Applications of Microseismic Monitoring Technique in Coal Mines: A State-of-the-Art Review

Abstract

:1. Introduction

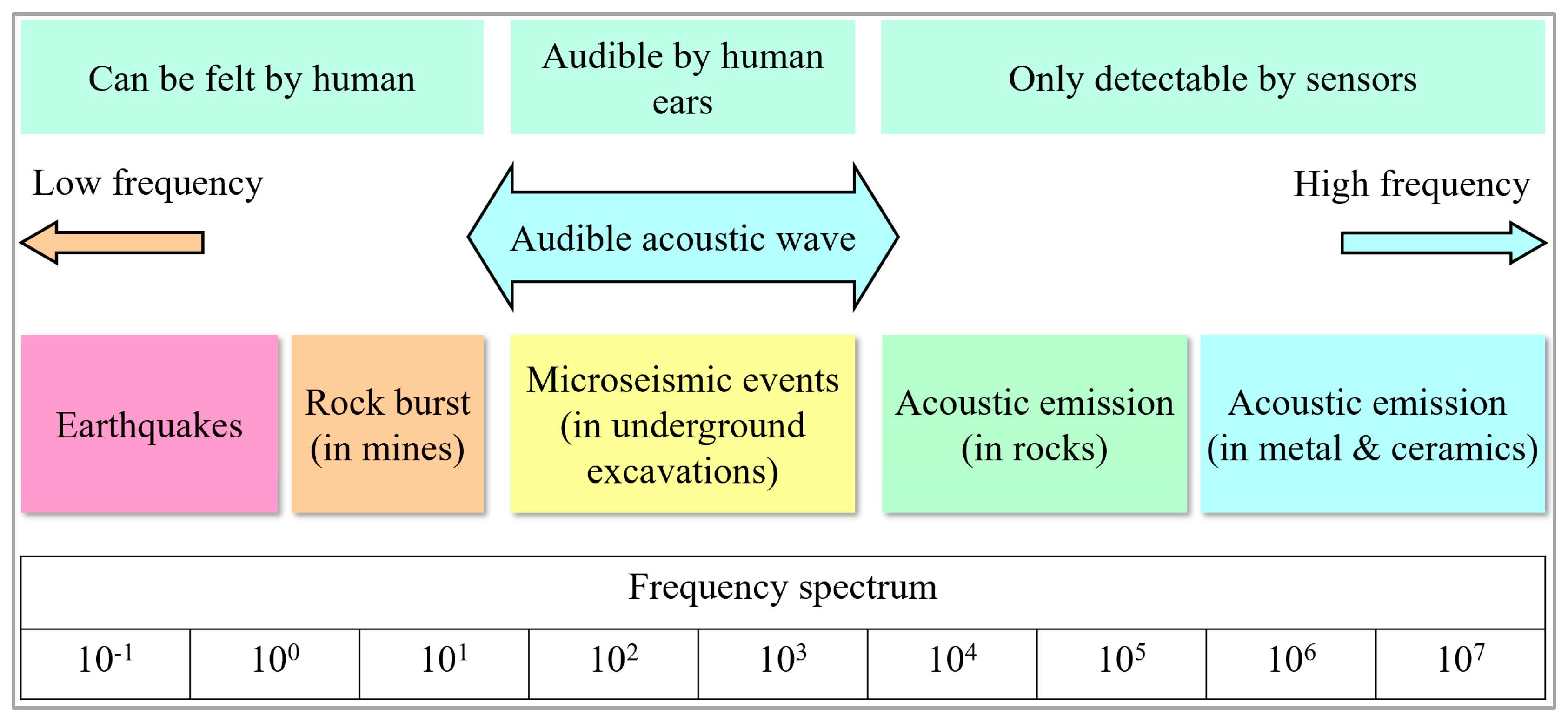

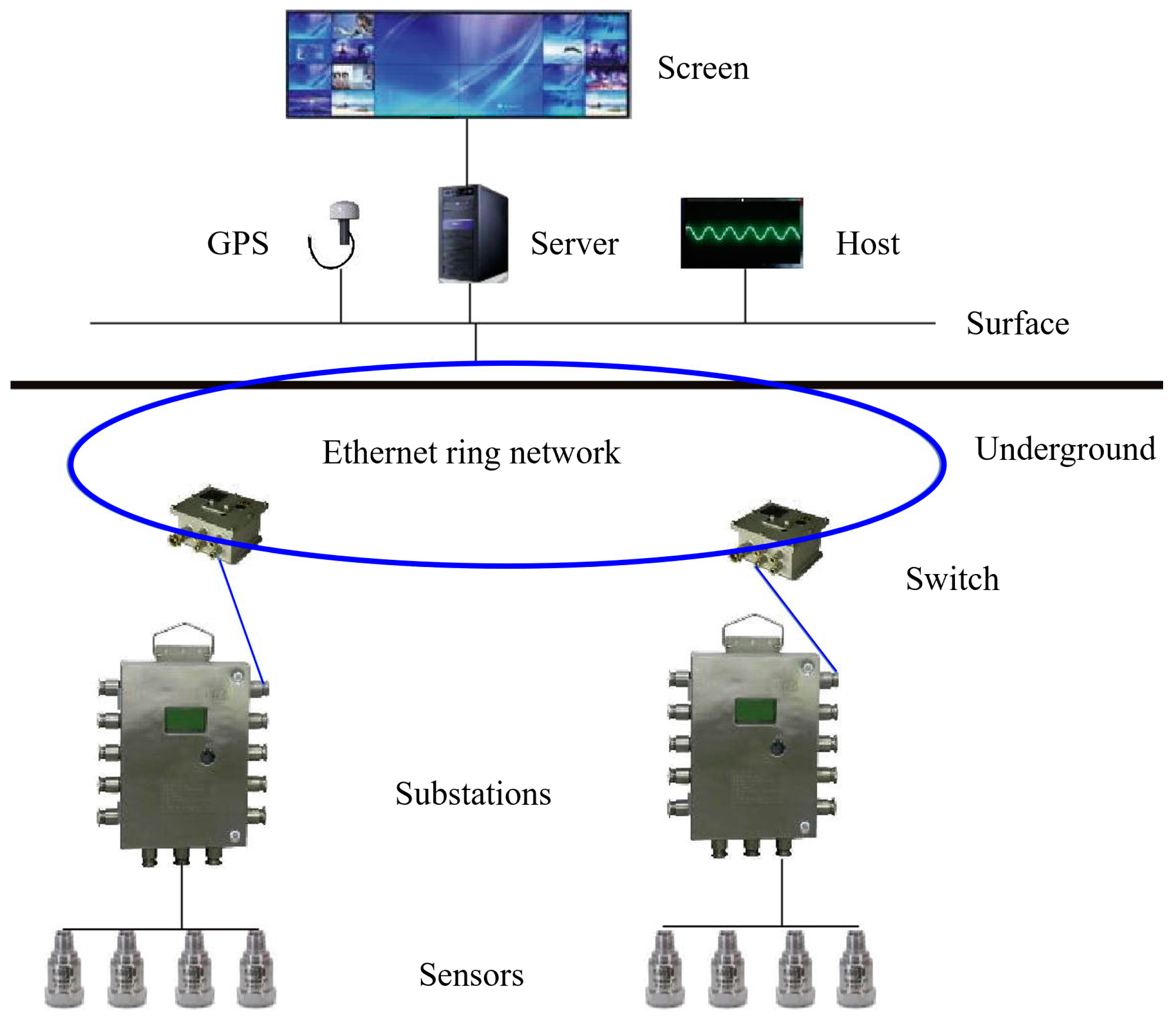

2. Fundamental Aspects of Microseismic Monitoring Technique

2.1. Microseismic Monitoring Principle

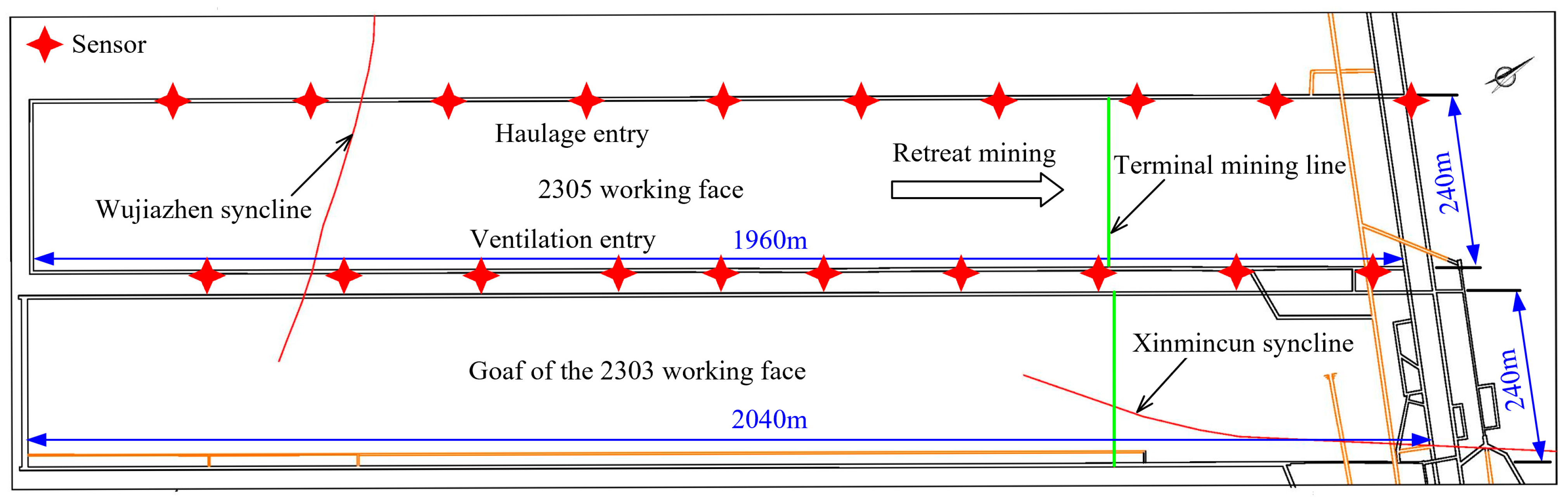

2.2. Microseismic Source Location and Sensor Layout

2.3. Microseismic Parameters

3. Interpretation of Mining-Induced Microseismicity

3.1. Microseismic Focal Mechanism

3.2. Stress Inversion

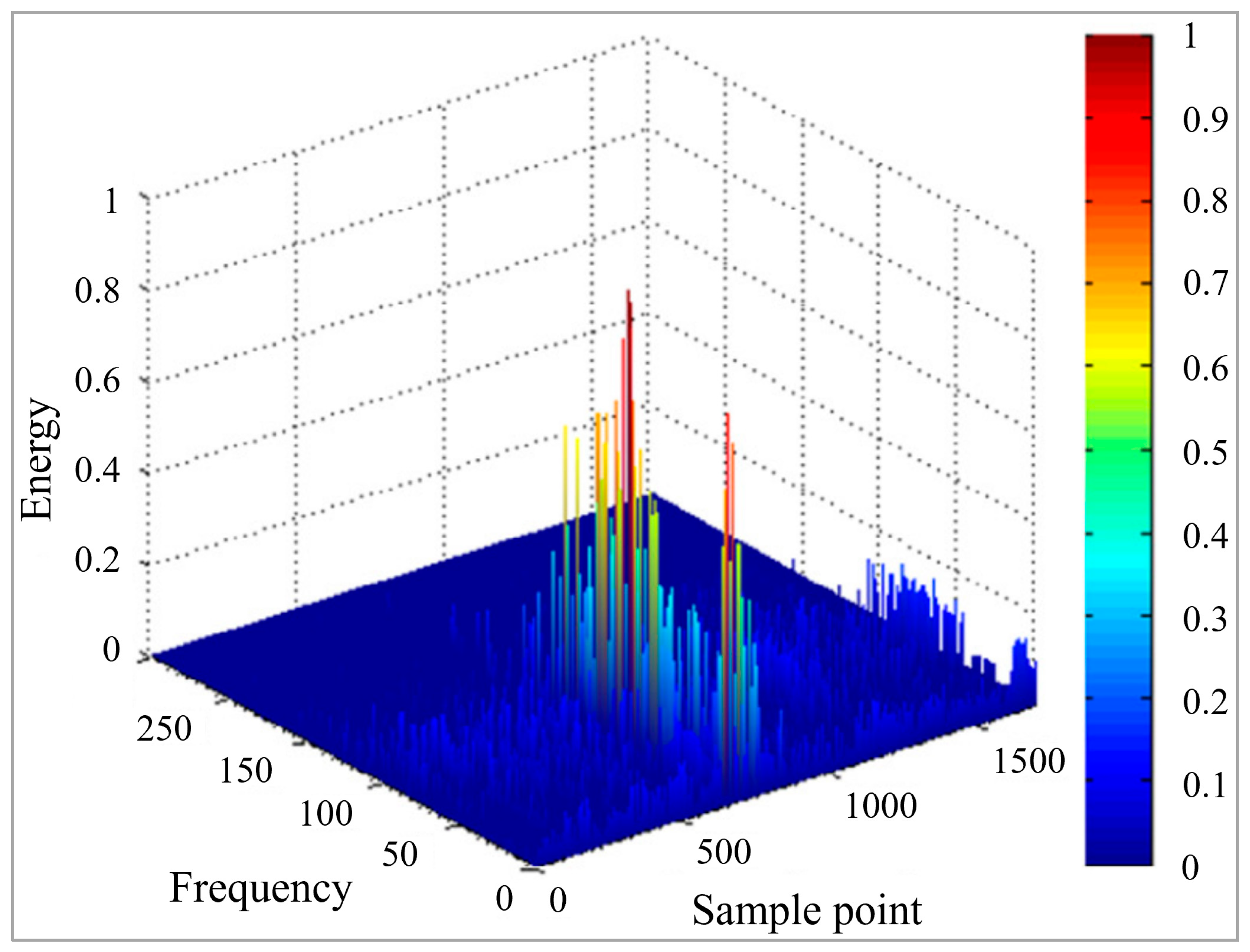

3.3. Spectral Analysis

4. Applications of Microseismic Monitoring in Coal Mine

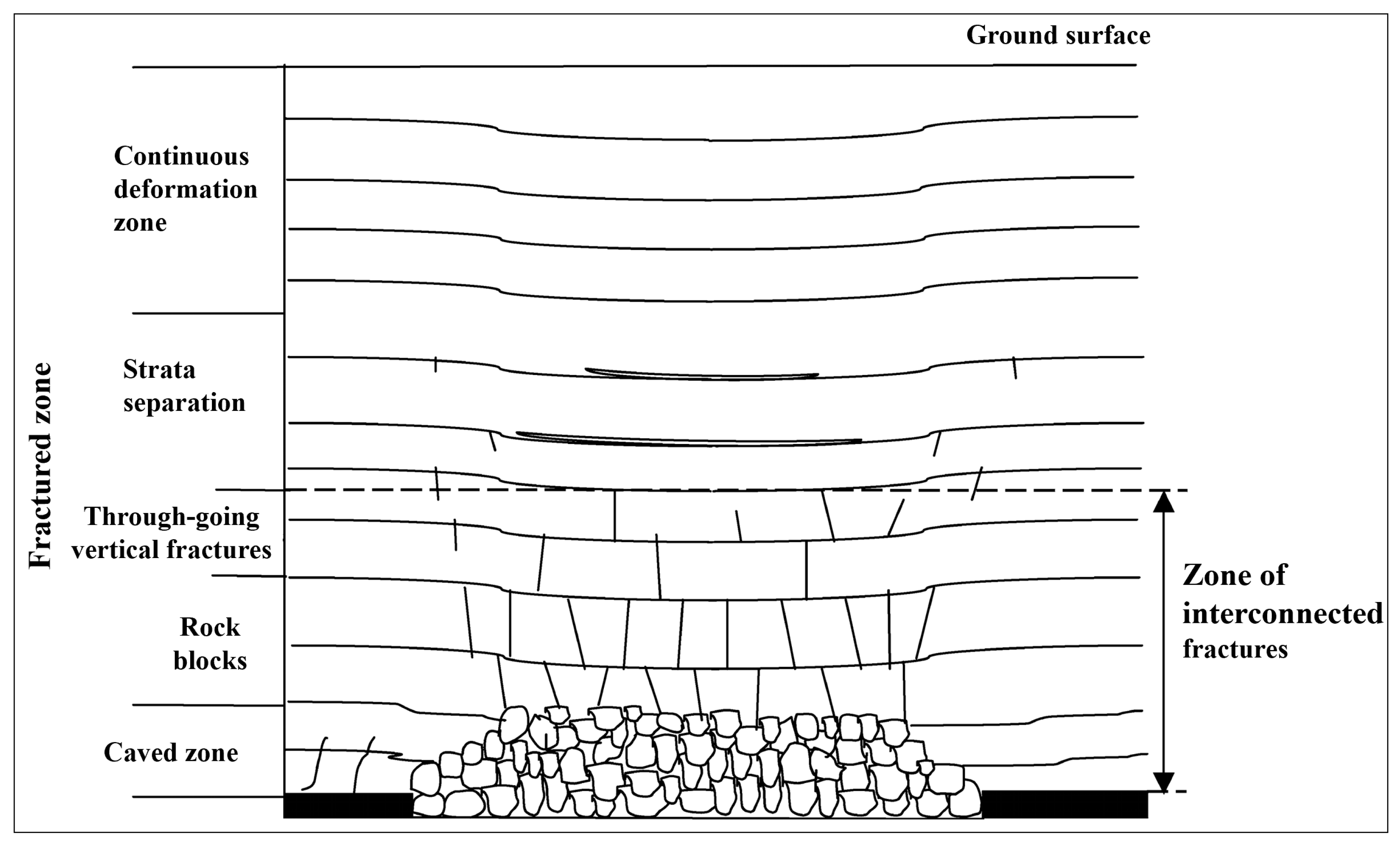

4.1. Roof Strata Behavior

4.2. Rockburst

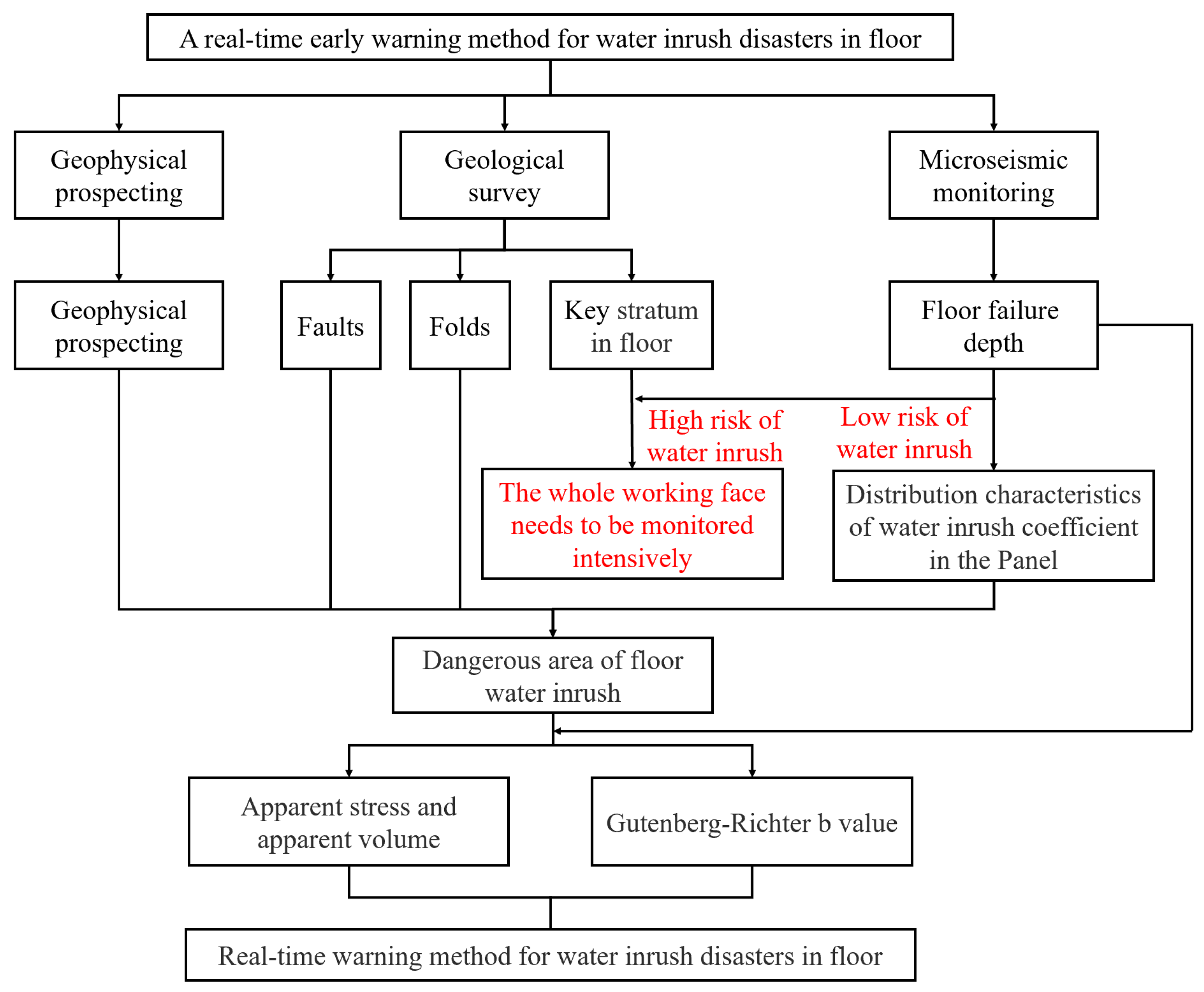

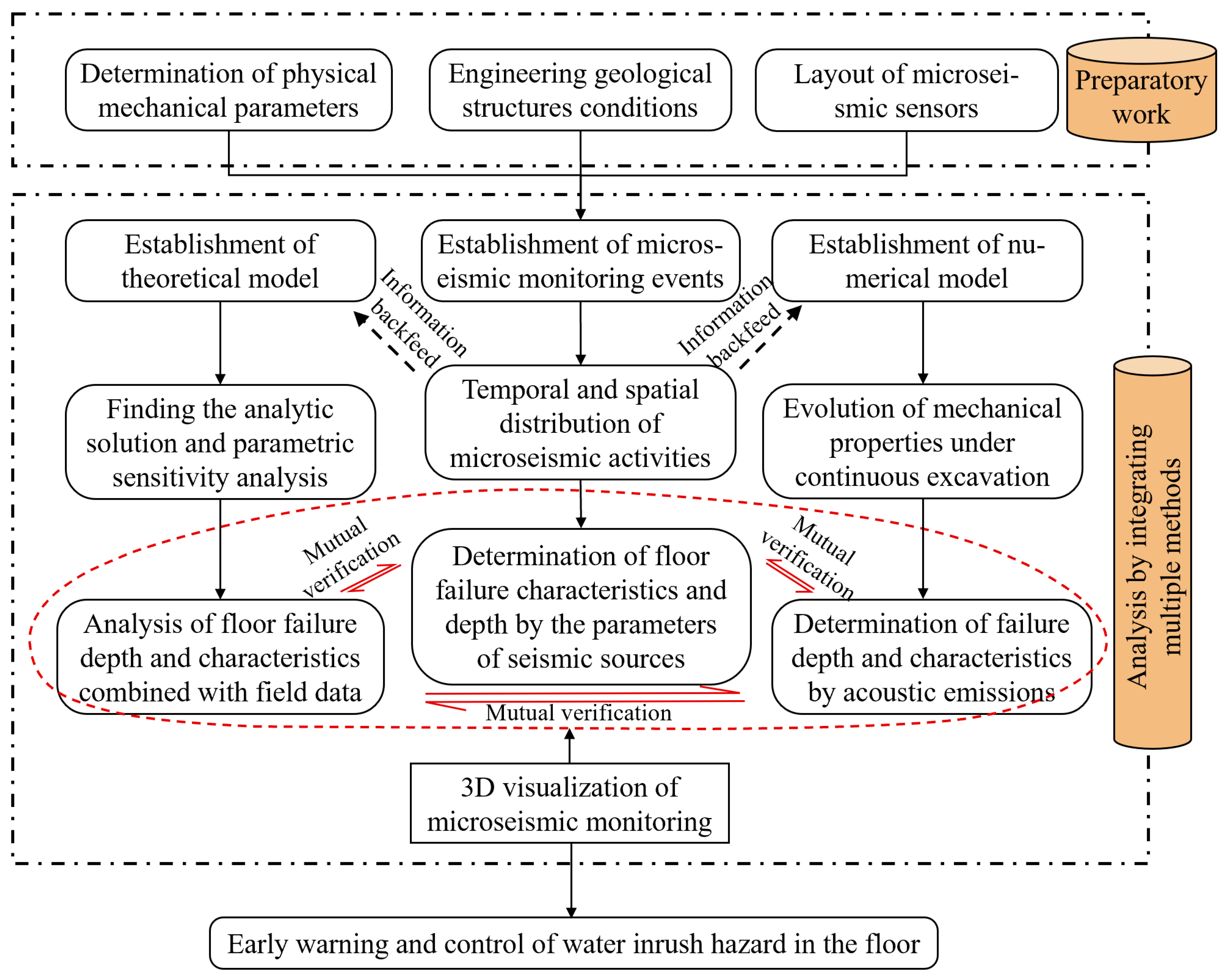

4.3. Water Inrush

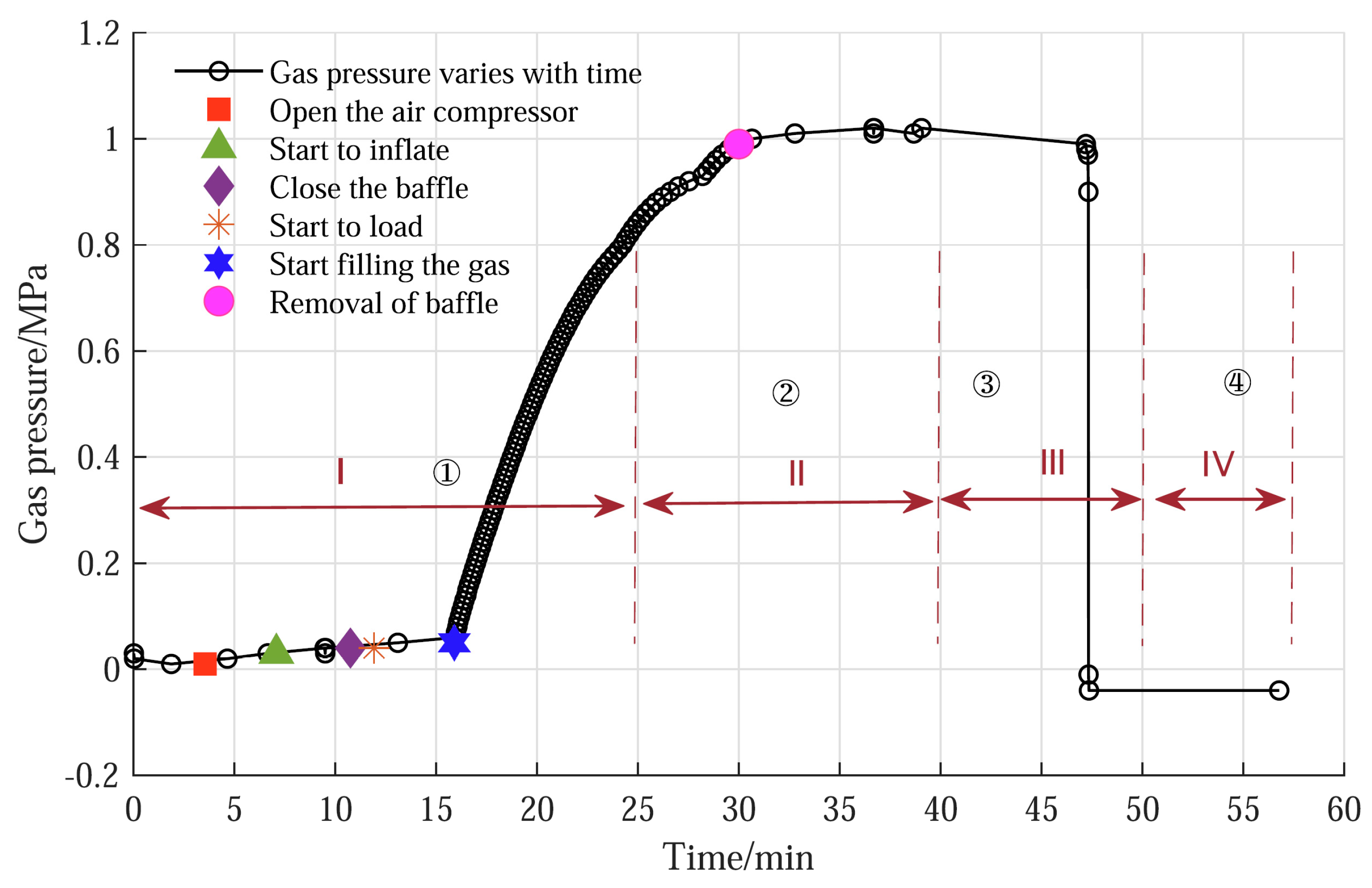

4.4. Coal and Gas Outburst

5. Some Prospects of the Microseismic Monitoring Technique in Coal Mines

5.1. Improving the Location Accuracy of Microseismicity

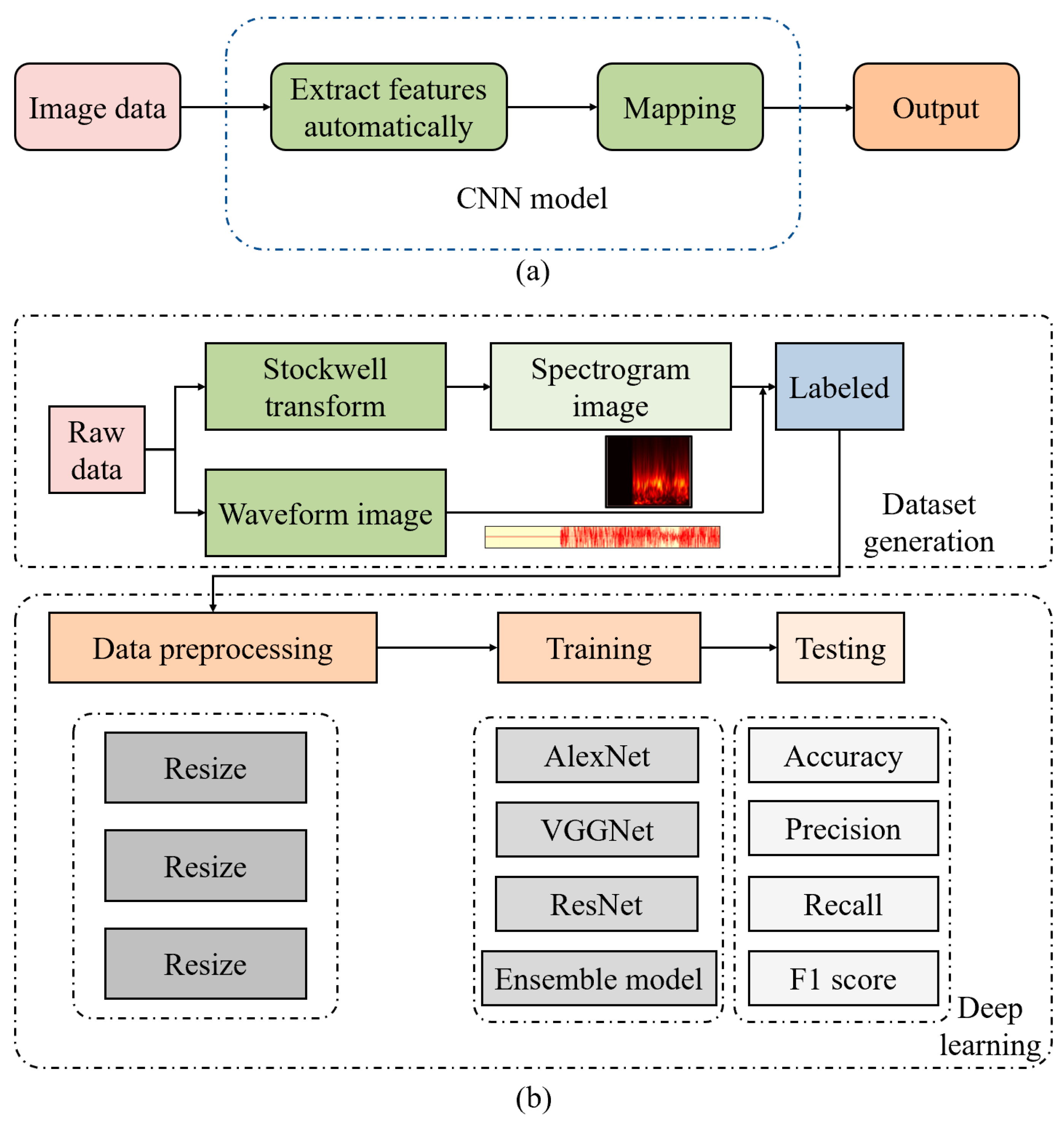

