Processing, Quality and Elemental Safety of Fish

Abstract

:1. Introduction

2. The Fish Generalities

3. Fish Production

4. Food and Fish Safety

Microbiology and Safety of Fish

5. Control and Prevention of Diseases Transmitted by Fish Consumption

6. Post-Mortem in Fish

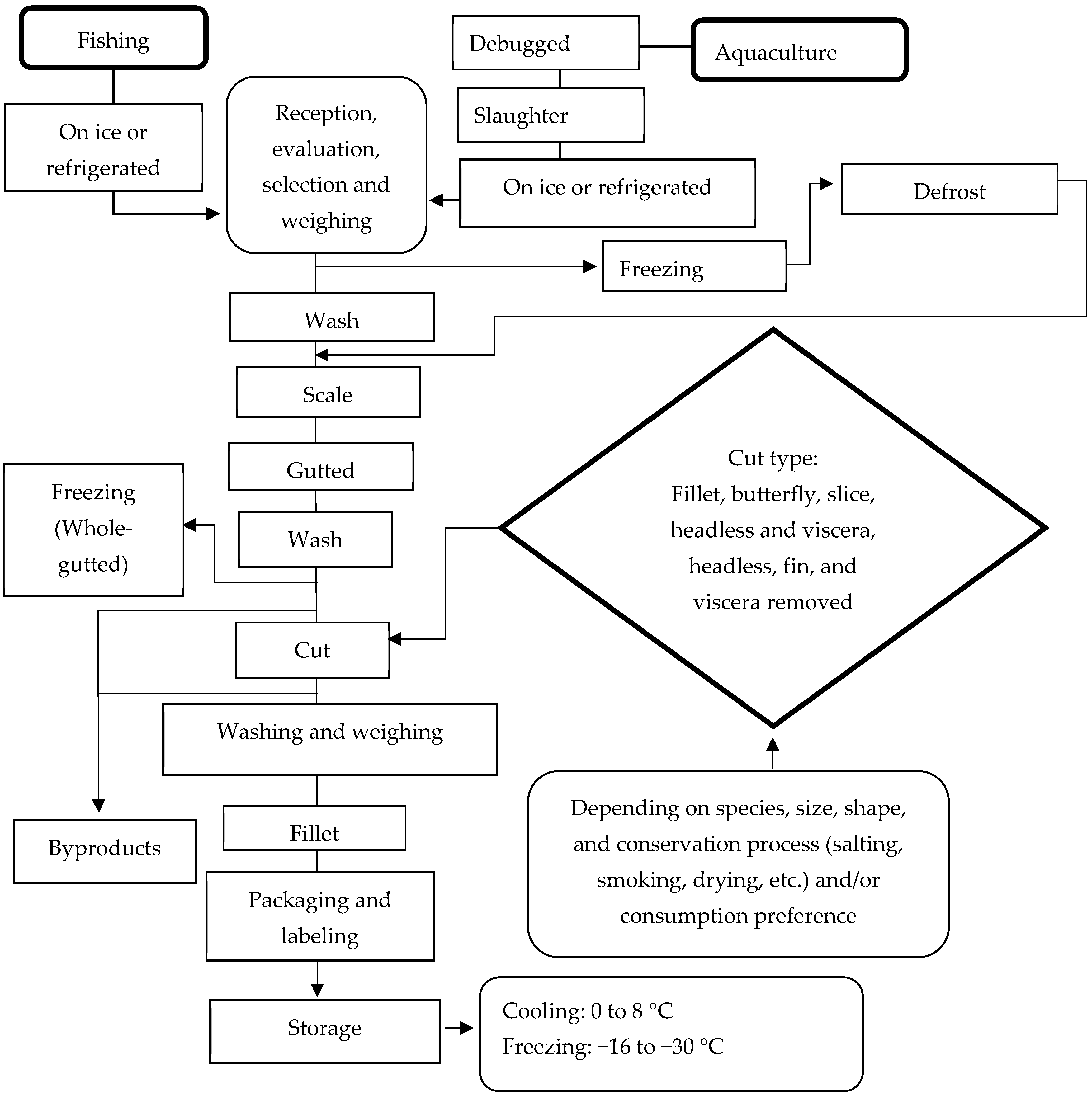

7. Fish Processing and Preservation

- Chilled

- Refrigeration

- Freezing

- Cooking

- Canned

- Drying

- Salting

- Smoked

- Pickled

- Vacuum packaging and modified atmospheres

- Fermented

- Other alternative preservation methods

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Paiva Soares, K.M.; Gonçalves, A.A. Qualidade e segurança do pescado. Rev. Do Inst. Adolfo Lutz 2012, 71, 1–10. Available online: https://periodicos.saude.sp.gov.br/RIAL/article/download/32384/31215 (accessed on 2 February 2024). [CrossRef]

- Rodrigo Valenzuela, B.; Gladys Morales, I.; Marcela González, A.; Jessica Morales, P.; Julio Sanhueza, C.; Valenzuela, B.A. N-3 long chain polyunsaturated fatty acids and cardiovascular disease. Rev. Chil. De Nutr. 2014, 41, 319–327. [Google Scholar] [CrossRef]

- Restrepo-Betancurt Luis, F.; Rodríguez-Espinosa, H.; Valencia, Y.D. Characterization of fish and seafood consumption in university population from the city of Medellin—Colombia. Univ. Y Salud 2016, 18, 257–265. Available online: http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0124-71072016000200007&lng=en&tlng=es (accessed on 7 January 2024).

