A Method for Evaluating the Spatial Layout of Fire Stations in Chemical Industrial Parks

Abstract

:1. Introduction

2. Methods

2.1. General Framework

- ■

- Establish a set of PTBRs as R = {R1, R2, …, Rn}, where R1~Rn represent each PTBR, and n is the total number of PTBRs in the park.

- ■

- Establish a set of fire risk levels as W = {W1, W2, …, Wm}, where W1~Wm are the fire risk levels of PTBRs, and m represents the total number of risk levels.

- ■

- Establish a set of required fire rescue time standards as T = {T1, T2, …, Tm}, where T1, T2, … Tm are the required fire rescue time standards for the fire risk levels W1, W2, … Wm.

- ■

- Traverse the set R to establish a set of required fire rescue times as X = {X1, X2, …, Xn}, where X1~Xn are the required fire rescue times for the corresponding PTBRs. The required fire rescue time for each PTBR should be determined based on its fire risk level. The fire risk assessment technology will be described in the following section.

- ■

- Establish a set of fire stations as F = {F1, F2, …, Fk}, where F1~Fk represent the fire stations in the chemical industrial park, and k is the total number of fire stations.

- ■

- Establish the minimum distance path from each PTBR to each fire station aswhere Pij represents the minimum distance path from Ri to Fj, and where i ranges from 1 to n and j ranges from 1 to k.

- ■

- Estimate the fire rescue time from each PTBR to each fire station aswhere V represents the estimated running speed of fire engines in the chemical industrial park, and tij represents the estimated fire rescue time from Ri to Fj.

- ■

- Calculate the difference between the estimated fire rescue time and the required fire rescue time, tij − Xi, j = 1, 2, … k, and make the following judgments: (a) If tij − Xi < 0, then Ci = 1, where Ci is the first state register of the point Ri, and Ci = 1 indicates that the point Ri is covered by fire station Fj; (b) If the situation tij − Xi < 0 occurs more than once, then Hi = 1, where Hi is the second status register of the point Ri, and Hi = 1 indicates that the point Ri is covered by two or more fire stations.

- ■

- Traverse Ri, i = 1, 2, … n, calculate C = ΣCi, where C represents the number of PTBRs covered by fire stations. Then, calculate H = ΣHi, where H represents the number of PTBRs covered by two or more fire stations.

