Dynamic Stability Finite Difference Time Domain Analysis of Landfill Based on Hypergravity Test

Abstract

:1. Introduction

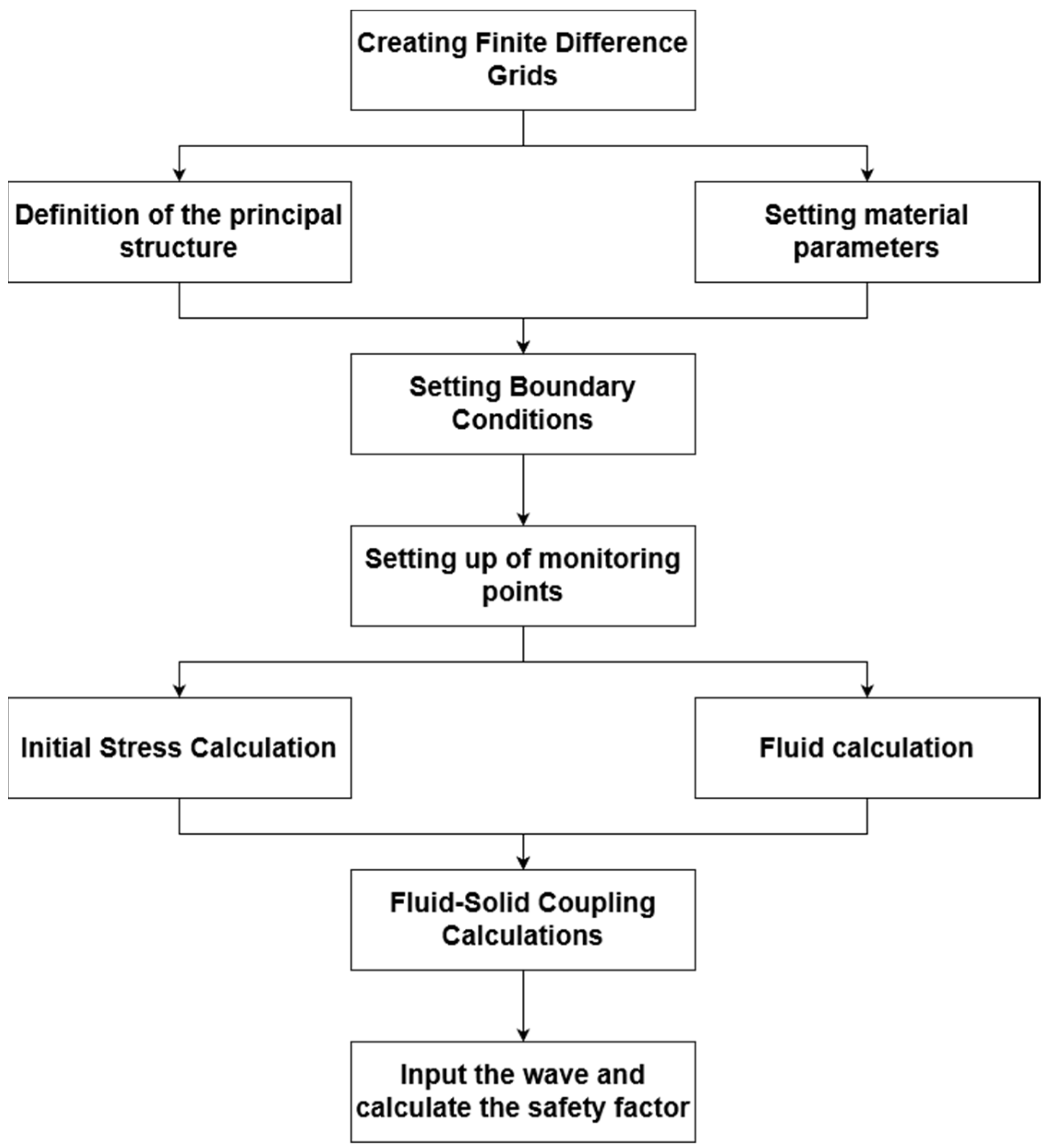

2. Dynamic Calculation Method for Landfill Based on FLAC3D

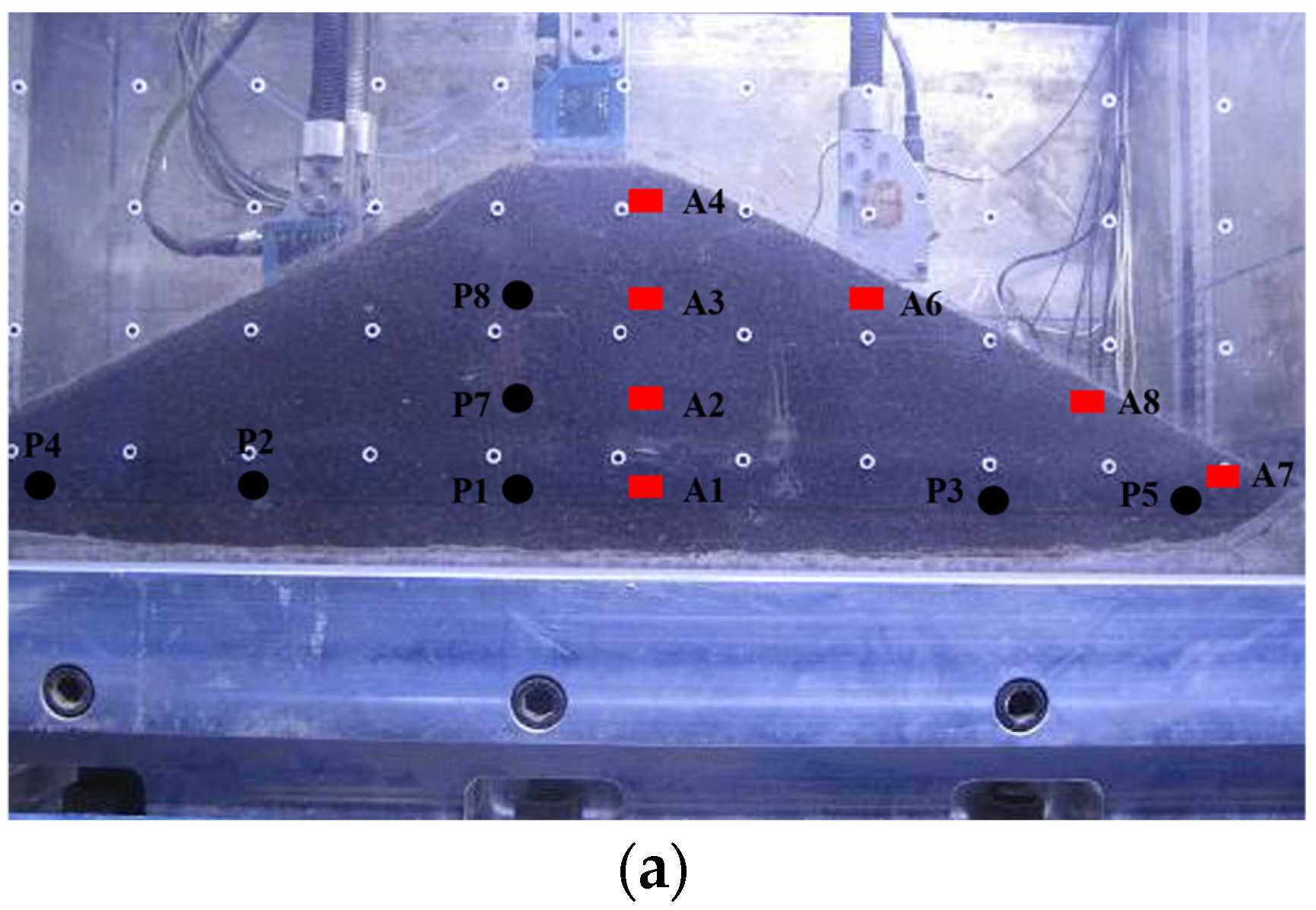

