Critical Steps and Conditions to Be Included in a Business Model in Logistics, Seeking Competitive Advantage from the Perspective of the Modern Digital Age and Industry 4.0

Abstract

:1. Introduction

2. Theoretical Background

2.1. Innovative Business Models in Industry 4.0

- Process optimization, both internal and external: This shift placed a heavy focus on incremental innovation, which enhances a company without necessitating major changes. New technologies are only implemented when the architecture of value creation (key resources and activities) is optimized to boost performance and productivity (lower costs, time and failure rates, train personnel, etc.) without taking significant risks.

- This specific incremental innovation focuses on improving value delivery (value proposition through product and service offerings, customer segment, channels, and customer interactions) in order to improve the user experience.

- Based on the core principles of sharing uncertainty with other actors, focusing on the primary activity (core or unique company activities), and obtaining new critical skills and resources from partners, the real business model that this model presents offers radical innovation. Utilizing this idea is now feasible thanks to technologies like Big Data, Cloud Computing, Augmented Reality, and Virtual Reality. This strategy establishes a close relationship between the business’s value-creation process and that of the other stakeholders.

- A brand-new business model based on cutting-edge technologies and emphasizes, among other things, big data, cloud computing, etc., in order to provide cutting-edge and intelligent products and services, is introduced in new business models that focus on intelligent products and services. Therefore, it is required to make a major innovation that modifies almost every aspect of the business model.

- Integration of planning and programming processes.

- Digitized process automation.

- Real-time quality control.

- Structured processes and activities in real time and end-to-end.

- Personalized and online organized procedures.

- Customer-centric online ordering system.

- Maintaining core technologies oriented towards online principles.

- Personalized and online organized planning, control, and production improvement.

2.2. Digital Transformation

- Top management involvement and commitment.

- Organizational strategy.

- Digitization of the supply chain.

- Smart products and services.

- Digitization of the organization.

- Adaptation of workers in Industry 4.0.

