A State-of-the-Art Review on the Study of the Diffusion Mechanism of Fissure Grouting

Abstract

:1. Introduction

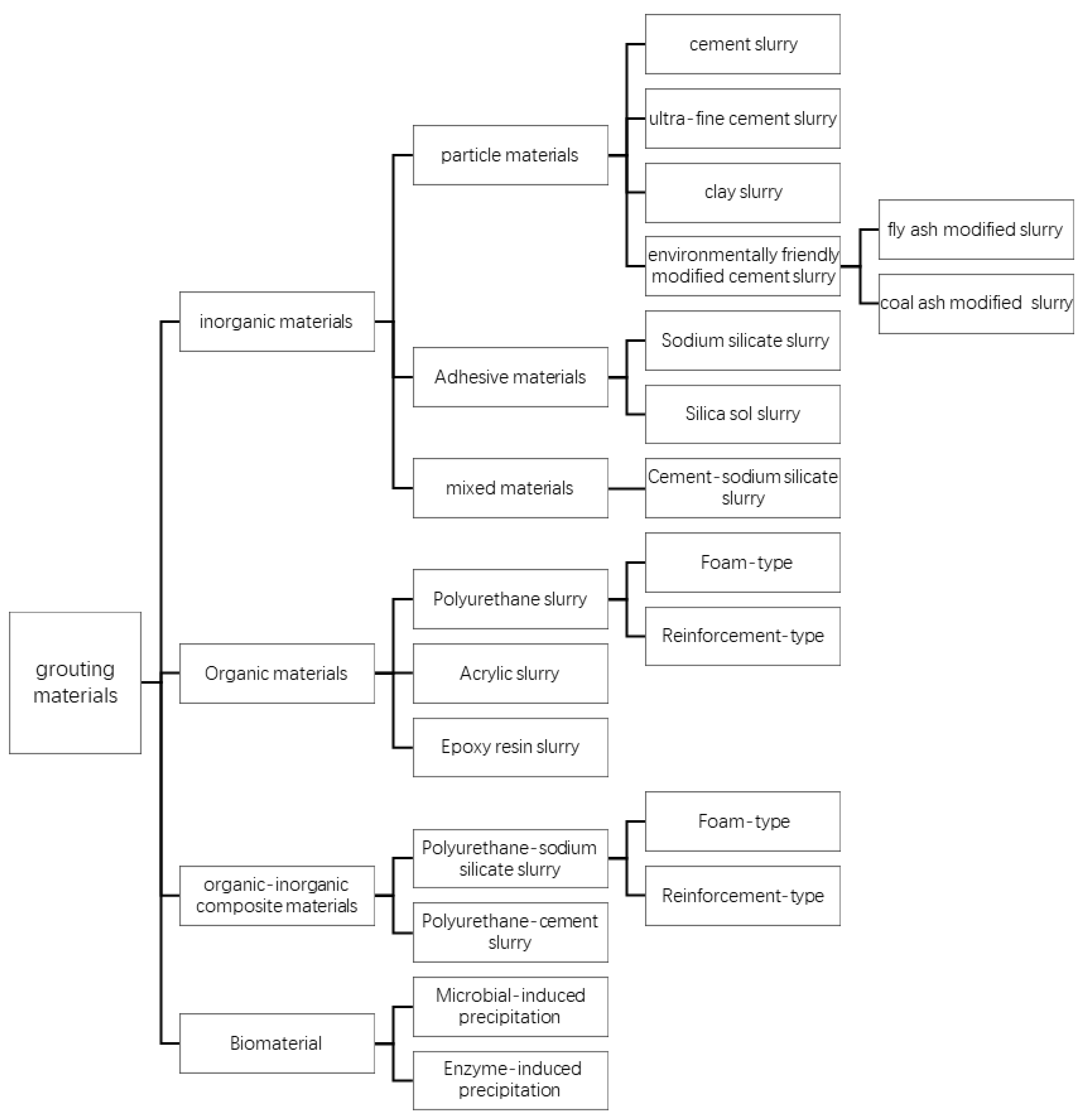

2. Current Status of Research on Grouting Materials

2.1. Inorganic Grouting Materials

2.2. Organic Grouting Materials

3. The Current Status of Research on the Theory of Seepage Diffusion of Fissure Grouting in the Rock Body

3.1. Existing Diffusion Theories

3.2. Current Status of Research on the Percolation Effect on Slurry Diffusion in Fissured Media

3.3. Current Status of Research on the Self-Expansion Effect of Slurry on the Diffusion of Slurry in Fissure Media

3.4. Difficulties in Continuing Breakthroughs in the Future

- (1)

- There are several factors that contribute to the complexity of the grouting process, and further exploration is needed. These factors include complex interactions between liquids and rocks, the morphology and distribution of fissures, the properties of grouting material, the control of grouting pressure and flow rate, heterogeneity in rock and soil layers, and environmental conditions such as temperature and humidity changes. The irregular and diverse morphology and distribution of fissures, such as horizontal, vertical, inclined, branching, and converging types, pose challenges to accurately describing the fluid flow and diffusion during grouting.

- (2)

- The existing research lacks practical guidance and often relies on ideal conditions, so it is unclear to what extent these findings are applicable to practical engineering. The theory of infiltration grouting mostly focuses on slurry diffusion in single network fissures while ignoring the diffusion of slurry in porous media or media with uneven pore sizes. Moreover, the current research primarily examines the influence of slurry fluid characteristics on diffusion, ignoring the role of pore structure characteristics in the diffusion mechanism.

- (3)

- The existing research on high-polymer grouting diffusion theory primarily examines small-pore fissures and cleavage diffusion, ignoring the diffusion mechanism in large-pore gravel media and the influence of water flow. Experimental studies mainly investigate the relationship between grouting parameters, diffusion morphology, and solidification body radius without considering the spatial and temporal evolution of a medium’s dynamic response during the diffusion process.

- (4)

- In practical engineering, studying the diffusion mechanism of slurry in a single grouting hole is insufficient. In many cases, the area of the disease is relatively large, and multiple grouting holes need to be filled. This involves the selection of grouting hole types, the spacing between adjacent grouting holes, and the determination of the grouting sequence. Selecting appropriate grouting hole types and spacing can achieve twice the result with half the effort in terms of the effectiveness and cost of disease treatment. However, there is currently no mature theoretical basis for the layout of grouting holes in engineering disease treatment. The selection of existing grouting hole layout parameters often does not consider the filtration effect caused by slurry particles or only relies on on-site experience.

