A Quality Management Method for Prefabricated Building Design Based on BIM and VR-Integrated Technology

Abstract

1. Introduction

2. Literature Review

2.1. Quality Management of Prefabricated Buildings

2.2. Application of BIM Technology in the Building Design Phase

2.3. Application of BIM and VR Integrated Technology in the Field of Construction

3. Methods

3.1. Identification and Analysis of Quality Factors Based on AHP

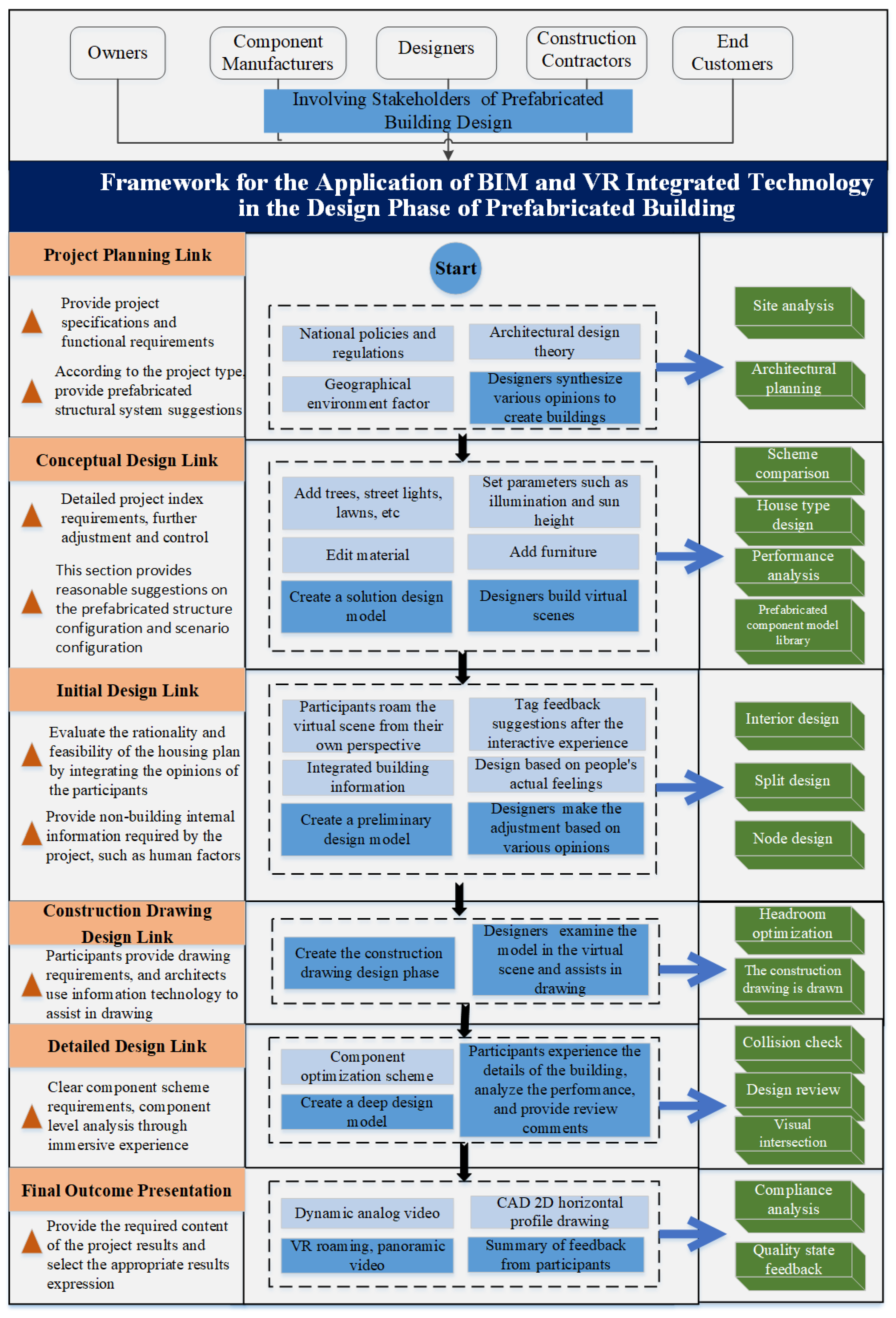

3.2. Framework for the Application of BIM and VR-Integrated Technology in the Design Phase of Prefabricated Building

- Utilizing the extensive integrated architectural data of BIM technology and the highly performed visual expression of VR systems to address the two significant challenges in the current designs, the unknown architectural effects and project control difficulties. With this help, errors caused by insufficient design and asymmetric design information will be significantly reduced, and design efficiency and accuracy will greatly improve.

