Deep Soft Rock Tunnel Perimeter Rock Control Technology and Research

Abstract

:1. Introduction

2. Roadway Surrounding Rock Control Technology

2.1. Mechanics of Roadway Destabilization

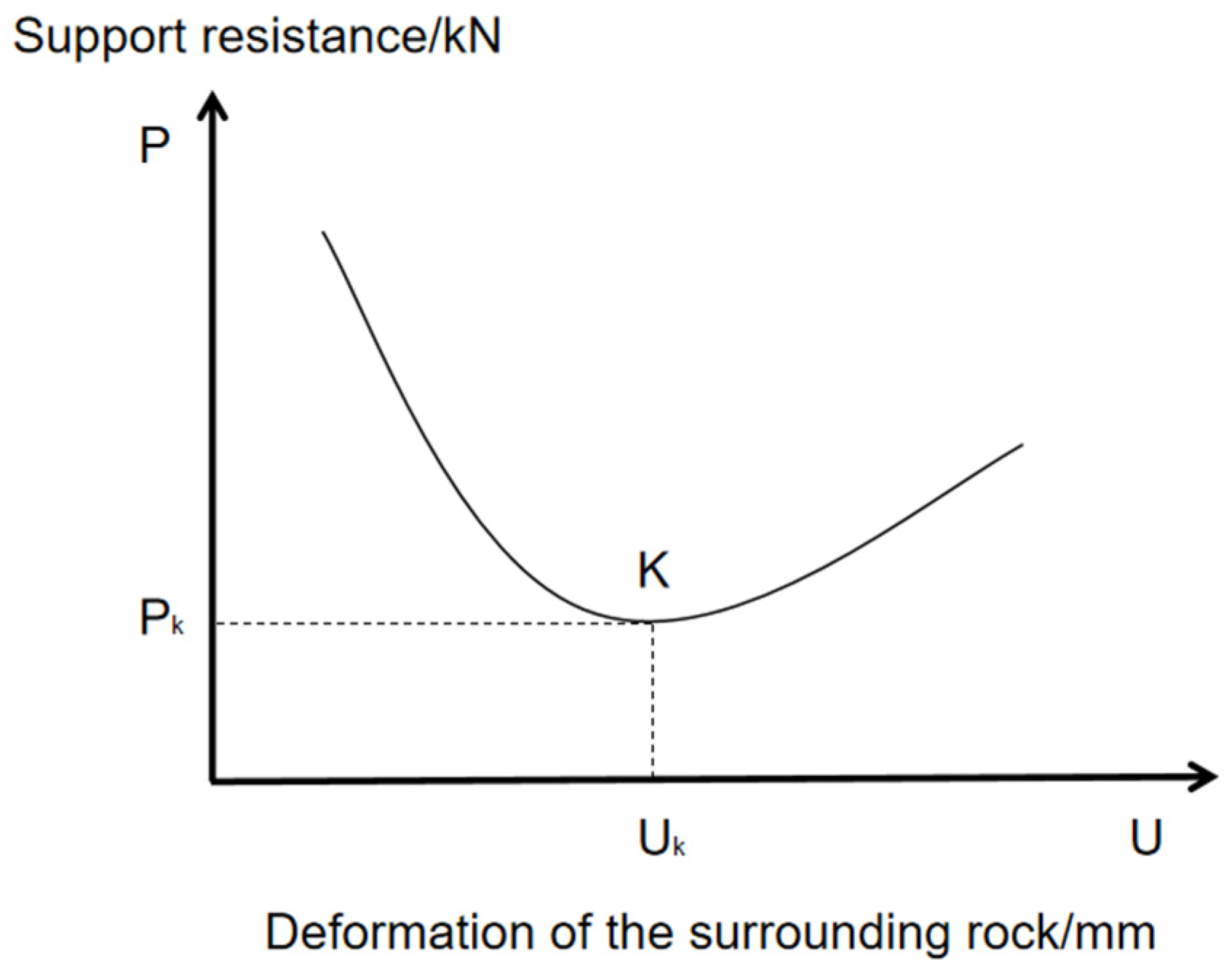

2.2. Analysis of Deformation of Broken Surrounding Rock in Deep Roadway

