Experimental Study on the Dynamic Mechanical Properties and Crashing Behaviors of Limestone Under High Temperatures in Real-Time

Abstract

1. Introduction

2. Materials and Methods

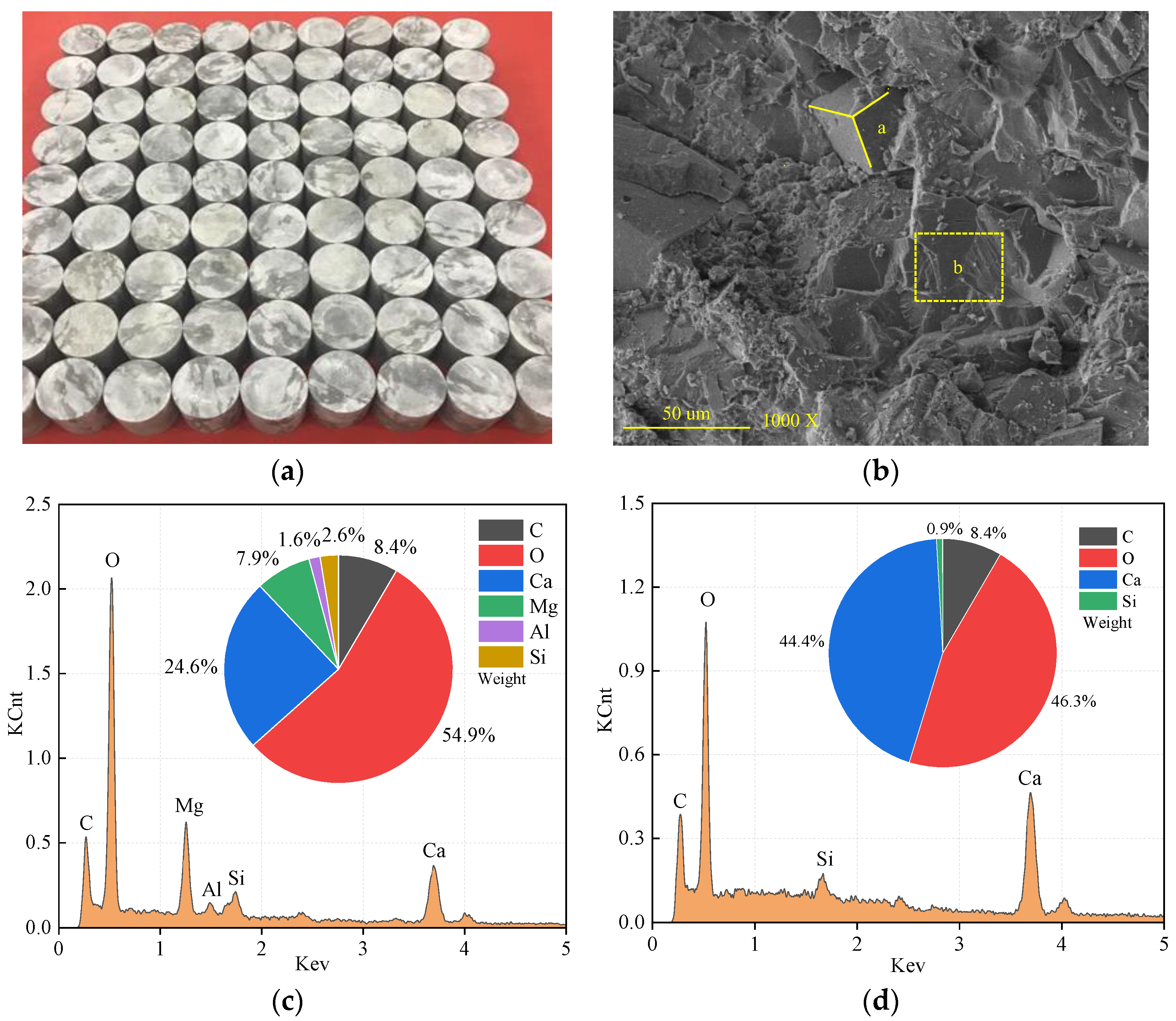

2.1. Materials and Specimen Preparation