5.2. Efficient and Intelligent Processing of Microseismic Data

5.3. Comprehensive Assessment of Mining-Induced Instabilities

5.4. Development of Microseismic Monitoring Equipment

6. Conclusions

- The microseismic monitoring technique is capable of capturing coal/rock fractures at different scales, which is challenging for the traditional stress and deformation monitoring methods. Microseismicities contain abundant coal/rock fracturing information, and the quantitative interpretation of mining-induced microseismicities contributes to studying the generation process of disasters in coal mines. Furthermore, the microseismic monitoring technique is effective for the assessment of coal/rock instabilities and early warning of disasters.

- Some source parameters and statistical parameters of microseismicities are effective and sensitive in evaluating the stress regime and characterizing the damage of surrounding rocks. These microseismic parameters can be used in conjunction with other monitoring methods, e.g., laser scanning and electromagnetic radiation, which are meaningful for the mitigation and control of mining-induced disasters.

- Though fruitful achievements have been made in coal mines using the microseismic monitoring technique, there are certain problems to be addressed. To better monitor, warn, and control the disasters in deep coal mines, future research should focus on a precise microseismic source location method, an efficient and intelligent data processing method, a comprehensive assessment method for mining-induced instabilities, and the development of new microseismic equipment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency. Coal 2023, France. 2023. Available online: https://www.iea.org/reports/coal-2023 (accessed on 1 December 2023).

- Xie, H.P.; Gao, M.Z.; Zhang, R.; Peng, G.Y.; Wang, W.L.; Li, A.Q. Study on the mechanical properties and mechanical response of coal mining at 1000 m or deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Xie, H.P.; Ju, Y.; Ren, S.H.; Gao, F.; Liu, J.Z.; Zhu, Y. Theoretical and technological exploration of deep in situ fluidized coal mining. Front. Energy 2019, 13, 603–611. [Google Scholar] [CrossRef]

