Analysis and Multi-Objective Optimization of the Rate of Penetration and Mechanical Specific Energy: A Case Study Applied to a Carbonate Hard Rock Reservoir Based on a Drill Rate Test Using Play-Back Methodology

Abstract

1. Introduction

2. Theory of Pre-Operational Testing

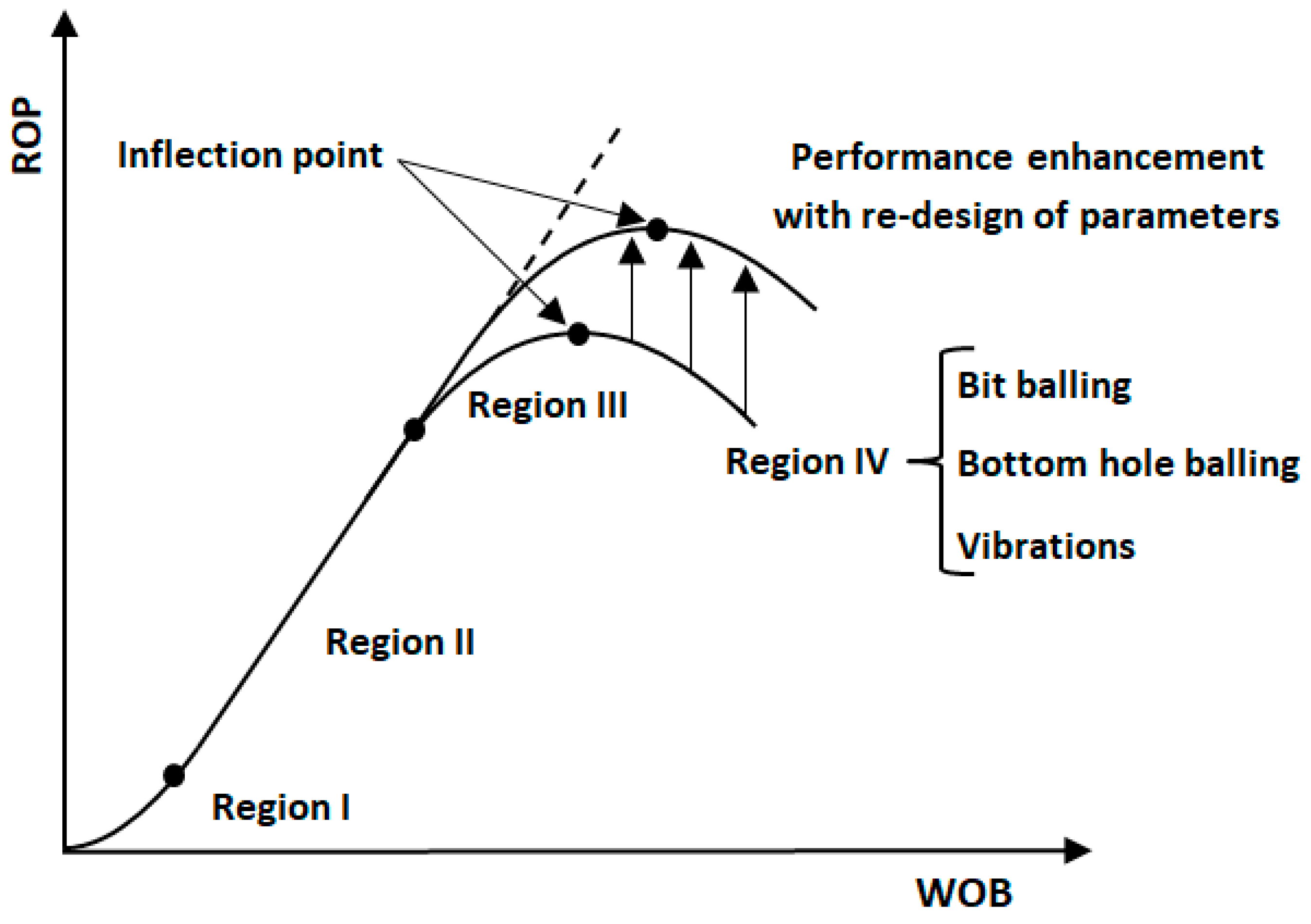

- Region I: When starting the drilling process, it is necessary to increase the WOB value, i.e., there is only drill bit penetration after a determined WOB value. This way, an increase in the ROP is the result of a disproportionate increase in the WOB;

- Region II: This is defined by a constant slope line with the highest possible efficiency, where an increase in the WOB results in a proportional increase in the ROP;

- Region III: This is defined as the region in which the ROP stops responding linearly with an increase in the WOB. In this region, the inflection point is found, i.e., the maximum ROP value for determining the combination between the WOB and RPM. Region IV starts from the inflection point;

- Region IV: This region is characterized by processes that restrict the energy transfer, cause vibrations, and reduce the process efficiency. “Bit balling” and “bottom hole balling” are terms commonly used to describe the accumulation of gravel on the drill bit and bottom hole that inhibits the transfer of a part of the WOB to the cutting structure of the drill bit [52]. Downhole vibrations can be divided into three distinct behaviors: whirl (lateral), stick–slip (torsional), and bit bounce (axial). These cause drill bit and downhole tool failures, consequently increasing the cost and time of the drilling process.