2.2. SHPB with Real-Time Temperature Control System

2.3. Test Process

2.4. Principles and Methods

3. Results and Interpretations

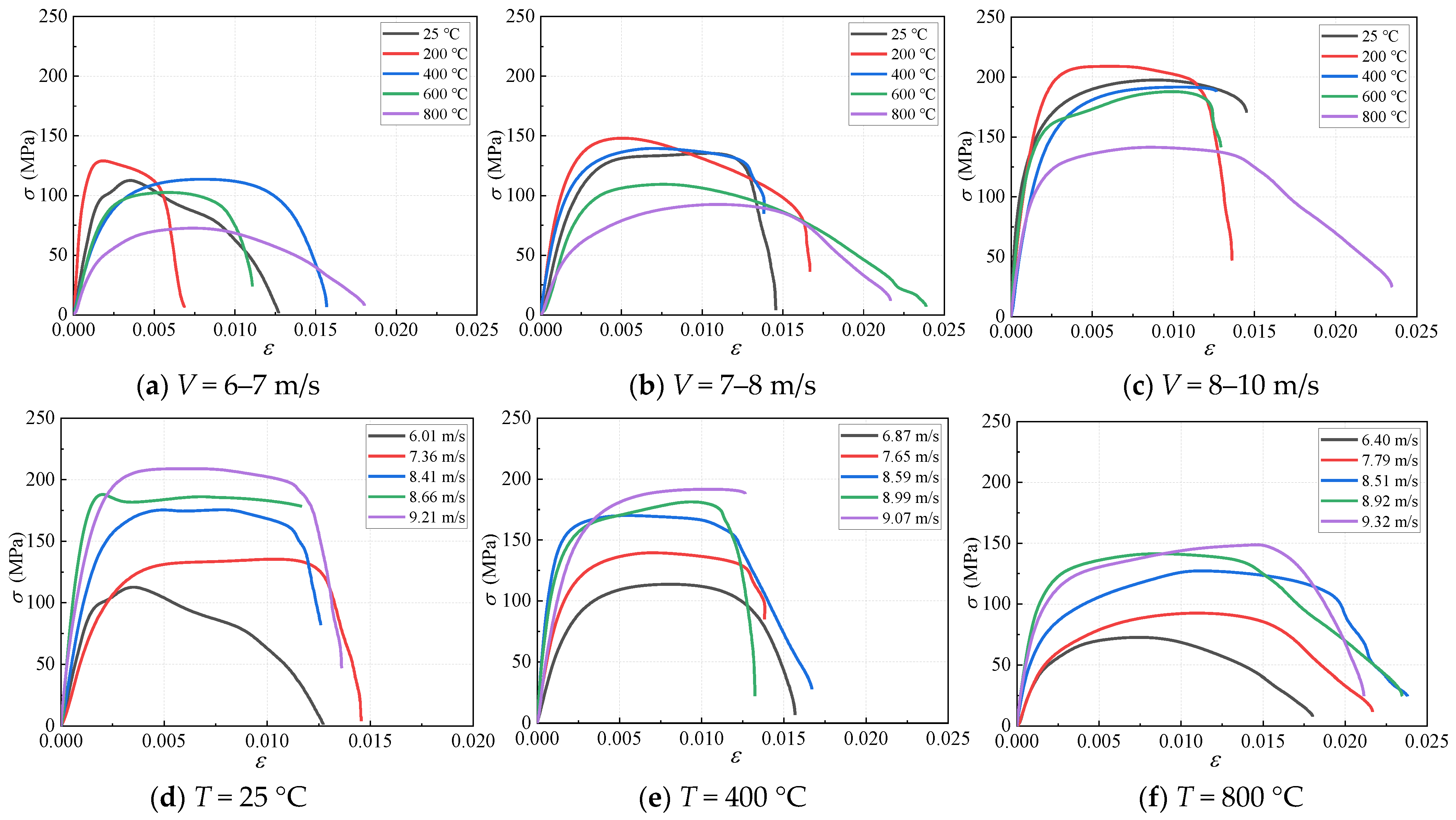

3.1. Dynamic Stress–Strain Behavior

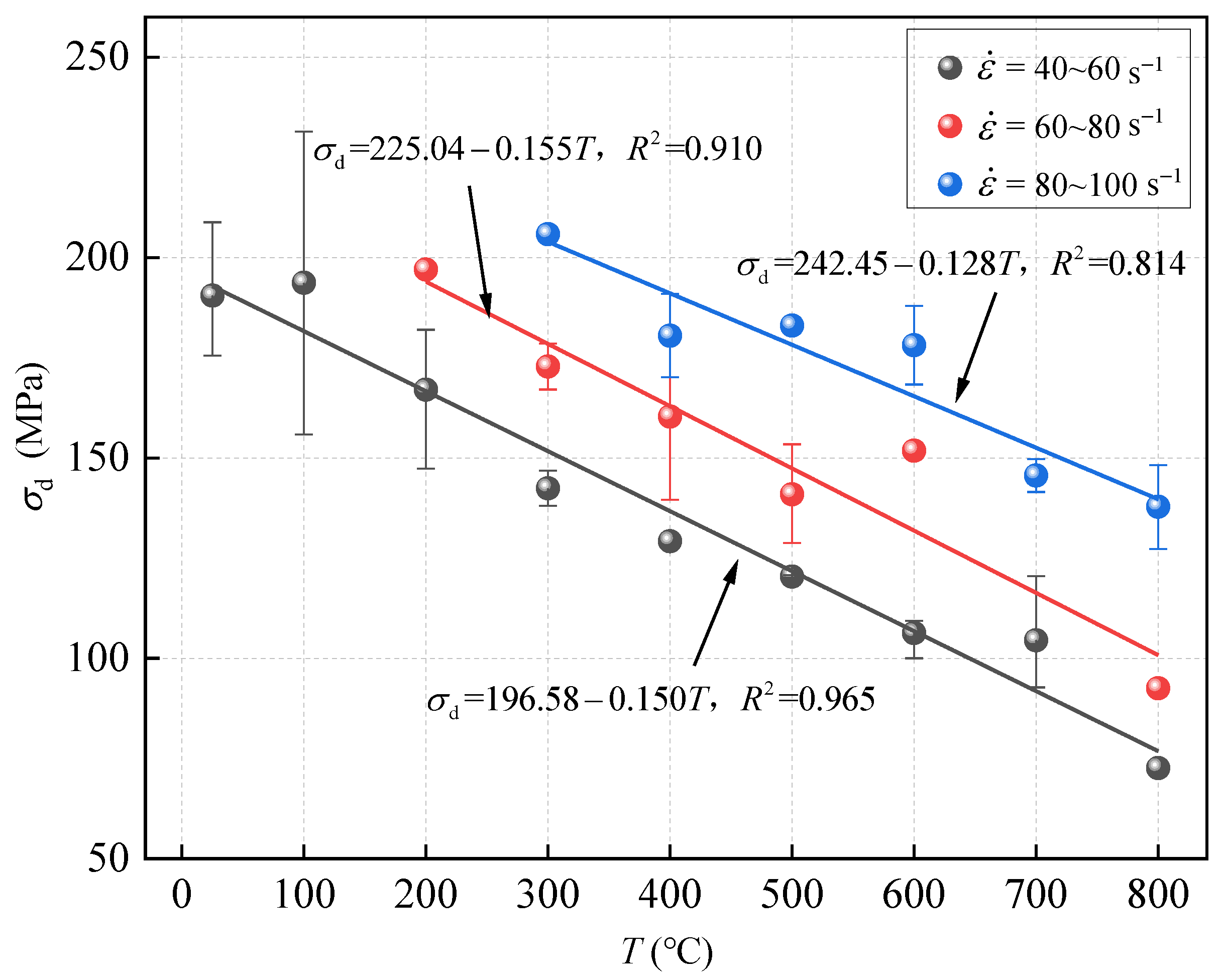

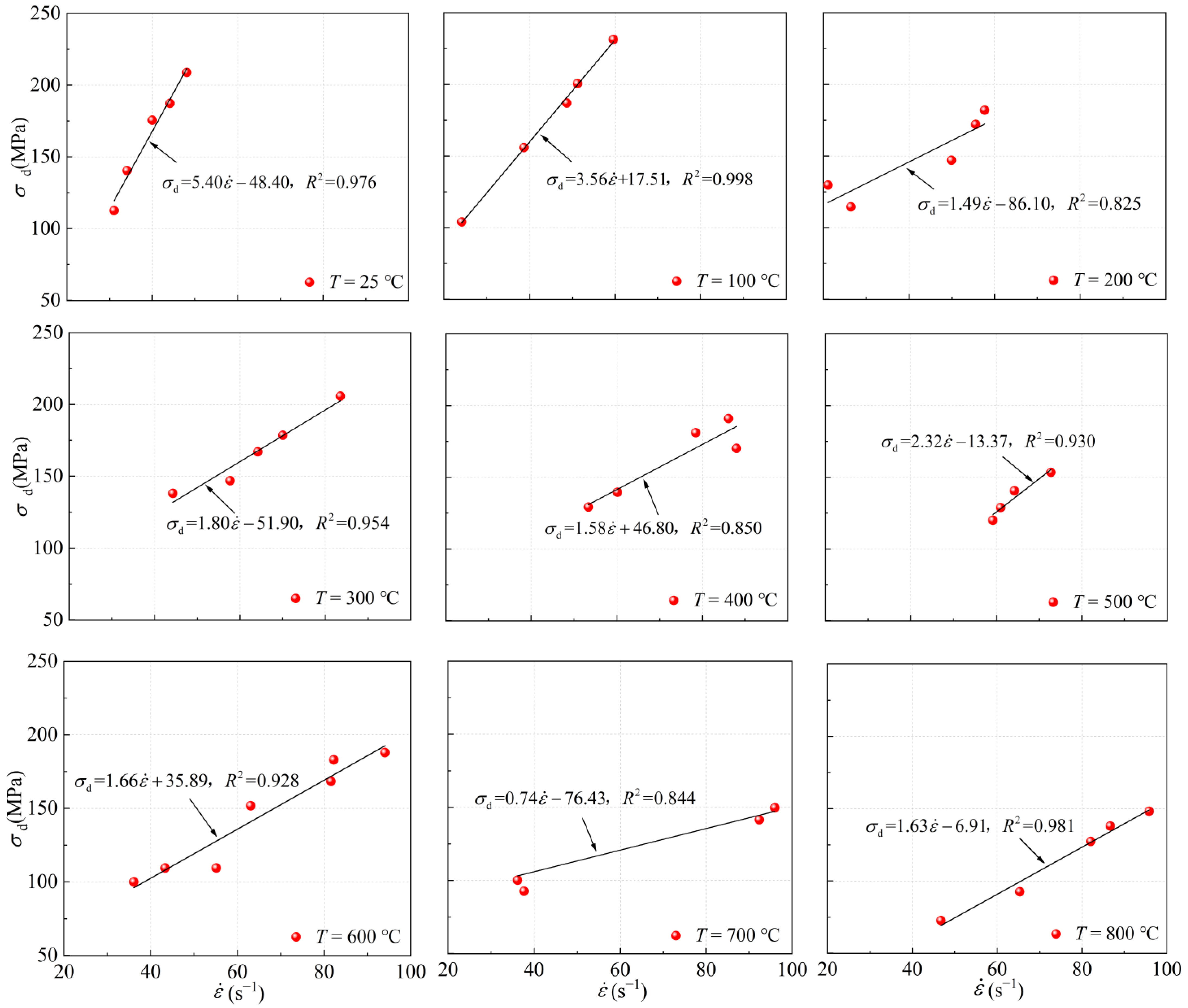