- Xie, H.P.; Ju, Y.; Gao, F.; Gao, M.Z.; Zhang, R. Groundbreaking theoretical and technical conceptualization of fluidized mining of deep underground solid mineral resources. Tunn. Undergr. Space Technol. 2017, 67, 68–70. [Google Scholar] [CrossRef]

- Kang, H.P.; Gao, F.Q.; Xu, G.; Ren, H.W. Mechanical behaviors of coal measures and ground control technology for China’s deep coal mines–A review. J. Rock Mech. GeoTechnol. Eng. 2023, 15, 37–65. [Google Scholar] [CrossRef]

- Kang, H.P.; Wu, Y.; Gao, F.; Lin, J.; Jiang, P. Fracture characteristics in rock bolts in underground coal mine roadways. Int. J. Rock Mech. Min. Sci. 2013, 62, 105–112. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Zhao, J.; Ju, M.H.; De Silva, R.V.; Rathnaweera, T.D.; Bandara, A.K. Opportunities and challenges in deep mining: A brief review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Kouame, K.J.A.; Jiang, F.X.; Zhu, S.T. Research on cause of dynamic disaster of deep mining control in China and its further prevention application in Ivory Coast. GeoTechnol. Geol. Eng. 2017, 35, 1141–1149. [Google Scholar] [CrossRef]