- Adopting a collaborative design platform, integrating highly performed visual and intuitive experiences with continuous interactive feedback during the design process and evaluation, starting from human perception and a first-person perspective. This platform reduces design collisions and blind spots, multi-dimensionally integrates BIM concepts, and reinforces the comprehensive applicability of BIM models, including material rendering, design review, roaming, collision detection, sustainability analysis, etc., thus improving quality management during the prefabricated building design process.

- Integrating VR technology’s highly performed visual expression into the design process and using three-dimensional dynamic simulation and interactive experiences. Real project simulations and renderings help compare and optimize different plans, achieving the best design performance.

3.2.1. Project Planning Link

3.2.2. Conceptual Design Link

3.2.3. Initial Design Link

3.2.4. Construction Drawing Design Link

3.2.5. Detailed Design Link

3.2.6. Final Outcome Presentation

4. Case Study

4.1. Prefabricated Component Model Library and Model Data Processing

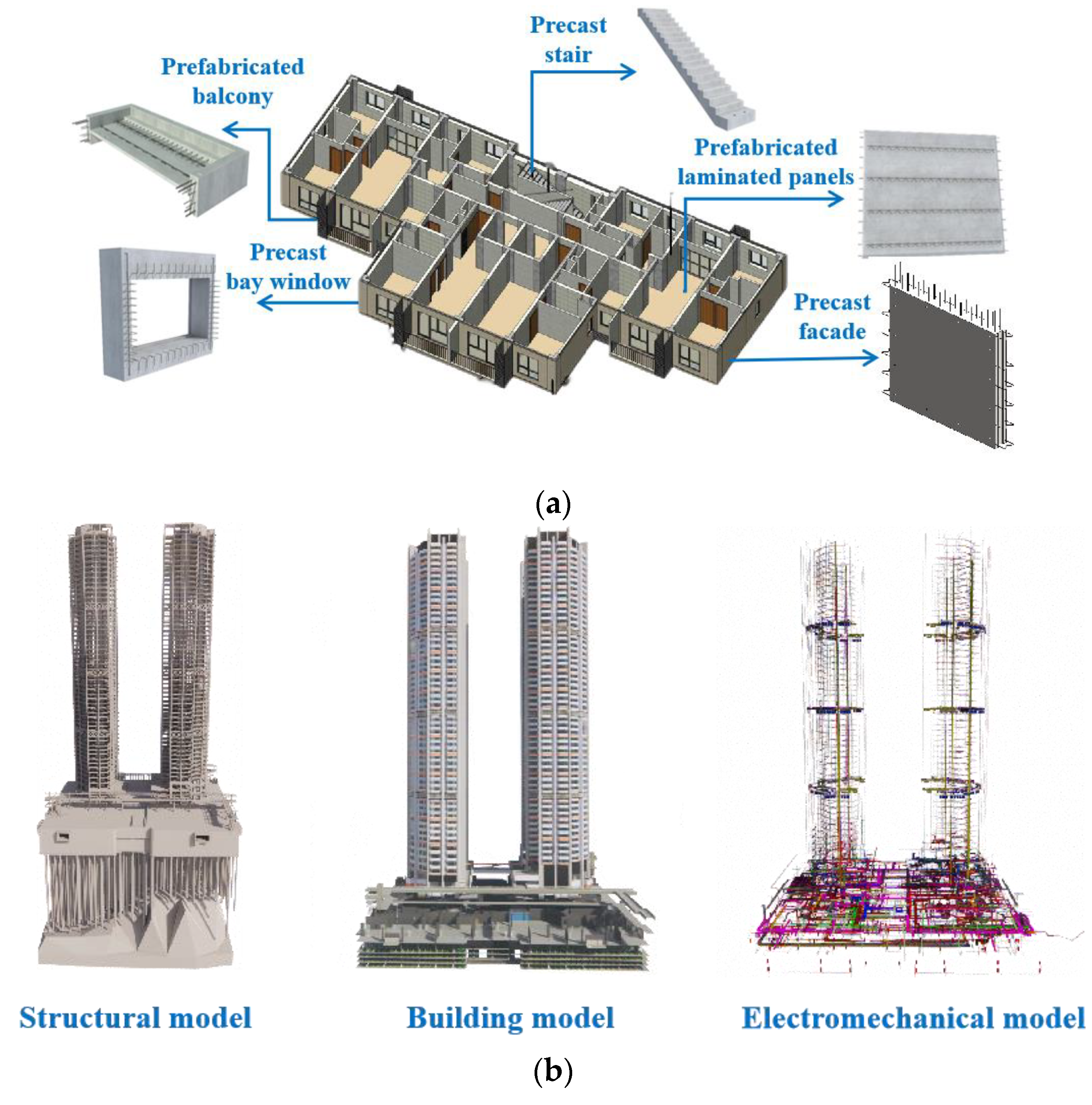

4.1.1. Prefabricated Component Model Library

4.1.2. Processing and Conversion of Model Data

4.2. Interior Scheme Design and Scene Design

4.2.1. Interior Scheme Design

4.2.2. Scene Design and Material Selection

4.3. Visual Collaborative Design

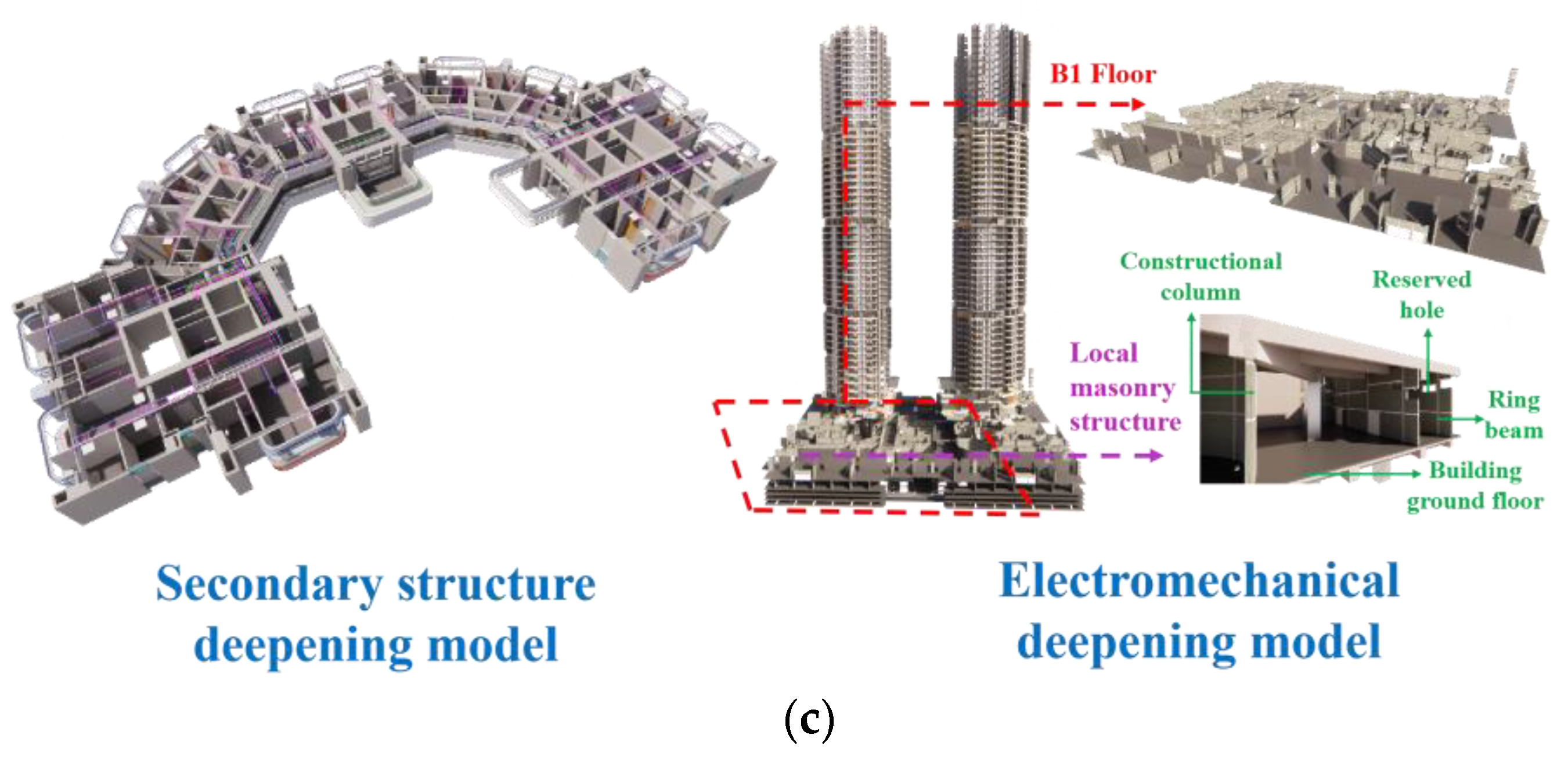

4.4. Design Check

4.4.1. Collision Check

4.4.2. Design Review and Quality Status Feedback

4.5. Outputs

5. Results and Discussion

5.1. Testing and Evaluation

- System Usability Scale (SUS): 10 Likert-scale questions scored out of 5 [41], encompassing positive and negative aspects.

- Objective Performance Evaluation: Through controlled experiments comparing this method with two existing traditional design methods, the usability of this method is quantitatively analyzed. It mainly compares and examines the number of design errors detected in collision tests and the number of design errors or queries raised in drawing reviews during the design evaluation phase of prefabricated buildings.