3.2. Dynamic Compressive Strength

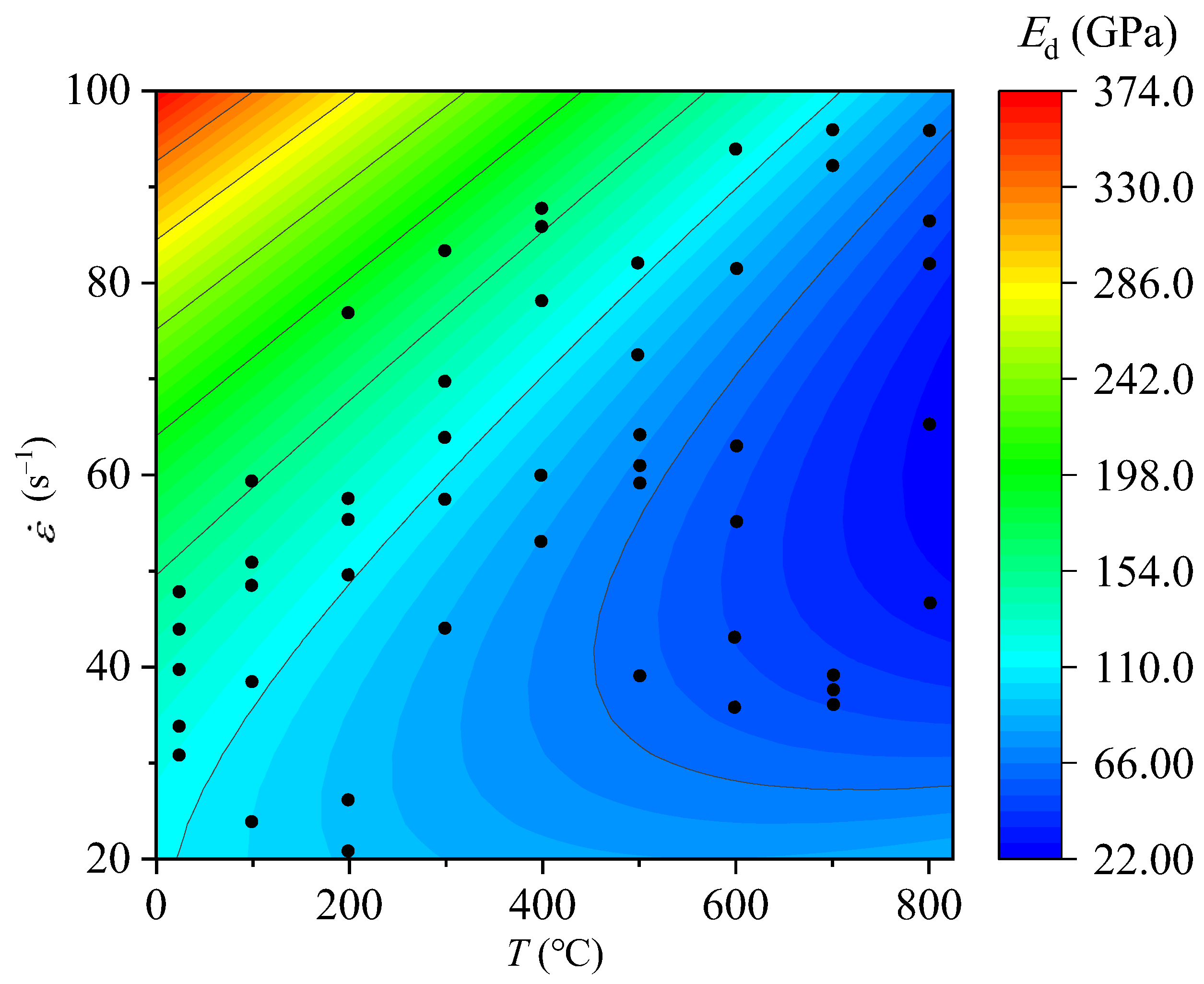

3.3. Dynamic Elastic Modulus

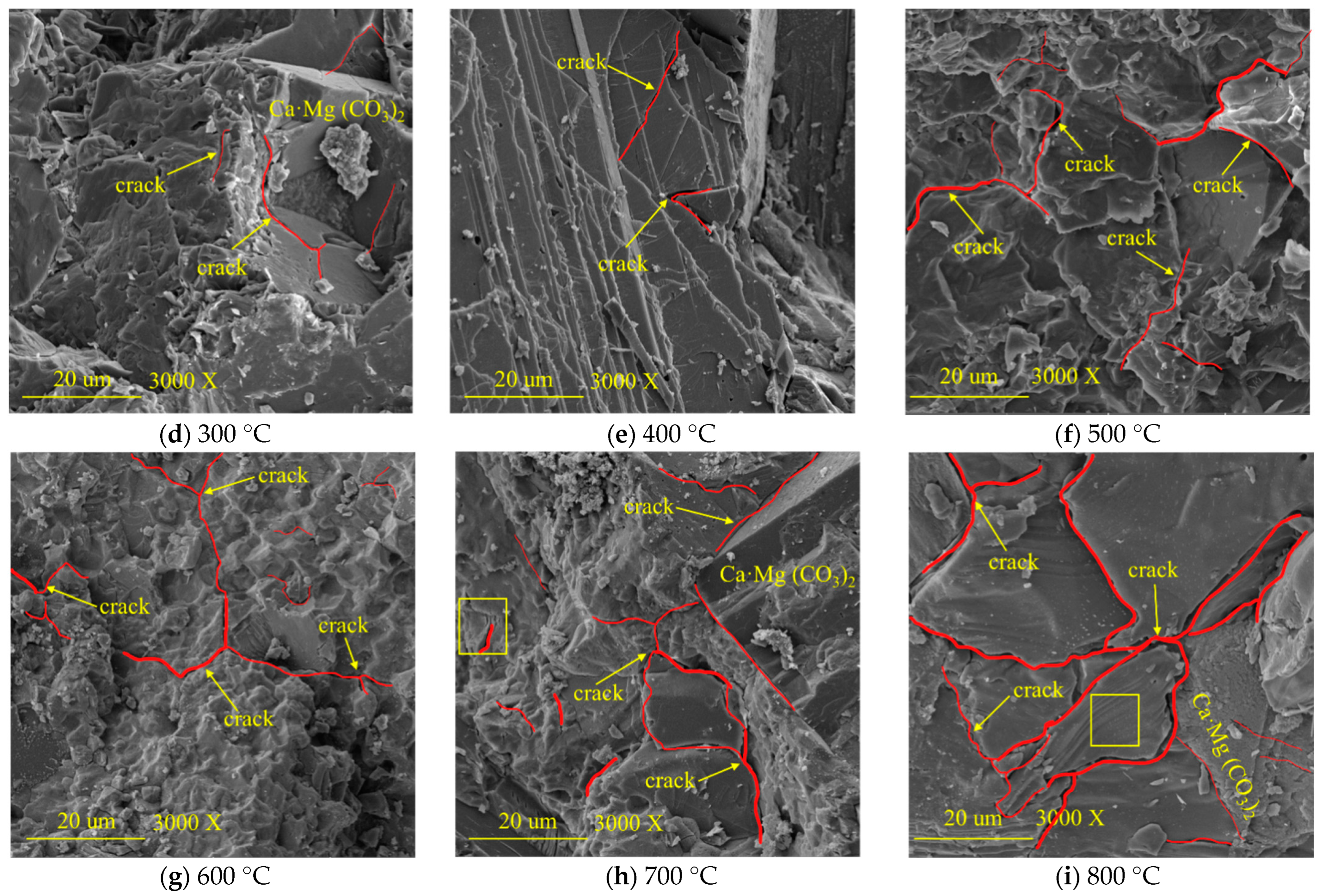

3.4. Macro-Fracture Characteristics

4. Discussions

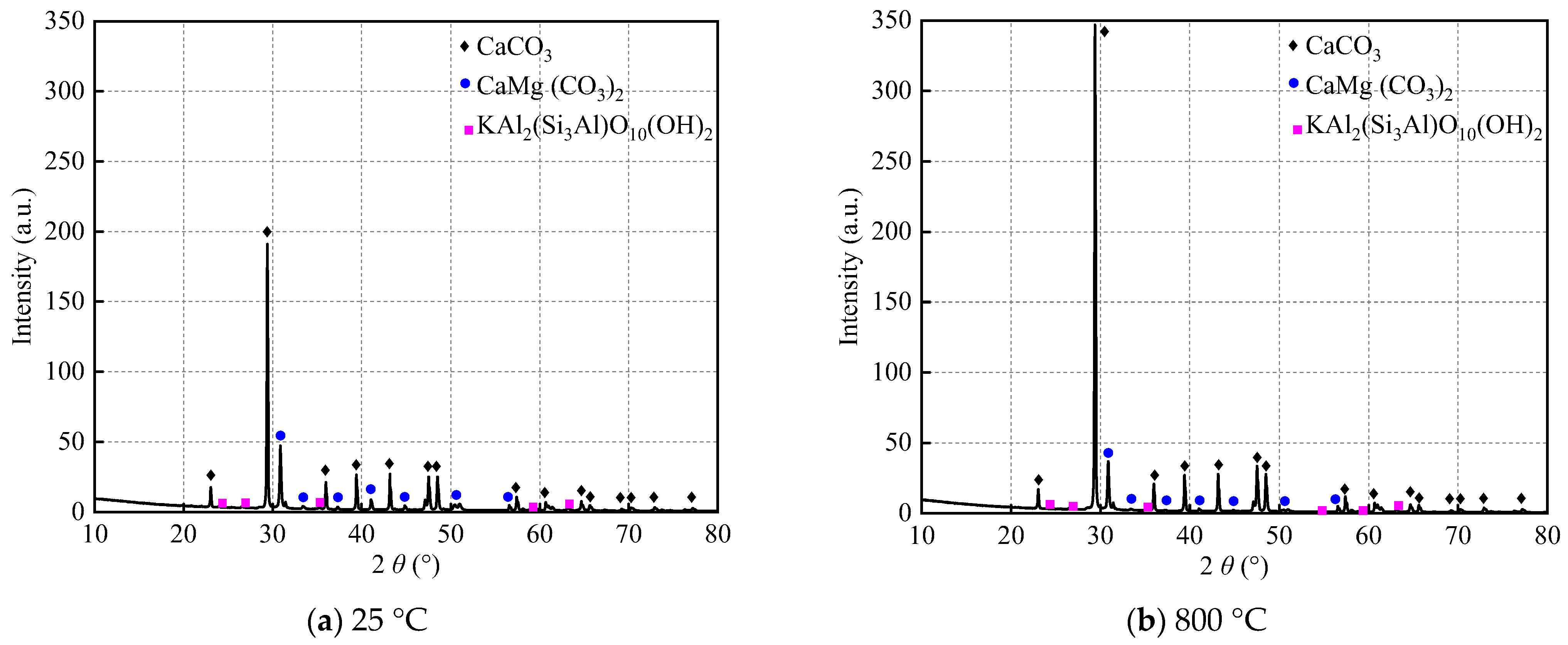

4.1. Effects of High Temperatures on the Mineral Composition

