Dynamic Energy Management Strategy of a Solar-and-Energy Storage-Integrated Smart Charging Station

Abstract

:1. Introduction

- Introducing a novel dynamic EMS for charging stations integrating solar energy and ESSs, with simulation and analysis based on the actual situation in Taiwan.

- Confirming the multiple benefits of ESSs in contracted capacity management, peak shaving, and energy arbitrage.

- Demonstrating that implementing the energy management strategy proposed in this paper can increase the overall net income, achieving 1.25 times the income compared to merely setting up a charging station.

2. Description

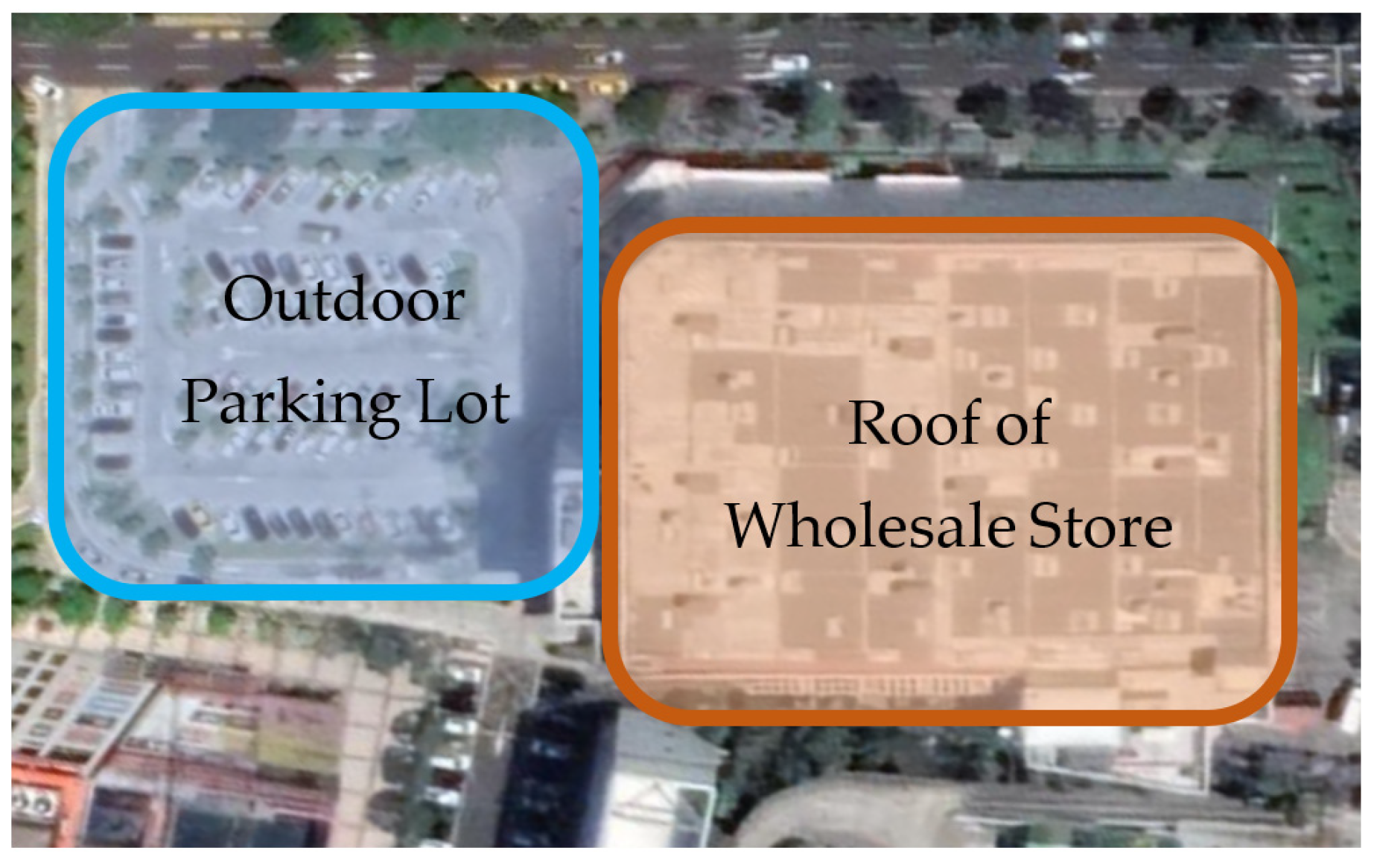

2.1. A Real-Wolrd Scenario

2.2. Taipower Electricity Tariff of EV Charging and Swapping Facility

3. The Integrated System of Photovoltaic Energy Storage and Fast Charging Station

3.1. System Structure and System Size

3.2. Energy Storage System

3.3. Supervisory Platform of EMS

- (1)

- Control and Supervision: This part is primarily responsible for the design of optimization and control strategies. It discerns varying operational messages from EVs based on time and allocates the power plans formulated for each time point to the battery, EVs, and grid interface.

- (2)

- Data Collection: Through an industrial computer, the charging station periodically retrieves system data, including power, voltage, phase angle, and charging and discharging times. Simultaneously, the computer also accesses information from the environmental service database, such as sunlight, ambient temperature, humidity, and wind speed. These data points are consolidated, stored, and transmitted to a cloud server for subsequent data processing.

- (3)

- Monitoring and Visualization: Through Human–Machine Interface (HMI) software, interaction and information exchange are facilitated between the system and users. This empowers users to monitor real-time information such as grid-supplied power, environmental conditions, power generated by photovoltaics (PV), profits, and costs via an intelligent panel. The control end collaborates in generating cumulative charts or tables at various time intervals (daily, weekly, monthly, and overall). Additionally, personalized settings are adjustable, encompassing language translation and the customization of EV charging preferences (e.g., fast charging or other special requirements).

- (4)

- Communication and Connectivity: The converter, EV supply equipment (EVSE), industrial computer, and intelligent panel are all linked to the backend server through Internet Protocol (IP) configuration. Communication is established via HTTP with any network client, enabling remote web services. Moreover, on-site sensors and other RS485 communication devices can potentially acquire data through wireless means.