- Open-Ended Interview Theme Analysis: Following the principle of voluntariness, 15 stakeholders who had participated in the survey questionnaire were invited for open-ended interviews and theme analysis, aiming to evaluate the usefulness, functionality, spatial experience, and challenges of the method.

5.2. Reliability of the Evaluation Tool

5.3. Usability Evaluation

5.3.1. Objective Performance Evaluation

5.3.2. System Usability Scale Evaluation

5.4. Open-Ended Interview Theme Analysis

- What advantages have you found in prefabricated building design using BIM and VR-integrated technology compared to traditional design methods? (Effectiveness)

- Can this method improve the quality of the design phase? (Functionality)

- How is the spatial experience different from this method compared to traditional design methods? (Spatial Experience)

- What challenges do you think will arise from the comprehensive application of this method? (Challenges)

5.4.1. Effectiveness

- (1)

- Improvement of Design Tools. Participants (n = 12) believed that this method optimized the 2D drawing output process, enabling the automatic export of detailed component drawings, construction node details, design annotations, and other complex drawings. This method also enhanced the accuracy and precision of prefabricated building design drawings, aiding in comprehensive quality control of design drawings at the design phase. Participants (n = 8) expressed that project stakeholders could effectively select different design outcomes per their needs, enhancing the comprehensiveness and objectivity of the final design review and providing a solid foundation for project communication in subsequent construction and operation phases. Participants (n = 3) mentioned, “This method requires BIM model data to support import, reading, conversion, and output functionalities, demanding richness, integration, and uniformity in model data. This will stimulate the number and scope of collaborative design software, supporting collaborative design development in the prefabricated building.”

- (2)

