Abstract

To study the phenomenon of large deformation and the failure of roadways under dynamic pressure, this paper takes the 10607 gas drainage roadway as the research object and presents the results of a theoretical derivation of equations for the boundary of the plastic zone of a dynamic pressure roadway with and without supporting force. The impacts of the mining influence coefficient and supporting force on the plastic zone boundary were explored for various lateral pressure coefficients. As the supporting force was increased, it was observed that there was a slight reduction in the radius of the plastic zone of the dynamic pressure roadway, while its scope and shape barely changed. Based on the failure mechanism of the dynamic pressure roadway, active and passive support technology was proposed, and the support effect was analyzed using FLAC3D 5.0 numerical simulation software for the case of the 10607 gas drainage roadway.

1. Introduction

The complexity of coal mining conditions in China is on the rise, and the proportion of mining in close-range coal seams is gradually expanding [1]. In tandem, roadway damage under the influence of dynamic pressure is becoming prominent. Frequent damage phenomena, such as roadway tunnels’ roofs breaking and falling, anchor bolts and cables shearing and detaching, and shoulder corners of the roadways severely squeezing and deforming, require regular repairs and maintenance. This has seriously affected the daily use of roadways and personnel safety, and the situation has gradually attracted the attention of experts and scholars [2,3].

Many experts have analyzed and summarized the phenomena of damage to roadways due to the impact of dynamic pressure, revealing the damage mechanisms at work through theoretical derivation and numerical simulation [4,5]. Fan et al. [6] believe that the underlying factor behind significant deformation in deep roadways subjected to dynamic pressure is attributed to the development of precarious plastic regions. The main factor leading to the shift of the plastic zone from a stable state to an unstable one is attributed to external influences, including tectonic stress and mining activities. Rong et al. [7] found that the stability of the surrounding rock and the large loose circle is often compromised under current support conditions, leading to significant deformation in the rock adjacent to roadways when subjected to dynamic pressure. According to the limit analysis theory, a roadway soft rock failure model was developed by Zhang et al. [8], and they analyzed the fracture evolution process of surrounding rocks subjected to various mining stresses. Wang et al. [9] developed a model to analyze the structure of the overlying rock and stress distribution in coal pillars within a goaf roadway subjected to dynamic pressure. They also proposed theoretical criteria for assessing the stability of both the “arch beam” structure and coal pillars in goaf entry roadways subjected to dynamic pressure. Zhao et al. [10] established models of F-shaped roof structures with long and short arms for various mining stages in the initial working area, and they presented stress calculation approaches for the surrounding rock on the gob side of a roadway. Ma et al. [11] investigated the mechanism of structural evolution in goaf roof roadways when subjected to dynamic pressure, computed the roof pressure for the short arm beam dynamic pressure model, formulated a calculation formula for identifying roof fractures, and derived a criterion for determining roof fracture occurrence. Wang et al. [12] employed numerical simulation techniques to examine the instability properties of coal roadways with composite roofs. They uncovered the progressive evolution patterns of fractures, as well as the modes of instability and failure in roadways surrounding rock subjected to multiple dynamic pressures.

In addition, the selection of roadway support under dynamic pressure is intricately intertwined with roadway section shape and surrounding rock condition, which must be met for specific geological and mining conditions [13], and dynamic loads contribute to the use of a support that is not only more durable but yielding [14]. Some scholars have improved the support technology of dynamic pressure roadways and proposed targeted support schemes. Ma et al. [15] observed that the effectiveness of U-shaped steel supports in mitigating deformation and damage to roadways under dynamic pressure was limited. Wang et al. [16] studied the stress field in a side coal roadway of a goaf under the influence of mining, and they suggested a support scheme that combines “anchor cable + grouting + single pillar”. Zhu et al. [17] developed a mechanical model to analyze the behavior of rock beams on roadways’ floors subjected to dynamic pressure, quantified the displacement when each load acted independently, and proposed a control method of “bottom crane + bottom corner anchor + floor anchor” to control roadways under dynamic pressure. Sun et al. [18] studied the deformation and failure mechanism of roadways under dynamic pressure in the entire process from excavation to working face mining, and they proposed a method of combining high pre-stress constant resistance support and roof-cutting technology (HPCR-RC). Jiang et al. [19] proposed a collaborative approach to control pressure relief during directional roof cutting in strong roadways subjected to dynamic pressure. They also developed a three-dimensional model testing system to compare the effectiveness of their method with the conventional approach. Meng et al. [20] conducted a theoretical analysis on the radii and displacement deformations occurring in roadway plastic zones subjected to dynamic pressure, and they proposed a support system consisting of “anchor + anchor cable + shotcrete + deep and shallow borehole grouting + invert” to limit the roadway deformation. Xie et al. [21,22] conducted an analysis on the damage characteristics of rocks surrounding roadways when subjected to deep dynamic pressure. They innovatively introduced a collaborative control technology involving external anchoring and internal unloading to effectively restrict significant deformations in the roadway. Lv et al. [23] introduced a control strategy of “slow production, long–short control” for roadways under dynamic pressure affected by mining, and they designed a “high-strength yield bolt (cable) + steel belt” coupling support scheme.

Although the above studies have produced certain scientific results, few scholars have analyzed the impact of the dynamic pressure coefficient on the plastic zone of the surrounding rock during the study of the mechanisms of changes. Moreover, most of the support improvement solutions for roadways under dynamic pressure are still active supports, and these support solutions can play a certain supporting role in dynamic pressure roadways. However, under the influence of multiple strong dynamic pressures, there is still a risk of the anchor bolt and anchor cable being sheared and broken, and there is a potential for localized instability of the rock adjacent to the roadway, which does not effectively address the issue of controlling the surrounding rock.

Therefore, we have focused on investigating the influence coefficient of roadways when subjected to dynamic pressure. As a result, we have derived an implicit equation that describes the boundary of the plastic zone surrounding a roadway under dynamic pressure and with a nonuniform stress field. Additionally, our study has examined how the influence coefficient affects both the shape and extent of this plastic zone. Simultaneously, the effect of support resistance on the plastic zone of a roadway under dynamic pressure was analyzed, and based on this, a joint support scheme comprising an anchor cable and channel steel beam–CFST column combined bracket is proposed to achieve the protection of rocks surrounding roadways under dynamic pressure.

2. Project Introduction

2.1. Geological Conditions

The Malan Coal Mine is located in Taiyuan City, Shanxi Province, China. Its yearly production capacity is designed to reach 4 million tons. It has a high gas content and is a high-gas mine. In the process of mining coal resources, various disasters and accidents will occur, such as gas explosions, coal dust explosions, coal and gas outbursts, etc. The “U”-type ventilation system is adopted in the working face, and when the absolute gas emission of the working face is greater than 5 m3/min, gas extraction must be carried out. The primary focus of the mine is on extracting coal from the #02 coal seam, which has an average thickness measuring 1.8 m and is located at a depth of approximately 400 m. As the #02 coal seam contains a significant amount of gas, it is necessary to extract the gas before mining, so a gas drainage roadway has been established within the #2 coal seam. After the drainage is completed, the gas drainage roadway will be used as the mining roadway of the #2 coal seam, fulfilling the goal of “one roadway for multiple purposes”. The #2 coal seam has an average thickness of 1.3 m and is located approximately 7 m below the #02 coal seam [24].

Mining work at the #02 coal seam working face will be carried out after gas extraction is completed. Due to the proximity of the #02 and #2 coal seams, the gas drainage roadway located at the #2 coal seam will then be affected by repeated mining, affecting the stability of the roadway and even endangering mine production and personnel safety, which could have a significant impact on the future utilization of the roadway. Therefore, it is necessary to analyze and summarize the damage characteristics of the roadway under the influence of mining, reveal the damage mechanisms of the roadway under dynamic pressure, and propose safe and efficient surrounding rock control technology accordingly.

2.2. Damage Characteristics of the Roadway under Dynamic Pressure

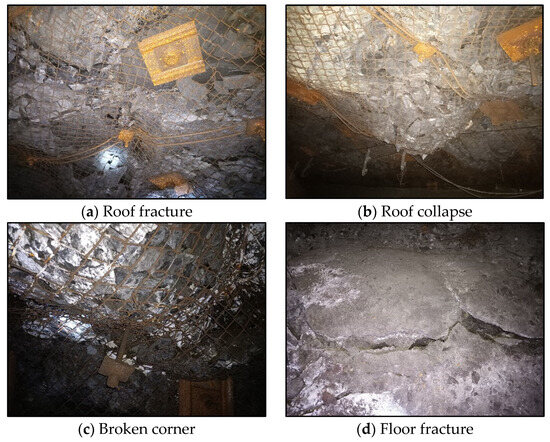

Through an in-depth analysis of the damage around the gas drainage roadway of the Malan Coal Mine, it was observed that the deformation triggered during roadway excavation was relatively normal. The utilization of traditional anchor bolts and cable supports proved adequate in ensuring the stability of the roadway and meeting normal use conditions. However, the mining pressure on the gas drainage roadway became evident when the #02 coal seam working face above it was extracted, resulting in significant deformation and damage to the surrounding rock.

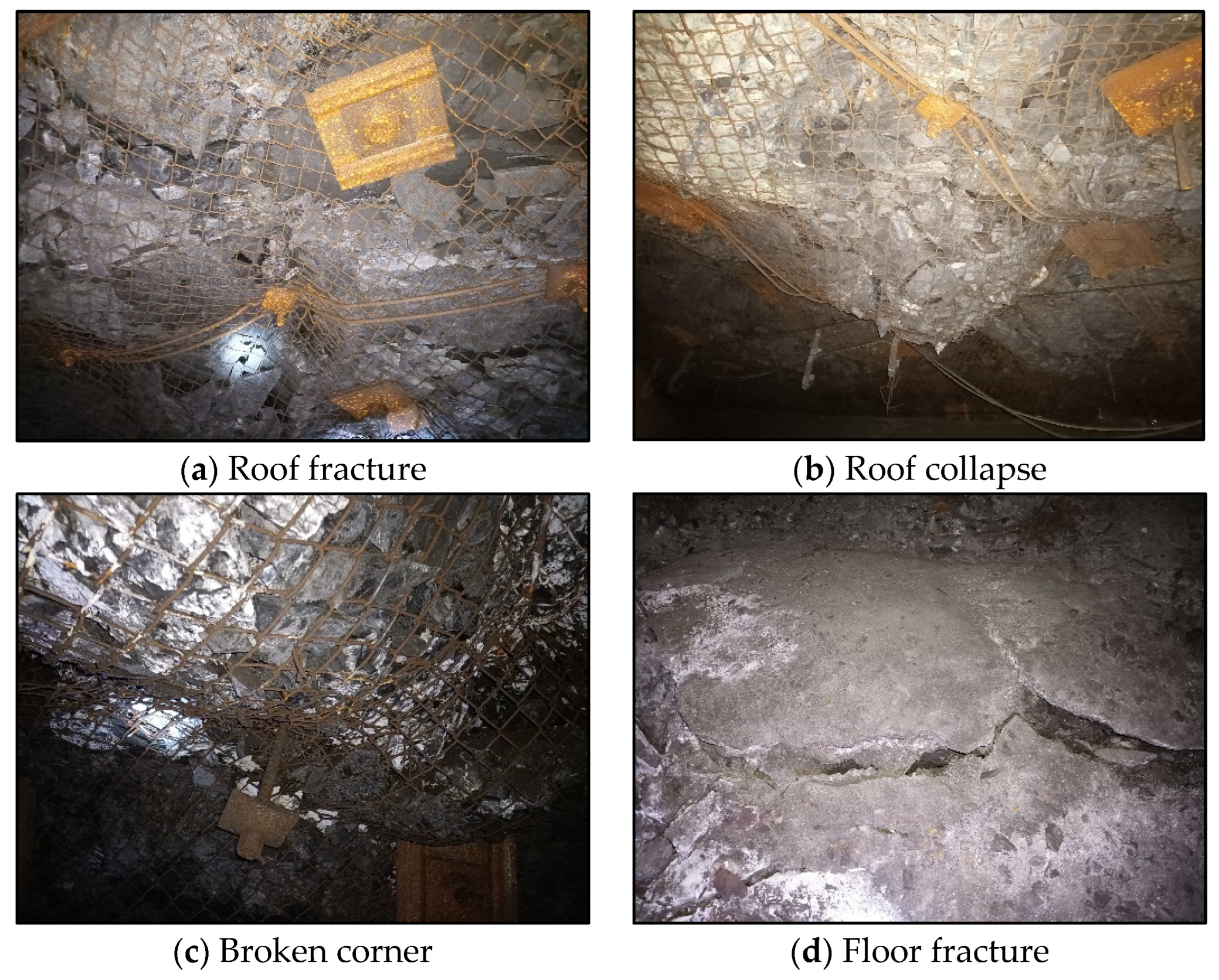

Figure 1 shows the deformation characteristics of the roadway under the influence of mining in the Malan Coal Mine. The rock of the roof is seriously broken, and some parts of the rock have come away in blocks that are trapped by the metal steel mesh, forming a net bag shape. The rock at the corners of the roadway is also quite broken, with obvious shrinkage, and the phenomenon can be observed of anchor bolts shearing and falling off. Furthermore, the roadway floor has irregular bulges and is broken into large blocks. Collectively, this demonstrates substantial deformation and damage to the rock surrounding the roadway under dynamic pressure within the Malan Coal Mine, adversely affecting its safe utilization. We sought to uncover the damage mechanisms at play.

Figure 1.

Deformation characteristics of the roadway under dynamic pressure in the Malan Coal Mine.

3. Damage Mechanisms of the Roadway’s Surrounding Rock under Dynamic Pressure

3.1. Roadway Mechanics Model

From its excavation to the completion of its service life, Malan Coal Mine’s gas drainage roadway is subject to disturbances caused by both excavation activities and the mining pressure exerted from the upper coal seam. The surrounding rock experiences a relatively intricate stress state as a consequence of this process. To effectively unpick its workings and facilitate theoretical calculations, the following assumptions were made:

- (1)

- We simplified the roadway into a circle, assuming uniform properties of the surrounding rock throughout its length;

- (2)

- We considered that the roadway was surrounded by a linear elastic body that was both homogeneous and isotropic in nature;

- (3)

- The original rock stresses in both horizontal and vertical directions were approximated as uniform stresses;

- (4)

- The mining influence coefficient K was introduced to indicate the degree of influence of coal seam mining on the stress of the surrounding rock, and it was divided into the vertical mining influence coefficient K1 and the horizontal mining influence coefficient K2 [25].

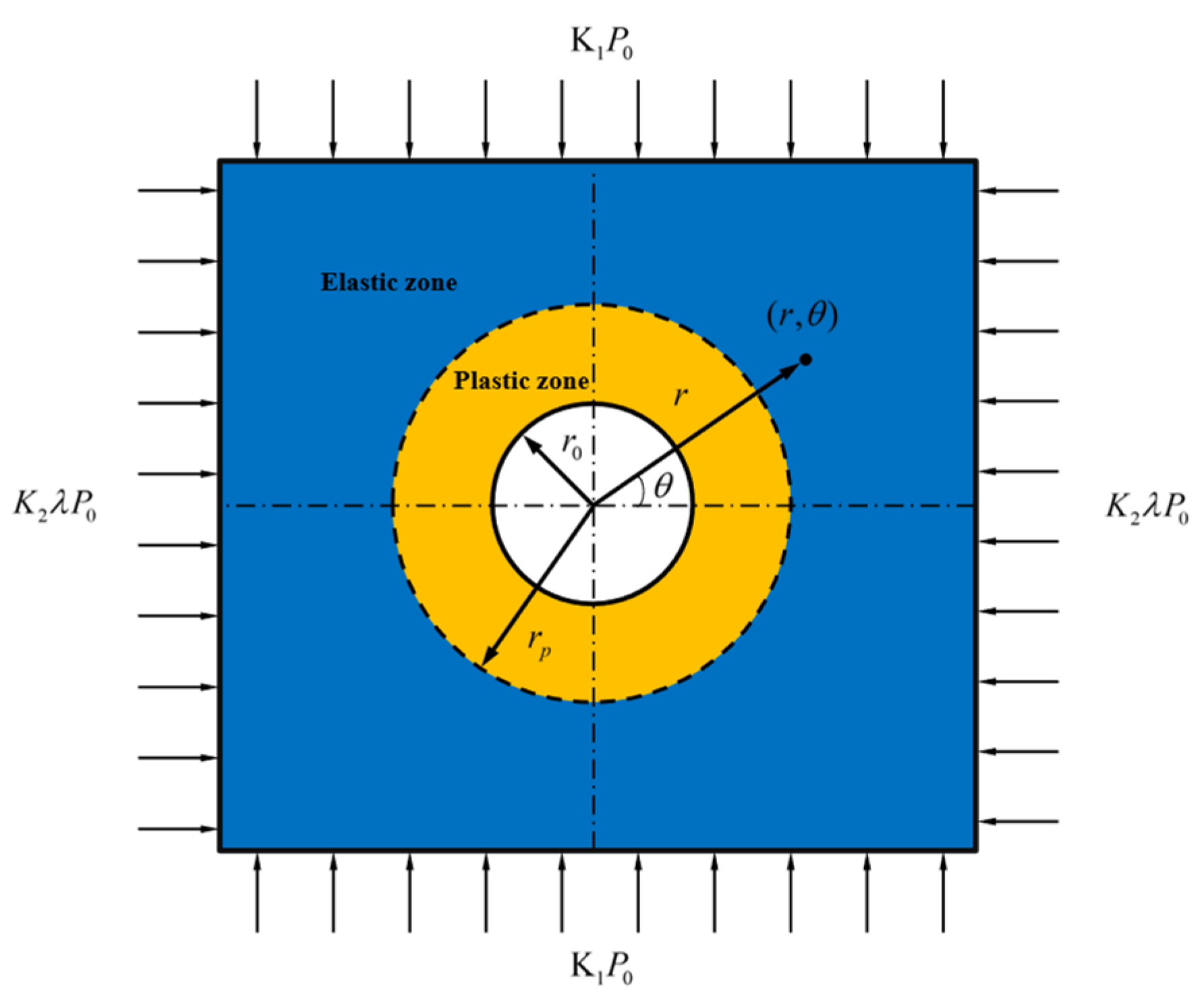

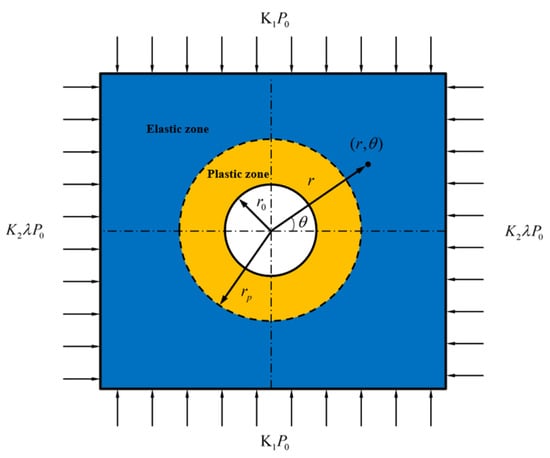

Based on the above assumptions, it was possible to analyze the stress distribution of the roadway’s surrounding rock as a problem involving plane strain. This made it possible to construct a mechanical model for this roadway under dynamic pressure, as depicted in Figure 2.