4. Smart EMS Control

4.1. Dynamic Energy Management System Strategy

4.1.1. Off-Peak Daytime Hours (Summer 6:00–16:00/Non-Summer 6:00–15:00)

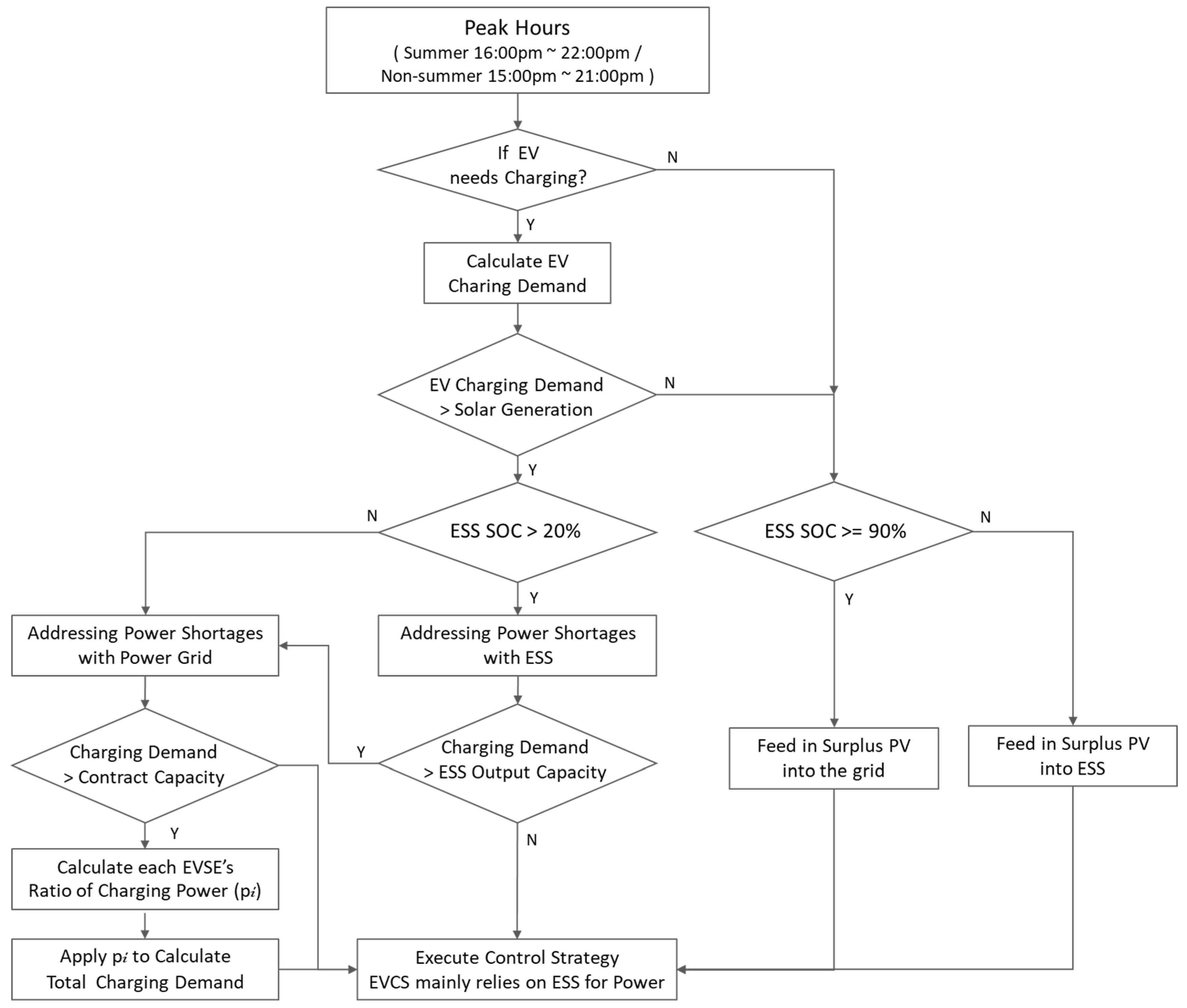

4.1.2. Peak Hours (Summer 16:00–22:00/Non-Summer 15:00–21:00)

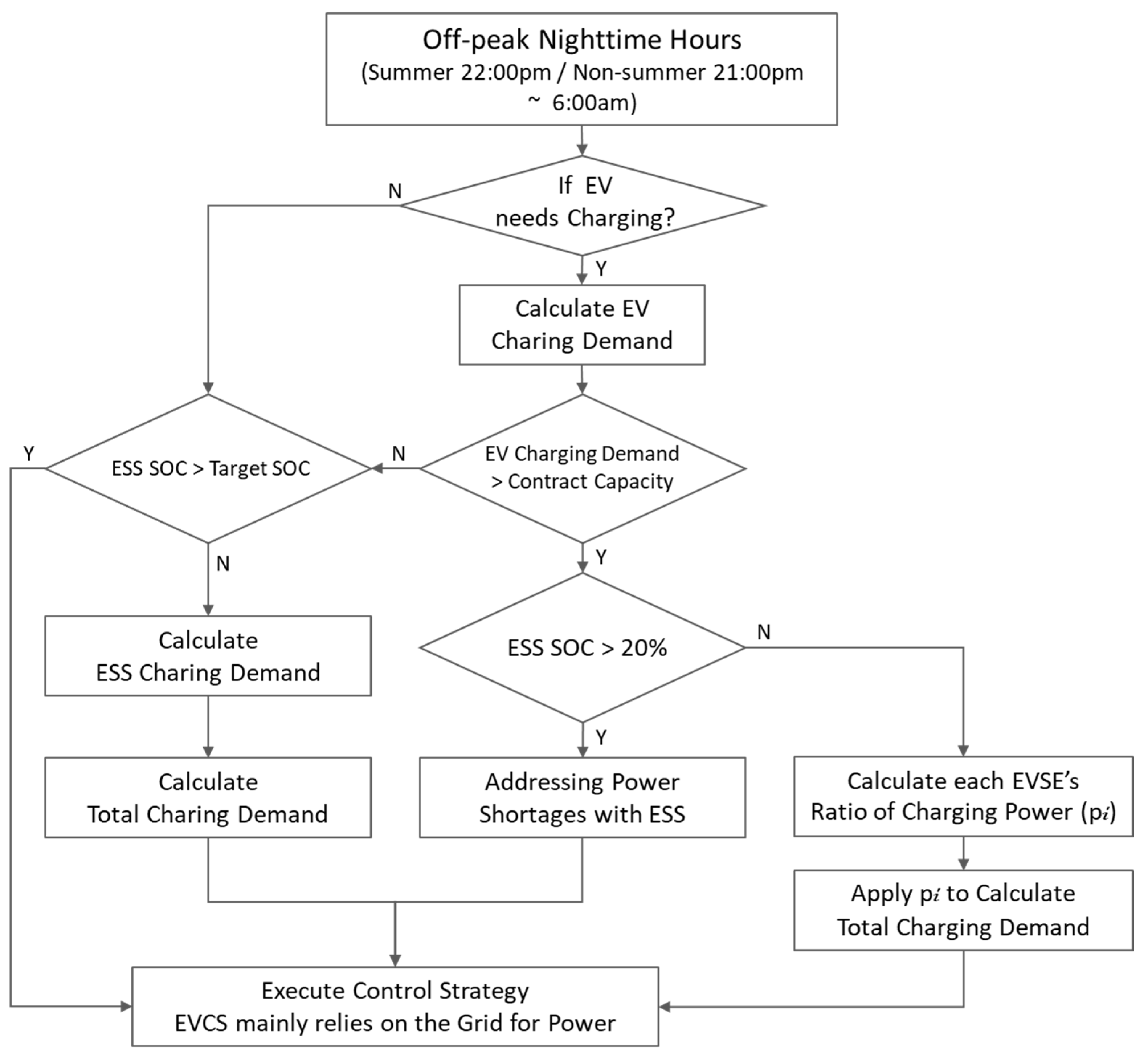

4.1.3. Off-Peak Nighttime Hours (Summer 22:00–6:00/Non-Summer 21:00–6:00)

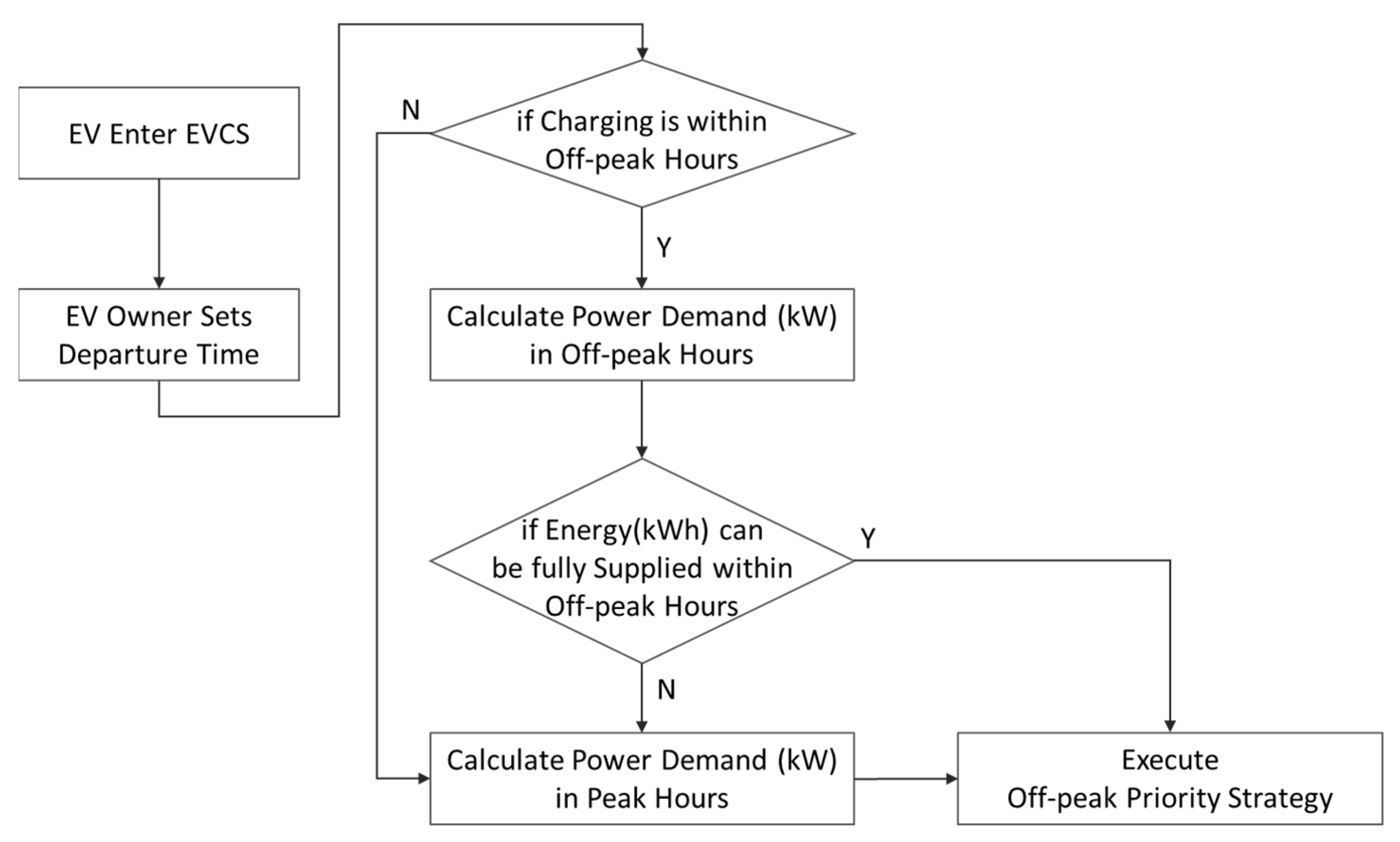

4.2. Off-Peak Priority Strategy

5. Simulation Inputs and Results

5.1. Simulation Inputs