- Optimization of Workflow. Participants (n = 11) believed that the design environment created by BIM and VR-integrated technology provided a platform for real-time design participation and immersive virtual reality experiences for all project stakeholders and the public. This enabled different roles to fully engage in the design process, offering real-time feedback on professional opinions and fostering the development of multi-threaded workflows. Therefore, it avoided common issues in traditional design methods, such as frequent design conflicts, lengthy coordination meetings, delays in design change communication, and significant discrepancies between drawings and models, severely affecting the quality and efficiency of prefabricated building design.

- (3)

- Shift in Design Thinking. Participants (n = 8) believed this method had led to a shift toward holistic thinking and a lifecycle awareness among designers. Specifically, in the early design phases, when a virtual site was created, the designers would take environmental factors (e.g., sunlight, sound, and wind) into account to propose project planning solutions; in subsequent phases like scheme design, preliminary design, and construction drawing design, there was a continuous “communication-dialogue” with the architecture, finalizing design contents based on real human experiences and refining the design proposals. After the design proposals were completed, the integration of models, simulations, and immersive experiences was used to test the feasibility of the plans to select the best building materials and interior design furniture, focusing on user experience feedback. Participants (n = 5) also mentioned that the design process now included simulations and considerations for construction feasibility and operational maintenance, contributing to the lifecycle development of prefabricated buildings.

5.4.2. Functionality

- (1)

- Participants (n = 9) believed that starting from the project research and planning phase, inputting relevant data of the building project into the virtual scenes helped enhance the scientific nature and accuracy of the architectural scheme.