Figure 2.

Mechanical model of the roadway under dynamic pressure.

3.2. Boundary Equation of the Plastic Zone

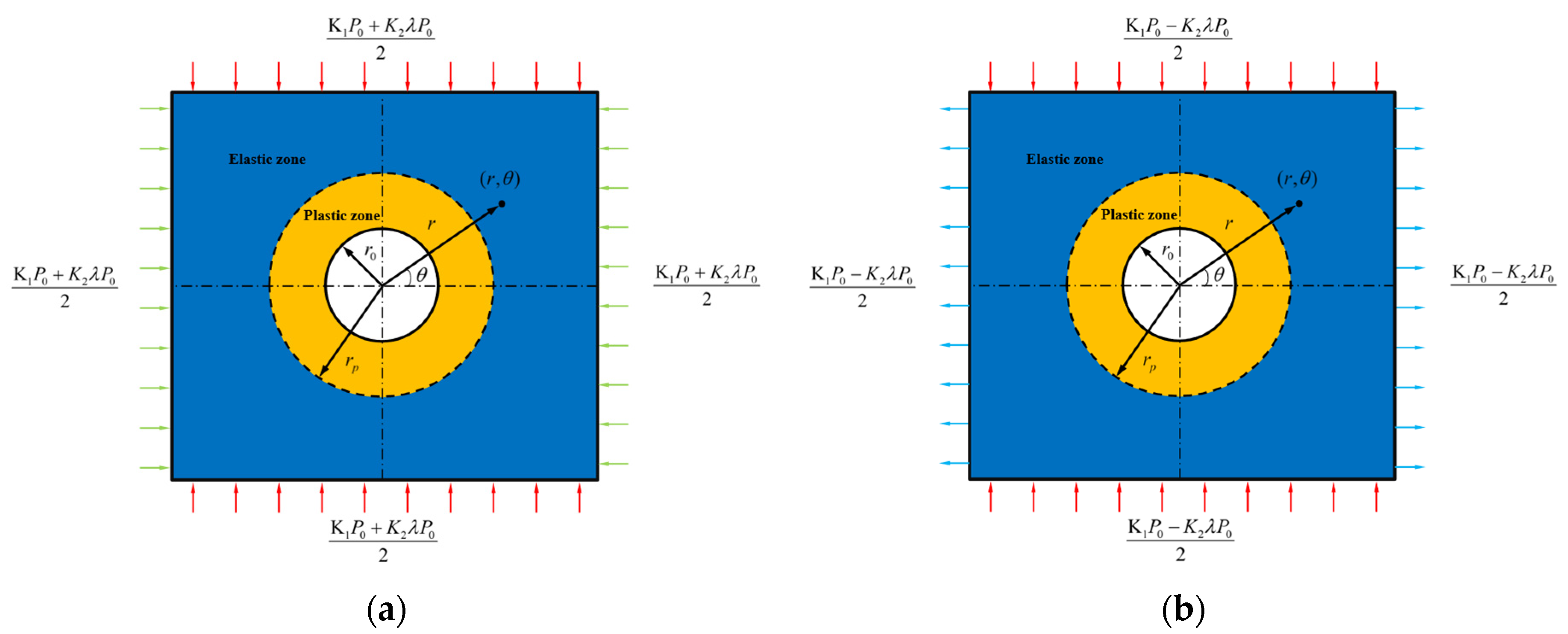

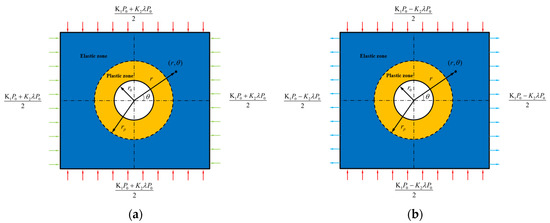

Based on the principles of elastic mechanics, when calculating the stress of the roadway surrounding rock under two-way non-isobaric conditions, the load can be decomposed into two parts, that is, the stress of the surrounding rock shown in Figure 2 is decomposed into the two parts in Figure 3a,b. Each situation is calculated separately, and finally, the stress component under the original load can be obtained by superimposing the two parts of the solution [26].

As shown in Figure 3a, the static equilibrium equation and geometric equation are

And the constitutive equation is

At the same moment, the boundary circumstances of the rock encircling the roadway are

By combining Formulas (1)–(3), part one of the stress state at any point in the rock surrounding the roadway is [26]

Then, as shown in Figure 3b, the stress boundary condition at an infinite distance from the roadway is

The expression for converting the stress components in the Cartesian coordinate system into the polar coordinate system is

In addition, the inner boundary of the roadway meets the following conditions:

By combining Formulas (5)–(7), part two of the stress state at any point in the rock surrounding the roadway is [26]

In these formulas, σr, σθ, and τrθ represent the radial stress, hoop stress, and shear stress, respectively, at any point of the rock surrounding the roadway in polar coordinates, MPa; σx and σy represent the horizontal stress and vertical stress, respectively, at any point of the rock surrounding the roadway in Cartesian coordinates, MPa; r is the distance from the point to the roadway center, m; θ represents the deviation between the line connecting the point and the center of the roadway and the horizontal direction, (°); λ represents the lateral pressure coefficient; and r0 is the roadway radius, m.

By superimposing the two parts of the solution, the stress field of the rock surrounding the two-way non-isobaric roadway under the action of dynamic pressure can be obtained. The stress expression at any point of the rock surrounding the roadway is as follows [26]:

As shown in Formula (10), the principal stresses in surrounding rock can be determined in the polar coordinate system by transforming stress equations from the cartesian coordinate system [25].

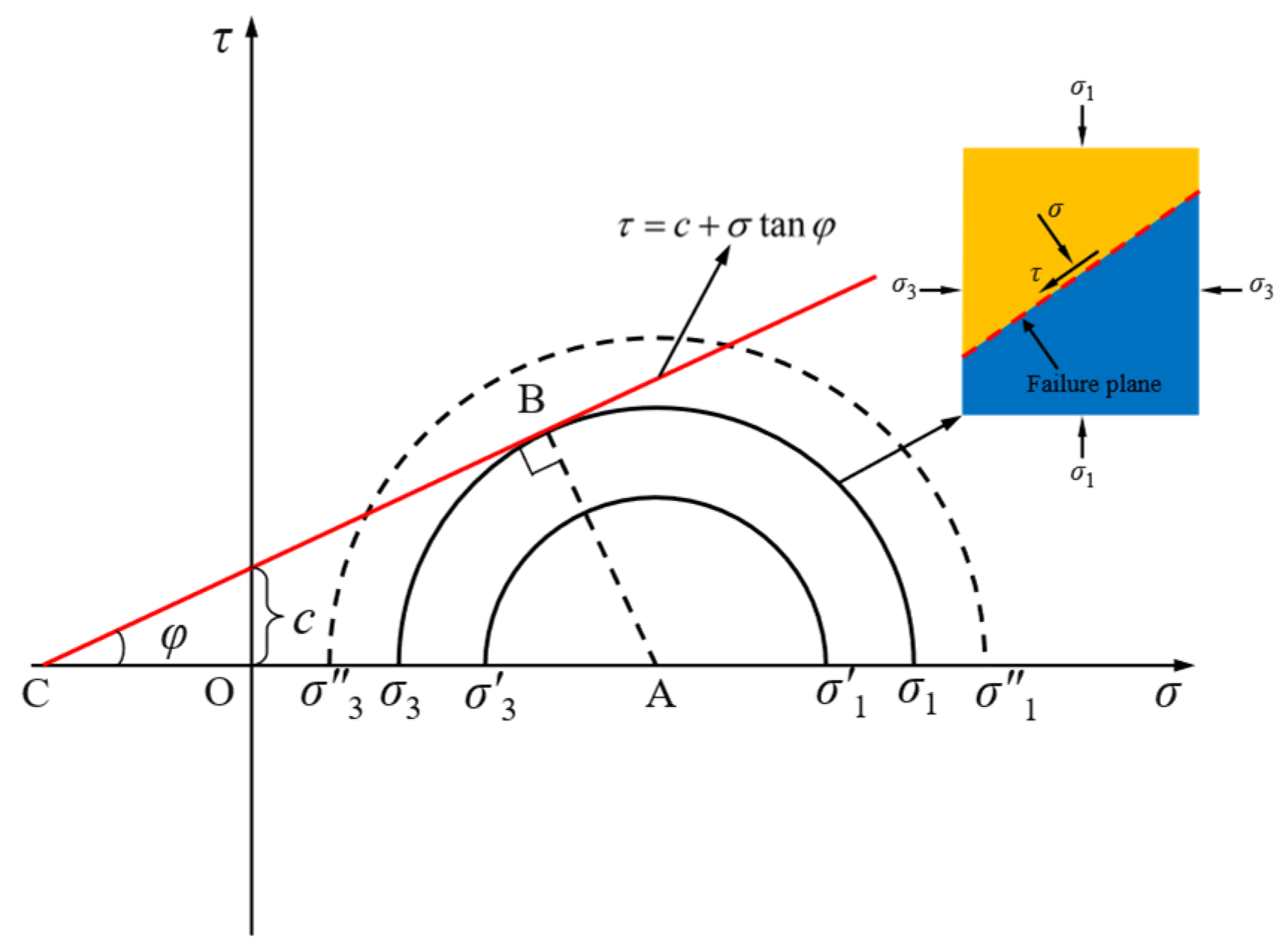

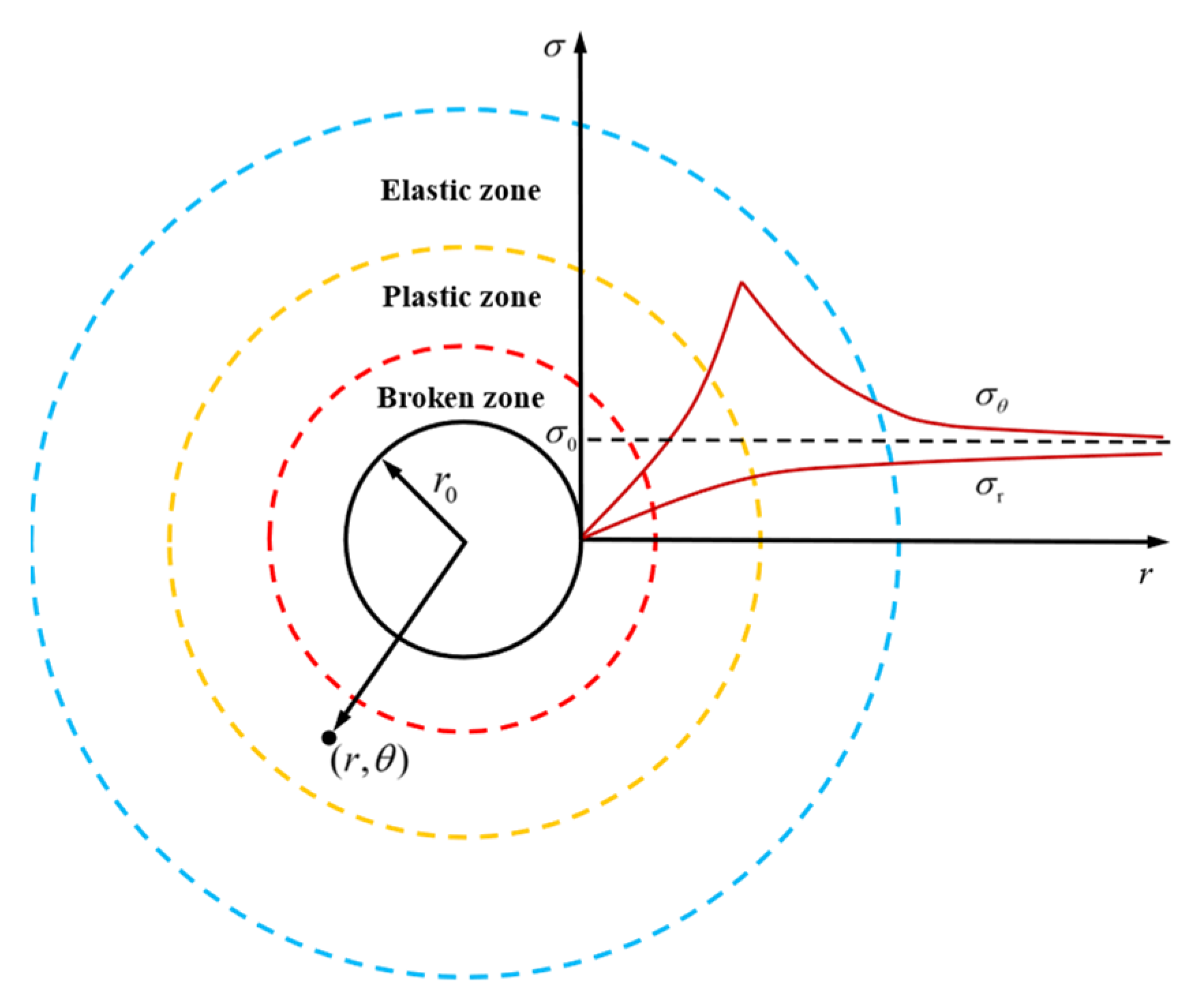

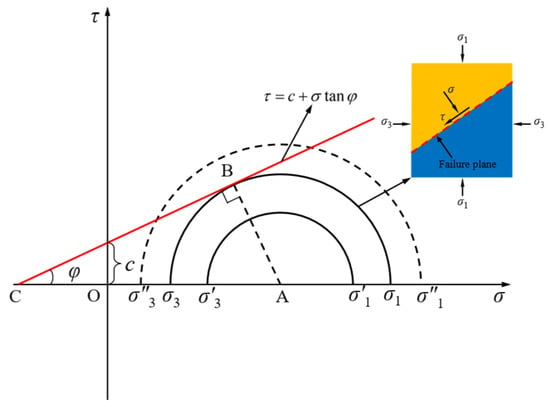

Assume that the rock surrounding the roadway can continuously transition to an ideal plastic state, as shown in Figure 4. According to the Mohr-Coulomb yield criterion, when the ratio of shear stress to normal stress on the rock shear surface reaches the maximum value, the rock is in a limited equilibrium state and is about to undergo yield failure [27]. The relationship between the maximum principal stress and the minimum principal stress at this time is shown in Formula (11) and is simplified to Formula (12) [28].

Figure 4.

Mohr-Coulomb yield criterion.

In the formula, σ1 represents the maximum principal stress, σ3 represents the minimum principal stress, c represents the cohesion force, and φ represents the internal friction angle.

Then, according to Formulas (10) and (12), the polar coordinate expression of the Mohr-Coulomb yield criterion can be obtained, as shown in Formula (13) [28] as follows:

Substituting Formula (9) into Formula (13) for calculation, the binary implicit function about r and θ can be obtained, and the expression is as shown in Formula (14) [28] as follows:

When the above function f (θ, r) = 0, an implicit equation of the boundary of the plastic zone of the rock surrounding the nonuniform stress field of the dynamic pressure roadway can be obtained. According to this equation, the distribution shape and evolution of the plastic zone of the surrounding rock can be studied.

3.3. Distribution Shape and Evolution of Plastic Zones

According to the boundary equation of the plastic zone of the rock surrounding the roadway under dynamic pressure, the shape of the plastic zone is related to the dynamic pressure coefficient, original rock stress, lateral pressure coefficient, roadway radius, internal friction angle, cohesion, and other factors. When the size of the roadway under dynamic pressure and the mechanical properties of the surrounding rock remain unchanged, the size and boundary of the plastic zone depend on the size of the dynamic pressure coefficient. Hence, an analysis was conducted on roadways with varying coefficients of lateral pressure to investigate the impact of vertical and horizontal mining activities on the boundary of the plastic zone of surrounding rock.

