Synergistic Improvement in Setting and Hardening Performance of OPC-CSA Binary Blended Cement: Combined Effect of Nano Calcium Carbonate and Aluminum Sulfate

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Preparation of Cement Paste

2.3. Experiments

2.3.1. Performance Evaluation

2.3.2. Calorimetry

2.3.3. XRD

2.3.4. MIP

3. Results and Discussion

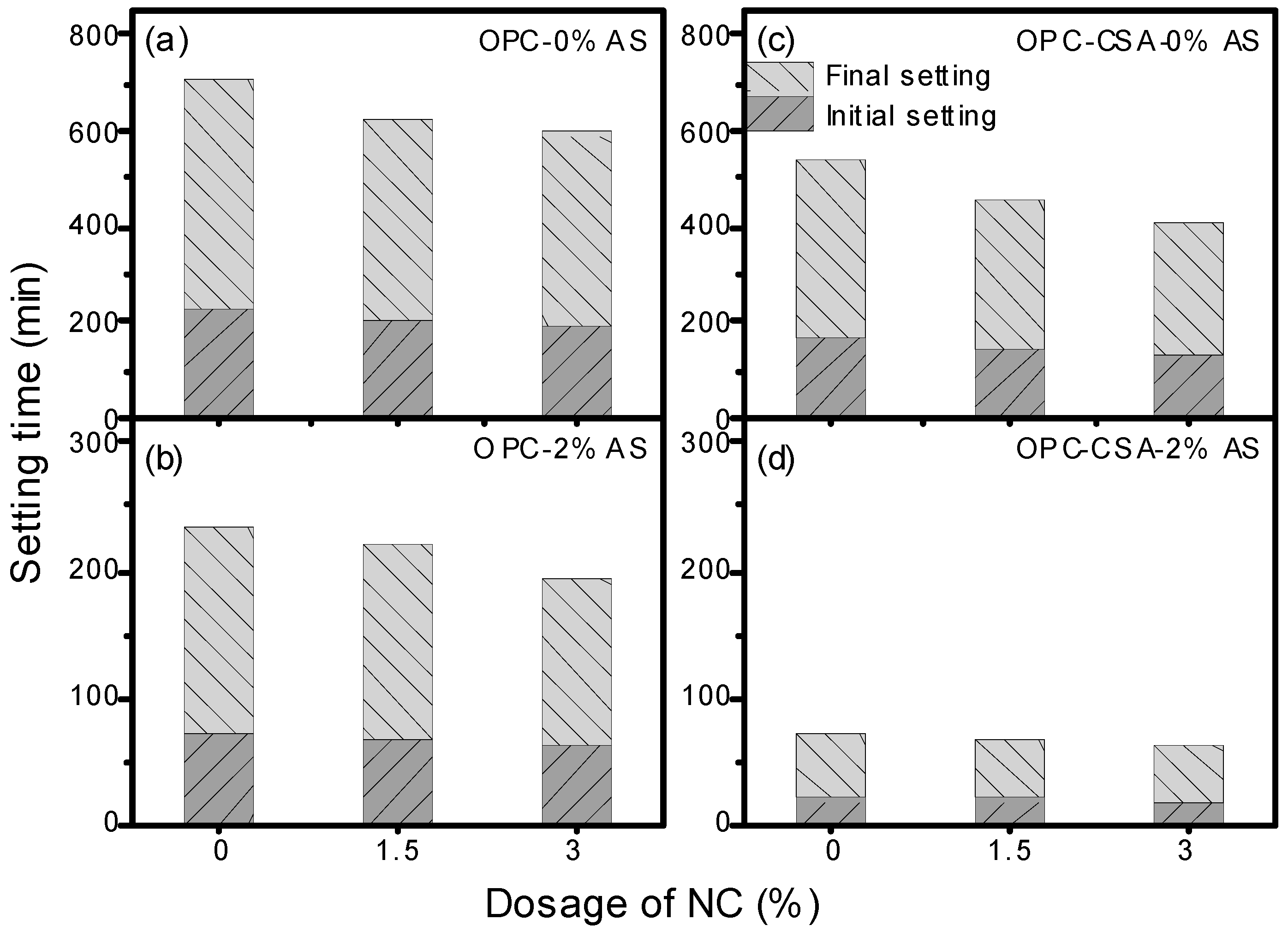

3.1. Setting Time

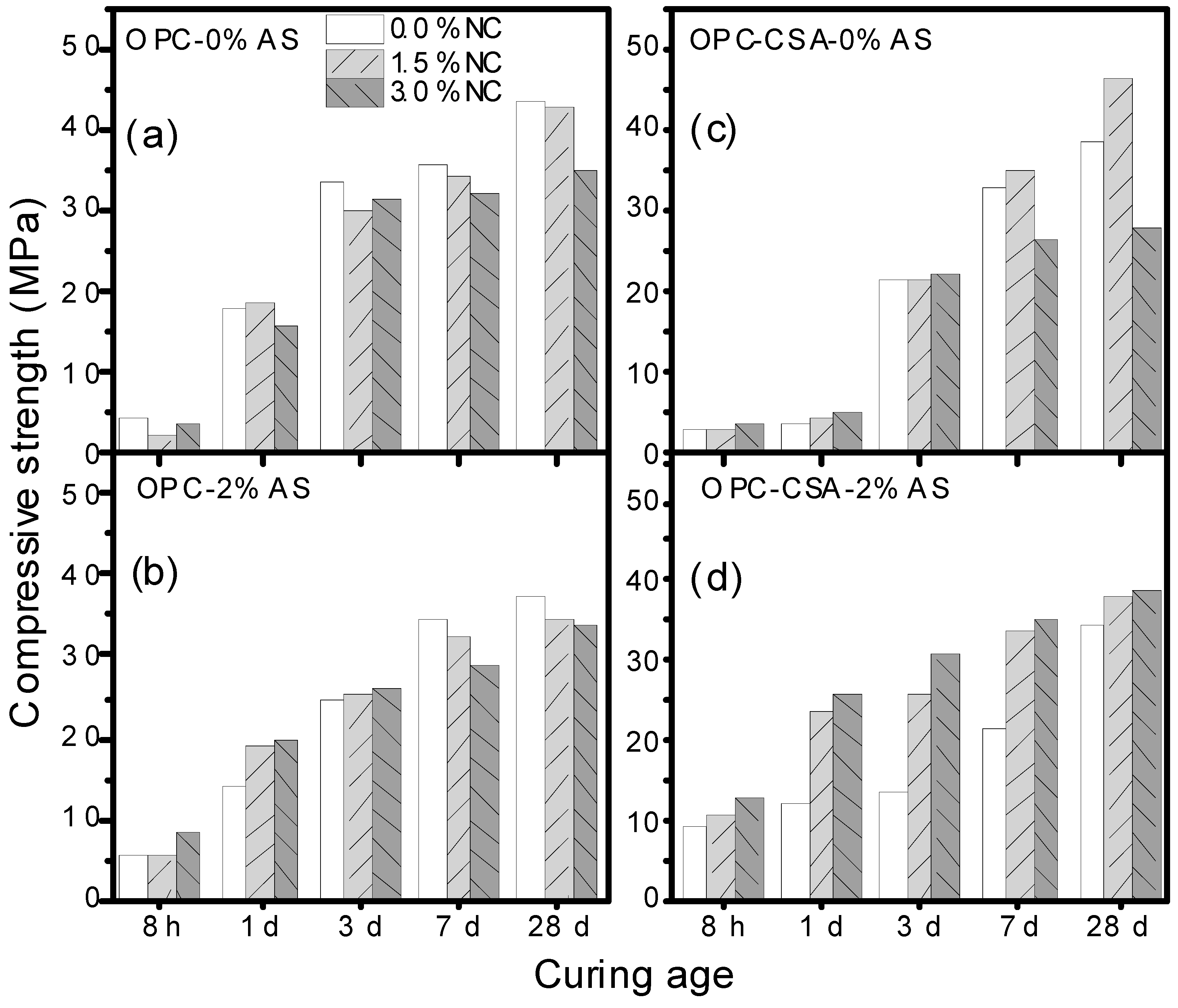

3.2. Compressive Strength

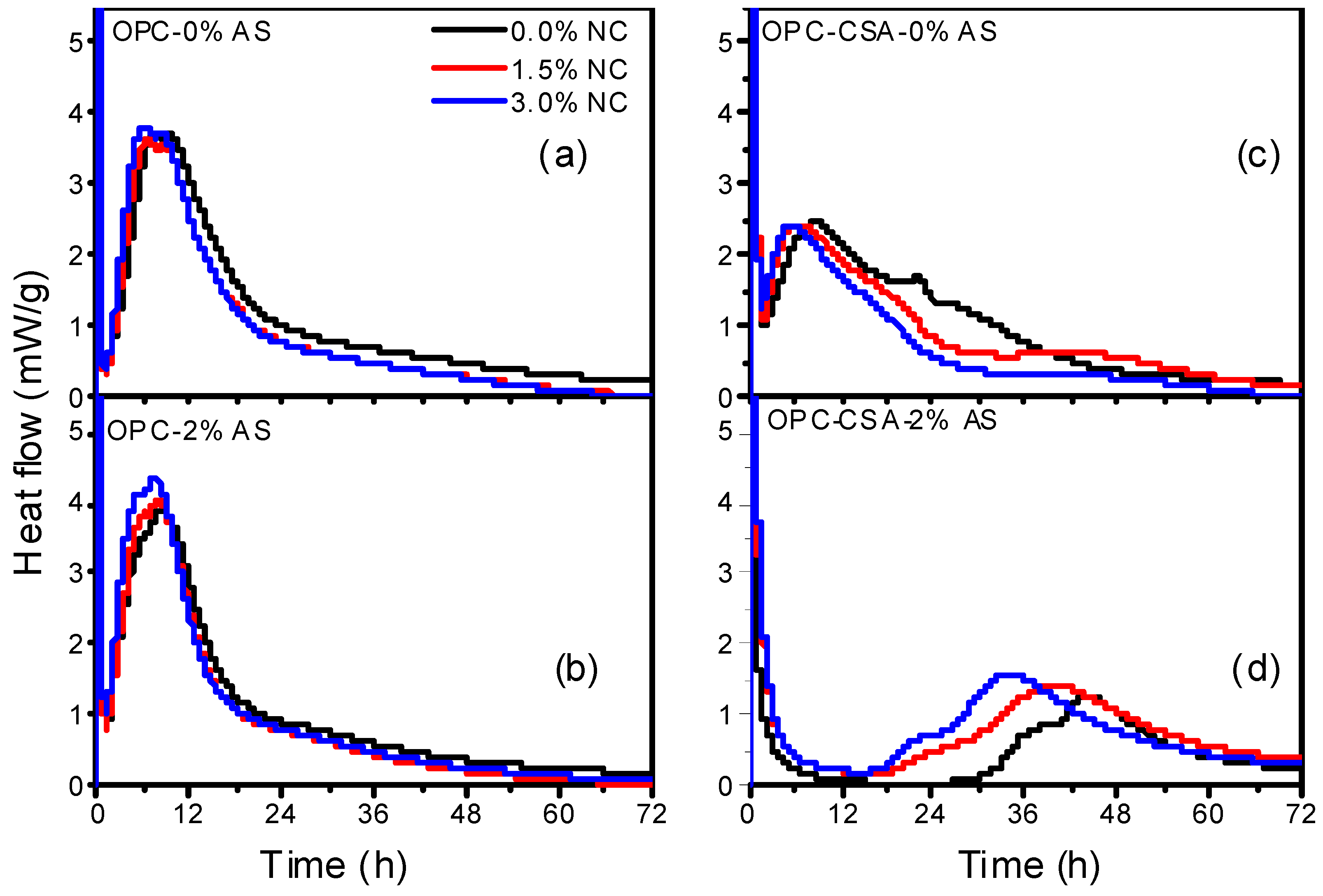