4. Research Status of the Numerical Simulation of Fissure Grouting in Rock Masses

4.1. Numerical Simulation Methods

4.2. Progress in Numerical Simulation Methods for the Study of Slurry Diffusion in Fissure Media

4.3. Future Research Priorities

- (1)

- An optimization method for grouting based on numerical simulation technology should be developed while continuing to improve the accuracy and computational efficiency of simulation technology. Interdisciplinary collaboration should be strengthened by combining numerical simulation with traditional construction processes and physical experiments to optimize grouting schemes and improve engineering quality. In-depth research on grouting processes and technologies should continue to comprehensively improve construction efficiency and engineering benefits.

- (2)

- Polymers are complex diffusers with phase-transition characteristics. When establishing numerical models, the phase transition characteristics of high polymers from liquid to solid during diffusion should be considered. The internal driving force of the expansion of polymer slurry due to chemical reactions and the influence of water on the chemical reaction of the slurry should be considered to establish a more accurate numerical model of polymer diffusion. In future research on grouting in rock fissures with high polymers, the influence of various factors such as fissure dip angle, fissure networks, and fissure seepage should be comprehensively considered. Further analysis should be carried out to establish a prediction model with lower error in order to obtain results that are closer to the real grouting environment in fissured rock masses.

- (3)

- Due to the uneven distribution of fissures in rock masses, the grouting volume has high uncertainty. Therefore, accurately determining the properties, occurrence, roughness, density, and scale of grouting holes and nearby rock fissures in rock masses is the basis for predicting the diffusion distance of slurry correctly. Currently, research on strengthening the detection methods for rock fissure parameters is not sufficient. While further exploring the fissures themselves, more superior and intelligent numerical simulation methods need to be developed to better simulate real fissures.