- FAO. The State of World Fisheries and Aquaculture 2022. Towards Blue Transformation; Food and Agriculture Organization (FAO): Rome, Italy, 2022. [Google Scholar] [CrossRef]

- Palomino-Camargo, C.; González-Muñoz, Y.; Pérez-Sira, E.; Aguilar, V.H. Delphi methodology in food safety management and foodborne disease prevention. Rev. Peru. De Med. Exp. Y Salud Pública 2018, 35, 483–490. [Google Scholar] [CrossRef]

- Fuente Salcido, N.M.D.L.; Barboza Corona, J.E. Inocuidad y bioconservación de alimentos. Acta Univ. 2010, 20, 43–52. Available online: https://www.redalyc.org/articulo.oa?id=41613084005 (accessed on 9 January 2024). [CrossRef]

- Vásquez Ampuero, J.M.; Tasayco Alcántara, W.R.; Chuquiyauri Talenas, M.Á.; Apac Sotil, S. Microbiological evaluation of fish and seafood available in Huánuco’s markets. Investig. Valdizana 2018, 12, 75–82. [Google Scholar] [CrossRef]

- Huss, H.H. Quality and quality changes in fresh fish. In FAO Fisheries Technical Paper—348; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 1995; ISBN 92-5-103507-5. Available online: https://www.fao.org/3/V7180E/V7180E00.htm (accessed on 19 January 2024).

- Balbuena, R.E.D. Manual Básico sobre Procesamiento e Inocuidad de Productos de la Acuicultura. Ministerios de Agricultura y Ganaderia, Republica de Paraguay; Organización para las Naciones Unidas para la Alimentación y la Agricultura (FAO): Roma, Italy, 2014; Available online: https://www.fao.org/3/i3835s/i3835s.pdf (accessed on 20 January 2024).

- Márquez Figueroa, Y.V.; Mercedes Cabello, A.; Villalobos Luz, B.; Guevara, G.; Figuera García, B.E.; Vallenilla González, O.M. Physico-chemical and microbiological changes observed during the technological process of tuna canning. Zootec. Trop. 2006, 24, 17–29. Available online: http://ve.scielo.org/scielo.php?script=sci_arttext&pid=S0798-72692006000100002&lng=es&tlng=es (accessed on 28 December 2023).

- Rodríguez Melis, A. Aplicación de Nuevas Tecnologías en la Conservación y Comercialización de Salmón Coho (“Oncorhynchus kisutch”): Efecto Sobre la Calidad y el Valor Agregado. Ph.D. Thesis, Universidad de Santiago de Compostela, Santiago de Compostela, Spain, 2015. Available online: https://digital.csic.es/bitstream/10261/129595/1/Tesis_Alicia_Rodr%C3%ADguez.pdf (accessed on 20 December 2023).

- Castellanos Ferreiro, R. Los cambios fisicoquímicos del pescado durante su preparación. Hospitalidad-Esdai 2015, 28, 25–40. Available online: https://scripta.up.edu.mx/server/api/core/bitstreams/745de096-0a95-4995-89ab-990d5a5bde16/content (accessed on 19 December 2023).

- Castro González, M.I.; Maafs Rodríguez Ana, G.; Galindo Gómez, C. Fatty acids in different edible fish species from Mexico. Rev. De Biol. Trop. 2013, 61, 1981–1998. Available online: http://www.scielo.sa.cr/scielo.php?script=sci_arttext&pid=S0034-77442013000500032&lng=en&tlng=es (accessed on 10 December 2023).

- CONAPESCA. Anuario Estadístico de Acuacultura y Pesca de la Comisión Nacional de Acuacultura y Pesca 2021. Comisión Nacional de Acuicultura y Pesca. Gobierno de México. 2021. Available online: https://nube.conapesca.gob.mx/sites/cona/dgppe/2021/ANUARIO_ESTADISTICO_DE_ACUACULTURA_Y_PESCA_2021.pdf (accessed on 10 December 2023).

- Cárdenas Bonilla, A.; Noriega Orozco, L. Manual de Buenas Prácticas de Manufactura en el Procesamiento Primario de Productos Acuícolas. Centro de Investigación en Alimentación y Desarrollo, A.C. Unidad Guaymas en Aseguramiento de Calidad y Aprovechamiento Sustentable de Recursos Naturales y el Servicio Nacional de Sanidad, Inocuidad y Calidad Agroalimentaria, SAGARPA, 1ra Edición. 2003. Available online: http://publico.senasica.gob.mx/includes/asp/download.asp?IdDocumento=21457&IdUrl=39673&objeto=Documento&IdObjetoBase=21457&down=true (accessed on 2 December 2023).