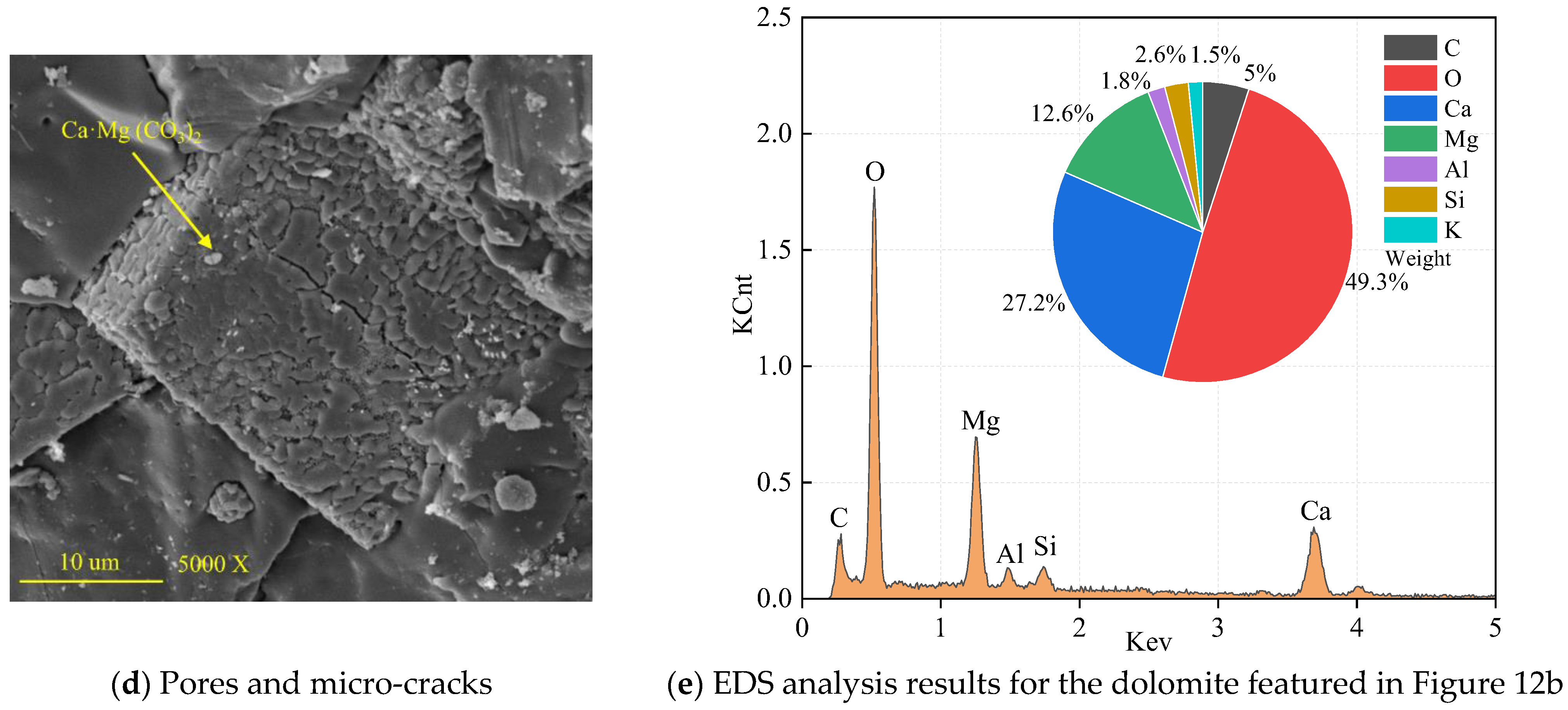

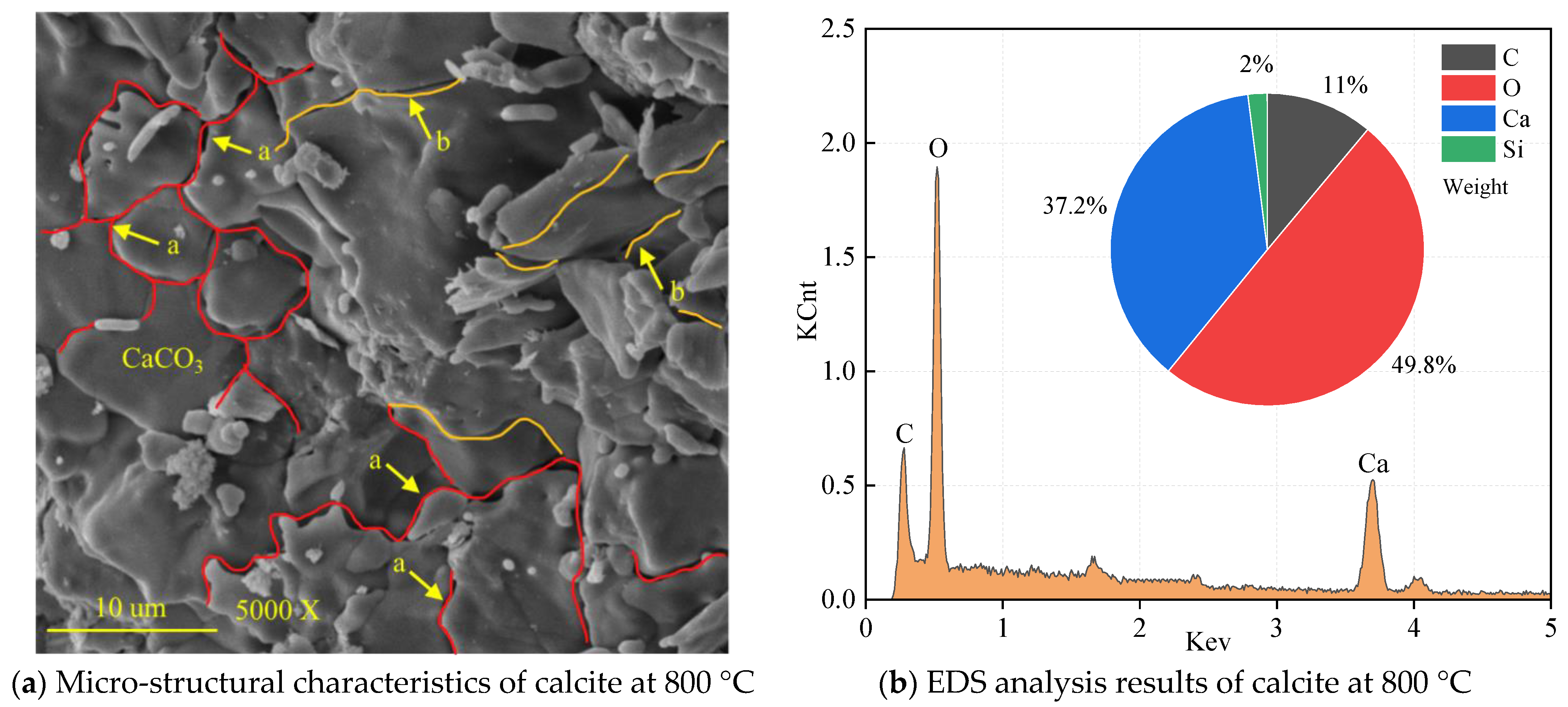

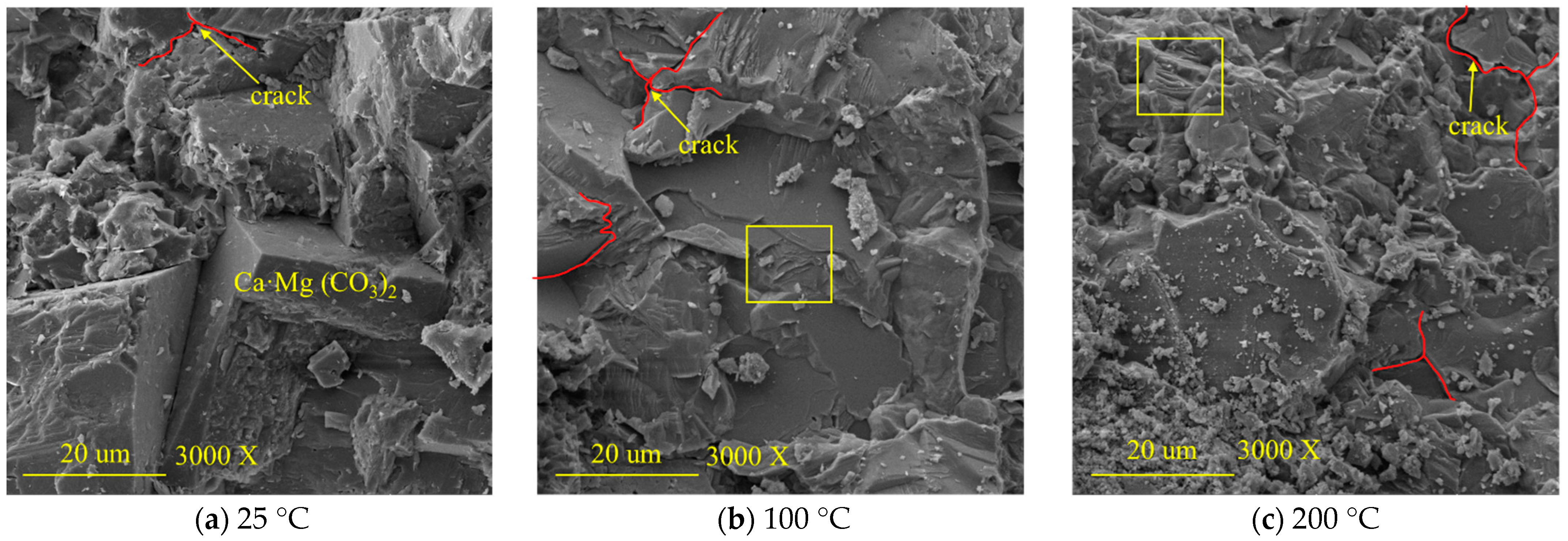

4.2. Effects of Temperature-Impact Loading on Microstructure

4.3. Challenges of Deep Mining Operations Under High-Temperature Conditions

5. Conclusions

- (1)