5. Current Status of Experimental Research on Grouting Modeling of Fissured Rock Bodies

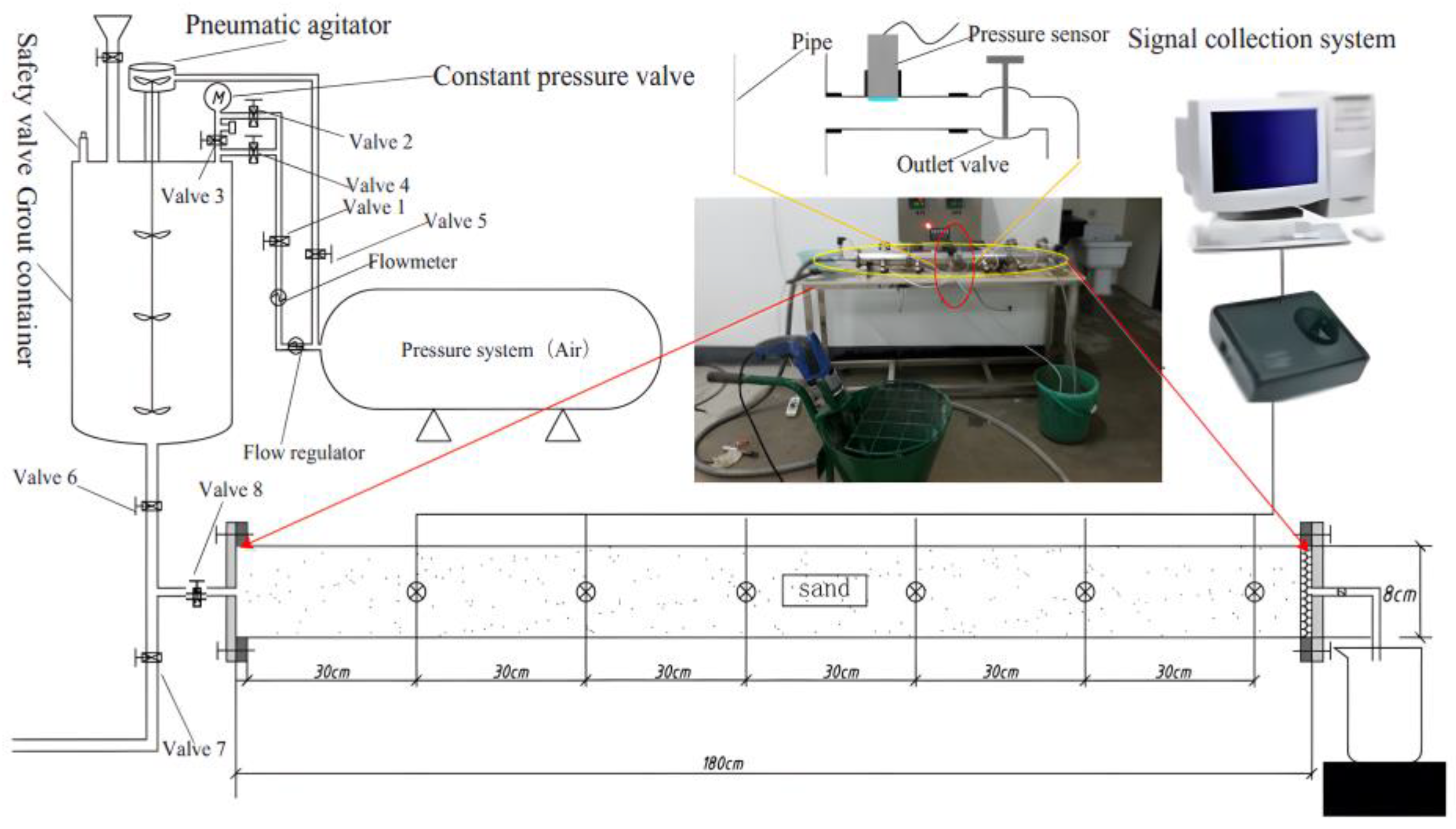

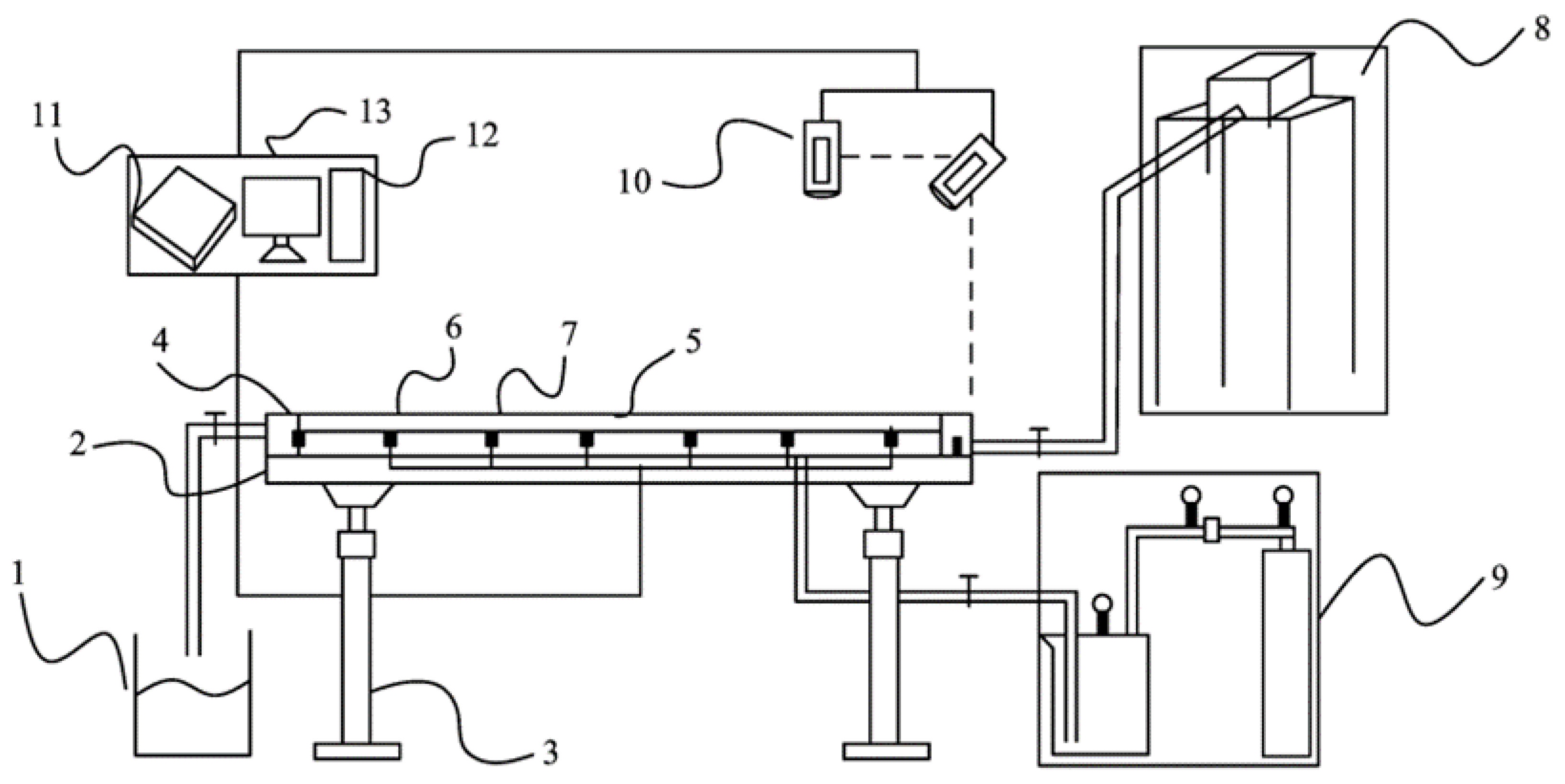

5.1. Research, Development, and Testing of Spatiotemporal Diffusion Modeling Systems for the Cement Slurry Grouting of Fissures