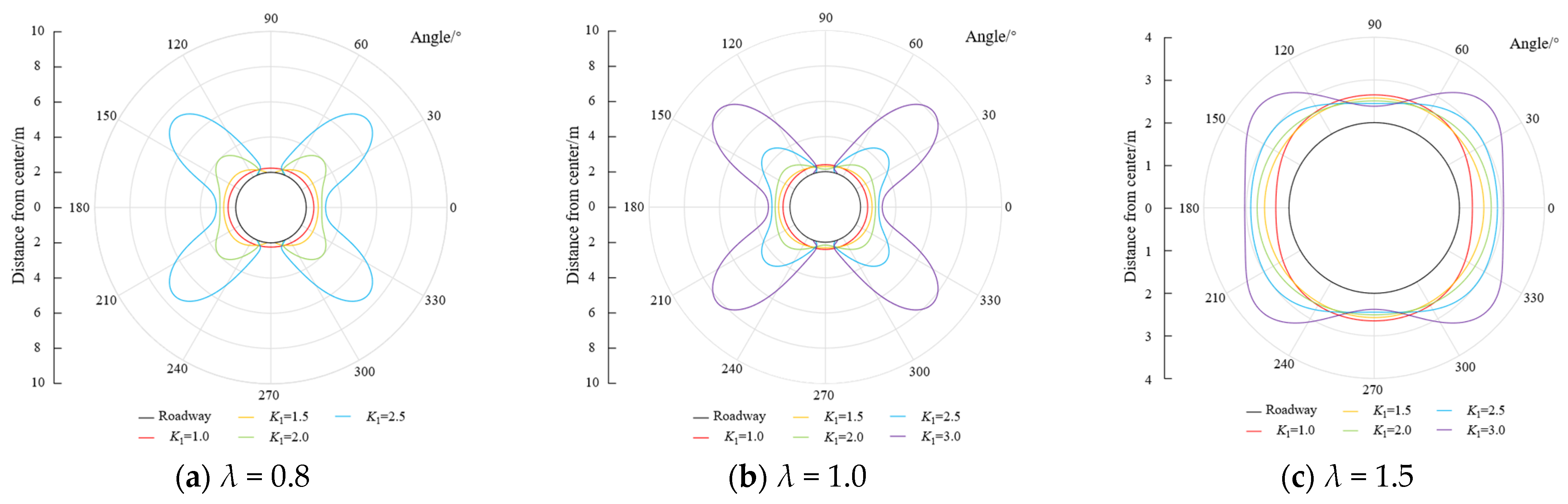

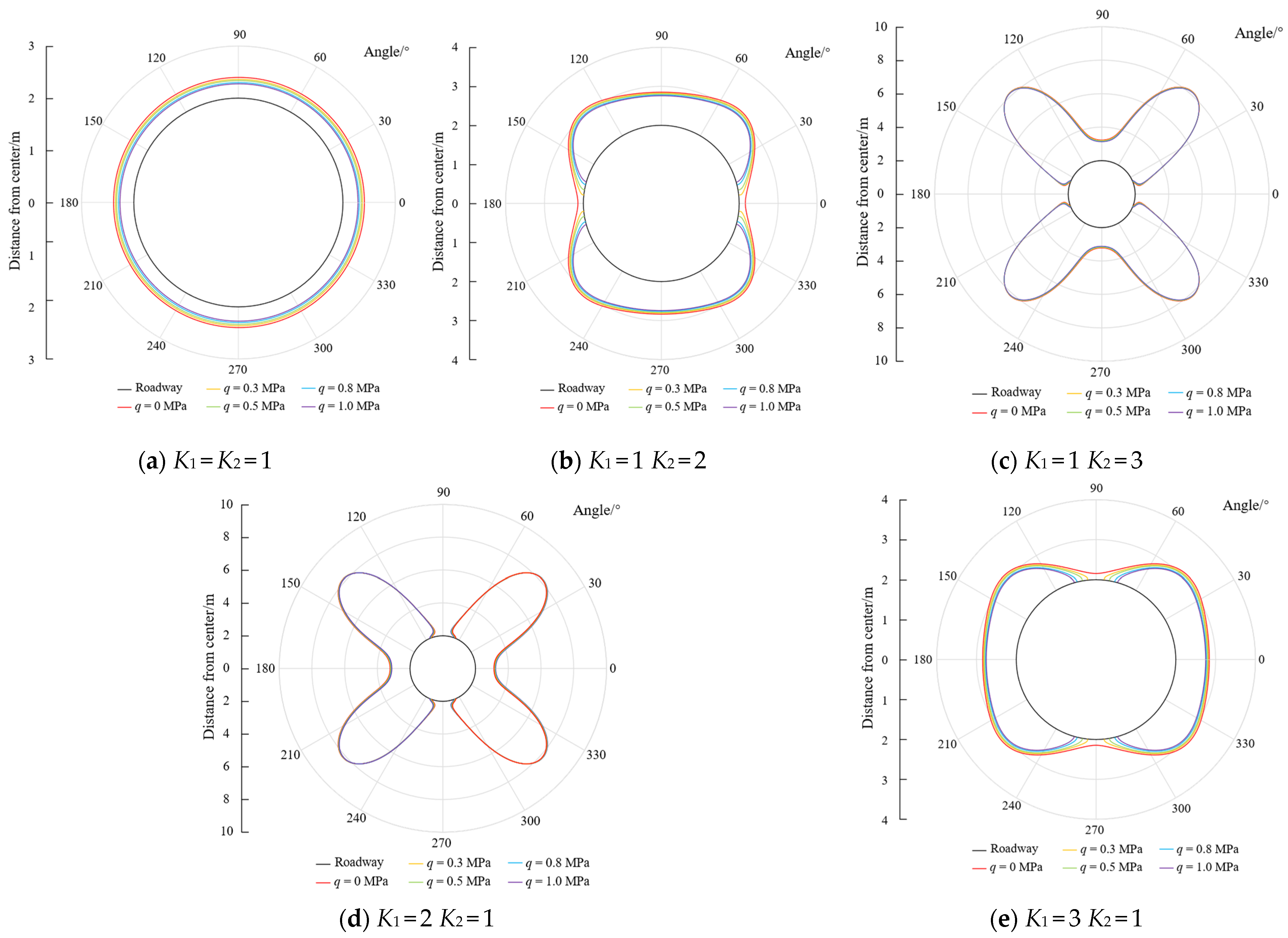

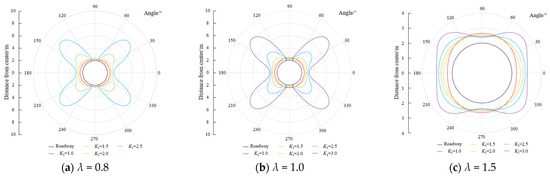

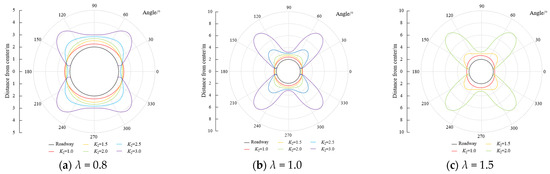

When the roadway is located below the mining working face, the roadway will be affected by vertical mining. Taking three common lateral pressure coefficients λ = 0.8, λ = 1.0, and λ = 1.5 as examples, Figure 5 shows the distribution of the plastic zone of the surrounding rock under the influence of vertical dynamic pressure.

Figure 5.

Distribution of the plastic zone subjected to vertical dynamic pressure.

Figure 5a shows the plastic zone of the roadway’s surrounding rock when λ is 0.8. When K1 is 1.0, the shape of the plastic zone of the surrounding rock is elliptical, and the roadway is under the action of static load and is not affected by dynamic pressure. The plastic zones at the sides of the roadway are larger, and the plastic zones of the roof and floor are smaller. When K1 increases to 1.5, the plastic zone expands from the upper part to the deep part of the surrounding rock, and the zone becomes roughly butterfly shaped. As K1 further increases, the plastic zone gradually expands in the four directions of the top and bottom corners of the roadway, and the butterfly shape becomes more obvious.

Figure 5b shows the plastic zone of the roadway’s surrounding rock when λ is 1.0. When K1 is 1.0, the shape of the plastic zone of the roadway under static load is circular. As K1 increases, the shape evolution pattern is similar to that in Figure 5a, and the distribution shape evolves from circular to butterfly. However, the influence of K1 is relatively weakened. As shown in Figure 5c, when K1 is 1.0, the shape of the plastic zone of the roadway under static load is elliptical, and the shape of the plastic zone changes from an ellipse to a rounded rectangle as K1 increases. The plastic zones at the sides of the roadway gradually increase, while the plastic zones at the roof and floor weaken slightly. As λ increases, the influence of K1 on the distribution shape and range of the plastic zone gradually weakens.

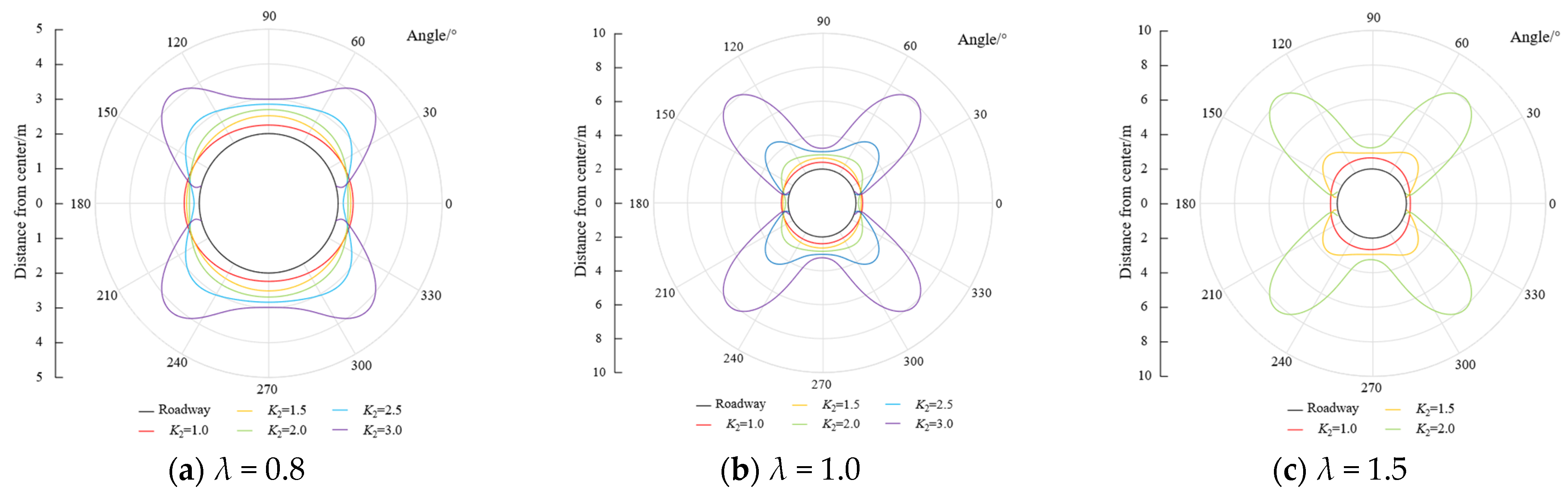

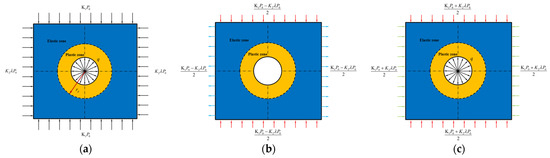

When the roadway and the mining face are in the same coal seam, the rock surrounding the roadway will be affected by horizontal mining. The corresponding plastic zone of the surrounding rock is shown in Figure 6. Figure 6a shows the distribution shape of the plastic zone when λ is 0.8. As K2 increases, the shape of the plastic zone changes from elliptical to butterfly. The scope of the plastic zone gradually increases and extends toward the roof and floor of the roadway, while the plastic zones at both sides of the roadway gradually weaken.

Figure 6.

Distribution of the plastic zone subjected to horizontal dynamic pressure.

When λ is 1.0 or 1.5, the plastic zone of the roadway’s surrounding rock is as shown in Figure 6b,c. As K2 increases, the radius of the plastic zone increases significantly, gradually extending to the four corners of the roadway’s surrounding rock, and the butterfly shape becomes more obvious. As λ increases, the influence of K2 on the distribution shape and range of the plastic zone becomes increasingly obvious.

Through the above analysis and combined with the plastic zone distribution shape, we have identified four distinct types for delineating the boundaries of the plastic zone in the rock surrounding the roadway subjected to dynamic pressure.

- Circle: Under bidirectional isobaric conditions, the plastic zone boundary of the roadway forms a standard circle;

- Elliptical shape: Under bidirectional anisobaric conditions, the plastic zone boundary of the roadway is similar to an elliptical shape;

- Rounded rectangle: Under bidirectional anisobaric conditions, a shape similar to a rounded rectangle will appear during the transformation process of the plastic zone boundary of the roadway from an ellipse to a butterfly shape;

- Butterfly shape: Under bidirectional anisobaric conditions, as the value of K and λ change, the boundary of the plastic zone gradually transforms from an elliptical shape to a butterfly shape.

3.4. Analysis of the Damage Mechanism of the Roadway’s Surrounding Rock under Dynamic Pressure

By establishing a mechanical model of a roadway under nonuniform, dynamic pressure, a more in-depth study was conducted of the morphological evolution and distribution range of the surrounding rock’s plastic zone under the influence of mining. Combined with the deformation characteristics of roadways under dynamic pressure, we have inferred that the primary factors contributing to significant deformation and failure of roadways subjected to dynamic pressure are as follows:

- (1)

- Original rock stress conditions. The gas drainage roadway is buried approximately 400 m deep and is subject to relatively large stress on the original rock. After the excavation of the roadway, there has been a shift in the stress state of the surrounding rock from three-dimensional to unidirectional. Consequently, the surrounding rock is susceptible to damage and displays indications of localized fragmentation and loosening.

- (2)

- Development of fissures in surrounding rocks. The fractures in the broken surrounding rock develop rapidly under the influence of mining, eventually causing severe plastic damage. In addition, there are often various interlayers inside coal seams. The shear and tensile properties of the interlayers are low, and they are prone to damage and sliding, resulting in layered protrusions.

- (3)

- Surrounding rock stress environment. During the mining process of close coal seams, the severe mine pressure caused by the excavation of the upper group of coal will seriously damage the stability of the gas drainage roadway and cause serious plastic damage. Under the influence of the advanced support pressure of the mining working face, the rock surrounding the roadway will be seriously damaged, and anchor cables cannot resist the pressure. In addition, the interlayer dislocation of broken surrounding rock will most likely shear anchor cables and other supporting components, leading to support failure and ultimately causing overall roadway instability and damage.

4. Effect of Supporting Force on the Plastic Zone of the Surrounding Rock

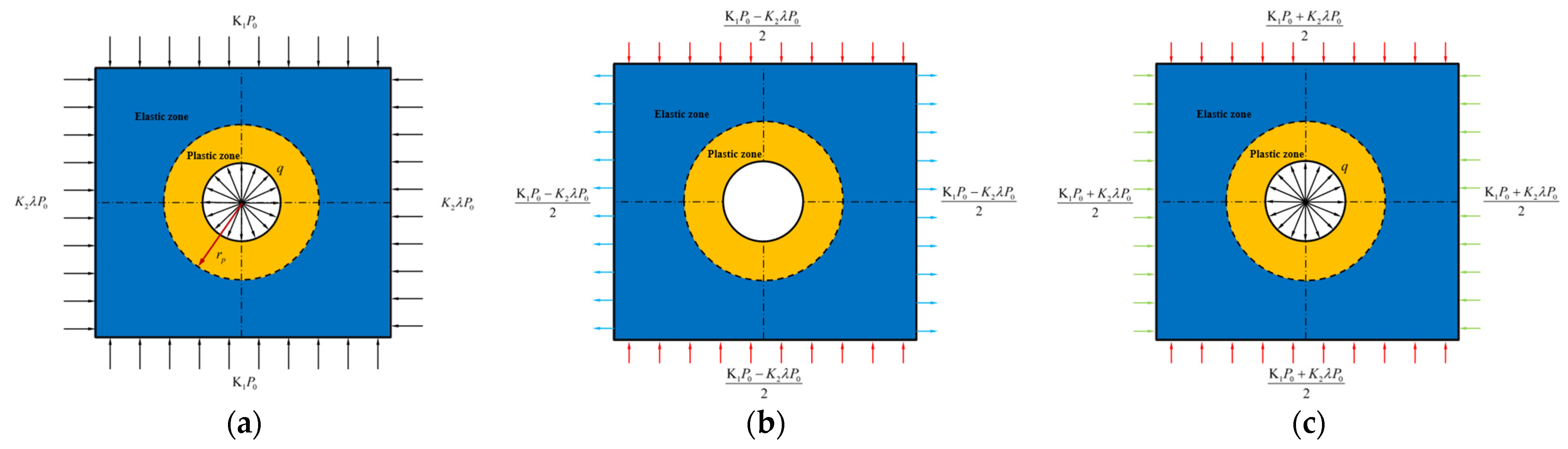

An implicit equation for the plastic zone boundary of the rock surrounding the roadway in a nonuniform stress field under dynamic pressure and subject to the action of supporting force can be deduced after following the steps outlined in Section 3. First, a roadway under a dynamic pressure mechanical model considering supporting force is established, as shown in Figure 7a, and then decomposed into two situations, as shown in Figure 7b,c. Through calculation, the binary implicit function of r and θ can be obtained as shown in Formula (15).

In the formula, P1 = (K1 P0 + K2λP0)/ 2, and P2 = (K1 P0 − K2λP0)/ 2.

