Abstract

Through experimental research and theoretical analysis, this study primarily aimed to compare the behavior of cement screeds made in a traditional manner with those made with the addition of microreinforcement. The study also explored the possibility of using electrofilter ash as a component of screeds, examining the advantages and disadvantages of partial substitution of cement with fly ash. The contribution of this article is the experimental research on the characteristics of fresh and hardened cement composites, as well as the parameters influencing the structure and behavior of cement screeds during their use. It has been determined that by using electrofilter ash as a partial replacement for cement, satisfactory values of physical–mechanical and deformation characteristics of fine-grained cement composite can be achieved. Through analysis of the obtained results and influential parameters of these composites, the optimal design approach has been explored. This relevant information could potentially provide reliable recommendations to designers and contractors for the production of quality and durable cement screeds.

1. Introduction

Considering that cement screed is frequently installed in floor constructions exposed to heavy traffic, such as floors in industrial and commercial buildings, highway warehouses, stations, hospital halls, and similar structures, it is subjected to significant loads, including concentrated loads. Acting over relatively small areas, these loads generate high local pressure responsible for damage and defects in the screed [1].

There is often a need for the repair and rehabilitation of floor constructions, with damages manifesting over time, sometimes immediately after construction. Technical specifications for cement screeds typically focus on basic data, but the need for additional information on characteristics and proper material selection is underscored.

Poorly executed cement screeds can lead to high reconstruction costs and losses due to the cessation of activities during rehabilitation, pointing to structural defects in the lower zones of screeds [2].

Numerous engineers and researchers have explored cement screeds and their diverse properties. For example, the thermal properties of recycled glass claddings and their significance for the energy efficiency of a building were studied by Alani and others [3]. Moriera and colleagues investigated improved thermal and acoustic performances of cement claddings, exploring the possibility of reducing their weight by adding cork granules obtained as waste during production [4]. The use of waste materials as constituents of screeds was also examined by Boehme and others, who assessed the impact of recycled concrete as an aggregate, derived from fine fractions, in cement claddings [5].

Using electrofilter ash in concrete screed is becoming a common practice. This situation entails both environmentally and economically positive effects [6]. Apart from the evident ecological and economic advantages, substituting a portion of cement with supplementary cementitious materials (SCMs) also provides engineering benefits, such as enhanced workability, decreased risk of segregation, and mitigation of shrinkage and cracking [7].

Since electrofilter ash has pozzolanic properties, whose activity is defined as the ability to produce materials with hydraulic properties in the presence of water and lime Ca(OH)2, and relatively high grinding fineness, this powdered material can be used as a mineral additive in the production of cement, i.e., it may be a partial replacement for Portland cement in composite materials [8].

The partial replacement of Portland cement with SCMs, including fly ash, clays, ground granular blast-furnace slag, limestone filler, silica fume, and metakaolin, has garnered significant attention in recent years [9]. The construction industry is concerned about its impact on global warming, mainly due to carbon emissions (CO2) from activities like material production, construction, transportation, and waste generation. Portland cement (PC) production is a major source of CO2, with 1 kg of PC generating approximately 0.8–0.9 kg of CO2 [10].

Adding fibers to the cement–composite mix improves its strength and behavior by delaying the initiation of cracks and controlling their propagation. Commonly used fibers in the concrete mixture include steel fibers (SF), carbon fibers (CF), and polymer fibers (PF). Steel fibers are considered the most popular, as they can significantly increase the tensile and compressive strength of hardened concrete more than other types of fibers. Despite this, the use of polypropylene fibers has proven effective in enhancing the mechanical properties of hardened cement composite and is widely used in various applications [11].

While polypropylene is not a natural fiber, it can serve as an environmentally friendly option when sourced from recycling. Its integration into concrete not only facilitates plastic recycling and reuse but also improves the performance of the cement-based composite. This enhancement extends to reducing shrinkage, improving tensile properties, and enhancing post-cracking behavior [12].

Cracks in concrete, especially under tensile loads, can lead to durability and serviceability concerns due to their propensity to propagate. Incorporating micro-plastic fibers, such as polypropylene fibers, can mitigate plastic shrinkage in concrete and enhance toughness in post-cracking zones [13]. Synthetic fibers have attracted the interest of the scientific community due to their exceptional durability (absence of corrosion) and lightweight, and thermal properties, with a specific emphasis on fostering anti-spalling behavior [14].

The subject of the research is the physical–mechanical and deformation characteristics of fine-grained cement composites, which vary depending on the mixing ratios of the components, additives, and material compaction. The research aimed to define the effects of micro-reinforcement additives on the properties of cement screed mortar and explore the use of electrofilter ash as a component in the screed, considering the advantages and disadvantages of partial cement substitution with fly ash.

Through the analysis of the results, the research provided an informational basis for optimal design and offered recommendations to designers and contractors for the creation of quality and durable cement screeds.

2. Experimental Research

The experimental investigation involved the preparation and testing of cement-based mortar compositions, as well as mortar compositions that incorporated fly ash (to substitute 20% of the cement mass). Alongside these, the following materials were used: river aggregate, water, synthetic polypropylene fibers, and a superplasticizer.

The analysis of the experimental research was conducted by comparing mortar mixes for cement screeds made using Portland cement as a binder (traditional method) with cement screeds that had a partial substitution of Portland cement with electrofilter ash. The addition of micro-reinforcement and superplasticizer to these mixes aimed to determine the impact of these additives on the alteration of physical, mechanical, workability, and other properties.

The experiments were carried out in the accredited Laboratory for Materials and Structures at the Faculty of Civil Engineering in Belgrade.