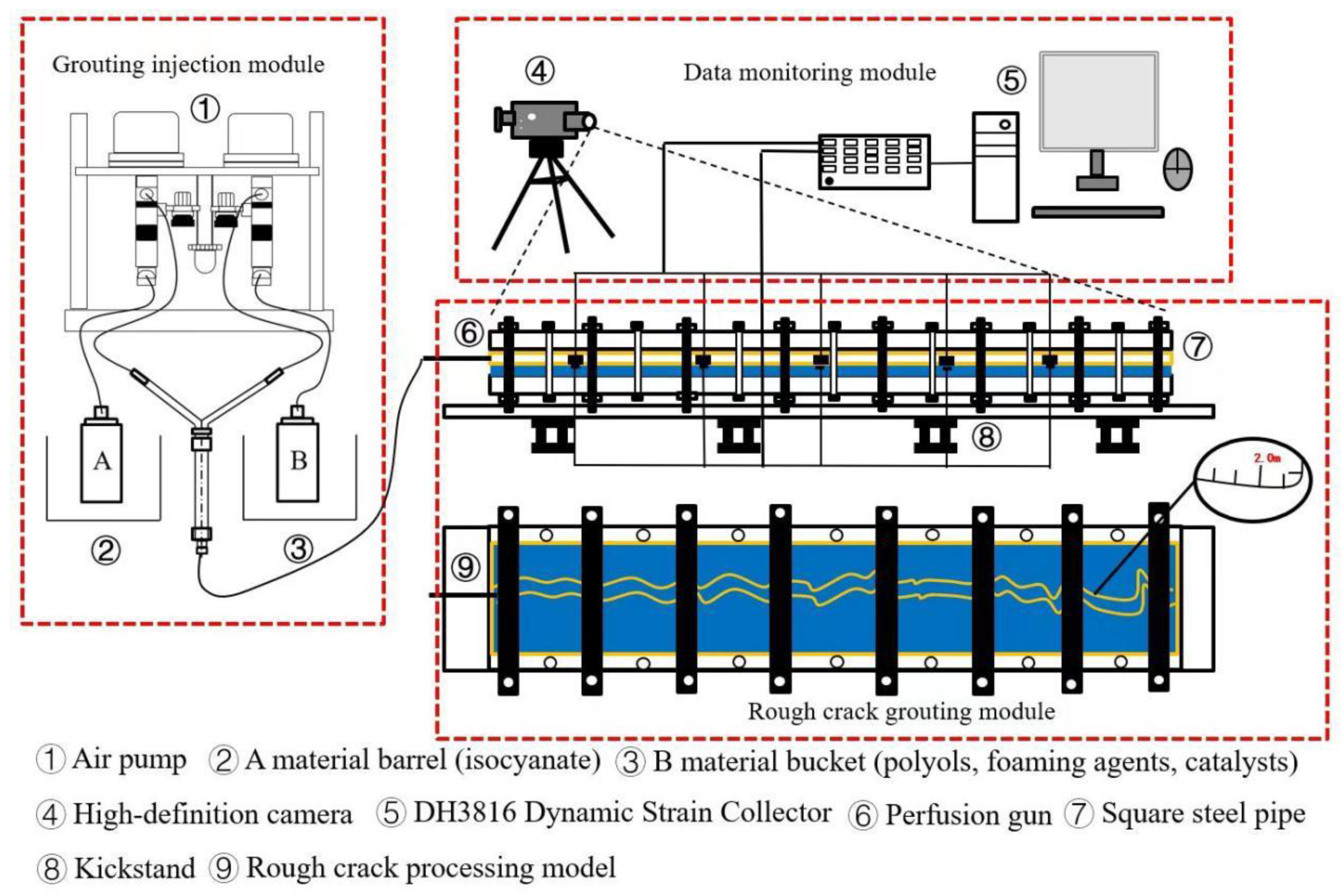

5.2. Research, Development, and Testing of Spatiotemporal Diffusion Modeling Systems for the Polymer Grouting of Fissures

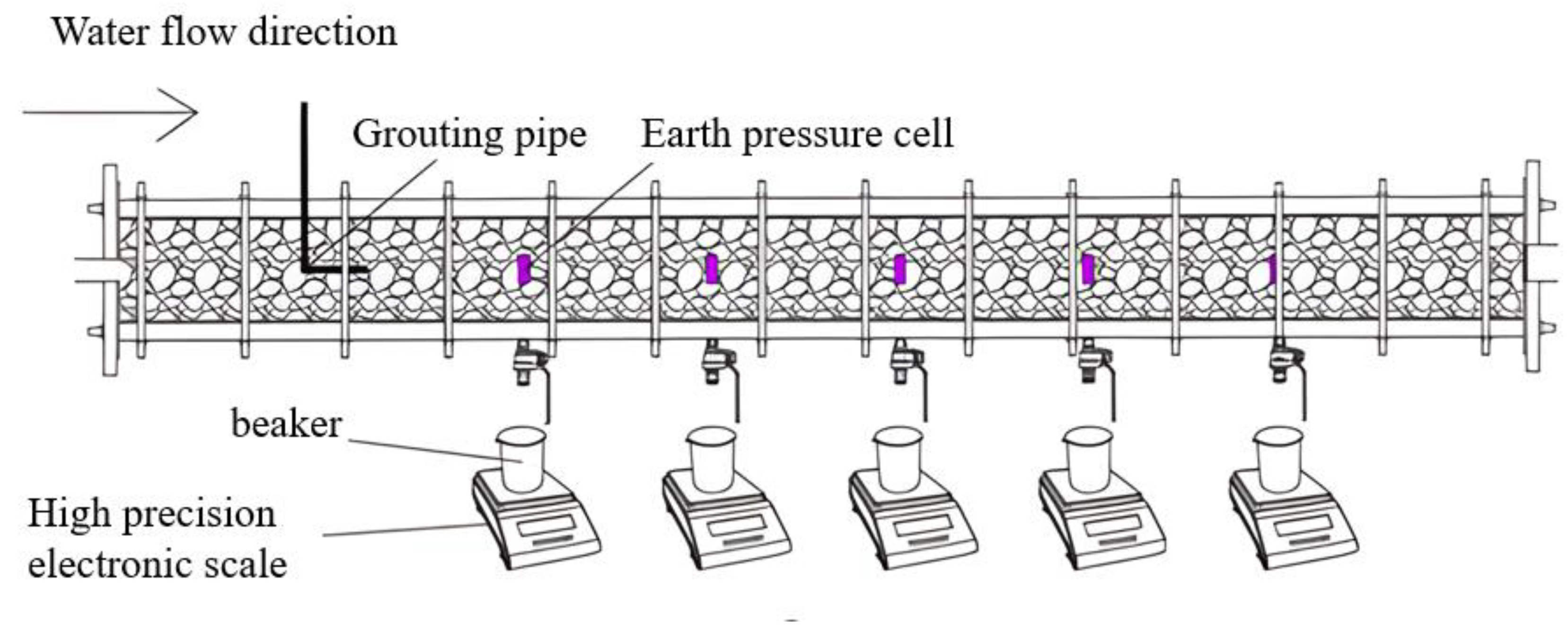

5.3. Development and Testing of the Multi-Hole Grouting Diffusion Model Test System

5.4. Future Directions for Research Development

- (1)

- For experimental research on fissured rock masses, exploring the spatiotemporal evolution of the rheological properties of grout and porosity at any testing point and time (in space and time) can help to better reveal the micro-mechanisms of the evolution of grout diffusion pressure. However, current research on high-polymer grouting experiments mostly focuses on the diffusion of fissures and small pores, while there is relatively little research on large porous gravel media. The influence of water flow on high polymer diffusion is mostly ignored. The experimental research mainly focuses on the relationship between grouting parameters, the form of diffusion, and the radius of the diffusion solidification body without considering the spatiotemporal evolution of the medium’s dynamic response during grout diffusion.

- (2)

- There are still many factors that affect the diffusion of cement slurry or high polymers in fissured media, and relatively few factors have been examined in actual experiments. Therefore, more factors need to be considered, such as introducing smarter devices, developing new experimental systems, and examining the influence of different water flow rates on grout diffusion simultaneously. The influence of high-polymer foaming agent dosage, preheating temperature, gel time, and other factors on diffusion also needs to be examined.

- (3)

- There are many materials available for grouting technology currently, and in the future, new grouting materials and composite materials can be developed specifically for fissured rock mass grouting. These new materials can be used for the development of experimental systems to further improve grouting efficiency.

6. Conclusions and Prospects

- (1)

- The current research on fissure grouting flow and diffusion theory faces several challenges and unresolved issues. Firstly, the interaction between the grout and the rock mass during the grouting process is complex and influenced by various factors such as fissure morphology and distribution, grouting materials, grouting pressure, and flow rate. This complexity makes it difficult to accurately describe fluid flow and diffusion. Secondly, existing research lacks guidance for practical engineering applications and mostly focuses on idealized conditions without considering diffusion in actual engineering porous media and the heterogeneity of pore channels.