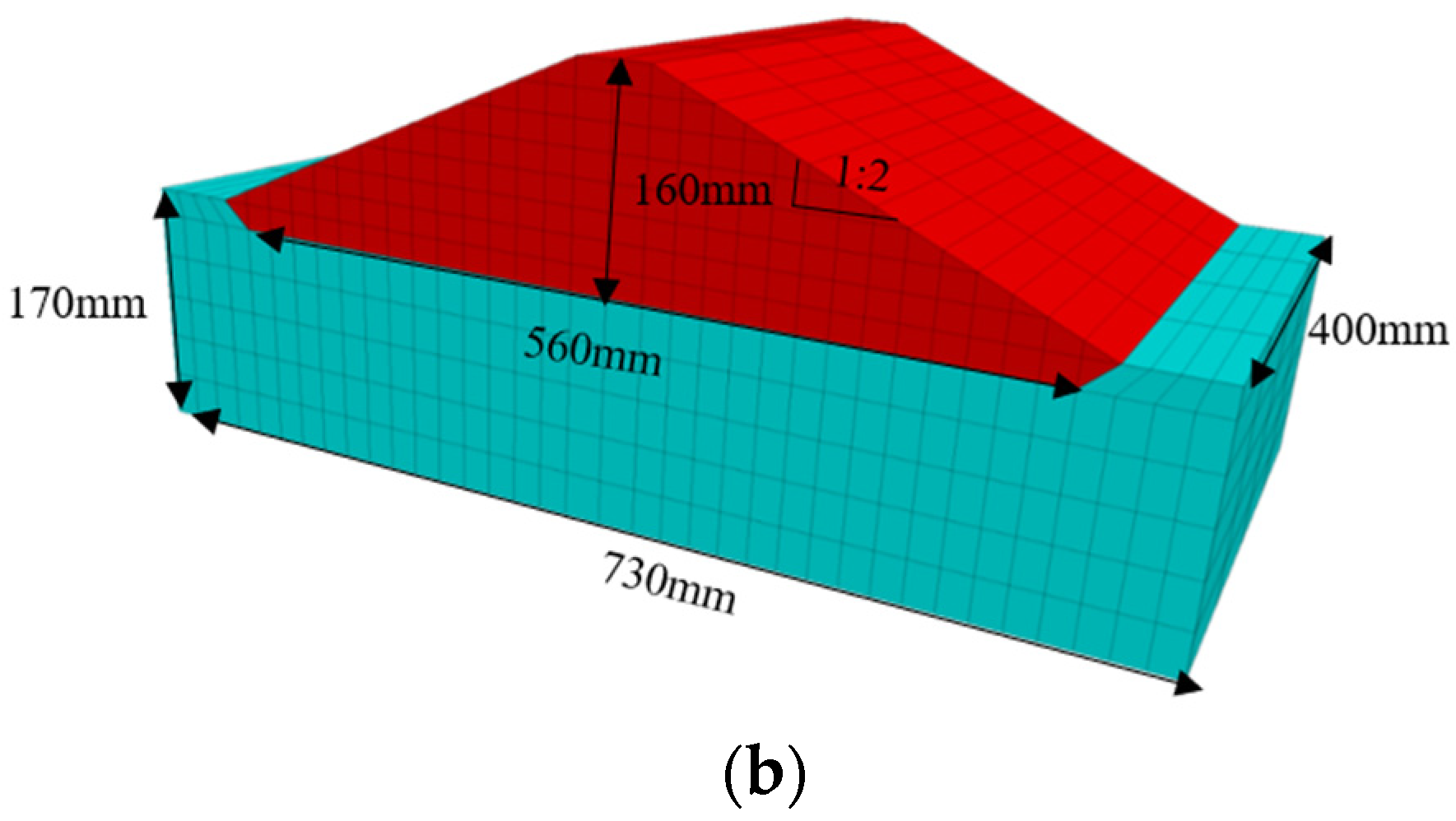

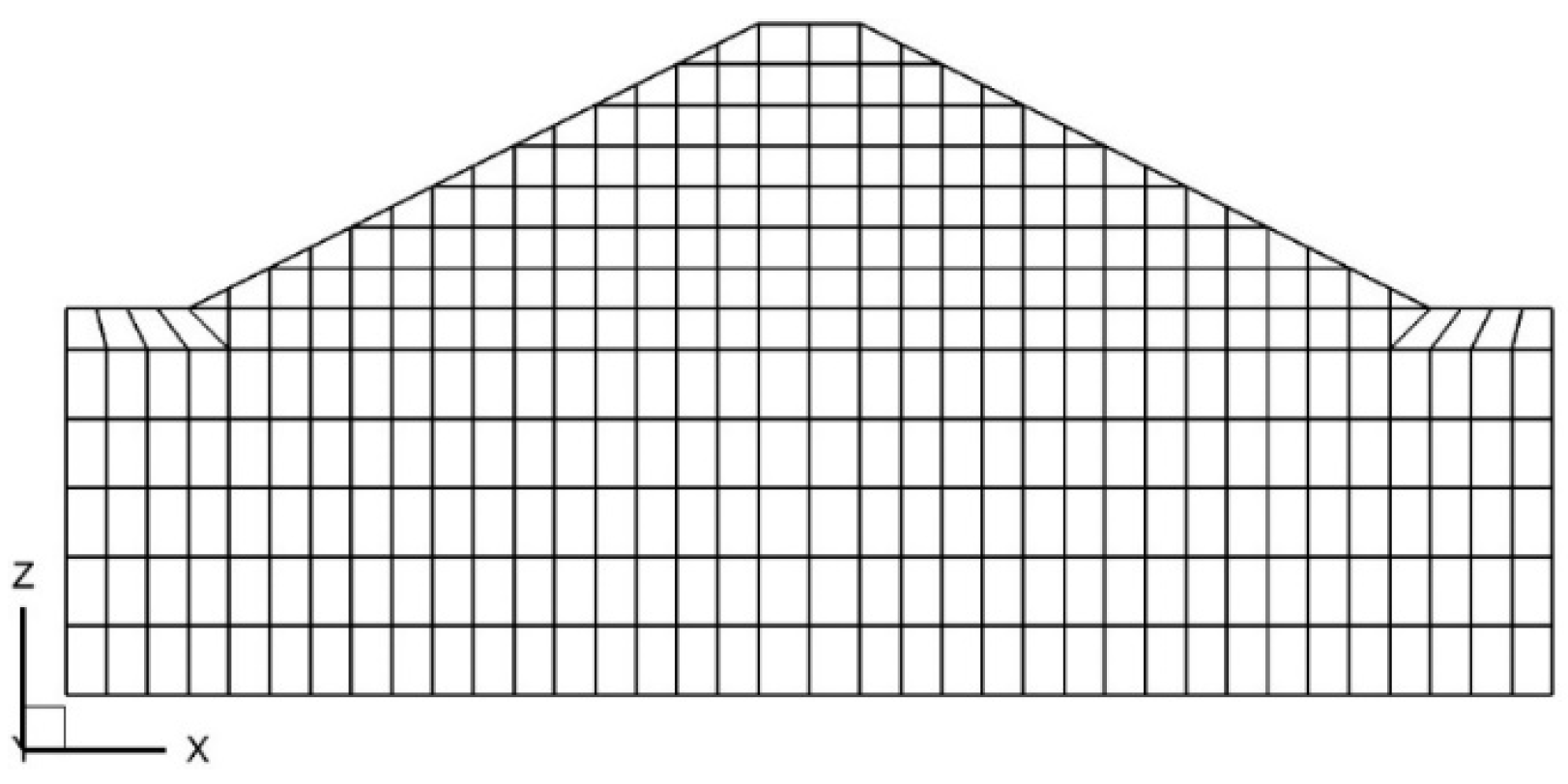

3. Establishment of Computational Model

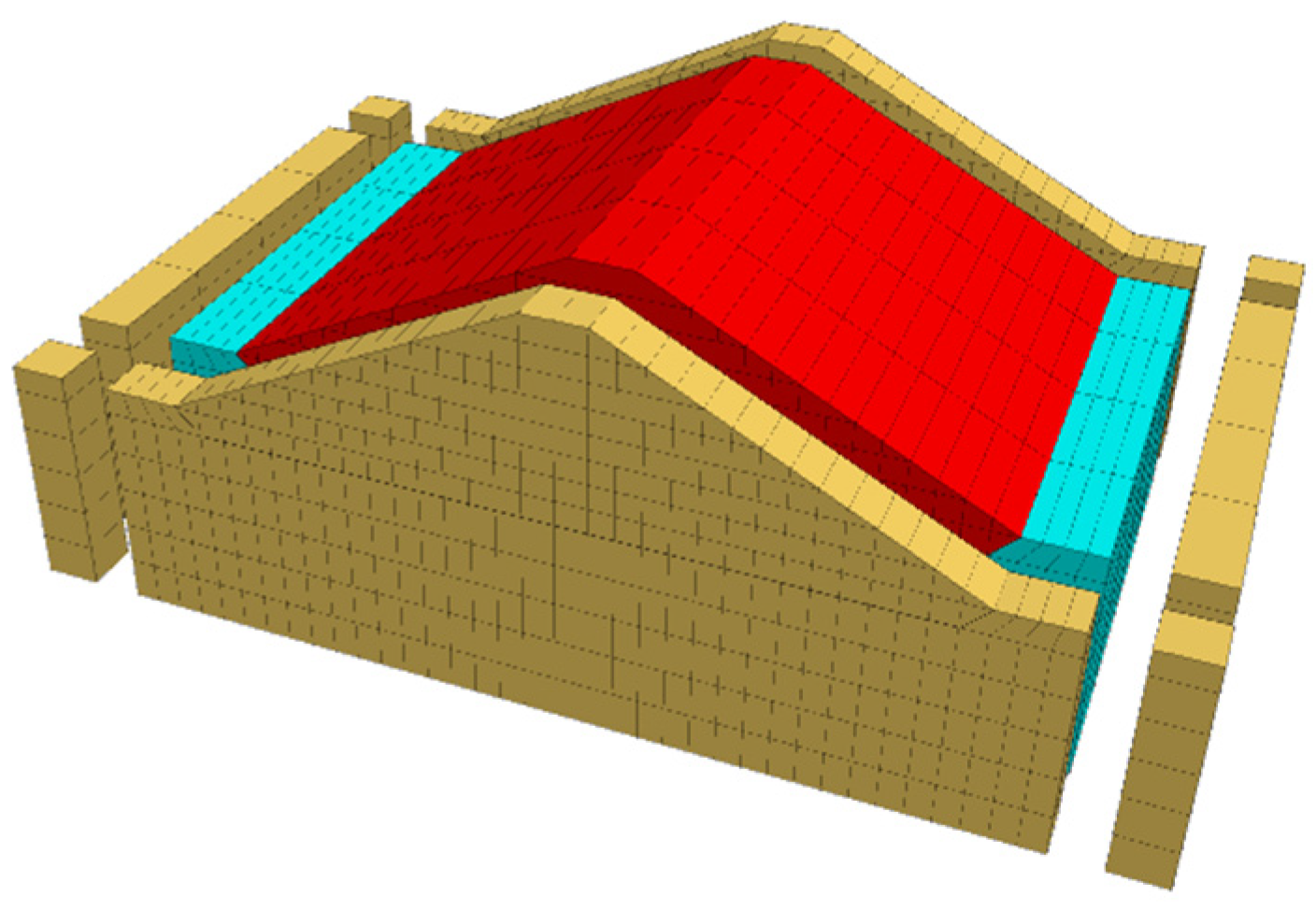

3.1. Model

3.2. Material Parameters

3.3. Mechanical Damping Settings

3.4. Boundary Conditions