5.1.1. PV Power Generation

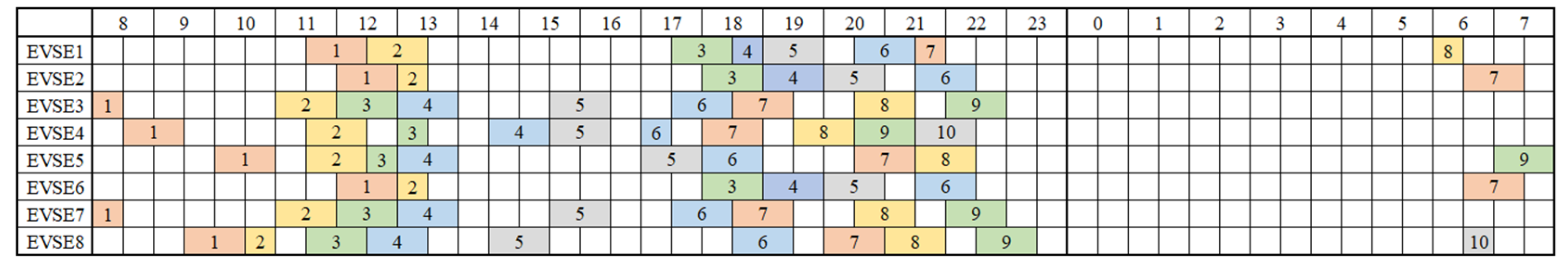

5.1.2. Charging Demand

5.1.3. Others

5.2. Simulation Results

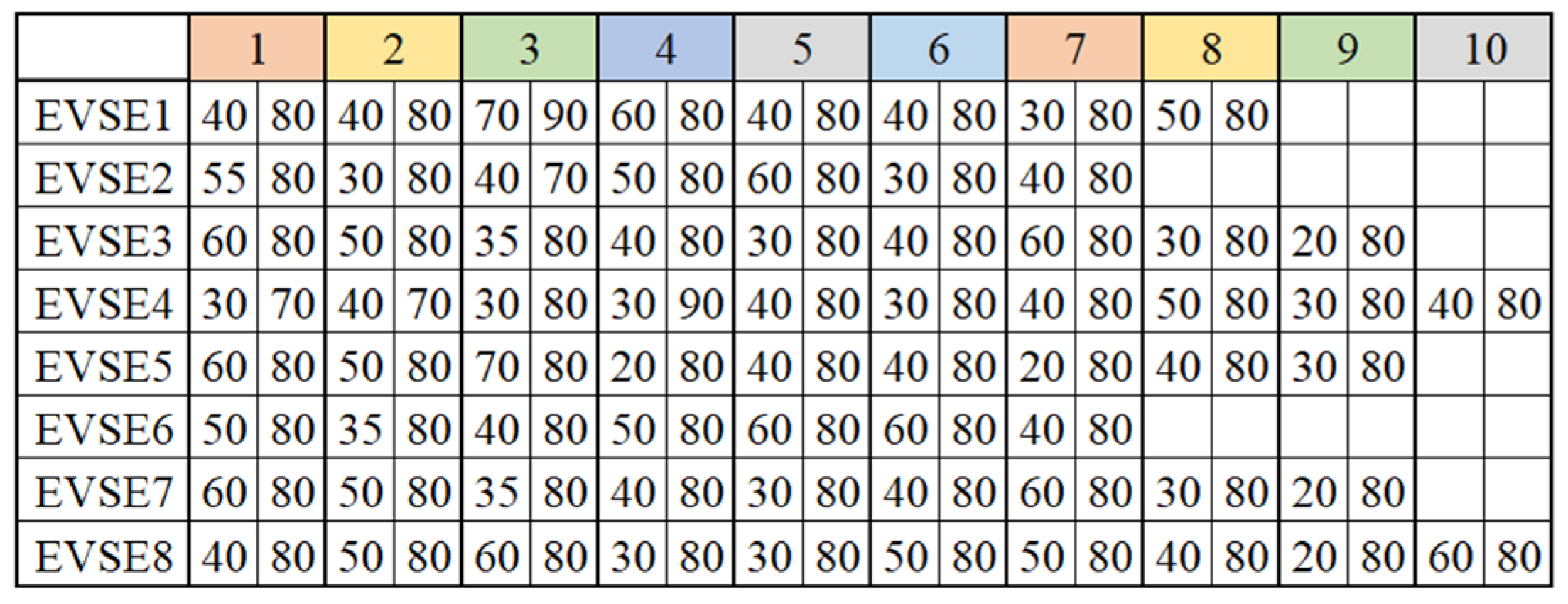

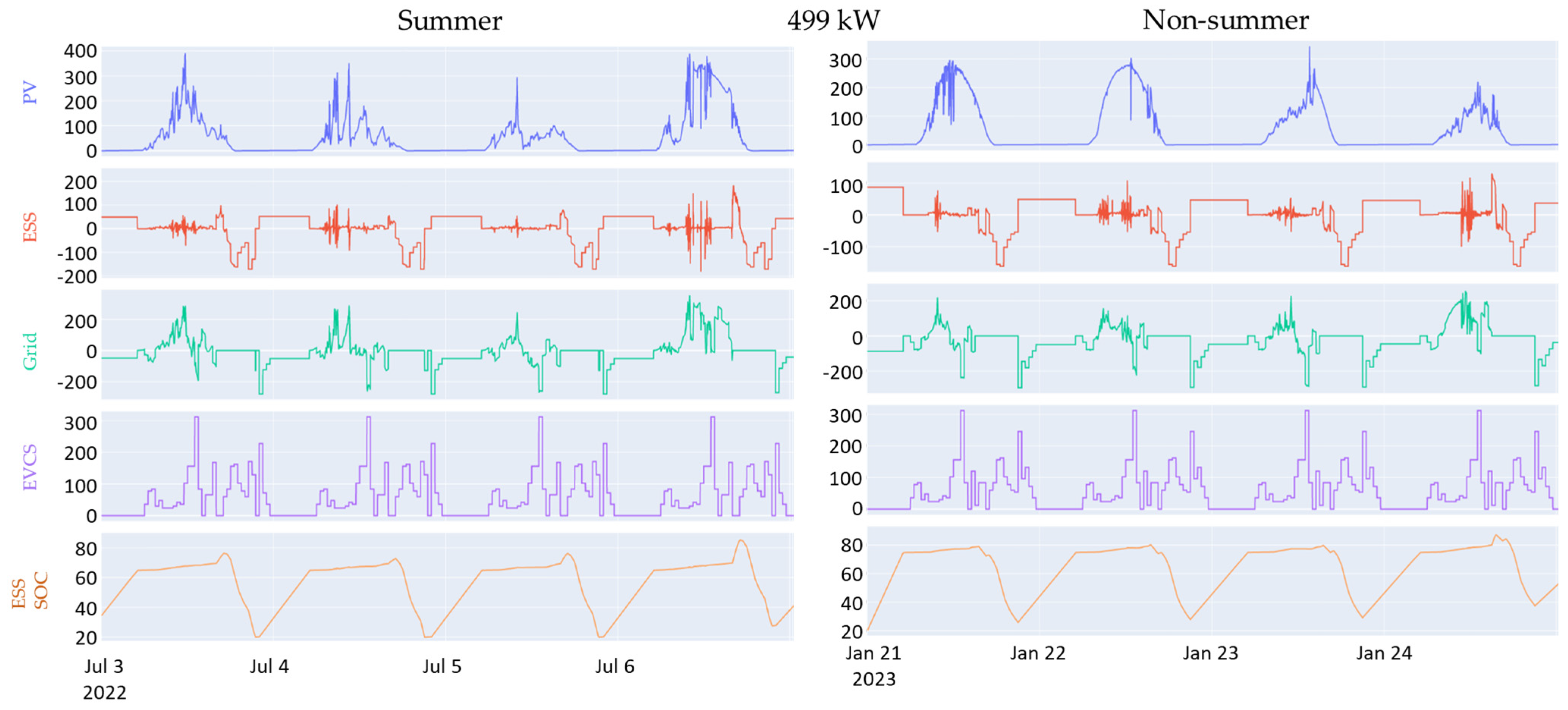

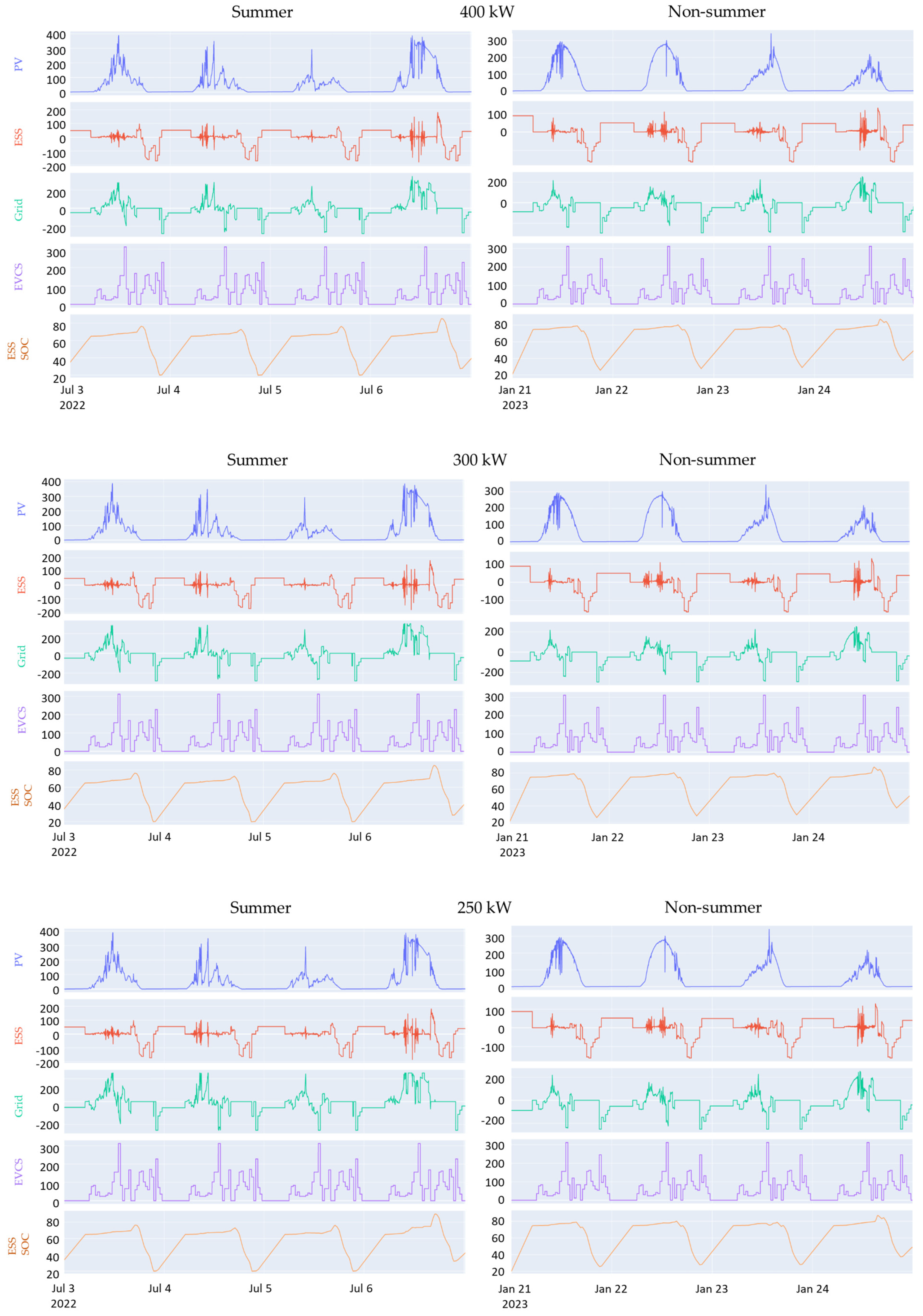

5.2.1. Charging Power Comparison—With and without Smart EMS

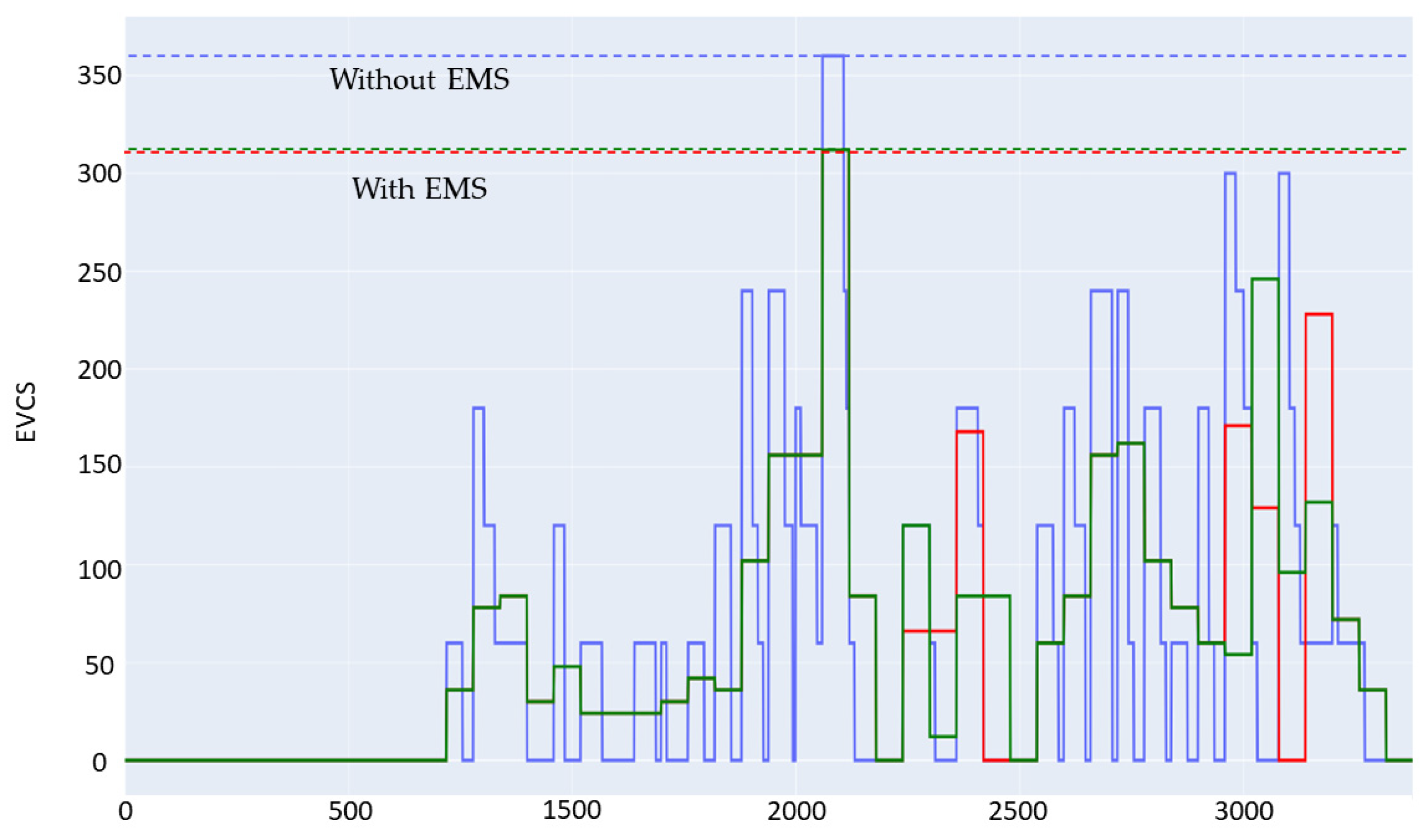

5.2.2. Charging Power Comparison—Off-Peak Priority Strategy

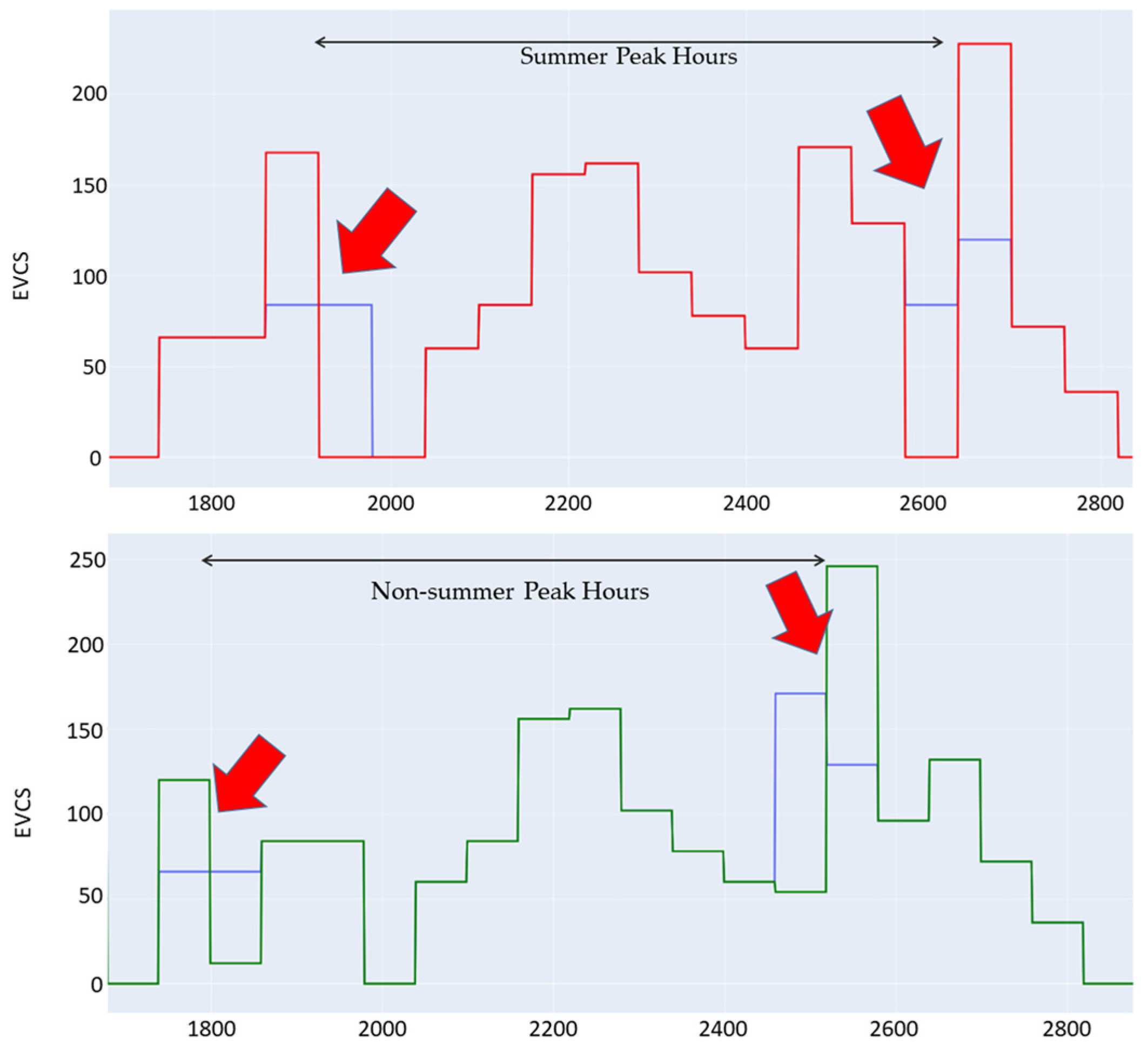