2.1. Experimental Research Program

While planning the experimental phase of the research, the initial assumption was made that the optimal composition of the cement screed could be defined through the analysis of component materials. Additionally, it was assumed that the optimal amount of micro-reinforcement directly influences the deformation properties of the cement screed.

The composition of mortar mixes was designed based on the following initial conditions:

- Constant ratio of binder to aggregate to avoid negative effects on certain physical–mechanical properties of the mortar;

- Consistency of cement screeds that should correspond to the description “moist as soil”, leading to an assumed water–cement ratio of 0.38;

- Assumed density of freshly installed mortar;

- Addition of micro-reinforcement in the amount of 1.0 kg/m3;

- Use of electrofilter ash as a substitute for cement in the amount of 20%;

- Addition of plasticizer at a ratio of 1% by weight of cement.

Testing of mortar-mix samples was conducted using prismatic samples of dimensions 4 × 4 × 16 cm. The following properties were analyzed within the research:

Fresh concrete

- Consistency;

- Density.

Hardened concrete

- Compressive strength;

- Flexural strength;

- Dynamic modulus of elasticity;

- Shrinkage.

All series of mortar mixtures were made with the same type of cement, the same type and particle size distribution of aggregates, and potable water. The following materials were used for the preparation of the mentioned composites:

- CEM I 42.5 R (Lafarge Beočin Cement Factory, 21300 Beočin, Serbia);

- Aggregate (“Moravac”, fraction 0/4 mm, river Morava, Serbia);

- Fly ash (Kolubara Thermal Power Plant, 11563 Veliki Crnjani, Serbia);

- Polypropylene fibers (type: monofilament, wavy fibers, length 12 mm, Sika Srbija, 22310 Šimanovci, Serbia);

- Plasticizer (“Sika Estriplast”, Sika Srbija, 22310 Šimanovci, Serbia).

For the purposes of experimental research, according to the research program, the preparation and testing of the properties of two different types of mortar mixes for cement composites is foreseen. The groups are marked as follows:

- A—mortar mixture with ordinary Portland cement as the binder;

- B—mortar mixture with electrofilter ash as a partial replacement for cement and superplasticizer in its composition.

Individual types of mortar compositions are labeled with Roman numerals I and II, each number representing the designation of the mortar series within groups A and B:

- A-I series—standard cement mixture;

- A-II series—cement mixture with the addition of microfibers;

- B-I series—cement mixture with electrofilter ash and superplasticizer;

- B-II series—cement mixture with electrofilter ash, superplasticizer, and the addition of microfibers.

2.2. Component Materials and Method

Examinations of fundamental physical and mechanical characteristics of component materials have been conducted for the purpose of designing and understanding the effects each of them may have on the properties of mortar cement composites.

2.2.1. Cement

The type of cement used for mortar preparation is ordinary Portland cement of grade 42.5 CEM I 42.5R (Lafarge Beočin Cement Factory). Table 1 shows the physical and mechanical test results carried out on the cement.

Table 1.

Properties of the cement used according to the manufacturer.

2.2.2. Aggregate

The river aggregate used in this research is natural sand, originating from the Morava River, with a fraction of 0/4 mm. The quarry from which the aggregate was extracted is ‘Bumbarius Elit’, located in Belgrade. The density of sand is 1627 kg/m3. The particle size distribution of the aggregate is provided in Table 2.

Table 2.

Particle size grading of the aggregate.

2.2.3. Mineral Additive

Fly ash originates from the Kolubara thermal power plant in Veliki Crnjani. Before being used in mortar, the ash is activated mechanically (by grinding) and then sieved through a screen with an opening of 0.9 mm. Chemical composition of electrostatic electrofilter ash is shown in Table 3.

Table 3.

Chemical composition of electrostatic electrofilter ash.

2.2.4. Polypropylene Fiber

Synthetic monofilament polypropylene fibers 12 mm in length, from the manufacturer Sika Fibers, Switzerland, were utilized for micro-reinforcement. Properties of synthetic fibers as per the manufacturer is provided in Table 4.

Table 4.

Properties of synthetic fibers as per the manufacturer.

3. Properties of the Tested Mortars

3.1. Mix Proportion Design

During the design of mortar compositions, a procedure based on the knowledge of the bulk density of freshly installed mortar is applied, utilizing the so-called mass–volume equation [15]:

where:

γm sv = mc + ma + mw

γm sv is density (kg/m3);

mc is the mass of cement (kg);

ma is the mass of aggregate (kg);

mw is the mass of water (kg).

The quantities of component materials of mortar were calculated approximately based on the assumed density, assumed water–cement ratio (0.38) and adopted mixing proportions of cement and aggregate (1:3). The assumed density of the mortar mixes for the A-II series-containing fibers is empirically set at 2200 kg/m3, while, for the A-I series, an adopted density of 2100 kg/m3 is assumed.

In the following table (Table 5) the adopted quantity of necessary material for making 1 m3 of mortar mixture for cement screeds is given.

Table 5.

Quantities of materials for 1 m3 of the mortar mixtures.

Mortar mixtures were prepared in a counter-current laboratory concrete mixer with a vertical axis, with an effective mixing capacity of 60 L (see Figure 1).

Figure 1.

The procedure for testing consistency.

After dry mixing the measured quantities of cement and sand for 30 s, fibers are added and mixing continues for another 30 s. Water was carefully added until achieving a satisfactory consistency, described as “moist as earth”, for the next 30 s. The mixing duration for the mortar components was extended by 3 min (180 s) compared to the standard mixes, resulting in a total of 4.5 min for the micro-reinforced mixes. This was done to ensure a more uniform dispersion of fibers within the cement matrix. Samples were then incorporated into prescribed three-part molds with dimensions of 4 × 4 × 16 cm (Figure 2).

Figure 2.