3.5. Water Level Setting

3.6. Seismic Wave

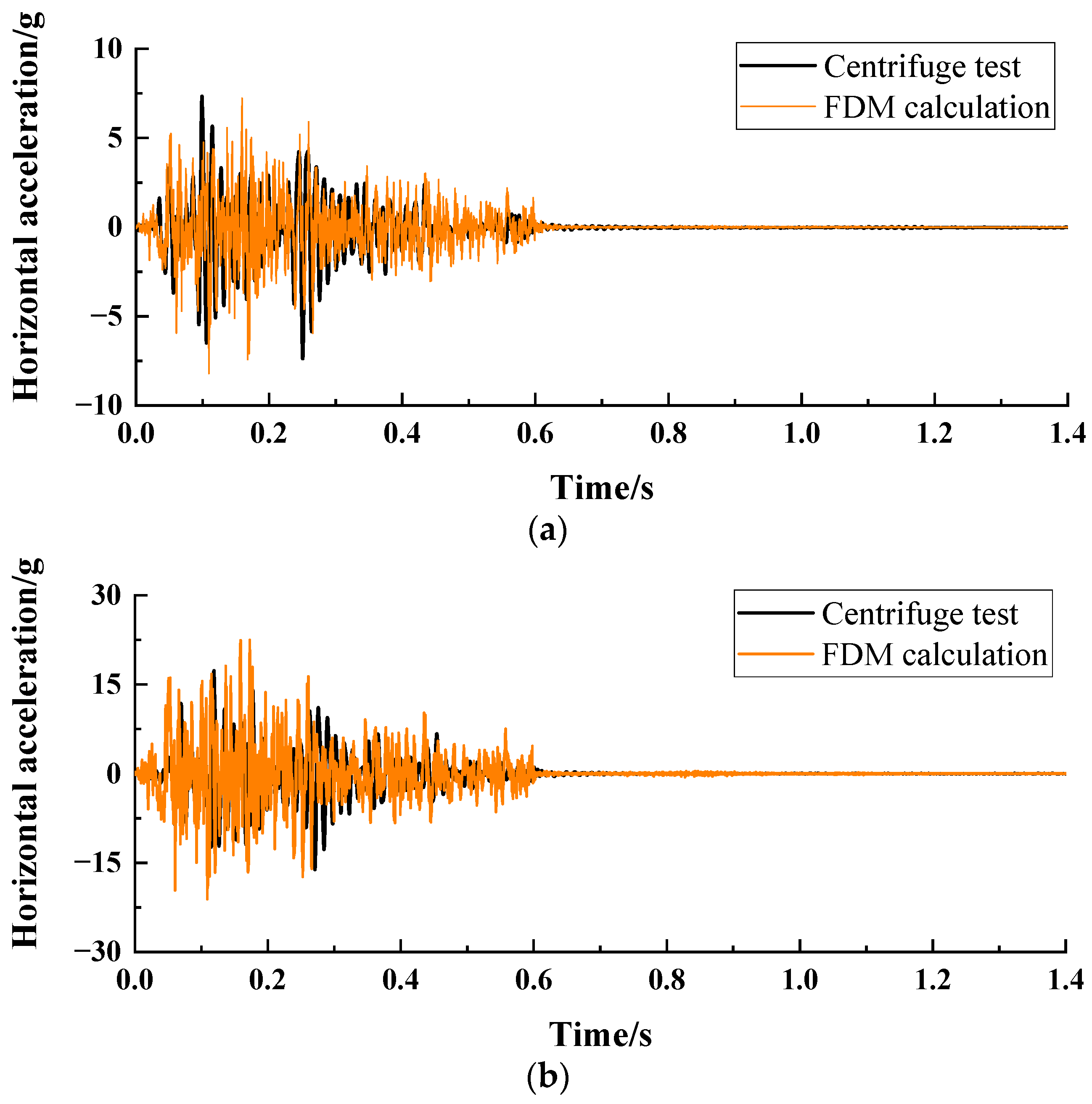

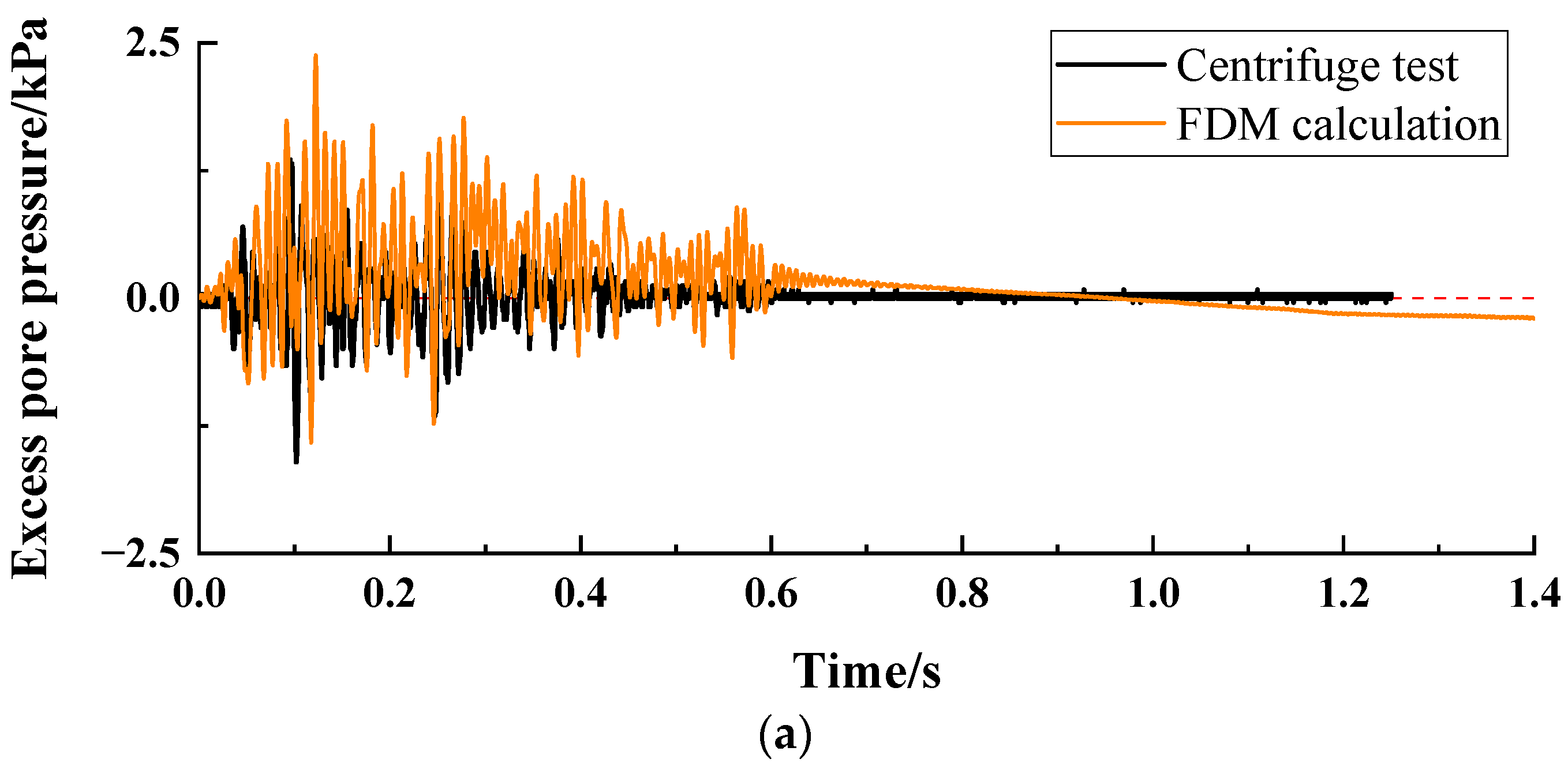

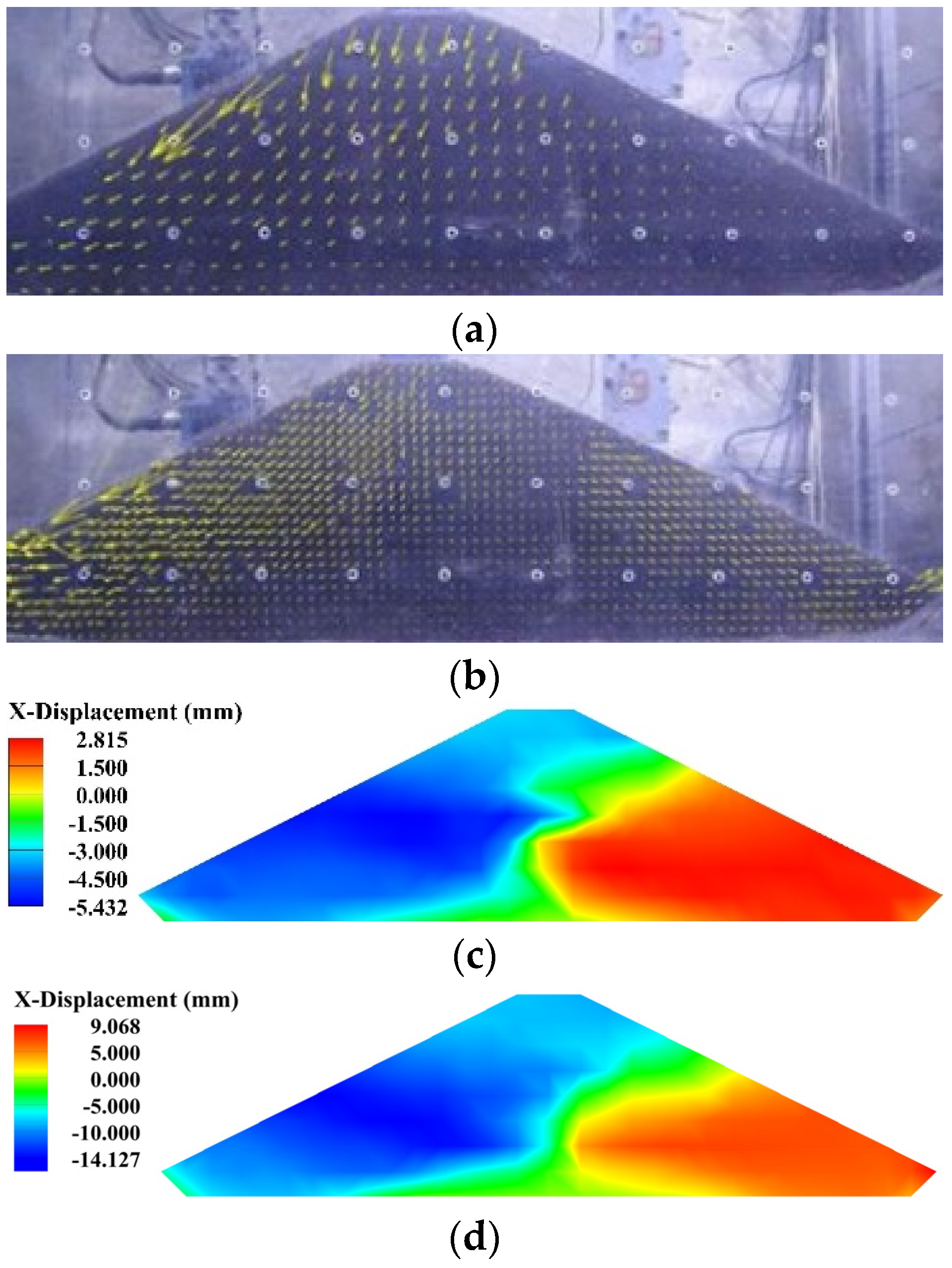

4. Numerical Model Verification

5. Analysis of Dynamic Stability

5.1. Method for Calculating the Dynamic Safety Factor

5.2. Analysis of the Seismic Stability of a Landfill using Safety Factor Time History

5.3. The Impact of the Values of Solid Waste Strength Parameters on Stability

6. Conclusions

- (1)

- The seismic acceleration, pore pressure, and deformation response of the landfill obtained through FDM nonlinear dynamic analysis are consistent with the results of centrifuge tests. The development process of pore pressure and deformation under seismic action matches the acceleration time history;

- (2)