5.2.3. EVCS Operating Results under Different Contract Capacity

5.2.4. Operational Income of EVCS

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IEA. CO2 Emissions in 2022, Paris. 2023. Available online: https://www.iea.org/reports/co2-emissions-in-2022 (accessed on 3 April 2023).

- IEA. Global EV Outlook 2023, Paris. 2023. Available online: https://www.iea.org/reports/global-ev-outlook-2023 (accessed on 16 May 2023).

- Razmjoo, A.; Ghazanfari, A.; Jahangiri, M.; Franklin, E.; Denai, M.; Marzband, M.; Astiaso Garcia, D.; Maheri, A. A Comprehensive Study on the Expansion of Electric Vehicles in Europe. Appl. Sci. 2022, 12, 11656. [Google Scholar] [CrossRef]

- Saldaña, G.; San Martin, J.I.; Zamora, I.; Asensio, F.J.; Oñederra, O. Electric vehicle into the grid: Charging methodologies aimed at providing ancillary services considering battery degradation. Energies 2019, 12, 2443. [Google Scholar] [CrossRef]

- Dang, Q. Electric vehicle (EV) charging management and relieve impacts in grids. In Proceedings of the 2018 9th IEEE International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Charlotte, NC, USA, 25–28 June 2018; pp. 1–5. [Google Scholar]

- Khalid, M.R.; Khan, I.A.; Hameed, S.; Asghar, M.S.J.; Ro, J.S. A Comprehensive Review on Structural Topologies, Power Levels, Energy Storage Systems, and Standards for Electric Vehicle Charging Stations and Their Impacts on Grid. IEEE Access 2021, 9, 128069–128094. [Google Scholar] [CrossRef]