- (2)

- Participants (n = 13) believed that this method, based on the highly performed visualization of VR technology, allowed design participants of various roles to provide realistic architectural requirements from their perspective, such as clients’ requirements on overall project planning and architectural design, the designer’s consideration of architectural aesthetics, the structural engineer’s validation of structural reliability, and the public’s daily needs for building functionality. This is conducive to managing the overall integrity of the design, improving work efficiency and quality.

- (3)

- Participants (n = 8) believed this method had increased public participation and influence. This method went beyond just the project planning research phase, since it allowed experiencing the architectural functionality from a first-person perspective and enabled the public to contribute design opinions and everyday life needs. Incorporating public feedback and real human experience design improved the final product’s acceptability and increased product satisfaction.

- (4)

- Participants (n = 15) believed that by using the collaborative design platform of BIM and VR-integrated technology, the stakeholders could maintain continuous communication, provide feedback, experience, and interact throughout the design process, which would avoid collisions and “blind spots” between architectural design and project implementation, preemptively eliminate design errors and significantly enhance the quality of prefabricated building design.

5.4.3. Sense of Space Experience

5.4.4. Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Fung, I.W.H.; Sing, M.C.P.; Ogunlana, S. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Navaratnam, S.; Satheeskumar, A.; Zhang, G.; Nguyen, K.; Venkatesan, S.; Poologanathan, K. The challenges confronting the growth of sustainable prefabricated building construction in Australia: Construction industry views. J. Build. Eng. 2022, 48, 103935. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, F.; Ji, Y.; Tong, W.; Liu, G.; Li, H.; Hu, X. Quality control for offsite construction: Review and future directions. J. Constr. Eng. Manag. ASCE 2022, 148, 14. [Google Scholar] [CrossRef]

- Yang, S.; Hou, Z.; Chen, H. Network model analysis of quality control factors of prefabricated buildings based on the complex network theory. Buildings 2022, 12, 1874. [Google Scholar] [CrossRef]

- Gan, Y.; Shen, L.; Chen, J.; Tam, V.W.Y.; Tan, Y.; Illankoon, I.M.C.S. Critical factors affecting the quality of industrialized building system projects in China. Sustainability 2017, 9, 216. [Google Scholar] [CrossRef]

- Liu, H.; Duan, Y. Production and construction quality management system of prefabricated buildings based on BIM technology. IJISE Int. J. Ind. Syst. Eng. 2023, 43, 103–114. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Michele, F.; Klose, E.M.; Alemanno, M.L.V.; Isabella, G.; Gabriele, S. In user study on virtual reality for design reviews in architecture. In Proceedings of the 2020 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct), Recife, Brazil, 9–13 November 2020. [Google Scholar]

- Ye, S. Design and evaluation for immersive virtual reality learning environment: A systematic literature review. Sustainability 2023, 15, 1964. [Google Scholar]

- Coletto, M. ISO 9000 Quality Standards. In Quality Management: Tools, Methods, and Standards; De Monte, T., Marco, S., Guido, O., Eds.; Emerald Publishing Limited: Bingley, UK, 2019; pp. 187–198. [Google Scholar]

- Zhang, J.; Wang, M.; Zhao, L.; Chen, M. Analysis of factors affecting prefabricated building quality based on ISM-BN. Sustainability 2023, 15, 9682. [Google Scholar] [CrossRef]

- Lee, D.; Han, K. In vision-based quality assessment of prefabricated components using images and camera poses. In Proceedings of the Construction Research Congress 2020, Tempe, AZ, USA, 9 November 2020; pp. 1021–1029. [Google Scholar]

- Duan, Y.; Li, G. In analysis on the quality problems and preventive measures of prefabricated building construction. In Proceedings of the 2018 7th International Conference on Advanced Materials and Computer Science (ICAMCS 2018), Dalian, China, 21 December 2018; pp. 411–414. [Google Scholar]

- Chang, C.; Wang, J.; Li, H. Identification and control of quality elements for prefabricated concrete constructions. J. Shenyang Jianzhu Univ. 2016, 18, 59–63. [Google Scholar]

- Masood, R.; Lim, J.B.P.; Gonzalez, V.A. Performance of the supply chains for New Zealand prefabricated house-building–ScienceDirect. Sustain. Cities Soc. 2020, 64, 102537. [Google Scholar] [CrossRef]