3.3. Hydration Process

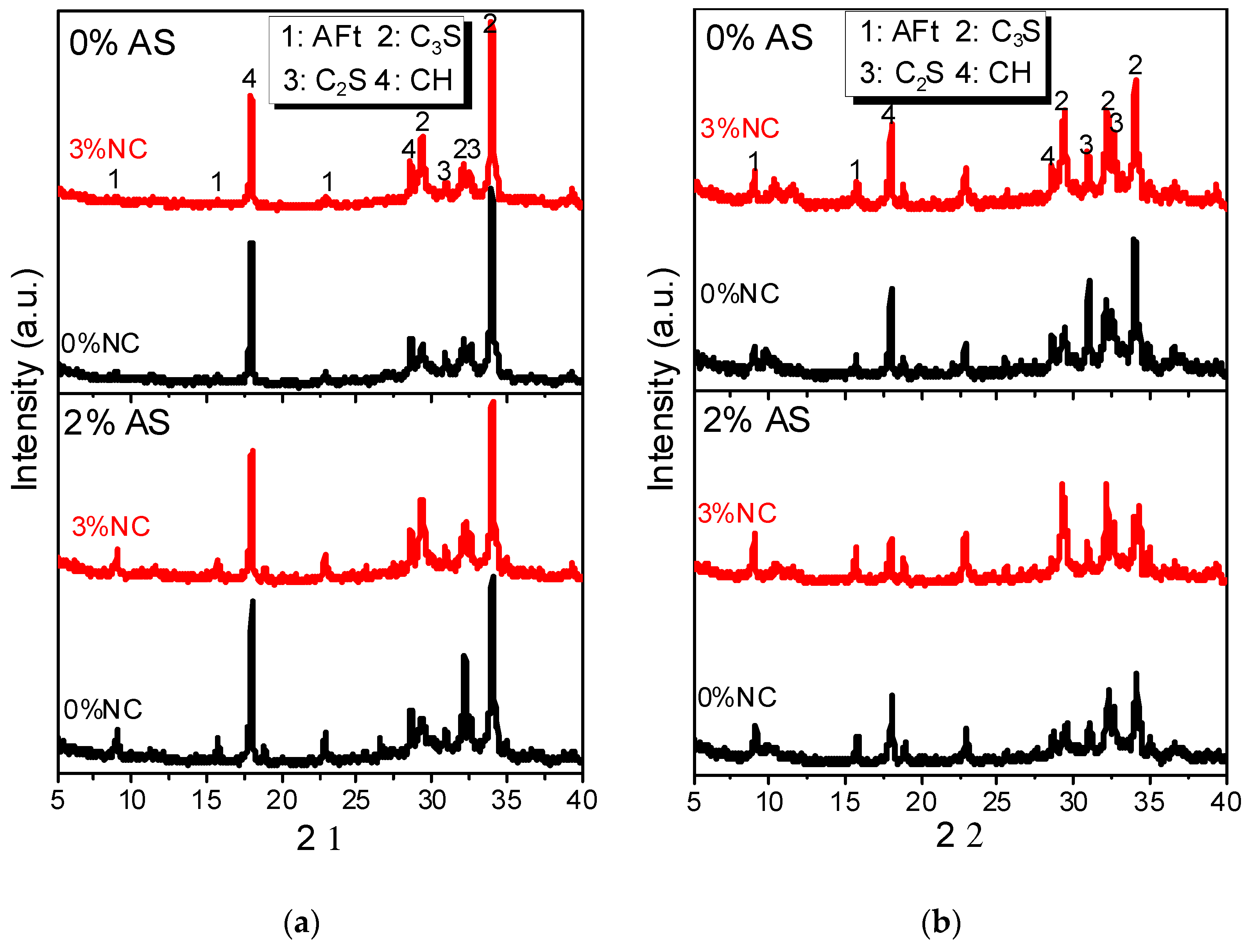

3.4. XRD

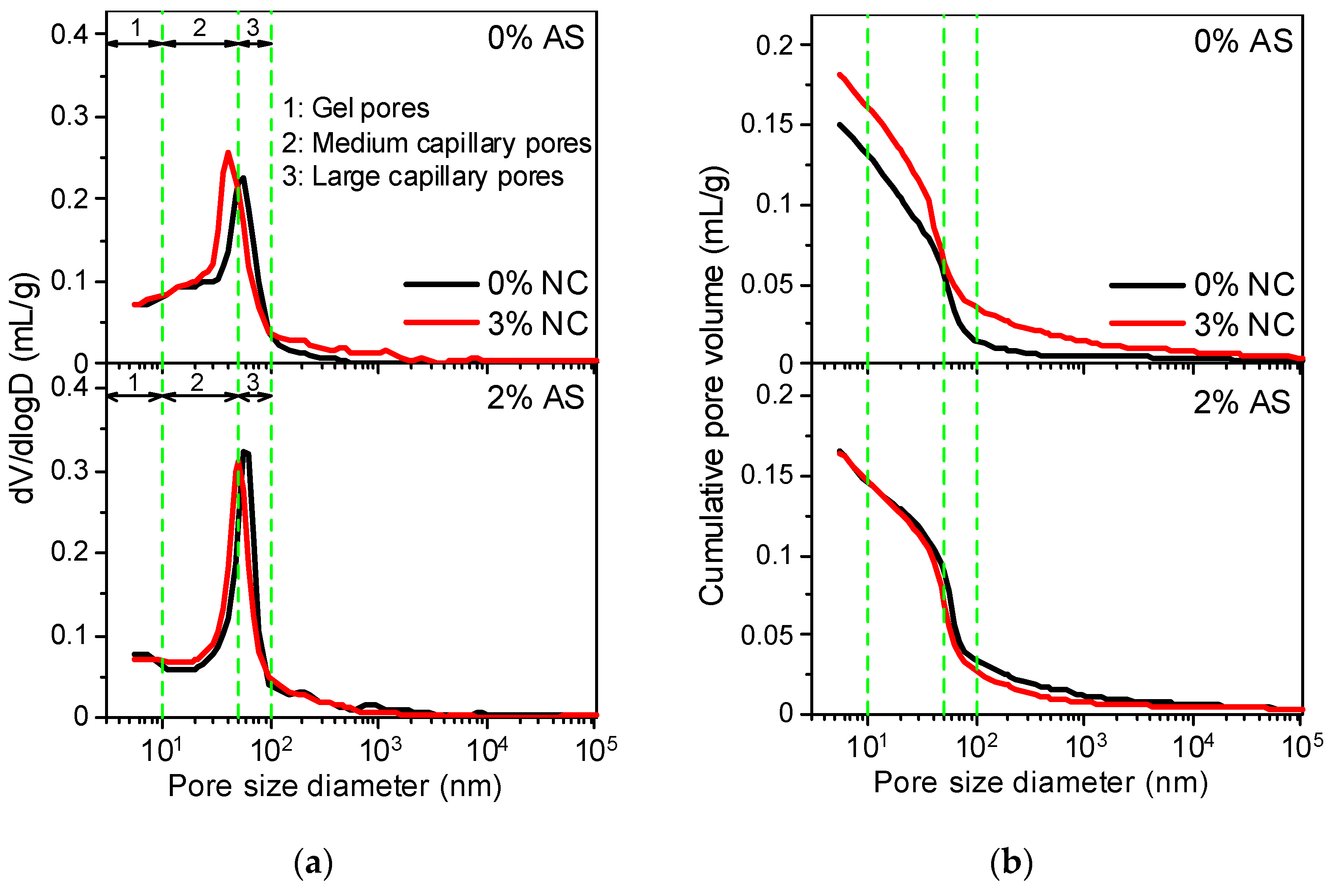

3.5. MIP

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rudnicki, T.; Stałowski, P. Fast-Setting Concrete for Repairing Cement Concrete Pavement. Materials 2023, 16, 5909. [Google Scholar] [CrossRef]

- Seehra, S.; Gupta, S.; Kumar, S. Rapid setting magnesium phosphate cement for quick repair of concrete pavements—Characterisation and durability aspects. Cem. Concr. Res. 1993, 23, 254–266. [Google Scholar] [CrossRef]

- Mo, F.; Li, B.; Li, M.; Fang, Z.; Fang, S.; Jiang, H. Rapid-Hardening and High-Strength Steel-Fiber-Reinforced Concrete: Effects of Curing Ages and Strain Rates on Compressive Performance. Materials 2023, 16, 4947. [Google Scholar] [CrossRef]