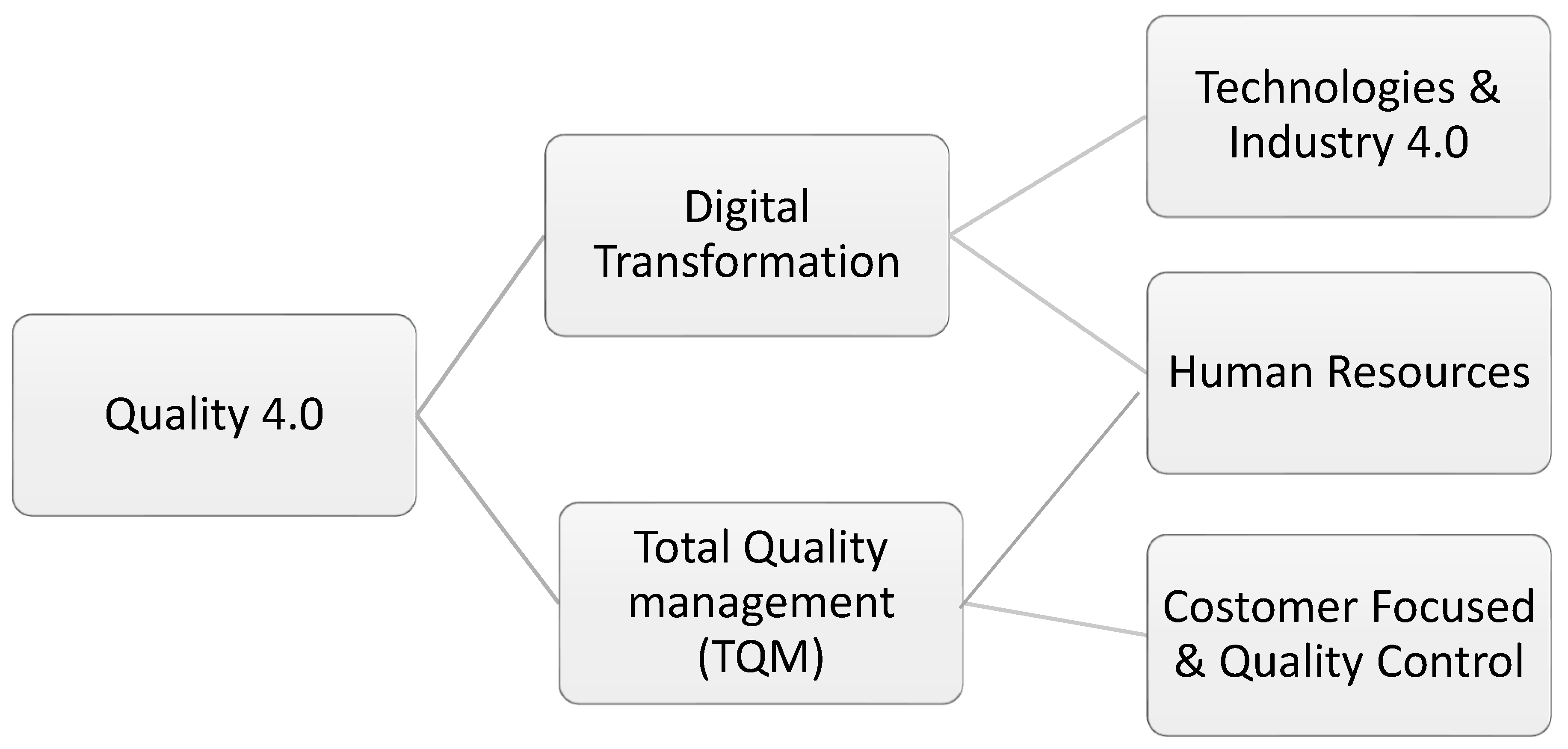

2.3. Quality 4.0 and Logistics

2.4. Human Resources and Logistics 4.0

- Role replacement by technology.

- Technology support and performance enhancement.

- Decision-making and support in the dualities of big data analytics to automate decision-making processes or assist human decisions based on data.

- The identification of unique materials and linkage to IoT technologies and smart sensors that can do so will improve product tracking and tracing in and out of plants.

- Real-time access to data and information from many sources is made possible by the information flow that occurs as a result of its systems integration, which also makes use of cloud computing.

- Automation, robots, and new manufacturing techniques will bring about new products and intelligent/smart transportation systems that can support or replace manual labor in manual jobs.

- Known as material flow handling technologies, these technologies include external human augmentation to improve human performance, prevent workplace injuries, and facilitate the lifting and moving of heavy objects. They also include assistive wheeled robots that transport materials to assembly stations. Logistics operators may now use data analysis tools thanks to the Visual Analytics solution, which transforms data into reliable knowledge.

- Information flow management technologies include hands-free workstations with better facility signage and navigation, video conferencing between staff members for group problem-solving, and mobile devices that allow users to access digital dashboards and related data while taking inventory.

- Material flow management technologies, which mostly refer to intelligent cargo handling tools (like trucks, cranes, and forklifts) and share real-time data about their location and status to help logistics operators with management tasks and equipment control (like identifying idle time and bottlenecks, keeping track of maintenance status, etc.), are also covered in this section. Also included are smart containers that can exchange real-time data about various characteristics such as location, temperature, humidity, CO2 level, and vibra-tactile level.

3. Materials and Methods

- Step 1:

- Formulation of the problem

- Step 2:

- Search strategy

- Step 3:

- Selection and evaluation of papers

- Step 4:

- Final classification and presentation of data

4. Results

5. Discussion

5.1. Main Trends and Concerns

5.2. Main Trends and Concerns

- Understanding the opportunities: Industry 4.0 technologies provide opportunities to improve the financial performance, environmental performance, and social impact of logistics sectors. It is important to give special consideration to these opportunities and how they align with the company’s goals.

- System Integration and Digital Twin: Focus on system integration and digital twin technologies. These can help with a virtual representation of physical assets, enabling better planning and decision making.

- Human-Centered Technological Transformation: In any case, technological transformation is human-centered. This means that the technology should be designed to work seamlessly with the existing workforce.

- Collaboration and integration: Logistics 4.0 is able to collaborate and integrate with Industry 4.0 processes and systems. This integration can create a common and synergistic relationship between shippers, manufacturers, and end users.

- Addressing challenges: The challenges in this case do not stop, as more and more emerge. In addition to the main ones mentioned above, there are also those related to different sustainability indicators, unclear benefits, environmental impacts in the life cycle, issues of inequality and technological maturity, etc.

- Cost reduction: Industry 4.0 technologies such as IoT sensors, predictive analytics, and automation can optimize various aspects of logistics, leading to cost savings through improved efficiency in inventory management, order processing, and transportation.

- Resource optimization: Real-time data from connected devices enables better resource allocation, reducing waste and minimizing excess inventory or underutilized assets.

- Real-time tracking: IoT devices and sensors facilitate real-time tracking of goods throughout the supply chain, providing improved visibility. This can lead to better decision making and more accurate demand forecasting.

- Data-driven Insights: Advanced analytics and machine-learning algorithms can turn collected data into actionable insights, enabling organizations to make informed decisions and quickly adapt to market changes.