3. Materials and Methods

3.1. Data Acquisition

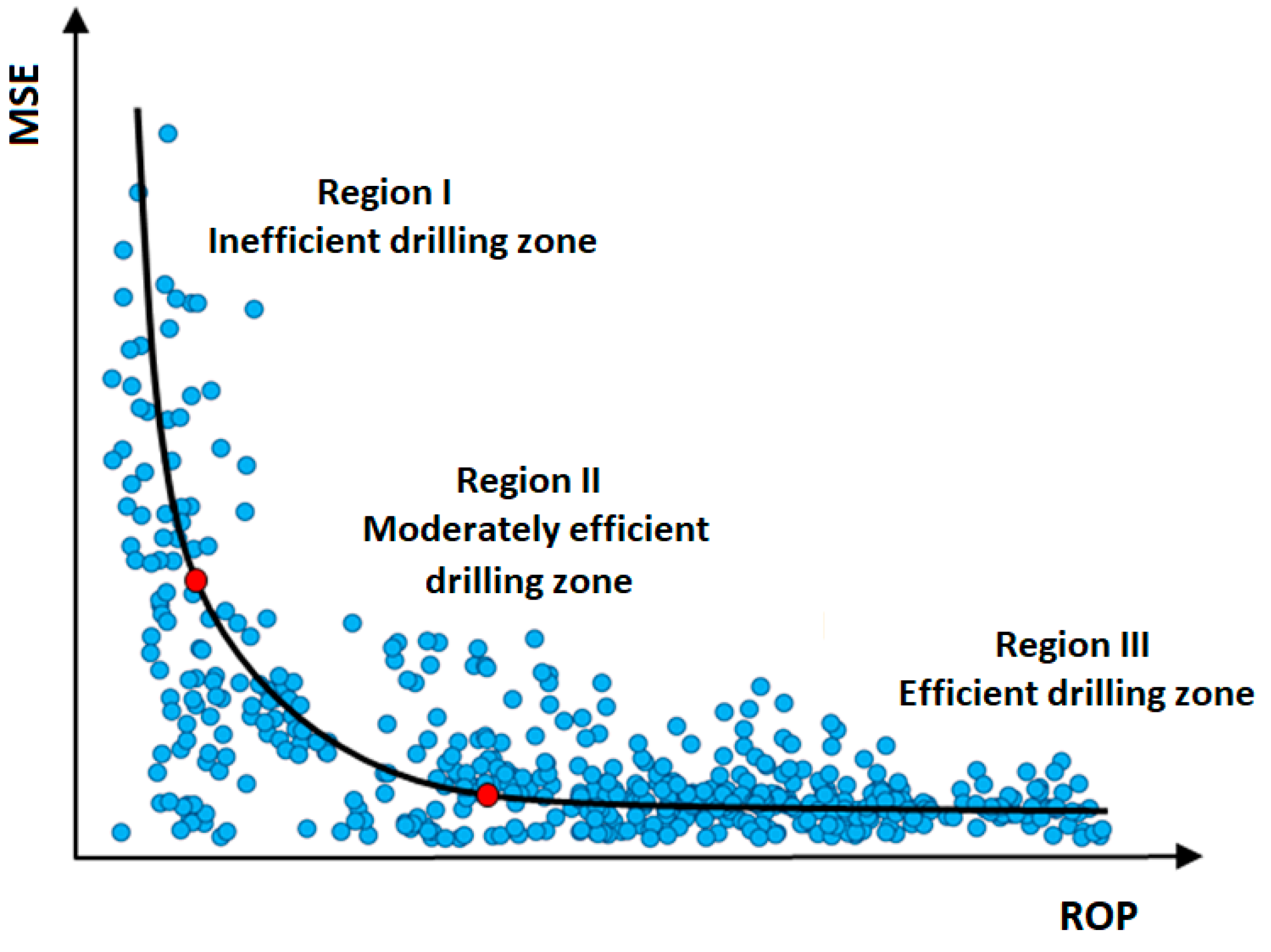

3.2. Mechanical Specific Energy

3.3. Drill Rate Test

3.4. Desirability Method

- Nominal-the-best (NTB): The value of the estimated response [(x)] is expected to achieve a particular target value (T). The NTB response is defined as per Equation (2).

- Larger-the-best (LTB): The target value (T) must reach the maximum value of the function. For this response type, the individual desirability function is defined as per Equation (3).

- Smaller-the-best (STB): The target value (T) must reach the minimum value of the function. For this response type, the individual desirability function is defined as per Equation (4).