When f (θ, r) = 0, an implicit equation for the boundary of the plastic zone of the rock surrounding the roadway under dynamic pressure and in a nonuniform stress field subject to supporting force can be obtained.

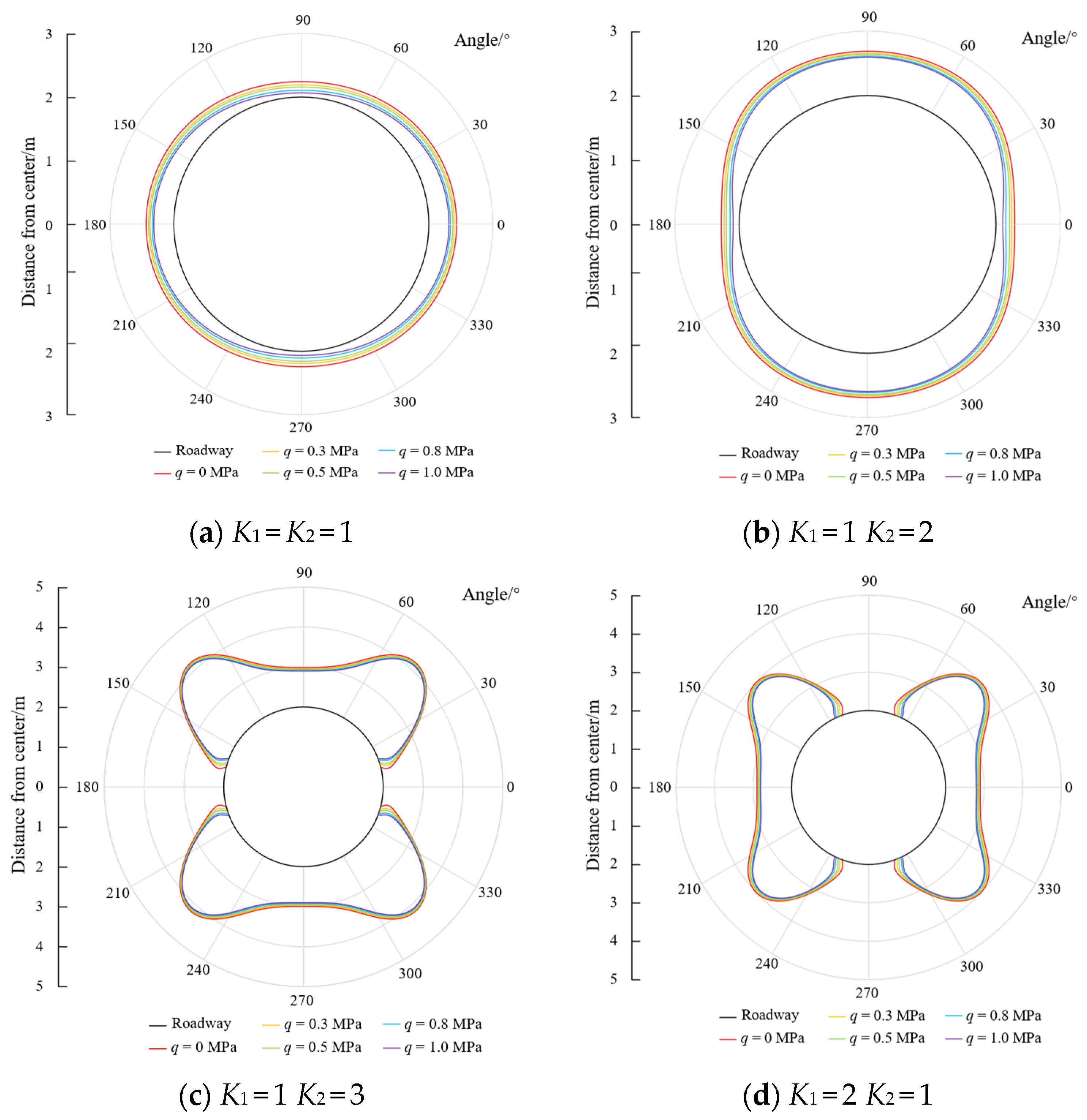

When using the existing technology and equipment, the supporting force is not of the same order of magnitude as the resistance needed to completely control the deformation of the surrounding rock. The supporting force applies to active types of support that can exert preload force, including anchor bolts and anchor cables, and it is approximately a few percent of the in situ stress. For example, the supporting force range of anchor bolts is 0.05~0.8 MPa, and the maximum support resistance that hydraulic supports can provide is only 0.6 MPa [28]. At the same time, in the current situation, the maximum support resistance provided by support equipment materials generally does not exceed 1 MPa. Therefore, the distribution range and change rules of the plastic zone boundary of the rock surrounding the roadway under dynamic pressure were studied when the supporting forces were 0, 0.3 MPa, 0.5 MPa, 0.8 MPa, and 1.0 MPa, respectively.

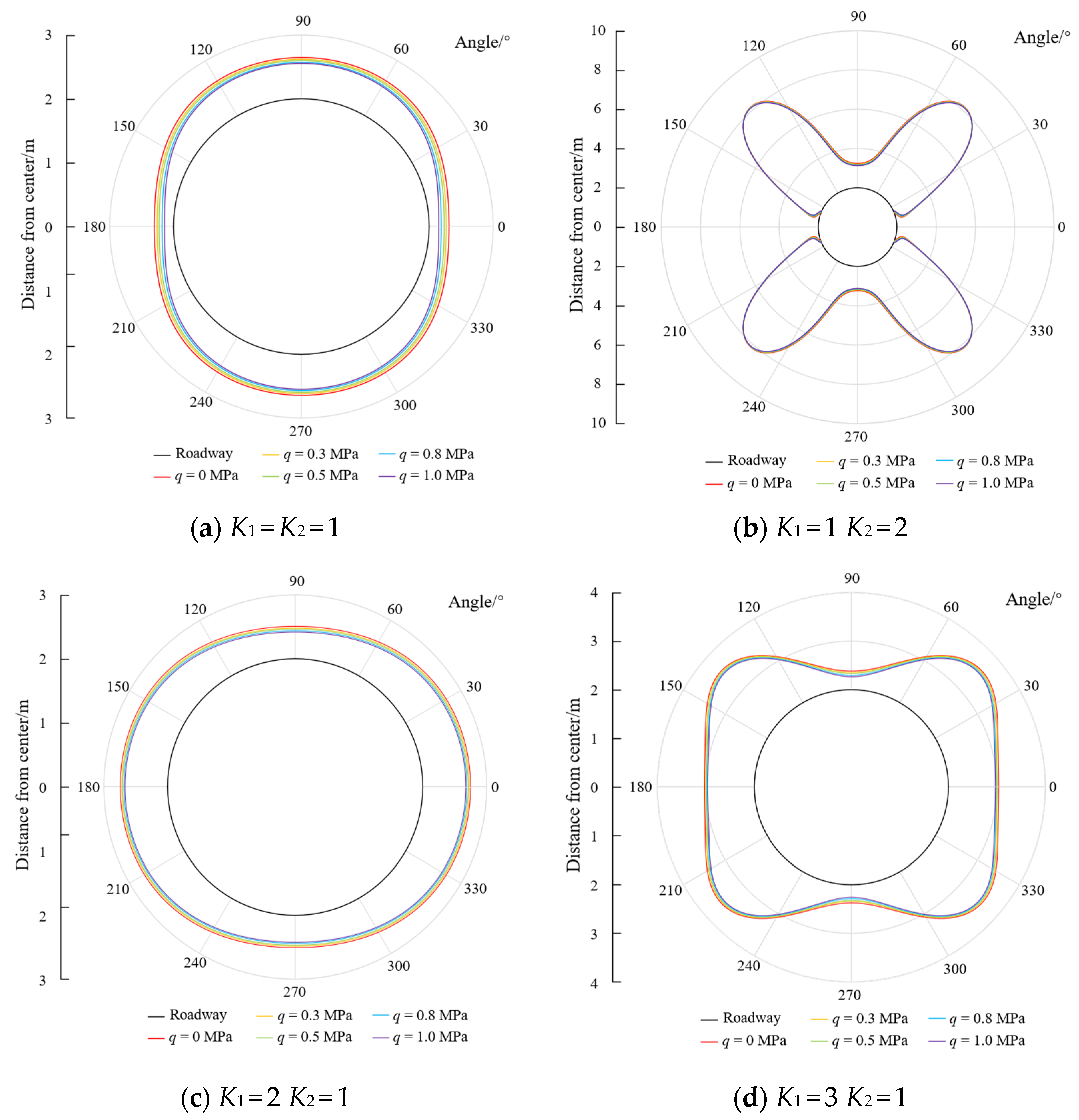

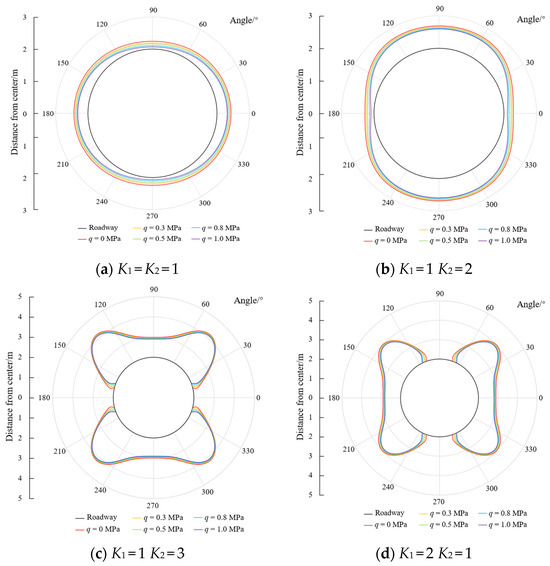

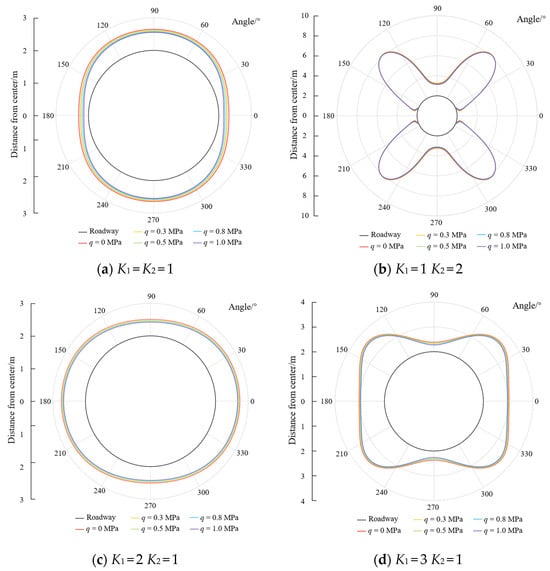

When λ is 0.8, the relationship between the supporting force and the boundary of the plastic zone of the surrounding rock is shown in Figure 8. When the roadway is not affected by mining, the shape of the plastic zone is elliptical, with larger plastic zones at both sides of the roadway and smaller plastic zones at the roof and floor. As the supporting force increases, there is a certain reduction in the size of the plastic zone, but the decrease is very small, as shown in Figure 8a. When the roadway is only affected by horizontal mining, the shape of the plastic zone is shown in Figure 8b,c. As the horizontal mining influence coefficient increases, the shape of the plastic zone changes from elliptical to butterfly, and the plastic zone gradually expands to the roof and floor corners of the roadway. As the supporting force increases, the plastic zone decreases slightly, but its shape does not change. When the roadway is only affected by vertical mining, the shape of the plastic zone is shown in Figure 8d. It is butterfly shaped, and the two butterfly wings are symmetrical. As the supporting force increases, the plastic zone gradually decreases, but the decrease is very small.

Figure 8.

Relationship between the supporting force and plastic zone (λ = 0.8).

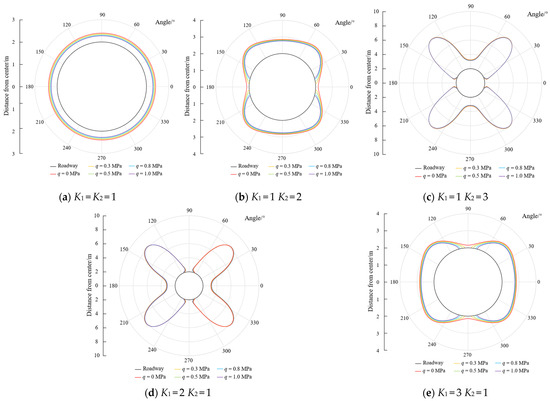

When λ is 1.0, the relationship between the supporting force and the plastic zone of the surrounding rock is shown in Figure 9. When the roadway is not affected by mining, the shape of the plastic zone forms a uniform circle. With the application of supporting force, the shape of the plastic zone does not change, though its radius decreases slightly, as shown in Figure 9a. Figure 9b,c show the distribution shape of the plastic zone when the roadway is only affected by horizontal mining. It is butterfly shaped but facing horizontally, and the two butterfly wings are symmetrical. With the increase in the horizontal mining influence coefficient, the scope of the plastic zone gradually increases, and the butterfly shape gradually appears, but the scope of the plastic zone does not significantly shrink with the increase in supporting force. Figure 9d,e show the distribution shape of the plastic zone when the roadway is only affected by vertical mining. It is still butterfly shaped, and the two butterfly wings are symmetrically distributed. The plastic zone is mainly distributed in the upper part of the roadway, and the supporting force has little impact on its distribution range.

Figure 9.

Relationship between the supporting force and plastic zone (λ = 1.0).

Figure 10 shows the relationship between the supporting force and the plastic zone of the surrounding rock when λ is 1.5. As shown in Figure 10a, when the roadway is not affected by mining, the shape of the plastic zone is elliptical, and it is distributed mainly at the roof and floor of the roadway. As the supporting force increases, the scope of the plastic zone decreases slightly, but the shape is still elliptical. Figure 10b presents the roadway when only affected by horizontal mining. The plastic zone of the surrounding rock is butterfly shaped and concentrated at the top and bottom of the roadway. The increase in support resistance has a smaller impact on the reduction in the plastic zone. Figure 10c,d show the distribution pattern of the plastic zone of the roadway’s surrounding rock when the roadway is only affected by vertical mining. This time, the plastic zone is mainly located at the two sides of the roadway, and as the vertical mining influence coefficient increases, its shape changes from elliptical to butterfly. At the same time, the radius of the plastic zone decreases to a certain extent as the support resistance increases, but the amplitude is small.

Figure 10.

Relationship between the supporting force and plastic zone (λ = 1.5).

5. Dynamic Pressure Control Technology for a Roadway’s Surrounding Rock

5.1. Basic Concepts of Surrounding Rock Control

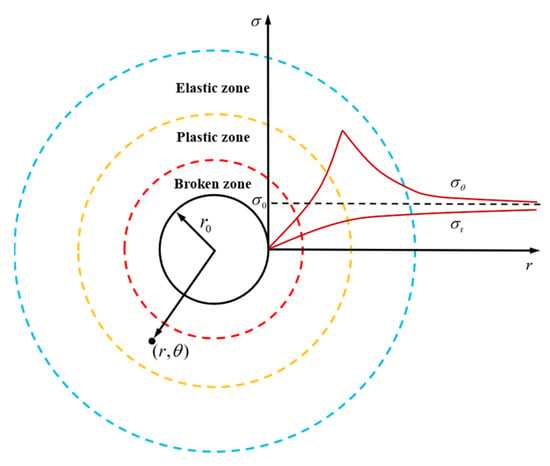

After the roadway was excavated, the stress field of the original rock around the roadway underwent secondary stress redistribution due to damage, as depicted in Figure 11. At the simultaneous occurrence, there was a gradual formation and development of the plastic zone in the surrounding rock, necessitating prompt support for the roadway. Anchor bolts and cables are frequently employed for the purpose of providing support to newly excavated roadways, thereby minimizing the deformation of the surrounding rock formations and guaranteeing the overall safety of the roadway. At present, the shallow section of the roadway can be effectively supported by traditional anchor bolts and cable supports to ensure a stable load-bearing structure.

Figure 11.

Distribution of rock surrounding the roadway.

However, roadways under dynamic pressure often have to withstand one or more mining impacts during their service life. Due to the displacement of rock formations caused by intense dynamic pressure, the anchor cables frequently experience shearing, leading to support failure and localized instability in the surrounding rock. The stable bearing body formed before also begins to lose stability, eventually leading to the damage of the roadway, and even roof collapse and other phenomena [29].