- Demand forecasting: Industry 4.0 applications can improve the accuracy of demand forecasting, reducing the risk of overstock or inventory and helping organizations maintain optimal inventory levels.

- Supplier collaboration: Improved communication and data sharing with suppliers through Industry 4.0 technologies can lead to better coordination, faster response times, and improved overall supply chain performance.

- Faster response times: Improved visibility and streamlined processes enable faster response times to customer requirements, leading to higher levels of customer satisfaction.

- Accurate Order Fulfillment: Automation and real-time tracking help ensure accurate and timely order fulfillment, enhancing the overall customer experience.

- Predictive maintenance: IoT-enabled predictive maintenance can reduce the risk of equipment failures, minimizing downtime and potential disruptions to logistics operations.

- Compliance and security: Industry 4.0 applications can improve regulatory compliance and enhance security measures, reducing the risk of legal issues and protecting the supply chain from potential threats.

- Innovation leadership: Organizations that successfully implement Industry 4.0 applications demonstrate leadership in innovation, positioning themselves as forward-thinking and adaptable in a competitive marketplace.

- Flexibility and Agility: The ability to quickly adapt to market changes, demand, or disruptions gives organizations a competitive advantage over those with traditional logistics systems.

- Energy efficiency: Smart, connected systems can contribute to energy efficiency, leading to long-term cost savings and environmental sustainability.

6. Conclusions

Funding

Conflicts of Interest

References

- Miqueo, A.; Torralba, M.; Yagüe-Fabra, J. Lean Manual Assembly 4.0: A Systematic Review. Appl. Sci. 2020, 10, 8555. [Google Scholar] [CrossRef]

- Dobrowolska, M.; Knop, L. Fit to Work in the Business Models of the Industry 4.0 Age. Sustainability 2020, 12, 4854. [Google Scholar] [CrossRef]

- Vu, O.T.K.; Duarte Alonso, A.; Buitrago Solis, M.A.; Goyzueta, S.; Nguyen, T.; McClelland, R.; Tran, T.D.; Nguyen, N.; Huynh, H.T.N.; Atay, E. A dynamic capabilities approach of Industry 4.0: The experiences of managers operating in two emerging economies. Eur. Bus. Rev. 2023, 35, 137–160. [Google Scholar] [CrossRef]

- Richard, S.; Pellerin, R.; Bellemare, J.; Perrier, N. A business process and portfolio management approach for Industry 4.0 transformation. Bus. Process Manag. J. 2021, 27, 505–528. [Google Scholar] [CrossRef]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the Relation between Lean Manufacturing, Industry 4.0, and Sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Naeem, H.M.; Di Maria, E. Customer participation in new product development: An Industry 4.0 perspective. Eur. J. Innov. Manag. 2022, 25, 637–655. [Google Scholar] [CrossRef]

- Veile, J.; Schmidt, M.; Voigt, K. Toward a new era of cooperation: How industrial digital platforms transform business models in Industry 4.0. J. Bus. Res. 2022, 143, 387–405. [Google Scholar] [CrossRef]

- Ferrigno, G.; Del Sarto, N.; Piccaluga, A.; Baroncelli, A. Industry 4.0 base technologies and business models: A bibliometric analysis. Eur. J. Innov. Manag. 2023, 26, 502–526. [Google Scholar] [CrossRef]

- Resende, C.; Geraldes, C.; Rodrigues Lima Junior, F. Decision Models for Supplier Selection in Industry 4.0 Era: A Systematic Literature Review. Procedia Manuf. 2021, 55, 492–499. [Google Scholar] [CrossRef]

- Saha, P.; Talapatra, S.; Belal, H.; Jackson, V. Unleashing the Potential of the TQM and Industry 4.0 to Achieve Sustainability Performance in the Context of a Developing Country. Glob. J. Flex. Syst. Manag. 2022, 23, 495–513. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and managerial challenges in the path toward Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Cricelli, L.; Strazzullo, S. Innovation in the supply chain and big data: A critical review of the literature. Eur. J. Innov. Manag. 2022, 25, 479–497. [Google Scholar] [CrossRef]

- El Hamdi, S.; Abouabdellah, A. Logistics: Impact of Industry 4.0. Appl. Sci. 2022, 12, 4209. [Google Scholar] [CrossRef]

- Magdy Elhusseiny, H.; Crispim, J. A Review of Industry 4.0 Maturity Models: Adoption of SMEs in The Manufacturing and Logistics Sectors. Procedia Comput. Sci. 2023, 219, 236–243. [Google Scholar] [CrossRef]