- Soto Varela, Z.; Pérez Lavalle, L.; Estrada Alvarado, D. Bacteria causing of foodborne diseases: An overview at colombia. Rev. Salud Uninorte 2016, 32, 105–122. [Google Scholar] [CrossRef]

- Avdalov, N. Manual de Calidad y Procesamiento para Venta Minorista de Pescado. Proyecto: “Mejoramiento de los Mercados Internos de Productos Pesqueros en América Latina y el Caribe”. Centro para los Servicios de Información y Asesoramiento sobre la Comercialización de los Productos Pesqueros de América Latina y el Caribe. INFOPESCA. 2010. Available online: https://www.infopesca.org/sites/default/files/complemento/publilibreacceso/971//Manual%20operarios.pdf (accessed on 19 December 2023).

- Sheng, L.; Wang, L. The microbial safety of fish and fish products: Recent advances in understanding its significance, contamination sources, and control strategies. Compr. Rev. Food Sci. Food Saf. 2021, 20, 738–786. [Google Scholar] [CrossRef]

- Gauthier, D.T. Bacterial zoonoses of fishes: A review and appraisal of evidence for linkages between fish and human infections. Vet. J. 2015, 203, 27–35. [Google Scholar] [CrossRef]

- Novotny, L.; Dvorska, L.; Lorencova, A.; Beran, V.; Pavlik, I. Fish: A potential source of bacterial pathogens for human beings. Vet. Med. 2004, 49, 343–358. [Google Scholar] [CrossRef]

- Bertullo, E.; Pollak, A. Análisis de Peligros y Evaluación de Riesgos en Productos Pesqueros Sensíbles Comercializados en el Uruguay. Instituto de Investigaciones Pesqueras y Universidad de la República. 2006. Available online: https://aquadocs.org/bitstream/handle/1834/1580/7moSMVU.pdf?sequence=1 (accessed on 5 December 2023).

- Puig Peña, Y.; Leyva Castillo, V.; Álvarez Almanza, D. Parásitos de transmisión alimentaria en Cuba: Una revisión de la literatura. Rev. Cuba. De Aliment. Y Nutr. 2013, 23, 130–138. Available online: https://www.medigraphic.com/pdfs/revcubalnut/can-2013/can131j.pdf (accessed on 15 December 2023).

- Lima dos Santos, C.A. Enfermedades transmitidas por pescado¿ Que pasa en el sur. Infopesca Int. 2012, 51, 11–15. Available online: https://www.infopesca.org/sites/default/files/complemento/articulossel/51/N%C2%BA%2051%20Enfermedades%20transmitidas.pdf (accessed on 12 January 2024).

- FDA. Foodborne Pathogens Resources for Medical Professionals—Food Safety for Moms to Be. U.S. Food and Drug Administration. (FDA). Government USA. 2018. Available online: https://www.fda.gov/food/people-risk-foodborne-illness/foodborne-pathogens-resources-medical-professionals-food-safety-moms-be (accessed on 5 December 2023).

- Sorsa, M.; Mamo, G.; Abera, L. Major fish-borne bacterial and parasitic zoonoses in Ethiopia: A review. Int. J. Fauna Biol. Stud. 2019, 6, 50–58. Available online: https://www.faunajournal.com/archives/2019/vol6issue4/PartA/6-4-5-199.pdf (accessed on 10 December 2023).

- Cortés-Sánchez, A.D.J.; Salgado-Cruz, M.d.l.P.; Diaz-Ramírez, M.; Torres-Ochoa, E.; Espinosa-Chaurand, L.D. A Review on Food Safety: The Case of Citrobacter sp., Fish and Fish Products. Appl. Sci. 2023, 13, 6907. [Google Scholar] [CrossRef]

- Kobuszewska, A.; Wysok, B. Fish as a source of foodborne bacteria. Medycyna Weterynaryjna-Veterinary Med.-Sci. Pract. 2023, 79, 117–122. [Google Scholar] [CrossRef]

- Florez Duque, A.V.; Moreno Arango, M.A.; Franco Tobón, Y.N. Aminas Biógenas encontradas en carnes, pescado y productos cárnicos: Formación y efectos en la salud. Hechos Microbiológicos 2023, 14, 26–44. [Google Scholar] [CrossRef]

- Alerte, V.; Sandra Cortés, A.; Janepsy Díaz, T.; Jeannette Vollaire, Z.; Eugenia M., E.M.; Verónica Solari, G.; Jaime Cerda, L.; Marisa Torres, H. Foodborne disease outbreaks around the urban Chilean areas from 2005 to 2010. Rev. Chil. De Infectología 2012, 29, 26–31. [Google Scholar] [CrossRef]

- Espinosa, L.; Varela, C.; Martínez, E.V.; Cano-Portero, R. Brotes de enfermedades transmitidas por alimentos. España, 2008–2011 (excluye brotes hídricos). Boletín Epidemiológico Sem. 2014, 22, 130–145. Available online: https://revista.isciii.es/index.php/bes/issue/view/195/147 (accessed on 12 January 2024).

- Chong, A.; Peñuelas, M.; Guerrero, M.; Cabezas, C.; Díaz, O.; Martín, C.; Varela, C. Brotes de transmisión alimentaria. Red Nacional de Vigilancia Epidemiológica. 2012–2020. Boletín Epidemiológico Sem. 2021, 29, 53–63. Available online: https://revista.isciii.es/index.php/bes/article/download/1157/1520 (accessed on 14 January 2024).