- Kumar, M.; Panda, K.P.; Naayagi, R.T.; Thakur, R.; Panda, G. Comprehensive Review of Electric Vehicle Technology and Its Impacts: Detailed Investigation of Charging Infrastructure. Appl. Sci. 2023, 13, 8919. [Google Scholar] [CrossRef]

- Justo, J.J.; Mwasilu, F.; Lee, J.; Jung, J.-W. AC-microgrids versus DC-microgrids with distributed energy resources: A review. Renew. Sustain. Energy Rev. 2013, 24, 387–405. [Google Scholar] [CrossRef]

- Wang, D.; Locment, F.; Sechilariu, M. Modelling, Simulation, and Management Strategy of an Electric Vehicle Charging Station Based on a DC Microgrid. Appl. Sci. 2020, 10, 2053. [Google Scholar] [CrossRef]

- Kouka, K.; Masmoudi, A.; Abdelkafi, A.; Krichen, L. Dynamic energy management of an electric vehicle charging station using photovoltaic power. Sustain. Energy Grids Netw. 2020, 24, 100402. [Google Scholar] [CrossRef]

- Cheikh-Mohamad, S.; Sechilariu, M.; Locment, F. Real-Time Power Management Including an Optimization Problem for PV-Powered Electric Vehicle Charging Stations. Appl. Sci. 2022, 12, 4323. [Google Scholar] [CrossRef]

- Yap, K.Y.; Chin, H.H.; Klemeš, J.J. Solar Energy-Powered Battery Electric Vehicle charging stations: Current development and future prospect review. Renew. Sustain. Energy Rev. 2022, 169, 112862. [Google Scholar] [CrossRef]

- Robisson, B.; Guillemin, S.; Marchadier, L.; Vignal, G.; Mignonac, A. Solar Charging of Electric Vehicles: Experimental Results. Appl. Sci. 2022, 12, 4523. [Google Scholar] [CrossRef]

- The Energy Storage System Integrated with Photovoltaic Power Generation—Taiwan’s 2022 Bidding and Capacity Allocation Guidelines—MOEA (Ministry of Economic Affairs, R.O.C.). Available online: https://www.moeaea.gov.tw/ecw/populace/Law/Content.aspx?menu_id=20835 (accessed on 19 April 2023).

- Taipower Company Business Rules—Chapter 6 Power Supply Methods and Engineering-TPC (Taipower Company). Available online: https://www.taipower.com.tw/tc/page.aspx?mid=158 (accessed on 27 May 2023).

- Olivier, A.; Dessaint, L.A. Experimental validation of a battery dynamic model for EV applications. World Electr. Veh. J. 2009, 3, 289–298. [Google Scholar]

| Taipower Electricity Tariff | Summer (June–September) | Non- Summer (October–May) | |||||

|---|---|---|---|---|---|---|---|

| Basic | Charged by Household | Per Household Per Month | 262.50 | ||||

| Contract Capacity | Per kWh Per Month | 47.20 | 34.60 | ||||

| Variable | Monday to Friday | Peak | Summer | 16:00~22:00 | Per kWh | 8.35 | — |

| Non-summer | 15:00~21:00 | — | 8.13 | ||||

| Off-peak | Summer | 00:00~16:00 22:00~24:00 | 2.05 | 1.95 | |||

| Non-summer | 00:00~15:00 21:00~24:00 | ||||||

| Saturday, Sunday, and Holiday | All Day | ||||||

| ESS Power | ESS Capacity | Solar Installation Capacity | |

|---|---|---|---|

| Proportion of Configuration | 1.0 (kW) | 2.61 (kWh) | 1.5 (kW) |

| Installation Capacity | 300 kW | 800 kWh | 450 kW |

| Season | EVCS Setting | kWh/Cost | Contract Capacity | Basic Rate | Grid Supply | EVCS Demand | ESS Charging | PV for EV Charging | PV Fed in Grid |

|---|---|---|---|---|---|---|---|---|---|

| July 2022 Summer | Without EMS | kWh | 499 kW | - | 43,560.00 | 43,560.00 | - | - | - |

| $/kWh | 47.20 | - | 4.64 | 5.19 | - | - | - | ||

| Total Cost ($) | 23,552.80 | 262.50 | 202,131.00 | 225,946.30 | - | - | - | ||

| With EMS/ 499 kW | kWh | 499 kW | - | 19,251.54 | 43,560.00 | 14,597.78 | 26,003.38 | 34,789.52 | |

| $/kWh | 47.20 | - | 2.17 * | 4.79 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 23,552.80 | 262.50 | 41,783.58 | 209,010.35 | 55,000.00 | 88,411.48 | 118,284.35 | ||

| With EMS/ 400 kW | kWh | 400 kW | - | 19,251.54 | 43,560.00 | 14,597.78 | 26,003.38 | 34,789.52 | |

| $/kWh | 47.20 | - | 2.17 * | 4.69 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 18,880.00 | 262.50 | 41,783.58 | 204,337.55 | 55,000.00 | 88,411.48 | 118,284.35 | ||

| With EMS/ 300 kW | kWh | 300 kW | - | 19,249.33 | 43,560.00 | 14,598.93 | 26,002.24 | 34,758.95 | |

| $/kWh | 47.20 | - | 2.17 * | 4.58 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 14,160.00 | 262.50 | 41,779.06 | 199,609.18 | 55,000.00 | 88,407.63 | 118,180.42 | ||

| With EMS/ 250 kW | kWh | 250 kW | - | 18,868.16 | 43,560.00 | 14,755.03 | 29,880.81 | 33,916.46 | |

| $/kWh | 47.20 | - | 2.15 * | 4.80 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 11,800.00 | 262.50 | 40,478.53 | 209,135.79 | 55,000.00 | 101,594.76 | 115,315.96 | ||

| January 2023 non-summer | Without EMS | kWh | 499 kW | - | 43,560.00 | 43,560.00 | - | - | - |

| $/kWh | 34.60 | - | 4.44 | 4.84 | - | - | - | ||

| Total Cost ($) | 17,265.40 | 262.50 | 193,401.00 | 210,928.90 | - | - | - | ||

| With EMS/ 499 kW | kWh | 499 kW | - | 23,257.84 | 43,560.00 | 12,337.60 | 19,480.37 | 21,275.97 | |

| $/kWh | 34.60 | - | 1.95 * | 4.23 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 17,265.40 | 262.50 | 45,352.79 | 184,113.96 | 55,000.00 | 66,233.26 | 72,338.32 | ||

| With EMS/ 400 kW | kWh | 400 kW | - | 23,257.84 | 43,560.00 | 12,337.60 | 19,480.37 | 21,275.97 | |