- (2)

- The diffusion theory of polymer grouting tends to focus on fissures and small pores, neglecting the influence of large-pore gravel media and water flow on diffusion. Moreover, in engineering practice, the diffusion mechanisms and layout parameters of multiple grout holes need to be considered, but there is currently a lack of a mature theoretical basis and comprehensive methods that account for the filtration effect caused by grout particle movement. Therefore, further research is needed to address these issues and improve the accuracy and practicality of the fissure grouting flow and diffusion theory.

- (3)

- The numerical simulation study of rock fracture grouting is of great significance for engineering projects such as mines and tunnels and can provide guidance for grouting design and construction. It improves efficiency, quality, environmental protection, and safety. Future research should focus on optimizing grouting methods, considering phase transition characteristics of high polymers, comprehensively analyzing factors like fissure characteristics, and developing advanced detection and simulation methods for accurate prediction and simulation of grouting in real fissured rock masses.

- (4)

- Experimental research on grouting in fractured rock masses forms the basis for the engineering design and practical implementation of rock mass grouting projects. This research includes studying the properties of fractures and grouting characteristics, the influence of grouting parameters on grouting effectiveness, deformation, and stress characteristics of rock masses after grouting, and exploring the spatiotemporal evolution of slurry characteristics and porosity in fractures. Future research will focus on developing more efficient and accurate experimental methods, advanced grouting technologies, comprehensive and precise rock mass models, and improving the control and monitoring capabilities of grouting processes. Additionally, in-depth analysis can be conducted on the mechanisms and treatment methods for poor grouting in rock masses, distribution patterns of fractures, exploration of optimization methods for grouting parameters, and grout quality testing techniques. The development and application of new materials also hold the potential to enhance grouting efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, Z.; Wang, M.; Liu, R.; Zhang, H.; Zhang, C.; Liu, Y.; Bai, J.; Zhang, L. Study of the viscosity-temperature characteristics of cement-sodium silicate grout considering the time-varying behaviour of viscosity. Constr. Build. Mater. 2021, 306, 124818. [Google Scholar] [CrossRef]

- Jin, J.; Zhang, G.; Qin, Z.; Liu, T.; Shi, J.; Zuo, S. Viscosity enhancement of self-consolidating cement-tailings grout by biomass fly ash vs. chemical admixtures. Constr. Build. Mater. 2022, 340, 127802. [Google Scholar] [CrossRef]

- Li, P.; Wang, C.Q.; Fan, G.X.; Liu, Y.; Xiong, J.C. Study on time-varying viscosity of cement and sodium silicate grout under seawater condition. Constr. Build. Mater. 2021, 269, 121223. [Google Scholar] [CrossRef]

- Yin, W.; Li, X.; Sun, T.; Chen, Y.; Xu, F.; Yan, G.; Xu, M.; Tian, K. Utilization of waste glass powder as partial replacement of cement for the cementitious grouts with superplasticizer and viscosity modifying agent binary mixtures: Rheological and mechanical performances. Constr. Build. Mater. 2021, 286, 122953. [Google Scholar] [CrossRef]

- Lee, H.; Jung, W.T.; Chung, W. Post-tension near-surface mounted strengthening system for reinforced concrete beams with changes in concrete condition. Compos. Part B Eng. 2019, 161, 514–529. [Google Scholar] [CrossRef]

- Ryou, J.; Jung, J. Characteristics of thermo-gelation biopolymer solution injection into porous media. Constr. Build. Mater. 2023, 384, 131451. [Google Scholar] [CrossRef]

- Xue, Q.; Li, J.; Liu, L. Experimental study on anti-seepage grout made of leachate contaminated clay in landfill. Appl. Clay Sci. 2013, 80–81, 438–442. [Google Scholar] [CrossRef]

- Zhu, Z.; Xu, X.; Liu, R.; Liu, P.; Tang, H.; Gong, Y.; Zhang, C.; Li, X.; Liu, Y.; Bai, J.; et al. Feasibility study of highly alkaline biomass ash to activate alkali-activated grouts. Constr. Build. Mater. 2023, 393, 132067. [Google Scholar] [CrossRef]

- Pedrotti, M.; Wong, C.; El Mountassir, G.; Lunn, R.J. An analytical model for the control of silica grout penetration in natural groundwater systems. Tunn. Undergr. Space Technol. 2017, 70, 105–113. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, X.; Zhang, L.; Yao, J.; Yan, X. Inversion of fractures based on equivalent continuous medium model of fractured reservoirs. J. Pet. Sci. Eng. 2017, 151, 496–506. [Google Scholar] [CrossRef]

- Wei, J.; Han, C.; Zhang, W.; Xie, C.; Zhang, L.; Li, X.; Zhang, C.; Jiang, J. Mechanism of fissure grouting based on step-wise calculation method. Rock Soil Mech. 2019, 40, 913–925. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, X.; Deng, S.; Chen, W.; Shi, Z.; Xue, L.; Lv, M. Grouting Process Simulation Based on 3D Fracture Network Considering Fluid–Structure Interaction. Appl. Sci. 2019, 9, 667. [Google Scholar] [CrossRef]

- Liu, B.; Sang, H.; Kang, Y.; Liu, Q.; Luo, C.; Zhao, C. Development of grouting simulation test system for rock mass fracture network and its application. Chin. J. Rock Mech. Eng. 2020, 39, 540–549. [Google Scholar] [CrossRef]

- Li, S.; Pan, D.; Xu, Z.; Lin, P.; Zhang, Y. Numerical simulation of dynamic water grouting using quick-setting slurry in rock fracture: The Sequential Diffusion and Solidification (SDS) method. Comput. Geotech. 2020, 122, 103497. [Google Scholar] [CrossRef]

- Wang, X.; Li, L.; Mu, W.; Yang, T.; An, J.; Du, Y. Diffusion mechanism of cement-based slurry in frozen and thawed fractured rock mass in alpine region. Constr. Build. Mater. 2024, 411, 134584. [Google Scholar] [CrossRef]

- Qin, Q.; Meng, Q.; Yi, P.; Wu, K.; Wang, C. Investigation on the rheology, self-shrinkage, pore structure, and fractal dimension of coral powder-cement slurry. J. Build. Eng. 2023, 77, 107517. [Google Scholar] [CrossRef]