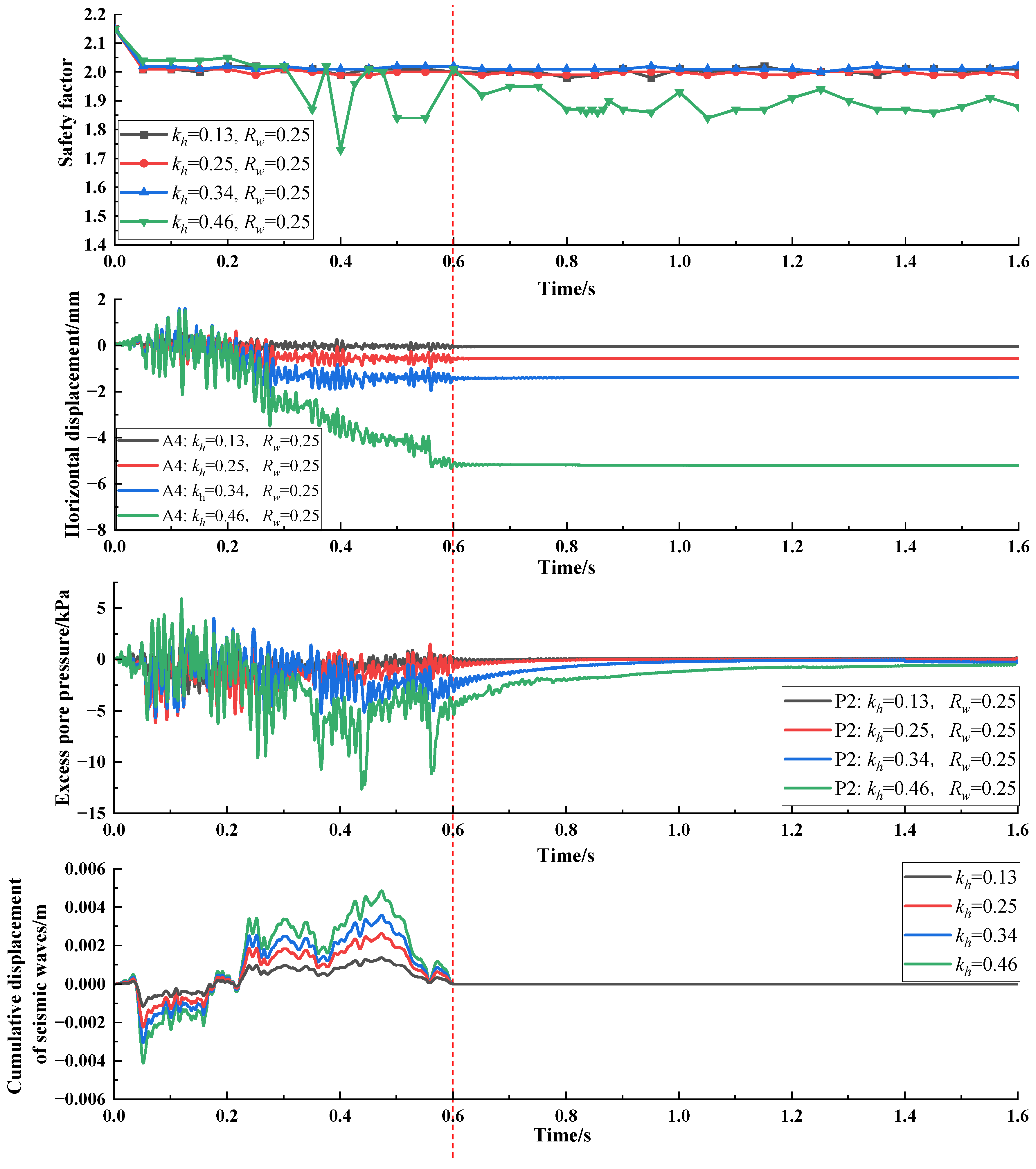

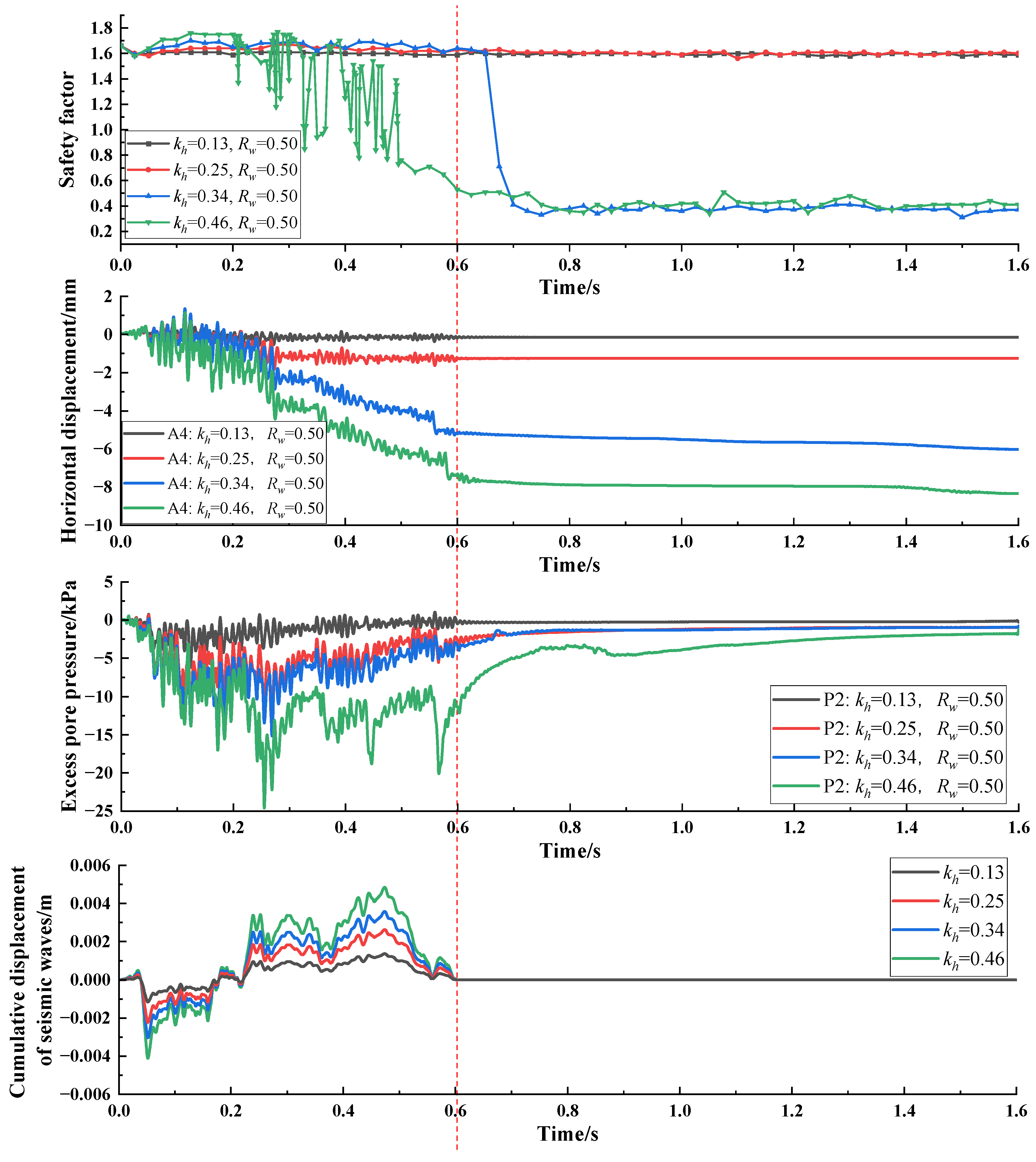

- The time history curve of the safety factor obtained based on the seismic response of the landfill is closely related to the dissipation of deformation and excess pore pressure, providing an approach to clearly and effectively assess the seismic stability of landfills. Under low water levels and small earthquake magnitude conditions, the stability of the landfill is good, though the cumulative deformation caused by earthquakes can slightly decrease the safety factor. Under high water levels and high-intensity earthquakes, the safety factor of the landfill may decrease to a critical point;