Embedding cement mortar.

3.2. Consistency

In laboratory conditions, the consistency of cement mortar is determined in accordance with the procedure described in the standard SRPS EN 1015-11:2019 [16], as depicted in Figure 1. The calculation of the Vebe degree is done according to the following formula:

where:

N = (V1/V0) × t

- V0 is volume before vibration (V0 = 5.5 L);

- V1 is volume after vibration;

- t is vibration time in seconds.

The results of the consistency testing of mortar mixtures using the VEBE method are presented for each series of mortar mixtures in the following tables.

3.3. Density

The density of fresh mortar mix was tested immediately after placement, in accordance with the standard SRPS ISO 6276 [17], by measuring the mass of samples that have the shape of a prism with dimensions of 4 × 4 × 16 cm, using the following formula:

where:

Mm,sv is the mass of embedded mortar;

Vm,sv is the volume of samples.

3.4. Compressive Strength

The compressive strength, being the most important mechanical characteristic of cement composites, was tested on prism-shaped samples with dimensions of 4 × 4 × 16 cm at the ages of 28 days, according to the SRPS EN 1015-11:2019 standard [18].

The compressive strength value (fp) is calculated based on the formula:

where:

Pgr is the breaking force (N);

A0 is the cross-sectional area (cm2).

The results of testing the mean values of compressive strength for each series of mortars are shown in tabular form.

3.5. Flexural Strength

The flexural strength test was carried out according to the SRPS EN 1015-11:2019 standard [18] on samples taken from each cement-mix series at 28 days old (Figure 3). The respective values were determined by calculating the arithmetic mean of the test results obtained from three samples, utilizing a recognized template for evaluating flexural strength when force is applied at the midpoint of the span:

where:

Figure 3.

Testing the flexural strength on samples.

- fzs—Flexural strength (MPa);

- Pgr—Breaking force (KN);

- a—Length of the side of the square (cross-sectional area of the sample) (m);

- l—Span length (m).

3.6. Dynamic Modulus of Elasticity (ED)

The dynamic modulus of elasticity (ED) of cement mortars was examined in terms of their deformation properties at the age of 28 days using the resonant-frequency method, following the procedure described in the SRPS EN 12390-13:2021 standard [19].

To determine the dynamic modulus of elasticity, resonant frequencies of longitudinal oscillations of samples were measured using the disposition depicted in Figure 4. The value was calculated using the following relation:

where:

Figure 4.

Disposition for testing the dynamic modulus of elasticity.

f is the measured resonant frequency in Hz (1/s);

l is the length of the prism in meters (mm);

γ is the density in kilograms per cubic meter (kg/m3).

The results of testing the dynamic modulus of elasticity, obtained as the arithmetic mean of testing the three samples, are presented in tabular form.

3.7. Shrinkage

Shrinkage represents the rheological deformation characterized by a decrease in the dimensions of mortar over time without the influence of external forces. It occurs approximately proportionally in all directions [20].

Testing of shrinkage deformations was conducted according to the SRPS B.C8.029 standard [21] on samples with special, non-corroding benchmarks (Figure 5).

Figure 5.

Shrinkage-deformation measurement comparator.

Based on the measured changes in the length of the measuring base, the shrinkage dilations were calculated using the formula:

where the symbols used represent:

εsk(t)—shrinkage dilation at the age of t days;

Δl(t)—change in length of the measuring base after t days;

l0—initial length of the measuring base, which is 16 cm;

s(3) and s(t)—readings on the measuring device after 3 days and after t days, respectively.

In the test report, the values are rounded to 0.01 mm/m and presented in tabular form. Individual results of the measurement of time deformations of shrinkage were obtained on samples of mortar mixtures over a period of 4 months. The mean values of the test results, at characteristic ages of the samples, are given in Table 6.

Table 6.

Shrinkage test results over a period of 4 months.

4. Results and Discussion

The experimental results of fresh and hardened mortar mixtures are displayed in tabular format (Table 7) alongside graphical representations. This presentation facilitates direct analysis and conclusion making.

Table 7.

Results of tested properties of cement composites.

In formulating mortar mixtures for cement screeds, established theoretical principles of concrete technology and the specific characteristics that define these composites were considered. Our approach was informed by the authors’ previous research, insights gleaned from the literature, and guidance provided by manufacturers.

4.1. Analysis of the Results of Testing Mortar in the Fresh State

The mortar of series A-I has the highest value of Vebe degrees (16.33), which represents the measure of consistency according to this method. According to SRPS EN standards, it belongs to class V2.

During the design of mortar-mixture compositions, it was assumed that in micro-reinforced composites of series (A-II) prepared with a small amount of fibers, there would be no change in the workability of fresh mixtures [22].

During the preparation of the mortar mixture of series A-II, it was observed that the mixture became more inert and stiff, leading to the use of additional water compared to the projected amount. As a result, the Vebe degrees value for the mortar mixture of series A-II is lower than the reference value and amounts to 11.87, which falls into the same class of stiff consistency V2.

Mortar mixtures for cement screeds of series B exhibit expectedly lower Vebe degree values (11.06; 10.02), as confirmed by research from numerous authors. Electrofilter fly ash in the cement paste contributes to increased plasticity and better cohesion [23], alters the behavior of cement-paste dispersion [24], reduces segregation and bleeding, and influences the reduction of hydration heat.

The plasticizer used in preparing mortar mixtures of series B, creates a thin coating around the cement particles and electrofilter ash, resulting in a notable reduction of friction within the mixture. As a result, the viscosity of series B mortar mixtures is lower than that of series A.

The values of densities of fresh mortar mixtures are a reliable indicator of the characteristics of the hardened composite. Increasing density results in more compact mortars with better physical and mechanical properties.

