|---|

| Temperature of magnet T (°C) | 32 | RF 90° pulse width P1 (μs) | 3.80 |

| RF frequency SF (MHz) | 12.68 | RF 180° pulse width P2 (μs) | 10.20 |

| RF offset frequency O1 (Hz) | 682,035.1 | Repeat sampling interval TW (ms) | 500 |

| RFD (ms) | 0.020 | Sampling number TD | 99,980 |

| Analog gain (RG1) | 20.0 | Data radius DR | 1 |

| Cumulative collecting times (NS) | 8 | Pulse echo times NECH | 5000 |

| Grade | Symbol | Name | Pore Diameter rp | Remarks |

|---|---|---|---|---|

| I | GI | Micropore | <0.01 μm | Containing 0.002–0.01 μm transitional pores, partially cementing pores |

| II | GII | Small pore | 0.01–0.1 μm | Containing 0.01–0.1 μm transitional pores, partially cementing pores |

| III | GIII | Mesopore | 0.1–10 μm | Containing 0.1–100 μm capillary opening |

| IV | GIV | Macropore | 10–100 μm | Containing 0.1–100 μm capillary opening |

| V | GV | Larger pore | >100 μm | Containing air pores, visible to the naked eye |

| Grade | Symbol | Name | Pore Diameter Φ |

|---|---|---|---|

| I | GTI | Small pore throat | <0.1 μm |

| II | GTII | Medium pore throat | 0.1–1 μm |

| III | GTIII | Large pore throat | 1–25 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Wang, G.; Wang, R.; Liu, B.; Wang, K. The Mesoscopic Damage Mechanism of Jointed Sandstone Subjected to the Action of Dry–Wet Alternating Cycles. Appl. Sci. 2024, 14, 10346. https://doi.org/10.3390/app142210346

Zhang L, Wang G, Wang R, Liu B, Wang K. The Mesoscopic Damage Mechanism of Jointed Sandstone Subjected to the Action of Dry–Wet Alternating Cycles. Applied Sciences. 2024; 14(22):10346. https://doi.org/10.3390/app142210346

Chicago/Turabian StyleZhang, Liang, Guilin Wang, Runqiu Wang, Bolong Liu, and Ke Wang. 2024. "The Mesoscopic Damage Mechanism of Jointed Sandstone Subjected to the Action of Dry–Wet Alternating Cycles" Applied Sciences 14, no. 22: 10346. https://doi.org/10.3390/app142210346

APA StyleZhang, L., Wang, G., Wang, R., Liu, B., & Wang, K. (2024). The Mesoscopic Damage Mechanism of Jointed Sandstone Subjected to the Action of Dry–Wet Alternating Cycles. Applied Sciences, 14(22), 10346. https://doi.org/10.3390/app142210346