Experimental and Numerical Analysis of the Solar Collector with Stainless Steel Scourers Added to the Absorber Surface

Abstract

1. Introduction

2. Materials and Methods

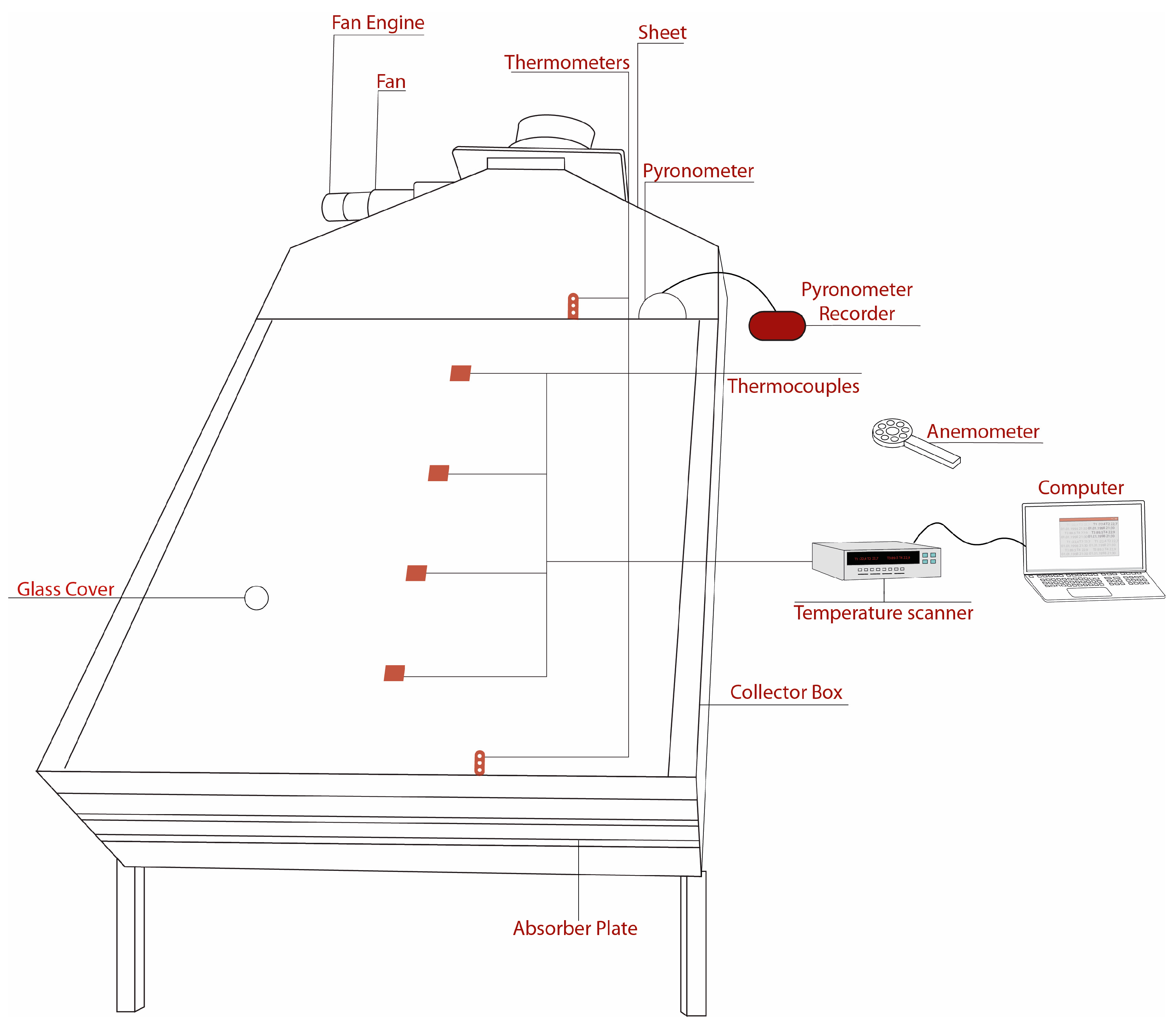

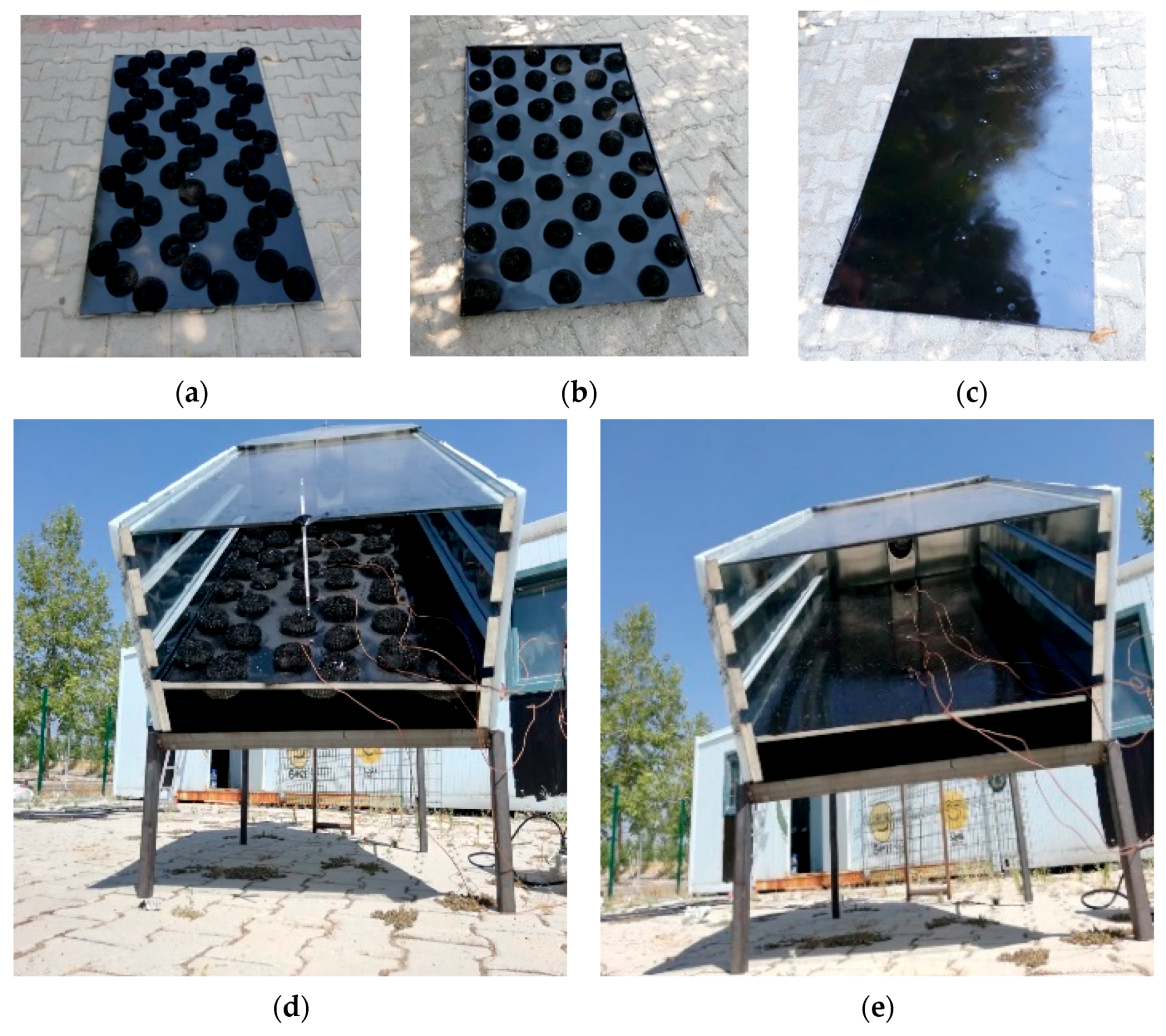

2.1. Experimental Study

2.2. Data Reduction

2.3. Uncertainty Analysis

