Optimized Water Distillation Layout for Detritiation Purpose

Abstract

1. Introduction

2. The Heat Pump Assisted Distillation

3. Process Simulations

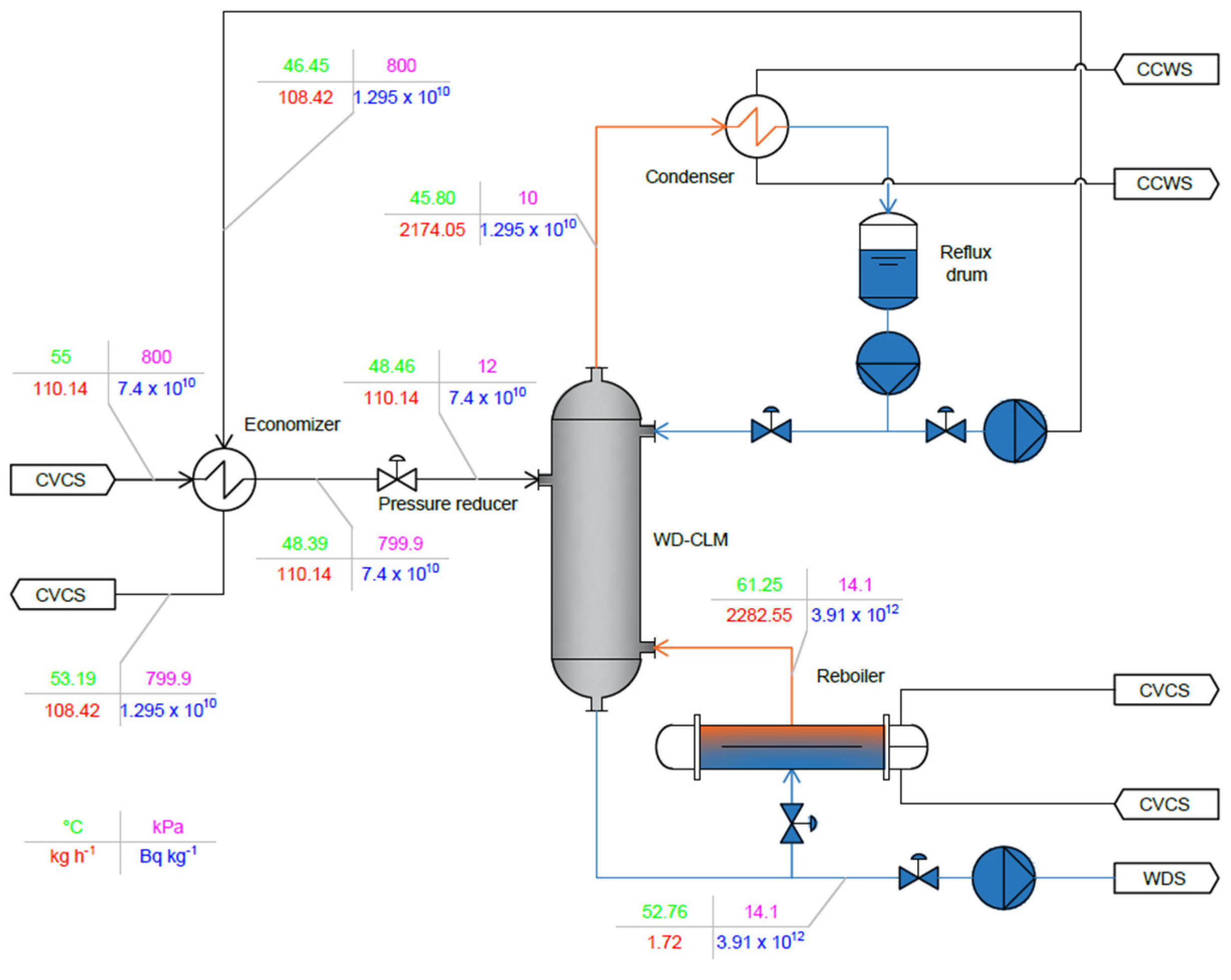

3.1. Standalone Distillation

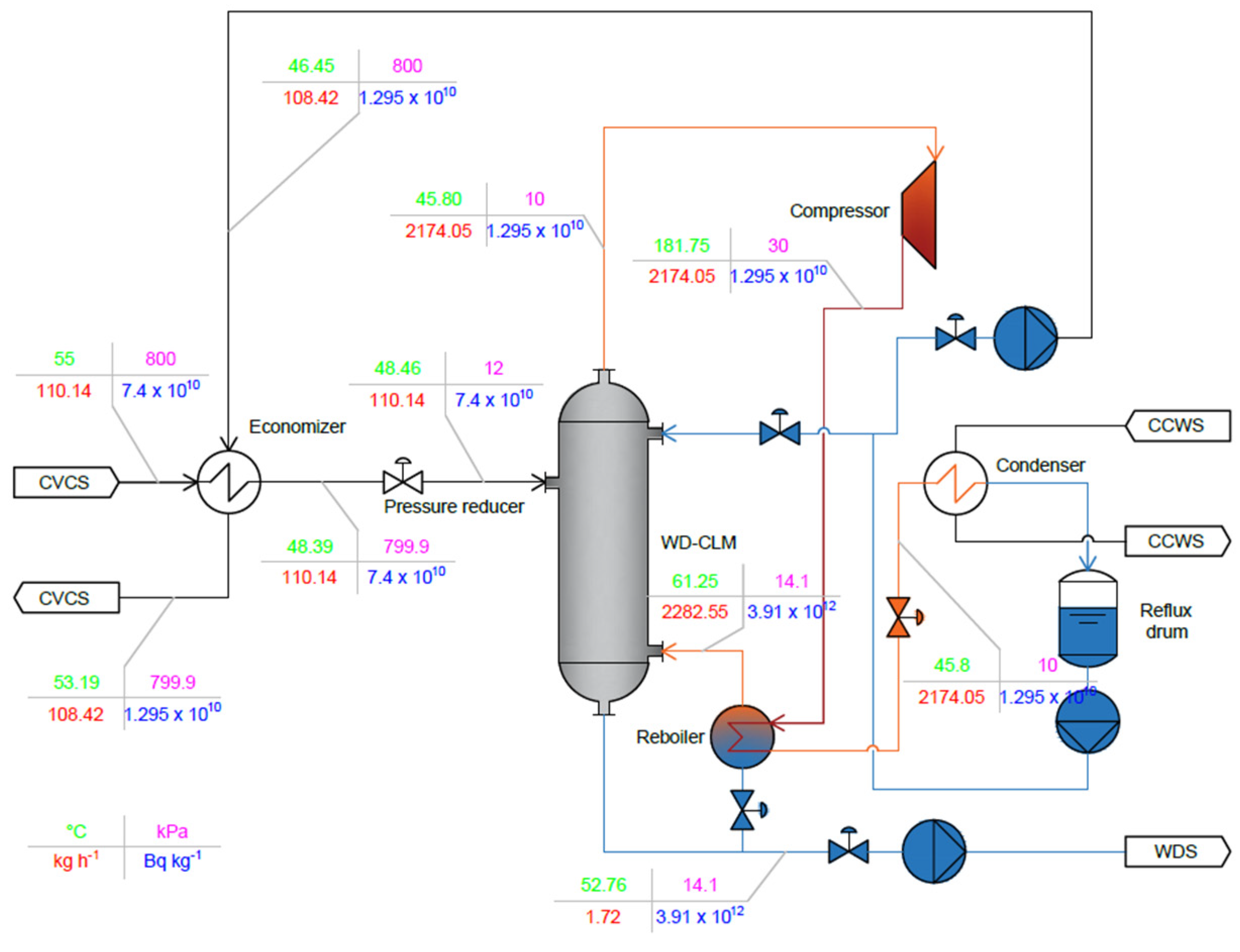

3.2. Mechanical Vapor Recompression

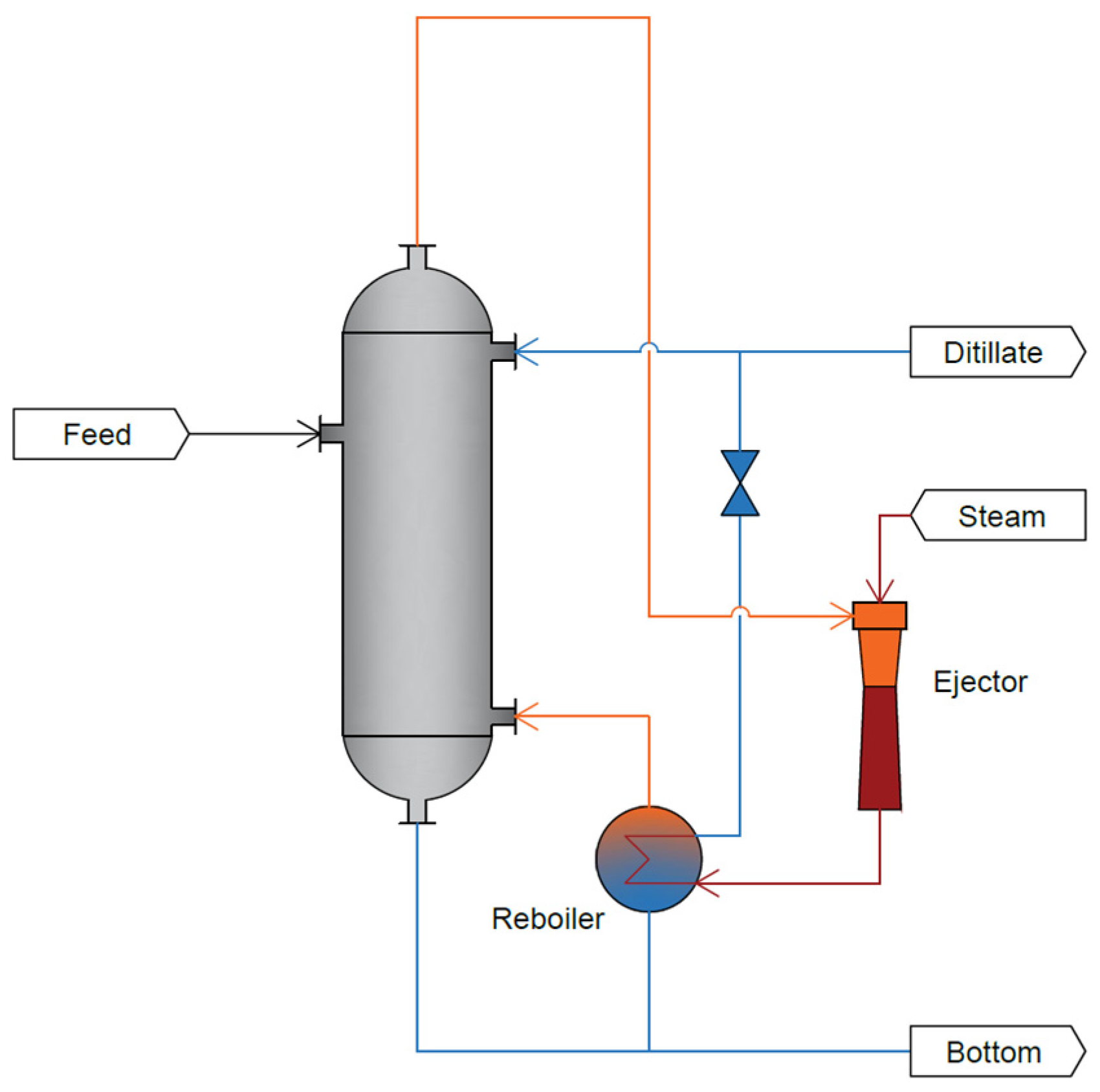

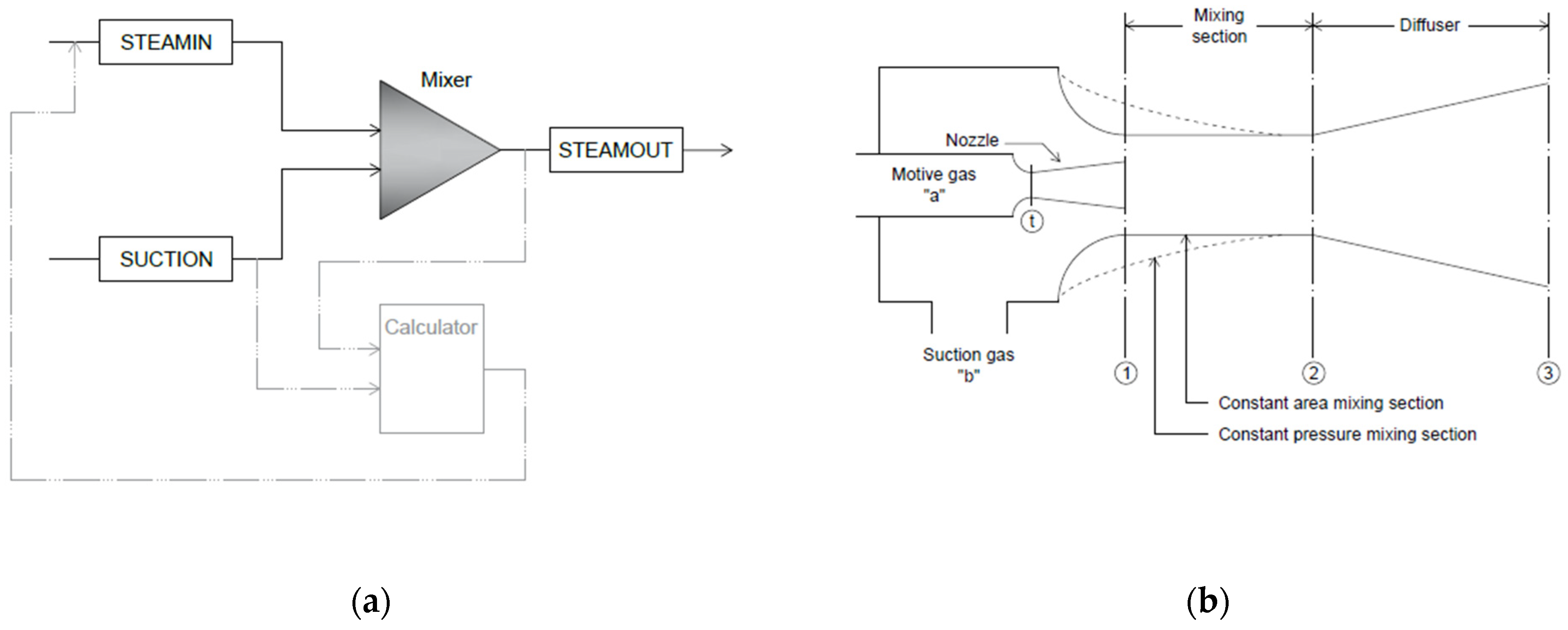

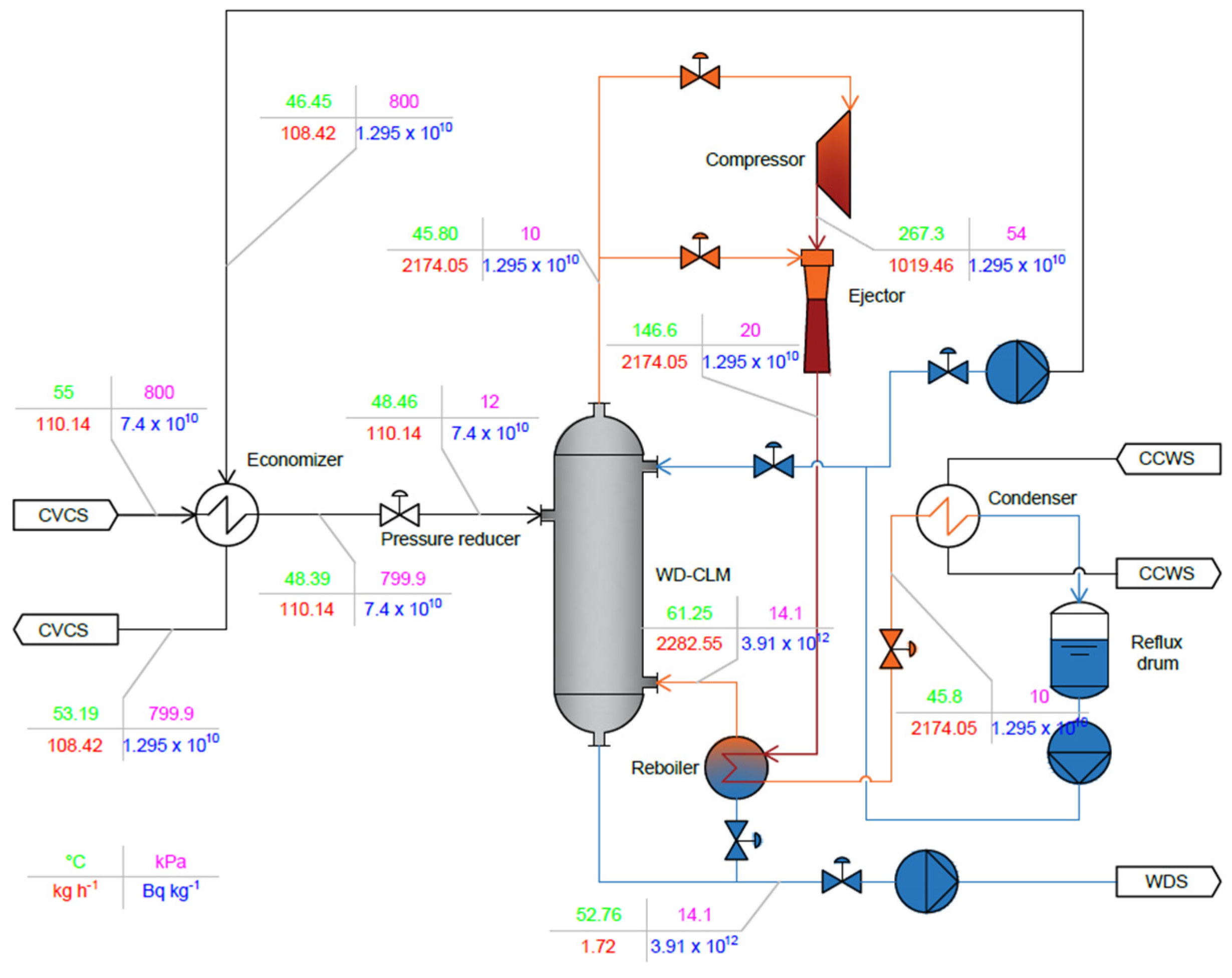