4. Results

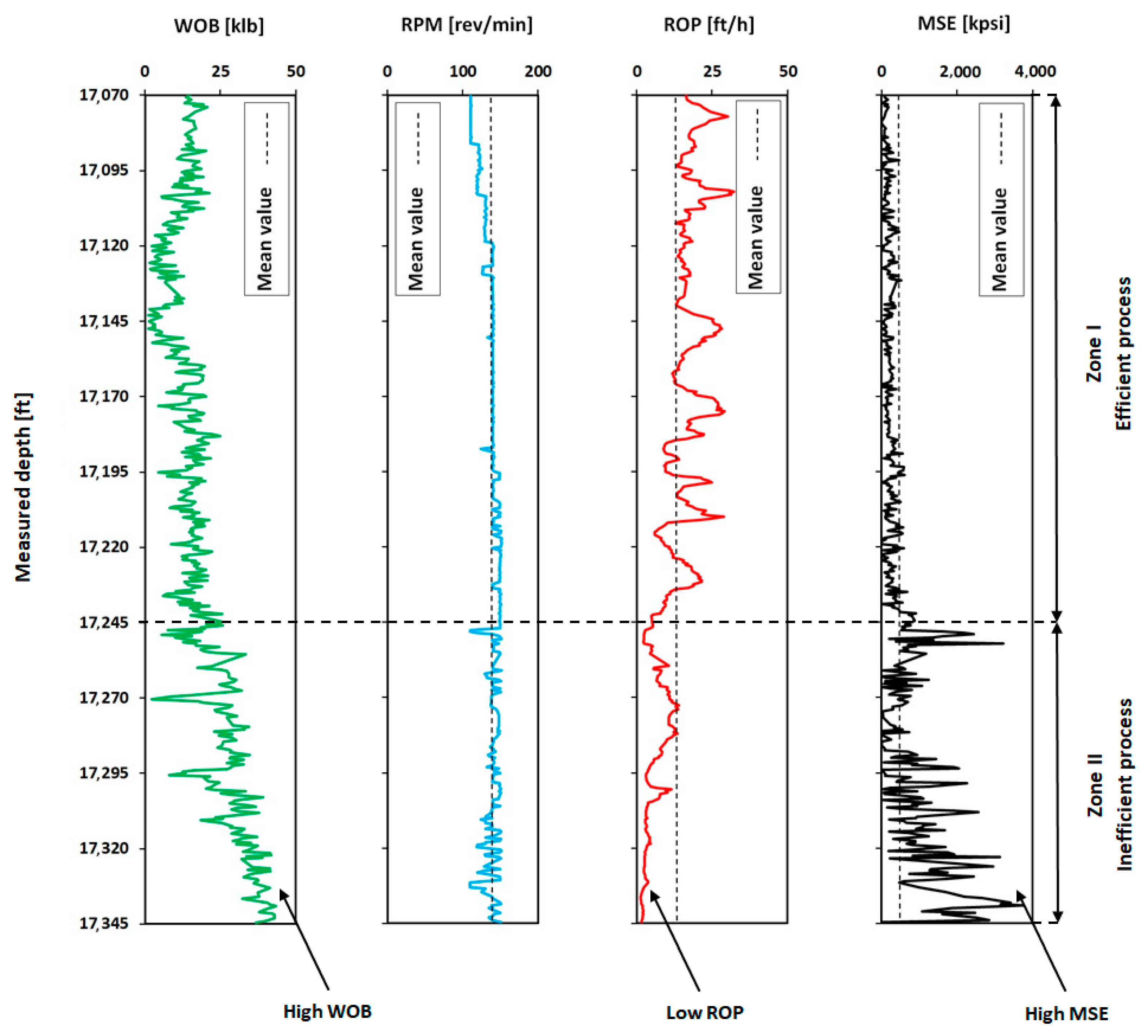

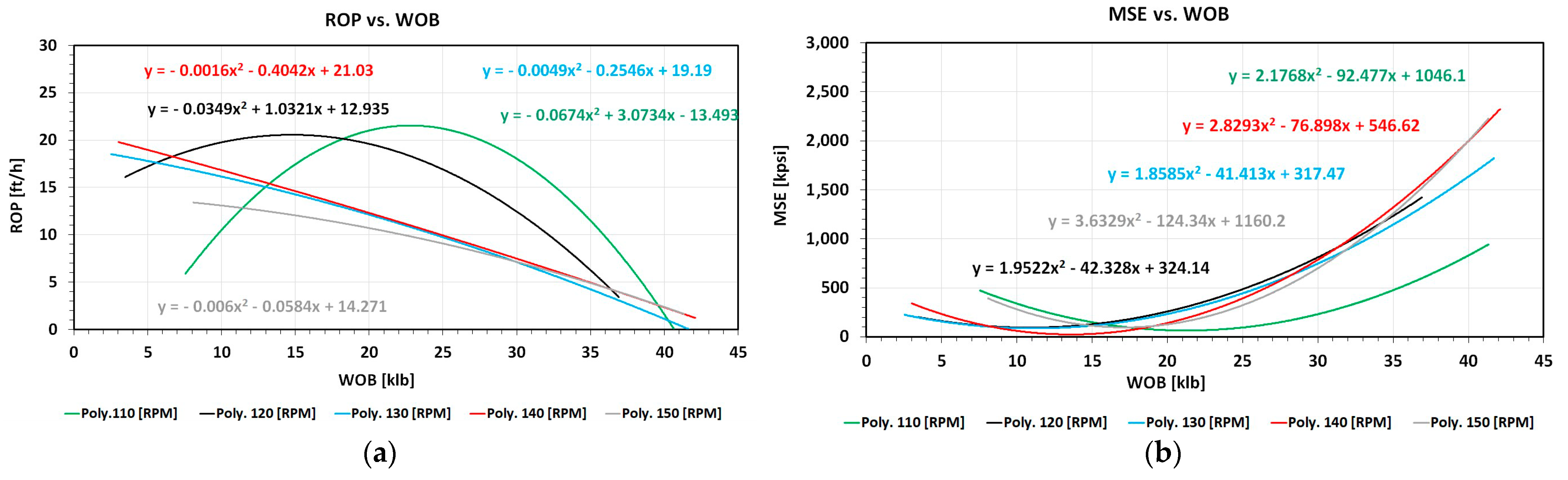

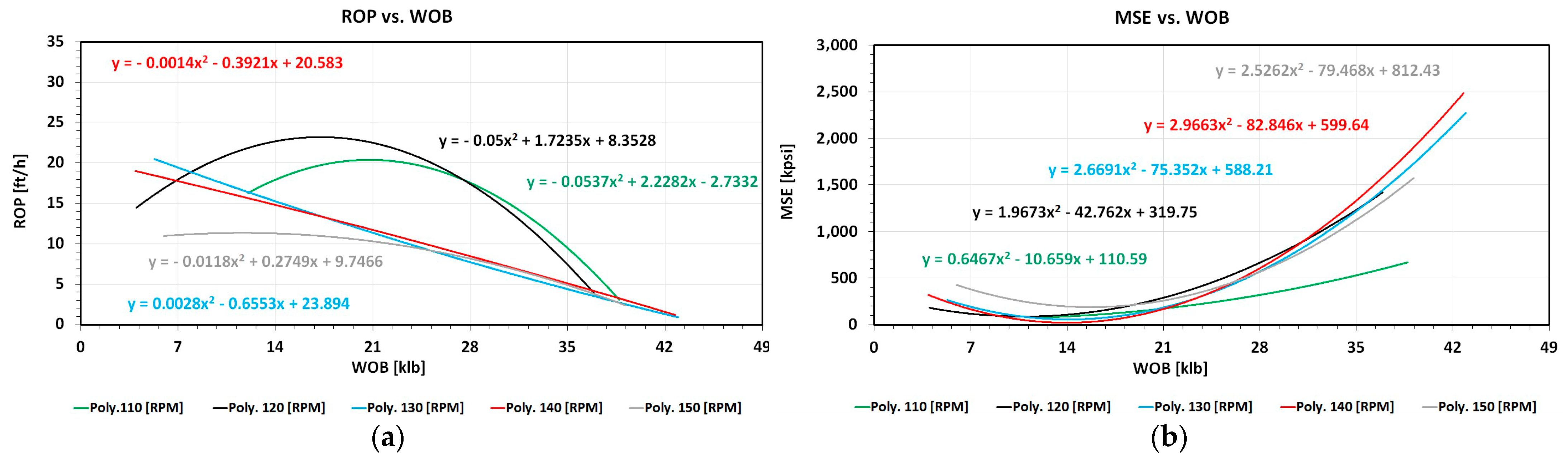

4.1. 2D Analysis

4.2. Drill Rate Test

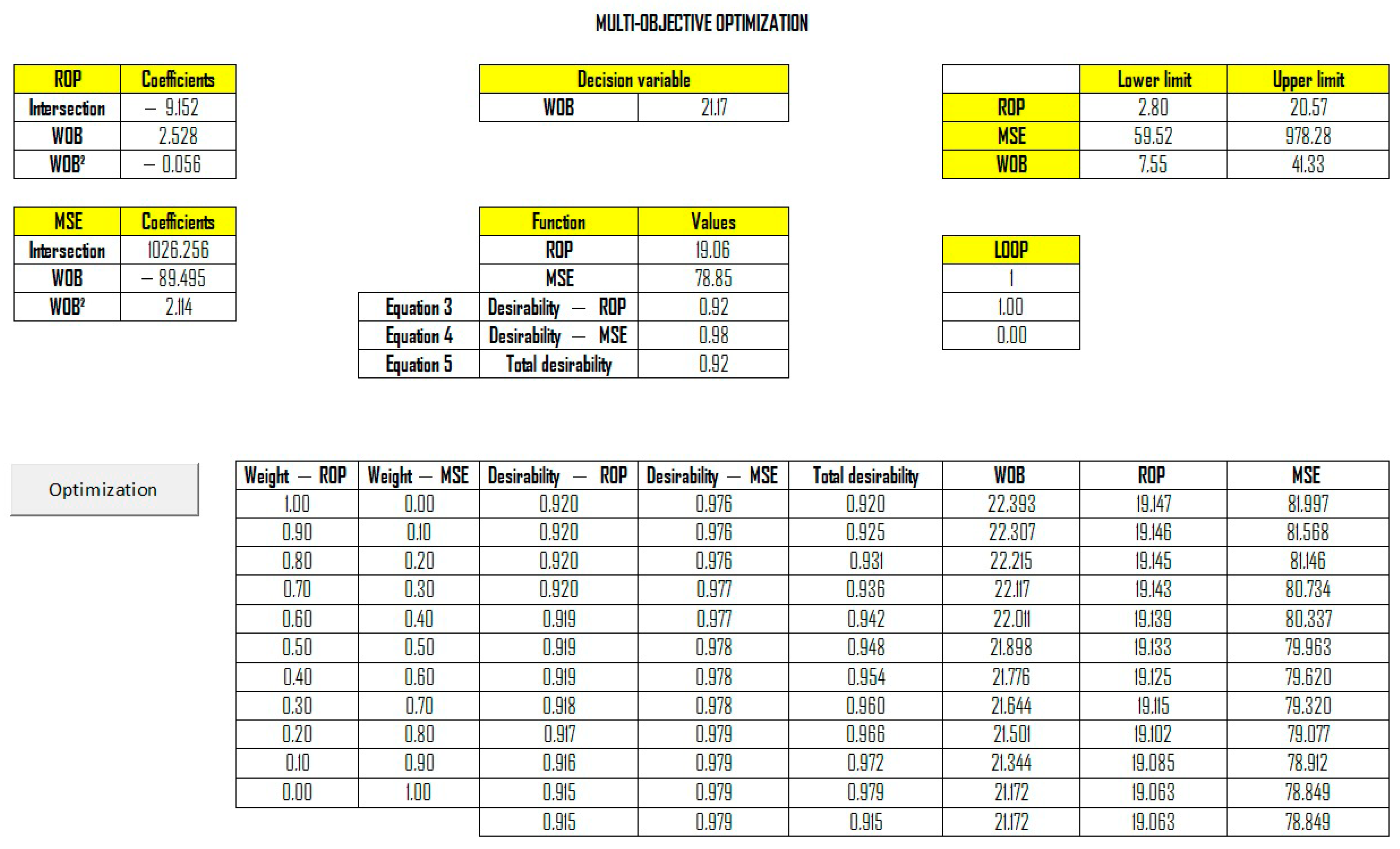

4.3. Multi-Objective Optimization

| Weight | 110 [rev/min] | 120 [rev/min] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ROP - | MSE - | Desirability (D) - | WOB [klb] | ROP [ft/h] | MSE [kpsi] | Desirability (D) - | WOB [klb] | ROP [ft/h] | MSE [kpsi] | |

| 01 | 1.00 | 0.00 | 0.92 | 22.39 | 19.14 | 81.99 | 0.65 | 16.61 | 21.14 | 158.30 |

| 02 | 0.90 | 0.10 | 0.92 | 22.30 | 19.14 | 81.56 | 0.68 | 16.24 | 21.14 | 151.17 |

| 03 | 0.80 | 0.20 | 0.93 | 22.21 | 19.14 | 81.14 | 0.71 | 15.86 | 21.12 | 144.24 |

| 04 | 0.70 | 0.30 | 0.93 | 22.11 | 19.14 | 80.73 | 0.74 | 15.46 | 21.09 | 137.57 |

| 05 | 0.60 | 0.40 | 0.94 | 22.01 | 19.13 | 80.33 | 0.77 | 15.04 | 21.04 | 131.20 |

| 06 | 0.50 | 0.50 | 0.94 | 21.89 | 19.13 | 79.96 | 0.81 | 14.58 | 20.97 | 125.24 |

| 07 | 0.40 | 0.60 | 0.95 | 21.77 | 19.12 | 79.62 | 0.84 | 14.09 | 20.88 | 119.77 |

| 08 | 0.30 | 0.70 | 0.96 | 21.64 | 19.11 | 79.32 | 0.88 | 13.56 | 20.76 | 114.96 |

| 09 | 0.20 | 0.80 | 0.96 | 21.50 | 19.10 | 79.07 | 0.92 | 12.98 | 20.60 | 111.01 |

| 10 | 0.10 | 0.90 | 0.97 | 21.34 | 19.08 | 78.91 | 0.97 | 12.34 | 20.38 | 108.24 |

| 11 | 0.00 | 1.00 | 0.97 | 21.17 | 19.06 | 78.84 | 1.02 | 11.61 | 20.10 | 107.15 |

| Weight | 110 [rev/min] | 120 [rev/min] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ROP - | MSE - | Desirability (D) - | WOB [klb] | ROP [ft/h] | MSE [kpsi] | Desirability (D) - | WOB [klb] | ROP [ft/h] | MSE [kpsi] | |

| 01 | 1.00 | 0.00 | 0.99 | 22.79 | 21.53 | 69.22 | 0.81 | 14.77 | 20.55 | 124.86 |

| 02 | 0.90 | 0.10 | 0.99 | 22.68 | 21.53 | 68.52 | 0.82 | 14.46 | 20.55 | 120.37 |

| 03 | 0.80 | 0.20 | 0.99 | 22.57 | 21.53 | 67.82 | 0.84 | 14.14 | 20.54 | 116.06 |