3. Engineering Application of Roadway Support Technology

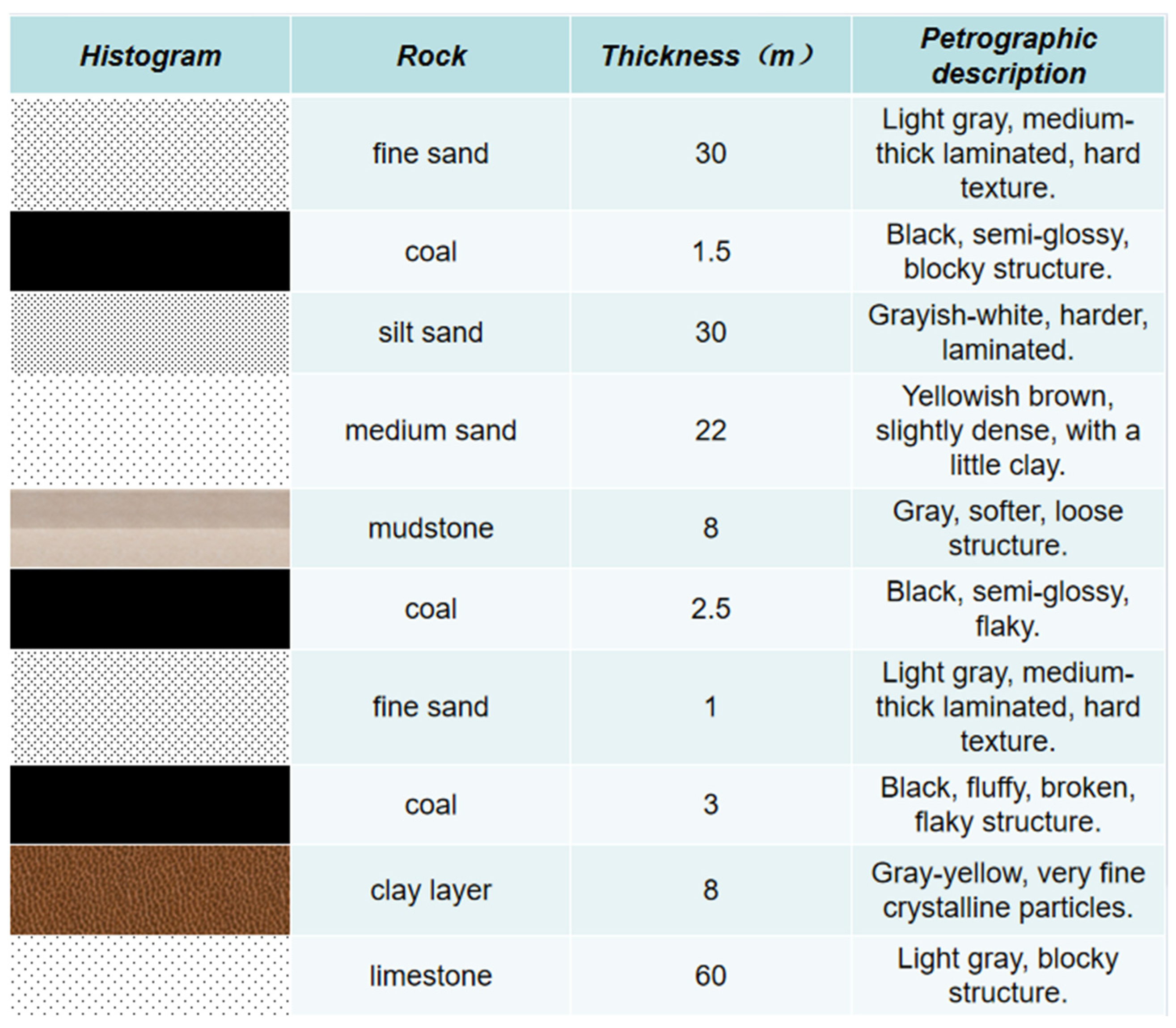

3.1. Project Overview

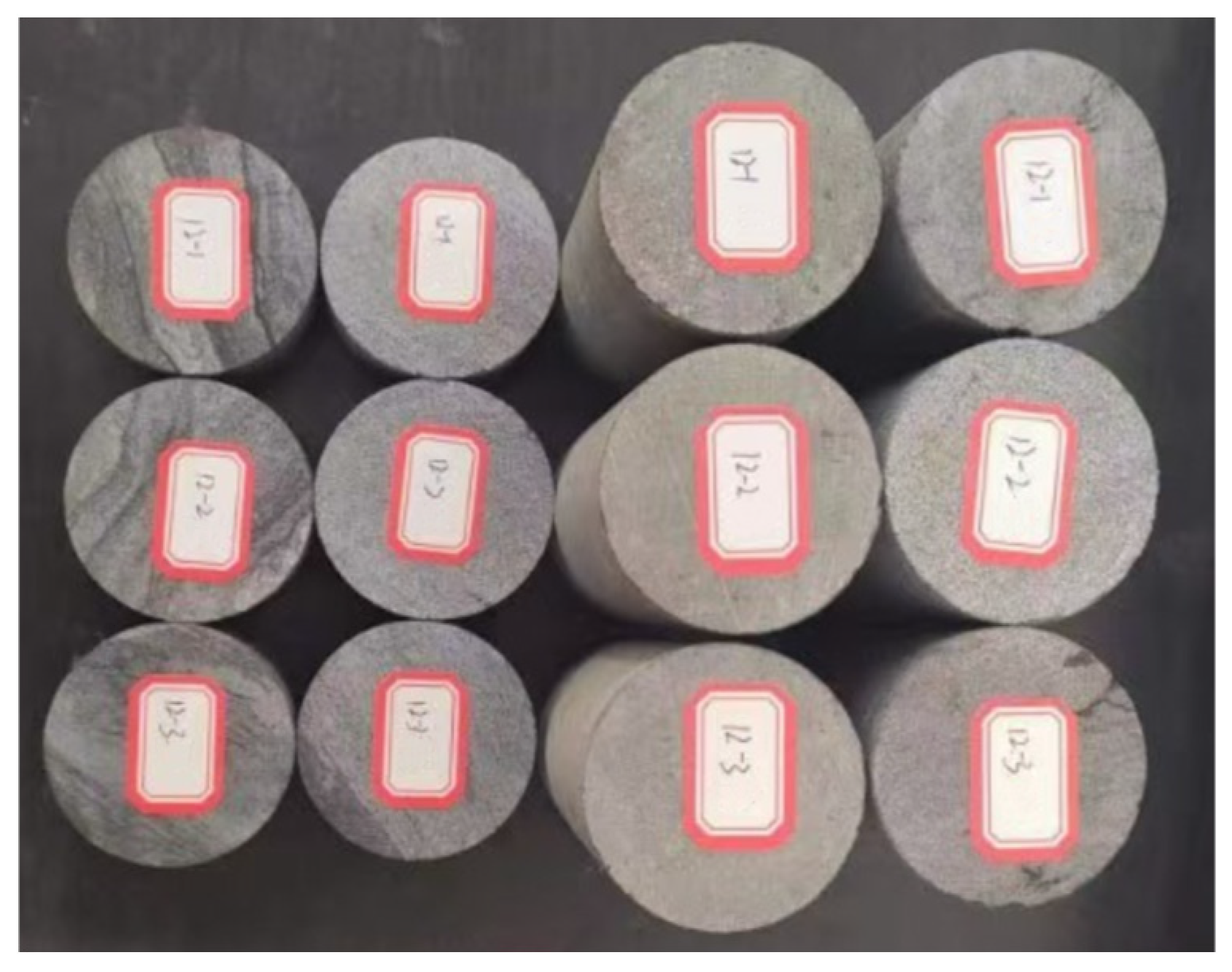

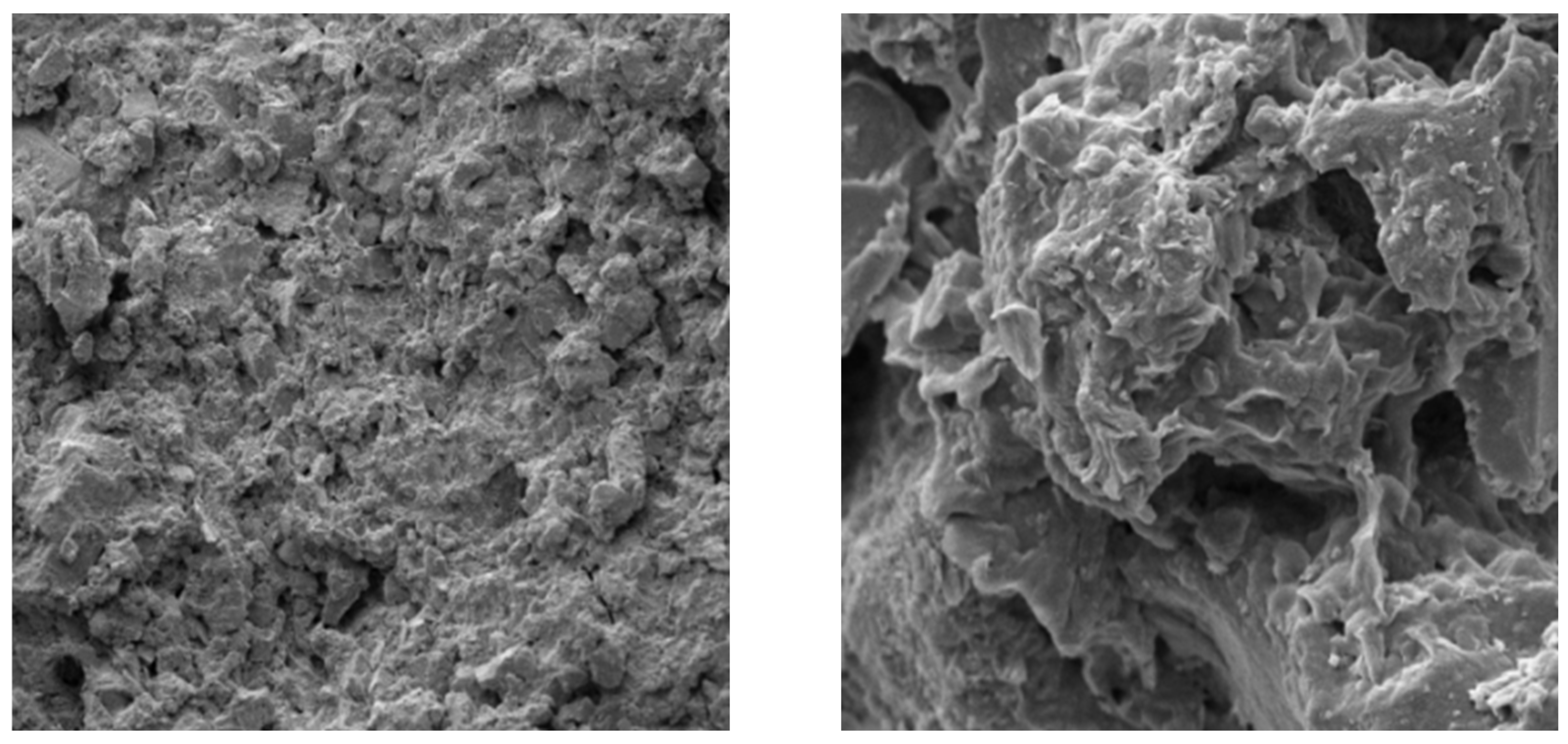