3.3. Thermal Vapor Recompression

3.4. Results Summary

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Federici, G. Testing needs for the development and qualification of a breeding blanket for DEMO. Nucl. Fusion 2023, 63, 125002. [Google Scholar] [CrossRef]

- Santucci, A.; Incelli, M.; Noschese, L.; Moreno, C.; Di Fonzo, F.; Utili, M.; Tosti, S.; Day, C. The issue of Tritium in DEMO coolant and mitigation strategies. Fusion Eng. Des. 2020, 158, 111759. [Google Scholar] [CrossRef]

- Narcisi, V.; Quartararo, A.; Moscato, I.; Santucci, A. Analysis of Coolant Purification Strategies for Tritium Control in DEMO Water Primary Coolant. Energies 2023, 16, 617. [Google Scholar] [CrossRef]

- Spagnuolo, G.A.; Arredondo, R.; Boccaccini, L.V.; Chiovaro, P.; Ciattaglia, S.; Cismondi, F.; Coleman, M.; Cristescu, I.; D’amico, S.; Day, C.; et al. Integrated design of breeding blanket and ancillary systems related to the use of helium or water as a coolant and impact on the overall plant design. Fusion Eng. Des. 2021, 173, 112933. [Google Scholar] [CrossRef]

- Utili, M.; Bassini, S.; Cataldo, S.; Di Fonzo, F.; Kordac, M.; Hernandez, T.; Kunzova, K.; Lorenz, J.; Martelli, D.; Padino, B.B.; et al. Development of anti-permeation and corrosion barrier coatings for the WCLL breeding blanket of the European DEMO. Fusion Eng. Des. 2021, 170, 112453. [Google Scholar] [CrossRef]

- Utili, M.; Alberghi, C.; Candido, L.; Di Fonzo, F.; Papa, F.; Venturini, A. Design of the Test Section for the Experimental Validation of Antipermeation and Corrosion Barriers for WCLL BB. Appl. Sci. 2022, 12, 1624. [Google Scholar] [CrossRef]