- Bettiol, M.; Capestro, M.; Di Maria, E.; Grandinetti, R. Leveraging on intra- and inter-organizational collaboration in Industry 4.0 adoption for knowledge creation and innovation. Eur. J. Innov. Manag. 2023, 26, 328–352. [Google Scholar] [CrossRef]

- Marius Müller, J. Business model innovation in small- and medium-sized enterprises: Strategies for industry 4.0 providers and users. J. Manuf. Technol. Manag. 2019, 30, 1127–1142. [Google Scholar] [CrossRef]

- Abiodun, T.S.; Rampersad, G.; Brinkworth, R. Driving smartness for organizational performance through Industry 4.0: A systems perspective. J. Manuf. Technol. Manag. 2023, 34, 40–63. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Stefanoni, A.; Silvestri, C.; Ioppolo, G. Industry 4.0 technologies as a lever for sustainability in the communication of large companies to stakeholders. Eur. J. Innov. Manag. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Di Toma, P.; Ghinoi, S. Overcoming hierarchy in business model innovation: An actor-oriented approach. Eur. J. Innov. Manag. 2021, 24, 1057–1081. [Google Scholar] [CrossRef]

- Grabowska, S.; Saniuk, S. Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment. J. Open Innov. Technol. Mark. Complex. 2022, 8, 57. [Google Scholar] [CrossRef]

- Dressler, M.; Paunovic, I. Converging and diverging business model innovation in regional intersectoral cooperation–exploring wine industry 4.0. Eur. J. Innov. Manag. 2021, 24, 1625–1652. [Google Scholar] [CrossRef]

- Kafetzopoulos, D. Understanding BMI from Industry 4.0, knowledge management and market uncertainty perspective. Bus. Process Manag. J. 2023, 29, 1522–1542. [Google Scholar] [CrossRef]

- Kafetzopoulos, D. Ambidextrous leadership: A narrative literature review for theory development and directions for future research. Balt. J. Manag. 2022, 17, 206–232. [Google Scholar] [CrossRef]

- Mielcarek, P.; Dymitrowski, A. Business model innovation based on new technologies—Is it resources driven and dependent? Eur. Bus. Rev. 2022, 34, 729–748. [Google Scholar] [CrossRef]

- Aquilani, B.; Piccarozzi, M.; Abbate, T.; Codini, A. The Role of Open Innovation and Value Co-creation in the Challenging Transition from Industry 4.0 to Society 5.0: Toward a Theoretical Framework. Sustainability 2020, 12, 8943. [Google Scholar] [CrossRef]

- Nottbrock, C.; Van Looy, A.; De Haes, S. Impact of digital Industry 4.0 innovations on interorganizational value chains: A systematic literature review. Bus. Process Manag. J. 2023, 29, 43–76. [Google Scholar] [CrossRef]

- Marcon, E.; Le Dain, M.A.; Frank, A. Designing business models for Industry 4.0 technologies provision: Changes in business dimensions through digital transformation. Technol. Forecast. Soc. Chang. 2022, 185, 122078. [Google Scholar] [CrossRef]

- Martínez-Olvera, C.; Mora-Vargas, J. A Comprehensive Framework for the Analysis of Industry 4.0 Value Domains. Sustainability 2019, 11, 2960. [Google Scholar] [CrossRef]

- Ibara, D.; Ganzarain, G.; Ignacio-Igartua, J. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Tortorella, G.; Saurin, T.A.; Fogliatto, F.S.; Tlapa, D.; Moyano-Fuentes, J.; Gaiardelli, P.; Seyedghorban, Z.; Vassolo, R.; Mac Cawley, A.F.; Sunder, M.V.; et al. The impact of Industry 4.0 on the relationship between TPM and maintenance performance. J. Manuf. Technol. Manag. 2022, 33, 489–520. [Google Scholar] [CrossRef]

- Muller, J.; Buliga, O.; Voigt, K.I. The role of absorptive capacity and innovation strategy in the design of industry 4.0 business Models—A comparison between SMEs and large enterprises. Eur. Manag. J. 2021, 39, 333–343. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2020, 12, 86. [Google Scholar] [CrossRef]

- Tsipoulanidis, A.; Nanos, I. Contemporary Potentials and Challenges of Digital Logistics and Supply Chain Management. Int. J. Innov. Technol. Manag. 2022, 19, 2241003. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales, S.O.; Aldrette-Malacara, A. Digital supply chain model in Industry 4.0. J. Manuf. Technol. Manag. 2020, 31, 887–933. [Google Scholar] [CrossRef]