- (3)

- The instability of the landfill during earthquakes lags behind the earthquake loading process, which is related to the development of deformation and pore pressure during earthquakes. In the initial stage of earthquake loading, the safety factor of the landfill slightly increases as negative excess pore pressure accumulates. However, as the accumulated deformation caused by earthquake action weakens the landfill and the rebound of negative excess pore pressure reduces the effective stress, the safety factor gradually decreases. After the dissipation of negative excess pore pressure, the safety factor reaches its minimum value;

- (4)

- The parameters of MSW are conservative in terms of the value taken via the 10% strain at failure, leading to landfill instability during strong earthquakes. When the strength parameters are determined based on a 20% strain at failure, the stability of the high-water-level landfills is good under seismic intensities of Level III, but instability still occurs under maximum seismic intensity;

- (5)

- The strength parameters of MSW directly affect the seismic stability of high-water-level landfills. When the strength parameters are determined based on 10% and 20% strain at failure, instability occurs in high-water-level landfills under maximum Level I seismic intensity. This differs from observations made in centrifugal model experiments. Further research is needed to determine strength parameter values in the dynamic response analysis of solid waste;

- (6)

- Factors that affect the difference between centrifuge test results and FDM nonlinear analysis results include assumptions, boundary conditions, parameter values in numerical calculations, and experimental factors such as loading, operation, and equipment, which have not been explored.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, K.N.; Goel, S. Characterization of Municipal Solid Waste (MSW) and a Proposed Management Plan for Kharagpur, West Bengal, India. Resour. Conserv. Recycl. 2009, 53, 166–174. [Google Scholar] [CrossRef]

- Hla, S.S.; Roberts, D. Characterisation of Chemical Composition and Energy Content of Green Waste and Municipal Solid Waste from Greater Brisbane, Australia. Waste Manag. 2015, 41, 12–19. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C. Municipal Solid Waste Management in Beijing: Characteristics and Challenges. Waste Manag. Res. 2013, 31, 67–72. [Google Scholar] [CrossRef]

- Zhan, L.-T.; Xu, H.; Chen, Y.-M.; Lü, F.; Lan, J.-W.; Shao, L.-M.; Lin, W.-A.; He, P.-J. Biochemical, Hydrological and Mechanical Behaviors of High Food Waste Content MSW Landfill: Preliminary Findings from a Large-Scale Experiment. Spec. Themat. Issue Sanit. Landfilling 2017, 63, 27–40. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Zhang, Y.; Luo, D.; Chong, Z.; Li, E.; Kong, X. A Review of Municipal Solid Waste in China: Characteristics, Compositions, Influential Factors and Treatment Technologies. Environ. Dev. Sustain. 2021, 23, 6603–6622. [Google Scholar] [CrossRef]

- Fernandez, G.; Hendron, D.; Castro, A. Pore Pressure Induced Slide in Municipal Solid Waste Doña Juana Landfill—Bogota, Colombia. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; Volume 4, pp. 2253–2256. [Google Scholar] [CrossRef]

- Matasovic, N.; Kavazanjian, E., Jr.; Augello, A.J.; Bray, J.D.; Seed, R.B. Solid Waste Landfill Damage Caused by 17 January 1994 Northridge Earthquake. Northridge Calif. Earthq. 1994, 17, 221–229. [Google Scholar]

- Lavigne, F.; Wassmer, P.; Gomez, C.; Davies, T.A.; Sri Hadmoko, D.; Iskandarsyah, T.Y.W.M.; Gaillard, J.; Fort, M.; Texier, P.; Boun Heng, M.; et al. The 21 February 2005, Catastrophic Waste Avalanche at Leuwigajah Dumpsite, Bandung, Indonesia. Geoenvironmental Disasters 2014, 1, 10. [Google Scholar] [CrossRef]

- Merry, S.M.; Kavazanjian, E., Jr.; Fritz, W.U. Reconnaissance of the July 10, 2000, Payatas Landfill Failure. J. Perform. Constr. Facil. 2005, 19, 100–107. [Google Scholar] [CrossRef]

- Haque, M.A. Dynamic Chracteristics and Stability Analysis of Muncipal Solid Waste in Bioreactor Landfills. Ph.D. Thesis, The University of Texas at Arlington, Arlington, TX, USA, 2007. [Google Scholar]

- Li, J. Studies on Static and Seismic Stability of Landfills with High Water Level by Centrifugal Model Tests. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2018. [Google Scholar]

- Idriss, I.M.; Fiegel, G.L.; Hudson, M.B.; Mundy, P.K.; Herzig, R. Seismic Response of the Operating Industries Landfill. In Earthquake Design and Performance of Solid Waste Landfills; ASCE: San Diego, CA, USA, 1995; pp. 83–118. [Google Scholar]

- Matasović, N.; Kavazanjian, E. Cyclic Characterization of OII Landfill Solid Waste. J. Geotech. Geoenvironmental Eng. 1998, 124, 197–210. [Google Scholar] [CrossRef]

- Augello Anthony, J.; Bray Jonathan, D.; Abrahamson Norman, A.; Seed Raymond, B. Dynamic Properties of Solid Waste Based on Back-Analysis of OII Landfill. J. Geotech. Geoenvironmental Eng. 1998, 124, 211–222. [Google Scholar] [CrossRef]

- Peng, R. Stability of Municipal Solid Waste Landfill within High Water Level. Ph.D. Thesis, Beihang University, Beijing, China, 2016. [Google Scholar]

- Kavazanjian, E.; Gutierrez, A. Large Scale Centrifuge Test of a Geomembrane-Lined Landfill Subject to Waste Settlement and Seismic Loading. Waste Manag. 2017, 68, 252–262. [Google Scholar] [CrossRef]