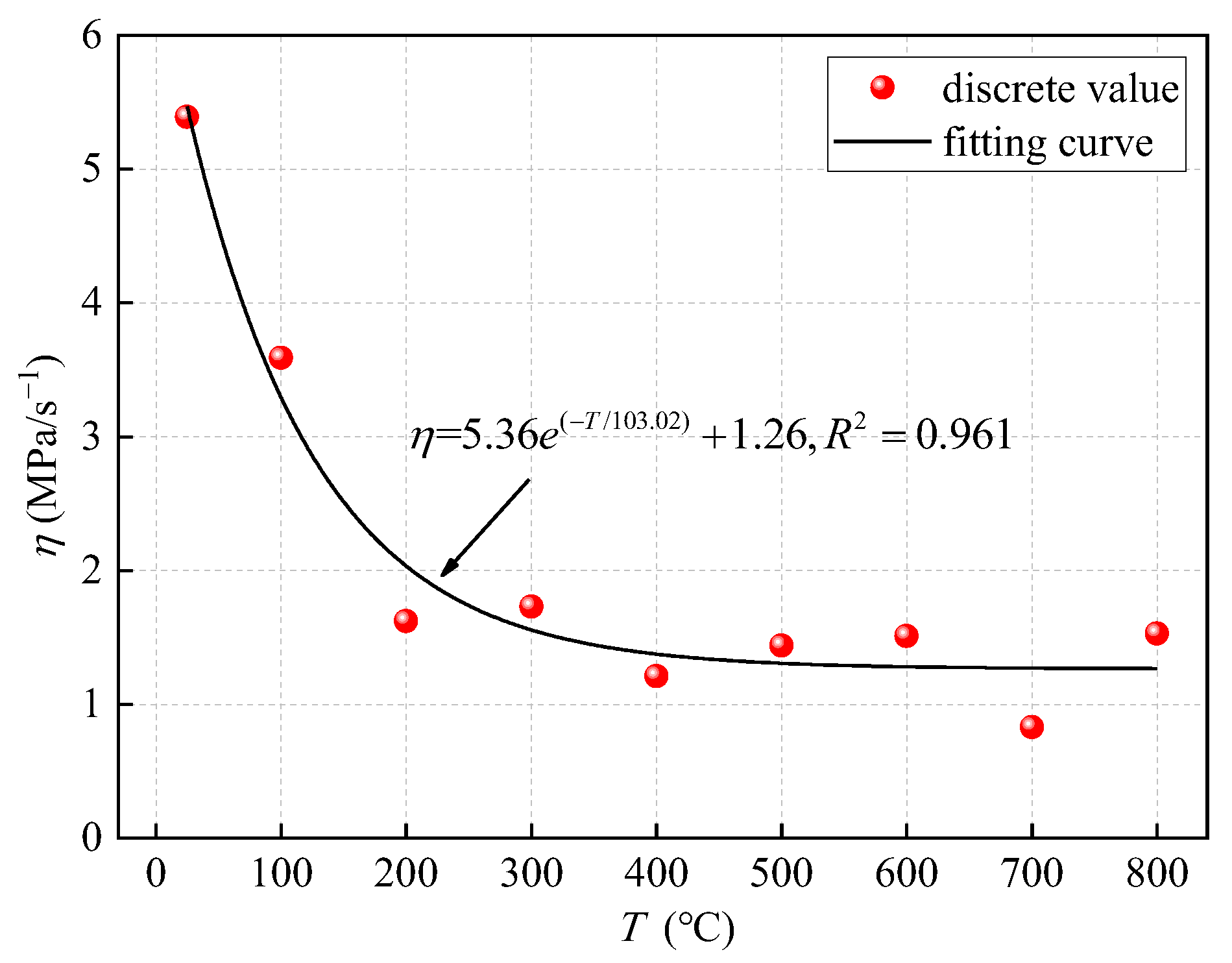

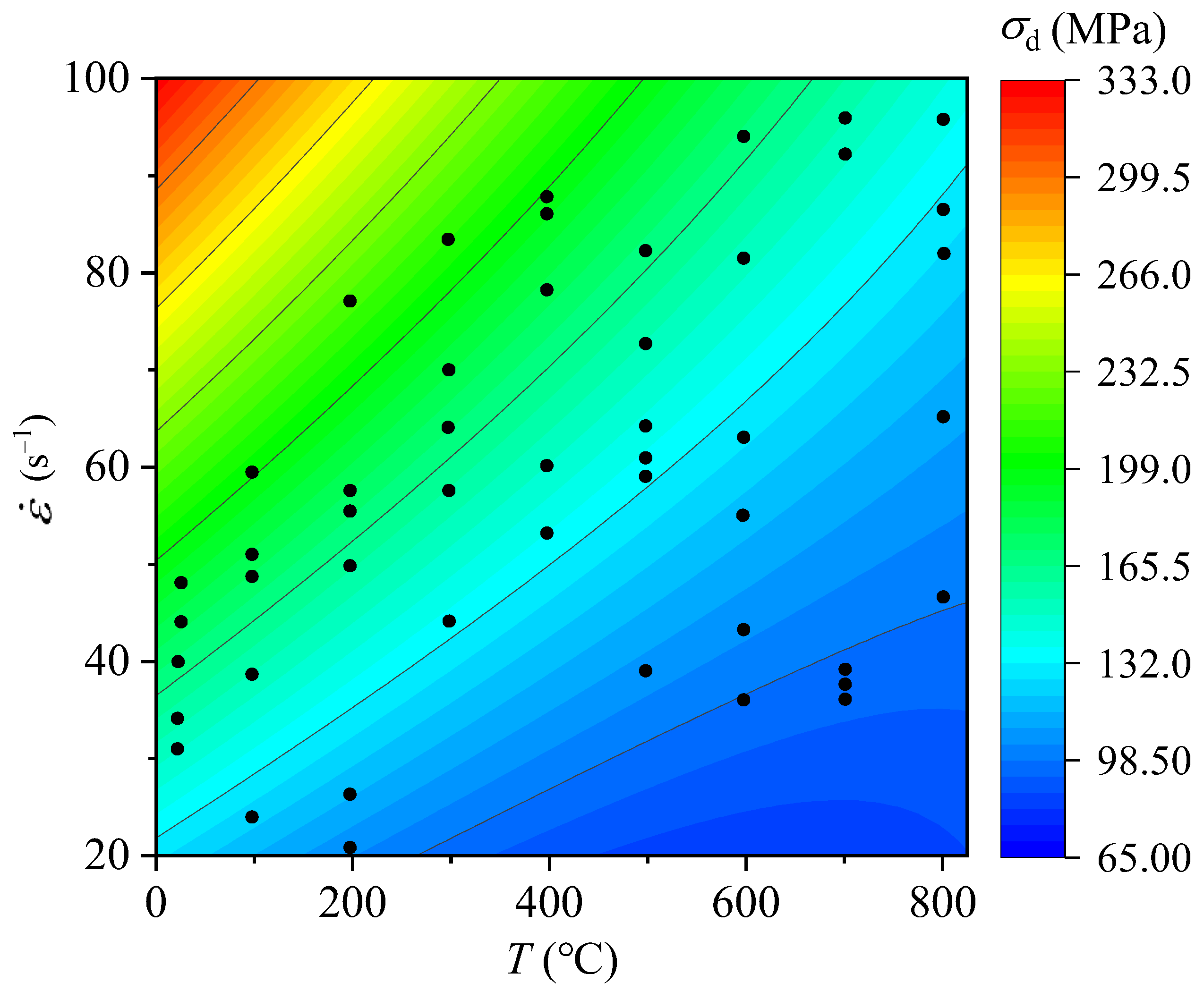

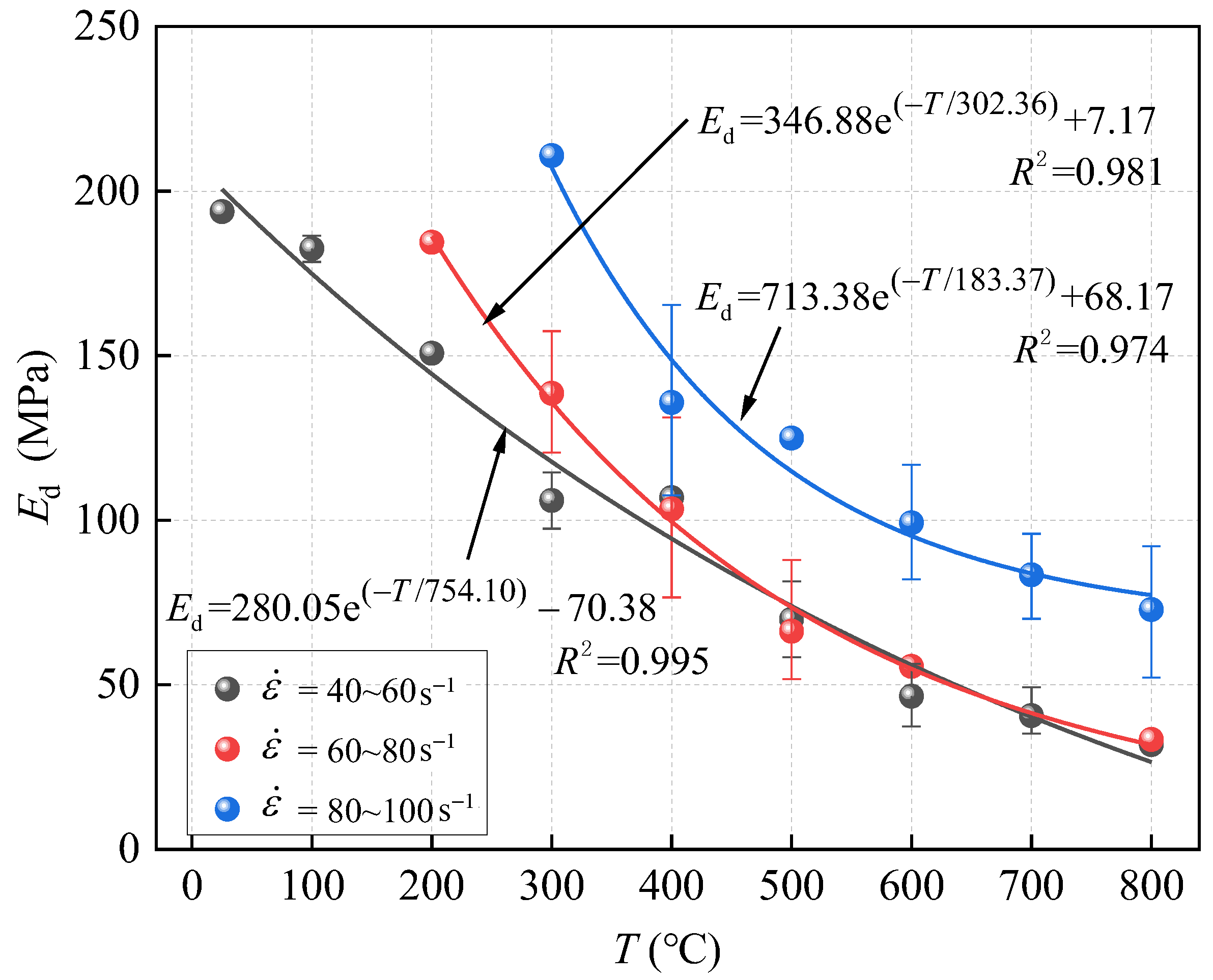

- Under the coupling effect of real-time temperature and impact loading, the dynamic stress–strain curve of the limestone specimen has no evident compaction stage, while the strain rate demonstrates a nearly linear correlation with the impact velocity across different temperatures. As the temperature increases, the dynamic compressive strength of the limestone specimen decreases linearly at a rate of 0.15 MPa/°C within the strain rate interval of 40–60 s−1, 60–80 s−1, and 80–100 s−1. Additionally, a negative exponential nonlinear relationship is established to describe the variation of elastic modulus with temperature.