The results of testing densities in the fresh state indicate that the addition of polypropylene fibers in the mixtures does not significantly affect the change in values. Similarly, it can be observed that mortar-mixture samples containing 20% electrofilter ash have densities lower by 5 to 10%, which is expected considering that the specific gravity of electrofilter ash (2190 kg/m3) is significantly lower than that of cement (3100 kg/m3).

4.2. Analysis of the Results of Testing Mortar in the Hard State

4.2.1. Flexural and Compressive Strength

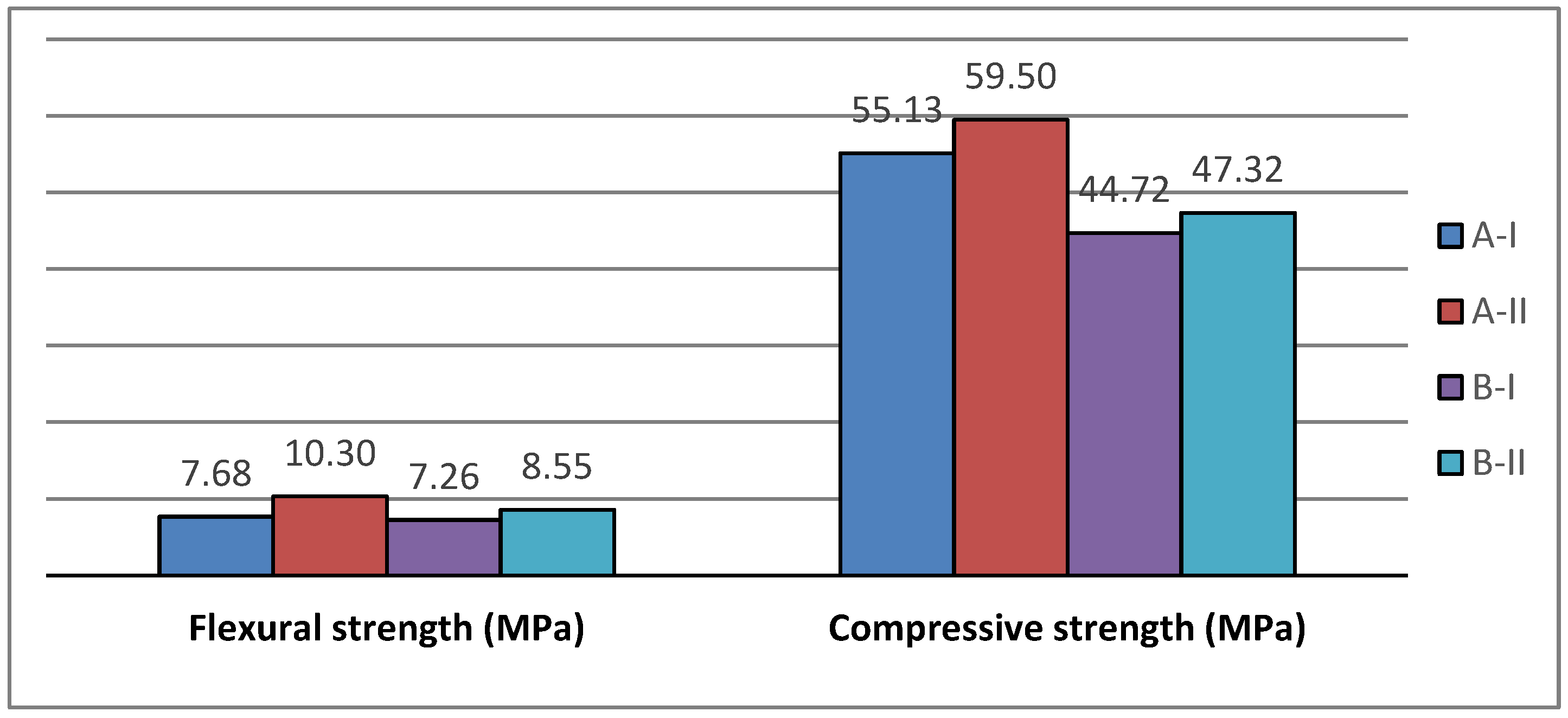

On standard specimens of prism shape, dimensions 4 × 4 × 16 mm, obtained values of flexural strength and compressive strength at the age of 28 days are depicted in Figure 6.

Figure 6.

Flexural and compressive strength of samples aged 28 days.

From the results of the flexural strength tests on samples at the age of 28 days, it can be observed that:

- The use of polypropylene fibers leads to an increase in the flexural strength values in series A-II (34.1%) compared to A-I, which can be explained by the fact that better adhesion with the fibers is achieved within the mortar matrix, resulting in improved resistance to bending;

- The application of fibers results in an increase in flexural strength values (17.77%) in series containing electrofilter ash B-II compared to B-I, although this difference is less prominent in these series;

- The flexural strength values of series B-I and series A-I differ by 5.78%. The addition of fly ash does not significantly affect the reduction in flexural strength values, which is in line with studies conducted by other authors [25].

Based on the test results of compressive strength at the age of 28 days and by comparing the recorded values, it was observed that:

- The series of mortar mixtures for cement grouts containing electrofilter ash B-I and B-II record a decrease in compressive strength of 23.28% and 25.74%, respectively, compared to series A-I and A-II that do not contain electrofilter ash as a partial replacement for cement;

- The application of polypropylene fibers causes an increase in compressive strength values for series A-II (7.93%) and series B-II (5.81%) compared to the series A-I and B-I;

- Mortar mixtures containing micro-reinforcement (series A-II and B-II) exhibit higher strengths compared to the standard (A-I and B-I) by approximately 10%, which is consistent with studies by other authors [26];

- By replacing cement with electrofilter ash in the amount of 20%, along with the addition of polypropylene fibers, the compressive strength obtained is lower by 14.17% compared to traditionally prepared mortar mixture for cement grouts, represented by series A-I.