- Li, W.; Yi, Y.; Puppala, A.J. Comparing carbide sludge-ground granulated blastfurnace slag and ordinary Portland cement: Different findings from binder paste and stabilized clay slurry. Constr. Build. Mater. 2022, 321, 126382. [Google Scholar] [CrossRef]

- Liu, J.; Wang, M.; Liu, N.; Teng, L.; Wang, Y.; Chen, Z.; Shi, C. Development of ultra-fine SAP powder for lower-shrinkage and higher-strength cement pastes made with ultra-low water-to-binder ratio. Compos. Part B Eng. 2023, 262, 110810. [Google Scholar] [CrossRef]

- Ivanov, K.S.; Korotkov, E.A. Effect of Sodium Silicate Slurries on the Properties of Alkali-Activated Materials. Inorg. Mater. 2017, 53, 973–979. [Google Scholar] [CrossRef]

- Holmboe, M.; Wold, S.; Petterson, T. Effects of the injection grout Silica sol on bentonite. Phys. Chem. Earth Parts A/B/C 2011, 36, 1580–1589. [Google Scholar] [CrossRef]

- Zhu, M.; Sui, H.; Yang, H. The differences between soil grouting with cement slurry and cement-water glass slurry. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 108. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, G.; Yuan, Y. Basic Properties and Engineering Application of Bentonite-Cement-Water Glass Grouting. KSCE J. Civ. Eng. 2020, 24, 2742–2750. [Google Scholar] [CrossRef]

- Wei, K.; Zhao, W.; Fan, H. Optimization of silica sol grouting material based on response surface methodology. Bull. Chin. Ceram. Soc. 2022, 41, 2015–2023. [Google Scholar] [CrossRef]

- An, S.; Liu, J.; Cheng, L.; Guo, L.; Zhou, D. Rheological and mechanical properties of full-tailings backfill material prepared by ultrafine-iron-tailings-powder-based consolidation agent. Constr. Build. Mater. 2024, 417, 135286. [Google Scholar] [CrossRef]

- Wu, Y.; Qiao, W.G.; Liu, H.N.; Li, Y.Z.; Zhang, S.; Xi, K.; Zhang, L. Research on sustainable development of fine-grained material cement slurry. Constr. Build. Mater. 2021, 302, 124155. [Google Scholar] [CrossRef]

- Chen, J.J.; Ng, P.L.; Xu, L.; Kwan, A.K.H. Use of nano-silica sol in concrete: Performance and influence mechanisms. Constr. Build. Mater. 2024, 411, 134582. [Google Scholar] [CrossRef]

- Du, M.; Zhang, B.; Li, P.; Zhao, P.; Su, H.; Du, X. Study on the nanoscale mechanical properties of graphene oxide-enhanced shear resisting cement. Rev. Adv. Mater. Sci. 2022, 61, 552–562. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Zhang, B.; Hou, D.; Li, H.; Li, L.; Wang, J.; Lin, C. A preliminary investigation of the properties of potassium magnesium phosphate cement-based grouts mixed with fly ash, water glass and bentonite. Constr. Build. Mater. 2020, 237, 117501. [Google Scholar] [CrossRef]

- Zhang, J.; Pei, X.; Wang, W.; He, Z. Hydration process and rheological properties of cementitious grouting material. Constr. Build. Mater. 2017, 139, 221–231. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Y.; Cao, C.; Chai, J. Experimental Study on Flow Water Diffusion of Cement-Sodium Silicate Grouting in Rough Fracture Model. KSCE J. Civ. Eng. 2023, 27, 1955–1965. [Google Scholar] [CrossRef]

- Vasiliki, P.; Kyriakos, C. Performance of brick masonry prisms retrofitted with fiber reinforced lime-based grouts. Constr. Build. Mater. 2024, 411, 134370. [Google Scholar]

- Pan, H.; Wu, X.; Song, K.; Zhang, Y.; Zhao, Q. Preparation of calcium sulphoaluminate cement-Portland cement-gypsum based sleeve grouting material: Performance optimization and tensile properties of sleeve connector. Constr. Build. Mater. 2024, 418, 135341. [Google Scholar] [CrossRef]

- Mujah, D. Compressive strength and chloride resistance of grout containing ground palm oil fuel ash. J. Clean. Prod. 2016, 112, 712–722. [Google Scholar] [CrossRef]

- Lin, C.; Dai, W.; Li, Z.; Wang, Y. Study on the inorganic synthesis from recycled cement and solid waste gypsum system: Application in grouting materials. Constr. Build. Mater. 2020, 251, 118930. [Google Scholar] [CrossRef]

- Wang, J.; Fan, K.; Du, J.; Xu, J.; Dong, X.; Li, X.; Ding, Y. Effect of organosilicon modified epoxy resin on slurry viscosity and mechanical properties of polyurethane grouting materials. Constr. Build. Mater. 2023, 387, 131585. [Google Scholar] [CrossRef]

- Li, M.; Fang, H.; Zhang, C.; Du, M.; Wang, F. Study on the new polyurethane material suitable for foaming in water. Constr. Build. Mater. 2022, 354, 129163. [Google Scholar] [CrossRef]

- Cui, Y.; Tan, Z.; An, C. Research and application of multi-functional acrylic resin grouting material. Constr. Build. Mater. 2022, 359, 129381. [Google Scholar] [CrossRef]

- Dou, J.; Zhang, G.; Li, S.; Tian, C.; Ji, C.; Zhang, C. Properties of Degraded Waste PET-Modified Styrene-Acrylic Emulsions for Cement Slurry Materials. Adv. Civ. Eng. 2019, 2019, 4624907. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.; Yang, J.; Wang, F. A novel vertical waterproofing joint with trapezoidal steel plate connections for steel–concrete underground silos: Bending test and numerical simulation. Tunn. Undergr. Space Technol. 2023, 137, 105150. [Google Scholar] [CrossRef]

- Pan, W.; Zhang, C.; Wang, C.; Fang, H.; Wang, F.; Qin, Z.; Zhang, J.; Wang, L. Compressive fatigue resistance and related microscopic mechanisms in foamed polyurethane grouting materials for roadbed rehabilitation. Int. J. Fatigue 2023, 171, 107593. [Google Scholar] [CrossRef]