- Efthymiou, O.K.; Ponis, S.T. Industry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature Review. Sustainability 2021, 13, 11643. [Google Scholar] [CrossRef]

- Hrouga, M.; Sbihi, A. Logistics 4.0 for supply chain performance: Perspectives from a retailing case study. Bus. Process Manag. J. 2023, 29, 1892–1919. [Google Scholar] [CrossRef]

- Mihardjo, L.; Sasmoko, S.; Alamsjah, S.; Elidjen, E. Digital leadership role in developing business model innovation and customer experience orientation in industry 4.0. Manag. Sci. Lett. 2019, 9, 1749–1762. [Google Scholar] [CrossRef]

- Tseng, Y.-C.; Hung, H.-W.; Lin, B.-W. Win the next war vs. innovate or die: Framing the digital transformation across the Taiwanese sectors. Eur. J. Innov. Manag. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Tortorella, G.; Prashar, A.; Antony, J.; Mac Cawley, A.F.; Vassolo, R.; Sony, M. Role of leadership in the digitalisation of manufacturing organisations. J. Manuf. Technol. Manag. 2023, 34, 315–336. [Google Scholar] [CrossRef]

- Nadeem, K.; Wong, S.; Za, S.; Venditti, M. Digital transformation and industry 4.0 employees: Empirical evidence from top digital nations. Technol. Soc. 2024, 76, 102434. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Introna, V.; Santolamazza, A.; Cesarotti, V. Maintenance transformation through Industry 4.0 technologies: A systematic literature review. Comput. Ind. 2020, 123, 103335. [Google Scholar] [CrossRef]

- Avwokeni, A.J. Strategic leadership and transactional leadership: The mediating effect of digital leadership in the world of Industry 4.0. J. Econ. Adm. Sci. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Kokot, K.; Kokotec, I.D.; Calopa, M.K. Impact of Leadership on Digital Transformation. In Proceedings of the 2021 IEEE Technology & Engineering Management Conference—Europe (TEMSCON-EUR), Dubrovnik, Croatia, 17–20 May 2021; Volume 14, pp. 1–6. [Google Scholar]

- Ghobakhloo, M.; Iranmanesh, M. Digital transformation success under Industry 4.0: A strategic guideline for manufacturing SMEs. J. Manuf. Technol. Manag. 2021, 32, 1533–1556. [Google Scholar] [CrossRef]

- Rossini, M.; Powell, D.; Kundu, K. Lean supply chain management and Industry 4.0: A systematic literature review. Int. J. Lean Six Sigma 2022, 14, 253–276. [Google Scholar] [CrossRef]

- Steiber, A.; Alänge, S.; Ghosh, S.; Goncalves, D. Digital transformation of industrial firms: An innovation diffusion view. Eur. J. Innov. Manag. 2021, 24, 799–819. [Google Scholar] [CrossRef]

- Birkel, H.; Müller, J. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J.A.; McDermott, O. Motivations, barriers and readiness factors for Quality 4.0 implementation: An exploratory study. TQM J. 2021, 33, 1502–1515. [Google Scholar] [CrossRef]

- Johnson, S. Quality 4.0: A trend within a trend. Quality 2019, 58, 21–23. [Google Scholar]

- Antony, J.; Sony, M.; Furterer, S.; McDermott, O. Quality 4.0 and its impact on organizational performance: An integrative viewpoint. TQM J. 2021, 34, 2069–2084. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J. Essential ingredients for the implementation of Quality 4.0: A narrative review of literature and future directions for research. TQM J. 2020, 32, 779–793. [Google Scholar] [CrossRef]

- Liu, H.; Liu, R.; Gu, X.; Yang, M. From total quality management to Quality 4.0: A systematic literature review and future research agenda. Front. Eng. Manag. 2023, 10, 191–205. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. The readiness of manufacturing industries to transit to Quality 4.0. Int. J. Qual. Reliab. Manag. 2023, 40, 1729–1752. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. Quality 4.0 transition framework for Tanzanian manufacturing industries. TQM J. 2023, 35, 1417–1448. [Google Scholar] [CrossRef]

- Zulfiqar, M.; Antony, J.; Swarnakar, V.; Sony, M. A readiness assessment of Quality 4.0 in packaging companies: An empirical investigation. Total Qual. Manag. Bus. Excell. 2023, 34, 1334–1352. [Google Scholar] [CrossRef]

- Alzahrani, B.; Bahaitham, H.; Andejany, M.; Elshennawy, A. How Ready Is Higher Education for Quality 4.0 Transformation according to the LNS Research Framework? Sustainability 2021, 13, 5169. [Google Scholar] [CrossRef]