- ■

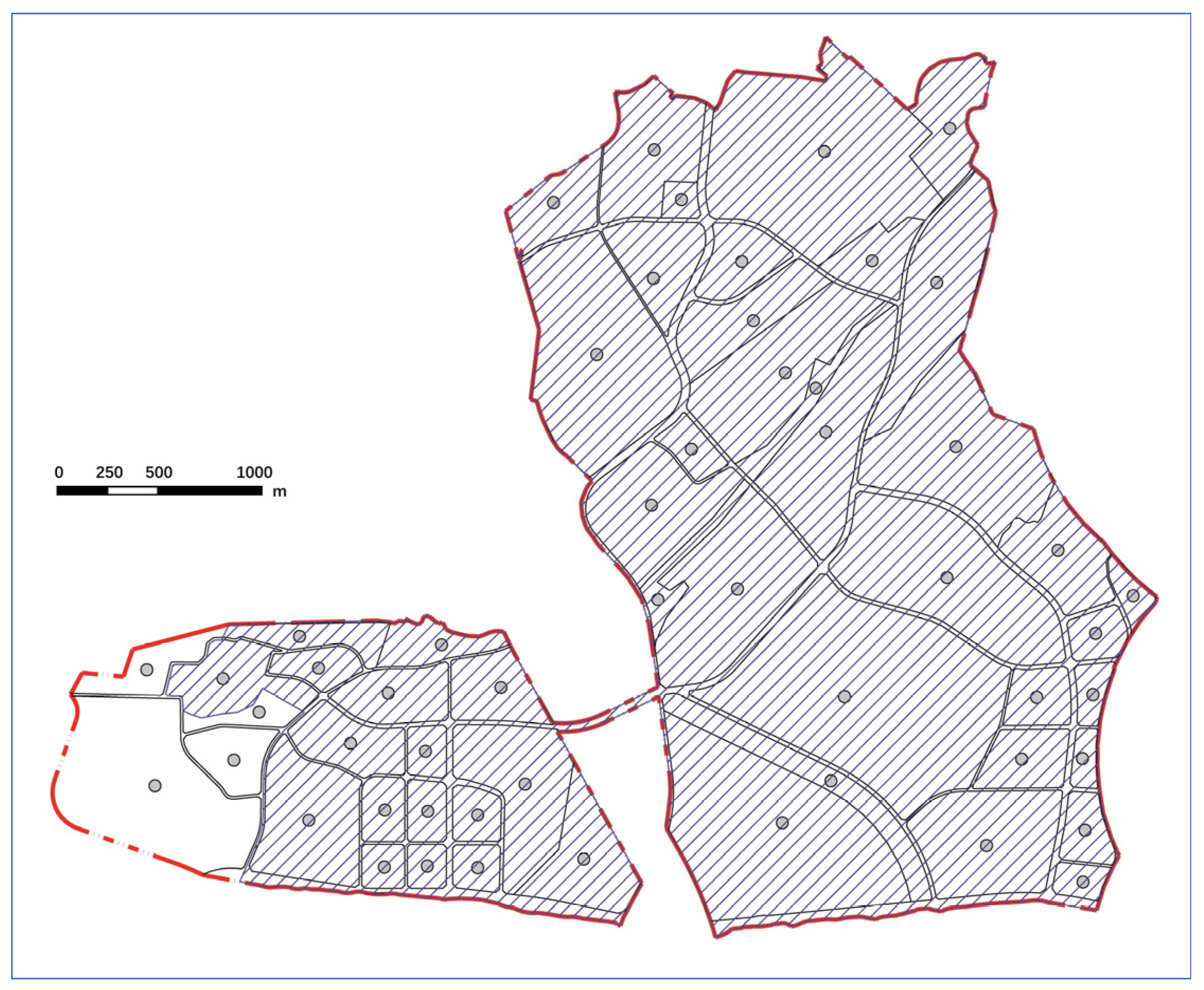

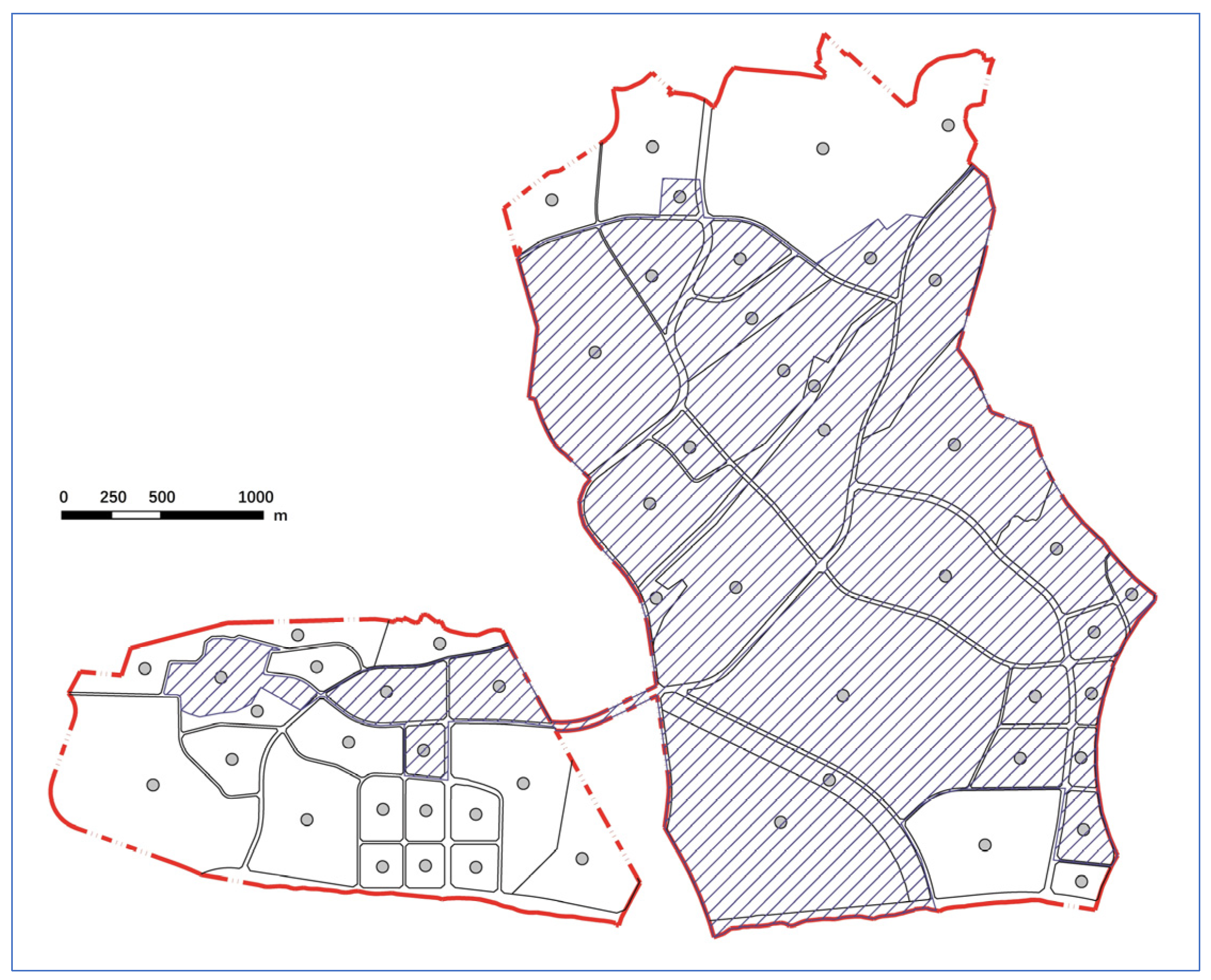

- Calculate the coverage rate of fire stations as

- ■

- Calculate the overlap-coverage rate of fire stations as

- ■

- Determine the standard αs for the coverage rate of fire stations. If α ≥ αs, the coverage rate of fire stations meets the standard.

- ■

- Determine the standard γs for the overlap-coverage rate of fire stations. If γ ≤ γs, the overlap-coverage rate of fire stations meets the standard.