- (2)

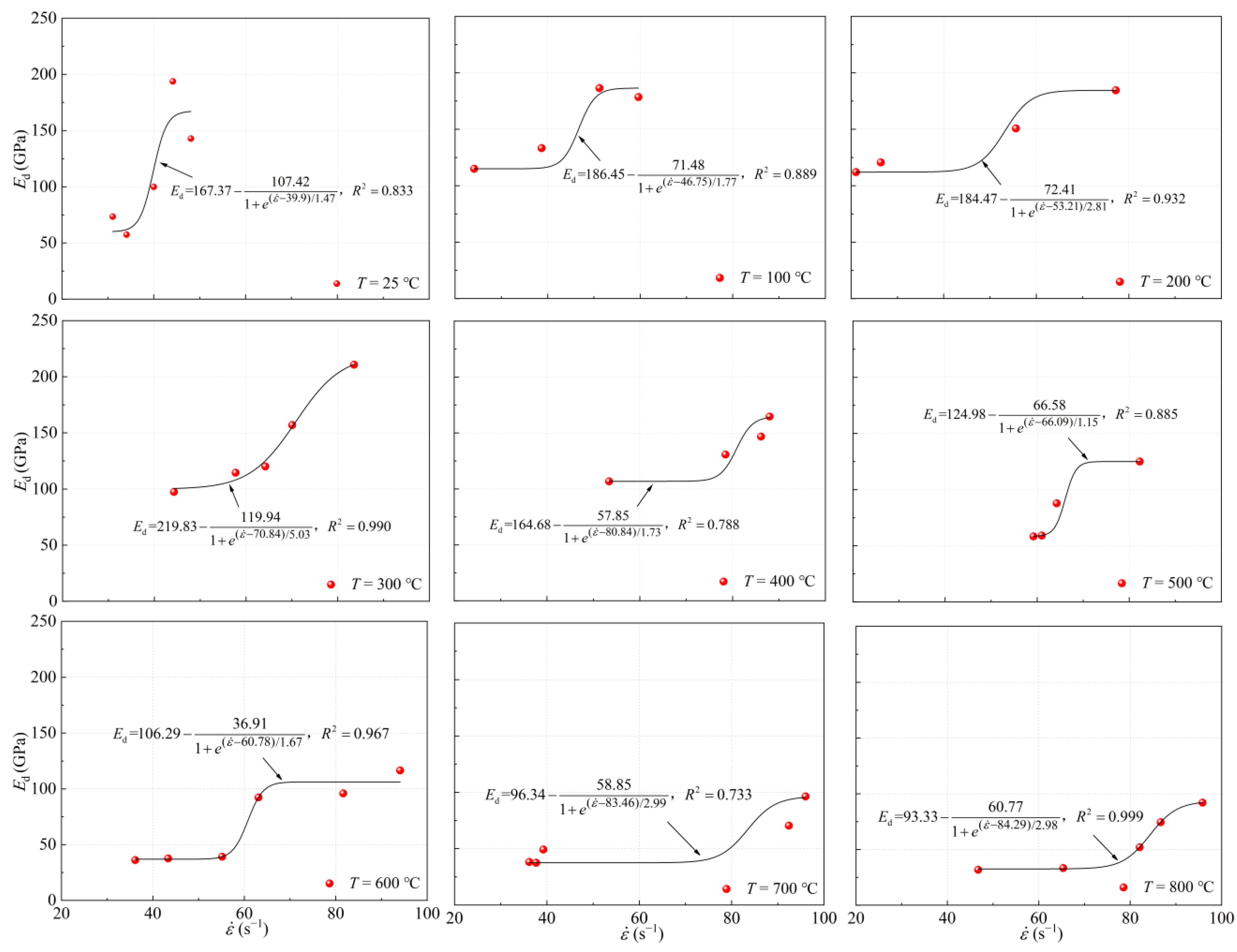

- The dynamic compressive strength increases linearly with strain rate at different temperature ranges of 25–800 °C. The temperature sensitivity coefficient η is defined to quantify the influence of temperature on the variation of dynamic compressive strength with strain rate, and a quantitative relationship is established accordingly. Moreover, the correlation between dynamic elastic modulus and strain rate can be characterized by a Boltzmann function. The macroscopic fracture characteristics of the limestone specimen under real-time temperature and the impact load are also obtained.