- Friesema Ingrid, H.M.; Slegers-Fitz-James, I.A.; Wit, B.; Franz, E. Surveillance and characteristics of food-borne outbreaks in the Netherlands, 2006 to 2019. EuroSurveillance 2022, 27, 1–10. [Google Scholar] [CrossRef]

- EFSA Panel on Biological Hazards (BIOHAZ); Koutsoumanis, K.; Allende, A.; Bolton, D.; Bover-Cid, S.; Chemaly, M.; De Cesare, A.; Herman, L.; Hilbert, F.; Lindqvist, R.; et al. Persistence of microbiological hazards in food and feed production and processing environments. EFSA J. 2024, 22, e8521. [Google Scholar] [CrossRef]

- Romero-Jarero, J.M.; Negrete-Redondo, M.D.P. Presence of Gram negative bacteria in fish muscle of commercial importance in the Mexican Caribbean zone. Rev. Mex. De Biodivers. 2011, 82, 599–606. Available online: https://www.scielo.org.mx/scielo.php?pid=S1870-34532011000200019&script=sci_abstract&tlng=pt (accessed on 20 November 2023).

- Huss, H.H.; Ababouch, L.; Gram, L. Assessment and Management of Seafood Safety and Quality. In FAO Fisheries Technical Paper 444; Food and Agriculture Organization of the United Nations: Rome, Italy, 2003; ISBN 92-5-104954-8. Available online: https://www.fao.org/3/y4743e/y4743e00.htm#Contents (accessed on 25 November 2023).

- Speranza, B.; Racioppo, A.; Bevilacqua, A.; Buzzo, V.; Marigliano, P.; Mocerino, E.; Scognamiglio, R.; Corbo, M.R.; Scognamiglio, G.; Sinigaglia, M. Innovative Preservation Methods Improving the Quality and Safety of Fish Products: Beneficial Effects and Limits. Foods 2021, 10, 2854. [Google Scholar] [CrossRef]

- Rodríguez Gómez, J.M. Consecuencias Higiénicas de la Alteración de los Alimentos. Monografías de la Real Academia Nacional de Farmacia. 2010. pp. 19–66. Available online: http://www.aeemt.com/contenidos_socios/Recursos/Documentos_interes/Consecuencia_Higienica_Alteracion_Alimentos_2012.pdf (accessed on 12 November 2023).

- Kopper, G.; Calderón, G.; Schneider, S.; Domínguez, W.; Gutiérrez, G.; Rosell, C.; Mejía, D. Enfermedades Transmitidas por Alimentos y su Impacto Socioeconómico. Informe de la Organización de las Naciones Unidas para la Agricultura y la Alimentación; FAO: Rome, Italy, 2009; Volume 6, pp. 1–194. Available online: http://www.proyectosame.com/brotes/Apoyo/Bibliograf%C3%ADa/26.%20Enfermedades%20transmitidas%20por%20alimentos.pdf (accessed on 25 January 2024).

- Fuertes Vicente, H.G.; Paredes López, F.; Saavedra Gálvez, D.I. Good Practice Manufacturing and Preservation Onboard: Fish safe. Big Bang Faustiniano. 2014. Available online: https://revistas.unjfsc.edu.pe/index.php/BIGBANG/article/view/234/233 (accessed on 1 February 2024).

- OMS-FAO. Cinco Claves para una Mayor Inocuidad de los Productos de Acuicultura con Objeto de Proteger la Salud Pública. Organización Mundial de la Salud (OMS); Organización de las Naciones Unidas para la Alimentación y la Agricultura (FAO): Rome, Italy, 2016; ISBN 978 92 4 351031 6. Available online: https://iris.who.int/bitstream/handle/10665/251672/9789243510316-spa.pdf?sequence=1 (accessed on 23 January 2024).

- WHO. Five Keys to Safer Food Manual; World Health Organization (WHO): Geneva, Switzerland, 2007; ISBN 9789241594639. Available online: https://iris.who.int/bitstream/handle/10665/43546/9789241594639_eng.pdf?sequence=1 (accessed on 9 February 2024).

- Avdalov, N. Manual para Empresas Elaboradoras de Filetes de Tilapia Frescos; CFC/FAO/INFOPESCA Organización de las Naciones Unidas para la Alimentación y la Agricultura (FAO): Rome, Italy, 1999; Available online: http://www.infopesca.org/sites/default/files/complemento/publilibreacceso/1276//NORMA%20FILETE%20-TIP%20DEF.pdf (accessed on 6 January 2024).

- CXC 1-1969. General Principles of Food Hygiene. World Health Organization. Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/es/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXC%2B1-1969%252FCXC_001s.pdf (accessed on 8 January 2024).

- Código de Prácticas para el Pescado y los Productos Pesqueros, 2nd ed.; Organización Mundial de la Salud (OMS): Geneva, Switzerland; Organización de las Naciones Unidas para la Agricultura y la Alimentación (FAO): Roma, Italy, 2012; Available online: https://www.fao.org/3/i2382s/i2382s.pdf (accessed on 12 December 2023).