3.2. Determination of the Physical and Mechanical Parameters of the Surrounding Rock

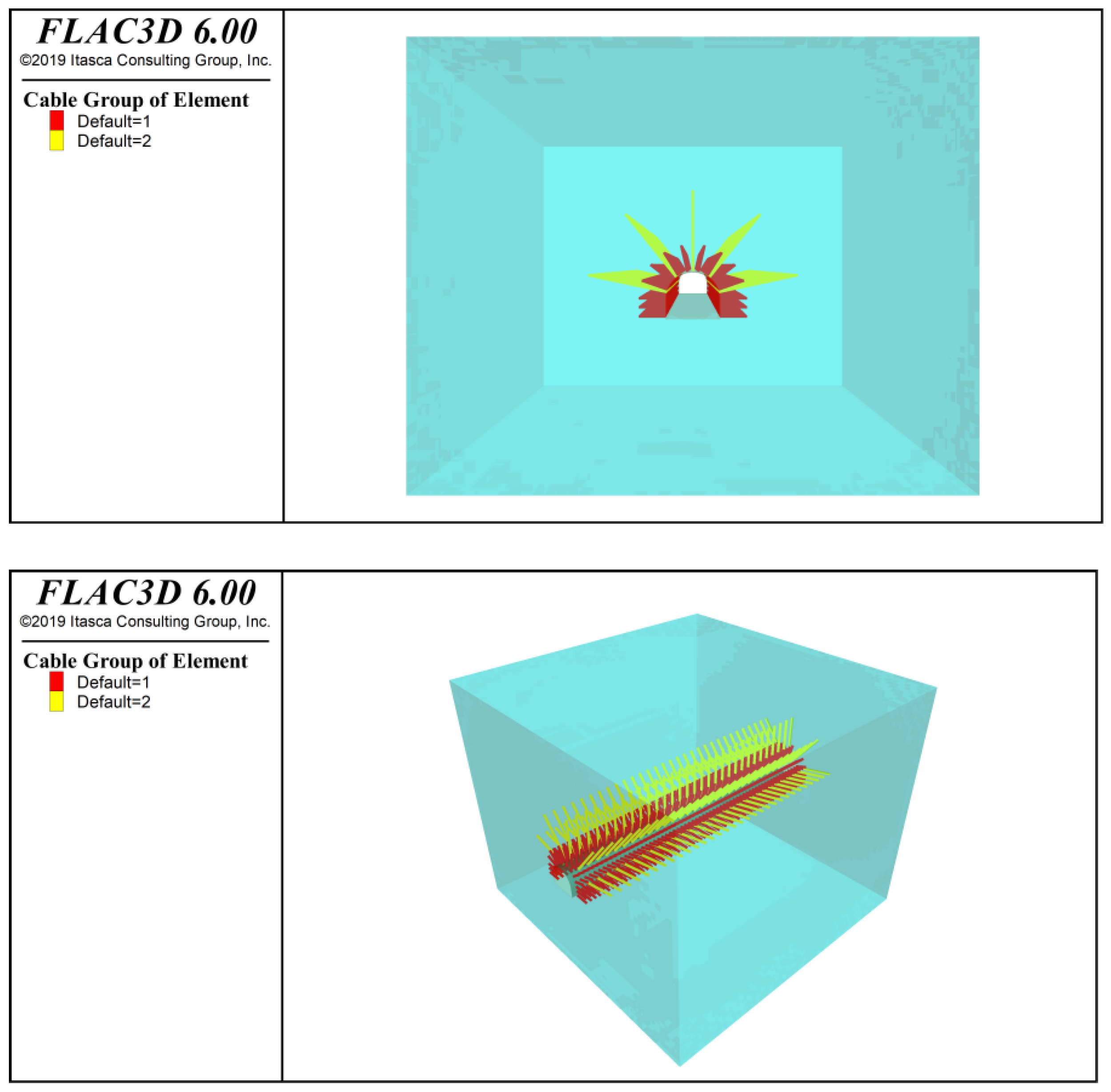