- Ghazy, A.; Bassuoni, M.T.; Shalaby, A. Nano-Modified Fly Ash Concrete: A Repair Option for Concrete Pavements. ACI Mater. J. 2016, 113, 231–242. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, C.; Ma, Y.; Xiao, Y.; Liu, Y. Accelerators for shotcrete–Chemical composition and their effects on hydration, microstructure and properties of cement-based materials. Constr. Build. Mater. 2021, 281, 122557. [Google Scholar] [CrossRef]

- Yang, R.; He, T.; Xu, Y. Preparation of alkali free liquid accelerator for shotcrete with fluorosilicic acid waste liquid and its accelerating mechanism. Cem. Concr. Compos. 2022, 131, 104600. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, C.; Lei, L.; Ma, Y.; Liu, J.; Hu, X. Formulation of an alkali-free accelerator and its effects on hydration and mechanical properties of Portland cement. Cem. Concr. Compos. 2022, 129, 104485. [Google Scholar] [CrossRef]

- Wang, W.; Zeng, L.; Du, S.; Qiao, M.; Chen, J.; Zhu, B. The Influence of Alkali-Free Shotcrete Accelerators on Early Age Hydration and Property Development within Cement Systems. Materials 2022, 15, 6907. [Google Scholar] [CrossRef]

- Briendl, L.G.; Mittermayr, F.; Baldermann, A.; Steindl, F.R.; Sakoparnig, M.; Letofsky-Papst, I.; Galan, I. Early hydration of cementitious systems accelerated by aluminium sulphate: Effect of fine limestone. Cem. Concr. Res. 2020, 134, 106069. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Kothari, A.; Tole, I.; Hedlund, H.; Ellison, T.; Cwirzen, A. Partial replacement of OPC with CSA cements–effects on hydration, fresh and hardened properties. Adv. Cem. Res. 2022, 35, 207–224. [Google Scholar] [CrossRef]

- Yang, Z.; Ye, H.; Yuan, Q.; Li, B.; Li, Y.; Zhou, D. Factors Influencing the Hydration, Dimensional Stability, and Strength Development of the OPC-CSA-Anhydrite Ternary System. Materials 2021, 14, 7001. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Li, B.; Yuan, Q.; Shi, Z.; Xie, Y.; Shi, C. Rheological behavior of Portland clinker-calcium sulphoaluminate clinker-anhydrite ternary blend. Cem. Concr. Compos. 2019, 104, 103403. [Google Scholar] [CrossRef]

- Hou, Y.F.; Chang, Y.; Huang, T.Y. Effect of proportion of ternary cementitious materials on properties of self-leveling mortar. Bull. Chin. Ceram. Soc. 2020, 39, 1408–1414. [Google Scholar]

- Cui, S. Investigation on the Silicate-Sulphoaluminate Compound System Cement; Beijing University of Technology: Beijing, China, 2005. [Google Scholar]

- Mehairi, A.G.; Husein, M.M. Enhancement of cement properties by means of in situ grown nanoparticles. Constr. Build. Mater. 2020, 261, 120496. [Google Scholar] [CrossRef]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar] [CrossRef]

- Li, W.; Long, C.; Tam, V.W.; Poon, C.-S.; Duan, W.H. Effects of nano-particles on failure process and microstructural properties of recycled aggregate concrete. Constr. Build. Mater. 2017, 142, 42–50. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, J.-P.; Bai, Y.-L. Linkage of multi-scale performances of nano-CaCO3 modified ultra-high performance engineered cementitious composites (UHP-ECC). Constr. Build. Mater. 2020, 234, 117418. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Zhao, X.; Xu, W.; Niu, D. Effect of nano calcium carbonate on hydration characteristics and microstructure of cement-based materials: A review. J. Build. Eng. 2022, 50, 104220. [Google Scholar] [CrossRef]

- Bankir, M.B.; Ozturk, M.; Sevim, U.K.; Depci, T. Effect of n-CaCO3 on fresh, hardened properties and acid resistance of granulated blast furnace slag added mortar. J. Build. Eng. 2020, 29, 101209. [Google Scholar] [CrossRef]

- Péra, J.; Husson, S.; Guilhot, B. Influence of finely ground limestone on cement hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef]