- FDA. CFR—Code of Federal Regulations Title 21. Title 21—Food and Drugs. Chapter I—Food and Drug Administration. Department of Health and Human Services. Subchapter b—Food for Human Consumption. Part 117. Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Human Food. U.S. Food and Drug Administration (FDA). 2019. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=117 (accessed on 29 November 2023).

- FDA. Title 21—Food and Drugs. Chapter I—Food and Drug Administration. Department of Health and Human Services. SubChapter B—Food for Human Consumption. Part 123 Fish and Fishery Products. U.S. Food and Drug Administration (FDA). 2019. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfCFR/CFRSearch.cfm?CFRPart=123&showFR=1 (accessed on 29 November 2023).

- Reglamento (CE) No 178/2002 del Parlamento Europeo y del Consejo de 28 de Enero de 2002. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:2002R0178:20080325:ES:PDF (accessed on 11 January 2024).

- Reglamento (CE) Nº 852/2004 del Parlamento Europeo y del Consejo de 29 de Abril de 2004. Relativo a la Higiene de los Productos Alimenticios. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/PDF/?uri=CELEX:32004R0852 (accessed on 12 January 2024).

- Comisión Europea. Comunicación de la Comisión. Sobre la Aplicación de Sistemas de Gestión de la Seguridad Alimentaria que Contemplan Programas de Prerrequisitos (PPR) y Procedimientos Basados en los Principios del APPCC, Incluida la Facilitación/Flexibilidad Respecto de su Aplicación en Determinadas Empresas Alimentarias (2016/C 278/01). Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/PDF/?uri=CELEX:52016XC0730(01) (accessed on 13 January 2024).

- Reglamento (CE) Nº 853/2004 del Parlamento Europeo y del Consejo de 29 de Abril de 2004 por el que se Establecen Normas Específicas de Higiene de los Alimentos de Origen Animal. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/PDF/?uri=CELEX:32004R0853 (accessed on 13 January 2024).

- Reglamento (CE) Nº 854/2004 del Parlamento Europeo y del Consejo de 29 de Abril de 2004. por el que se Establecen Normas Específicas para la Organización de Controles Oficiales de los Productos de Origen Animal Destinados al Consumo Humano. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/PDF/?uri=CELEX:32004R0854 (accessed on 13 January 2024).

- Reglamento (CE) No 2073/2005 de la Comisión de 15 de Noviembre de 2005. Relativo a los Criterios Microbiológicos Aplicables a los Productos Alimenticios. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/PDF/?uri=CELEX:32005R2073 (accessed on 13 January 2024).

- Reglamento (UE) No 2017/625 del Parlamento Europeo y del Consejo de 15 de Marzo de 2017 Relativo a los Controles y Otras Actividades Oficiales Realizados para Garantizar la Aplicación de la Legislación sobre Alimentos y Piensos, y de las Normas sobre Salud y Bienestar de los Animales, Sanidad Vegetal y Productos Fitosanitarios. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/PDF/?uri=CELEX:32017R0625 (accessed on 13 January 2024).

- CECOPESCA. Guía de Requerimientos en las Certificaciones en el Sector Acuícola. Centro Técnico Nacional de Conservación de Productos de la Pesca y la Acuicultura (CECOPESCA). Ministerio de Agricultura, Alimentación y Medio Ambiente. Gobierno de España. 2012. Available online: https://www.mapa.gob.es/es/pesca/temas/calidad-seguridad-alimentaria/13-Guia_Certif-Acuicola_tcm7-248642_tcm30-285798.pdf (accessed on 1 November 2023).

- NOM-242-SSA1-2009. Norma Oficial Mexicana. Productos y Servicios. Productos de la Pesca Frescos, Refrigerados, Congelados y Procesados. Especificaciones Sanitarias y Métodos de Prueba. Available online: https://www.dof.gob.mx/normasOficiales/4295/salud2a/salud2a.htm (accessed on 2 February 2024).

- NOM-251-SSA1-2009. Norma Oficial Mexicana. Prácticas de Higiene para el Proceso de Alimentos, Bebidas o Suplementos Alimenticios. Available online: https://www.dof.gob.mx/normasOficiales/3980/salud/salud.htm (accessed on 2 February 2024).

- NOM-128-SSA1-1994. Norma Oficial Mexicana. Que Establece la Aplicación de un Sistema de Análisis de Riesgos y Control de puntos Críticos en la Planta Industrial Procesadora de Productos de la Pesca. Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=4888152&fecha=12/06/1996#gsc.tab=0 (accessed on 2 February 2024).

- NMX-F-605-NORMEX-2018. Norma Oficial Mexicana. Alimentos-Manejo Higiénico en el Servicio de Alimentos Preparados para la Obtención del Distintivo “H”. Available online: https://dof.gob.mx/nota_detalle.php?codigo=5567750&fecha=13/08/2019#gsc.tab=0 (accessed on 4 February 2024).