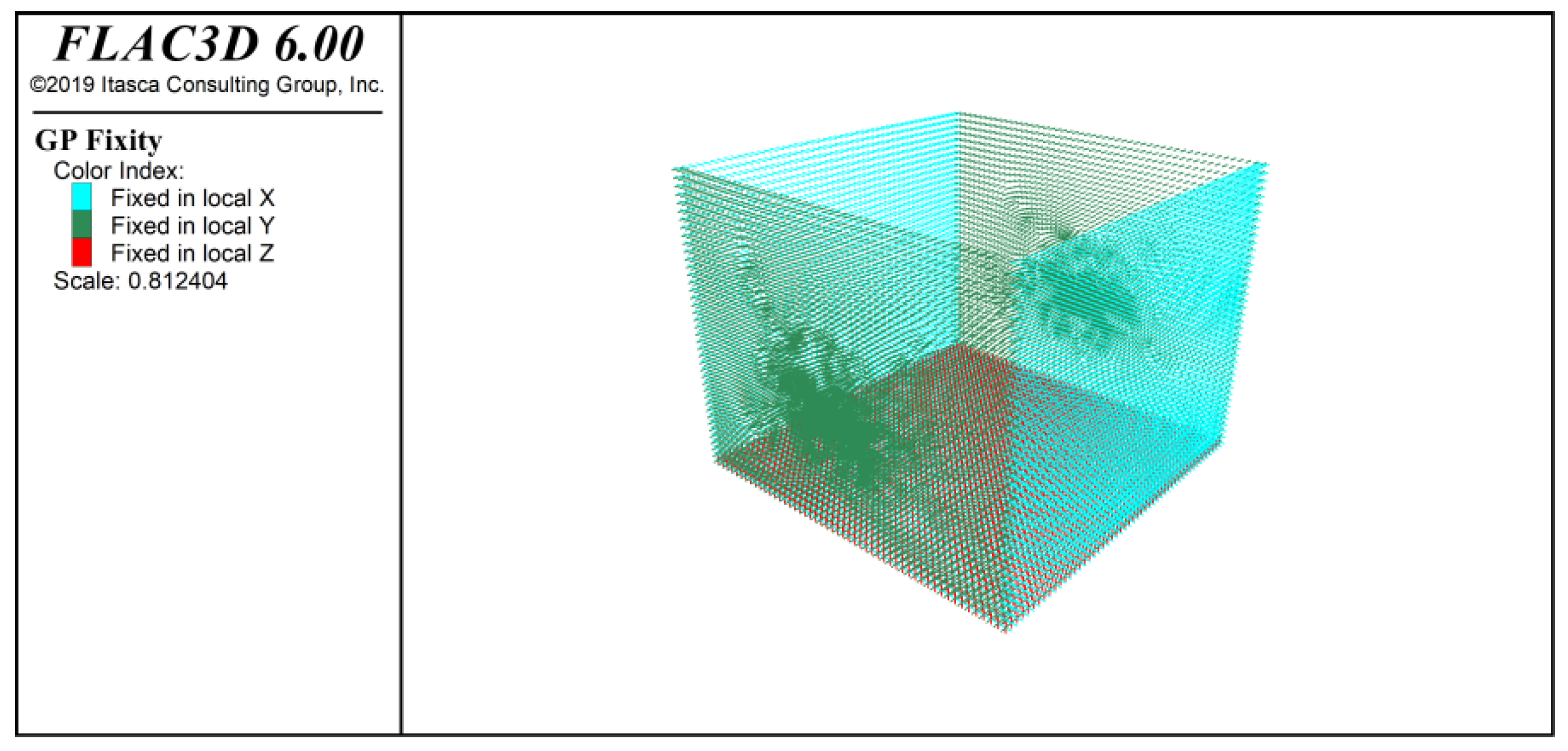

3.3. Numerical Modeling

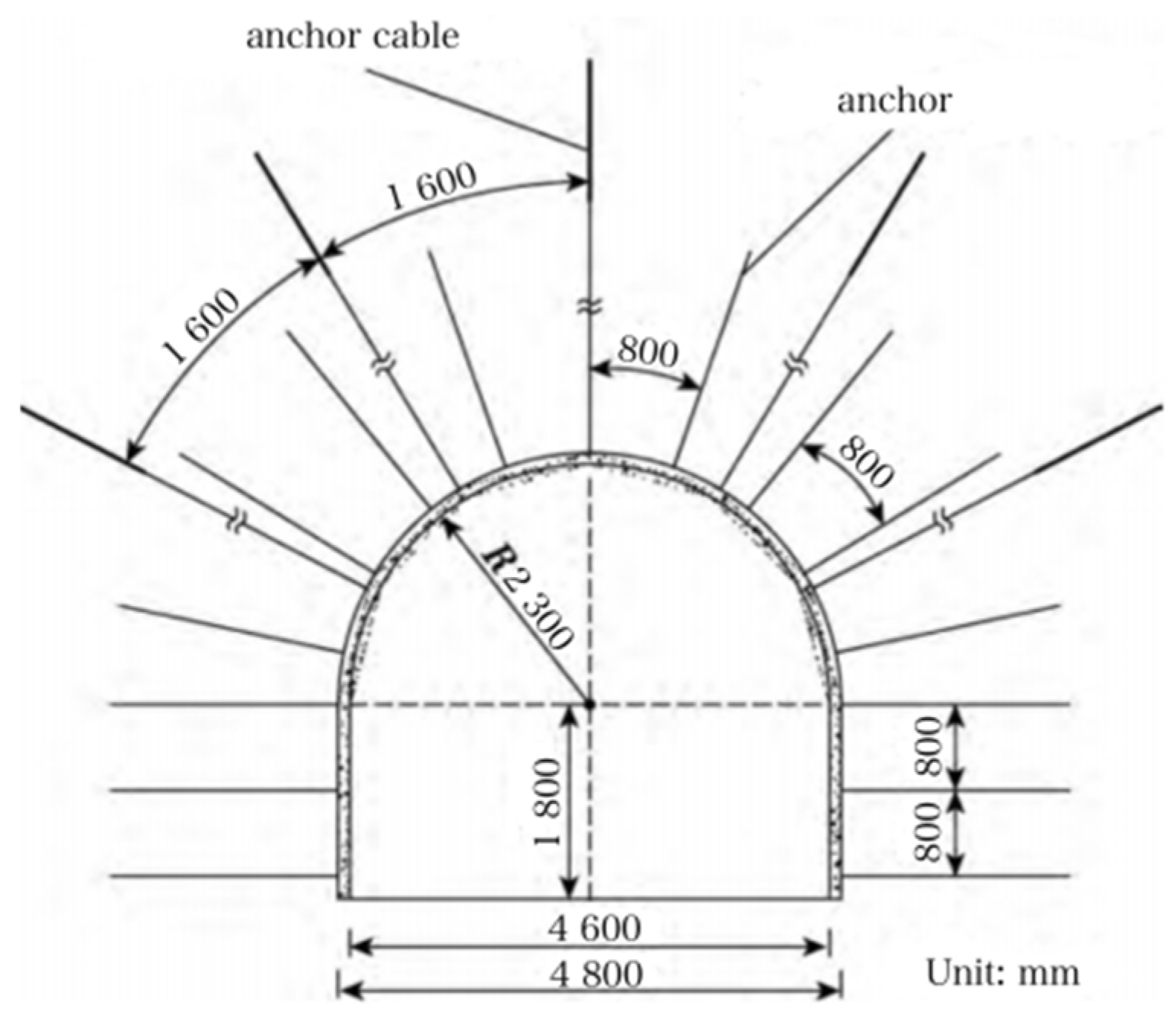

4. Roadway Support Program Design

4.1. Design of Permanent Support Parameters

- (1)

- The formula for calculating the total length of the anchor is as follows:

- (2)

- The spacing between rows of anchors is calculated as follows.