- (3)

- The real-time high temperature leads to a decrease in dolomite content and an increase in calcite content due to the thermal decomposition of dolomite, resulting in a significant reduction in the mechanical properties of the limestone specimen. With the increasing real-time temperature, the number of micro-cracks on the fracture surface of the specimen under impact loading is greater, the crack width is wider, and the breakage degree is higher. As a result, the fracture characteristics of the calcite mineral components change from brittle failure to brittle–ductility failure. The action mechanism of real-time high temperatures on the physical and chemical properties of limestone can be categorized into three characteristics: physical reinforcement, physical degradation, and physical and chemical deterioration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.P.; Gao, M.Z.; Zhang, R.; Peng, G.Y.; Wang, W.Y.; Li, A.Q. Study on the mechanical properties and mechanical response of coal mining at 1000 m or deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Chandelle, V.; Jacquemin, C.; Létolle, R.; Mostade, M.; Pirard, J.P.; Somers, Y. Underground coal gasification on the Thulin site: Results of analysis from post-burn drillings. Fuel 1993, 72, 949–963. [Google Scholar] [CrossRef]

- Perkins, G. Underground coal gasification—Part II: Fundamental phenomena and modeling. Prog. Energy Combust. Sci. 2018, 67, 234–274. [Google Scholar] [CrossRef]

- Sygała, A.; Bukowska, M.; Janoszek, T. High temperature versus geomechanical parameters of selected rocks–the present state of research. J. Sust. Min. 2013, 12, 45–51. [Google Scholar] [CrossRef]

- Tomas, R.; Cano, M.; Pulgarin, L.F.; Brotons, V.; Benavente, D.; Miranda, T.; Vasconcelos, G. Thermal Effect of High Temperatures on the Physical and Mechanical Properties of a Granite Used in UNESCO World Heritage Sites in North Portugal. J. Build. Eng. 2021, 43, 102823. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Viete, D.R.; Chen, B.J.; Perera, M.S.A. Transformation plasticity and the effect of temperature on the mechanical behaviour of Hawkesbury sandstone at atmospheric pressure. Eng. Geol. 2012, 151, 120–127. [Google Scholar]

- Wagner, H. Deep mining: A rock engineering challenge. Rock Mech. Rock Eng. 2019, 52, 1417–1446. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Determination of the Extent of the Rock Destruction Zones around a Gasification Channel on the Basis of Strength Tests of Sandstone and Claystone Samples Heated at High Temperatures up to 1200 °C and Exposed to Water. Energies 2021, 14, 6464. [Google Scholar] [CrossRef]

- Hokka, M.; Black, J.; Tkalich, D. Effects of strain rate and confining pressure on the compressive behavior of kuru granite. Int. J. Impact Eng. 2016, 91, 183–193. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H.; Tian, W.L.; Yin, P.F.; Jing, H.W. Effect of high temperature on deformation failure behavior of granite specimen containing a single fissure under uniaxial compression. Rock Mech. Rock Eng. 2019, 52, 2087–2107. [Google Scholar] [CrossRef]

- Heuze, F.E. High-temperature mechanical, physical and thermal properties of granitic rocks—A review. Int. J. Rock Mech. Min. Sci. 1983, 20, 3–10. [Google Scholar] [CrossRef]

- Mao, R.; Mao, X.; Zhang, L.; Liu, R. Effect of loading rates on the characteristics of thermal damage for mudstone under different temperatures. Int. J. Min. Sci. Technol. 2015, 25, 797–801. [Google Scholar] [CrossRef]

- Yin, T.B.; Shu, R.H.; Li, X.B.; Wang, P.; Liu, X.L. Comparison of mechanical properties in high temperature and thermal treatment granite. Trans. Nonferrous Met. Soc. China 2016, 26, 1926–1937. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Derek, E.; Wang, J.G.; Fan, L.F. An experimental study of effect of high temperature on the permeability evolution and failure response of granite under triaxial compression. Rock Mech. Rock Eng. 2020, 53, 4403–4427. [Google Scholar] [CrossRef]

- Kahraman, E. Investigation of the Effects of Two Different Cooling Treatments on the Physico-Mechanical and Microstructural Properties of Granite after High Temperatures. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 142. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J. An experimental study on the physico-mechanical properties of two post-high-temperature rocks. Eng. Geol. 2015, 185, 63–70. [Google Scholar] [CrossRef]

- Wang, F.; Konietzky, H.; Fruehwirt, T.; Dai, Y. Laboratory Testing and Numerical Simulation of Properties and Thermal-Induced Cracking of Eibenstock Granite at Elevated Temperatures. Acta Geotech. 2020, 15, 2259–2275. [Google Scholar] [CrossRef]

- Wang, Z.; He, A.; Shi, G.; Mei, G. Temperature effect on AE energy characteristics and damage mechanical behaviors of granite. Int. J. Geomech. 2017, 18, 04017163. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, M.W.; Han, L.J.; Pu, H.; Chen, Y.L. Experimental research on the influence of loading rate on the mechanical properties of limestone in a high-temperature state. Bull. Eng. Geol. Environ. 2019, 78, 3479–3492. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Mao, X.B.; Li, M.; Li, B.; Liu, R.X.; Lu, A.H. Brittle–ductile transition of mudstone in coal measure rock strata under high temperature. Int. J. Geomech. 2020, 20, 04019149. [Google Scholar] [CrossRef]

- Isaka, B.L.A.; Gamage, R.P.; Rathnaweera, T.D.; Perera, M.S.A.; Chandrasekharam, D.; Kumari, W.G.P. An Influence of Thermally-Induced Micro-Cracking under Cooling Treatments: Mechanical Characteristics of Australian Granite. Energies 2018, 11, 1338. [Google Scholar] [CrossRef]

- Hu, J.J.; Xie, H.P.; Sun, Q.; Li, C.B.; Liu, G.K. Changes in the thermos dynamic properties of alkaline granite after cyclic quenching following high temperature action. Int. J. Min. Sci. Technol. 2021, 31, 843–852. [Google Scholar] [CrossRef]

- Xia, K.W.; Wang, S.; Xu, Y.; Chen, R.; Wu, B.B. Advances in experimental studies for deep rock dynamics. Chin. J. Rock Mech. Eng. 2021, 40, 448–474. [Google Scholar]

- Yan, Z.L.; Dai, F.; Liu, Y.; Li, Y.Z.; You, W. Experimental investigation of pre-flawed rocks under combined static-dynamic loading: Mechanical responses and fracturing characteristics. Int. J. Mech. Sci. 2021, 211, 106755. [Google Scholar] [CrossRef]

- Li, X.B.; Gong, F.Q.; Tao, M.; Dong, L.J.; Du, K.; Ma, C.D.; Zhou, Z.L.; Yin, T.B. Failure mechanism and coupled static-dynamic loading theory in deep hard rock mining: A review. J. Rock Mech. Geotech. Eng. 2017, 9, 767–782. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef]

- Zhao, G.M.; Xie, L.X.; Meng, X.R. A damage-based constitutive model for rock under impacting load. Int. J. Min. Sci. Technol. 2014, 24, 505–511. [Google Scholar] [CrossRef]

- Millon, O.; Ruiz-Ripoll, M.L.; Hoerth, T. Analysis of the Behavior of Sedimentary Rocks Under Impact Loading. Rock Mech. Rock Eng. 2016, 49, 4257–4272. [Google Scholar] [CrossRef]

- Li, J.C.; Rong, L.F.; Li, H.B.; Hong, S.N. An SHPB test study on stress wave energy attenuation in jointed rock masses. Rock Mech. Rock Eng. 2019, 52, 403–420. [Google Scholar] [CrossRef]

- Wang, P.; Yin, T.B.; Li, X.B.; Zhang, S.S.; Bai, L. Dynamic Properties of thermally treated granite subjected to cyclic impact loading. Rock Mech. Rock Eng. 2019, 52, 991–1010. [Google Scholar] [CrossRef]

- Zhou, X.P.; Wang, Y.T.; Qian, Q.H. Numerical simulations of failure characteristics of rock materials under blasting loads using the conjugated bond-pair-based peri dynamics. Sci. Sin. Phys. Mech. Astron. 2020, 50, 024607. (In Chinese) [Google Scholar] [CrossRef]

- Ai, D.H.; Zhao, Y.C.; Wang, Q.F.; Li, C.W. Crack propagation and dynamic properties of coal under SHPB impact loading: Experimental investigation and numerical simulation. Theor. Appl. Fract. Mec. 2022, 105, 10239. [Google Scholar] [CrossRef]

- Kong, X.G.; Wang, E.Y.; Li, S.G.; Lin, H.F.; Zhang, Z.B.; Ju, Y.Q. Dynamic mechanical characteristics and fracture mechanism of gas-bearing coal based on SHPB experiments. Theor. Appl. Fract. Mec. 2020, 105, 102395. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.Z.; Zhou, J.; Li, E.M.; Qiu, P.Y.; Gou, Y.G. High strain rate compressive strength behavior of cemented paste backfill using split Hopkinson pressure bar. Int. J. Min. Sci. Technol. 2021, 31, 387–399. [Google Scholar] [CrossRef]

- Yin, T.B.; Jin, F.Y.; Li, Q.; Li, X.B. Effects of microwave radiation on dynamic compressive properties of basalt. Trans. Nonferrous Met. Soc. China 2022, 32, 3388–3403. [Google Scholar] [CrossRef]