- Ferrari, A.; Mangano, G.; Cagliano, A.C.; De Marco, A. 4.0 technologies in city logistics: An empirical investigation of contextual factors. Oper. Manag. Res. 2023, 16, 345–362. [Google Scholar] [CrossRef]

- Beham, A.; Raggl, S.; Hauder, V.A.; Karder, J.; Wgner, S.; Affenzeller, M. Performance, Quality, and Control in Steel Logistics 4.0. Procedia Manuf. 2020, 42, 429–433. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daroczi, M. A review of quality 4.0: Definitions, features, technologies, applications, and challenges. Total Qual. Manag. Bus. Excell. 2022, 33, 1164–1182. [Google Scholar] [CrossRef]

- Bazan, P.; Estevez, E. Industry 4.0 and business process management: State of the art and new challenges. Bus. Process Manag. J. 2022, 28, 62–80. [Google Scholar] [CrossRef]

- Jotabá, M.N.; Fernandes, C.I.; Gunkel, M.; Kraus, S. Innovation and human resource management: A systematic literature review. Eur. J. Innov. Manag. 2022, 25, 1–18. [Google Scholar] [CrossRef]

- Rossini, M.; Cifone, F.D.; Kassem, B.; Costa, F.; Portioli-Staudacher, A. Being lean: How to shape digital transformation in the manufacturing sector. J. Manuf. Technol. Manag. 2021, 32, 239–259. [Google Scholar] [CrossRef]

- Galanti, T.; De Vincenzi, C.; Buonomo, I.; Benevene, P. Digital Transformation: Inevitable Change or Sizable Opportunity? The Strategic Role of HR Management in Industry 4.0. Adm. Sci. 2023, 13, 30. [Google Scholar] [CrossRef]

- Margherita, E.G.; Bua, I. The Role of Human Resource Practices for the Development of Operator 4.0 in Industry 4.0 Organisations: A Literature Review and a Research Agenda. Businesses 2021, 1, 18–33. [Google Scholar] [CrossRef]

- Obermayer, N.; Csizmadia, T.; Hargitai, D.M. Influence of Industry 4.0 technologies on corporate operation and performance management from human aspects. Meditari Account. Res. 2022, 30, 1027–1049. [Google Scholar] [CrossRef]

- Da Silva, R.M.; Frederico, G.F.; Garza-Reyes, J.A. Logistics Service Providers and Industry 4.0: A Systematic Literature Review. Logistics 2023, 7, 11. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Romero, D.; Cavalieri, S. Smart Logistics and The Logistics Operator 4.0. IFAC-PapersOnLine 2020, 53, 10615–10620. [Google Scholar] [CrossRef]

- Zoubek, M.; Simon, M. Evaluation of the Level and Readiness of Internal Logistics for Industry 4.0 in Industrial Companies. Appl. Sci. 2021, 11, 6130. [Google Scholar] [CrossRef]

- Kostrzewski, M.; Varjan, P.; Gnap, J. Solutions Dedicated to Internal Logistics 4.0. In Sustainable Logistics and Production in Industry 4.0; Springer: Cham, Switzerland, 2020; Volume 15, pp. 243–262. [Google Scholar]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Borangiu, T.; Răileanu, S. A smart palletising planning and control model in Logistics 4.0 framework. Int. J. Prod. Res. 2023, 61, 8580–8597. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Higgins, J.; Green, S. Cochrane Handbook for Systematic Reviews of Interventions; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Elo, S.; Kyngäs, H. The qualitative content analysis process. J. Adv. Nurs. 2008, 62, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Yu, H.; Solvang, W.D.; Wang, K. The application of Industry 4.0 technologies in sustainable logistics: A systematic literature review (2012–2020) to explore future research opportunities. Environ. Sci. Pollut. Res. 2022, 29, 9560–9591. [Google Scholar] [CrossRef]

- Mosser, J.; Pellerin, R.; Bourgault, M.; Danjou, C.; Perrier, N. GRMI4.0: A guide for representing and modeling Industry 4.0 business processes. Bus. Process Manag. J. 2022, 28, 1047–1070. [Google Scholar] [CrossRef]

- Santos, B.; Dieste, M.; Orzes, G.; Charrua-Santos, F. Resources and capabilities for Industry 4.0 implementation: Evidence from proactive Portuguese SMEs. J. Manuf. Technol. Manag. 2023, 34, 25–43. [Google Scholar] [CrossRef]