- He, Z.L.; Lu, C.P.; Zhang, X.F.; Guo, Y.; Meng, Z.H.; Xia, L. Numerical and field investigations of rockburst mechanisms triggered by thick-hard roof fracturing. Rock Mech. Rock Eng. 2022, 55, 6863–6886. [Google Scholar] [CrossRef]

- Xiao, Z.M.; Gu, S.T.; Zhang, Y.Z.; Wang, H. An effective control method of rock burst induced by shear instability of fault structure under complicated geological conditions. Bull. Eng. Geol. Environ. 2023, 82, 105. [Google Scholar] [CrossRef]

- Pan, C.; Xia, B.W.; Zuo, Y.J.; Yu, B.; Ou, C.N. Mechanism and control technology of strong ground pressure behaviour induced by high-position hard roofs in extra-thick coal seam mining. Int. J. Min. Sci. Technol. 2022, 32, 499–511. [Google Scholar] [CrossRef]

- Wang, H.W.; Xue, S.; Jiang, Y.D.; Deng, D.X.; Shi, S.Z.; Zhang, D.Q. Field investigation of a roof fall accident and large roadway deformation under geologically complex conditions in an underground coal mine. Rock Mech. Rock Eng. 2018, 51, 1863–1883. [Google Scholar] [CrossRef]

- Cao, Z.D.; Gu, Q.X.; Huang, Z.; Fu, J.J. Risk assessment of fault water inrush during deep mining. Int. J. Min. Sci. Technol. 2022, 32, 423–434. [Google Scholar] [CrossRef]

- Ma, D.; Li, Q.; Cai, K.C.; Zhang, J.X.; Li, Z.H.; Hou, W.T.; Sun, Q.; Li, M.; Du, F. Understanding water inrush hazard of weak geological structure in deep mine engineering: A seepage-induced erosion model considering tortuosity. J. Cent. South Univ. 2023, 30, 517–529. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, E.Y.; Li, Z.H.; Gao, F.; Zhang, Z.Z.; Li, B.L.; Zhang, X. Identification of coal and gas outburst-hazardous zones by electric potential inversion during mining process in deep coal seam. Rock Mech. Rock Eng. 2022, 55, 3439–3450. [Google Scholar] [CrossRef]

- Tang, J.P.; Zhang, X.; Sun, S.J.; Pan, Y.S.; Li, L.M. Evolution characteristics of precursor information of coal and gas outburst in deep rock cross-cut coal uncovering. Int. J. Coal Sci. Technol. 2022, 9, 5. [Google Scholar] [CrossRef]

- Wu, B.; Wang, J.X.; Zhong, M.Y.; Xu, C.C.; Qu, B.L. Multidimensional analysis of coal mine safety accidents in China–70 years review. Min. Metall. Explor. 2023, 40, 253–262. [Google Scholar] [CrossRef]

- He, X.Q.; Zhou, C.; Song, D.Z.; Li, Z.L.; Cao, A.Y.; He, S.Q.; Khan, M. Mechanism and monitoring and early warning technology for rockburst in coal mines. J. Miner. Metall. Mater. 2021, 28, 1097–1111. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.Y.; Zhang, J.X.; Bai, H.B. A state-of-the-art review on rock seepage mechanism of water inrush disaster in coal mines. Int. J. Coal Sci. Technol. 2022, 9, 50. [Google Scholar] [CrossRef]

- Ma, Y.K.; Nie, B.S.; He, X.Q.; Li, X.C.; Meng, J.Q.; Song, D.Z. Mechanism investigation on coal and gas outburst: An overview. Int. J. Min. Metall. Mater. 2020, 27, 872–887. [Google Scholar] [CrossRef]

- Fuławka, K.; Stolecki, L.; Szumny, M.; Pytel, W.; Jaśkiewicz-Proć, I.; Jakić, M.; Nöger, M.; HartliEb, P. Roof fall hazard monitoring and evaluation—State-of-the-art review. Energies 2022, 15, 8312. [Google Scholar] [CrossRef]

- Ge, M.C. Efficient mine microseismic monitoring. Int. J. Coal Geol. 2005, 64, 44–56. [Google Scholar] [CrossRef]

- Mendecki, A.J.; Van Aswegen, G.; Mountfort, P. A guide to routine seismic monitoring in mines. In A handbook on Rock Engineering Practices for Tabular Hard Rock Mines; Creda Communications: Cape Town, South Africa, 1999; pp. 287–309. [Google Scholar]

- Obert, L. The microseismic method: Discovery and early history. In Proceedings of the 1st Conference of Acoustic Emission/Microseismic Activity in Geological Structures and Materials, State College, PA, USA, 9–11 June 1975; Trans Tech Publications: Clausthal-Zellerfeld, Germany, 1975; pp. 11–12. [Google Scholar]

- Cook, N.G.W. The seismic location of rockbursts. In Proceedings of the 5th Rock Mechanics Symposium, Minneapolis, MN, USA, 3–5 May 1962; Pergamon Press: Oxford, UK, 1963; pp. 493–518. [Google Scholar]

- Cook, N.G.W. Seismicity associated with mining. Eng. Geol. 1976, 10, 99–122. [Google Scholar] [CrossRef]

- Young, R.P.; Maxwell, S.C.; Urbancic, T.I.; Feignier, B. Mining-induced microseismicity: Monitoring and applications of imaging and source mechanism techniques. Pure Appl. Geophys. 1992, 139, 697–719. [Google Scholar] [CrossRef]

- Tang, C.A.; Wang, J.M.; Zhang, J.J. Preliminary engineering application of microseismic monitoring technique to rockburst prediction in tunneling of Jinping II project. J. Rock Mech. Geotechnol. Eng. 2010, 2, 193–208. [Google Scholar] [CrossRef]

- Li, B.; Xu, N.W.; Xiao, P.W.; Xia, Y.; Zhou, X.; Gu, G.K.; Yang, X.G. Microseismic monitoring and forecasting of dynamic disasters in underground hydropower projects in southwest China: A review. J. Rock Mech. Geotechnol. Eng. 2023, 15, 2158–2177. [Google Scholar] [CrossRef]

- Xu, N.W.; Tang, C.A.; Li, L.C.; Zhou, Z.; Sha, C.; Liang, Z.Z.; Yang, J.Y. Microseismic monitoring and stability analysis of the left bank slope in Jinping first stage hydropower station in southwestern China. Int. J. Rock. Mech. Min. Sci. 2011, 48, 950–963. [Google Scholar] [CrossRef]

- Maxwell, S.C.; Rutledge, J.; Jones, R.; Fehler, M. Petroleum reservoir characterization using downhole microseismic monitoring. Geophysics 2010, 75, 75A129–75A137. [Google Scholar] [CrossRef]

- Mukuhira, Y.; Asanuma, H.; Niitsuma, H.; Häring, M.O. Characteristics of large-magnitude microseismic events recorded during and after stimulation of a geothermal reservoir at Basel, Switzerland. Geothermics 2013, 45, 1–17. [Google Scholar] [CrossRef]

- Kraft, T.; Mignan, A.; Giardini, D. Optimization of a large-scale microseismic monitoring network in northern Switzerland. Geophys. J. Int. 2013, 195, 474–490. [Google Scholar] [CrossRef]

- Xue, Y.R.; Song, D.Z.; Chen, J.Q.; Li, Z.L.; He, X.Q.; Wang, H.L.; Zhou, C.; Sobolev, A. Integrated rockburst hazard estimation methodology based on spatially smoothed seismicity model and Mann-Kendall trend test. Int. J. Rock Mech. Min. Sci. 2023, 163, 105329. [Google Scholar] [CrossRef]

- Urbancic, T.I.; Trifu, C.I. Recent advances in seismic monitoring technology at Canadian mines. J. Appl. Geophys. 2000, 45, 225–237. [Google Scholar] [CrossRef]

- Salvoni, M.; Dight, P.M. Rock damage assessment in a large unstable slope from microseismic monitoring-MMG Century mine (Queensland, Australia) case study. Eng. Geol. 2016, 210, 45–56. [Google Scholar] [CrossRef]

- Mutke, G.; Lurka, A.; Zembaty, Z. Prediction of rotational ground motion for mining-induced seismicity—Case study from Upper Silesian Coal Basin, Poland. Eng. Geol. 2020, 276, 105767. [Google Scholar] [CrossRef]

- Conrad, W.J. Microseismic Monitoring of a Room and Pillar Retreat Coal Mine in Southwest Virginia; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 2016. [Google Scholar]

- Ghosh, G.K.; Sivakumar, C. Application of underground microseismic monitoring for ground failure and secure longwall coal mining operation: A case study in an Indian mine. J. Appl. Geophys. 2018, 150, 21–39. [Google Scholar] [CrossRef]