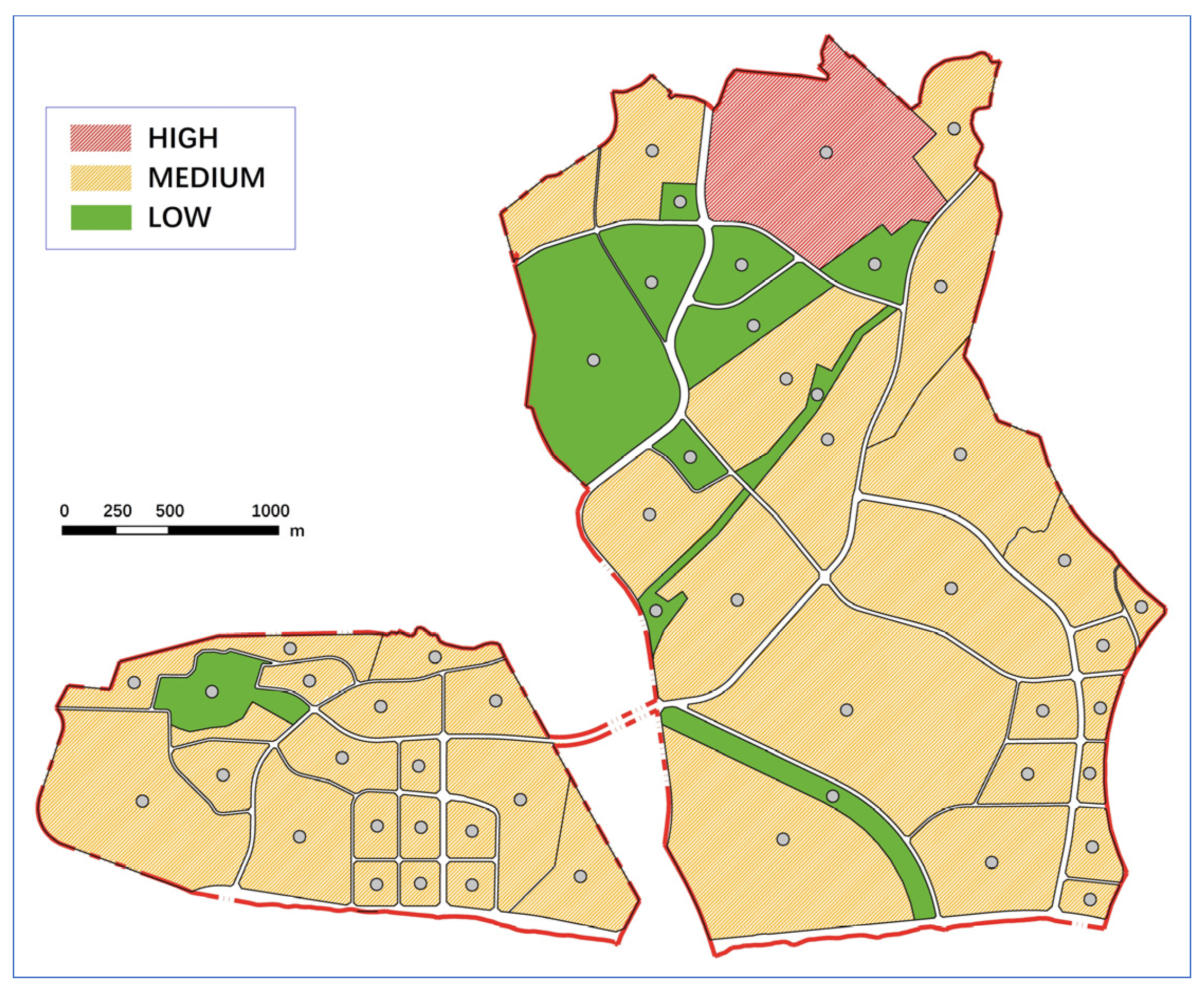

2.2. Fire Risk Assessment

2.3. Required Fire Rescue Time

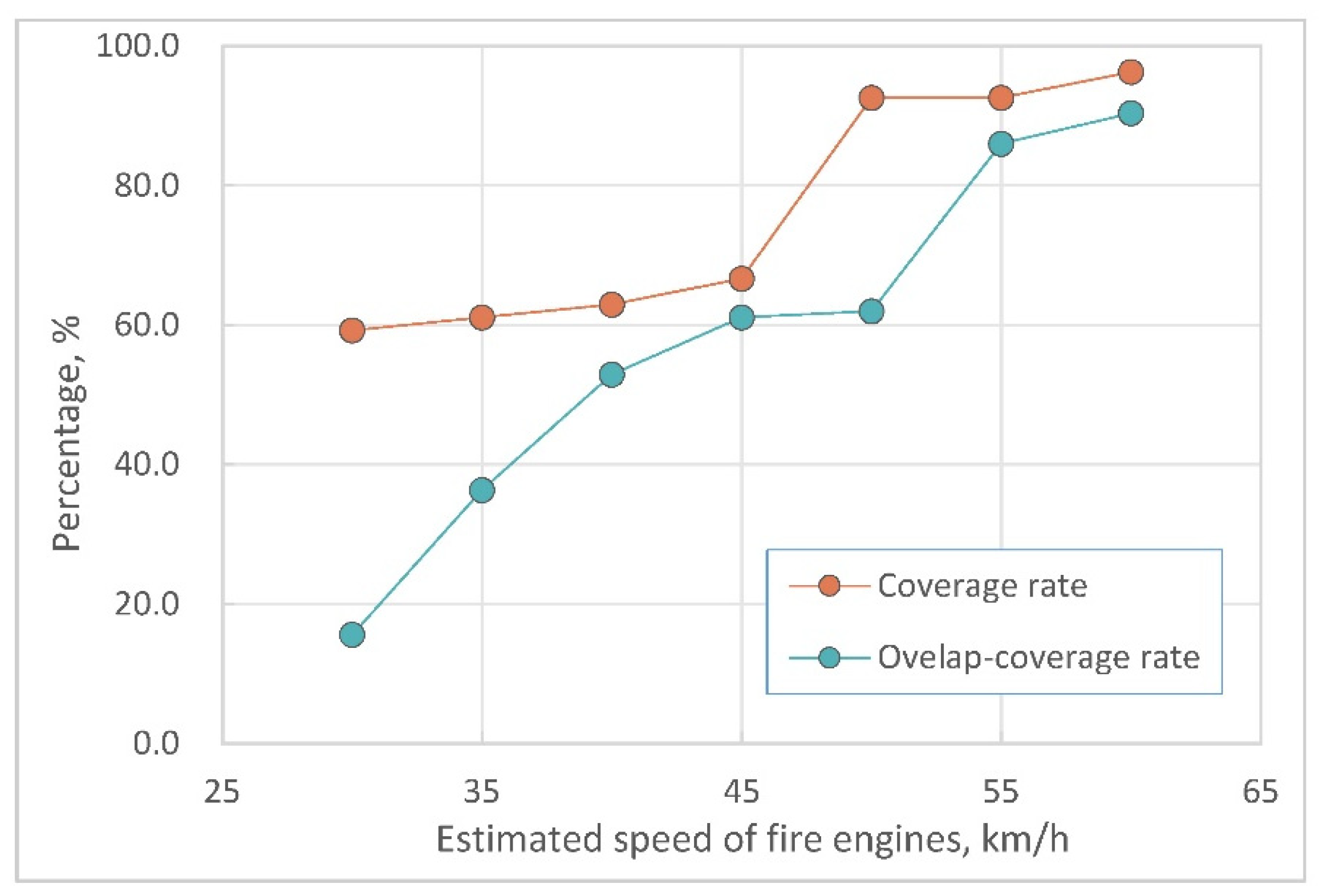

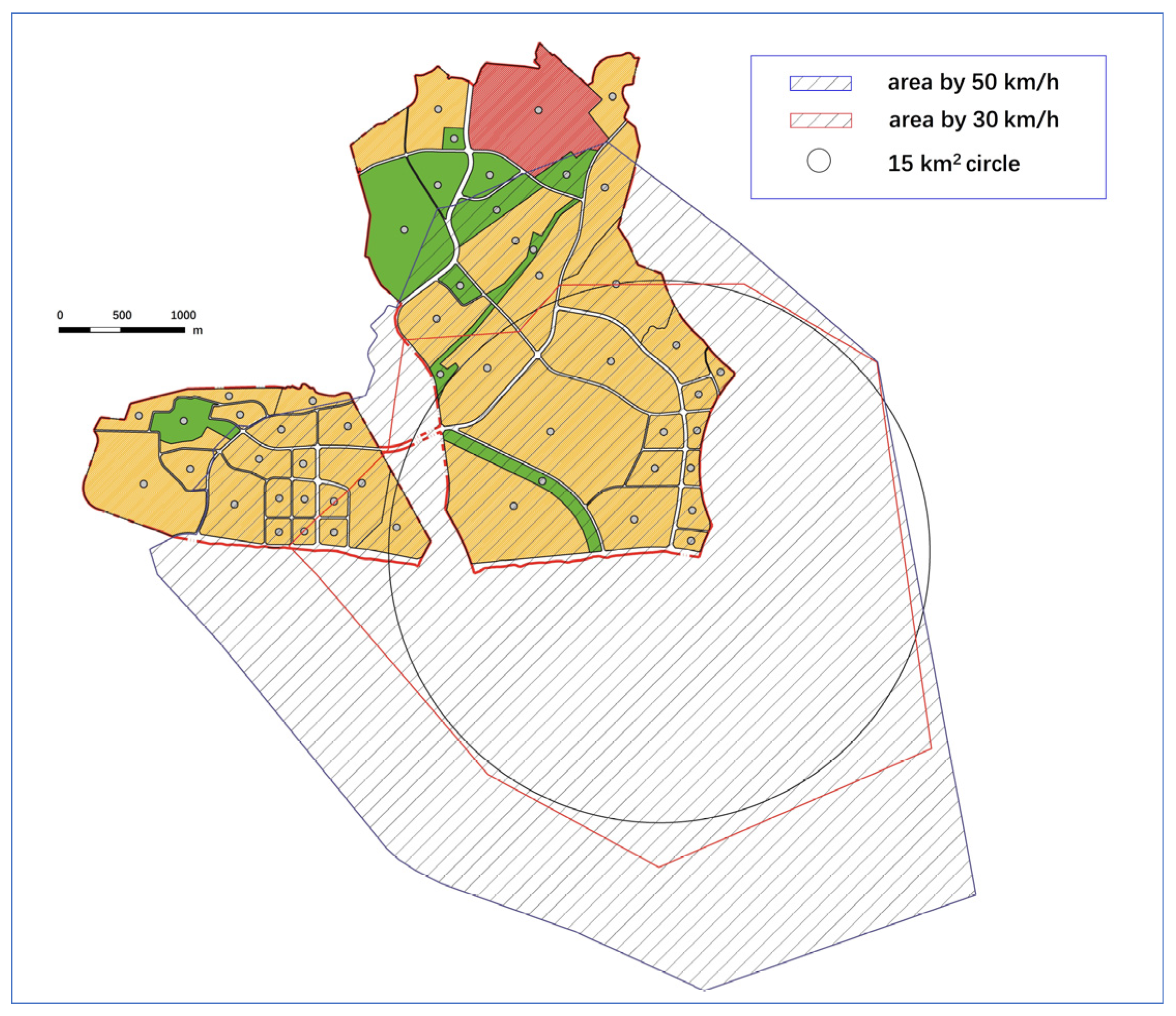

2.4. Estimated Fire Rescue Time

2.5. Rationality Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, P.; Chen, G.; Wang, L.; Reniers, G. Optimizing emergency rescue and evacuation planning with intelligent obstacle avoidance in a chemical industrial park. J. Loss Prev. Process. Ind. 2018, 56, 119–127. [Google Scholar] [CrossRef]