- (3)

- The formula for calculating the total length of the anchor cable is as follows:

- (4)

- Suspension theory was used to calculate the row spacing between anchor cables using the following formula:

4.2. Overhead Support and Reinforced Support

4.3. On-Site Monitoring of Perimeter Rock Deformation

5. Conclusions

- (1)

- The rupture and delamination of the rock layer are the main reasons for the damage to the roadway roof, and the elastic–plastic deformation of the surrounding rock has been completed shortly after digging in order to stop further deformation of the surrounding rock. This requires a suitable support timing and support program. Allowing the perimeter rock to creep within a certain range and releasing a certain amount of pressure not only results in a better bearing capacity and stronger resistance to perimeter rock deformation, but also allows the rock to better cope with the impact of mining pressure.

- (2)

- Using the rock samples taken from the site, the samples were subjected to an electron microscope scanning test and indoor triaxial test to obtain the physical and mechanical parameters of the surrounding rock of the roadway, and to establish a numerical model to calculate the maximum values of the roof subsidence and bottom bulge of the roadway. These values were found to be 66.3 mm and 120 mm, respectively, while the total amount of approximation was found to be about 180 mm, and the amount of approximation of the two gangs was found to be about 165 mm. The joint support program of an anchor rod + anchor cable + 36U steel metal support + netting + matting + backwall filling is proposed.

- (3)

- The displacement of the surrounding rock of the roadway is regularly monitored by the digital convergence meter, and the displacement of the surrounding rock of the roadway is obtained after the roadway is excavated and under the influence of mining. The maximum value of roof subsidence is 455 mm, and the maximum value of the two sides of the roadway is 303 mm. There are obvious convergence characteristics, and the support program can effectively control the deformation and damage of the surrounding rock.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, M.; Xie, H.; Peng, S.; Jiang, Y. Study on rock mechanics in deep mining engineering. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Kang, H.; Fan, M.; Gao, F.; Zhang, H. Deformation and support of rock roadway at depth more than 1000 meters. Chin. J. Rock Mech. Eng. 2015, 34, 2227–2241. [Google Scholar]

- Yu, W.; Wang, W.; Huang, W.; Wu, H. Deformation mechanism and rework control technology of high stress and soft rock roadway. J. China Coal Soc. 2014, 39, 614–623. [Google Scholar]

- Zhao, C.; Li, Y.; Liu, G.; Huang, S. Study on surrounding rock support technology of deep soft rock roadway. Coal Sci. Technol. 2022, 50, 76–84. [Google Scholar]

- Ren, S.; Li, Z.; Zhou, W. Research on supporting technology of broken roof roadway in loose coal seam of coal mine. China Energy Environ. Prot. 2022, 44, 39–44. [Google Scholar]

- He, M. Latest progress of soft rock mechanics and engineering in China. J. Rock Mech. Geotech. Eng. 2014, 6, 165–179. [Google Scholar] [CrossRef]

- Guo, H.; Chen, X.; He, M.; Xi, S.; Tang, J. Frictional contact algorithm study on the numerical simulation of large deformations in deep soft rock tunnels. Min. Sci. Technol. 2010, 20, 524–529. [Google Scholar] [CrossRef]

- Gao, M.; Zhao, Y.; Li, M. Roof and support and bottom yielding support with whole section and O-shape control principle for soft rock roadway and engineering practice. Rock Soil Mech. 2014, 35, 2307–2313. [Google Scholar]

- He, M.; e Sousa, R.L.; Müller, A.; Vargas, E., Jr.; e Sousa, L.R.; Chen, X. Analysis of excessive deformations in tunnels for safety evaluation. Tunn. Undergr. Space Technol. 2015, 45, 190–202. [Google Scholar]

- Huang, M.; Zhou, Z.; Huang, Y.; Ou, J. A distributed self-sensing FRP anchor with built-in optical fiber sensor. Measurement 2013, 46, 1363–1370. [Google Scholar] [CrossRef]

- Huang, M.H.; Zhou, Z.; Ou, J.P. A novel durable intelligent fiber reinforced polymer anchor with embedded optical fiber Bragg grating sensors. Sci. China Technol. Sci. 2012, 55, 1455–1462. [Google Scholar] [CrossRef]

- Lai, L. Study on the overburden movement and ore pressure manifestation law of large-scale mining and high comprehensive mining surface. China Coal 2022, 48, 125–131. [Google Scholar]

- Liu, J. Study on the ore pressure law of thick coal seam comprehensive surface. Energy Technol. Manag. 2022, 47, 114–116. [Google Scholar]

- Huang, Q. Study on the movement law of overburden mining with large inclination angle. Coal Technol. 2019, 38, 39–43. [Google Scholar]