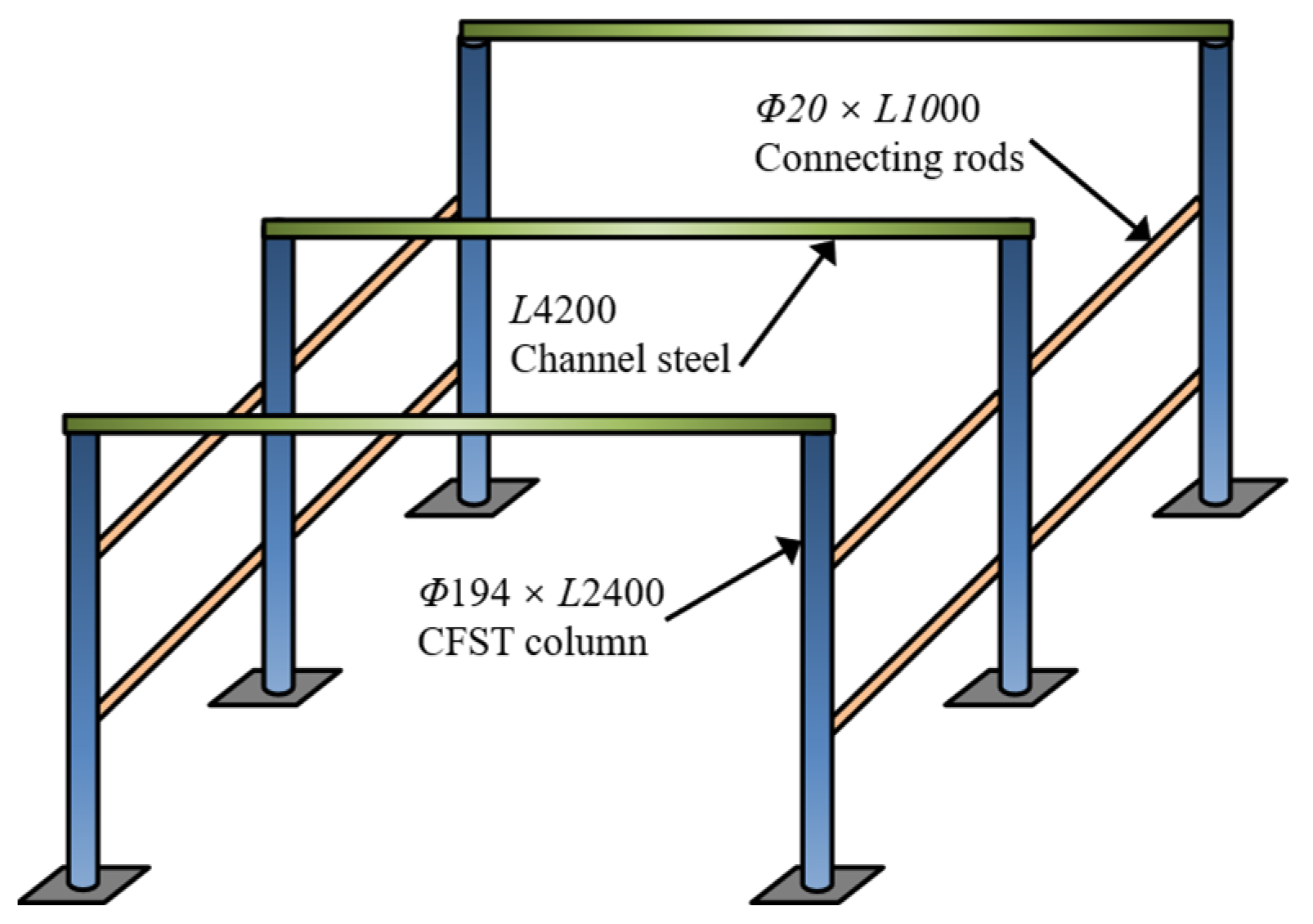

Therefore, considering the significant distortion and damage caused to the roadway under dynamic pressure, it becomes challenging for traditional anchor bolts and cables to ensure the stability of the surrounding rock. Consequently, passive supports, such as U-shaped steel frames and CFST supports, are necessary [30]. The high bearing capacity of passive supports limits the roadway displacement, achieving the purpose of controlling large deformation. Accordingly, an overall active and passive support technology comprising an anchor cable and channel steel beam–CFST column combined bracket is proposed herein to support roadways under dynamic pressure.

5.2. Support Mechanism of a Combined Bracket

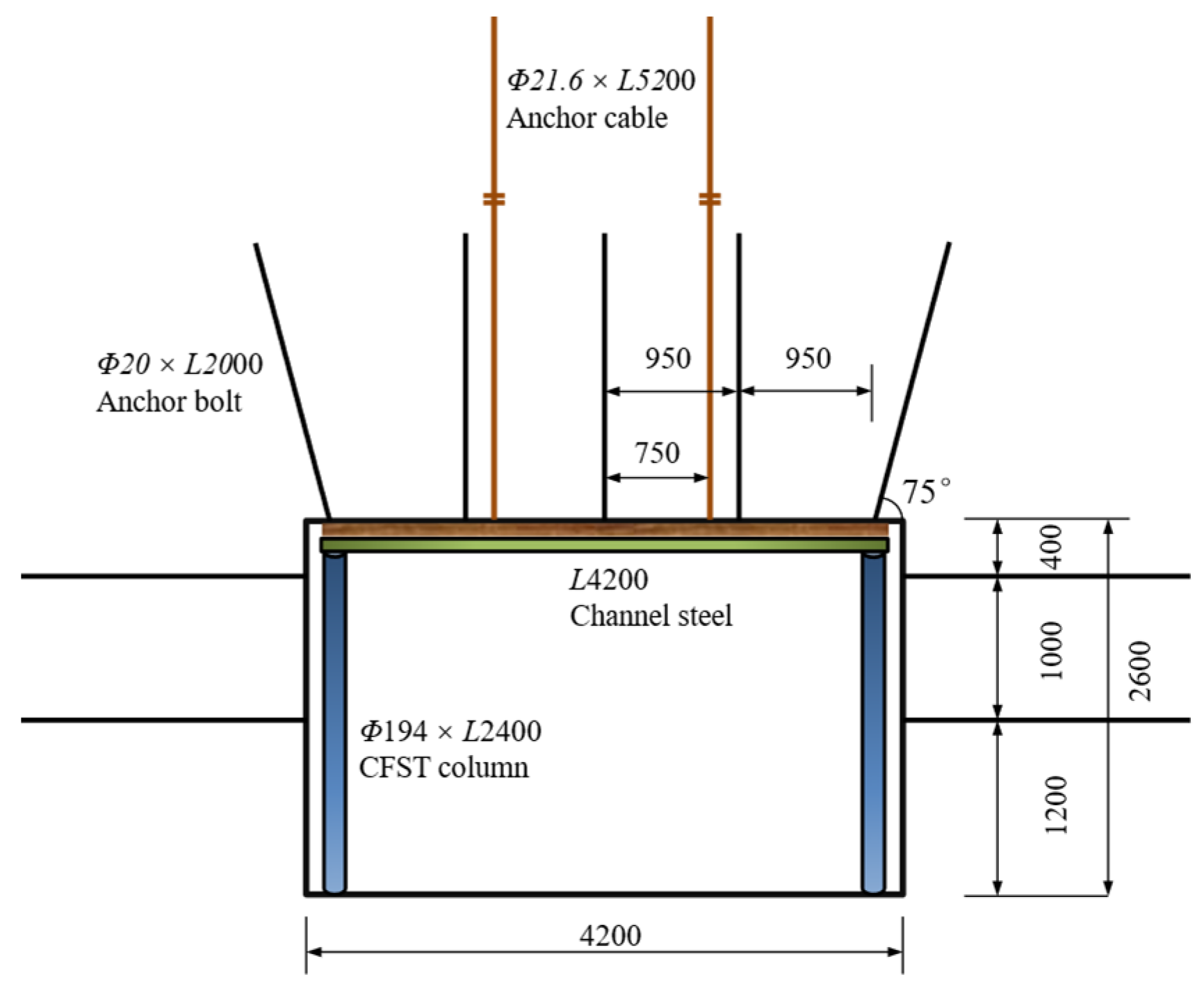

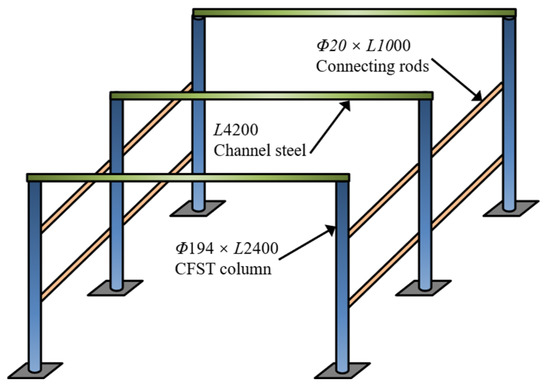

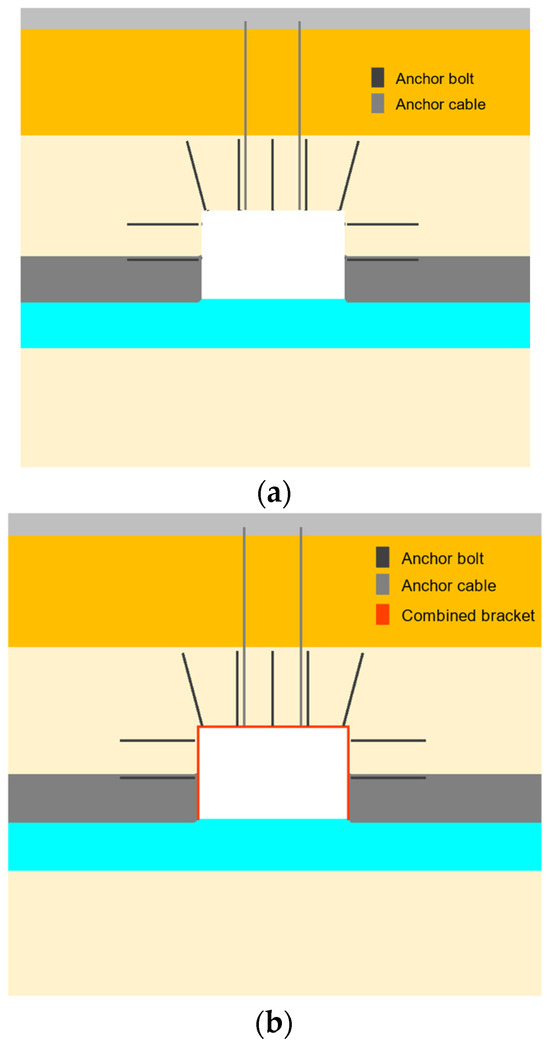

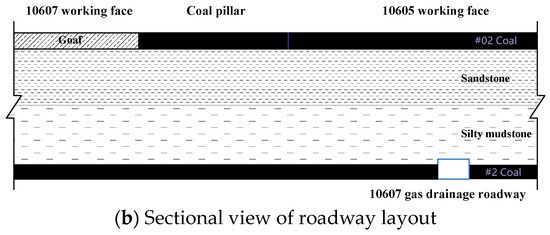

The overall active and passive support technology, comprising an anchor cable and channel steel beam–CFST column combined bracket, brings together anchor bolts and cables as the active support technology and a combined bracket as the passive support technology. When implementing this technology, the coordination between the anchoring stiffness of the anchor cables in the deep surrounding rock and the surface support stiffness of the adjacent rock enhances the overall stability of the supported surrounding rock. The combined bracket consisting of a channel steel beam and CFST columns is rectangular in shape, as depicted in Figure 12. The bottom of the CFST column is inserted into the roadway floor to a depth of about 300 mm and fixed with quick-drying cement.

Figure 12.

Schematic diagram of the combined bracket.

Rationally arranging anchor cables in key support areas, such as the roof and sides of the roadway, can enhance the structural stability and load-bearing capacity of the combined bracket, enabling it to effectively withstand substantial deformation caused by the surrounding rock. In turn, the combined bracket can provide better surface protection components for anchor cable supports and improve the anchoring efficacy of the anchor cables. Simultaneously, due to the pressure-giving performance of the combined support system, it can allow a certain degree of deformation in the surrounding rock during the initial stage of mining impact. In this way, the rock mass releases deformation energy, making the contact between the surrounding rock and the support more uniform.

Research indicates that enhancing the confining pressure exerted on the fractured rock mass surrounding the roadway can lead to a substantial enhancement in the residual strength of the surrounding rock and an increase in the load-bearing capacity of the superficial rock mass within the roadway [31]. As such, the overall active and passive support technology, comprising an anchor cable and channel steel beam–CFST column combined bracket, can enhance the stress conditions of the surrounding rock in roadways, boost its residual strength, and work together with the rock to withstand mining impacts.

5.3. Numerical Simulation Analysis of the Support Effect

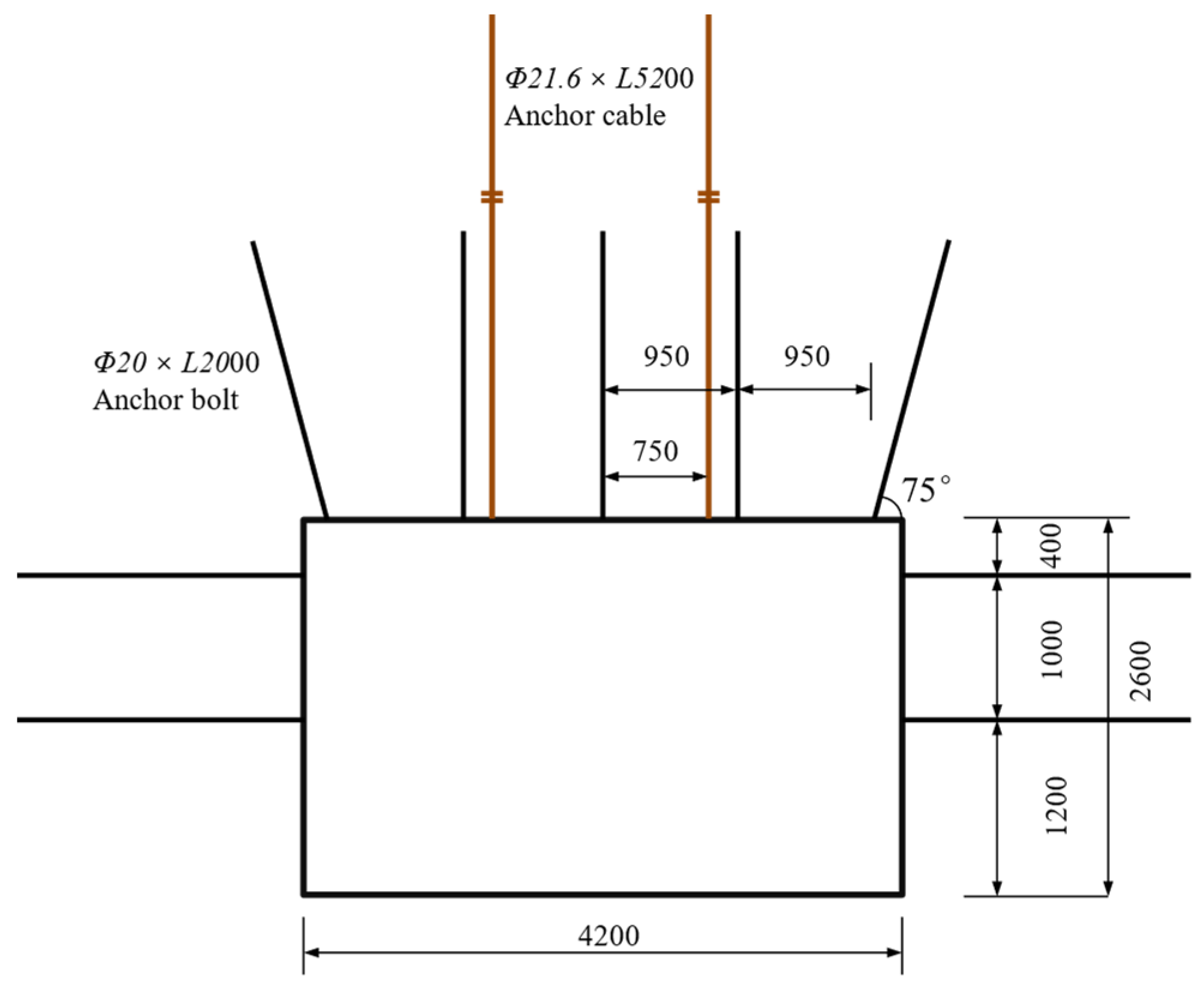

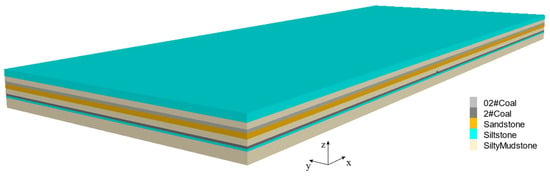

Taking the engineering geological conditions of the 10607 gas drainage roadway, a FLAC3D numerical simulation model was established. By conducting a simulation of the excavation process in the upper working face, an analysis was performed on the rock deformation surrounding the 10607 gas drainage roadway with various support techniques. The support effect of the overall active and passive support technology, comprising an anchor cable and channel steel beam–CFST column combined bracket, on roadways under dynamic pressure was also explored.