- Ramdani, B.; Binsaif, A.; Boukrami, E. Business model innovation: A review and research agenda. N. Engl. J. Entrep. 2019, 22, 89–108. [Google Scholar] [CrossRef]

- Andreini, D.; Bettinelli, C.; Foss, N.J.; Mismetti, M. Business model innovation: A review of the process-based literature. J. Manag. Gov. 2022, 26, 1089–1121. [Google Scholar] [CrossRef]

- Albrecht, T.; Baier, M.S.; Gimpel, H.; Meierhöfer, S.; Maximilian, R.; Schlüchtermann, J.; Will, L. Leveraging Digital Technologies in Logistics 4.0: Insights on Affordances from Intralogistics Processes. Inf. Syst. Front. 2023, 1, 1–20. [Google Scholar] [CrossRef]

- Felsberger, A.; Hasan Qaiser, F.; Choudhary, A.; Reiner, G. The impact of Industry 4.0 on the reconciliation of dynamic capabilities: Evidence from the European manufacturing industries. Prod. Plan. Control 2022, 33, 277–300. [Google Scholar] [CrossRef]

- West, S.; Stoll, O.; Meierhofer, J.; Züst, S. Digital Twin Providing New Opportunities for Value Co-Creation through Supporting Decision-Making. Appl. Sci. 2021, 11, 3750. [Google Scholar] [CrossRef]

- Holtschulte, A. IoT and Enterprise Software. In: Digital Supply Chain and Logistics with IoT. Manag. Prof. 2022, 16, 95–124. [Google Scholar]

- Vilas-Boas, J.; Rodrigues, J.; Alberti, A. Convergence of Distributed Ledger Technologies with Digital Twins, IoT, and AI for fresh food logistics: Challenges and opportunities. J. Ind. Inf. Integr. 2023, 31, 100393. [Google Scholar] [CrossRef]

- Grosse, E.h.; Sgarbossa, F.; Berlin, C.; Neumann, P. Human-centric production and logistics system design and management: Transitioning from Industry 4.0 to Industry 5.0. Int. J. Prod. Res. 2023, 61, 7749–7759. [Google Scholar] [CrossRef]

- Amr, M.; Ezzat, M.; Kassem, S. Logistics 4.0: Definition and Historical Background. In Proceedings of the Novel Intelligent and Leading Emerging Sciences Conference (NILES), Giza, Egypt, 28–30 October 2019; Volume 41, pp. 46–49. [Google Scholar]

- Wrobel-Lachowska, M.; Polak-Sopinska, A.; Wisniewski, Z. Challenges for Logistics Education in Industry 4.0. In Advances in Human Factors in Training, Education, and Learning Sciences; AHFE 2018. Advances in Intelligent Systems and Computing; Nazir, S., Teperi, A.M., Polak-Sopińska, A., Eds.; Springer: Cham, Switzerland, 2018; Volume 785. [Google Scholar]

- Galati, F.; Bigliardi, B. Industry 4.0: Emerging Themes and Future Research Avenues Using a Text Mining Approach. Comput. Ind. 2019, 109, 100–113. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 Implications in Logistics: An Overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Trkman, P.; McCormack, K.; de Oliveira, M.P.V.; Ladeira, M.B. The Impact of Business Analytics on Supply Chain Performance. Decis. Support Syst. 2010, 49, 318–327. [Google Scholar] [CrossRef]

- Obrecht, M.; Knez, M.; Szegedi, Z.; Nick, G.; Lisec, A. Review of Industry 4.0 and Forecasting Its Future within Trends in Logistics and Development of Legislation. Acad. J. Széchenyi István Univ. 2017, V, 59–70. [Google Scholar]

- ISO/IEC 27000; Information Technology—Security Techniques—Information Security Management Systems—Overview and Vocabulary, Technical Report. ISO: Geneva, Switzerland, 2018.

- IEC 62443-1-1; Industrial Communication Networks—Network and System Security—Part 1-1: Terminology, Concepts and Models. IEC Central Office: Geneva, Switzerland, 2018.