- Hao, Y.; Guo, C.; Shi, M.; Wang, F.; Xia, Y.; Wang, C. Application of polymer split grouting technology in earthen dam: Diffusion law and applicability. Constr. Build. Mater. 2023, 369, 130612. [Google Scholar] [CrossRef]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Lefebvre, L.; Keunings, R. Finite element modelling of the flow of chemically reactive polymeric liquids. Int. J. Numer. Methods Fluids 1995, 20, 319–334. [Google Scholar] [CrossRef]

- Mitani, T.; Hamada, H. Prediction of flow patterns in the polyurethane foaming process by numerical simulation considering foam expansion. Polym. Eng. Sci. 2003, 43, 1603–1612. [Google Scholar] [CrossRef]

- Zhang, H.; Yao, S.; Wang, J.; Zhou, R.; Zhu, Y.; Zou, D. Tensile properties of sulfoaluminate cement-based grouting materials toughened by in-situ polymerization of acrylamide. Constr. Build. Mater. 2023, 375, 130885. [Google Scholar] [CrossRef]

- Jia, H.; Li, X.; Lu, L.; Ma, Q.; Zhang, B.; Zhong, Y. Study on simulation method for planar fracture grouting of expansive polymer grout based on polymerization reaction mechanism. China Civ. Eng. J. 2022, 55, 50–61. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Q. Investigation on fundamental properties and chemical characterization of water-soluble epoxy resin modified cement grout. Constr. Build. Mater. 2021, 299, 123877. [Google Scholar] [CrossRef]

- Li, F.; Wang, C.; Xia, Y.; Hao, Y.; Zhao, P.; Shi, M.; Jia-wen, Z. Strength and Solidification Mechanism of Silt Solidified by Polyurethane. Adv. Civ. Eng. 2020, 2020, 8824524. [Google Scholar] [CrossRef]

- Guo, C.; Cui, C.; Wang, F. Case Study on Quick Treatment of Voids under Airport Pavement by Polymer Grouting. J. Mater. Civ. Eng. 2020, 32, 5020006. [Google Scholar] [CrossRef]

- Zhang, B.; Zhong, Y.H.; Guo, C.C.; Jin, B. Application Research of Ground Penetrating Radar Detection on the Metal Structure in Tunnel Lining. Appl. Mech. Mater. 2011, 90–93, 2163–2166. [Google Scholar]

- Zhang, Q.; Zhang, L.; Liu, R.; Li, S.; Zhang, Q. Grouting mechanism of quick setting slurry in rock fissure with consideration of viscosity variation with space. Tunn. Undergr. Space Technol. 2017, 70, 262–273. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, J.; Shao, L.; Cao, C.; Chai, J.; Qin, Y.; Cao, J. Numerical simulation investigation on the seepage characteristics of aperture dilated rough single fracture under two-way hydro-mechanical coupling effect. Gas Sci. Eng. 2023, 110, 204865. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, H.; Gao, Y. Mechanism of Grout Diffusion in Single Flat Fracture with Dynamic Water. J. Basic Sci. Eng. 2022, 30, 154–165. [Google Scholar]

- Yang, P.; Sun, X. Numerical simulation of chemical grouting in rough single cracks under dynamic water conditions. Chin. J. Undergr. Space Eng. 2017, 13, 950–954. [Google Scholar]

- Zhang, Q.; Zhang, L.; Liu, R.; Han, W.; Zhu, M.; Li, X.; Zheng, D.; Xu, X. Experimental study on diffusion of cement-sodium silicate grout in rock cracks. Rock Soil Mech. 2015, 36, 2159–2168. [Google Scholar] [CrossRef]

- Zhang, G.; Zhan, K.; Sui, W. Experimental study on the diffusion of chemical grouting in a single crack under different water flow rates. J. China Coal Soc. 2011, 36, 403–406. [Google Scholar] [CrossRef]

- Wang, Q.; Feng, Z.; Wang, L.; Tang, D.; Feng, C.; Li, S. Numerical simulation of diffusion range and grouting volume in rock cracks. J. China Coal Soc. 2016, 41, 2588–2595. [Google Scholar] [CrossRef]

- Zou, L.C.; Hakansson, U.; Cvetkovic, V. Yield-power-law fluid propagation in water-saturated fracture networks with application to rock grouting. Tunn. Undergr. Space Technol. 2020, 95, 103170. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhang, N.; Pan, D.; Xie, Z. Basic consolidation and impermeability laws for nano-silica-sol grouted mudstone. Constr. Build. Mater. 2023, 403, 133121. [Google Scholar] [CrossRef]

- Wang, K.; Wang, L.G.; Lu, Y.L.; Sun, X.K.; Zhang, K.W. Visualization study on the seepage effect of cement slurry in micro-cracks. J. China Coal Soc. 2020, 45, 990–997. [Google Scholar] [CrossRef]

- Zhou, Z.; Zang, H.; Wang, S.; Cai, X.; Du, X. Filtration-induced pressure evolution in permeation grouting. Struct. Eng. Mech. 2020, 75, 571–583. [Google Scholar] [CrossRef]

- Li, L.; Cao, Y.; Ding, C.; Zhang, Y.; Zhang, X.; Zhang, Y.; Chen, D.; Song, Z. Study on diffusion mechanism of compressible intelligent synchronous grouting materials based on permeability effect. J. Tongji Univ. (Nat. Sci. Ed.) 2023, 51, 1324–1333. [Google Scholar]

- Li, S.; Zheng, Z.; Liu, R.; Feng, X.; Sun, Z.; Zhang, L. Analysis of diffusion law of permeation grouting in porous media based on filtration effect. Chin. J. Rock Mech. Eng. 2015, 34, 2401–2409. [Google Scholar] [CrossRef]

- Li, S.; Feng, X.; Liu, R.; Zhang, L.; Han, W.; Zheng, Z. Study on diffusion law of grouting in sand media considering filtration effect. Rock Soil Mech. 2017, 38, 925–933. [Google Scholar] [CrossRef]

- Feng, X.; Li, S.; Liu, R.; Han, W.; Zhang, S. Theoretical and experimental study on the diffusion of cement slurry front considering filtration effect. Sci. Sin. Technol. 2017, 47, 1198–1206. [Google Scholar] [CrossRef]

- Fang, K.; Xia, T.; Bao, L.; Ye, J.; Chen, S. Study on diffusion of slurry in gravel layer considering filtration effect. Chin. J. Rock Mech. Eng. 2013, 32, 1443–1448. [Google Scholar]