5.3.1. Model Establishment

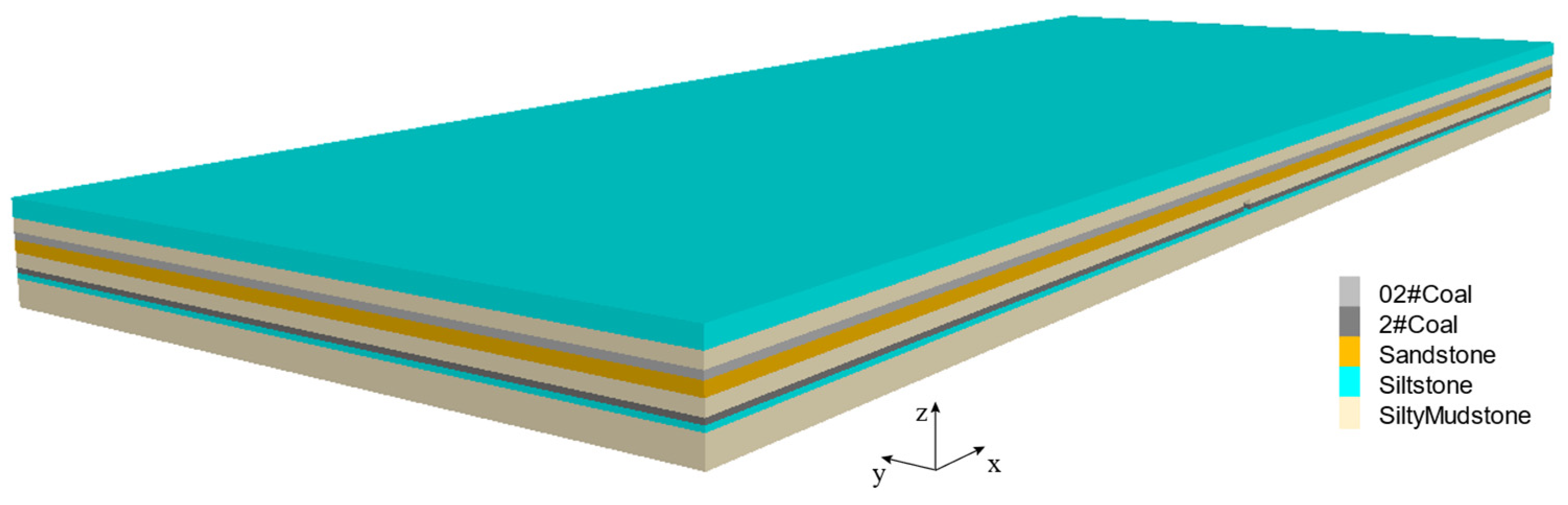

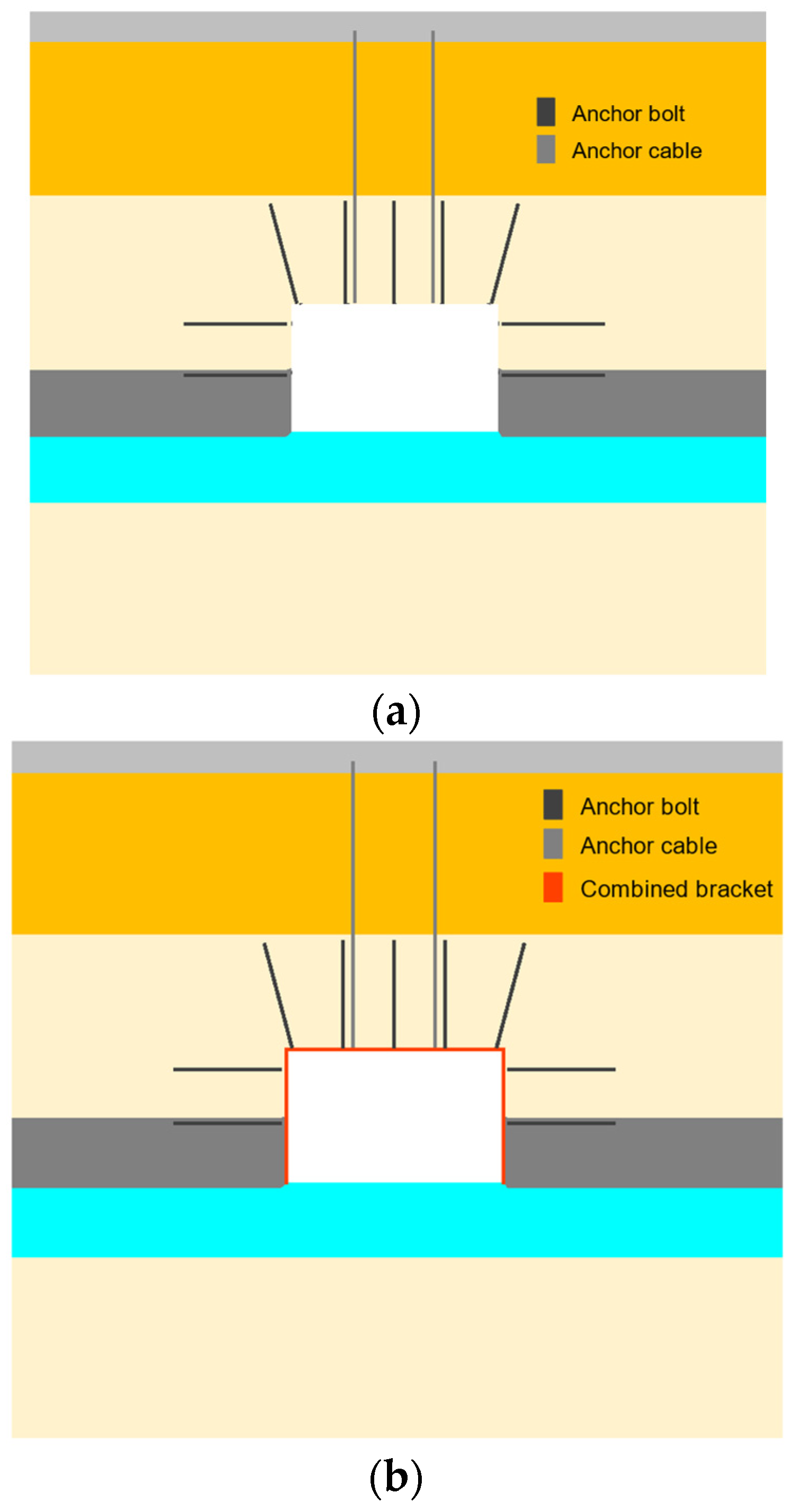

As shown in Figure 13, the size of the initial model is x × y × z =500 m × 200 m × 25.4 m. Referring to the on-site original rock stress test results, horizontal and vertical stresses were applied to the interior of the model, and the Mohr-Coulomb strength criterion was used in the calculation. To evaluate the impact of the combined support system on the stability of the rock surrounding the 10607 gas drainage roadway, different support schemes were modeled, as depicted in Figure 14. The mechanical parameters of rock strata and support are presented in Table 1, Table 2 and Table 3. The anchor bolts and anchor cables were simulated using the cable structural element, and the combined bracket was simulated using the pile structural element. Through the simulation of mining of the working face, a study was conducted to analyze the impact of various support strategies on the roadway affected by mining.

Figure 13.

Initial model.

Figure 14.

Simulation of different support schemes. (a) Support of anchor bolts and anchor cables. (b) Combined support of the anchor bolts, anchor cables, and combined bracket.

Table 1.

Mechanical parameters of the rock strata.

Table 2.

Mechanical parameters of the anchor bolt and anchor cable.

Table 3.

Mechanical parameters of the CFST column.

The model excavation sequence was the 10607 gas drainage roadway, 10607 working face, and 10605 working face. A null model was used to simulate the mining of the roadway and working face, and the goaf was reassigned and filled after mining. The mining and filling steps were both 10 m.

5.3.2. Effect Analysis

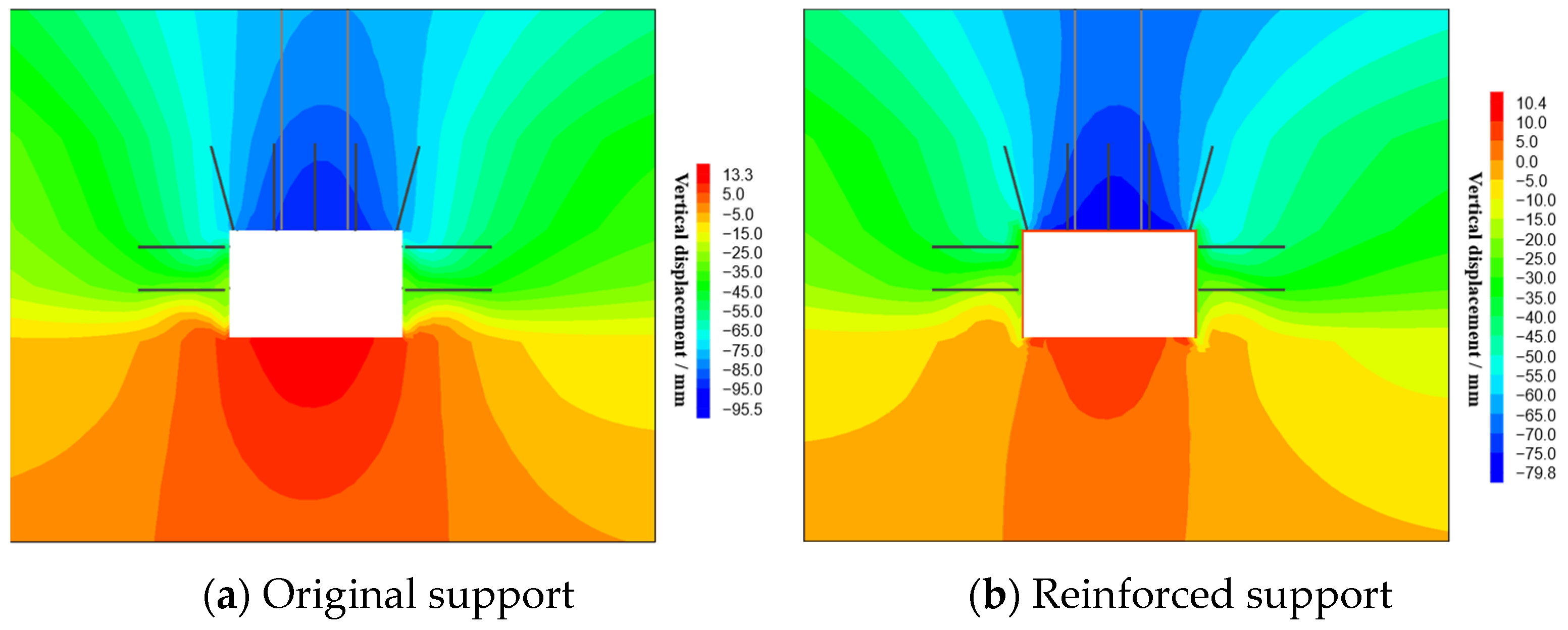

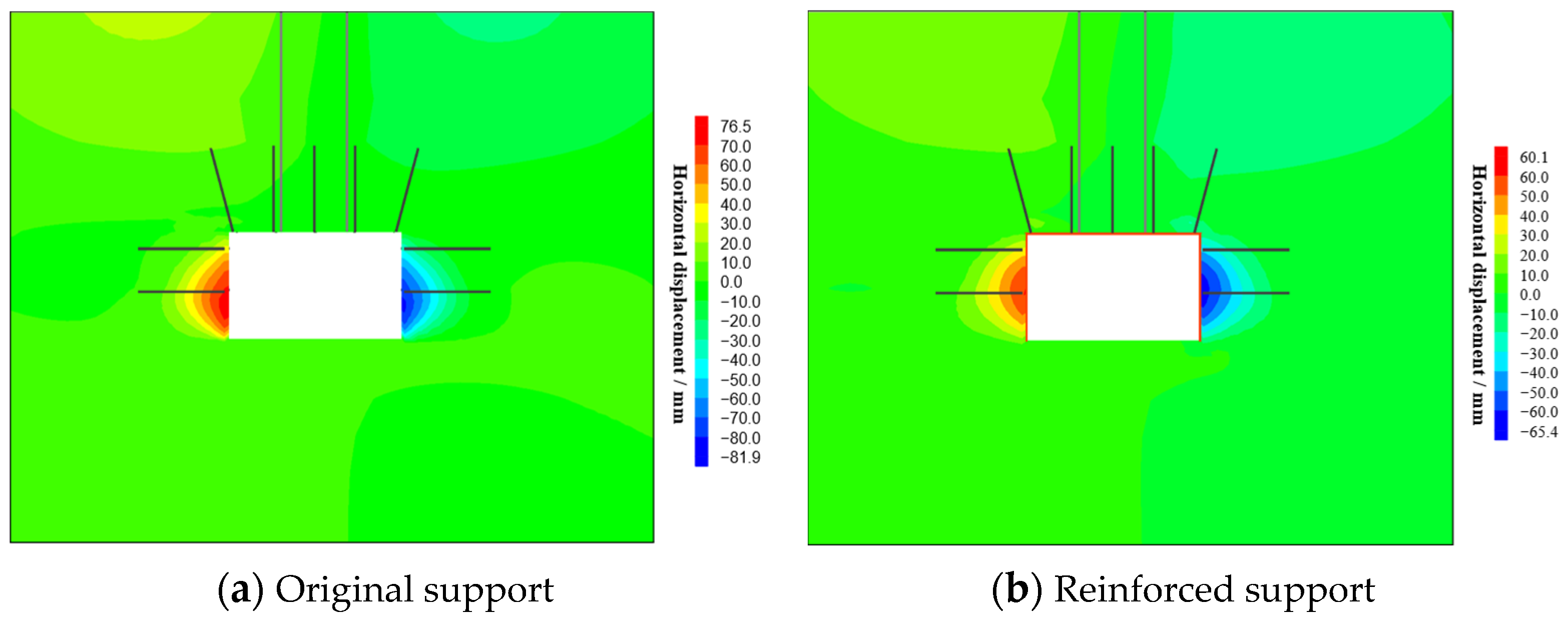

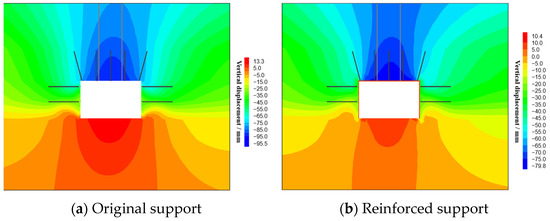

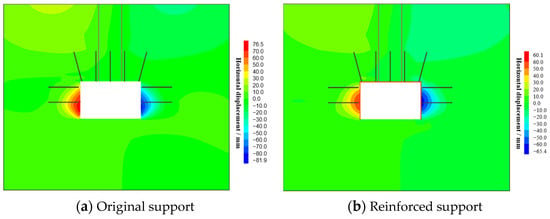

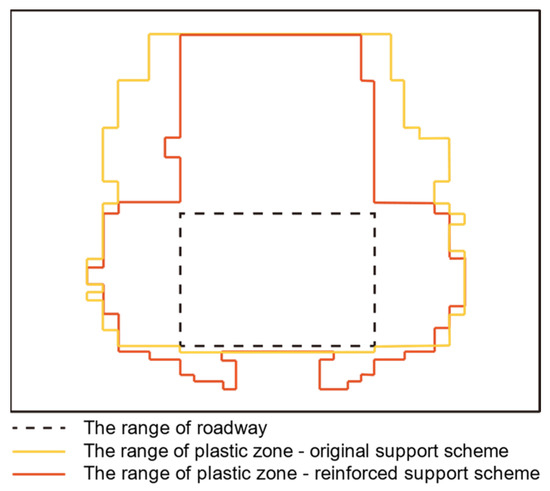

According to the numerical simulation findings, an analysis was conducted on the displacement and plastic zone of the roadway surrounding rock. This analysis considered both regular anchor cable support and reinforcement with combined brackets.

- (1)

- Displacement analysis

Figure 15 and Figure 16 show the vertical and horizontal displacement distribution of the roadway under dynamic pressure with different support schemes. The reinforced support scheme significantly reduces the deformation of the surrounding rock. It is evident that the subsidence of the roadway roof using the original support is 95.5 mm, the floor heave is 13.3 mm, the left side has moved 76.5 mm, and the right side has moved 81.9 mm. When the combined bracket is used to reinforce the roadway, the vertical displacement of the roof is 79.8 mm, the floor heave is 10.4 mm, the left side has moved 60.1 mm, and the right side has moved 65.4 mm.

Figure 15.

Vertical displacement distribution of the roadway’s surrounding rock.

Figure 16.

Horizontal displacement distribution of the roadway’s surrounding rock.

Compared with the original scheme, the reinforcement support scheme has optimized the support effects aimed at limiting roof subsidence, floor heave, and side convergence by 16.4%, 21.8%, and 20.8%, respectively. The impact on controlling the deformation of the surrounding rock is clearly evident.