- Xia, M.; Zhao, L.; Qiao, Y.; Yuan, Z.; Cui, Y.; Zhao, L.; Li, J. Analysis of factors affecting the quality of precast components based on Structural Equation Modeling. Arab. J. Sci. Eng. 2022, 47, 4171–4185. [Google Scholar] [CrossRef]

- Su, Y.; Zhao, J.; Xu, Y.; Si, H. Research on quality problems and improvement of production and construction of prefabricated building. Constr. Econ. 2016, 37, 43–48. [Google Scholar]

- Zhang, Z.; Yuan, Z.; Ni, G.; Lin, H.; Lu, Y. The quality traceability system for prefabricated buildings using blockchain: An integrated framework. Front. Eng. Manag. 2020, 7, 528–546. [Google Scholar] [CrossRef]

- Cao, J.; Ji, F.; Xie, B.; Wu, Z. BIM-based prefabricated construction quality management. J. Civ. Eng. Manag. 2017, 34, 109–113. [Google Scholar]

- Chen, L.; Luo, H. A BIM-based construction quality management model and its applications. Autom. Constr. 2014, 46, 64–73. [Google Scholar] [CrossRef]

- Zollinger, W.R.; Sutton, D.L.; Montler, G.; Seifried, M.M. BIM: Sharing project data reduces conflict. AACE Int. Trans. 2010, 1, 37–53. [Google Scholar]

- Redmond, A.; Hore, A.; Alshawi, M.; West, R. Exploring how information exchanges can be enhanced through Cloud BIM. Autom. Constr. 2012, 24, 175–183. [Google Scholar] [CrossRef]

- Kim, C.M.; Son, H.; Kim, C.W. Automated construction progress measurement using a 4D building information model and 3D data. Autom. Constr. 2013, 31, 75–82. [Google Scholar] [CrossRef]

- Wang, J.; Sun, W.; Shou, W.; Wang, X.; Sun, C. Integrating BIM and LiDAR for real-time construction quality control. J. Intell. Robot. Syst. 2015, 79, 417–432. [Google Scholar] [CrossRef]

- Park, C.S.; Lee, D.Y.; Kwon, O.S.; Wang, X. A framework for proactive construction defect management using BIM, augmented reality and ontology-based data collection template. Autom. Constr. 2013, 33, 61–71. [Google Scholar] [CrossRef]

- Du, J.; Zou, Z.; Shi, Y.; Zhao, D. Zero latency: Real-time synchronization of BIM data in virtual reality for collaborative decision-making. Autom. Constr. 2018, 85, 51–64. [Google Scholar] [CrossRef]

- Freeman, I.J.; Salmon, J.L.; Coburn, J.Q. In CAD integration in virtual reality design reviews for improved engineering model interaction. In Proceedings of the Asme International Mechanical Engineering Congress & Exposition, Phoenix, AZ, USA, 11 November 2016. [Google Scholar]

- Afzal, M.; Shafiq, M.T.; Jassmi, H.A. Improving construction safety with virtual-design construction technologies: A review. J. Inf. Technol. Constr. 2021, 26, 319–340. [Google Scholar] [CrossRef]

- Oladokun, T.T.; Ayodele, T.O.; Adegoke, A.S.; Olaleye, S.O.; Agbato, S.E.; Jinadu, A.D. Analysing the criteria for measuring the determinants of virtual reality technology adoption in real estate agency practice in Lagos: A DEMATEL method. Prop. Manag. 2022, 40, 285–301. [Google Scholar]

- Lucio, C.; Andrea, M.; Francesco, C.; Mauro, B.; Vito, P. In A novel 3D user interface for the immersive design review. In Proceedings of the IEEE Symposium on 3D User Interfaces 2015, Arles, France, 23–24 March 2015; pp. 175–176. [Google Scholar]

- Josef, W. Analyzing the potential of virtual reality for engineering design review. Autom. Constr. 2019, 104, 27–37. [Google Scholar]

- Kamat, V.R.; Martinez, J.C.; Fischer, M.; Golparvar-Fard, M.; Pena-Mora, F.; Savarese, S. Research in visualization techniques for field construction. J. Constr. Eng. Manag. ASCE 2010, 137, 853–862. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Lu, X.; Zhang, H. BIM-based integrated information framework for architectural and structural design model. J. Tongji Univ. 2010, 38, 948–953. [Google Scholar]

- Wang, X. BIM handbook: A guide to building information modeling for owners, managers, designers, engineers and contractors. AJCEB 2012, 12, 101–102. [Google Scholar] [CrossRef]