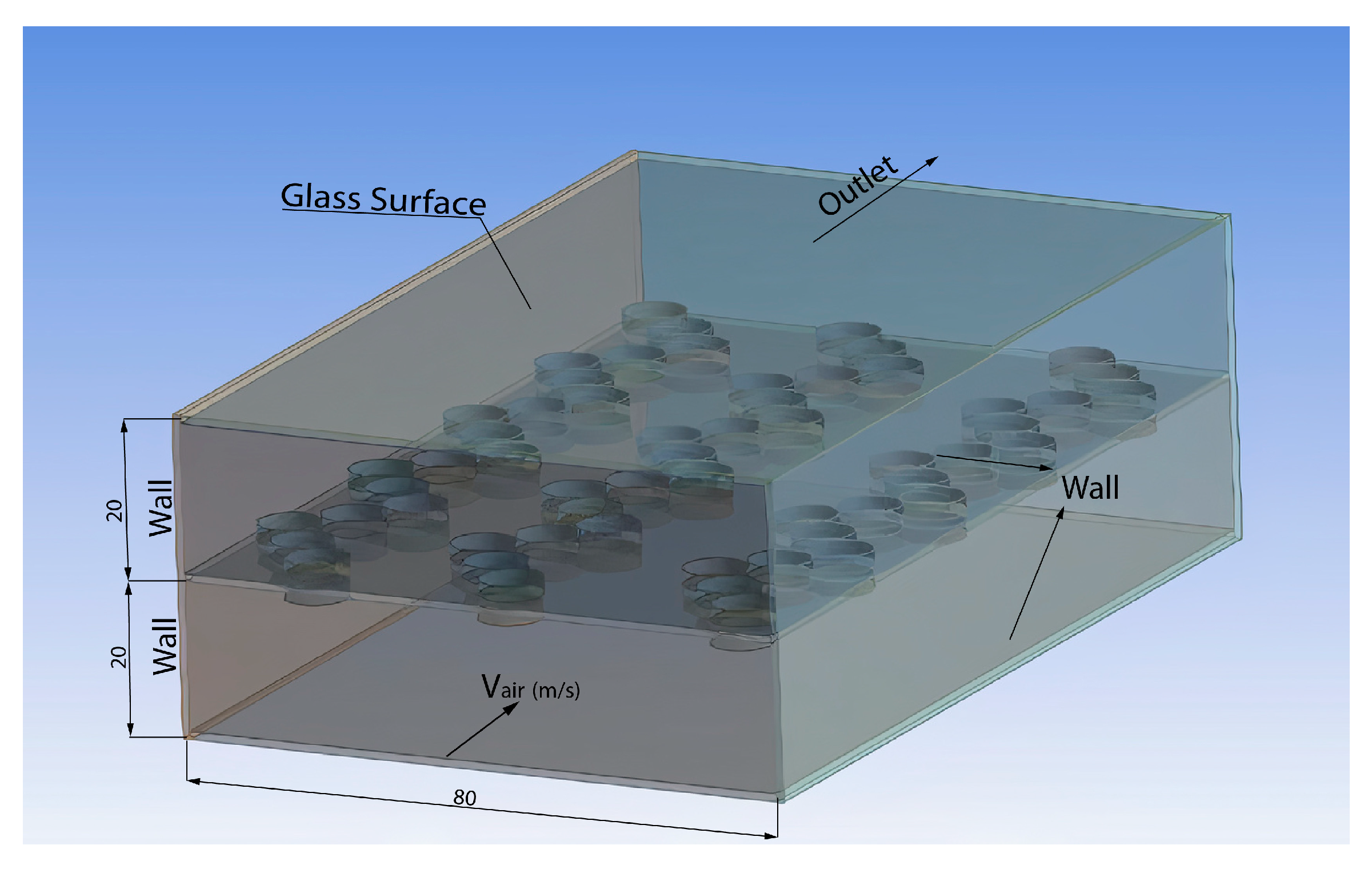

3. Numerical Analysis

3.1. Physical Problem

3.2. Governing Equations

3.3. Boundary Conditions

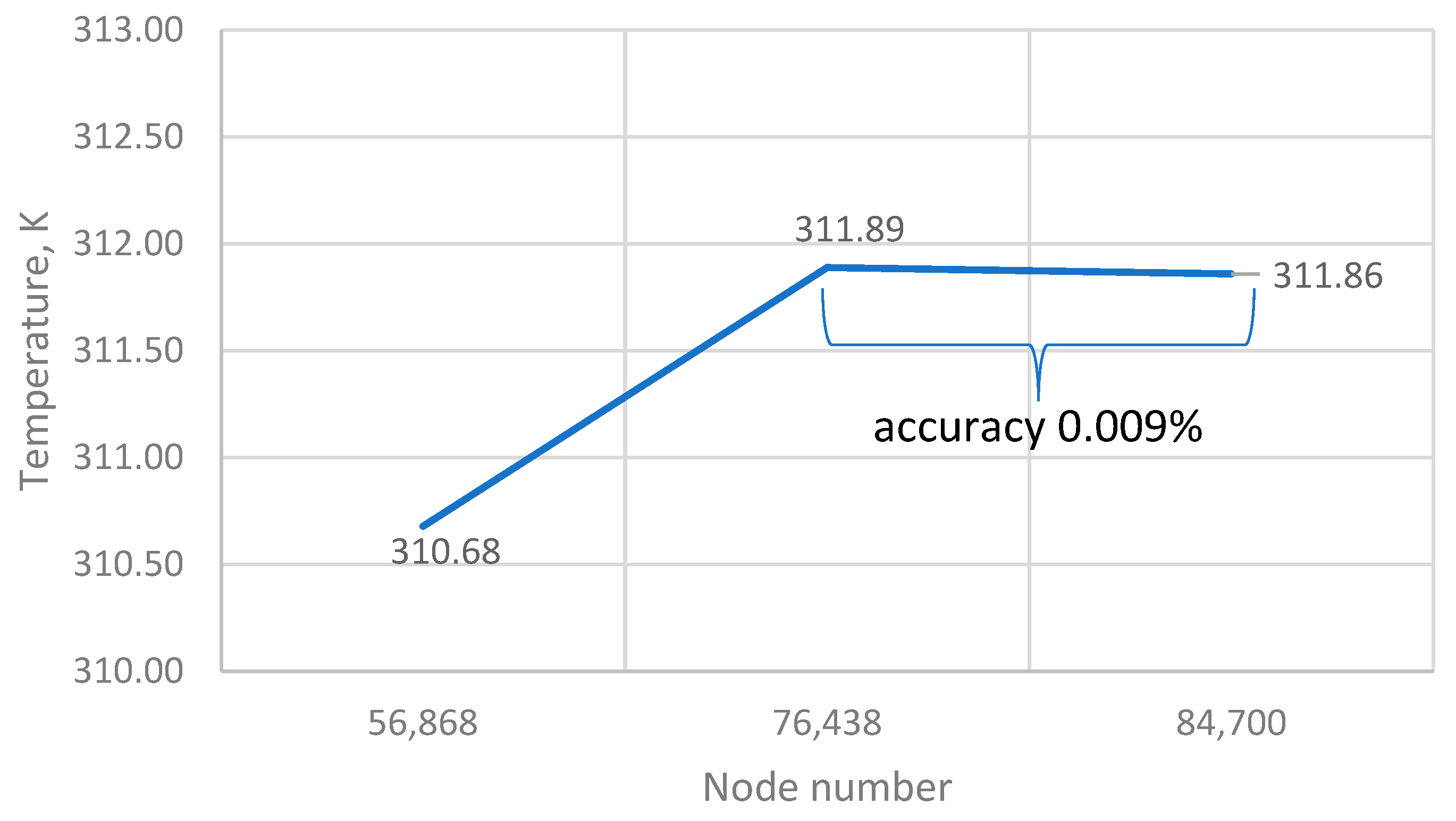

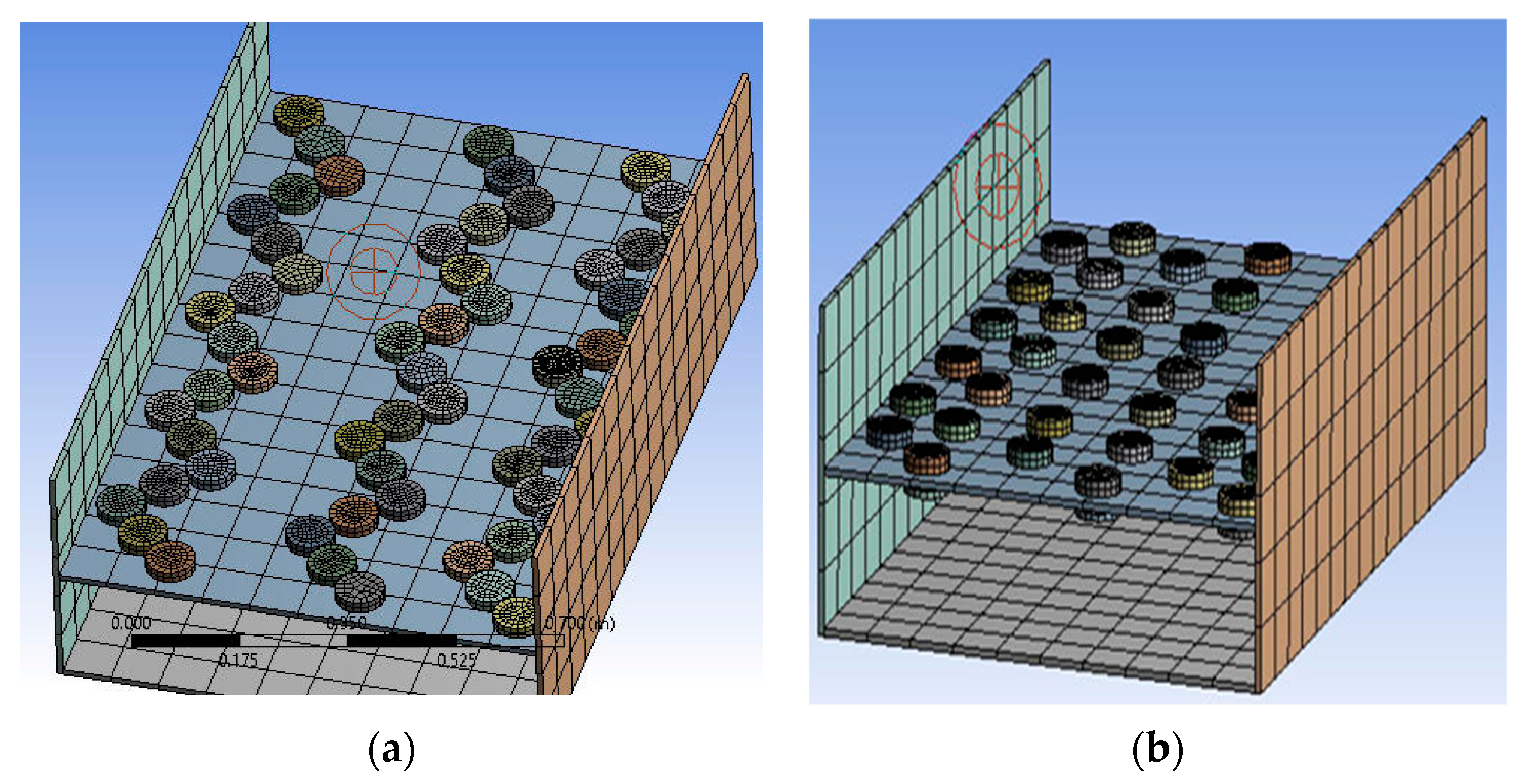

3.4. Mesh Structure

4. Results and Discussions

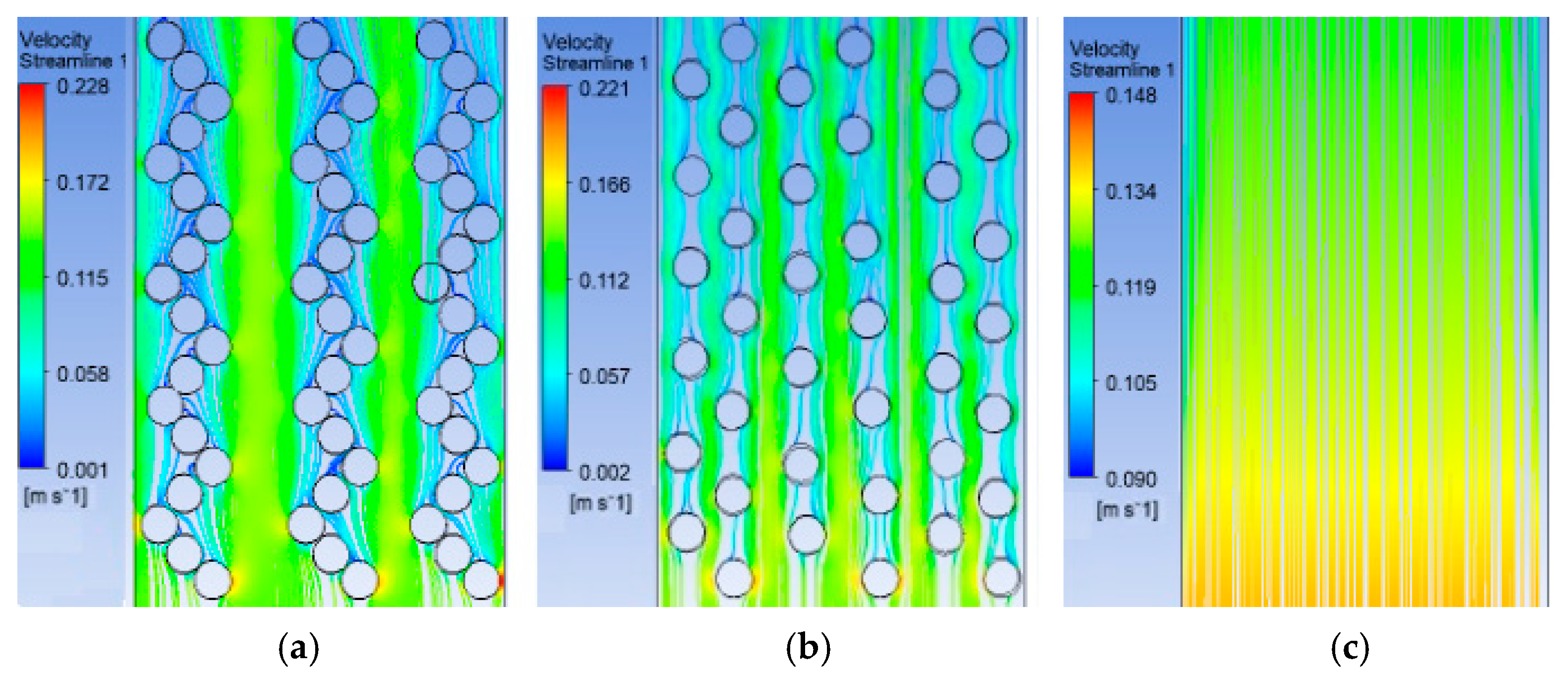

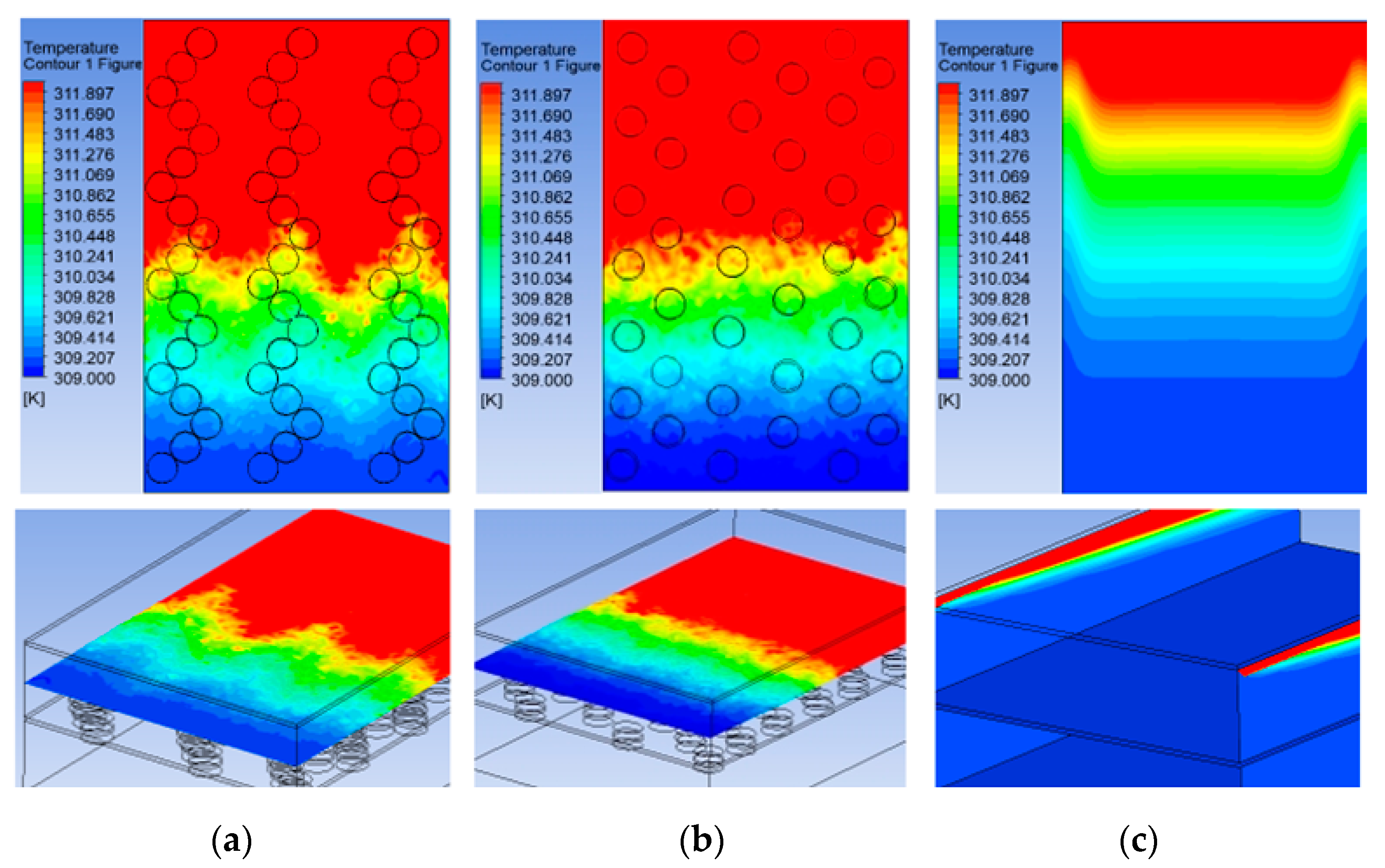