- Hernandez, F.A.; Arena, O.; Boccaccini, L.V.; Cristescu, I.; Del Nevo, A.; Sardain, P.; Spagnuolo, G.A.; Utili, M.; Venturini, A.; Zhou, G. Advancements in Designing the DEMO Driver Blanket System at the EU DEMO Pre-Conceptual Design Phase: Overview, Challenges and Opportunities. J. Nucl. Eng. 2023, 4, 565–601. [Google Scholar] [CrossRef]

- Pereslavtsev, P.; Hernandez, F.A.; Moscato, I.; Park, J.H. Neutronic Activity for Development of the Promising Alternative Water-Cooled DEMO Concepts. Appl. Sci. 2023, 13, 7383. [Google Scholar] [CrossRef]

- Arena, P.; Del Nevo, A.; Moro, F.; Noce, S.; Mozzillo, R.; Imbriani, V.; Giannetti, F.; Edemetti, F.; Froio, A.; Savoldi, L.; et al. The DEMO Water-Cooled Lead-Lithium Breeding Blanket: Design Status at the End of the Pre-Conceptual Design Phase. Appl. Sci. 2021, 11, 11592. [Google Scholar] [CrossRef]

- Narcisi, V.; Santucci, A. Water distillation for coolant purification system of DEMO water-cooled lithium lead breeding blanket. Fusion Eng. Des. 2023, 190, 113547. [Google Scholar] [CrossRef]

- Kiss, A.A.; Landaeta, A.J.F.; Ferreira, C.A.I. Towards energy efficient distillation technologies—Making the right choice. Energy 2012, 47, 531–542. [Google Scholar] [CrossRef]

- Chen, C.; Hou, J.; Li, J.; Chen, X.; Xiao, C.; Wang, Q.; Gong, Y.; Yue, L.; Zhao, L.; Ran, G.; et al. A water distillation detritiation facility and its performance test. Fusion Eng. Des. 2020, 153, 111460. [Google Scholar] [CrossRef]

- Fukada, S.; Miho, Y.; Ktayama, K. Tritium separation performance of adsorption/exchange distillation tower packed with structured packing. Fusion Eng. Des. 2018, 133, 64–69. [Google Scholar] [CrossRef]

- Yamamoto, I.; Kaba, A.; Kanagawa, A. H2O-HTO isotope separation by distillation of water—A dynamics of HETP of SUS Dixon ring in a small packed column. Fusion Eng. Des. 1989, 10, 315–318. [Google Scholar] [CrossRef]

- Sugiyama, T.; Kamewaka, H.; Enokida, Y.; Yamamoto, I. Channeling Stage Model for separative analysis of packed water distillation column. Fusion Eng. Des. 1998, 39–40, 1027–1032. [Google Scholar] [CrossRef]

- Kembleton, R.; Morris, J.; Siccino, M.; Maviglia, F.; The PROCESS team. EU-DEMO design space exploration and design drivers. Fusion Eng. Des. 2022, 178, 113080. [Google Scholar] [CrossRef]

- Narcisi, V.; Ciurluini, C.; Padula, G.; Giannetti, F. Analysis of EU-DEMO WCLL Power Conversion System in Two Relevant Balance of Plant Configurations: Direct Coupling with Auxiliary Boiler and Indirect Coupling. Sustainability 2022, 14, 5779. [Google Scholar] [CrossRef]

- Kiss, A.A.; Smith, R. Rethinking energy use in distillation processes for more sustainable chemical industry. Energy 2020, 203, 117788. [Google Scholar] [CrossRef]

- Jana, A.K. Advances in heat pump assisted distillation column: A review. Energy Convers. Manag. 2014, 77, 287–297. [Google Scholar] [CrossRef]

- Gopichand, S.; Devotta, S. Heat pump assisted distillation. X: Potential industrial applications. Int. J. Energy Res. 1988, 12, 569–582. [Google Scholar] [CrossRef]

- Annakou, O.; Mizsey, P. Rigorous investigation of heat pump assisted distillation. Heat Recover. Syst. CHP 1995, 15, 241–247. [Google Scholar] [CrossRef]