- Castronovo, F.; Nikolic, D.; Liu, Y.F.; Messner, J. In an evaluation of immersive virtual reality systems for design reviews. In Proceedings of the 13th International Conference on Construction Applications of Virtual Reality, London, UK, 30–31 October 2013. [Google Scholar]

- Yan, W.; Culp, C.; Graf, R. Integrating BIM and gaming for real-time interactive architectural visualization. Autom. Constr. 2011, 20, 446–458. [Google Scholar] [CrossRef]

- Boton, C. Supporting constructability analysis meetings with immersive virtual reality-based collaborative BIM 4D simulation. Autom. Constr. 2018, 96, 1–15. [Google Scholar] [CrossRef]

- Yu, T.; Man, Q.; Wang, Y.; Shen, Q.; Hong, J.; Zhang, J. Evaluating different stakeholder impacts on the occurrence of quality defects in offsite construction projects: A Bayesian-network-based model. J. Clean. Prod. 2019, 241, 118390. [Google Scholar] [CrossRef]

- Brooke, J. SUS—A quick and dirty usability scale. In Usability Evaluation In Industry; CRC Press: Boca Raton, FL, USA, 1996; pp. 189–194. [Google Scholar]

- Brade, J.; Lorenz, M.; Busch, M.; Hammer, N.; Tscheligi, M.; Klimant, P. Being there again: Presence in real and virtual environments and its relation to usability and user experience using a mobile navigation task. Int. J. Hum.-Comput. Stud. 2017, 101, 76–87. [Google Scholar] [CrossRef]

| Target Layer | Index Layer | Weight | Scheme Layer | Weight | Comprehensive Weight | Ranking |

|---|---|---|---|---|---|---|

| Factors influencing the quality of the prefabricated building design phase | Human factors | 0.3319 | Professional degree of the designers | 0.2212 | 0.0734 | 4 |

| Designer quality and safety training | 0.2183 | 0.0725 | 5 | |||

| Software operating level of the designer | 0.2577 | 0.0855 | 2 | |||

| Experience level of the designers | 0.3028 | 0.1005 | 1 | |||

| Management factors | 0.0964 | Efficiency and cohesion of the design task quality inspection | 0.3546 | 0.0342 | 15 | |

| Design unit internal quality management system | 0.4735 | 0.0456 | 13 | |||

| Design the quality supervision system | 0.1719 | 0.0166 | 17 | |||

| Technical factors | 0.2476 | Normalization of design | 0.1835 | 0.0454 | 14 | |

| Constructability of the design | 0.2053 | 0.0508 | 12 | |||

| Build the rationality of the split | 0.1371 | 0.0339 | 16 | |||

| The information level of the design | 0.2217 | 0.0549 | 10 | |||

| Design quality requirements are not clear | 0.2524 | 0.0625 | 8 | |||

| Information factors | 0.3241 | Lack of communication and coordination among various specialties of the design units | 0.1755 | 0.0569 | 9 | |

| Lack of communication and coordination between the design unit and the component manufacturer | 0.2131 | 0.0691 | 6 | |||

| Lack of communication and coordination between design unit and construction unit | 0.2053 | 0.0665 | 7 | |||

| Timeliness of design change delivery | 0.2437 | 0.0790 | 3 | |||

| The design model was not associated with the quality data | 0.1624 | 0.0526 | 11 |

| Participant ID | Gender | Age a | Role | Previous VR Exp. | Previous BIM Exp. | Construction Experience (Unit: Year) | Participate in the Interview |