- Xu, H. Study on the law of ore pressure display in the working face with large inclination angle. China Min. Mag. 2022, 31, 102–109. [Google Scholar]

- Liu, J.; Dong, G. Study on the breaking law of roof of extra thick loose overlying coal mining face. Shanxi Coking Coal Sci. Technol. 2013, 37, 10–12+15. [Google Scholar]

- Jarred, D.J.; Haberfield, C.M. Tendon/grout interface performance in grouted anchors. In Ground Anchorages and Anchored Structures; Thomas Telford: London, UK, 1997. [Google Scholar]

- Stillborg, B. Experimental Investigation of Steel Cables for Rock Reinforcement in Hard Rock. Ph.D. Thesis, Lulea University of Technology, Luleå, Sweden, 1984. [Google Scholar]

- Goto, Y.; Obata, M.; Maeno, H.; Kobayashi, Y. Failure mechanism of new bond-type anchor anchor bolt subject to tension. J. Struct. Eng. 1993, 119, 1168–1187. [Google Scholar] [CrossRef]

- Cook, R.A. Behavior of chemically bonded anchors. J. Struct. Eng. 1993, 119, 2744–2762. [Google Scholar] [CrossRef]

- Obata, M.; Inoue, M.; Goto, Y. The failure mechanism and the pull-out strength of a bond-type anchor near a free edge. Mech. Mater. 1998, 28, 113–122. [Google Scholar] [CrossRef]

- Bylapudi, G. Corrosion of Rock Anchors in US Coal Mines. Master’s Thesis, Southern Illinois University at Carbondale, Carbondale, IL, USA, 2010. [Google Scholar]

- Zhang, G. Study on the law of roof collapse of the 3207 large mining height working face of Shanxi Holsinghe Coal Mine. Zhongzhou Coal 2016, 20, 68–70. [Google Scholar]

- Wang, H. Numerical analysis of the first collapse of the roof of the coal mining face. Energy Sci. Technol. 2022, 20, 22–27. [Google Scholar]

- Li, Z.; Wang, F.; Tian, B.; Wu, J.; Jing, L.; Zhang, H. Numerical simulation study on support technology of soft rock roadway in Daliu Coal Mine. China Coal 2022, 48, 20–26. [Google Scholar]

- Lin, T.; Liu, S.; Wang, M. Research on surrounding rock control technology of soft rock roadway based on combined support with O-type arch. China Coal 2015, 22, 60–63. [Google Scholar]

- Li, C.; Zhao, Y.; Zhang, J.; Ma, W.; Deng, X. Research on Control Mechanism and Supporting Technology of Peripheral Rock in Deep Soft Rock Roadway; China University of Mining and Technology Publishing House: Xuzhou, China, 2020; Volume 4, pp. 8–12. [Google Scholar]

| Sectional Grouping | Nodal Direction | Nodal Tendency | Sectional Inclination | Joint Spacing |

|---|---|---|---|---|

| A | Vertical orientation | NW | 85°~90° | 6~10 cm |

| B | Vertical orientation | NE | 70°~90° | 14~16 cm |

| Rock Type | Gravitational Density γ (kN/m3) | Modulus of Elasticity E (Mpa) | Compressive Strength (Mpa) | Tensile Strength (Mpa) | Poisson’s Ratio μ | Angle of Internal Friction (°) | Cohesive Force c (Mpa) |

|---|---|---|---|---|---|---|---|

| Sand stone | 25.5 | 12,139 | 75.65 | 8.57 | 0.26 | 33.21 | 3.96 |

| Mud stone | 22.4 | 9055 | 44.35 | 4.05 | 0.28 | 28.35 | 2.24 |

| Coal | 14.05 | 3525 | 43.21 | 0.85 | 0.015 | 30.21 | 1.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Yang, Y. Deep Soft Rock Tunnel Perimeter Rock Control Technology and Research. Appl. Sci. 2025, 15, 278. https://doi.org/10.3390/app15010278

Liu G, Yang Y. Deep Soft Rock Tunnel Perimeter Rock Control Technology and Research. Applied Sciences. 2025; 15(1):278. https://doi.org/10.3390/app15010278

Chicago/Turabian StyleLiu, Gang, and Yu Yang. 2025. "Deep Soft Rock Tunnel Perimeter Rock Control Technology and Research" Applied Sciences 15, no. 1: 278. https://doi.org/10.3390/app15010278

APA StyleLiu, G., & Yang, Y. (2025). Deep Soft Rock Tunnel Perimeter Rock Control Technology and Research. Applied Sciences, 15(1), 278. https://doi.org/10.3390/app15010278