| 04 | 0.70 | 0.30 | 0.99 | 22.45 | 21.53 | 67.14 | 0.86 | 13.81 | 20.52 | 111.97 |

| 05 | 0.60 | 0.40 | 0.99 | 22.32 | 21.52 | 66.48 | 0.88 | 13.46 | 20.49 | 108.14 |

| 06 | 0.50 | 0.50 | 0.99 | 22.17 | 21.51 | 65.86 | 0.90 | 13.09 | 20.46 | 104.62 |

| 07 | 0.40 | 0.60 | 0.99 | 22.02 | 21.49 | 65.28 | 0.92 | 12.70 | 20.40 | 101.48 |

| 08 | 0.30 | 0.70 | 0.99 | 21.85 | 21.47 | 64.77 | 0.94 | 12.28 | 20.34 | 98.79 |

| 09 | 0.20 | 0.80 | 0.99 | 21.66 | 21.45 | 64.35 | 0.96 | 11.84 | 20.25 | 96.66 |

| 10 | 0.10 | 0.90 | 0.99 | 21.46 | 21.41 | 64.06 | 0.99 | 11.36 | 20.15 | 95.23 |

| 11 | 0.00 | 1.00 | 0.99 | 21.24 | 21.37 | 63.95 | 1.01 | 10.84 | 20.01 | 94.70 |

| Weight | 110 [rev/min] | 120 [rev/min] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ROP - | MSE - | Desirability (D) - | WOB [klb] | ROP [ft/h] | MSE [kpsi] | Desirability (D) - | WOB [klb] | ROP [ft/h] | MSE [kpsi] | |

| 01 | 1.00 | 0.00 | 1.06 | 20.75 | 20.38 | 167.90 | 0.73 | 17.23 | 23.20 | 167.19 |

| 02 | 0.90 | 0.10 | 1.04 | 20.20 | 20.37 | 159.26 | 0.75 | 16.82 | 23.19 | 157.10 |

| 03 | 0.80 | 0.20 | 1.02 | 19.61 | 20.31 | 150.26 | 0.77 | 16.37 | 23.17 | 147.11 |

| 04 | 0.70 | 0.30 | 1.00 | 18.95 | 20.21 | 140.85 | 0.80 | 15.90 | 23.11 | 137.29 |

| 05 | 0.60 | 0.40 | 0.98 | 18.21 | 20.04 | 131.02 | 0.82 | 15.39 | 23.03 | 127.70 |

| 06 | 0.50 | 0.50 | 0.97 | 17.38 | 19.77 | 120.73 | 0.85 | 14.84 | 22.92 | 118.45 |

| 07 | 0.40 | 0.60 | 0.96 | 16.42 | 19.38 | 109.97 | 0.88 | 14.23 | 22.75 | 109.70 |

| 08 | 0.30 | 0.70 | 0.96 | 15.28 | 18.78 | 98.73 | 0.92 | 13.56 | 22.53 | 101.68 |

| 09 | 0.20 | 0.80 | 0.96 | 13.86 | 17.83 | 87.08 | 0.95 | 12.80 | 22.22 | 94.77 |

| 10 | 0.10 | 0.90 | 0.98 | 12.04 | 16.31 | 76.00 | 0.99 | 11.92 | 21.79 | 89.58 |

| 11 | 0.00 | 1.00 | 1.00 | 12.04 | 16.31 | 76.00 | 1.04 | 10.86 | 21.17 | 87.37 |