- Wang, K.K.; Tang, C.A.; Ma, K.; Yu, G.F.; Ji, Y.L. Cross-related microseismic location based on improved particle swarm optimization and the double-difference location method of jointed coal rock mass. Waves Random Complex Media 2021, 2021, 2009151. [Google Scholar] [CrossRef]

- Khan, M.; He, X.Q.; Song, D.Z.; Tian, X.H.; Li, Z.L.; Xue, Y.R.; Aslam, K.S. Extracting and Predicting Rock Mechanical Behavior Based on Microseismic Spatio-temporal Response in an Ultra-thick Coal Seam Mine. Rock Mech. Rock Eng. 2023, 56, 3725–3754. [Google Scholar] [CrossRef]

- Di, Y.Y.; Wang, E.Y.; Li, Z.H.; Liu, X.F.; Huang, T.; Yao, J.J. Comprehensive early warning method of microseismic, acoustic emission, and electromagnetic radiation signals of rock burst based on deep learning. Int. J. Rock Mech. Min. Sci. 2023, 170, 105519. [Google Scholar] [CrossRef]

- Mondal, D.; Roy, P.N.S. Fractal and seismic b-value study during dynamic roof displacements (roof fall and surface blasting) for enhancing safety in the longwall coal mines. Eng. Geol. 2019, 253, 184–204. [Google Scholar] [CrossRef]

- Driad-Lebeau, L.; Lahaie, F.; Al Heib, M.; Josien, J.P.; Bigarré, P.; Noirel, J.F. Seismic and geotechnical investigations following a rockburst in a complex French mining district. Int. J. Coal Geol. 2005, 64, 66–78. [Google Scholar] [CrossRef]

- Li, T.; Mei, T.T.; Sun, X.H.; Lv, Y.G.; Sheng, J.Q.; Cai, M. A study on a water-inrush incident at Laohutai coalmine. Int. J. Rock Mech. Min. Sci. 2013, 59, 151–159. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Morioka, H.; Minami, M.; Maejima, T.; Tasaka, Y.; Kurose, H. FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations. Int. J. Rock Mech. Min. Sci. 2007, 44, 550–564. [Google Scholar] [CrossRef]

- Cheng, J.L.; Song, G.D.; Sun, X.Y.; Wen, L.F.; Li, F. Research developments and prospects on microseismic source location in mines. Engineering 2018, 4, 653–660. [Google Scholar] [CrossRef]

- Ge, M.C. Analysis of source location algorithms: Part I. Overview and non-iterative methods. J. Acoust. Emiss. 2003, 21, 14–28. [Google Scholar]

- Cong, S.; Wang, Y.H.; Cheng, J.Y. Coal mine microseismic velocity model inversion based on first arrival time difference. Arab. J. Geosci. 2019, 12, 1–9. [Google Scholar] [CrossRef]

- Zheng, Y.K.; Wang, Y.B.; Chang, X. Wave equation based microseismic source location and velocity inversion. Phys. Earth Planet. Inter. 2016, 261, 46–53. [Google Scholar] [CrossRef]

- Dong, L.J.; Sun, D.Y.; Li, X.B.; Du, K. Theoretical and experimental studies of localization methodology for AE and microseismic sources without pre-measured wave velocity in mines. IEEE Access 2017, 5, 16818–16828. [Google Scholar] [CrossRef]

- Kinscher, J.; Bernard, P.; Contrucci, I.; Mangeney, A.; Piguet, J.P.; Bigarre, P. Location of microseismic swarms induced by salt solution mining. Geophys. J. Int. 2015, 200, 337–362. [Google Scholar] [CrossRef]

- Dong, L.J.; Zou, W.; Li, X.B.; Shu, W.W.; Wang, Z.W. Collaborative localization method using analytical and iterative solutions for microseismic/acoustic emission sources in the rockmass structure for underground mining. Eng. Fract. Mech. 2019, 210, 95–112. [Google Scholar] [CrossRef]

- Zhou, J.; Shen, X.J.; Qiu, Y.G.; Shi, X.Z.; Khandelwal, M. Cross-correlation stacking-based microseismic source location using three metaheuristic optimization algorithms. Tunn. Undergr. Space Technol. 2022, 126, 104570. [Google Scholar] [CrossRef]

- Wang, K.K.; Tang, C.A.; Ma, K.; Wang, X.T.; Li, Q. An automatic recognition method of microseismic signals based on s transformation and improved gaussian mixture model. Adv. Civ. Eng. 2020, 2020, 8825990. [Google Scholar] [CrossRef]

- Sato, Y.; Skoko, D. Optimum distribution of seismic observation points. II. Bull. Earthquake Res. Inst. 1965, 43, 451–458. [Google Scholar]

- Kijko, A. An algorithm for the optimum distribution of a regional seismic network—I. Pure Appl. Geophys. 1977, 115, 999–1009. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, G.J.; Liu, Y.; Zhang, N.; Xue, J.H.; Zhang, W. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- Cheng, G.W.; Tang, C.A.; Li, L.C.; Chuai, X.Y.; Yang, T.H.; Wei, L.K. Micro-fracture precursors of water flow channels induced by coal mining: A case study. Mine Water Environ. 2021, 40, 398–414. [Google Scholar] [CrossRef]

- Li, Y.; Yang, T.H.; Liu, H.L.; Wang, H.; Hou, X.G.; Zhang, P.H.; Wang, P.T. Real-time microseismic monitoring and its characteristic analysis in working face with high-intensity mining. J. Appl. Geophys. 2016, 132, 152–163. [Google Scholar] [CrossRef]

- Mendecki, A.J.; Lynch, R.; Malovichko, D. Routine micro-seismic monitoring in mines. In Proceedings of the Australian Earthquake Engineering Society 2010 Conference, Perth, Australia, 26–28 November 2010; pp. 1–33. [Google Scholar]

- Mendecki, A.J. Keynote address: Real time quantitative seismology in mines. In Proceedings of the Third International Symposium on Rockbursts and Seismicity in Mines, Kingston, ON, Canada, 16–18 August 1993; pp. 287–295. [Google Scholar]

- Van Aswegen, G.; Butler, A.G. Applications of quantitative seismology in South African gold mines. In Proceedings of the Third International Symposium on Rockbursts and Seismicity in Mines, Kingston, ON, Canada, 16–18 August 1993; pp. 261–266. [Google Scholar]

- Mendecki, A.J. Seismic Monitoring in Mines; Chapman and Hall: London, UK, 1997. [Google Scholar]

- Gutenberg, B.; Richter, C.F. Frequency of earthquakes in California. Bull. Seismol. Soc. Am. 1944, 34, 185–188. [Google Scholar] [CrossRef]

- Utsu, T. A statistical study on the occurrence of aftershocks. Geophys. Mag. 1961, 30, 521–605. [Google Scholar]

- Eyre, T.S.; van der Baan, M. Overview of moment-tensor inversion of microseismic events. Lead. Edge 2015, 34, 882–888. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Martin, C.D. A Tensile Model for the Interpretation of Microseismic Events near Underground Openings. Pure Appl. Geophys. 1998, 153, 67–92. [Google Scholar] [CrossRef]

- Gibowicz, S.J.; Young, R.P.; Talebi, S.; Rawlence, D.J. Source parameters of seismic events at the Underground Research Laboratory in Manitoba, Canada: Scaling relations for events with moment magnitude smaller than −2. Bull. Seismol. Soc. Am. 1991, 81, 1157–1182. [Google Scholar]

- Gibowicz, S.J.; Kijko, A. An Introduction to Mining Seismology; Academic Press: San Diego, CA, USA, 1994. [Google Scholar]

- Boatwright, J.; Fletcher, J.B. The partition of radiated energy between P and S waves. Bull. Seismol. Soc. Am. 1984, 74, 361–376. [Google Scholar] [CrossRef]

- Duan, Y.; Si, G.Y.; Canbulat, I.; Luo, X. Temporal-spatial characterization of mining-induced seismicity in the vicinity of a dyke–A case study. Eng. Geol. 2022, 307, 106788. [Google Scholar] [CrossRef]

- Mu, W.Q.; Li, L.C.; Zhang, Y.S.; Yu, G.F.; Ren, B. Failure mechanism of grouted floor with confined aquifer based on mining-induced data. Rock Mech. Rock Eng. 2023, 56, 2897–2922. [Google Scholar] [CrossRef]

- Wojtecki, Ł.; Mendecki, M.J.; Zuberek, W.M.; Knopik, M. An attempt to determine the seismic moment tensor of tremors induced by destress blasting in a coal seam. Int. J. Rock Mech. Min. Sci. 2016, 83, 162–169. [Google Scholar] [CrossRef]

- Gilbert, F. Excitation of the normal modes of the Earth by earthquake sources. Geophys. J. Int. 1970, 22, 223–226. [Google Scholar] [CrossRef]

- Song, C.H.; Lu, C.P.; Zhang, X.F.; Wang, C.; Xie, H.D.; Yan, X.Y.; Wang, H.W. Moment tensor inversion and stress evolution of coal pillar failure mechanis. Rock Mech. Rock Eng. 2022, 55, 2371–2383. [Google Scholar] [CrossRef]