- Yang, M.; Feng, X.; Liu, G. Heat integration of heat pump assisted distillation into the overall process. Appl. Energy 2016, 162, 1–10. [Google Scholar] [CrossRef]

- Wang, C.; Zhuang, Y.; Liu, L.; Zhang, L.; Du, J. Heat pump assisted extractive distillation sequences with intermediate- boiling entrainer. Appl. Therm. Eng. 2021, 186, 116511. [Google Scholar] [CrossRef]

- Day, C.; Battes, K.; Butler, B.; Davies, S.; Farina, L.; Frattolillo, A.; George, R.; Giegerich, T.; Hanke, S.; Hartl, T.; et al. The pre-concept design of the DEMO tritium, matter injection and vacuum systems. Fusion Eng. Des. 2022, 179, 113139. [Google Scholar] [CrossRef]

- Feng, X.; Berntsson, T. Critical COP for an economically feasible industrial heat-pump application. Appl. Therm. Energy 1997, 17, 93–101. [Google Scholar] [CrossRef]

- Sawitri, D.R.; Budiman, A. Comparative study of Heat Pump Assisted Distillation Column and Its Application for Pressure Swing Distillation Process. IOP Conf. Ser. Mater. Sci. Eng. 2020, 778, 012159. [Google Scholar] [CrossRef]

- Aldehani, M. Hydrogen-Water Isotope Exchange in a Trickle Bed Column by Process Simulation and 3D Computational Fluid Dynamics Modelling. Ph.D. Thesis, Faculty of Science and Technology, Engineering, Lancaster University, Lancaster, UK, 2016. Available online: https://eprints.lancs.ac.uk/id/eprint/82667 (accessed on 19 July 2023).

- Van Hook, W.A. Vapor Pressures of the Isotopic Waters and Ices. J. Phys. Chem. 1968, 72, 1234–1244. [Google Scholar] [CrossRef]

- Perry, R.H.; Green, D. Perry’s Chemical Engineers’ Handbook, 6th ed.; McGrawn Hill: New York, NY, USA, 1984. [Google Scholar]

- DeFrate, L.A.; Hoerl, A.E. Optimum Design of Ejectors Using Digital Computers. Chem. Eng. Prog. Symp. Ser. 1959, 55, 46. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Number of columns | -- | 1 |

| Number of theoretical stages, including condenser and reboiler | -- | 130 |

| Feeding stage, from top | -- | 48 |

| Packing | -- | CY Gauze, by Sulzer |

| Column height | m | 14.17 |

| Column diameter | m | 1.52 |

| Feed flow rate | kg h−1 | 110 |

| Bottom flow rate | kg h−1 | 1.72 |

| Bottom tritium specific activity | Bq kg−1 | 3.7 × 1012 |

| Distillate flow rate | kg h−1 | 108.28 |

| Distillate tritium specific activity | Bq kg−1 | 1.628 × 1010 |

| Boil-up flow rate | kg h−1 | 2281 |

| Reflux flow rate | kg h−1 | 2172 |

| Pressure drops | kPa | 4.25 |

| Compressor Outlet Pressure (kPa) | Compressor Outlet Temperature (°C) | Compressor Net Power Required (kW) | Condenser Power (kW) | Required Heat Transfer Area of Reboiler (m2) |

|---|---|---|---|---|

| 15 | 92.25 | 55.19 | 55.40 | 81.12 |

| 20 | 127.81 | 98.07 | 98.34 | 29.54 |

| 25 | 156.94 | 133.28 | 133.57 | 19.36 |

| 30 | 181.75 | 163.49 | 163.79 | 15.01 |

| 35 | 203.45 | 190.12 | 190.41 | 12.56 |

| 40 | 222.80 | 213.99 | 214.29 | 10.98 |

| 45 | 240.28 | 235.99 | 236.27 | 9.92 |

| 50 | 256.27 | 255.82 | 256.10 | 9.05 |

| 55 | 271.01 | 274.50 | 274.78 | 8.42 |

| 60 | 284.70 | 291.79 | 292.07 | 7.89 |

| 65 | 297.49 | 307.98 | 308.27 | 7.44 |

| 70 | 309.50 | 323.23 | 323.52 | 7.07 |

| 75 | 320.83 | 337.66 | 337.95 | 6.75 |

| 80 | 331.56 | 351.37 | 351.66 | 6.47 |

| A2At | wa (kg h−1) | wb (kg h−1) | Ta (°C) | T3 (°C) | pa (kPa) | Condenser Power (kW) | Compressor Power (kW) | Required Heat Transfer Area of Reboiler (m2) |