4.4. Analysis of Costs

| WOB [klb] | ROP [ft/h] | RPM [rev/min] | Depth Range [ft] | Time [h] | Drilling Cost [USD] |

|---|---|---|---|---|---|

| 2.30–43.31 | 1.29–13.97 | 109.36–151.77 | 99.49 | 25.42 | 1,387,335 |

| 110 [rev/min] | 120 [rev/min] | |||||||

|---|---|---|---|---|---|---|---|---|

| Time [h] | Cost [USD] | Time Savings [h] | Cost Savings [USD] | Time [h] | Cost [USD] | Time Savings [h] | Cost Savings [USD] | |

| 01 | 5.07 | 274,454 | 20.38 | 1,103,880 | 4.59 | 248,473 | 20.86 | 1,129,862 |

| 02 | 5.07 | 274,460 | 20.38 | 1,103,874 | 4.59 | 248,537 | 20.86 | 1,129,797 |

| 03 | 5.07 | 274,480 | 20.38 | 1,103,855 | 4.59 | 248,743 | 20.85 | 1,129,591 |

| 04 | 5.07 | 274,516 | 20.38 | 1,103,819 | 4.60 | 249,116 | 20.85 | 1,129,219 |

| 05 | 5.07 | 274,572 | 20.38 | 1,103,763 | 4.61 | 249,688 | 20.84 | 1,128,647 |

| 06 | 5.07 | 274,652 | 20.38 | 1,103,682 | 4.62 | 250,501 | 20.82 | 1,127,834 |

| 07 | 5.07 | 274,762 | 20.37 | 1,103,573 | 4.65 | 251,612 | 20.80 | 1,126,722 |

| 08 | 5.08 | 274,908 | 20.37 | 1,103,426 | 4.67 | 253,102 | 20.77 | 1,125,233 |

| 09 | 5.08 | 275,099 | 20.37 | 1,103,235 | 4.71 | 255,085 | 20.74 | 1,123,250 |

| 10 | 5.08 | 275,347 | 20.36 | 1,102,988 | 4.76 | 257,737 | 20.69 | 1,120,597 |

| 11 | 5.09 | 275,664 | 20.36 | 1,102,670 | 4.82 | 261,346 | 20.62 | 1,116,989 |

| 110 [rev/min] | 120 [rev/min] | |||||||

|---|---|---|---|---|---|---|---|---|

| Time [h] | Cost [USD] | Time Savings [h] | Cost Savings [USD] | Time [h] | Cost [USD] | Time Savings [h] | Cost Savings [USD] | |

| 01 | 4.50 | 243,975 | 20.94 | 1,134,359 | 4.72 | 255,613 | 20.73 | 1,122,722 |

| 02 | 4.50 | 243,984 | 20.94 | 1,134,351 | 4.72 | 255,653 | 20.73 | 1,122,682 |

| 03 | 4.50 | 244,013 | 20.94 | 1,134,322 | 4.72 | 255,781 | 20.72 | 1,122,553 |

| 04 | 4.51 | 244,066 | 20.94 | 1,134,269 | 4.73 | 256,011 | 20.72 | 1,122,324 |

| 05 | 4.51 | 244,149 | 20.94 | 1,134,186 | 4.73 | 256,356 | 20.71 | 1,121,978 |

| 06 | 4.51 | 244,269 | 20.94 | 1,134,066 | 4.74 | 256,839 | 20.70 | 1,121,496 |

| 07 | 4.51 | 244,434 | 20.93 | 1,133,900 | 4.75 | 257,482 | 20.69 | 1,120,852 |

| 08 | 4.52 | 244,656 | 20.93 | 1,133,678 | 4.77 | 258,320 | 20.68 | 1,120,015 |

| 09 | 4.52 | 244,950 | 20.92 | 1,133,385 | 4.79 | 259,393 | 20.66 | 1,118,941 |

| 10 | 4.53 | 245,334 | 20.92 | 1,133,000 | 4.81 | 260,761 | 20.63 | 1,117,573 |

| 11 | 4.54 | 245,836 | 20.91 | 1,132,498 | 4.85 | 262,505 | 20.60 | 1,115,829 |

| 110 [rev/min] | 120 [rev/min] | |||||||

|---|---|---|---|---|---|---|---|---|

| Time [h] | Cost [USD] | Time Savings [h] | Cost Savings [USD] | Time [h] | Cost [USD] | Time Savings [h] | Cost Savings [USD] | |

| 01 | 4.76 | 257,756 | 20.69 | 1,120,578 | 4.18 | 226,437 | 21.27 | 1,151,898 |

| 02 | 4.76 | 257,958 | 20.68 | 1,120,376 | 4.18 | 226,521 | 21.26 | 1,151,813 |

| 03 | 4.77 | 258,645 | 20.67 | 1,119,690 | 4.19 | 226,797 | 21.26 | 1,151,537 |

| 04 | 4.80 | 259,977 | 20.65 | 1,118,358 | 4.20 | 227,306 | 21.25 | 1,151,028 |

| 05 | 4.84 | 262,196 | 20.61 | 1,116,138 | 4.21 | 228,104 | 21.24 | 1,150,230 |

| 06 | 4.91 | 265,692 | 20.54 | 1,112,643 | 4.23 | 229,270 | 21.21 | 1,149,065 |

| 07 | 5.01 | 271,132 | 20.44 | 1,107,202 | 4.26 | 230,915 | 21.18 | 1,147,419 |

| 08 | 5.17 | 279,802 | 20.28 | 1,098,532 | 4.31 | 233,213 | 21.14 | 1,145,122 |

| 09 | 5.44 | 294,609 | 20.01 | 1,083,725 | 4.37 | 236,438 | 21.08 | 1,141,897 |

| 10 | 5.95 | 322,154 | 19.50 | 1,056,180 | 4.45 | 241,080 | 21.00 | 1,137,255 |

| 11 | 5.95 | 322,154 | 19.50 | 1,056,180 | 4.58 | 248,122 | 20.87 | 1,130,213 |

5. Conclusions

- The new concept of pre-operational testing based on the MSE showed promise through effective improvements in the drilling processes.