- Chen, G.; Wang, S.; Tan, X. Evaluation model for safety capacity of chemical industrial park based on acceptable regional risk. Chin. J. Chem. Eng. 2015, 23, 121–127. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J. Facts related to August 12, 2015 explosion accident in Tianjin, China. Process. Saf. Prog. 2015, 34, 313–314. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, S.; Zhou, A.; Chen, J. A brief report on the March 21, 2019 explosions at a chemical factory in Xiangshui, China. Process. Saf. Prog. 2019, 38, e12060. [Google Scholar] [CrossRef]

- Challands, N. The Relationships between Fire Service Response Time and Fire Outcomes. Fire Technol. 2010, 46, 665–676. [Google Scholar] [CrossRef]

- JB 152-2017; Construction Standards for Urban Fire Stations. National Development and Reform Commission and Ministry of Housing and Urban-Rural Development of P.R. China: Beijing, China, 2017.

- Yu, Z.; Xu, L.; Chen, S.; Jin, C. Research on Urban Fire Station Layout Planning Based on a Combined Model Method. ISPRS Int. J. Geo-Inf. 2023, 12, 135. [Google Scholar] [CrossRef]

- Chen, M.; Wang, K.; Dong, X.; Li, H. Emergency rescue capability evaluation on urban fire stations in China. Process. Saf. Environ. Prot. 2020, 135, 59–69. [Google Scholar] [CrossRef]

- Park, P.Y.; Jung, W.R.; Yeboah, G.; Rempel, G.; Paulsen, D.; Rumpel, D. First responders’ response area and response time analysis with/without grade crossing monitoring system. Fire Saf. J. 2016, 79, 100–110. [Google Scholar] [CrossRef]

- Wang, J.; Liu, H.; An, S.; Cui, N. A new partial coverage locating model for cooperative fire services. Inf. Sci. 2016, 373, 527–538. [Google Scholar] [CrossRef]

- Kc, K.; Corcoran, J. Modelling residential fire incident response times: A spatial analytic approach. Appl. Geogr. 2017, 84, 64–74. [Google Scholar] [CrossRef]

- Aktas, E.; Özaydin, Ö.; Bozkaya, B.; Ülengin, F.; Önsel, S. Optimizing Fire Station Locations for the Istanbul Metropolitan Municipality. Interfaces 2013, 43, 240–255. [Google Scholar] [CrossRef]

- Zhang, B.; Peng, J.; Li, S. Covering location problem of emergency service facilities in an uncertain environment. Appl. Math. Model. 2017, 51, 429–447. [Google Scholar] [CrossRef]

- Yu, W.; Guan, M.; Chen, Y. Fire stations siting with multiple objectives and geospatial big data. Earth Sci. Inform. 2021, 14, 141–160. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, X.; Murray, A.T. Location optimization of urban fire stations: Access and service coverage. Comput. Environ. Urban Syst. 2019, 73, 184–190. [Google Scholar] [CrossRef]

- Wang, K.; Li, Z.; Zhou, J. Two decision-making approaches to fire station location in a fuzzy environment. J. Inf. Comput. Sci. 2014, 11, 4779–4793. [Google Scholar] [CrossRef]

- Sirbiladze, G.; Ghvaberidze, B.; Matsaberidze, B.; Midodashvili, B. New fuzzy approach to facility location problem for extreme environment. J. Intell. Fuzzy Syst. 2019, 37, 7883–7893. [Google Scholar] [CrossRef]

- Murray, A.T. Optimising the spatial location of urban fire stations. Fire Saf. J. 2013, 62, 64–71. [Google Scholar] [CrossRef]

- Ming, J.; Richard, J.-P.P.; Qin, R.; Zhu, J. Distributionally robust optimization for fire station location under uncertainties. Sci. Rep. 2022, 12, 5394. [Google Scholar] [CrossRef] [PubMed]

- Drakulic, D.; Takaci, A.; Marić, M. Fuzzy covering location problems with different aggregation operators. Filomat 2017, 31, 513–522. [Google Scholar] [CrossRef]

- Rodriguez, S.A.; De la Fuente, R.A.; Aguayo, M.M. A facility location and equipment emplacement technique model with expected coverage for the location of fire stations in the Concepción province, Chile. Comput. Ind. Eng. 2020, 147, 106522. [Google Scholar] [CrossRef]

- Han, B.; Hu, M.; Zheng, J.; Tang, T. Site Selection of Fire Stations in Large Cities Based on Actual Spatiotemporal Demands: A Case Study of Nanjing City. ISPRS Int. J. Geo-Inf. 2021, 10, 542. [Google Scholar] [CrossRef]