- NOM-051-SCFI/SSA1-2010. Norma Oficial Mexicana. Especificaciones Generales de Etiquetado para Alimentos y Bebidas no Alcohólicas Preenvasados—Información Comercial y Sanitaria. Available online: https://www.dof.gob.mx/normasOficiales/4010/seeco11_C/seeco11_C.htm (accessed on 3 February 2024).

- Dávalos, S.; Zamora, D.; Natividad, B.; Tercero, J.; Vásquez, C.; Quiñones, E. Alimentos marinos: Tipificación y proceso de almacenamiento. Rev. Digit. Univ. 2005, 6, 1–14. Available online: https://www.ru.tic.unam.mx/bitstream/handle/123456789/965/sep_art90.pdf?sequence=1 (accessed on 8 December 2023).

- Jiménez, H.; Carreño, O.; Lacera, A. Guía Técnica para el Manejo, Conservación y Trasformación del Pescado; ACIP-PRONATTA. Santa Marta, Colombia. 2001. Available online: http://bibliotecadigital.agronet.gov.co/bitstream/11348/5010/1/200671817163_Guia%20manejo%20conservacion%20y%20transformacion%20de%20pescado.pdf (accessed on 2 November 2023).

- Navarro Segura, L. Optimización del Envasado y Conservación Refrigerada de la Dorada (Sparus aurata) Fresca de Acuicultura, Entera y Fileteada. Ph.D. Thesis, Universidad Politécnica de Cartagena, Cartagena, Spain, 2020. Available online: https://repositorio.upct.es/bitstream/handle/10317/9180/lns_C.pdf?sequence=4 (accessed on 12 January 2024).

- INPESCA. Cortes y Procesamiento de Productos Acuícolas. Instituto Nicaraguense De La Pesca Y Acuicultura (INPESCA). 2023. Available online: http://www.inpesca.gob.ni/images/FOMENTO/2020/Cartilla_Corte_y_procesamiento.pdf (accessed on 1 February 2024).

- EUFIC. ABC en el Procesamiento de la Comida (Infografía). The European Food Information Council (EUFIC). 2018. Available online: https://www.eufic.org/es/produccion-de-alimentos/articulo/abc-en-el-procesamiento-de-la-comida (accessed on 3 February 2024).

- Prado-Toledo, I.Y.; Ramos-Santoyo, K.N.; Guzmán-Robles, M.L.; Cortés-Sánchez, A.D.J. Analysis of the Degree of Quality of Fish Fillet in Refrigeration. Open J. Appl. Sci. 2022, 12, 744–756. [Google Scholar] [CrossRef]

- PAHO. Clasificación de los Alimentos y Sus Implicaciones en la Salud. Oficina Regional para las Américas de la Organización Mundial de la Salud. Organización Panamericana de la Salud (PAHO). 2023. Available online: https://www3.paho.org/ecu/1135-clasificacion-alimentos-sus-implicaciones-salud.html (accessed on 5 November 2023).

- Latham Michael, C. Nutrición Humana en el Mundo en Desarrollo. Organización de las Naciones Unidas para la Agricultura y la Alimentación. Colección FAO: Alimentación y Nutrición N° 29. De las Naciones Unidas para la Agricultura y la Alimentación, Roma. 2002. Available online: https://www.fao.org/3/w0073s/w0073s00.htm#Contents (accessed on 2 December 2023).

- Abraha, B.; Admassu, H.; Mahmud, A.; Tsighe, N.; Shui, X.W.; Fang, Y. Effect of processing methods on nutritional and physico-chemical composition of fish: A review. MOJ Food Process Technol. 2018, 6, 376–382. [Google Scholar] [CrossRef]

- Ortíz Peña, E.V.; Escalante, R.E. Producción y Tecnología de Pescados; SENA: Bogotá, Colombia, 1988; Available online: https://repositorio.sena.edu.co/bitstream/handle/11404/5437/divulgacion_tecnologica_3.PDF?sequence=1&isAllowed=y (accessed on 10 December 2023).

- Wicki, G.; Panné Huidobro, S.E.; Manca, E. Manual para el Proceso de Productos de la Acuicultura, 1st ed.; Consejo Federal de Inversiones; Dirección de Acuicultura de la Nación: Buenos Aires, Argentina, 2006; Available online: https://www.magyp.gob.ar/sitio/areas/acuicultura/bpa/_archivos//161115_Manual%20para%20el%20proceso%20de%20productos%20de%20la%20acuicultura.pdf (accessed on 19 December 2023).

- Inocente-Quiroz, F.E.; Eccoña-Sota, A.; Silva-Paz, R.J. Minimally processed foods: Generalities, processing, consumption and physical, chemical and biological changes. Agroindustrial Sci. 2021, 11, 117–126. Available online: https://revistas.unitru.edu.pe/index.php/agroindscience/article/download/3454/4129 (accessed on 2 February 2024). [CrossRef]

- CECOPESCA. Guía para el Aprovechamiento de los Subproductos de Pescado para la Obtención de Productos Funcionales y Bioactivos. Centro Técnico Nacional de Conservación de Productos de la Pesca y la Acuicultura. CECOPESCA. Ministerio de Agricultura, Alimentación y Medio Ambiente. Gobierno de España. 2012. Available online: https://www.mapa.gob.es/eu/pesca/temas/calidad-seguridad-alimentaria/06-Guia_Subproductos_tcm7-248616_tcm35-285791.pdf (accessed on 5 December 2023).