- The combination of the highest ROP and the lowest MSE allows us to perform an efficient drilling operation, preventing machinery and equipment overload, and consequently showing possible ways to improve the operational efficiency.

- The desirability method, as per Derringer and Suich (1980), allowed rooms to optimize drilling process satisfactorily, which may be extended to other operations and scenarios.

- For the WOB intervals of 3, 5, and 7 [klb], a good fit of the parameters was obtained, and as an interesting outcome for the industry, it was determined that a DRT using 5 and 7 [klb] may be sufficient to be applied in a real-time field operation.

- Through the parameters obtained from pre-operational tests, specifically for the data analyzed, it was possible to obtain eventual cost-saving and time-saving values ranging from USD 1,056,180 to 1,151,898 and 19.50 to 21.27 [h], respectively.

- The results of this research can be applied to the exploration of other natural resources, such as natural hydrogen and geothermal sources.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| D | Total desirability |

| DHAP | Downhole annulus pressure |

| DHAT | Downhole annulus temperature |

| DOT | Drill rate test |

| DRT | Drill-off test |

| ECD | Equivalent circulating density |

| EGS | Enhanced geothermal system |

| FLOW | Flow rate |

| GRG | Generalized reduced gradient |

| HC | Hydrocarbons |

| L | Lower limit |

| LTB | Larger-the-best |

| MD | Measured depth |

| MSE | Mechanical specific energy |

| NTB | Nominal-the-best |

| NTP | Total non-productive time |

| O–G | Oil and gas |

| RPM | Drill string rotary speed |

| ROP | Rate of penetration |

| SPP | Standpipe pressure |

| STB | Smaller-the-best |

| T | Target value |

| TOB | Torque-on-bit |

| U | Upper limit |

| UCSS | Ultimate confined compressive strength |

| USD | United States dollar |

| WOB | Weight-on-bit |

References

- Hazbeh, O.; Aghdam, S.K.Y.; Ghorbani, H.; Mohamadian, N.; Alvar, M.A.; Moghadasi, J. Comparison of accuracy and computational performance between the machine learning algorithms for rate of penetration in directional drilling well. Pet. Res. 2021, 6, 271–282. [Google Scholar] [CrossRef]

- Mello, V.L.; Lupinacci, W.M. Mineralogy based classification of carbonate rocks using elastic parameters: A case study from Buzios Field. Pet. Sci. Eng. 2022, 209, 109962. [Google Scholar] [CrossRef]

- Godoi, J.M.A.; dos Santos Matai, P.H.L. Enhanced oil recovery with carbon dioxide geosequestration: First steps at Pre-salt in Brazil. J. Pet. Explor. Prod. 2021, 11, 1429–1441. [Google Scholar] [CrossRef]

- Castro, T.M.; Lupinacci, W.M. Comparison between conventional and NMR approaches for formation evaluation of presalt interval in the Buzios Field, Santos Basin, Brazil. J. Pet. Sci. Eng. 2022, 208, 109679. [Google Scholar] [CrossRef]

- Zambrini, J.; Lupinacci, W.M.; Gamboa, L.A.P.; Neves, I.A.; Cherene, R.; Azul, M.O. The impact of the complex evaporites features’ on the seismic illumination of the underlying rocks: A case study in the Brazilian presalt. J. Pet. Sci. Eng. 2020, 191, 107177. [Google Scholar] [CrossRef]

- Ferreira, D.J.A.; Dutra, H.P.L.; Castro, T.M.; Lupinacci, W.M. Geological process modeling and geostatistics for facies reconstruction of presalt carbonates. Mar. Pet. Geol. 2021, 124, 104828. [Google Scholar] [CrossRef]

- Peçanha, A.A.; Lupinacci, W.M.; Ferreira, D.J.A.; Freire, A.F.M. A workflow for reservoir characterization applied to presalt coquinas from the Linguado Field, Campos Basin, Brazil. J. Pet. Sci. Eng. 2019, 183, 106451. [Google Scholar] [CrossRef]

- Deng, S.; Yang, S.; Chi, Y.; Lei, Y.; Peng, H.; Zhang, Y.; Wang, L. Bit optimization method for rotary impact drilling based on specific energy model. J. Pet. Sci. Eng. 2022, 218, 110977. [Google Scholar] [CrossRef]

- Guo, Y.; Ren, G.; Yang, F.; Yang, Y.; Bokov, D.O.; Fardeeva, I.N. An analytical method to select appropriate linear and non-linear correlations on the effectiveness of penetration rate parameter towards mechanical specific energy. Energy Rep. 2021, 7, 3647–3654. [Google Scholar] [CrossRef]

- Najjarpour, M.; Jalalifar, H.; Norouzi-Apourvari, S. The effect of formation thickness on the performance of deterministic and machine learning models for rate of penetration management in inclined and horizontal wells. J. Pet. Sci. Eng. 2020, 191, 107160. [Google Scholar] [CrossRef]

- Lehmann, F.; Anders, E.; Voigt, M.; Reich, M.; Kunze, G. Electric Impulse Technology: Long Run Drilling in Hard Rocks. Oil Gas Eur. Mag. 2015, 41, 42–45. [Google Scholar] [CrossRef]

- Al-Sudani, J.A. Real-time monitoring of mechanical specific energy and bit wear using control engineering systems. J. Pet. Sci. Eng. 2017, 149, 171–182. [Google Scholar] [CrossRef]

- Najjarpour, M.; Jalalifar, H.; Norouzi-Apourvari, S. Fifty years of experience in rate of penetration management: Managed pressure drilling technology, mechanical specific energy concept, bit management approach and expert systems—A review. J. Pet. Sci. Eng. 2021, 208, 109184. [Google Scholar] [CrossRef]

- Hassan, A.; Elkatatny, S.; Al-Majed, A. Coupling rate of penetration and mechanical specific energy to Improve the efficiency of drilling gas wells. J. Nat. Gas Sci. Eng. 2020, 83, 103558. [Google Scholar] [CrossRef]

- Tunkiel, A.T.; Sui, D.; Wiktorski, T. Reference dataset for rate of penetration benchmarking. J. Pet. Sci. Eng. 2021, 196, 108069. [Google Scholar] [CrossRef]

- Kor, K.; Altun, G. Is Support Vector Regression method suitable for predicting rate of penetration? J. Pet. Sci. Eng. 2020, 194, 107542. [Google Scholar] [CrossRef]

- de Oliveira, L.S.R.; Nascimento, A.; Mantegazini, D.Z.; Nascimento, N. Drilling optimization of petroleum wells: A data analysis of the drilling fluid flow-rate influence in ROP. Lat. Am. J. Energy Res. 2021, 8, 59–66. [Google Scholar] [CrossRef]

- Namuq, M.A.; Reich, M.; Al-Zoubi, A. Numerical simulation and modeling of a laboratory MWD mud siren pressure pulse propagation in fluid filled pipe. Oil Gas-Eur. Mag. 2012, 38, 125–130. [Google Scholar]