- Yu, Y. Optimization for Fire Station Location Planning Based on Travel Time of Fire Vehicles. In Proceedings of the 2012 Eighth International Conference on Computational Intelligence and Security, Guangzhou, China, 17–18 November 2012; pp. 328–331. [Google Scholar]

- Boschetti, M.; Maniezzo, V. A set covering based matheuristic for a real-world city logistics problem. Int. Trans. Oper. Res. 2015, 22, 169–195. [Google Scholar] [CrossRef]

- Chaudhary, P.; Chhetri, S.K.; Joshi, K.M.; Shrestha, B.M.; Kayastha, P. Application of an Analytic Hierarchy Process (AHP) in the GIS interface for suitable fire site selection: A case study from Kathmandu Metropolitan City, Nepal. Socio-Econ. Plan. Sci. 2016, 53, 60–71. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, D.; Yan, L. Evaluating spatial configuration of fire stations based on real-Time traffic. Case Stud. Therm. Eng. 2021, 25, 100957. [Google Scholar] [CrossRef]

- Kc, K.; Corcoran, J.; Chhetri, P. Spatial optimisation of fire service coverage: A case study of Brisbane, Australia. Geogr. Res. 2018, 56, 270–284. [Google Scholar] [CrossRef]

- Chevalier, P.; Thomas, I.; Geraets, D.; Goetghebeur, E.; Janssens, O.; Peeters, D.; Plastria, F. Locating fire stations: An integrated approach for Belgium. Socio-Econ. Plan. Sci. 2012, 46, 173–182. [Google Scholar] [CrossRef]

- Dong, X.; Li, Y.; Pan, Y.; Huang, Y.; Cheng, X. Study on Urban Fire Station Planning based on Fire Risk Assessment and GIS Technology. Procedia Eng. 2018, 211, 124–130. [Google Scholar] [CrossRef]

- Zhou, J. Research on Layout Optimization Method of Urban Fire Station Based on Fire Risk Assessment. Adv. Mater. Res. 2013, 838–841, 2162–2169. [Google Scholar] [CrossRef]

- Chen, M.; Wang, K.; Yuan, Y.; Yang, C. A POIs Based Method for Location Optimization of Urban Fire Station: A Case Study in Zhengzhou City. Fire 2023, 6, 58. [Google Scholar] [CrossRef]

- Wang, W.; Xu, Z.; Sun, D.; Lan, T. Spatial Optimization of Mega-City Fire Stations Based on Multi-Source Geospatial Data: A Case Study in Beijing. ISPRS Int. J. Geo-Inf. 2021, 10, 282. [Google Scholar] [CrossRef]

- Wang, K.; Yuan, Y.; Chen, M.; Wang, D. A POIs based method for determining spatial distribution of urban fire risk. Process. Saf. Environ. Prot. 2021, 154, 447–457. [Google Scholar] [CrossRef]

- Liu, X. The Petrochemical Park Fire Safety Planning Study Based on Fire Risk Analysis. Adv. Mater. Res. 2012, 518–523, 1045–1051. [Google Scholar] [CrossRef]

- Zheng, W. Discussion on Fire Planning for Large-Scale Petrochemical Industrial Park. Adv. Mater. Res. 2013, 807–809, 272–275. [Google Scholar] [CrossRef]

- Wan, H.; Yun, Y. Study on Fire Safety Planning in Chinese Petrochemical Industry Parks. Adv. Mater. Res. 2012, 260–261, 279–283. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, X.; Wei, R.; Huang, S.; Zhang, X. Study on Location of Fire Stations in Chemical Industry Parks from a Public Safety Perspective: Considering the Domino Effect and the Identification of Major Hazard Installations for Hazardous Chemicals. Fire 2023, 6, 218. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, M. Risk Assessment of Major Hazards and Its Application in Urban Planning: A Case Study. Risk Anal. 2012, 32, 566–577. [Google Scholar] [CrossRef]

- He, Z.; Weng, W. A Dynamic and Simulation-Based Method for Quantitative Risk Assessment of the Domino Accident in Chemical Industry. Process. Saf. Environ. Prot. 2020, 144, 79–92. [Google Scholar] [CrossRef]

- Pak, S.; Kang, C. Increased Risk to People around Major Hazardous Installations and the Necessity of Land Use Planning in South Korea. Process. Saf. Environ. Prot. 2021, 149, 325–333. [Google Scholar] [CrossRef]

- Xu, X.; Zhu, H. Fire Station Planning Method Based on Identification of Major Hazards in Chemical Parks. In Proceedings of the Annual Scientific and Technical Conference of the China Fire Protection Association, Beijing, China, 23 September 2020. (In Chinese). [Google Scholar]

- Safety Supervision General Administration Ⅲ [2009] No. 116, Notice of the State Administration of Work Safety on Publishing the Catalogue of the First Batch of Key Supervised Hazardous Chemical Processes, China State Administration of Work Safety; China State Administration of Work Safety: Beijing, China, 2009.