- (2)

- Plastic zone analysis

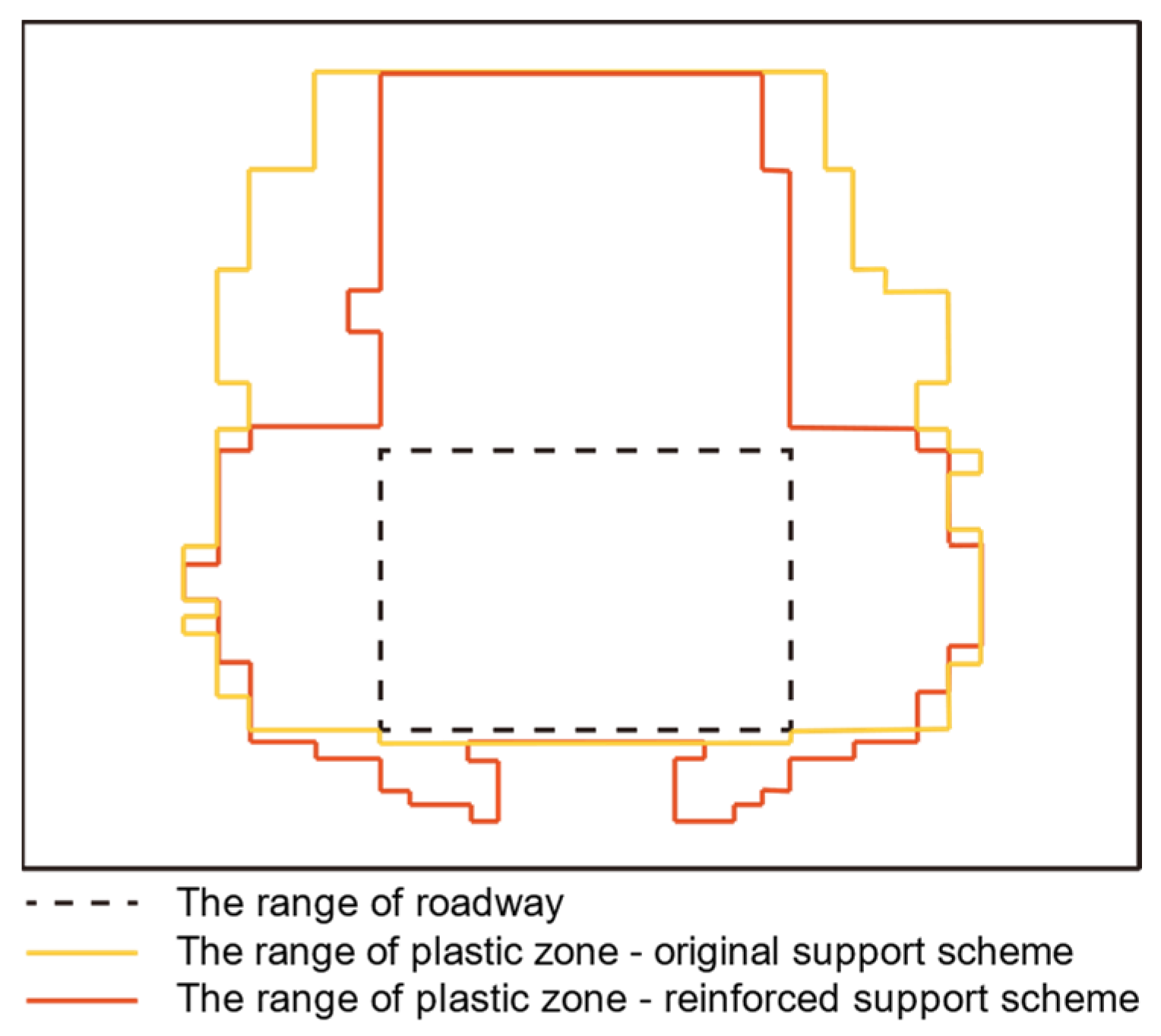

Figure 17 illustrates the distribution of the plastic zone of the roadway surrounding rock when subjected to dynamic pressure, considering various support schemes. When the original support scheme is adopted, the plastic zone is primarily concentrated at the roof and sides, with a distinct development of a plastic zone at the shoulder angle. Meanwhile, since the floor is siltstone with relatively good lithology, the plastic zone exhibits a limited extent. Under reinforced support, the plastic zone at the shoulder corner of the roadway is significantly weakened and is mostly concentrated above the roadway roof, while the plastic zone at the bottom corner is increased.

Figure 17.

Boundary of the plastic zone of the roadway’s surrounding rock.

Combined with the analysis of the on-site conditions, it is believed that the roof surrounding rock has a certain degree of pressure relief effect after the use of the combined bracket reinforcement scheme, and the combined bracket can play a passive supporting role, which makes the plastic zone of the shoulder angle of the roadway reduced to a certain extent, while the concrete filled steel tube columns on both sides are affected by the advanced supporting pressure, resulting in an increase in the plastic zone of the bottom corners.

6. Engineering Site

6.1. Original Roadway Support Scheme

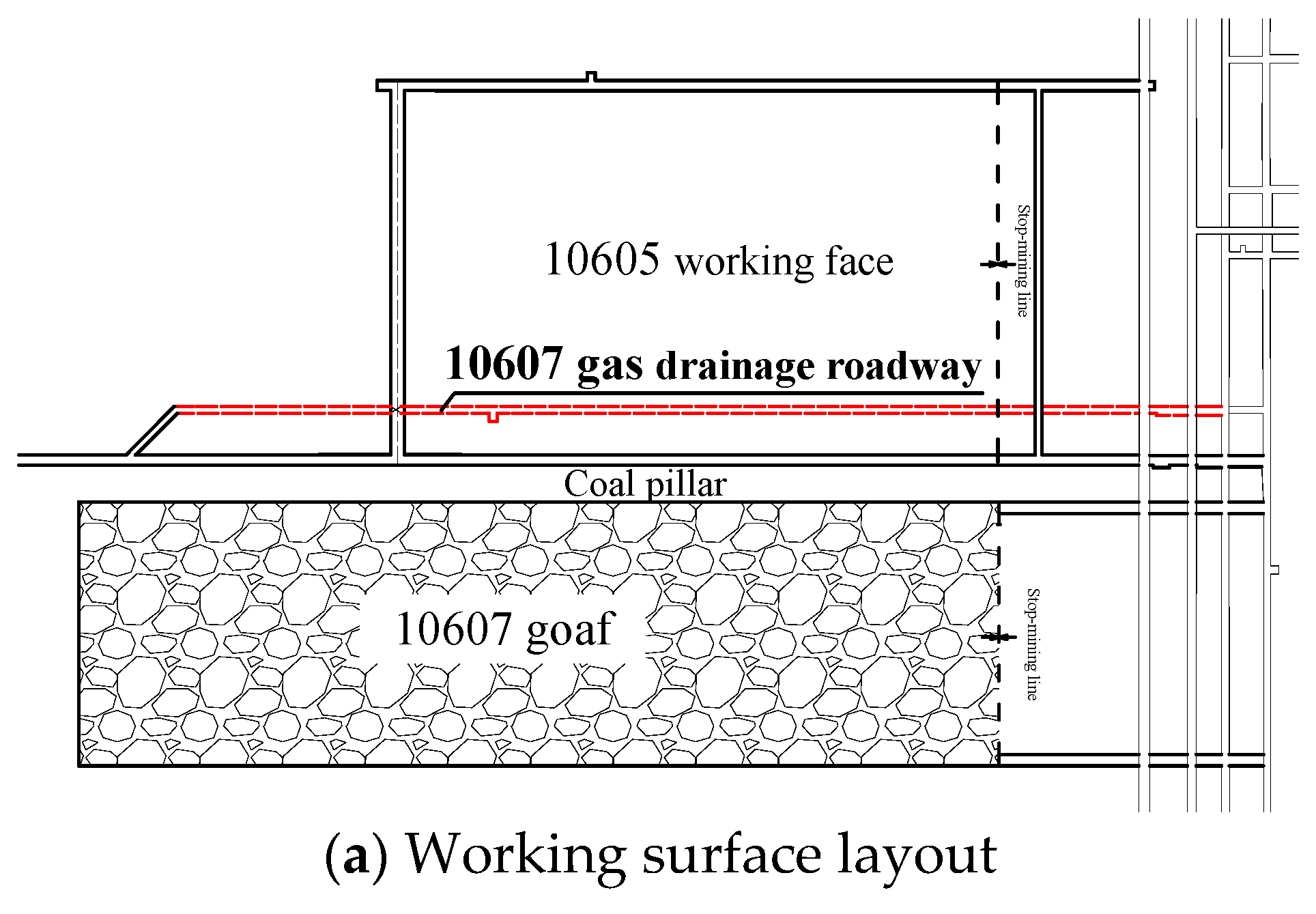

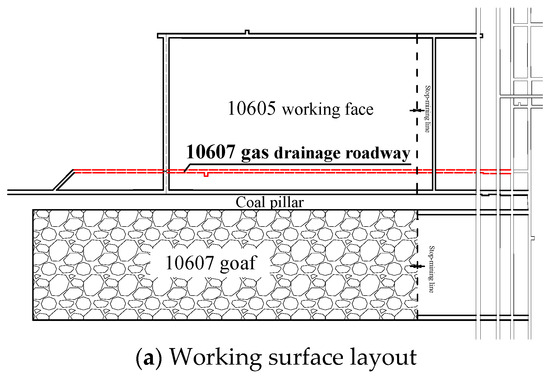

The 10607 gas drainage roadway, located in the #2 coal seam, is utilized for the extraction of gas from both the 10607 and 10605 working faces of the #02 coal seam. Furthermore, it will serve as a mining roadway during the mining of the #2 coal seam, thus realizing a multipurpose function (Shan et al. [24]). Figure 18 displays the layout of the 10607 gas drainage roadway.

Figure 18.

The layout of the roadway.

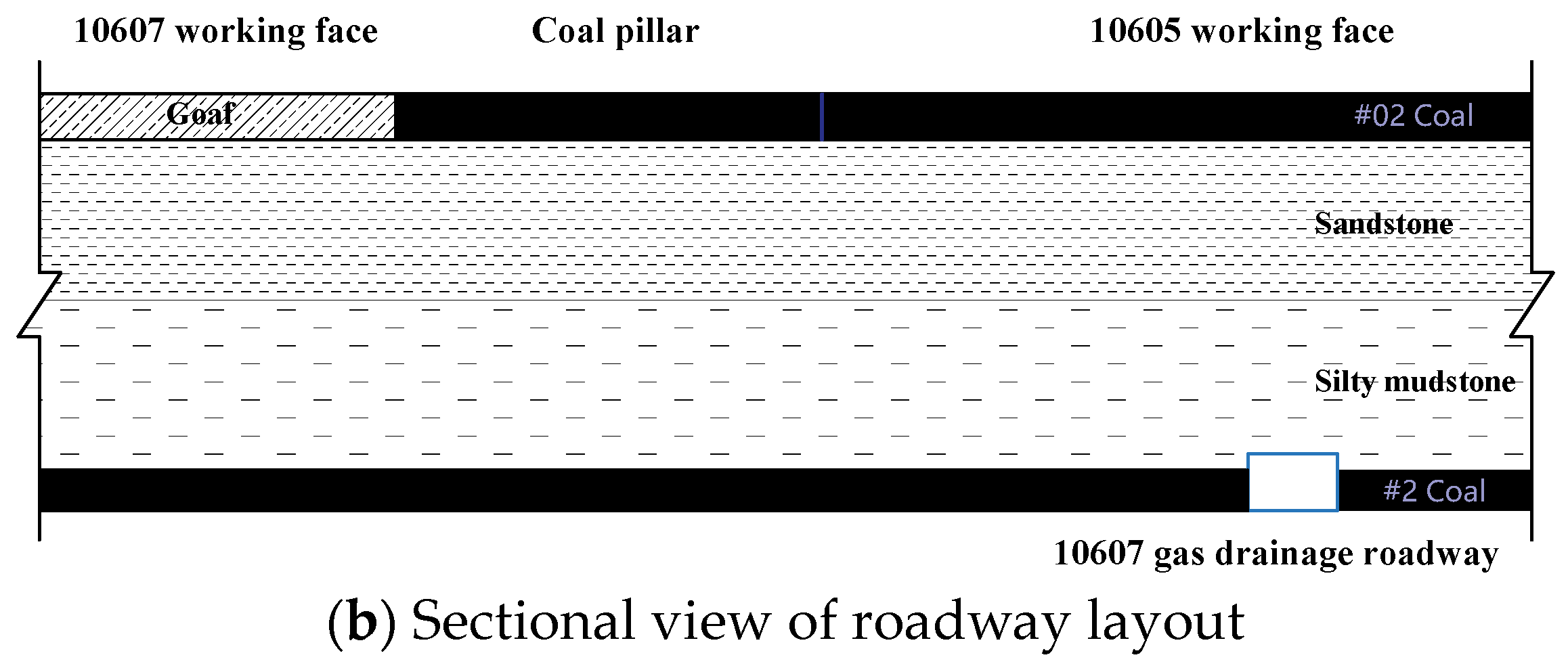

The 10607 gas drainage roadway features a rectangular shape with dimensions of 4200 mm in width and 2600 mm in height. The original support scheme consists of anchor bolts and anchor cables, and the design is based on the predicted load of the roadway roof. The roof adopts Φ20 × 2000 mm rebar anchor bolts + metal diamond mesh + reinforced steel belt + Φ21.6 × 52,000 mm anchor cables + pressed pallet joint support, and the two sides use Φ20 × 2000 mm rebar anchors + W pallets + metal diamond mesh for joint support [24], as illustrated in Figure 19.

Figure 19.

Original support scheme.

6.2. Roadway Reinforcement Design

Based on our analysis of the damage mechanisms of roadways under dynamic pressure, an overall active and passive support technology has been proposed, comprising an anchor cable and channel steel beam–CFST column combined bracket, and the reliability of this support technology has been verified using numerical simulation software. This has shown that since the 10607 gas drainage roadway only has conventional anchor cable supports, the roadway surrounding rock will suffer damage as a result of mining activities. Therefore, the roadway needs to be reinforced in advance to ensure that it can maintain the stability of the surrounding rock under the influence of mining.

As shown in Figure 20, the reinforcement support scheme uses a channel steel beam–CFST column combined bracket to passively support the surrounding rock, and this is combined with the active support of the anchor cables used in the original scheme to jointly cope with the impact of mining the 10605 working face. To guarantee the durability and stability of the roadway under various dynamic pressures, a combination bracket with a substantial support reaction force is employed in the design scheme.

Figure 20.

Overall active and passive support scheme.

The CFST columns are made of Φ194 × 8 mm seamless steel pipes, the channel steel is made of the 14#b model, and we employ C40 fast-hardening concrete. The anchor bolts and anchor cables have breaking loads of 200 kN and 180 kN, respectively, while the ultimate bearing capacity of the CFST columns is 1954 kN. Considering that the roadway has a long service life and will need to withstand many mining disturbances, the design distance between the brackets is 1000 mm.

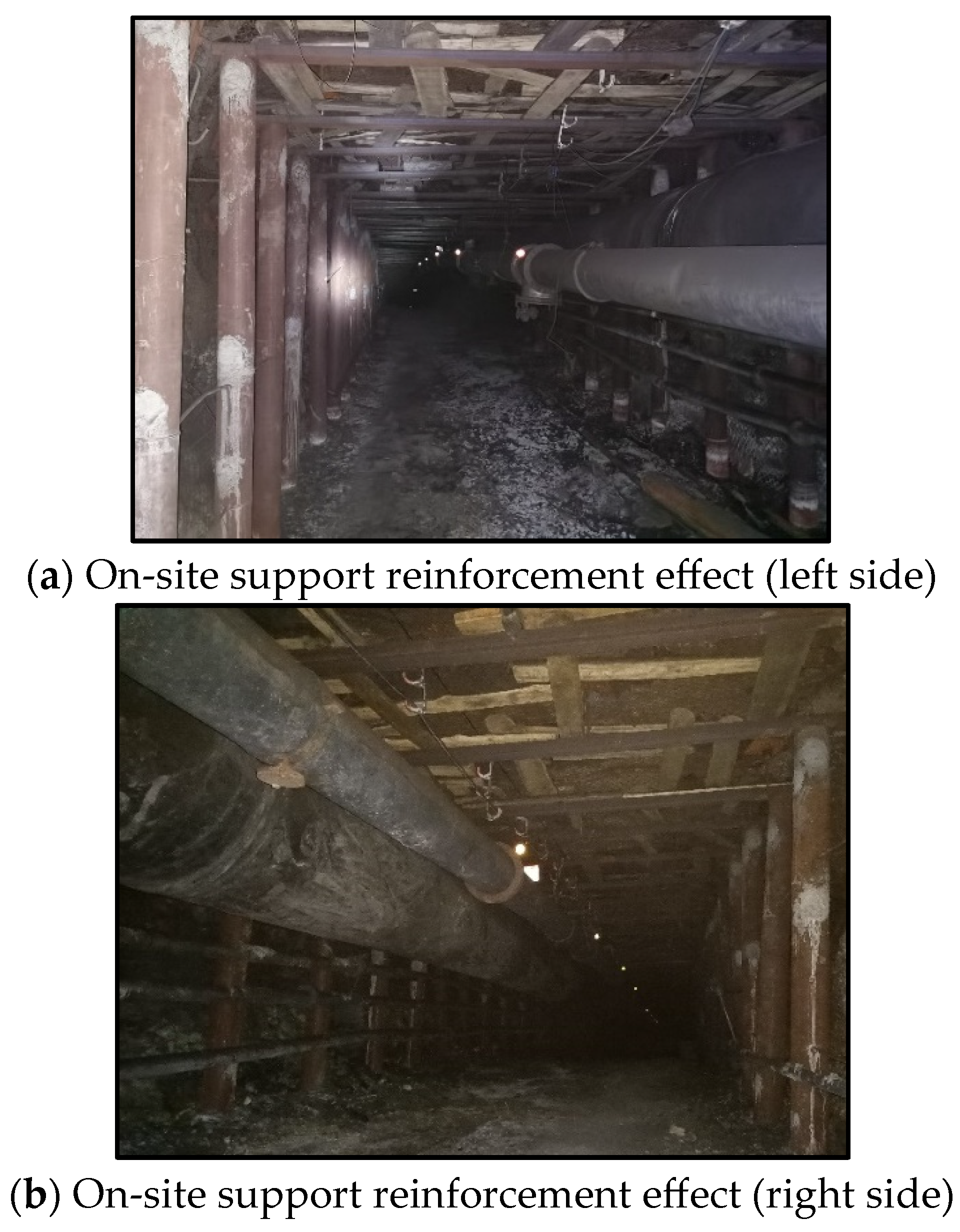

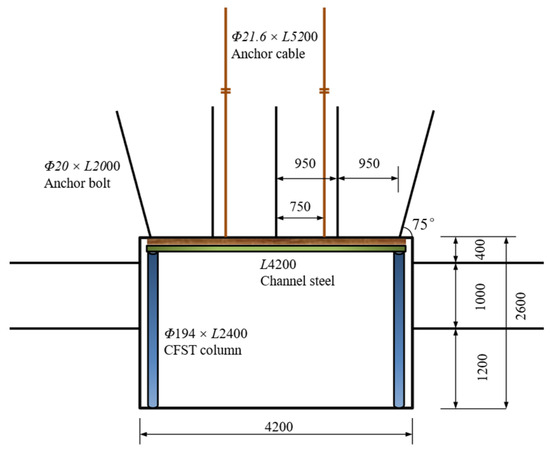

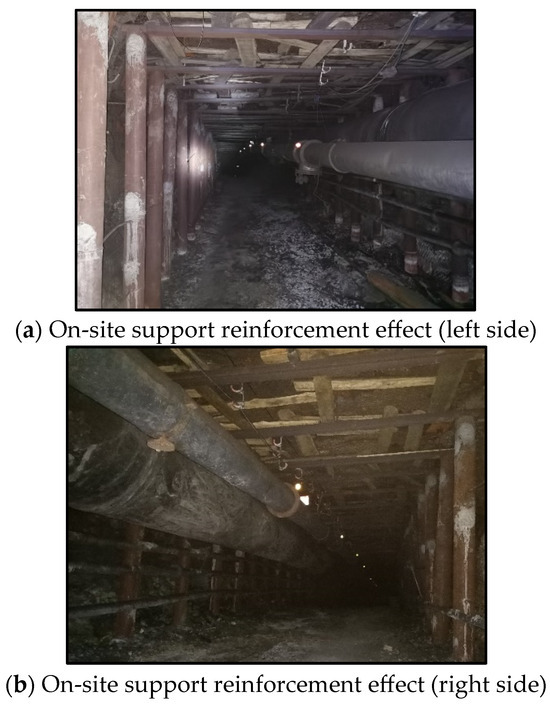

6.3. On-Site Support Effect Analysis

When taking into account the geological composition of the 10607 gas drainage roadway and its specific site conditions, it can be observed that the middle section of the roadway is composed of silty mudstone for its roof, siltstone for its floor, silty mudstone for its upper sides, and #2 coal for its lower sides. The slope of the floor in this section is small and gentle, which facilitates the installation of the combined bracket and the mixing of concrete on-site. Therefore, this section was selected as the support reinforcement test section, and the on-site support effect is shown in Figure 21.