4.2.2. Dynamic Modulus of Elasticity

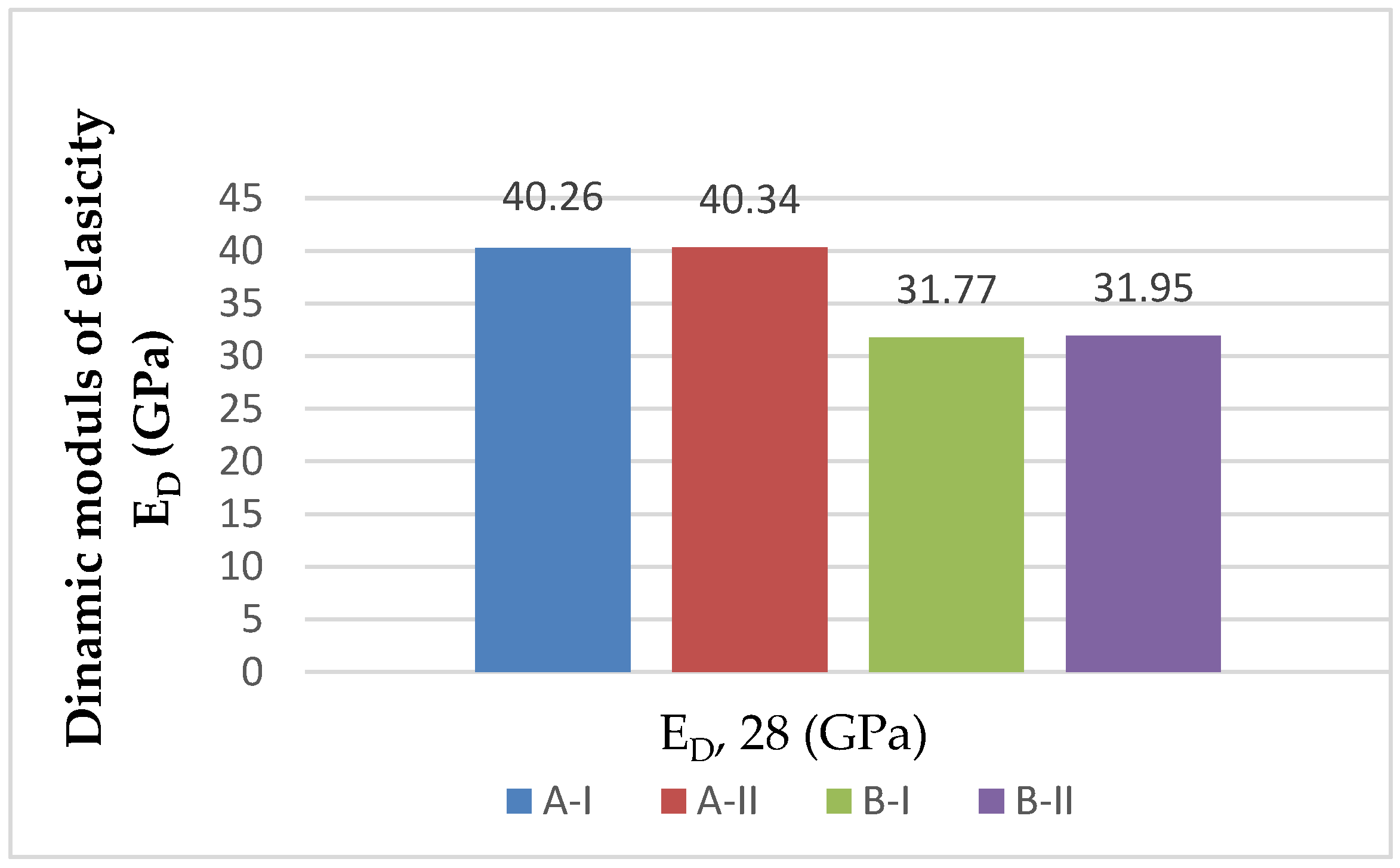

The results of the testing of the dynamic modulus of elasticity ED, at the age of 28 days, are shown in Figure 7.

Figure 7.

Dynamic modulus of elasticity (ED) of samples aged 28 days.

Based on the presented diagram, the following conclusions can be drawn:

- The results of testing the dynamic modulus of elasticity of treated mortar mixtures at the age of 28 days show that series containing electrofilter ash have a lower dynamic modulus of elasticity by 26.72% and 26.26%, respectively. This is in line with claims made by other authors that electrofilter ash has a pronounced impact on reducing the values of the modulus of elasticity [27];

- The addition of synthetic fibers in the series has a minimal impact on the change in the dynamic modulus of elasticity. In both series A and B, samples containing fibers exhibit only a slight increase in the dynamic modulus (the largest percentage difference being 0.5%), which can be primarily explained by the low percentage participation of microreinforcement within the cement matrix.