- Ma, K.; Sun, X.Y.; Tang, C.A.; Wang, S.J.; Yuan, F.Z. An early warning method for water inrush in Dongjiahe coal mine based on microseismic moment tensor. J. Cent. South Univ. 2020, 27, 3133–3148. [Google Scholar] [CrossRef]

- Wu, K.B.; Zou, J.P.; Jiao, Y.Y.; Zhang, X.F.; Wang, C. Focal mechanism of strong ground seismicity induced by deep coal mining. Rock Mech. Rock Eng. 2023, 56, 779–795. [Google Scholar] [CrossRef]

- Cheng, G.W.; Li, L.C.; Zhu, W.C.; Yang, T.H.; Tang, C.A.; Zhang, Y.; Wang, Y. Microseismic investigation of mining-induced brittle fault activation in a Chinese coal mine. Int. J. Rock Mech. Min. Sci. 2019, 123, 104096. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, R.; Maiti, J.; Kumar, R.; Mandal, P.K. Assessment of mining induced stress development over coal pillars during depillaring. Int. J. Rock Mech. Min. Sci. 2011, 48, 805–818. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, G.J.; Zhang, N.; Zhao, T.B.; Liu, Y. Inversion of stress field evolution consisting of static and dynamic stresses by microseismic velocity tomography. Int. J. Rock Mech. Min. Sci. 2016, 87, 8–22. [Google Scholar] [CrossRef]

- Maxwell, S.C.; Young, R.P. Sequential velocity imaging and microseismic monitoring of mining-induced stress change. Pure Appl. Geophys. 1992, 139, 421–447. [Google Scholar] [CrossRef]

- Luxbacher, K.; Westman, E.; Swanson, P.; Karfakis, M. Three-dimensional time-lapse velocity tomography of an underground longwall panel. Int. J. Rock Mech. Min. Sci. 2008, 45, 478–485. [Google Scholar] [CrossRef]

- Nolet, G. A Breviary of Seismic Tomography; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Cai, W.; Dou, L.M.; Cao, A.Y.; Gong, S.Y.; Li, Z.L. Application of seismic velocity tomography in underground coal mines: A case study of Yima mining area, Henan, China. J. Appl. Geophys. 2014, 109, 140–149. [Google Scholar] [CrossRef]

- Wang, G.F.; Gong, S.Y.; Dou, L.M.; Wang, H.; Cai, W.; Cao, A.Y. Rockburst characteristics in syncline regions and microseismic precursors based on energy density clouds. Tunn. Undergr. Space Technol. 2018, 81, 83–93. [Google Scholar] [CrossRef]

- Li, X.L.; Li, Z.H.; Wang, E.Y.; Feng, J.J.; Chen, L.; Li, N.; Kong, X.J. Extraction of microseismic waveforms characteristics prior to rock burst using Hilbert–Huang transform. Measurement 2016, 91, 101–113. [Google Scholar] [CrossRef]

- Lu, C.P.; Dou, L.M.; Liu, B.; Xie, Y.S.; Liu, H.S. Microseismic low-frequency precursor effect of bursting failure of coal and rock. J. Appl. Geophys. 2012, 79, 55–63. [Google Scholar] [CrossRef]

- Shu, L.Y.; Liu, Z.S.; Wang, K.; Zhu, N.N.; Yang, J. Characteristics and Classification of Microseismic Signals in Heading Face of Coal Mine: Implication for Coal and Gas Outburst Warning. Rock Mech. Rock Eng. 2022, 55, 6905–6919. [Google Scholar] [CrossRef]

- Wang, Y.J.; Qiu, Q.; Lan, Z.Q.; Chen, K.Y.; Zhou, J.; Gao, P.; Zhang, W. Identifying microseismic events using a dual-channel CNN with wavelet packets decomposition coefficients. Comput. Geosci. 2022, 166, 105164. [Google Scholar] [CrossRef]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 44, 28–38. [Google Scholar] [CrossRef]

- Cheng, G.W.; Ma, T.H.; Tang, C.A.; Liu, H.Y.; Wang, S.J. A zoning model for coal mining-induced strata movement based on microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 94, 123–138. [Google Scholar] [CrossRef]

- Mondal, D.; Roy, P.N.S.; Kumar, M. Roof fall threat analysis using fractal pattern recognition and neural network over mine microseismicity in a Central Indian longwall panel overlain by massive sandstone roof. Geosyst. Geoenviron. 2023, 2, 100138. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, J.; Xiao, H.T. Case study on overburden fracturing during longwall top coal caving using microseismic monitoring. Rock Mech. Rock Eng. 2017, 50, 507–511. [Google Scholar] [CrossRef]

- Ning, J.G.; Wang, J.; Jiang, L.S.; Jiang, N.; Liu, X.S.; Jiang, J.Q. Fracture analysis of double-layer hard and thick roof and the controlling effect on strata behavior: A case study. Eng. Fail. Anal. 2017, 81, 117–134. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, Y.; Wang, H.Y.; Liu, P.F. Microseismic signals of double-layer hard and thick igneous strata separation and fracturing. Int. J. Coal Geol. 2016, 160, 28–41. [Google Scholar] [CrossRef]

- Lu, C.P.; Dou, L.M.; Zhang, N.; Xue, J.H.; Wang, X.N.; Liu, H.; Zhang, J.W. Microseismic frequency-spectrum evolutionary rule of rockburst triggered by roof fall. Int. J. Rock Mech. Min. Sci. 2013, 64, 6–16. [Google Scholar] [CrossRef]

- Cao, A.Y.; Dou, L.M.; Wang, C.B.; Yao, X.X.; Dong, J.Y.; Gu, Y. Microseismic precursory characteristics of rock burst hazard in mining areas near a large residual coal pillar: A case study from Xuzhuang coal mine, Xuzhou, China. Rock Mech. Rock Eng. 2016, 49, 4407–4422. [Google Scholar] [CrossRef]

- Wang, G.F.; Gong, S.Y.; Dou, L.M.; Cai, W.; Yuan, X.Y.; Fan, C.J. Rockburst mechanism and control in coal seam with both syncline and hard strata. Saf. Sci. 2019, 115, 320–328. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Wang, E.Y.; Feng, X.J.; Wang, C.; Qiu, L.M.; Wang, H. Assessment of rockburst risk in deep mining: An improved comprehensive index method. Nat. Resour. Res. 2021, 30, 1817–1834. [Google Scholar] [CrossRef]

- Dou, L.M.; Cai, W.; Cao, A.Y.; Guo, W.H. Comprehensive early warning of rock burst utilizing microseismic multi-parameter indices. Int. J. Min. Sci. Technol. 2018, 28, 767–774. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.M.; Zhang, M.; Cao, W.Z.; Shi, J.Q.; Feng, L.F. A fuzzy comprehensive evaluation methodology for rock burst forecasting using microseismic monitoring. Tunn. Undergr. Space Technol. 2018, 80, 232–245. [Google Scholar] [CrossRef]

- Ogawa, T.; Oike, K.; Miura, T. Electromagnetic radiations from rocks. J. Geophys. Res. 1985, 90, 6245–6250. [Google Scholar] [CrossRef]

- Dou, L.M.; Lu, C.P.; Mu, Z.L.; Gao, M.S. Prevention and forecasting of rock burst hazards in coal mines. Min. Sci. Technol. 2009, 19, 585–591. [Google Scholar] [CrossRef]

- Li, X.L.; Wang, E.Y.; Li, Z.H.; Liu, Z.T.; Song, D.Z.; Qiu, L.M. Rock burst monitoring by integrated microseismic and electromagnetic radiation methods. Rock Mech. Rock Eng. 2016, 49, 4393–4406. [Google Scholar] [CrossRef]

- Mu, H.W.; Song, D.Z.; He, X.Q.; Li, Z.L.; Su, D.F.; Xue, Y.R. Regional local integrated rockburst monitoring and early warning for multi-seam mining. J. Geophys. Eng. 2021, 18, 725–739. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.G.; Wang, Z.S.; Hou, H.Q.; Shen, Y.F. Determining areas in an inclined coal seam floor prone to water-inrush by micro-seismic monitoring. Min. Sci. Technol. 2011, 21, 165–168. [Google Scholar]

- Ma, K.; Sun, X.Y.; Tang, C.A.; Yuan, F.Z.; Wang, S.J.; Chen, T. Floor water inrush analysis based on mechanical failure characters and microseismic monitoring. Tunn. Undergr. Space Technol. 2021, 108, 103698. [Google Scholar] [CrossRef]

- Zuo, J.P.; Wu, G.S.; Du, J.; Lei, B.; Li, Y.B. Rock strata failure behavior of deep ordovician limestone aquifer and multi-level control technology of water inrush based on microseismic monitoring and numerical methods. Rock Mech. Rock Eng. 2022, 55, 4591–4614. [Google Scholar] [CrossRef]

- Li, C.Y.; Zuo, J.P.; Xing, S.K.; Du, W.X.; Chuai, X.Y. Failure behavior and dynamic monitoring of floor crack structures under high confined water pressure in deep coal mining: A case study of Hebei, China. Eng. Fail. Anal. 2022, 139, 106460. [Google Scholar] [CrossRef]