- Qin, P. Numerical simulation of particle flow in grouted sand. J. Civ. Eng. Manag. 2017, 34, 30–38. [Google Scholar] [CrossRef]

- Li, X.; Wang, F.; Zhong, Y.; Guo, C.; Zhang, P. Simulation method for flow and diffusion of self-expanding polymer grouting material in two-dimensional fractures. Chin. J. Rock Mech. Eng. 2015, 34, 1188–1197. [Google Scholar] [CrossRef]

- Li, X.; Hao, M.; Zhong, Y.; Zhang, B.; Wang, F.; Wang, L. Experimental study on the diffusion characteristics of polyurethane grout in a fracture. Constr. Build. Mater. 2021, 273, 121711. [Google Scholar] [CrossRef]

- Liang, J.; Ma, S.; Du, X. Diffusion Model of Parallel Plate Crack Grouting Based on Foaming Expansion Characteristics of Polymer Slurry. Mathematics 2021, 9, 2907. [Google Scholar] [CrossRef]

- Xue, J.; Wang, H.; Zhao, C.; Yang, J.; Zhou, Z.; Li, D. Prediction of water-bearing fracture zone height and roof water filling mode in Jurassic coalfields of Ordos Basin. J. Min. Saf. Eng. 2020, 37, 1222–1230. [Google Scholar] [CrossRef]

- Ni, X.; Xu, C.; Li, W. Numerical simulation of grouting in micro-cracked rock mass considering fluid-solid coupling effect in subway tunnel. Tunn. Constr. 2018, 38, 1667–1673, (In Chinese and English). [Google Scholar]

- Liu, Q.; Suo, L. COMSOL Multiphysics simulation of crack flow transport in porous media of underground rock mass. Syst. Simul. Technol. 2019, 15, 184–187+197. [Google Scholar] [CrossRef]

- Shen, L.; Wang, Z.; Zeng, Y.; Li, Z.; Li, S. Lattice Boltzmann coupled percolation and dissolution model based on surface reaction of rough rock mass fracture. Chin. J. Rock Mech. Eng. 2019, 38, 1615–1626. [Google Scholar]

- Li, Z.; Liu, J.; Xu, R.; Liu, H.; Shi, W. Study of grouting effectiveness based on shear strength evaluation with experimental and numerical approaches. Acta Geotech. 2021, 16, 3991–4005. [Google Scholar] [CrossRef]

- Li, S.; Zhang, X.; Zhang, Q.; Sun, K. Research on diffusion mechanism and plugging method of grouting slurry for water inrush control in underground engineering. Chin. J. Rock Mech. Eng. 2011, 30, 2377–2396. [Google Scholar]

- Zhou, Z.; Du, X.; Wang, S.; Cai, X.; Chen, L. Micromechanism of the diffusion of cement-based grouts in porous media under two hydraulic operating conditions: Constant flow rate and constant pressure. Acta Geotech. 2019, 14, 825–841. [Google Scholar] [CrossRef]

- Yuan, J. A Visual Cross-Crack Dynamic Water Grouting Test Device; Wuhan Institute of Rock and Soil Mechanics, Chinese Academy of Sciences: Wuhan, China, 2016. [Google Scholar]

- Yu, W.; Li, P.; Zhang, X.; Wang, Q. Single variable Angle fracture model experimental study on dynamic water grouting. Rock Soil Mech. 2014, 35, 2137–2143+2149. [Google Scholar] [CrossRef]

- Yang, M.; Chen, M.; He, Y. Experimental study on grouting in fractured rock mass. Exp. Mech. 2001, 16, 105–112. [Google Scholar]

- Liang, J.; Du, X.; Fang, H.; Du, M.; Shi, M.; Gao, X.; Han, Y. Numerical and experimental study of diffusion law of foamed polymer grout in fracture considering viscosity variation of slurry. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2022, 128, 104674. [Google Scholar] [CrossRef]

- Du, X.; Liu, C.; Wang, C.; Fang, H.; Xue, B.; Gao, X.; Han, Y. Diffusion characteristics and reinforcement effect of cement slurry on porous medium under dynamic water condition considering infiltration. Tunn. Undergr. Space Technol. 2022, 130, 104766. [Google Scholar] [CrossRef]

- Zou, L.; Håkansson, U.; Cvetkovic, V. Two-phase cement grout propagation in homogeneous water-saturated rock fractures. Int. J. Rock Mech. Min. Sci. 2018, 106, 243–249. [Google Scholar] [CrossRef]

- Soga, K.; Au, S.K.A.; Jafari, M.R.; Bolton, M.D. Laboratory investigation of multiple grout injections into clay. Géotechnique 2004, 54, 81–90. [Google Scholar] [CrossRef]

- Peng, W.; Dong, Z.; Guo, C. Theoretical study on multiple holes grouting with natural boundary element method. Procedia Earth Planet. Sci. 2009, 1, 465–470. [Google Scholar] [CrossRef]

- Ren, B.; Mu, W.; Jiang, B.; Yu, G.; Li, L.; Wei, T.; Han, Y.; Xiao, D. Grouting Mechanism in Water-Bearing Fractured Rock Based on Two-Phase Flow. Geofluids 2021, 2021, 5585288. [Google Scholar] [CrossRef]

- Zhou, Z.; Du, X.; Wang, S.; Zang, H. Analysis and engineering application investigation of multiple-hole grouting injections into porous media considering filtration effects. Constr. Build. Mater. 2018, 186, 871–883. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Li, Z.; Fang, H.; Li, B.; Zhao, X.; Zhai, K.; Xue, B.; Wang, S. A State-of-the-Art Review on the Study of the Diffusion Mechanism of Fissure Grouting. Appl. Sci. 2024, 14, 2540. https://doi.org/10.3390/app14062540

Du X, Li Z, Fang H, Li B, Zhao X, Zhai K, Xue B, Wang S. A State-of-the-Art Review on the Study of the Diffusion Mechanism of Fissure Grouting. Applied Sciences. 2024; 14(6):2540. https://doi.org/10.3390/app14062540

Chicago/Turabian StyleDu, Xueming, Zhihui Li, Hongyuan Fang, Bin Li, Xiaohua Zhao, Kejie Zhai, Binghan Xue, and Shanyong Wang. 2024. "A State-of-the-Art Review on the Study of the Diffusion Mechanism of Fissure Grouting" Applied Sciences 14, no. 6: 2540. https://doi.org/10.3390/app14062540