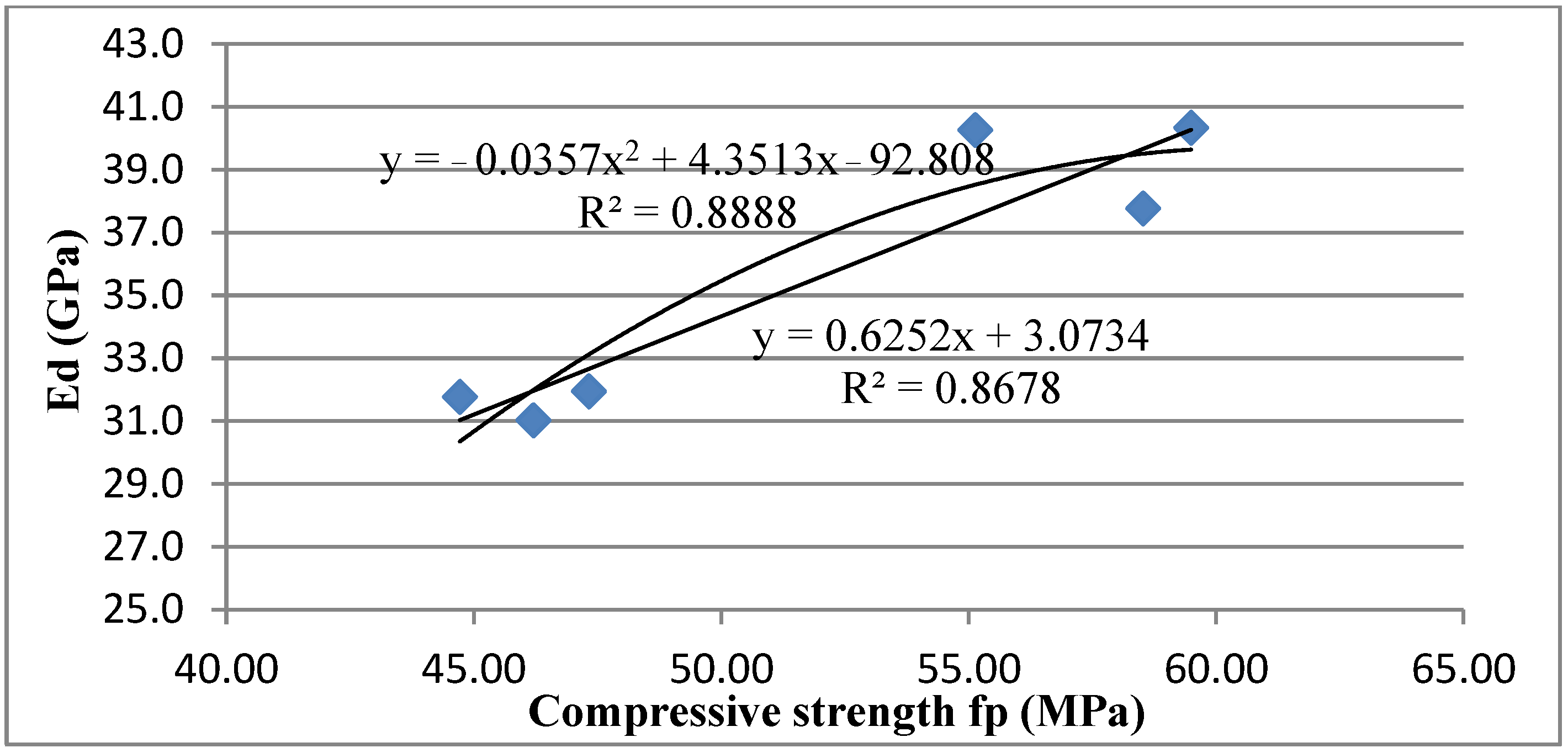

Taking into account the displayed values of the tested dynamic modulus of elasticity (ED) and compressive strength (fp), from the following diagram (Figure 8), it can be concluded that there is a good correlation between these parameters in both the quadratic parabolic functional dependency, with a correlation coefficient of r2 = 0.8888, and in the linear dependency, where r2 = 0.8678.

Figure 8.

Functional dependence between the dynamic modulus of elasticity and compressive strength at the age of 28 days.