- Safety Supervision General Administration Ⅲ [2011] No. 95, Notice of the State Administration of Work Safety on Publishing the List of the First Batch of Key Supervised Hazardous Chemicals, China State Administration of Work Safety; China State Administration of Work Safety: Beijing, China, 2011.

- GB 18218-2018; Identification of Major Hazard Installations for Hazardous Chemicals. China National Standardization Administration and State Administration for Market Regulation: Beijing, China, 2018.

- Li, G.; Sun, Z.; Zhu, J.; Zhang, G. Database construction and application of hazardous chemical explosion and fire accidents. Fire Sci. Technol. 2023, 42, 575–579. (In Chinese) [Google Scholar]

- GB/T 51328-2018; Standard for Urban Comprehensive Transport System Planning. State Administration for Market Regulation and Ministry of Housing and Urban-Rural Development of P.R. China: Beijing, China, 2018.

- Huang, A.-C.; Huang, C.-F.; Shu, C.-M. A Case Study for an Assessment of Fire Station Selection in the Central Urban Area. Safety 2023, 9, 84. [Google Scholar] [CrossRef]

| Identification | General Location | Area, km2 | FS Number | FS Coverage Rate | FS Overlap-Coverage Rate |

|---|---|---|---|---|---|

| Park A | North China | 15 | 3 | 94% | 76% |

| Park B | Northeast China | 13.02 | 2 | 97% | 24% |

| Park C | Southeast China | 6.60 | 4 | 96% | 82% |

| Park D | Southwest China | 4.50 | 1 | 98% | - |

| Park E | Southwest China | 18.57 | 3 | 62% | 0% |

| Park F | Southwest China | 4.74 | 1 | 100% | - |

| Park X | Southwest China | 11.33 | 2 | 92.6% | 62% |

| Indicator Name | Interpretation |

|---|---|

| Key supervised hazardous chemical processes | Chemical processes that are listed in the catalogue of key supervised hazardous chemical processes published by the China State Administration of Work Safety [42] |

| Key supervised hazardous chemicals | Chemicals that are listed in the list of key supervised hazardous chemicals published by the China State Administration of Work Safety [43] |

| Major hazard installations of hazardous chemicals | Installations that produce, store, use, and trade hazardous chemicals on a long-term or temporary basis, and where the quantity of hazardous chemicals equals or exceeds the threshold quantity according to the national standard [44]. (These installations are categorized into four levels from level I to level IV, with level I being the most hazardous.) |

| Criteria | Scoring | Weight | |||

|---|---|---|---|---|---|

| 0 | 50 | 75 | 100 | ||

| Number of key supervised hazardous chemical processes | 0 | - | - | 1 | 0.3 |

| Number of key supervised hazardous chemicals | 0 | 1 | 2–3 | ≥4 | 0.2 |

| Level of major hazard installations of hazardous chemicals | None | IV | III | I, II | 0.5 |

| Fire Risk Score | Fire Risk Level |

|---|---|

| + σ | High |

| Medium | |

| Low |

| Fire Risk Level | Required Fire Rescue Time |

|---|---|

| High | 3 min |

| Medium | 5 min |

| Low | 8 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Li, N.; Wu, X.; Liu, B. A Method for Evaluating the Spatial Layout of Fire Stations in Chemical Industrial Parks. Appl. Sci. 2024, 14, 2918. https://doi.org/10.3390/app14072918

Li L, Li N, Wu X, Liu B. A Method for Evaluating the Spatial Layout of Fire Stations in Chemical Industrial Parks. Applied Sciences. 2024; 14(7):2918. https://doi.org/10.3390/app14072918

Chicago/Turabian StyleLi, Liming, Ningning Li, Xiaochuan Wu, and Bo Liu. 2024. "A Method for Evaluating the Spatial Layout of Fire Stations in Chemical Industrial Parks" Applied Sciences 14, no. 7: 2918. https://doi.org/10.3390/app14072918