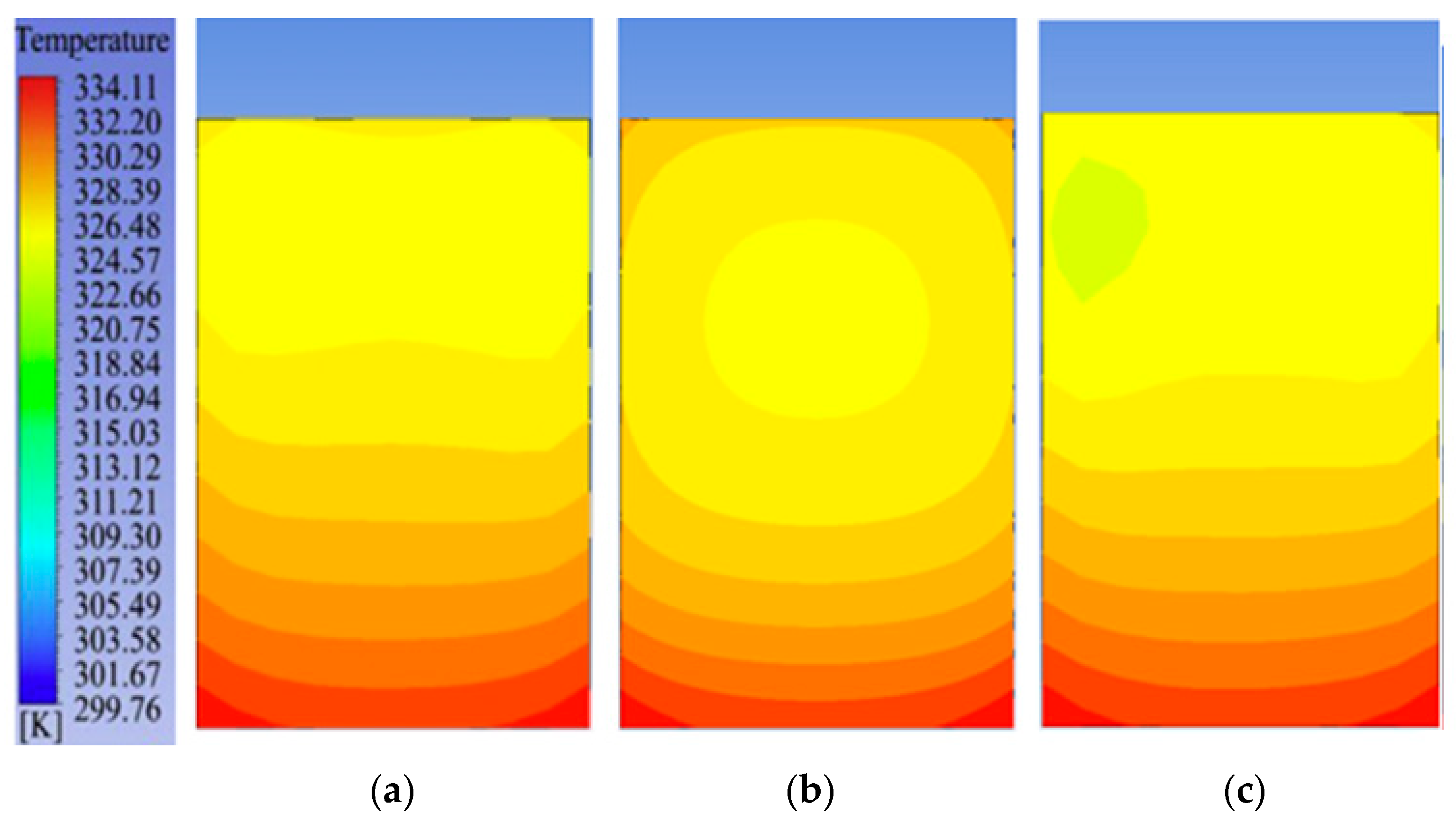

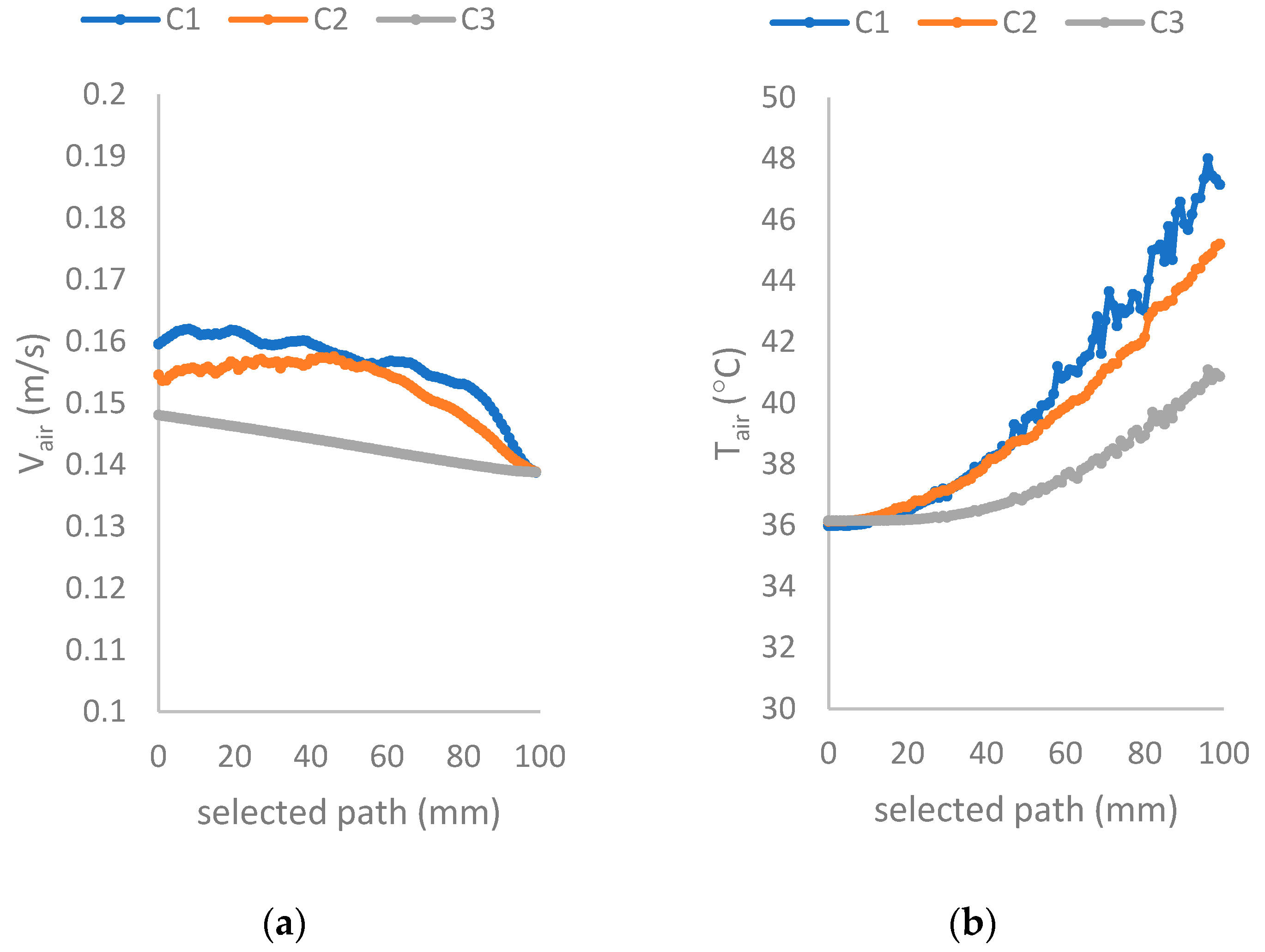

4.1. Numerical Results

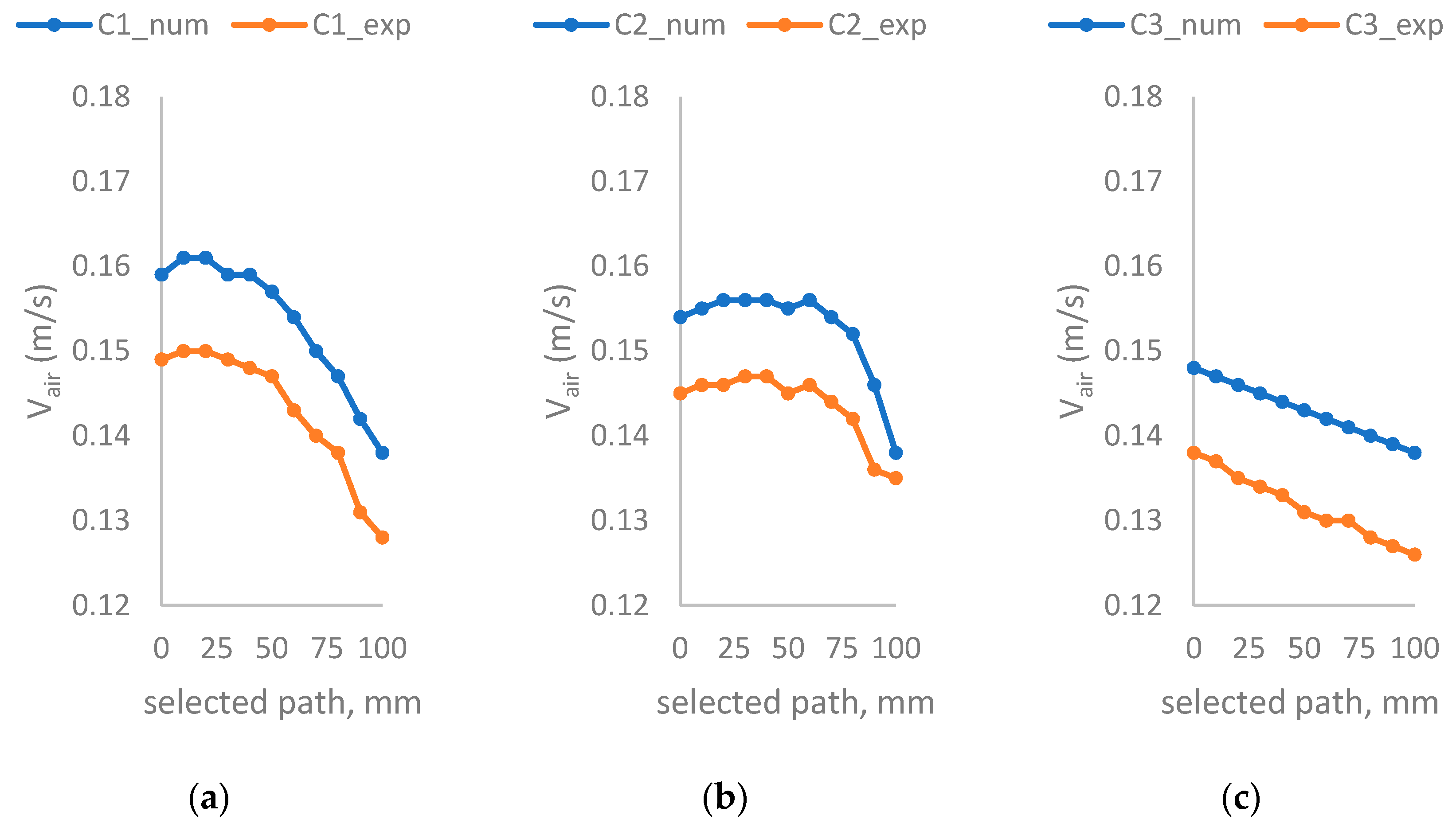

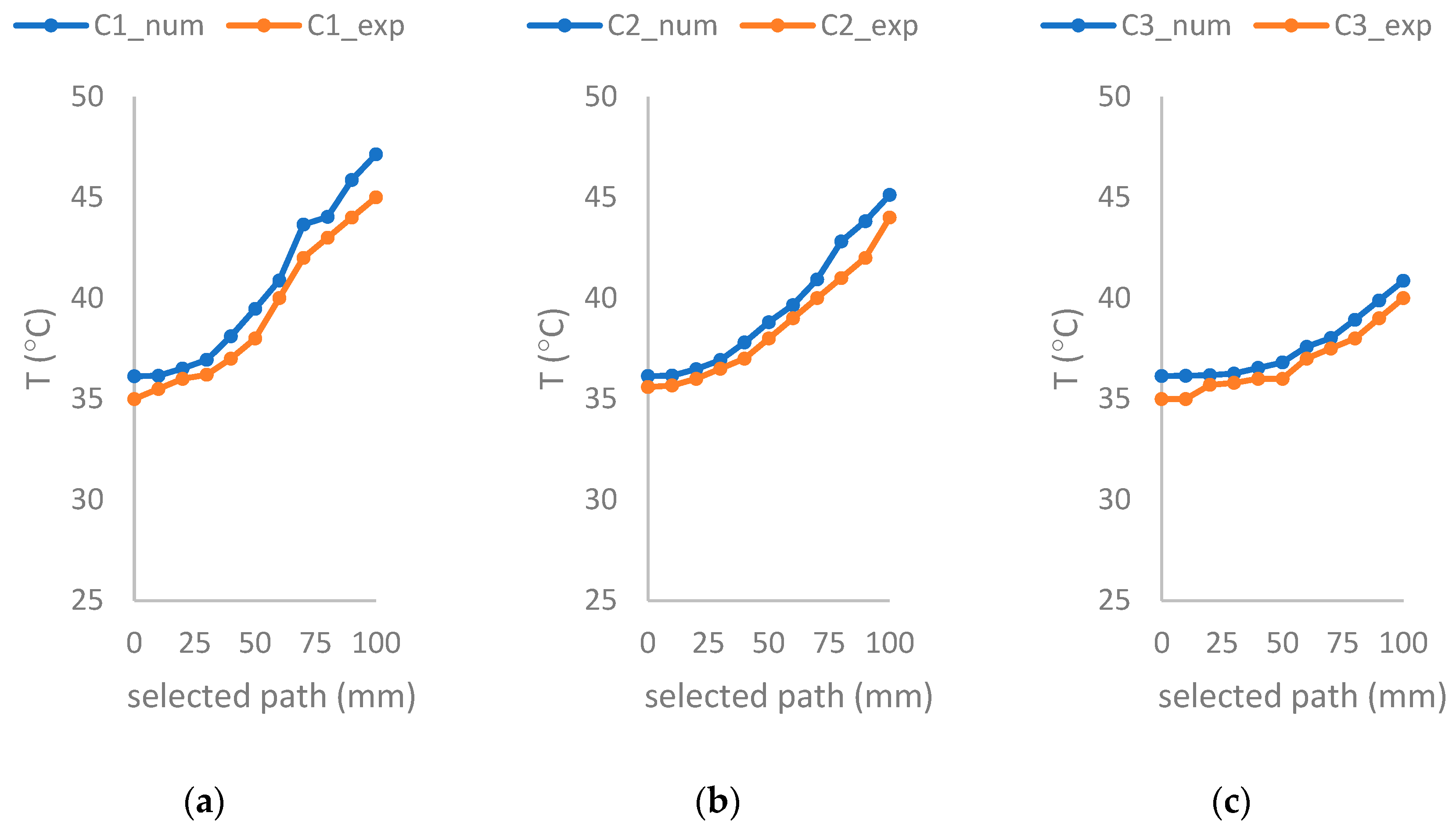

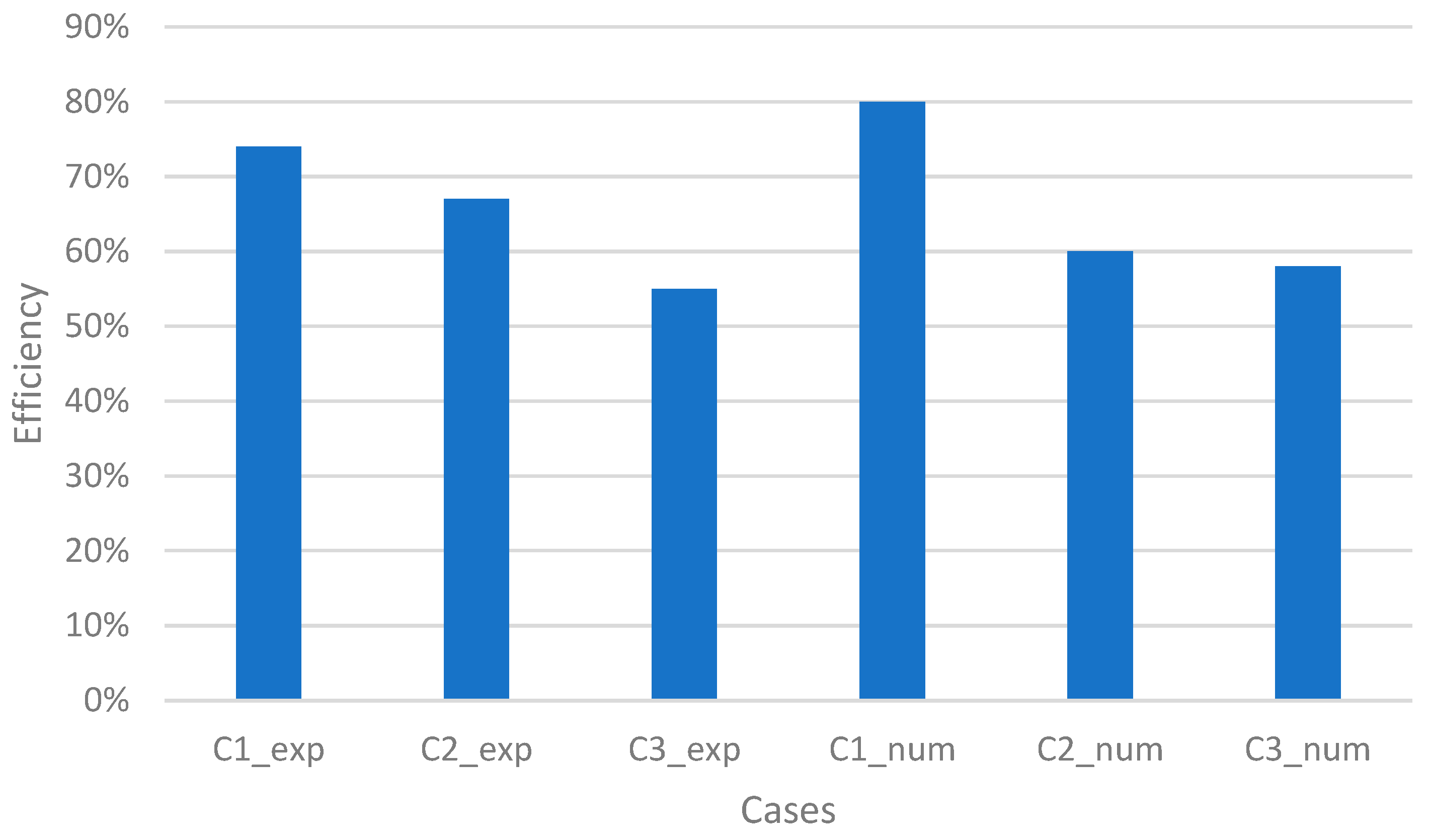

4.2. Comparisons of Numerical and Experimental Results

4.3. Comparison to the Literature