|---|---|---|---|---|---|---|---|---|

| 100 | 729.19 | 1549.71 | 963.75 | 368.82 | 1532 | 398.3 | 398.57 | 8.79 |

| 50 | 672.99 | 1605.91 | 730.87 | 263.47 | 596 | 264.24 | 264.52 | 10.48 |

| 25 | 775.66 | 1503.24 | 585.02 | 239.33 | 307 | 234.13 | 234.41 | 11.4 |

| 15 | 902.19 | 1376.72 | 504.98 | 235.16 | 207 | 228.95 | 229.23 | 11.6 |

| 10 | 1042.54 | 1236.36 | 446.86 | 235.18 | 153 | 228.98 | 229.26 | 11.6 |

| 5 | 1308.18 | 970.7 | 348.08 | 222.51 | 88 | 213.29 | 213.57 | 12.2 |

| A2At | wa (kg h−1) | wb (kg h−1) | Ta (°C) | T3 (°C) | pa (kPa) | Condenser Power (kW) | Compressor Power (kW) | Required Heat Transfer Area of Reboiler (m2) |

|---|---|---|---|---|---|---|---|---|

| 100 | 324.6 | 1954.29 | 695.3 | 146.3 | 510 | 120.4 | 120.1 | 24.2 |

| 50 | 383.15 | 1895.7 | 559.6 | 137.7 | 272 | 110.05 | 109.76 | 26 |

| 25 | 499.1 | 1779.7 | 456.9 | 140.05 | 160 | 112.8 | 112.5 | 25.5 |

| 15 | 624.57 | 11,654.3 | 396.1 | 145.2 | 116 | 119.1 | 118.89 | 24.4 |

| 10 | 755.8 | 1523 | 350.3 | 149.6 | 89 | 124.4 | 124.1 | 23.6 |

| 5 | 1019.46 | 1259.4 | 267.3 | 146.6 | 54 | 120.8 | 120.5 | 24.16 |

| Parameter | Unit | STD | MVR | TVR-CMP |

|---|---|---|---|---|

| Required heat transfer area | m2 | 23.3 | 29.8 | 24.16 |

| Excess surface | % | 32 | 29 | 7 |

| Tube Outer Diameter (OD) | mm | 25.4 | 30 | 30 |

| Pitch | mm | 31.75 | 37.5 | 37.5 |

| Shell OD | mm | 525 | 610 | 914 |

| Tube length | mm | 2850 | 2550 | 2100 |

| Number of tubes | -- | 140 | 166 | 425 |

| Shell-side free volume | m3 | 0.39 | 0.42 | 0.72 |

| Parameter | Unit | STD | MVR | TVR-CMP |

|---|---|---|---|---|

| Reboiler power | kW | 1517.39 * | -- | -- |

| Condenser power | kW | 1517.72 | 163.79 | 120.80 |

| Compressor power | kW | -- | 163.49 | 120.50 |

| Total power saving | % | -- | 78.4 | 84.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narcisi, V.; Santucci, A. Optimized Water Distillation Layout for Detritiation Purpose. Appl. Sci. 2024, 14, 1328. https://doi.org/10.3390/app14041328

Narcisi V, Santucci A. Optimized Water Distillation Layout for Detritiation Purpose. Applied Sciences. 2024; 14(4):1328. https://doi.org/10.3390/app14041328

Chicago/Turabian StyleNarcisi, Vincenzo, and Alessia Santucci. 2024. "Optimized Water Distillation Layout for Detritiation Purpose" Applied Sciences 14, no. 4: 1328. https://doi.org/10.3390/app14041328

APA StyleNarcisi, V., & Santucci, A. (2024). Optimized Water Distillation Layout for Detritiation Purpose. Applied Sciences, 14(4), 1328. https://doi.org/10.3390/app14041328