- Fan, C.J.; Li, S.; Luo, M.K.; Du, W.Z.; Yang, Z.H. Coal and gas outburst dynamic system. Int. J. Min. Sci. Technol. 2017, 27, 49–55. [Google Scholar] [CrossRef]

- Wang, A.H.; Song, D.Z.; He, X.Q.; Dou, L.M.; Li, Z.L.; Zu, Z.Y.; Lou, Q.; Zhao, Y.J. Investigation of coal and gas outburst risk by microseismic monitoring. PLoS ONE 2019, 14, e0216464. [Google Scholar] [CrossRef]

- Lu, C.P.; Dou, L.M.; Liu, H.; Liu, H.S.; Liu, B.; Du, B.B. Case study on microseismic effect of coal and gas outburst process. Int. J. Rock Mech. Min. Sci. 2012, 53, 101–110. [Google Scholar] [CrossRef]

- Si, G.Y.; Durucan, S.; Jamnikar, S.; Lazar, J.; Abraham, K.; Korre, A.; Shi, J.Q.; Zavšek, S.; Mutke, G.; Lurka, A. Seismic monitoring and analysis of excessive gas emissions in heterogeneous coal seams. Int. J. Coal Geol. 2015, 149, 41–54. [Google Scholar] [CrossRef]

- Ding, Y.L.; Dou, L.M.; Cai, W.; Chen, J.J.; Kong, Y.; Su, Z.G.; Li, Z.L. Signal characteristics of coal and rock dynamics with micro-seismic monitoring technique. Int. J. Min. Sci. Technol. 2016, 26, 683–690. [Google Scholar] [CrossRef]

- Zhang, E.H.; Zhou, B.K.; Yang, L.; Li, C.F.; Li, P. Experimental study on the microseismic response characteristics of coal and gas outbursts. Process. Saf. Environ. Prot. 2023, 172, 1058–1071. [Google Scholar] [CrossRef]

- Lagos, S.; Velis, D. Microseismic event location using global optimization algorithms: An integrated and automated workflow. J. Appl. Geophys. 2018, 149, 18–24. [Google Scholar] [CrossRef]

- Hassani, H.; Hloušek, F.; Alexandrakis, C.; Buske, S. Migration-based microseismic event location in the Schlema-Alberoda mining area. Int. J. Rock Mech. Min. Sci. 2018, 110, 161–167. [Google Scholar] [CrossRef]

- Huang, L.Q.; Hao, H.; Li, X.B.; Li, J. Source identification of microseismic events in underground mines with interferometric imaging and cross wavelet transform. Tunn. Undergr. Space Technol. 2018, 71, 318–328. [Google Scholar] [CrossRef]

- Chen, H.L.; Xue, S.; Zheng, X.L. Coal mine microseismic identification and first-arrival picking based on Conv-LSTM-Unet. Acta Geophys. 2023, 71, 161–173. [Google Scholar] [CrossRef]

- Zhu, M.B.; Cheng, J.Y.; Zhang, Z. Quality control of microseismic P-phase arrival picks in coal mine based on machine learning. Comput. Geosci. 2021, 156, 104862. [Google Scholar] [CrossRef]

- Tang, S.B.; Wang, J.X.; Tang, C.A. Identification of microseismic events in rock engineering by a convolutional neural network combined with an attention mechanism. Rock Mech. Rock Eng. 2021, 54, 47–69. [Google Scholar] [CrossRef]

- Li, J.M.; Tang, S.B.; Li, K.Y.; Zhang, S.C.; Tang, L.X.; Cao, L.Y.; Ji, F.Q. Automatic recognition and classification of microseismic waveforms based on computer vision. Tunn. Undergr. Space Technol. 2022, 121, 104327. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, T.H.; Zhang, P.H.; Zhou, J.R.; Yu, Q.L.; Deng, W.X. The analysis of rock damage process based on the microseismic monitoring and numerical simulations. Tunn. Undergr. Space Technol. 2017, 69, 1–17. [Google Scholar] [CrossRef]

- Singh, S.K.; Banerjee, B.P.; Raval, S. A review of laser scanning for geological and geotechnical applications in underground mining. Int. J. Min. Sci. Technol. 2023, 33, 133–154. [Google Scholar] [CrossRef]

- Zhang, S.; Bogus, S.M.; Lippitt, C.D.; Kamat, V.; Lee, S.H. Implementing remote-sensing methodologies for construction research: An unoccupied airborne system perspective. J. Constr. Eng. Manag. 2022, 148, 03122005. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, X.T.; Yao, Z.B.; Zhang, W.; Hu, L.; Wang, J.; Guo, X.Q.; Niu, W.J.; Quan, Y.W. Failure characteristics and development mechanism of fault rockburst in a deep TBM tunnel: A case study. Acta GeoTechnol. 2023, 18, 575–5596. [Google Scholar] [CrossRef]

| Accident Type | Deaths | Accident Type | Deaths |

|---|---|---|---|

| Gas explosion | 23,866 | Electromechanical accident | 1496 |

| Roof accident | 23,769 | Fire | 1092 |

| Haulage accident | 6381 | Blasting accident | 1053 |

| Mine water inrush | 5210 | Others | 4502 |

| Parameter | Description |

|---|---|

| Event count/rate | The number of microseismic events, and is used to reflect the frequency of rock fracture. |

| Seismic potency P | The seismic potency represents the co-seismic inelastic deformation at the microseismic source, and is written as , where, vP, S is P-wave or S-wave velocity, R is the distance from the microseismic source, ucorr(t) is the square of the seismic wave displacement pulse corrected for the far-field radiation pattern, and ts is source duration [61]. |

| Seismic energy E | The energy of the microseismic event reflects the intensity of rock fracturing. Seismic energy of the P-wave or S-wave can be calculated as , where, ρ denotes rock density [61]. |

| Seismic moment M0 | A parameter measures the inelastic deformation at the microseismic source, and can be calculated as M0 = μP, where, μ denotes rock shear modulus. |

| Apparent stress σA | Apparent stress is the ratio of the seismic energy E to the seismic potency P [61]. |

| Apparent volume VA | Apparent volume, often used together with the energy index, scales the rock volume with the inelastic change, and is written as VA = M02/(2μE) [62]. |

| Energy index EI | Energy index is the ratio of seismic energy E of a microseismic event to the average energy of microseismicities with potency P, and can be calculated as [63]. |

| Schmidt number Sc | A parameter measures the spatio-temporal complexity of seismic flow and reflects the potential instability, and can be calculated as , where, ΔV denotes the volume of interest, Δt is the time step, is the mean time of microseismicities, t1 is the start time of a time period, t2 is the end time of a time period, denotes the mean distance between interacting microseismicities, Mij is the seismic moment [64]. |

| Fault total area A(t) | Fault total area is defined as , where, k0 and k are the lower limit energy level and energy level of the microseismicity, respectively, N(k) denotes the event count of a given energy level k [58]. |

| b value | The slope of the Gutenberg and Richter relation written as log N = a-bM, where M is the magnitude, N is the number of seismicities with magnitude larger than M, a is a constant reflecting the level of seismicities [65]. |

| Lack of shock bL | A statistical parameter defined as , where, is the average energy level, and M0 is the initial energy level [66]. |

| Z value | Z value is a parameter to describe the rockburst risk defined as , where, and are the arithmetic mean of average magnitude samples in the statistical period and the observation period, respectively, N and n are the numbers of and samples, σM and σm are their standard deviations, respectively [58]. |

| Occurrence Time | Location | Description of the Rockburst |

|---|---|---|

| 19 June 2007 | 25080 working face of Yuejin coal mine | destructed a nearly 300-m-long roadway. |

| 5 June 2008 | 21201 working face of Qianqiu coal mine | killed 13 miners and damaged a 565-m-long roadway |

| 1 March 2011 | 25110 working face of Yuejin coal mine | damaged a 200-m-long roadway |

| 15 October 2012 | Xing’an coal mine | damaged a 104-m-long section of the roadway |

| 15 March 2013 | Junde coal mine | trapped 25 miners, and destructed the tailgate and headgate |

| 26 July 2015 | 3302 working face of Xingcun coal mine | damaged a 200-m-long roadway |

| 22 December 2015 | 13230 working face of Gengcun coal mine | damaged more than 160-m-long roadway |

| 15 September 2016 | Open-off cut of Junde coal mine | trapped and suffocated five miners |

| 20 October 2018 | Longyun Coal Industry Co., Ltd., Yuzhou, China | killed 21 miners |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Wang, Y.; Kou, M.; Liang, C. Applications of Microseismic Monitoring Technique in Coal Mines: A State-of-the-Art Review. Appl. Sci. 2024, 14, 1509. https://doi.org/10.3390/app14041509

Liu F, Wang Y, Kou M, Liang C. Applications of Microseismic Monitoring Technique in Coal Mines: A State-of-the-Art Review. Applied Sciences. 2024; 14(4):1509. https://doi.org/10.3390/app14041509

Chicago/Turabian StyleLiu, Fei, Yan Wang, Miaomiao Kou, and Changhui Liang. 2024. "Applications of Microseismic Monitoring Technique in Coal Mines: A State-of-the-Art Review" Applied Sciences 14, no. 4: 1509. https://doi.org/10.3390/app14041509