- Höhn, P.; Odebrett, F.; Shahid, K.; Paz, C.; Oppelt, J. Framework for automated generation of real-time rate of penetration models. J. Pet. Sci. Eng. 2022, 213, 110369. [Google Scholar] [CrossRef]

- Nascimento, A.; Elmgerbi, A.; Roohi, A.; Prohaska, M.; Thonhauser, G.; Gonçalves, J.L.; Mathias, M.H. Reverse Engineering: A New Well Monitoring and Analysis Methodology Approaching Playing-Back Drill-Rate Tests in Real-Time for Drilling Optimization. J. Energy Resour. Technol. 2017, 139, 012902. [Google Scholar] [CrossRef]

- Al-AbdulJabbar, A.; Mahmoud, A.A.; Elkatatny, S.; Abughaban, M. Artificial neural networks-based correlation for evaluating the rate of penetration in a vertical carbonate formation for an entire oil field. J. Pet. Sci. Eng. 2022, 208, 109693. [Google Scholar] [CrossRef]

- Alkinani, H.H.; Al-Hameedi, A.T.T.; Dunn-Norman, S. Data-driven recurrent neural network model to predict the rate of penetration: Upstream Oil and Gas Technology. Upstream Oil Gas Technol. 2021, 7, 100047. [Google Scholar] [CrossRef]

- Suppes, R.; Ebrahimi, A.; Krampe, J. Optimising casing milling Rate Of Penetration (ROP) by applying the concept of Mechanical Specific Energy (MSE): A justification of the concept’s applicability by literature review and a pilot study. J. Pet. Sci. Eng. 2019, 180, 918–931. [Google Scholar] [CrossRef]

- Hu, H.; Guan, Z.; Zhang, B.; Xu, Y.; Liu, Y.; Wang, B. Structure design of weight-on-bit self-adjusting PDC bit based on stress field analysis and experiment evaluation. J. Pet. Sci. Eng. 2021, 196, 107692. [Google Scholar] [CrossRef]

- Alsaihati, A.; Elkatatny, S.; Gamal, H. Rate of penetration prediction while drilling vertical complex lithology using an ensemble learning model. J. Pet. Sci. Eng. 2022, 208, 109335. [Google Scholar] [CrossRef]

- Brenjkar, E.; Biniaz Delijani, E. Computational prediction of the drilling rate of penetration (ROP): A comparison of various machine learning approaches and traditional models. J. Pet. Sci. Eng. 2022, 210, 110033. [Google Scholar] [CrossRef]

- Encinas, M.A.; Tunkiel, A.T.; Sui, D. Downhole data correction for data-driven rate of penetration prediction modeling. J. Pet. Sci. Eng. 2022, 210, 109904. [Google Scholar] [CrossRef]

- Gan, C.; Cao, W.H.; Liu, K.Z.; Wu, M. A novel dynamic model for the online prediction of rate of penetration and its industrial application to a drilling process. J. Process Control 2022, 109, 83–92. [Google Scholar] [CrossRef]

- Elkatatny, S. Real-time prediction of rate of penetration while drilling complex lithologies using artificial intelligence techniques. Ain Shams Eng. J. 2021, 12, 917–926. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, X.; Zhao, H.; Wu, M.; Cao, W.; Zhang, Y.; Liu, H. A novel rate of penetration prediction model with identified condition for the complex geological drilling process. J. Process Control 2021, 100, 30–40. [Google Scholar] [CrossRef]

- Najjarpour, M.; Jalalifar, H.; Norouzi-Apourvari, S. Half a century experience in rate of penetration management: Application of machine learning methods and optimization algorithms—A review. J. Pet. Sci. Eng. 2022, 208, 109575. [Google Scholar] [CrossRef]

- Barbosa, L.F.F.M.; Nascimento, A.; Mathias, M.H.; de Carvalho, J.A. Machine learning methods applied to drilling rate of penetration prediction and optimization—A review. J. Pet. Sci. Eng. 2019, 183, 106332. [Google Scholar] [CrossRef]

- Hegde, C.; Millwater, H.; Pyrcz, M.; Daigle, H.; Gray, K. Rate of penetration (ROP) optimization in drilling with vibration control. J. Nat. Gas Sci. Eng. 2019, 67, 71–81. [Google Scholar] [CrossRef]

- Shi, X.; Liu, G.; Gong, X.; Zhang, J.; Wang, J.; Zhang, H. An Efficient Approach for Real-Time Prediction of Rate of Penetration in Offshore Drilling. Math. Probl. Eng. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, W.; Gamwo, I.; Lin, J.S. Mechanical specific energy versus depth of cut in rock cutting and drilling. Int. J. Rock Mech. Min. Sci. 2017, 100, 287–297. [Google Scholar] [CrossRef]

- Anemangely, M.; Ramezanzadeh, A.; Behboud, M.M. Geomechanical parameter estimation from mechanical specific energy using artificial intelligence. J. Pet. Sci. Eng. 2019, 175, 407–429. [Google Scholar] [CrossRef]

- Chen, X.; Gao, D.; Guo, B.; Feng, Y. Real-time optimization of drilling parameters based on mechanical specific energy for rotating drilling with positive displacement motor in the hard formation. J. Nat. Gas Sci. Eng. 2016, 35, 686–694. [Google Scholar] [CrossRef]

- Rabia, H. Specific energy as a criterion for drill performance prediction. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1982, 19, 39–42. [Google Scholar] [CrossRef]

- Liang, H.; Chen, H.; Guo, J.; Bai, J.; Jiang, Y. Research on lithology identification method based on mechanical specific energy principle and machine learning theory. Expert Syst. Appl. 2022, 189, 116142. [Google Scholar] [CrossRef]

- Li, W.; Ling, X.; Pu, H. Development of a Cutting Force Model for a Single PDC Cutter Based on the Rock Stress State. Rock Mech. Rock Eng. 2020, 53, 185–200. [Google Scholar] [CrossRef]

- Bourdon, J.C.; Cooper, G.A.; McCann, D.P.; Peltier, B.P. Comparison of field and laboratory-simulated drill-off tests. SPE Drill. Eng. 1989, 4, 329–334. [Google Scholar] [CrossRef]

- Souto, T.C.; Nascimento, A. Metodologia para Otimização da Perfuração aplicada ao Pré-Sal: Análise através da Energia Mecânica Específica. Lat. Am. J. Energy Res. 2016, 1–13. Available online: https://scirp.org/reference/referencespapers.aspx?referenceid=2485138 (accessed on 10 December 2022).