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying the Current Trends and Future Perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Frank, A.; Mendes, G.; Ayala, N.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Tikwayo, L.N.; Mathaba, T.N.D. Applications of Industry 4.0 Technologies in Warehouse Management: A Systematic Literature Review. Logistics 2023, 7, 24. [Google Scholar] [CrossRef]

- Apruzzese, M.; Bruni, M.E.; Musso, S.; Perboli, G. 5G and Companion Technologies as a Boost in New Business Models for Logistics and Supply Chain. Sustainability 2023, 15, 11846. [Google Scholar] [CrossRef]

- Ferlito, R.; Faraci, R. Business model innovation for sustainability: A new framework. Innov. Manag. Rev. 2022, 19, 222–236. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Subramanian, N.; Eric Ngai, W.T. Quality management in the 21st century enterprises: Research pathway towards Industry 4.0. Int. J. Prod. Econ. 2019, 207, 125–129. [Google Scholar] [CrossRef]

- Saihi, A.; Awad, M.; Ben-Daya, M. Quality 4.0: Leveraging Industry 4.0 technologies to improve quality management practices—A systematic review. Int. J. Qual. Reliab. Manag. 2023, 40, 628–650. [Google Scholar] [CrossRef]

- Evangelista, P.; Kianto, A.; Hussinki, H.; Vanhala, M.; Nisula, A.-M. Knowledge-Based Human Resource Management, Logistics Capability, and Organizational Performance in Small Finnish Logistics Service Providers. Logistics 2023, 7, 12. [Google Scholar] [CrossRef]

- Jena, S.K.; Ghadge, A. An integrated supply chain—Human resource management approach for improved supply chain performance. Int. J. Logist. Manag. 2021, 32, 918–941. [Google Scholar] [CrossRef]

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. Eng. Manag. J. 2021, 33, 187–201. [Google Scholar] [CrossRef]

- Khan, S.; Singh, R.; Haleem, A.; Dsilva, J.; Ali, S.S. Exploration of Critical Success Factors of Logistics 4.0: A DEMATEL Approach. Logistics 2022, 6, 13. [Google Scholar] [CrossRef]

- Perotti, S.; Bastidas Santacruz, R.F.; Bremer, P.; Beer, J.E. Logistics 4.0 in warehousing: A conceptual framework of influencing factors, benefits and barriers. Int. J. Logist. Manag. 2022, 33, 193–220. [Google Scholar] [CrossRef]

- Sorkun, M.F. Digitalization in Logistics Operations and Industry 4.0: Understanding the Linkages with Buzzwords. In Digital Business Strategies in Blockchain Ecosystems; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Ferraro, S.; Leoni, L.; Cantini, A.; De Carlo, F. Trends and Recommendations for Enhancing Maturity Models in Supply Chain Management and Logistics. Appl. Sci. 2023, 13, 9724. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature Review and a Proposed Framework for Future Research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Hanifan, G.; Sharma, A.; Newberry, C. The Digital Supply Network a New Paradigm for Supply Chain Management; Accenture Strategy: Dublin, Ireland, 2014. [Google Scholar]

- Rodič, B. Industry 4.0 and the New Simulation Modelling Paradigm. Organizacija 2017, 50, 193–207. [Google Scholar] [CrossRef]

- Douaioui, K.; Fri, M.; Mabroukki, C.; Semma, E.A. The Interaction between Industry 4.0 and Smart Logistics: Concepts and Perspectives. In Proceedings of the 2018 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Tangier, Morocco, 26–27 April 2018. [Google Scholar]

| Journal Title | Number of Papers | Publishing House |

|---|---|---|

| Sustainability | 25 | MDPI |

| Journal of Manufacturing Technology Management | 13 | Emerald |

| Procedia Manufacturing | 12 | Elsevier |

| Procedia CIRP | 9 | Elsevier |

| Applied Sciences | 9 | MDPI |

| The TQM Journal | 9 | Emerald |

| Procedia Computer Science | 8 | Elsevier |

| IEEE Access | 8 | IEEE Xplore |

| International Journal of Quality & Reliability Management | 8 | Emerald |

| Journal of Cleaner Production | 6 | Elsevier |

| IFAC-PapersOnLine | 5 | Elsevier |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsarouhas, P.; Papaevangelou, N. Critical Steps and Conditions to Be Included in a Business Model in Logistics, Seeking Competitive Advantage from the Perspective of the Modern Digital Age and Industry 4.0. Appl. Sci. 2024, 14, 2701. https://doi.org/10.3390/app14072701

Tsarouhas P, Papaevangelou N. Critical Steps and Conditions to Be Included in a Business Model in Logistics, Seeking Competitive Advantage from the Perspective of the Modern Digital Age and Industry 4.0. Applied Sciences. 2024; 14(7):2701. https://doi.org/10.3390/app14072701

Chicago/Turabian StyleTsarouhas, Panagiotis, and Nikolaos Papaevangelou. 2024. "Critical Steps and Conditions to Be Included in a Business Model in Logistics, Seeking Competitive Advantage from the Perspective of the Modern Digital Age and Industry 4.0" Applied Sciences 14, no. 7: 2701. https://doi.org/10.3390/app14072701