- De Weerdt, K.; Ben Haha, M.; Le Saout, G.; Kjellsen, K.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- De Weerdt, K.; Kjellsen, K.; Sellevold, E.; Justnes, H. Synergy between fly ash and limestone powder in ternary cements. Cem. Concr. Compos. 2011, 33, 30–38. [Google Scholar] [CrossRef]

- Poudyal, L.; Adhikari, K.; Won, M. Mechanical and Durability Properties of Portland Limestone Cement (PLC) Incorporated with Nano Calcium Carbonate (CaCO3). Materials 2021, 14, 905. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Khayat, K.H.; Shi, C.; Tutikian, B.F.; Chen, Q. Mechanisms underlying the strength enhancement of UHPC modified with nano-SiO2 and nano-CaCO3. Cem. Concr. Compos. 2021, 119, 103992. [Google Scholar] [CrossRef]

- Shen, D.; Kang, J.; Shao, H.; Liu, C.; Li, M.; Chen, X. Cracking failure behavior of high strength concrete containing nano-CaCO3 at early age. Cem. Concr. Compos. 2023, 139, 104996. [Google Scholar] [CrossRef]

- Meng, T.; Yu, Y.; Wang, Z. Effect of nano-CaCO3 slurry on the mechanical properties and micro-structure of concrete with and without fly ash. Compos. Part B Eng. 2017, 117, 124–129. [Google Scholar] [CrossRef]

- GB8076-2008; Concrete Admixture. China Standards Press: Beijing, China, 2008.

- GB/T 37125-2018; Sulpho-Aluminate Cement Clinker. China Standards Press: Beijing, China, 2018.

- GB/T 35159-2017; Flash Setting Admixtures for Shotcrete. China Standards Press: Beijing, China, 2017.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China Standards Press: Beijing, China, 2021.

- Kawashima, S.; Seo, J.-W.T.; Corr, D.; Hersam, M.C.; Shah, S.P. Dispersion of CaCO3 nanoparticles by sonication and surfactant treatment for application in fly ash–cement systems. Mater. Struct. 2014, 47, 1011–1023. [Google Scholar] [CrossRef]

- Peng, Y.; Ma, K.; Long, G.; Xie, Y. Influence of nano-SiO2, nano-CaCO3 and nano-Al2O3 on rheological properties of cement–fly ash paste. Materials 2019, 12, 2598. [Google Scholar] [CrossRef]

- Damidot, D.; Rettel, A. Study of the interaction between the hydration of CA and of C3S at room temperature. In Proceedings of the 11th International Congress on the Chemistry of Cement (ICCC), Durban, South Africa, 11–16 May 2003; pp. 1845–1854. [Google Scholar]

- Nicoleau, L.; Schreiner, E.; Nonat, A. Ion-specific effects influencing the dissolution of tricalcium silicate. Cem. Concr. Res. 2014, 59, 118–138. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, J.; Liu, Z.; Sun, Z.; Stephan, D. Influence of water to cement ratio on the compatibility of polycarboxylate superplasticizer with Portland cement. Constr. Build. Mater. 2022, 341, 127846. [Google Scholar] [CrossRef]

- Su, Y.; Wu, C.; Li, J.; Li, Z.-X.; Li, W. Development of novel ultra-high performance concrete: From material to structure. Constr. Build. Mater. 2017, 135, 517–528. [Google Scholar] [CrossRef]

- Kakali, G.; Tsivilis, S.; Aggeli, E.; Bati, M. Hydration products of C3A, C3S and Portland cement in the presence of CaCO3. Cem. Concr. Res. 2000, 30, 1073–1077. [Google Scholar] [CrossRef]

- Sun, J.; Xu, K.; Shi, C.; Ma, J.; Li, W.; Shen, X. Influence of core/shell TiO2@SiO2 nanoparticles on cement hydration. Constr. Build. Mater. 2017, 156, 114–122. [Google Scholar] [CrossRef]

- Li, Y.; Bao, J.; Guo, Y. The relationship between autogenous shrinkage and pore structure of cement paste with mineral admixtures. Constr. Build. Mater. 2010, 24, 1855–1860. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Wu, Y.; Zhou, Y.; Tang, S. Hydration, shrinkage, pore structure and fractal dimension of silica fume modified low heat Portland cement-based materials. Constr. Build. Mater. 2021, 272, 121952. [Google Scholar] [CrossRef]