- Hleap Zapata, J.I.; Gutiérrez Castañeda, C.A. Fish hydrolysates—Production, profits and new developments in the industry—A review. Acta Agronómica 2017, 66, 311–322. Available online: https://revistas.unal.edu.co/index.php/acta_agronomica/article/view/52595/56855 (accessed on 2 January 2024). [CrossRef]

- Medina, V.; Jhonny, A. Conservación de Productos Pesqueros, 1st ed.; República Bolivariana de Venezuela. Ministerio para la Economía Popular; Instituto Nacional de Cooperación Educativa. 2005. Available online: https://www.inces.gob.ve/wrappers/AutoServicios/Aplicaciones_Intranet/Material_Formacion/pdf/ALIMENTACION/PESCADOR%20ARTESANAL%2001412233/CUADERNOS/CONSERVACION%20DE%20PRODUCTOS%20PESQUEROS.pdf (accessed on 8 January 2024).

- Mora, J.A. Fish processing yield in pacu (Piaractus brachypomus) and the hybrid Colossoma macropomum × P. brachypomus. Bioagro 2005, 17, 161–169. Available online: https://ve.scielo.org/scielo.php?script=sci_arttext&pid=S1316-33612005000300006 (accessed on 18 December 2023).

- Mazorriaga Rama, A.; Domenech González, R.; Mayordomo Feliu, T. Preelaboración y Conservación de Pescado, Crustáceos y Moluscos, 1st ed.; Paraninfo: Madrid, Spain, 2016. [Google Scholar]

- Aubourg, S.P. Effect of lipid damages on processed fish quality. Grasas Y Aceites 1999, 50, 218–224. Available online: https://digital.csic.es/bitstream/10261/21998/1/670.pdf (accessed on 2 February 2024).

- Avdalov, N. Manual de Control de Calidad y Manipulación de Productos Pesqueros para Pescadores y Procesadores Artesanales. Proyecto CFC/FAO/INFOPESCA, FSCFT 23, “Mejoramiento de la Pesca Artesanal en Centro América, México y el Caribé. 2009. Available online: http://www.infopesca.org/sites/default/files/complemento/publilibreacceso/321/Manual%20pescadores%20artesanales.pdf (accessed on 12 December 2023).

- Shawyer, M.; Medina Pizzali, A.F. El uso de hielo en pequeñas embarcaciones de pesca. In FAO Documento Técnico de Pesca 436; Organización de las Naciones Unidas para la Agricultura y la Alimentación (FAO): Rome, Italy, 2005; 120p, Available online: https://www.fao.org/3/y5013s/y5013s00.htm#Contents (accessed on 19 January 2024).

- Durruty, M.A. Análisis Físico-Químico, Sensorial y Consumo de Productos Pesqueros Ahumados (en Línea); UFASTA: Mar de Plata, Argentina, 2013; 164p, Available online: http://redi.ufasta.edu.ar:8082/jspui/bitstream/123456789/3161/2/2013_N_318.pdf (accessed on 2 February 2024).

- Darvishi, H.; Azadbakht, M.; Rezaeiasl, A.; Farhang, A. Drying characteristics of sardine fish dried with microwave heating. J. Saudi Soc. Agric. Sci. 2013, 12, 121–127. [Google Scholar] [CrossRef]

- Naranjo Morales, R.A. Estudio del Efecto Microbiologico de Diferentes Salmueras en Trucha (Oncorhynchus mikis) y Tilapia (Tilapia mossambica) para su Conservación y Almacenado. Bachelor’s Thesis, Universidad técnica de Ambato, Ambato, Ecuador, 2006. Available online: https://repositorio.uta.edu.ec/bitstream/123456789/3371/1/P105%20Ref.3034.pdf (accessed on 12 January 2024).

- Ramírez, C.H.; Almeida, L.J.E. Producción de pescado seco-salado utilizando secadores solares. Uniciencia 1986, 3, 101–105. Available online: https://www.revistas.una.ac.cr/index.php/uniciencia/article/download/5384/5214 (accessed on 2 February 2024).

- Martínez Layza, R.T. Tecnologías de Conservación de Filetes de Pescado Fresco. Bachelor’s Thesis, Facultad de Ciencias Agropecuarias, Universidad Nacional de Trujillo, Trujillo, Perú, 2016. Available online: https://dspace.unitru.edu.pe/server/api/core/bitstreams/d3014fda-be22-425a-9501-848782fec09d/content (accessed on 16 January 2024).

- Sánchez Torres, J.; Lam, R. Principios Técnicos de Salado y Secado del Pescado. Estudio Químico de la Sal en el Litoral. 1965. Available online: https://biblioimarpe.imarpe.gob.pe/bitstream/20.500.12958/238/1/INF%209.pdf (accessed on 13 January 2024).