- Nascimento, A.; Mathias, M.H.; Thonhauser, G.; Gonçalves, J.L.; Elmgerbi, A. Applicability of Automation and Drilling Optimization in Pre-salt Operations. DGMK/ÖGEW-Frühjahrstagung 2019, 107–115. [Google Scholar]

- Douziech, M.; Tosti, L.; Ferrara, N.; Parisi, M.L.; Pérez-López, P.; Ravier, G. Applying harmonised geothermal life cycle assessment guidelines to the rittershoffen geothermal heat plant. Energies 2021, 14, 820. [Google Scholar] [CrossRef]

- Diaz, M.B.; Kim, K.Y. Improving rate of penetration prediction by combining data from an adjacent well in a geothermal project. Renew. Energy 2020, 155, 1394–1400. [Google Scholar] [CrossRef]

- Ramba, V.; Selvaraju, S.; Subbiah, S.; Palanisamy, M.; Srivastava, A. Optimization of drilling parameters using improved play-back methodology. J. Pet. Sci. Eng. 2021, 206, 108991. [Google Scholar] [CrossRef]

- Webb, J.; Roze, E.; Jarret, C.; Le Roux, S.; Meija, C. Drilling engineering and formation evaluation: An integrated approach to improve real time drilling optimization. In Proceedings of the Paper Presented at the SPE Western Regional Meeting; SPE, 2016. Available online: https://onepetro.org/SPEWRM/proceedings-abstract/16WRM/All-16WRM/SPE-180400-MS/188159 (accessed on 10 December 2022).

- Rehm, B.; Schubert, J.; Haghshenas, A.; Paknejad, A.S. Managed Pressure Drilling; Elsevier, 2013; Available online: https://books.google.com/books?hl=pt-PT&lr=&id=NXejAQAAQBAJ&oi=fnd&pg=PP1&ots=NtqdNsKvYs&sig=LKZzHU_P_W_Hu5kHRK0Bj0NGCsE (accessed on 27 December 2022).

- Magzoub, M.I.; Salehi, s.; Hussein, I.A.; Nasser, M.S. Loss circulation in drilling and well construction: The significance of applications of crosslinked polymers in wellbore strengthening: A review. J. Pet. Sci. Eng. 2020, 185, 106653. [Google Scholar] [CrossRef]

- Nascimento, A.; Elmgerbi, A.; Roohi, A.; Prohaska, M.; Thonhauser, G.; Mathias, M.H. Dynamic Drill-rate Test Approach Appplied to a Pre-salt Case Study. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference; SPE, 2015. [Google Scholar] [CrossRef]

- Alali, A.M.; Abughaban, M.F.; Aman, B.M.; Ravela, S. Hybrid data driven drilling and rate of penetration optimization. J. Pet. Sci. Eng. 2021, 200, 108075. [Google Scholar] [CrossRef]

- Dupriest, F.E.; Koederitz, W.L. Maximizing drill rates with real-time surveillance of mechanical specific energy. In Proceedings of the Paper presented at the SPE/IADC Drilling Conference and Exhibition; SPE, 2005. Available online: https://onepetro.org/SPEDC/proceedings-abstract/05DC/All-05DC/SPE-92194-MS/72603 (accessed on 21 September 2022).

- Chen, X.; Fan, H.; Guo, B.; Gao, D.; Wei, H.; Ye, Z. Real-Time Prediction and Optimization of Drilling Performance Based on a New Mechanical Specific Energy Model. Arab. J. Sci. Eng. 2014, 39, 8221–8231. [Google Scholar] [CrossRef]

- Qin, J.; Yin, S.; Yang, N.; Chen, X.; Tian, B.; Xue, L.; Ma, Y. A New Mechanical Specific Energy Model for Composite Impact Drilling. Appl. Sci. 2022, 12, 10356. [Google Scholar] [CrossRef]

- Gandelman, R.A. Predição da ROP e Timização em Tempo Real de Parâmetros Operacionais na Perfuração de Poços. Ph.D. Thesis, Universidade Federal do Rio de Janeiro, 2012. Available online: http://186.202.79.107/download/predicao-da-rop-e-otimizacao-em-tempo-real.pdf (accessed on 11 April 2022).

- Hegde, C.; Gray, K. Evaluation of coupled machine learning models for drilling optimization. J. Nat. Gas Sci. Eng. 2018, 56, 397–407. [Google Scholar] [CrossRef]

- Gomes, F.M.; Pereira, F.M.; Silva, A.F.; Silva, M.M. Multiple response optimization: Analysis of genetic programming for symbolic regression and assessment of desirability functions. Knowl. Based Syst. 2019, 179, 21–33. [Google Scholar] [CrossRef]

- Jeong, I.J.; Kim, K.J. An interactive desirability function method to multiresponse optimization. Eur. J. Oper. Res. 2009, 195, 412–426. [Google Scholar] [CrossRef]

- Derringer, G.; Suich, R. Simultaneous Optimization of Several Response Variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

- Kadry, A.A.; Ebid, A.M.; Abdel-salaam, A.M.; El-Ganzoury, E.N.; Haggag, S.A. Parametric study of Unstiffened multi-planar tubular KK-Joints. Results Eng. 2022, 14, 100400. [Google Scholar] [CrossRef]

- Pinheiro, Y.; Vieira, L.; Nascimento, A.; Santos, F.; Mathias, M.; Thonhauser, G.; Hunt, J. Conception of a Web Operation System for Processing Petroleum Related Drilling Data: A Focus on Pre-Salt Real-Time Automation and Optimization. J. Softw. Eng. Appl. 2019, 12, 61–71. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mantegazini, D.Z.; Nascimento, A.; Dornelas, V.F.; Mathias, M.H. Analysis and Multi-Objective Optimization of the Rate of Penetration and Mechanical Specific Energy: A Case Study Applied to a Carbonate Hard Rock Reservoir Based on a Drill Rate Test Using Play-Back Methodology. Appl. Sci. 2024, 14, 2234. https://doi.org/10.3390/app14062234

Mantegazini DZ, Nascimento A, Dornelas VF, Mathias MH. Analysis and Multi-Objective Optimization of the Rate of Penetration and Mechanical Specific Energy: A Case Study Applied to a Carbonate Hard Rock Reservoir Based on a Drill Rate Test Using Play-Back Methodology. Applied Sciences. 2024; 14(6):2234. https://doi.org/10.3390/app14062234

Chicago/Turabian StyleMantegazini, Diunay Zuliani, Andreas Nascimento, Vitória Felicio Dornelas, and Mauro Hugo Mathias. 2024. "Analysis and Multi-Objective Optimization of the Rate of Penetration and Mechanical Specific Energy: A Case Study Applied to a Carbonate Hard Rock Reservoir Based on a Drill Rate Test Using Play-Back Methodology" Applied Sciences 14, no. 6: 2234. https://doi.org/10.3390/app14062234

APA StyleMantegazini, D. Z., Nascimento, A., Dornelas, V. F., & Mathias, M. H. (2024). Analysis and Multi-Objective Optimization of the Rate of Penetration and Mechanical Specific Energy: A Case Study Applied to a Carbonate Hard Rock Reservoir Based on a Drill Rate Test Using Play-Back Methodology. Applied Sciences, 14(6), 2234. https://doi.org/10.3390/app14062234