| $/kWh | 34.60 | - | 1.95 * | 4.15 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 13,840.00 | 262.50 | 45,352.80 | 180,688.56 | 55,000.00 | 66,233.26 | 72,338.32 | ||

| With EMS/ 300 kW | kWh | 300 kW | - | 23,257.71 | 43,560.00 | 12,337.83 | 19,480.37 | 21,275.97 | |

| $/kWh | 34.60 | - | 1.95 * | 4.07 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 10,380.00 | 262.50 | 45,352.54 | 177,230.58 | 55,000.00 | 66,233.26 | 72,338.32 | ||

| With EMS/ 250 kW | kWh | 250 kW | - | 23,228.92 | 43,560.00 | 12,374.16 | 19,508.40 | 21,261.59 | |

| $/kWh | 34.60 | - | 1.95 * | 4.03 * | - | 3.40 | 3.40 | ||

| Total Cost ($) | 8650.00 | 262.50 | 45,296.39 | 175,537.47 | 55,000.00 | 66,328.58 | 72,289.39 |

| July 2022 Summer | January 2023 Non-Summer | |||||

|---|---|---|---|---|---|---|

| Contract Capacity | Electricity Sale | PV | EVCS | Electricity Sale | PV | EVCS |

| Without EMS | Electricity Sale (kWh) | - | 43,560.00 | Electricity Sale (kWh) | - | 43,560.00 |

| Price per kWh ($) | - | 9.00 | Price per kWh ($) | - | 9.00 | |

| Revenue ($) | - | 392,040.00 | Revenue ($) | - | 392,040.00 | |

| Net Income ($) | - | 166,093.70 | Net Income ($) | - | 181,111.10 | |

| Net Income per kWh ($) | - | 3.81 | Net Income per kWh ($) | - | 4.16 | |

| Total Net Income ($) | 166,093.70 | Total Net Income ($) | 181,111.10 | |||

| With EMS/ 499 kW | Electricity Sale (kWh) | 34,789.52 | 43,560.00 | Electricity Sale (kWh) | 21,275.98 | 43,560.00 |

| Price per kWh ($) | 3.90 | 9.00 | Price per kWh ($) | 3.90 | 9.00 | |

| Revenue ($) | 135,679.11 | 392,040.00 | Revenue ($) | 82,976.30 | 392,040.00 | |

| Net Income ($) | 17,394.76 | 183,029.65 | Net Income ($) | 10,637.99 | 207,926.04 | |

| Net Income per kWh ($) | 0.50 | 4.20 | Net Income per kWh ($) | 0.50 | 4.77 | |

| Total Net Income ($) | 200,424.41 | Total Net Income ($) | 218,564.03 | |||

| With EMS/ 400 kW | Electricity Sale (kWh) | 34,789.52 | 43,560.00 | Electricity Sale (kWh) | 21,275.98 | 43,560.00 |

| Price per kWh ($) | 3.90 | 9.00 | Price per kWh ($) | 3.90 | 9.00 | |

| Revenue ($) | 135,679.11 | 392,040.00 | Revenue ($) | 82,976.30 | 392,040.00 | |

| Net Income ($) | 17,394.76 | 187,702.45 | Net Income ($) | 10,637.99 | 211,351.44 | |

| Net Income per kWh ($) | 0.50 | 4.31 | Net Income per kWh ($) | 0.50 | 4.85 | |

| Total Net Income ($) | 205,097.21 | Total Net Income ($) | 221,989.43 | |||

| With EMS/ 300 kW | Electricity Sale (kWh) | 34,758.95 | 43,560.00 | Electricity Sale (kWh) | 21,275.98 | 43,560.00 |

| Price per kWh ($) | 3.90 | 9.00 | Price per kWh ($) | 3.90 | 9.00 | |

| Revenue ($) | 135,559.89 | 392,040.00 | Revenue ($) | 82,976.30 | 392,040.00 | |

| Net Income ($) | 17,379.47 | 192,430.82 | Net Income ($) | 10,637.99 | 214,809.42 | |

| Net Income per kWh ($) | 0.50 | 4.42 | Net Income per kWh ($) | 0.50 | 4.93 | |

| Total Net Income ($) | 209,810.29 | Total Net Income ($) | 225,447.41 | |||

| With EMS/ 250 kW | Electricity Sale (kWh) | 32,602.01 | 43,560.00 | Electricity Sale (kWh) | 21,261.59 | 43,560.00 |

| Price per kWh ($) | 3.90 | 9.00 | Price per kWh ($) | 3.90 | 9.00 | |

| Revenue ($) | 127,147.84 | 392,040.00 | Revenue ($) | 82,920.19 | 392,040.00 | |

| Net Income ($) | 16,958.23 | 182,904.21 | Net Income ($) | 10,630.79 | 216,502.53 | |

| Net Income per kWh ($) | 0.50 | 4.20 | Net Income per kWh ($) | 0.50 | 4.97 | |

| Total Net Income ($) | 199,862.44 | Total Net Income ($) | 227,133.33 | |||

| EVCS Configuration | Net Operational Income | |||

|---|---|---|---|---|

| July 2022 Summer | January 2023 Non-Summer | Sum | Profit Comparison | |

| Without EMS | 166,093.70 | 181,111.10 | 347,204.80 | 1.00 |

| With EMS/499 kW | 200,424.41 | 218,564.03 | 418,988.44 | 1.21 |

| With EMS/400 kW | 205,097.21 | 221,989.43 | 427,086.64 | 1.23 |

| With EMS/300 kW | 209,810.29 | 225,447.41 | 435,257.70 | 1.25 |

| With EMS/250 kW | 199,862.44 | 227,133.33 | 426,995.77 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, K.-Y.; Tai, T.-C.; Li, B.-H.; Kuo, C.-C. Dynamic Energy Management Strategy of a Solar-and-Energy Storage-Integrated Smart Charging Station. Appl. Sci. 2024, 14, 1188. https://doi.org/10.3390/app14031188

Wu K-Y, Tai T-C, Li B-H, Kuo C-C. Dynamic Energy Management Strategy of a Solar-and-Energy Storage-Integrated Smart Charging Station. Applied Sciences. 2024; 14(3):1188. https://doi.org/10.3390/app14031188

Chicago/Turabian StyleWu, Kuo-Yang, Tzu-Ching Tai, Bo-Hong Li, and Cheng-Chien Kuo. 2024. "Dynamic Energy Management Strategy of a Solar-and-Energy Storage-Integrated Smart Charging Station" Applied Sciences 14, no. 3: 1188. https://doi.org/10.3390/app14031188