- Mehta, P. Studies on blended Portland cements containing Santorin earth. Cem. Concr. Res. 1981, 11, 507–518. [Google Scholar] [CrossRef]

- Bágel’, L.; Živica, V. Relationship between pore structure and permeability of hardened cement mortars: On the choice of effective pore structure parameter. Cem. Concr. Res. 1997, 27, 1225–1235. [Google Scholar] [CrossRef]

- Wolf, J.; Jansen, D.; Goetz-Neunhoeffer, F.; Neubauer, J. Relating phase transitions to pore size distributions and mechanical mortar properties in CSA-OPC-C$ based systems—The potential impact of delayed straetlingite formation. Cem. Concr. Res. 2021, 147, 106496. [Google Scholar] [CrossRef]

| Chemical Composition | OPC | CSA | Mineralogical Composition | OPC | CSA |

|---|---|---|---|---|---|

| CaO | 62.38 | 34.71 | C3S | 66.90 | - |

| SiO2 | 20.78 | 14.35 | C2S | 12.43 | 18.12 |

| Al2O3 | 4.53 | 27.14 | C3A | 7.42 | - |

| Fe2O3 | 3.22 | 3.09 | C4AF | 8.96 | - |

| MgO | 3.29 | 2.37 | Gypsum | 3.61 | 7.01 |

| Na2O | 0.32 | 0.21 | Anhydrite | 0.68 | 22.07 |

| K2O | 0.87 | 0.42 | Ye’elimite | - | 52.80 |

| SO3 | 3.97 | 15.88 | |||

| TiO2 | 0.34 | 1.02 | |||

| Other | 0.30 | 0.81 |

| Series | Sample | Cement | CSA | Water | AS | NC |

|---|---|---|---|---|---|---|

| OPC 0% AS | 0.0% NC | 100 | 0 | 40 | 0 | 0.0 |

| 1.5% NC | 100 | 0 | 40 | 0 | 1.5 | |

| 3.0% NC | 100 | 0 | 40 | 0 | 3.0 | |

| OPC 2% AS | 0.0% NC | 100 | 0 | 40 | 2 | 0.0 |

| 1.5% NC | 100 | 0 | 40 | 2 | 1.5 | |

| 3.0% NC | 100 | 0 | 40 | 2 | 3.0 | |

| OPC-CSA 0% AS | 0.0% NC | 80 | 20 | 40 | 0 | 0.0 |

| 1.5% NC | 80 | 20 | 40 | 0 | 1.5 | |

| 3.0% NC | 80 | 20 | 40 | 0 | 3.0 | |

| OPC-CSA 2% AS | 0.0% NC | 80 | 20 | 40 | 2 | 0.0 |

| 1.5% NC | 80 | 20 | 40 | 2 | 1.5 | |

| 3.0% NC | 80 | 20 | 40 | 2 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Liu, Z.; Hasan, M.M.; Zhang, L.; Ren, Q.; Lu, Z.; Sun, Z. Synergistic Improvement in Setting and Hardening Performance of OPC-CSA Binary Blended Cement: Combined Effect of Nano Calcium Carbonate and Aluminum Sulfate. Appl. Sci. 2024, 14, 2062. https://doi.org/10.3390/app14052062

Li H, Liu Z, Hasan MM, Zhang L, Ren Q, Lu Z, Sun Z. Synergistic Improvement in Setting and Hardening Performance of OPC-CSA Binary Blended Cement: Combined Effect of Nano Calcium Carbonate and Aluminum Sulfate. Applied Sciences. 2024; 14(5):2062. https://doi.org/10.3390/app14052062

Chicago/Turabian StyleLi, Huanhuan, Zhiwei Liu, Mohammad Mahadi Hasan, Liheng Zhang, Qiang Ren, Zichen Lu, and Zhenping Sun. 2024. "Synergistic Improvement in Setting and Hardening Performance of OPC-CSA Binary Blended Cement: Combined Effect of Nano Calcium Carbonate and Aluminum Sulfate" Applied Sciences 14, no. 5: 2062. https://doi.org/10.3390/app14052062