- Meng, Y.F.; Yang, Y.T.; Wang, W.B.; Dou, Q.B.; Suo, T. A new technique for performing tortional split Hopkinson bar experiments at high temperatures. Int. J. Impact Eng. 2022, 168, 104314. [Google Scholar] [CrossRef]

- Zhou, X.P.; Gu, S.Y. Dynamic mechanical properties and cracking behaviours of persistent fractured granite under impact loading with various loading rates. Theor. Appl. Fract. Mec. 2022, 118, 103281. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Jing, H.W.; Wu, J.Y.; Shi, X.S.; Gao, Y.; Yin, Q. Experimental investigation on damage characteristics and fracture behaviors of granite after high temperature exposure under different strain rates. Theor. Appl. Fract. Mec. 2020, 110, 102823. [Google Scholar] [CrossRef]

- Tian, W.L.; Yang, S.Q.; Elsworth, D.; Wang, J.G.; Li, X.Z. Permeability evolution and crack characteristics in granite under treatment at high temperature. Int. J. Rock. Mech. Min. 2020, 134, 104461. [Google Scholar] [CrossRef]

- Fan, L.F.; Yang, K.C.; Wang, M.; Wang, L.J.; Wu, Z.J. Experimental study on wave propagation through granite after high temperature treatment. Int. J. Rock. Mech. Min. 2021, 148, 104946. [Google Scholar] [CrossRef]

- Kong, X.X.; Lu, H.F.; Liu, C.Y.; Zhao, B.L. Experimental study on precursor characteristics of rock failure based on strain and temperature changes. Case Stud. Therm. Eng. 2023, 41, 102632. [Google Scholar] [CrossRef]

- Yuan, S.H.; Sun, Q.; Li, P.F.; Geng, J.S.; Zhang, H. Fracture properties and dynamic failure of three-point bending of yellow sandstone after subjected to high temperature conditions. Eng. Fract. Mech. 2022, 265, 108366. [Google Scholar] [CrossRef]

- Zhang, R.R.; Yang, Y.; Ma, D.D.; Ping, Q. Experimental study on effect of freeze-thaw cycles on dynamic mode-Ι fracture properties and microscopic damage evolution of sandstone. Eng. Fract. Mech. 2023, 279, 109043. [Google Scholar] [CrossRef]

- Zhou, C.T.; Xie, H.; Zhu, J.B.; Zhou, T. Failure criterion considering high temperature treatment for rocks from a micromechanical perspective. Theor. Appl. Fract. Mec. 2022, 118, 103226. [Google Scholar] [CrossRef]

- Pathiranagei, S.V.; Gratchev, I.; Sokolowski, K.A. Investigation of the Microstructura1 Characteristics of Heated Sandstone by Micro Computed Tomography Technique. Environ. Earth Sci. 2022, 81, 401. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J. Effect of strain rate on the dynamic compressive mechanical behaviors of rock material subjected to high temperatures. Mech. Mater. 2015, 82, 28–38. [Google Scholar] [CrossRef]

- Johnson, S.E.; Song, W.J.; Cook, A.C.; Vel, S.S.; Gerbi, C.C. The Quartz A↔β Phase Transition: Does It Drive Damage and Reaction in Continental Crust? Earth Planet. Sci. Lett. 2021, 553, 116622. [Google Scholar] [CrossRef]

- Xu, J.H.; Kang, Y.; Wang, Z.F.; Wang, X.C.; Zeng, D.P.; Su, D.F. Dynamic Mechanical Behavior of Granite under the Effects of Strain Rate and Temperature. Int. J. Geomech. 2020, 20, 04019177. [Google Scholar] [CrossRef]

- Ping, Q.; Su, H.P.; Ma, D.D.; Zhang, H.; Zhang, C.L. Experimental study on physical and dynamic mechanical properties of limestone after different high temperature treatments. Rock Soil Mech. 2021, 42, 932–942. (In Chinese) [Google Scholar]

- Wang, Z.L.; Shi, H.; Wang, J.G. Mechanical behavior and damage constitutive model of granite under coupling of temperature and dynamic loading. Rock Mech. Rock Eng. 2018, 51, 3045–3059. [Google Scholar] [CrossRef]

- Samtani, M.; Dollimore, D.; Wilburn, F.W.; Alexander, K. Isolation and identification of the intermediate and final products in the thermal decomposition of dolomite in an atmosphere of carbon dioxide. Thermochim. Acta 2001, 367, 285–295. [Google Scholar] [CrossRef]

- Zhao, W.Z.; Liu, Z.G.; Pan, P.Z. Crystalline Mineral Petrology; China Shanghai Scientific and Technical Publishers: Shanghai, China, 1960; pp. 198–201. [Google Scholar]

- Kong, L.Y.; Ostadhassan, M.; Hou, X.D.; Mann, M.; Li, C.X. Microstructure characteristics and fractal analysis of 3D-printed sandstone using micro-CT and SEM-EDS. J. Petrol. Sci. Eng. 2019, 175, 1039–1048. [Google Scholar] [CrossRef]

- Das, D.; Mishra, B.; Gupta, N. Understanding the influence of petrographic parameters on strength of differently sized shale specimens using XRD and SEM. Int. J. Min. Sci. Techno 2021, 31, 953–961. [Google Scholar] [CrossRef]

- Blinderman, M.S. Global Development of Commercial Underground Coal Gasification. IOP Conf. Ser. Earth Environ. Sci. 2017, 76, 012003. [Google Scholar] [CrossRef]

- Yang, D.; Koukouzas, N.; Green, M.; Sheng, Y. Recent Development on Underground Coal Gasification and Subsequent CO2 Storage. J. Energy Inst. 2016, 89, 469–484. [Google Scholar] [CrossRef]

- Mahanta, B.; Vishal, V.; Ranjith, P.G.; Singh, T.N. An Insight into Pore-Network Models of High-Temperature Heat-Treated Sandstones Using Computed Tomography. J. Nat. Gas. Sci. Eng. 2020, 77, 103227. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Lin, G.; Zhang, L.; Yu, H.; Di, K. Study on Dynamic Mechanical Properties and Failure Mechanism of Sandstones under Real-Time High Temperature. Geofluids 2021, 2021, e9628675. [Google Scholar] [CrossRef]

| T = 25 °C | T = 100 °C | T = 200 °C |

|---|---|---|

|  |  |

| T = 300 °C | T = 400 °C | T = 500 °C |

|  |  |

| T = 600 °C | T = 700 °C | T = 800 °C |

|  |  |

| T | Macro-Fracture Characteristics | |||

|---|---|---|---|---|

| V = 6.0–7.0 m/s | V = 7.0–8.0 m/s | V = 8.0–9.0 m/s | V = 9.0–10.0 m/s | |

| 25 °C |  |  |  |  |

| 800 °C |  |  |  |  |

| Mechanical Parameter | Strain Rate (s−1) | Temperatures (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | ||

| σd/MPa | 40~60 | 190.8 | 192.9 | 165.6 | 142.1 | 129.8 | 119.9 | 106.7 | 103.4 | 72.1 |

| 60~80 | - | - | 197.1 | 173.1 | 160.7 | 140.5 | 152.1 | - | 92.7 | |

| 80~100 | - | - | - | 205.7 | 180.5 | 182.6 | 178.5 | 145.1 | 138.1 | |

| Ed/GPa | 40~60 | 193.9 | 182.6 | 150.9 | 105.8 | 106.9 | 69.8 | 46.2 | 40.9 | 31.7 |

| 60~80 | - | - | 183.7 | 138.6 | 103.1 | 65.6 | 55.9 | - | 32.8 | |

| 80~100 | - | - | - | 209.9 | 135.3 | 125.1 | 99.4 | 83.3 | 72.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Li, B.; Wu, P.; Guo, S.; Zheng, Y.; Li, M.; Zhu, F. Experimental Study on the Dynamic Mechanical Properties and Crashing Behaviors of Limestone Under High Temperatures in Real-Time. Appl. Sci. 2024, 14, 10486. https://doi.org/10.3390/app142210486

Zhang L, Li B, Wu P, Guo S, Zheng Y, Li M, Zhu F. Experimental Study on the Dynamic Mechanical Properties and Crashing Behaviors of Limestone Under High Temperatures in Real-Time. Applied Sciences. 2024; 14(22):10486. https://doi.org/10.3390/app142210486

Chicago/Turabian StyleZhang, Lianying, Bing Li, Peng Wu, Shiru Guo, Yadong Zheng, Ming Li, and Fuqiang Zhu. 2024. "Experimental Study on the Dynamic Mechanical Properties and Crashing Behaviors of Limestone Under High Temperatures in Real-Time" Applied Sciences 14, no. 22: 10486. https://doi.org/10.3390/app142210486

APA StyleZhang, L., Li, B., Wu, P., Guo, S., Zheng, Y., Li, M., & Zhu, F. (2024). Experimental Study on the Dynamic Mechanical Properties and Crashing Behaviors of Limestone Under High Temperatures in Real-Time. Applied Sciences, 14(22), 10486. https://doi.org/10.3390/app142210486