4.2.3. Shrinkage

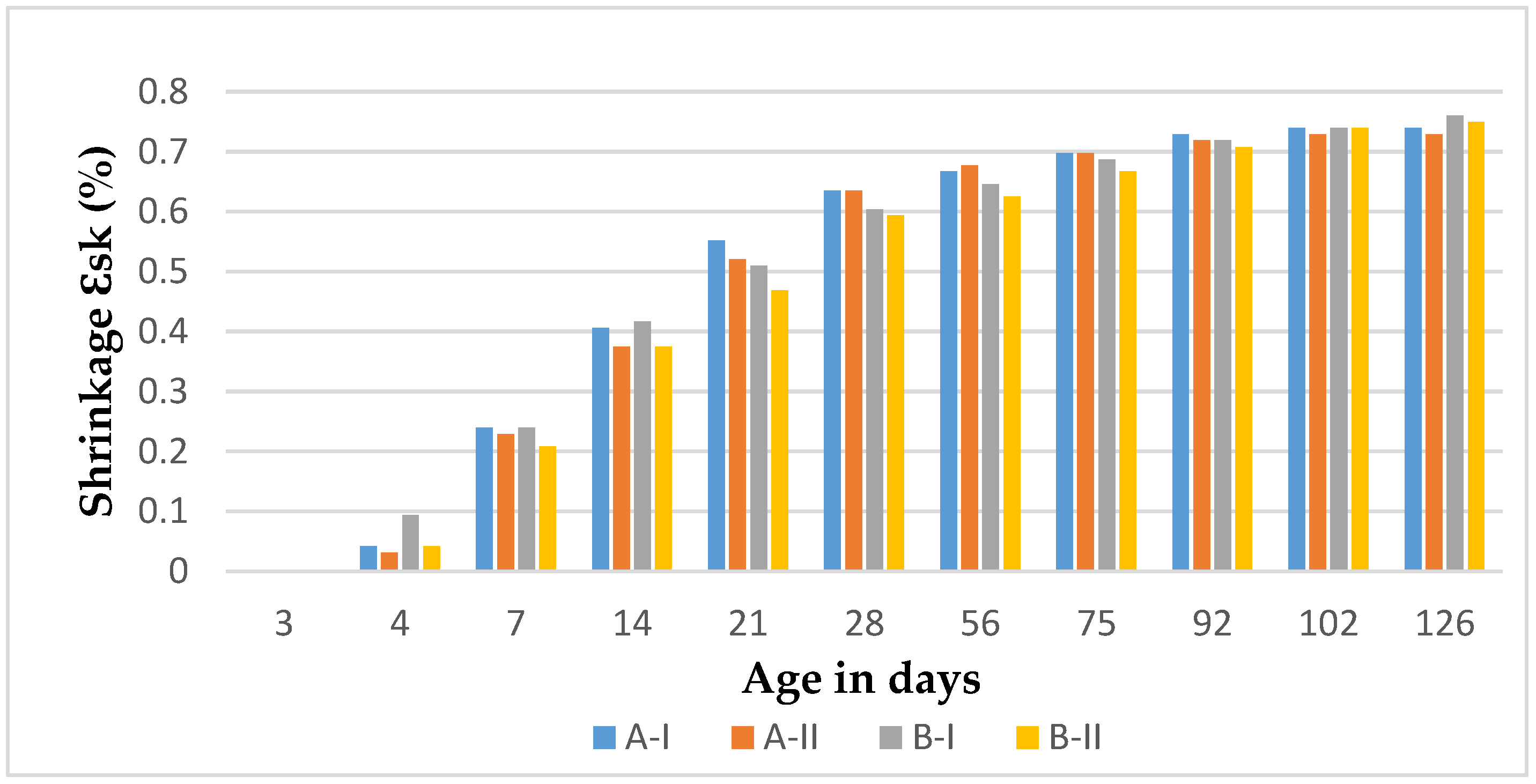

The results of the total shrinkage of all tested mortar composites as a function of time are shown in the form of a diagram (Figure 9).

Figure 9.

Shrinkage Ɛsk (‰) over a period of 4 months.

The results of the A-II series testing, which contains micro-reinforcement, show a reduction in shrinkage of only 1.5% on the 126th day of testing, while in earlier phases (on the 4th day), shrinkage dilations are 26.2% less compared to the standard. This can be explained by the fact that synthetic fibers are highly effective in the early period, while their modulus of elasticity is lower than that of the mortar, resulting in reduced crack formation and prolonged shrinkage in the later period when strength is higher.

Samples from series B, which contain fly ash, exhibit greater shrinkage compared to samples from series A made with ordinary Portland cement, confirming findings from other authors [28].

The difference in shrinkage in the early stages is more pronounced in samples from the B series that contain fibers. On the fourth day of testing, the shrinkage dilations of samples from the B-II series are 55.32% lower compared to samples from the B-I series, while on the 126th day, when the test results have stabilized, the shrinkage is proportionally 1.32% lower, similar to the A series samples.

Plastic shrinkage usually occurs within the initial few hours after the mortar is applied, and its adverse effects can be mitigated through proper and timely maintenance of the fresh mortar. Considering that samples embedded in molds are kept in a humid space (H > 90%) during the first 24 h after application, followed by an additional 48 h in water (T = 20 ± 2 °C), this method mainly eliminates the influence of plastic shrinkage.

5. Conclusions

To ensure that designers and contractors can correctly choose, apply, and install materials for cement screeds, it is essential to realistically assess the properties of the components, their relationships, manufacturing techniques, maintenance methods, and other influences according to the role that the cement screed plays within the complex system of the structure.

The physical–mechanical, deformational, and rheological characteristics of cement screeds can vary significantly based on the mixing proportions of components, the amount of water used, the presence of additives, the level of compaction of the material after solidification, manufacturing techniques, and maintenance practices. Thus, careful consideration and incorporation of all these factors are crucial when selecting and applying screed materials.

By analyzing the test results of mortar mixtures, conclusions were drawn that the optimal amount of micro-reinforcement in mortar mixtures for cement screed has a direct impact on increasing compressive strength and tensile strength, as well as reducing time-dependent deformations due to shrinkage, which is a prerequisite for their quality and durability.

For the use of electrofilter ash, which represents industrial waste material, as a partial replacement for cement in mortar mixtures for cement screeds, the research shows that the physical–mechanical and deformation properties of fly-ash-based composites are acceptable for higher loads that cement screeds endure compared to mortar for other purposes. The advantages of using fly ash include lower stiffness, increased plasticity, and better workability. Additionally, if microfibers are added to the mortar with a 20% ash replacement, the strength decreases by approximately 16% compared to the sample without fibers, where the strength decreases by 23%, resulting in reduced crack formation and prolonged shrinkage in the later period when strength is higher.

Author Contributions

Conceptualization, R.R.; methodology, R.R.; investigation, R.R.; writing—original draft preparation, R.R., L.M. and V.R.; writing—review and editing, K.B.T. and N.G.; visualization, N.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study is a part of the research in the doctoral thesis “Parametric Analysis of the Properties of Cement Screed When Applying Fabre Reinforcement and Shrinkage-Reducing Admixture” with UDC 693.554-033.2:692.533(043.3).