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vengadesan, E.; Senthil, R. A Review on recent developments in thermal performance, enhancement methods of flat plate solar Air Collector. Renew. Sustain. Energy 2020, 134, 110315. [Google Scholar] [CrossRef]

- Kishk, S.S.; ElGamal, R.A.; ElMasry, G.M. Effectiveness of recyclable aluminum cans in fabricating an efficient solar collector for drying agricultural products. Renew. Energy 2019, 133, 307–316. [Google Scholar] [CrossRef]

- Yadav, A.S.; Shukla, O.P.; Sharma, A.; Khan, I.A. CFD analysis of heat transfer performance of ribbed solar air heater. Mater. Today Proc. 2022, 62, 1413–1419. [Google Scholar] [CrossRef]

- Njomo, D. Unglazed selective absorber solar air collector: Heat exchange analysis. Heat Mass Transf. 2000, 36, 313–317. [Google Scholar] [CrossRef]

- Chaube, A.; Sahoo, P.K.; Solanki, S.C. Analysis of heat transfer augmentation and flow characteristics due to rib roughness over absorber plate of a solar air heater. Renew. Energy 2006, 31, 317–331. [Google Scholar] [CrossRef]

- Pashchenko, D.I. ANSYS Fluent CFD modeling of solar air-heater thermo-aerodynamics. Appl. Sol. Energy 2018, 54, 32–39. [Google Scholar] [CrossRef]

- Karim, M.A.; Hawlader, M.N.A. Performance investigation of flat plate, v-corrugated and finned air collectors. Energy 2006, 31, 452–470. [Google Scholar] [CrossRef]