- Signorini Porchietto, M.L. Productos fermentados. Capítulo 18. In Tecnología de Productos de Origen Acuático. Compiladores: Isabel Guerrero Legorreta, Marcelo; Rosmini y Roberto, R., Armenta, E., Eds.; Editorial Limusa: Ciudad de México, México, 2009; pp. 303–330. [Google Scholar]

- Ekonomou, S.I.; Boziaris, I.S. Non-thermal methods for ensuring the microbiological quality and safety of seafood. Appl. Sci. 2021, 11, 833. [Google Scholar] [CrossRef]

- Kontominas, M.G.; Badeka, A.V.; Kosma, I.S.; Nathanailides, C.I. Innovative seafood preservation technologies: Recent developments. Animals 2021, 11, 92. [Google Scholar] [CrossRef]

| Compound | Fillet Fish | ||

|---|---|---|---|

| Minimum % | Normal % | Maximum % | |

| Proteins | 6 | 16–21 | 28 |

| Lipids | 0.1 | 0.2–25 | 67 |

| Carbohydrates | <0.5 | ||

| Ashes | 0.4 | 1.2–1.5 | 1.5 |

| Water | 28 | 66–81 | 96 |

| Hazard | Agent(s) | Examples | References |

|---|---|---|---|

| Biological | Virus | Norovirus, astrovirus, hepatitis A, hepatitis E, adenovirus, rotavirus, and enterovirus. | [21,24,26] |

| Bacteria | E. coli, Shewanella spp., Bacillus cereus, Campylobacter jejuni, Aeromonas spp., Citrobacter spp., Legionella pneumophila, Mycobacterium spp., Streptococcus spp., Vibrio sp., Salmonella spp., Shigella spp., Plesiomonas shigelloides, Yersinia enterocolitica, Edwardsiella tarda, Listeria monocytogenes, Erysipelothrix rhusiopathiae, Leptospira spp., Nocardia spp., Staphylococcus aureus, Klebsiella pneumoniae, and Clostridium spp. | [19,20,21,24,25,26,27] | |

| Parasites | Capillaria philippinensis, Gnathostoma spp., Pseudoterranova spp., Phagicola spp., Clonorchis spp., Opisthorchis spp., Paragonimus spp., Anisakis spp., Phocanema spp., Angiostrongylus spp., Contracaecum spp., Diphyllobothrium spp., Heterophyes spp., Cryptosporidium spp., Giardia lamblia, and Eustrongylides spp. | [21,22,23,25,26] | |

| Chemical | Heavy metals | Nickel, cadmium, lead, arsenic, copper, and mercury. | [26] |

| Biotoxins | Gempilotoxin, tetrodotoxin, ciguatoxin, mycotoxins, maitotoxin, palytoxin, and okadaic acid. | [26] | |

| Biogenic amines | Cadaverine, espermidine, espermine, histamine, and putrescine. | [21,26,28] | |

| Organic compounds | Polybrominated diphenyl ethers, polycyclic aromatic hydrocarbons, polychlorinated biphenyls, dioxins, pesticides, antibiotics, hormones, and microplastics. | [21,26] |

| Fish Compound | Fresh Status | Spoilage Status | References |

|---|---|---|---|

| Skin | Brilliant coloration Transparent mucus Non-viscous | Discoloration Opaque mucus Viscous | [9,17,60,71] |

| Eyes | Convex Transparent Brillant | Concave Milky Opaque | [9,17,60,71] |

| Gills | Red-colored Brillant | Yellowish Brownish Colorless Viscose | [9,17,60,71] |

| Muscle appearance | Firm Elastic Uniform colored | Soft Stained | [9,17,60] |

| Odor | Fresh, ocean-like | Rotten/rancid Sulfides, amines, and ammonia | [9,17,60,71] |

| Internal organs | Brillant Defined | Autolysate Acid odor | [9,17] |

| Scales | Firm, bright, and detachment resistant | Easy detachment and low firmness | [60] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cortés-Sánchez, A.D.J.; Diaz-Ramírez, M.; Torres-Ochoa, E.; Espinosa-Chaurand, L.D.; Rayas-Amor, A.A.; Cruz-Monterrosa, R.G.; Aguilar-Toalá, J.E.; Salgado-Cruz, M.d.l.P. Processing, Quality and Elemental Safety of Fish. Appl. Sci. 2024, 14, 2903. https://doi.org/10.3390/app14072903

Cortés-Sánchez ADJ, Diaz-Ramírez M, Torres-Ochoa E, Espinosa-Chaurand LD, Rayas-Amor AA, Cruz-Monterrosa RG, Aguilar-Toalá JE, Salgado-Cruz MdlP. Processing, Quality and Elemental Safety of Fish. Applied Sciences. 2024; 14(7):2903. https://doi.org/10.3390/app14072903

Chicago/Turabian StyleCortés-Sánchez, Alejandro De Jesús, Mayra Diaz-Ramírez, Erika Torres-Ochoa, Luis Daniel Espinosa-Chaurand, Adolfo Armando Rayas-Amor, Rosy G. Cruz-Monterrosa, José Eleazar Aguilar-Toalá, and Ma. de la Paz Salgado-Cruz. 2024. "Processing, Quality and Elemental Safety of Fish" Applied Sciences 14, no. 7: 2903. https://doi.org/10.3390/app14072903