Acknowledgments

This paper is a part of the research UDK. 693.554-033.2:692.533(043.3).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Radulović, R.; Muravljov, M.; Denisenko, I. Quality of a cement screed prepared and applied in a traditional way. Build. Mater. Struct. 2010, 53, 52–60. [Google Scholar]

- Radulović, R.; Jevtić, D.; Radonjanin, V. The properties of the cement screeds with the addition of Polypropylene fibres and the shrinkage-reducing admixture. Build. Mater. Struct. 2016, 59, 17–35. [Google Scholar] [CrossRef]

- Alani, J.; MacMullen, J.; Telik, O.; Zhang, Z. Investigation into the thermal performance of recycled glass screed for construction purposes. Constr. Build. Mater. 2012, 29, 527–532. [Google Scholar] [CrossRef]

- Moreira, A.; Antonio, J.; Tadeu, A. Lightweight screed contaning cork granules. Cem. Concr. Compos. 2014, 49, 1–8. [Google Scholar] [CrossRef]

- Boehme, L.; Novakova, I.; Hubacek, A. Assessment of fine recycled concret aggregate in cement-based flowscreed. In Low-Tech and High-Tech Materials and Technologies for Sustainable Buildings, Proceeding of Conference “Central Europe towards Sustinable Building 2013”: Sustainable Building and Refurbishment for Next Generations; Faculty of Mechanical Engineering Czech Technical University in Prague: Prague, Czech Republic, 2013; pp. 1–10. Available online: https://www.cesb.cz/cesb13/proceedings/3_materials/CESB13_1131.pdf (accessed on 18 March 2024).

- Zobal, O.; Holčapek, O.; Reiterman, P. Frost Resistance of Concrete Screed with the Fly Ash Addition. Key Eng. Mater. 2016, 677, 80–85. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Feasibility of Non-Remanufactured Waste Bottle Glass as Supplementary Cementitious Material. Appl. Sci. 2024, 14, 2004. [Google Scholar] [CrossRef]

- Radulović, R.; Marković, L.; Miletić, M.; Marković, L.; Radojičić, V.; Elezović, N. Sustainability aspect of possible material substitution in construction industry. Therm. Sci. 2023, 27, 4961–4973. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterisation, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Ajayi, B.L.; Babafemi, A.J. Effects of Waste Plastic and Glass Aggregates on the Strength Properties of Ambient-Cured One-Part Metakaolin-Based Geopolymer Concrete. Appl. Sci. 2024, 14, 1856. [Google Scholar] [CrossRef]

- Tawfik, M.; El-said, A.; Deifalla, A.; Awad, A. Mechanical Properties of Hybrid Steel-Polypropylene Fiber Reinforced High Strength Concrete Exposed to Various Temperatures. Fibers 2022, 10, 53. [Google Scholar] [CrossRef]

- Acosta-Calderon, S.; Gordillo-Silva, P.; García-Troncoso, N.; Bompa, D.V.; Flores-Rada, J. Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties. Fibers 2022, 10, 31. [Google Scholar] [CrossRef]

- Monazami, M.; Gupta, R. Influence of Polypropylene, Carbon and Hybrid Coated Fiber on the Interfacial Microstructure Development of Cementitious Composites. Fibers 2021, 9, 65. [Google Scholar] [CrossRef]

- Signorini, C.; Volpini, V. Mechanical Performance of Fiber Reinforced Cement Composites Including Fully-Recycled Plastic Fibers. Fibers 2021, 9, 16. [Google Scholar] [CrossRef]

- Muravljov, M. Osnovi Teorije i Tehnologije Betona; Građevinska knjiga: Beograd, Serbia, 2010; ISBN 978-86-395-0614-8. [Google Scholar]

- SRPS EN 12350-3:2019; Testing Fresh Concrete—Part 3: Vebe Test. Institute for Standardization of Serbia: Beograd, Serbia, 2019.

- SRPS ISO 6276; Concrete, Compacted Fresh—Determination of Density. Institute for Standardization of Serbia: Beograd, Serbia, 1997.

- SRPS EN 1015-11:2019; Methods of Test for Mortar for Masonary—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Institute for Standardization of Serbia: Beograd, Serbia, 2019.

- SRPS EN 12390-13:2021; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. Institute for Standardization of Serbia: Beograd, Serbia, 2021.

- Šahinagić-Isović, M.; Markovski, G.; Ćećez, M. Deformacije skupljanja betona-uzroci i vrste. Građevinar 2012, 64, 727–734. [Google Scholar]

- SRPS B.C8.029:1979; Cements—Dry Shrinkage of Cement Mortars. Institute for Standardization of Serbia: Beograd, Serbia, 2020.

- Jevtić, D.; Zakić, D. Fiber reinforcement mortars and concretes: The possibilities of improvement physical—Mechanical properties. Constr. Build. Mater. 2006, 49, 35–44. [Google Scholar]

- Lane, R.O. Effects of Fly Ash on Freshly Mixed Concrete. Concr. Int. Des. Constr. 1983, 5, 50–52. [Google Scholar]

- Rudzinski, L. Effect of Fly Ashes on the Rheological Behavior of Cement Pasts. Mater. Struct. Res. Test. 1984, 17, 369–373. [Google Scholar]

- Despotović, I.; Ristić, N.; Grdić, Z.; Topličić-Ćurčić, G. Mogućnost Primene Elektrofilterskog Pepela i Recikliranog Agregata u Samougrađujućem betonu kao Značajan Doprinos Ekološkom Graditeljstvu; Građevinski Materijali u Savremenom Graditeljstvu: Beograd, Serbia, 2015. [Google Scholar]

- Jevtić, D.; Zakić, D. Uticaj vrste i količine polipropilenskih vlakana na mehanička svojstva kompozita tipa maltera i betona. Savez Inženjera Metal. Jugosl. 2002, 39–50. [Google Scholar]

- Radonjanin, V.; Malešev, M.; Marinković, S. Mogićnost primene starog betona kao nove vrste agregata u savremenom građevinarstvu. Zaštita Mater. 2010, 51, 178–188. [Google Scholar]

- Chindaprasirt, P.; Homwuttiwong, V.; Sirivivatnanon, V. Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar. Cem. Concr. Res. 2003, 34, 1087–1092. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).