|---|---|---|---|---|---|---|---|

| PA 1 | M | 36 | Owner | √ | √ | 14 | √ |

| PA 2 | F | 43 | Owner | √ | √ | 23 | |

| PA 3 | M | 39 | Owner | × | √ | 16 | |

| PA 4 | F | 52 | Owner | × | √ | 27 | √ |

| PA 5 | F | 33 | Designer— Architecture | √ | √ | 8 | √ |

| PA 6 | F | 55 | Designer —Structural Engineering | × | √ | 31 | √ |

| PA 7 | M | 44 | Designer —Architecture | × | √ | 20 | √ |

| PA 8 | M | 31 | Designer —Architecture | √ | √ | 9 | |

| PA 9 | F | 26 | Designer —Structural Engineering | √ | √ | 2 | √ |

| PA 10 | F | 27 | Designer —Plumbing | √ | √ | 4 | √ |

| PA 11 | M | 23 | Designer —Electrical Engineering | √ | √ | 2 | √ |

| PA 12 | M | 29 | Designer —Electrical Engineering | × | √ | 2 | |

| PA 13 | F | 38 | Designer —HVAC Engineering | √ | √ | 16 | √ |

| PA 14 | F | 26 | Component Manufacturer | √ | √ | 5 | √ |

| PA 15 | F | 31 | Component Manufacturer | × | √ | 10 | |

| PA 16 | F | 34 | Component Manufacturer | × | × | 16 | √ |

| PA 17 | M | 29 | Component Manufacturer | √ | √ | 7 | |

| PA 18 | M | 27 | Construction Contractor | √ | √ | 6 | √ |

| PA 19 | F | 25 | Construction Contractor | √ | √ | 3 | |

| PA 20 | F | 31 | Construction Contractor | √ | √ | 10 | |

| PA 21 | F | 45 | Construction Contractor | × | √ | 26 | √ |

| PA 22 | F | 52 | Customer | × | × | / | √ |

| PA 23 | M | 32 | Customer | √ | √ | / | √ |

| PA 24 | F | 38 | Customer | × | √ | / | |

| PA 25 | F | 44 | Customer | √ | √ | / | |

| PA 26 | M | 37 | Customer | × | × | / |

| Methods | Design Task | Architecture | Structural Engineering | Plumbing | Electrical Engineering | HVAC Engineering | Total |

|---|---|---|---|---|---|---|---|

| 2D drawing | Collision Detection | / | / | / | / | / | / |

| Drawing Review | 34 | 18 | 22 | 39 | 20 | 133 | |

| BIM | Collision Detection | 7 | 16 | 11 | 20 | 13 | 67 |

| Drawing Review | 26 | 15 | 14 | 23 | 14 | 92 | |

| BIM and VR | Collision Detection | 19 | 17 | 12 | 23 | 15 | 86 |

| Drawing Review | 18 | 14 | 12 | 21 | 13 | 78 |

| Number | System Usability Scale Items | M | SD |

|---|---|---|---|

| U5 | I found the various functions in this system were well integrated. | 4.43 | 0.87 |

| U9 | I felt very confident when using the system. | 4.15 | 0.79 |

| U7 | I think most people will learn to use this system very quickly. | 4.07 | 0.85 |

| U1 | I will frequently use this system. | 3.94 | 0.77 |

| U3 | The system is easy to use. | 3.82 | 0.95 |

| U10 | I need to learn a lot before I can get going with this system. | 2.13 | 0.74 |

| U4 | I need support from a technical person to use this system. | 2.04 | 0.68 |

| U6 | There are too many inconsistencies in this system. | 1.88 | 0.76 |

| U8 | The system is cumbersome to use. | 1.67 | 0.91 |

| U2 | The system is unnecessarily complicated. | 1.40 | 0.83 |

| Methods | Functional Use | Sensory Function | Spatial Function | Construction Information | Real- Time Inter- Action | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Static State | Dynamic State | Vision Sense | Auditory Sense | Tactile Sense | Gustation | Reality Space | Virtual Space | |||

| 2D drawing | √ | √ | √ | √ | ||||||

| BIM | √ | √ | √ | √ | ||||||

| BIM and VR | √ | √ | √ | √ | Develop | Develop | √ | √ | √ | √ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Wang, J.; Yu, B.; Chen, K. A Quality Management Method for Prefabricated Building Design Based on BIM and VR-Integrated Technology. Appl. Sci. 2024, 14, 1635. https://doi.org/10.3390/app14041635

Zhou M, Wang J, Yu B, Chen K. A Quality Management Method for Prefabricated Building Design Based on BIM and VR-Integrated Technology. Applied Sciences. 2024; 14(4):1635. https://doi.org/10.3390/app14041635

Chicago/Turabian StyleZhou, Min, Jiayuan Wang, Bo Yu, and Kunyang Chen. 2024. "A Quality Management Method for Prefabricated Building Design Based on BIM and VR-Integrated Technology" Applied Sciences 14, no. 4: 1635. https://doi.org/10.3390/app14041635

APA StyleZhou, M., Wang, J., Yu, B., & Chen, K. (2024). A Quality Management Method for Prefabricated Building Design Based on BIM and VR-Integrated Technology. Applied Sciences, 14(4), 1635. https://doi.org/10.3390/app14041635