Figure 21.

The effect of combined bracket support.

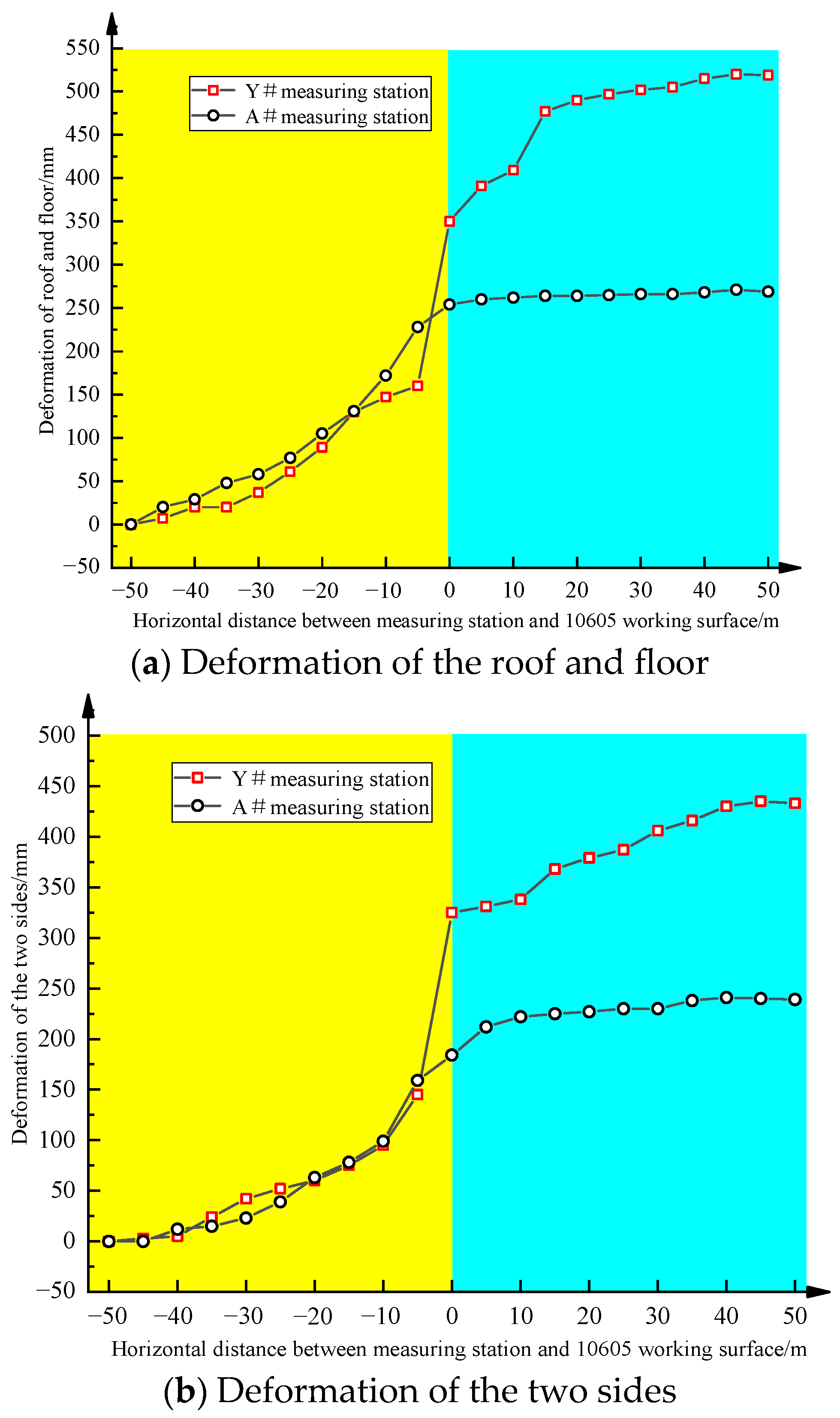

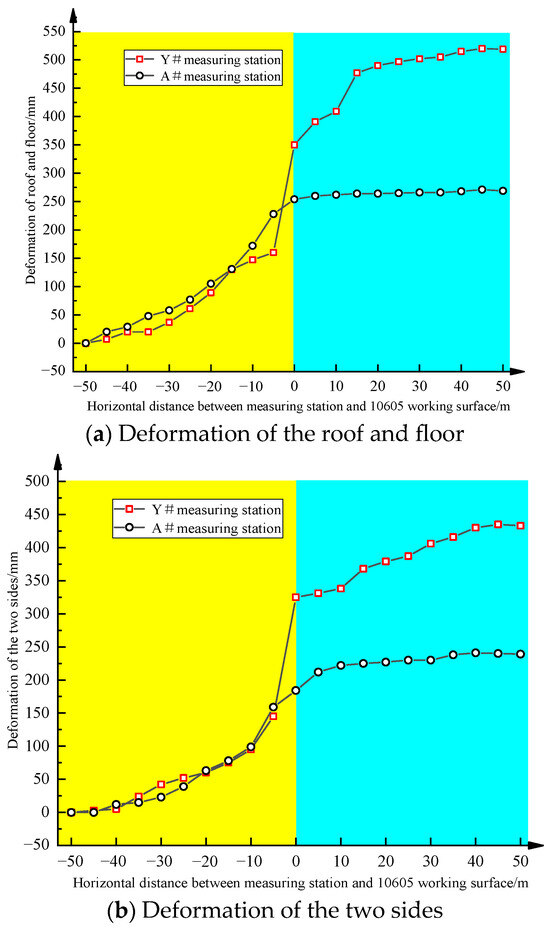

To assess the impact of the reinforcement scheme on support effectiveness, it was imperative to monitor the roadway deformation in relation to that observed under the original support scheme. In this case, we established two sets of measuring stations along the roadway, termed Y# and A#. The Y# measuring station monitored the roadway with the original support scheme, and A# monitored the roadway with the reinforcement scheme. During on-site monitoring, the cross-point method was used, and tools such as laser ranging instruments, steel tapes, hooks, and height gauges were applied to determine the vertical distance between the roof and floor, as well as the horizontal distance between both sides.

According to the on-site monitoring findings, the maximum displacements of the roof, side walls, and floor for which the excavation remains functional are 410 mm, 350 mm, and 80 mm, respectively. As depicted in Figure 22, the mining-induced impact resulted in a maximum roof subsidence of 520 mm for the original support section, while the reinforced support section experienced a maximum roof subsidence of 271 mm. The displacement of the two sides of the original support section reached a maximum of 435 mm, while the reinforced support section exhibited a maximum displacement of 241 mm. It is evident that the reinforcement support scheme significantly enhanced the effectiveness of mitigating roof subsidence and lateral displacement by 47.9% and 44.6%, respectively, when compared with the original scheme, and the surrounding rock deformation control effect was more obvious.

Figure 22.

Surrounding rock deformation monitoring data.

7. Conclusions

In this study, for the case of the 10607 gas drainage roadway, a formula for the boundary of the plastic zone of the rock surrounding the roadway under dynamic pressure was derived by establishing a roadway mechanics model. The impacts of the mining influence coefficient and supporting force on the plastic zone were studied, and an overall system of active and passive support technology was proposed. The following are our key contributions:

- (1)

- Through theoretical derivation, we determined the plastic zone boundary of dynamic pressure roadways under two-way non-isobaric conditions. The impact of vertical and horizontal mining on the boundary of the plastic zone was examined for various lateral pressure coefficients. Four fundamental shapes of the plastic zone boundary under dynamic pressure were proposed.

- (2)

- As the supporting force was increased, it was observed that there was a slight reduction in the radius of the plastic zone of the dynamic pressure roadway. However, the overall extent and shape of the plastic zone remained largely unaffected. These findings suggest that augmenting the current supporting force does not effectively control deformation and damage in dynamic pressure roadways.

- (3)

- Based on the distribution of the plastic zone of dynamic pressure roadway, an overall system of active and passive support technology was proposed, comprising an anchor cable and channel steel beam–CFST column combined bracket, and this was applied to the 10607 gas drainage roadway.

Author Contributions

Conceptualization, R.S.; data curation, D.L. and X.Z.; funding acquisition, R.S. and Z.L.; investigation, Y.W.; methodology, Z.L.; software, C.W. and Y.L.; visualization, D.L. and X.Z.; writing—original draft, Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. 51474218) and the Natural Science Foundation of Hebei Province (No. E2023402103).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The editor and reviewers are greatly appreciated by the authors for their meticulous reading of the manuscript and their invaluable recommendations.

Conflicts of Interest

Author Chunhe Wang was employed by the company China Construction Communications Engineering Group Corporation Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yang, X.L.; Wen, G.C.; Dai, L.C. Ground Subsidence and Surface Cracks Evolution from Shallow-Buried Close-Distance Multi-seam Mining: A Case Study in Bulianta Coal Mine. Rock Mech. Rock Eng. 2019, 52, 2835–2852. [Google Scholar] [CrossRef]

- Kang, H.P. Seventy years development and prospects of strata control technologies for coal mine roadways in China. Chin. J. Rock Mech. Eng. 2021, 40, 1–30. (In Chinese) [Google Scholar] [CrossRef]

- Qin, T.; Duan, B.Y.; Duan, Y.W. “Migrate-Transfer-Control” Support System of Surrounding Rock in the Deep Roadway and Its Application. Appl. Sci. 2023, 13, 6325. [Google Scholar] [CrossRef]

- Jin, D.Z.; Liu, Y.; Li, B.R. FLAC3D-based Analysis on Subgrade Workaround of Asphalt Pavement Structures under Various Loading Conditions. DEStech Trans. Eng. Technol. Res. 2017, 736–742. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Jin, D.; Ge, D. Identify the Micro-Parameters for Optimized Discrete Element Models of Granular Materials in Two Dimensions Using Hexagonal Close-Packed Structures. Materials 2023, 16, 3073. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Wang, W.J.; Yuan, C. Research on large deformation mechanism of deep roadway with dynamic pressure. Environ. Earth Sci. 2020, 8, 3348–3364. [Google Scholar] [CrossRef]

- Rong, H.; Guo, K.P.; Sun, D. Research on main influencing factors and complete support technology for dynamic pressure and large deformation roadway. Sci. Rep. 2023, 13, 4136. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Gao, S.S.; Yang, T. Study of the Failure Mechanism of Soft Rock Mining Roadways Based on Limit Analysis Theory. Appl. Sci. 2023, 13, 10323. [Google Scholar] [CrossRef]

- Wang, M.; Xu, Y.L.; Xu, Q.Y. Stability control of overburden and coal pillars in the gob-side entry under dynamic pressure. Int. J. Rock Mech. Min. Sci. 2023, 170, 105490. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Zhou, J.L.; Zhang, C. Failure mechanism of gob-side roadway in deep coal mining in the Xinjie mining area: Theoretical analysis and numerical simulation. J. Cent. South Univ. 2023, 30, 1631–1648. [Google Scholar] [CrossRef]

- Ma, Z.M.; Wang, Y.J.; Huang, L. Research on the Stability Mechanism of the Surrounding Rock of Gob-Side Entry Retaining by Roof Cutting in Dianping Coal Mine. Minerals 2022, 12, 965. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, N.; Kan, J.G. Instability Mode and Control Technology of Surrounding Rock in Composite Roof Coal Roadway under Multiple Dynamic Pressure Disturbances. Geofluids 2022, 2022, 8694325. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Choice of the Arch Yielding Support for the Preparatory Roadway Located near the Fault. Energies 2022, 15, 3774. [Google Scholar] [CrossRef]

- Wang, J.; Apel, D.B.; Xu, H. Evaluation of the Effects of Yielding Rockbolts on Controlling Self-Initiated Strainbursts: A Numerical Study. Energies 2022, 15, 2574. [Google Scholar] [CrossRef]

- Ma, Z.Q.; Jiang, Y.D.; Liu, Y. Investigation on support pattern of a coal mine roadway under dynamic pressure of mining—A case study. Int. J. Oil Gas Coal Technol. 2018, 18, 402–422. [Google Scholar] [CrossRef]

- Wang, D.Q.; He, F.L.; Wu, Y.H. Study on surrounding rock failure mechanism and rational coal pillar width of the gob-side coal roadway under influence of intense dynamic pressure. Energy Sci. Eng. 2023, 11, 1716–1733. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, C.Y.; Gu, W.Z. Research on Floor Heave Mechanisms and Control Technology for Deep Dynamic Pressure Roadways. Processes 2023, 11, 467. [Google Scholar] [CrossRef]

- Sun, X.M.; Zhao, W.C.; Wang, J. Research on Failure Mechanism and Stability Control Technology of Dynamic Pressure Roadway in Ultra-Thick Coal Seams Under a High Depth of Cover. Min. Metall. Explor. 2023, 40, 1955–1972. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Jiang, B.; Wang, Q. Model test research and application on control method of cooperative pressure relief by directional roof cutting for roadways with strong dynamic pressure. Environ. Earth Sci. 2023, 82, 434. [Google Scholar] [CrossRef]

- Meng, N.K.; Bai, J.B.; Yoo, C. Failure mechanism and control technology of deep soft-rock roadways: Numerical simulation and field study. Undergr. Space 2023, 12, 1–17. [Google Scholar] [CrossRef]

- Xie, S.R.; Jiang, Z.S.; Chen, D.D. A New Pressure Relief Technology by Internal Hole-Making to Protect Roadway in Two Sides of Deep Coal Roadway: A Case Study. Rock Mech. Rock Eng. 2022, 56, 1537–1561. [Google Scholar] [CrossRef]

- Xie, S.R.; Li, H.; Chen, D.D. New Technology of Pressure Relief Control in Soft Coal Roadways with Deep, Violent Mining and Large Deformation: A Key Study. Energies 2022, 15, 9208. [Google Scholar] [CrossRef]

- Lv, J.K.; Wan, Z.J.; Yang, Y.J. Failure characteristics and stability control technology of dynamic pressure roadway affected by the mining activity: A case study. Eng. Fail. Anal. 2022, 131, 105857. [Google Scholar] [CrossRef]

- Shan, R.L.; Wei, Y.H.; Wang, C.H. Research on the evolution of the deviatoric stress and control of a gas extraction roadway under mining influence. Environ. Earth Sci. 2023, 82, 425. [Google Scholar] [CrossRef]

- Huang, B.X.; Zhang, N.; Li, N. Large deformation theory of rheology and structural instability of the surrounding rock in deep mining roadway. J. China Coal Soc. 2020, 45, 911–926. (In Chinese) [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.J.; Yu, W.J. Large deformation failure mechanism of surrounding rock for gateroad under dynamic pressure in deep coal mine. J. China Coal Soc. 2016, 41, 2940–2950. (In Chinese) [Google Scholar] [CrossRef]

- Guo, X.F.; Zhao, Z.Q.; Gao, X. Analytical solutions for characteristic radii of circular roadway surrounding rock plastic zone and their application. Int. J. Min. Sci. Technol. 2019, 29, 263–272. [Google Scholar] [CrossRef]

- Wang, W.J.; Han, S.; Dong, E.Y. Boundary equation of plastic zone in roadway surrounding rocks considering supporting effect and its application. J. Min. Saf. Eng. 2021, 34, 749–755. (In Chinese) [Google Scholar] [CrossRef]

- Qin, D.D.; Wang, X.F.; Zhang, D.S. Study on Surrounding Rock-Bearing Structure and Associated Control Mechanism of Deep Soft Rock Roadway Under Dynamic Pressure. Sustainability 2019, 11, 1892. [Google Scholar] [CrossRef]

- Chen, B.; Zuo, Y.J.; Zheng, L.L. Deformation failure mechanism and concrete-filled steel tubular support control technology of deep high-stress fractured roadway. Tunn. Undergr. Space Technol. 2022, 129, 104684. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Pan, R. Failure mechanism of surrounding rock with high stress and confined concrete support system. Int. J. Rock Mech. Min. Sci. 2018, 102, 89–100. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).