- Thusyanthan, I.; Madabhushi, G.; Singh, S. Centrifuge Modeling of Solid Waste Landfill Systems—Part 2: Centrifuge Testing of Model Waste. Geotech. Test. J. 2006, 29, 223–229. [Google Scholar] [CrossRef]

- Sarmah, P.; Ishiguro, T.; Maruyama, K.; Xue, T.; Yamawaki, A.; Katsumi, T.; Takai, A.; Omine, K.; Doi, Y. Mechanical Behavior of Inert Waste Landfills under Seismic Condition. J. Mater. Cycles Waste Manag. 2022, 24, 2183–2200. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Seed, R.B.; Seed, H.B. Kettleman Hills Waste Landfill Slope Failure. I: Liner-System Properties. J. Geotech. Eng. 1990, 116, 647–668. [Google Scholar] [CrossRef]

- Qian, X.; Koerner, R.M. Modification to Translational Failure Analysis of Landfills Incorporating Seismicity. J. Geotech. Geoenvironmental Eng. 2010, 136, 718–727. [Google Scholar] [CrossRef]

- Feng, S.-J.; Gao, L.-Y. Seismic Analysis for Translational Failure of Landfills with Retaining Walls. Waste Manag. 2010, 30, 2065–2073. [Google Scholar] [CrossRef]

- Rathje, E.; Bray, J. Nonlinear Coupled Seismic Sliding Analysis of Earth Structures. J. Geotech. Geoenvironmental Eng. 2000, 126, 1002–1014. [Google Scholar] [CrossRef]

- Zania, V.; Psarropoulos, P.N.; Tsompanakis, Y. Base Sliding and Dynamic Response of Landfills. Adv. Eng. Softw. 2010, 41, 349–358. [Google Scholar] [CrossRef]

- Zania, V.; Tsompanakis, Y.; Psarropoulos, P.N. Seismic Displacements of Landfills and Deformation of Geosynthetics Due to Base Sliding. Geotext. Geomembr. 2010, 28, 491–502. [Google Scholar] [CrossRef]

- Feng, S.-J.; Chang, J.-Y.; Chen, H.-X. Seismic Analysis of Landfill Considering the Effect of GM-GCL Interface within Liner. Soil Dyn. Earthq. Eng. 2018, 107, 152–163. [Google Scholar] [CrossRef]

- Feng, S.-J.; Chang, J.-Y.; Shi, H.; Zheng, Q.-T.; Guo, X.-Y.; Zhang, X.-L. Failure of an Unfilled Landfill Cell Due to an Adjacent Steep Slope and a High Groundwater Level: A Case Study. Eng. Geol. 2019, 262, 105320. [Google Scholar] [CrossRef]

- Kavazanjian, E., Jr.; Matasovic, N.; Bonaparte, R.; Schmertmann, G.R. Evaluation of MSW Properties for Seismic Analysis. In Proceedings of the Specialty Conference on Geotechnical Practice in Waste Disposal, New Orleans, LA, USA, 24–26 February 1995; 1995; pp. 1126–1141. [Google Scholar]

- Yu, Y.; Rowe, R.K. Modelling Deformation and Strains Induced by Waste Settlement in a Centrifuge Test. Can. Geotech. J. 2018, 55, 1116–1129. [Google Scholar] [CrossRef]

- Feng, S.-J.; Chang, J.-Y. Seismic Analysis of Landfill Using Advanced Numerical Approach Considering Material and Contact Nonlinearity. Eng. Geol. 2023, 312, 106955. [Google Scholar] [CrossRef]

- Marti, J.; Cundall, P. Mixed Discretization Procedure for Accurate Modelling of Plastic Collapse. Int. J. Numer. Anal. Methods Geomech. 1982, 6, 129–139. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Yang, C.; Zhu, B.; Zhan, L. Centrifuge Modeling of Municipal Solid Waste Landfill Failures Induced by Rising Water Levels. Can. Geotech. J. 2017, 54, 1739–1751. [Google Scholar] [CrossRef]

- Indrasenan Thusyanthan, N.; Gopal Madabhushi, S.; Singh, S. Centrifuge Modeling of Solid Waste Landfill Systems—Part 1: Development of a Model Municipal Solid Waste. Geotech. Test. J. 2006, 29, 217–222. [Google Scholar] [CrossRef]

- Serón, F.J.; Sanz, F.J.; Kindelan, M.; Badal, J. Finite-Element Method for Elastic Wave Propagation. Commun. Appl. Numer. Methods 1990, 6, 359–368. [Google Scholar] [CrossRef]

- Anbazhagan, P.; SivakumarBabu, G.; Lakshmikanthan, P.; VivekAnand, K. Seismic Characterization and Dynamic Site Response of a Municipal Solid Waste Landfill in Bangalore, India. Waste Manag. Res. 2016, 34, 205–213. [Google Scholar] [CrossRef]

- Naveen, B.P. Measurement of Static and Dynamic Properties of Municipal Solid Waste at Mavallipura Landfill Site, India. Int. J. Geo-Eng. 2018, 9, 26. [Google Scholar] [CrossRef]

| Material | Dry Density (kg/m3) | Water Content (%) | Porosity Ratio | Poisson Ratio | Permeability Coefficient (m/s) | Friction Angle (°) | Cohesion (kPa) |

|---|---|---|---|---|---|---|---|

| Waste | 633 | 45 | 1.6 | 0.3 | 1 × 10−5 | 10% destruction strain | |

| 18.4 | 18.0 | ||||||

| 20% destruction strain | |||||||

| 24.0 | 28.6 | ||||||

| Cemented soil bedrock | 2100 | — | — | 0.2 | — | 35.0 | 500.0 |

| Geomembrane | 1000 | — | — | 0.3 | — | 17.7 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Li, J.; Lin, H. Dynamic Stability Finite Difference Time Domain Analysis of Landfill Based on Hypergravity Test. Appl. Sci. 2024, 14, 3006. https://doi.org/10.3390/app14073006

Sun L, Li J, Lin H. Dynamic Stability Finite Difference Time Domain Analysis of Landfill Based on Hypergravity Test. Applied Sciences. 2024; 14(7):3006. https://doi.org/10.3390/app14073006

Chicago/Turabian StyleSun, Lin, Junchao Li, and Haoyu Lin. 2024. "Dynamic Stability Finite Difference Time Domain Analysis of Landfill Based on Hypergravity Test" Applied Sciences 14, no. 7: 3006. https://doi.org/10.3390/app14073006

APA StyleSun, L., Li, J., & Lin, H. (2024). Dynamic Stability Finite Difference Time Domain Analysis of Landfill Based on Hypergravity Test. Applied Sciences, 14(7), 3006. https://doi.org/10.3390/app14073006