- Ammar, M.; Mokni, A.; Hatem, M.; Philippe, B. Numerical analysis of solar air collector provided with rows of rectangular fins. Energy Rep. 2020, 6, 3412–3424. [Google Scholar] [CrossRef]

- Badiei, Z.; Eslami, M.; Jafarpur, K. Performance improvements in solar flat plate collectors by integrating with phase change materials and fins: A CFD modeling. Energy 2020, 192, 116719. [Google Scholar] [CrossRef]

- Panchal, H.; Sohani, A.; Nguyen, N.V.; Shoeibi, S.; Khiadani, M.; Huy, P.Q.; Hoseinzadeh, S.; Kabeel, A.E.; Saboor, S.; Cuce, E. Performance evaluation of using evacuated tubes solar collector, perforated fins, and pebbles in a solar still—Experimental study and CO2 mitigation analysis. Environ. Sci. Pollut. Res. 2023, 30, 11769–11784. [Google Scholar] [CrossRef] [PubMed]

- Saxena, A.; Cuce, E.; Tiwari, G.N.; Kumar, A. Design and thermal performance investigation of a box cooker with flexible solar collector tubes: An experimental research. Energy 2020, 206, 118144. [Google Scholar] [CrossRef]

- Ozgen, F.; Dayan, A. Energy analysis of a solar air heater with an absorber plate made of porous material. Therm. Sci. 2021, 23, 333–337. [Google Scholar] [CrossRef]

- Ozgen, F.; Dayan, A. Design of an air solar collector with an absorber plate made of porous material. Int. J. Innov. Eng. Appl. 2021, 5, 11–17. [Google Scholar]

- Yahya, S.G.; Mao, X.; Jaworski, A.J. Experimental investigation of thermal performance of random stack materials for use in standing wave thermoacoustic refrigerators. Int. J. Refrig. 2017, 75, 52–63. [Google Scholar] [CrossRef]

- Abduljalil, A.S.; Yu, Z.; Jaworski, A.J. Selection and experimental evaluation of low-cost porous materials for regenerator applications in thermoacoustic engines. Mater. Des. 2011, 32, 217–228. [Google Scholar] [CrossRef]

- Kline, S.J.; McClintock, F.A. Describing Uncertainties in Single-Sample Experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Sethi, M.; Thakur, N.S. Correlations for solar air heater duct with dimpled shape roughness elements on absorber plate. Sol. Energy 2012, 86, 2852–2861. [Google Scholar] [CrossRef]

- Bhushan, A.; Kumar, R.; Perwez, A. Experimental investigations of thermal performance for flat and dimpled plate solar air heater under turbulent flow conditions. Sol. Energy 2022, 231, 664–683. [Google Scholar] [CrossRef]

- Lin, W.; Ren, H.; Ma, Z. Mathematical modelling and experimental investigation of solar air collectors with corrugated absorbers. Renew. Energy 2020, 145, 164–179. [Google Scholar] [CrossRef]

| ρ (kg/m3) | Cp (J/kgK) | k (W/mK) | ν (m2/s) | |

|---|---|---|---|---|

| Glass surface | 3000 | 500 | 1.8 | - |

| Air | 1.136 | 1007 | 0.026 | 1.655 × 10−5 |

| Path | C1_num | C2_num | C3_num | C1_exp | C2_exp | C3_exp |

|---|---|---|---|---|---|---|

| Air Velocities, (m/s) | ||||||

| 0 | 0.159 | 0.154 | 0.148 | 0.145 | 0.149 | 0.138 |

| 10 | 0.161 | 0.155 | 0.147 | 0.146 | 0.15 | 0.137 |

| 20 | 0.161 | 0.156 | 0.146 | 0.146 | 0.15 | 0.135 |

| 30 | 0.159 | 0.156 | 0.145 | 0.147 | 0.149 | 0.134 |

| 40 | 0.159 | 0.156 | 0.144 | 0.147 | 0.148 | 0.133 |

| 50 | 0.157 | 0.155 | 0.143 | 0.145 | 0.147 | 0.131 |

| 60 | 0.154 | 0.156 | 0.142 | 0.146 | 0.143 | 0.13 |

| 70 | 0.150 | 0.154 | 0.141 | 0.144 | 0.14 | 0.13 |

| 80 | 0.147 | 0.152 | 0.140 | 0.142 | 0.138 | 0.128 |

| 90 | 0.142 | 0.146 | 0.139 | 0.136 | 0.131 | 0.127 |

| 100 | 0.138 | 0.138 | 0.138 | 0.135 | 0.128 | 0.126 |

| Temperatures (°C) | ||||||

| 0 | 36.13 | 36.14 | 36.14 | 35.59 | 35.00 | 35 |

| 10 | 36.15 | 36.16 | 36.15 | 35.67 | 35.5 | 35 |

| 20 | 36.51 | 36.48 | 36.18 | 36 | 36 | 35.7 |

| 30 | 36.94 | 36.93 | 36.26 | 36.5 | 36.2 | 35.8 |

| 40 | 38.11 | 37.8 | 36.54 | 37 | 37 | 36 |

| 50 | 39.47 | 38.81 | 36.81 | 38 | 38 | 36 |

| 60 | 40.88 | 39.66 | 37.59 | 39 | 40 | 37 |

| 70 | 43.65 | 40.93 | 38.02 | 40 | 42 | 37.5 |

| 80 | 44.03 | 42.81 | 38.93 | 41 | 43 | 38 |

| 90 | 45.86 | 43.82 | 39.89 | 42 | 44 | 39 |

| 100 | 47.14 | 45.12 | 40.86 | 44 | 45 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Can, O.F.; Celik, N.; Ozgen, F.; Kistak, C.; Taskiran, A. Experimental and Numerical Analysis of the Solar Collector with Stainless Steel Scourers Added to the Absorber Surface. Appl. Sci. 2024, 14, 2629. https://doi.org/10.3390/app14062629

Can OF, Celik N, Ozgen F, Kistak C, Taskiran A. Experimental and Numerical Analysis of the Solar Collector with Stainless Steel Scourers Added to the Absorber Surface. Applied Sciences. 2024; 14(6):2629. https://doi.org/10.3390/app14062629

Chicago/Turabian StyleCan, Omer Faruk, Nevin Celik, Filiz Ozgen, Celal Kistak, and Ali Taskiran. 2024. "Experimental and Numerical Analysis of the Solar Collector with Stainless Steel Scourers Added to the Absorber Surface" Applied Sciences 14, no. 6: 2629. https://doi.org/10.3390/app14062629

APA StyleCan, O. F., Celik, N., Ozgen, F., Kistak, C., & Taskiran, A. (2024). Experimental and Numerical Analysis of the Solar Collector with Stainless Steel Scourers Added to the Absorber Surface. Applied Sciences, 14(6), 2629. https://doi.org/10.3390/app14062629