Oil Sludge as a Rejuvenator for Aged Bitumen: Structural and Thermal Effect

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Physical Property Tests

2.2.1. Penetration Test

2.2.2. Softening Point

2.3. Rheological Properties

2.4. FTIR Spectroscopy

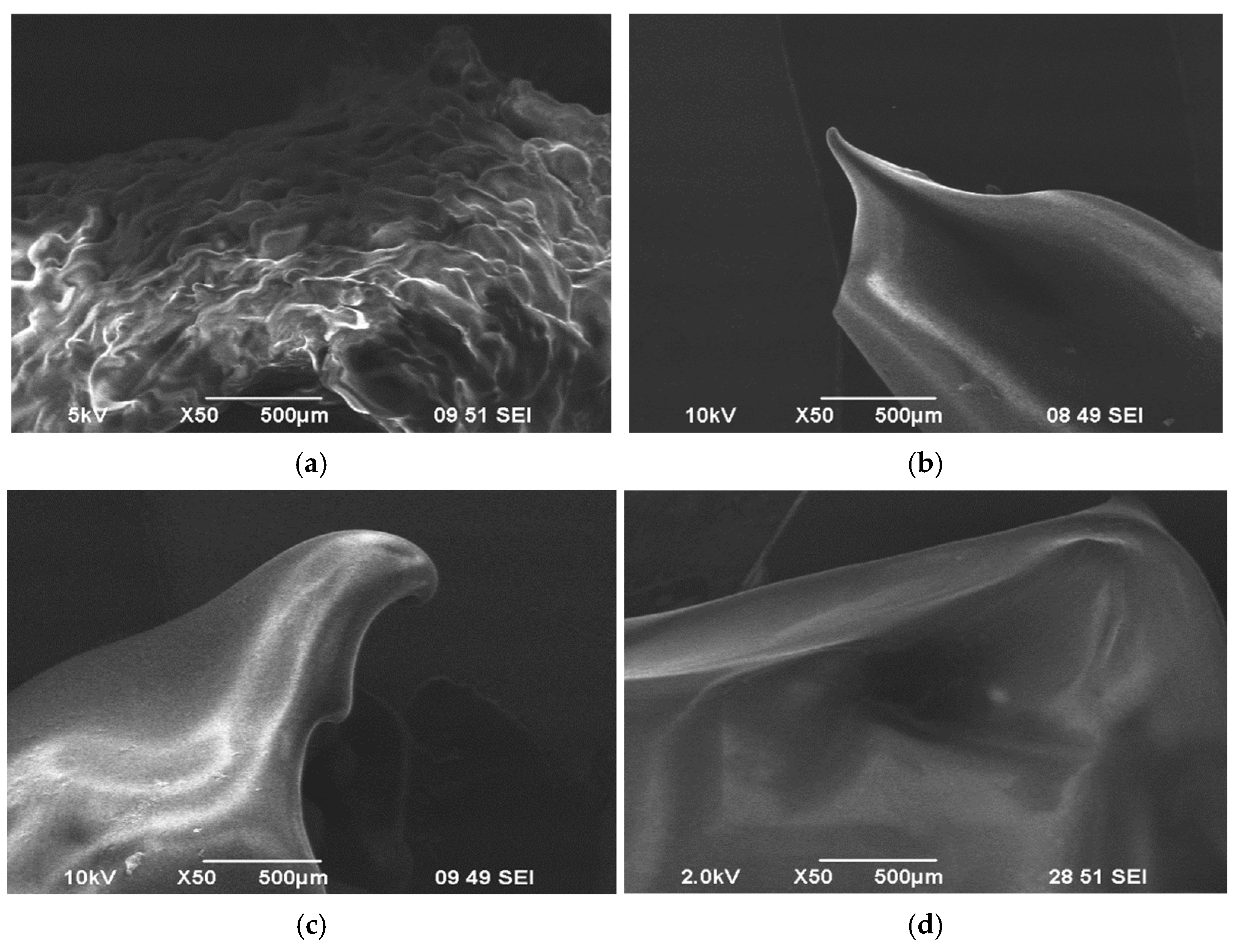

2.5. Scanning Electron Microscopy (SEM)

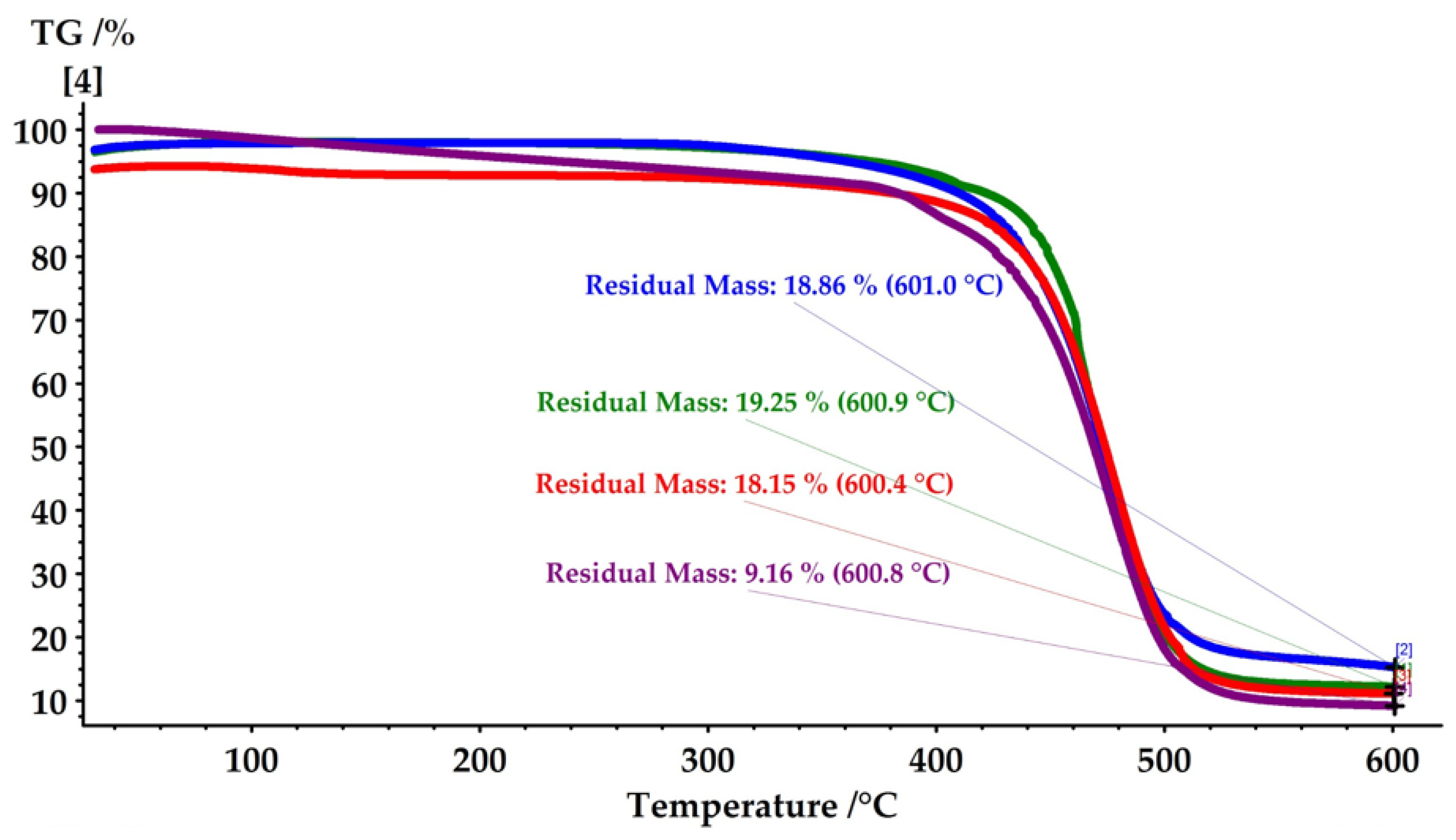

2.6. Thermogravimetric Analysis (TGA)

2.7. SARA Fractionation

3. Results

3.1. Study of Physical Properties of Aged Bitumen After Introduction of Oil Sludge

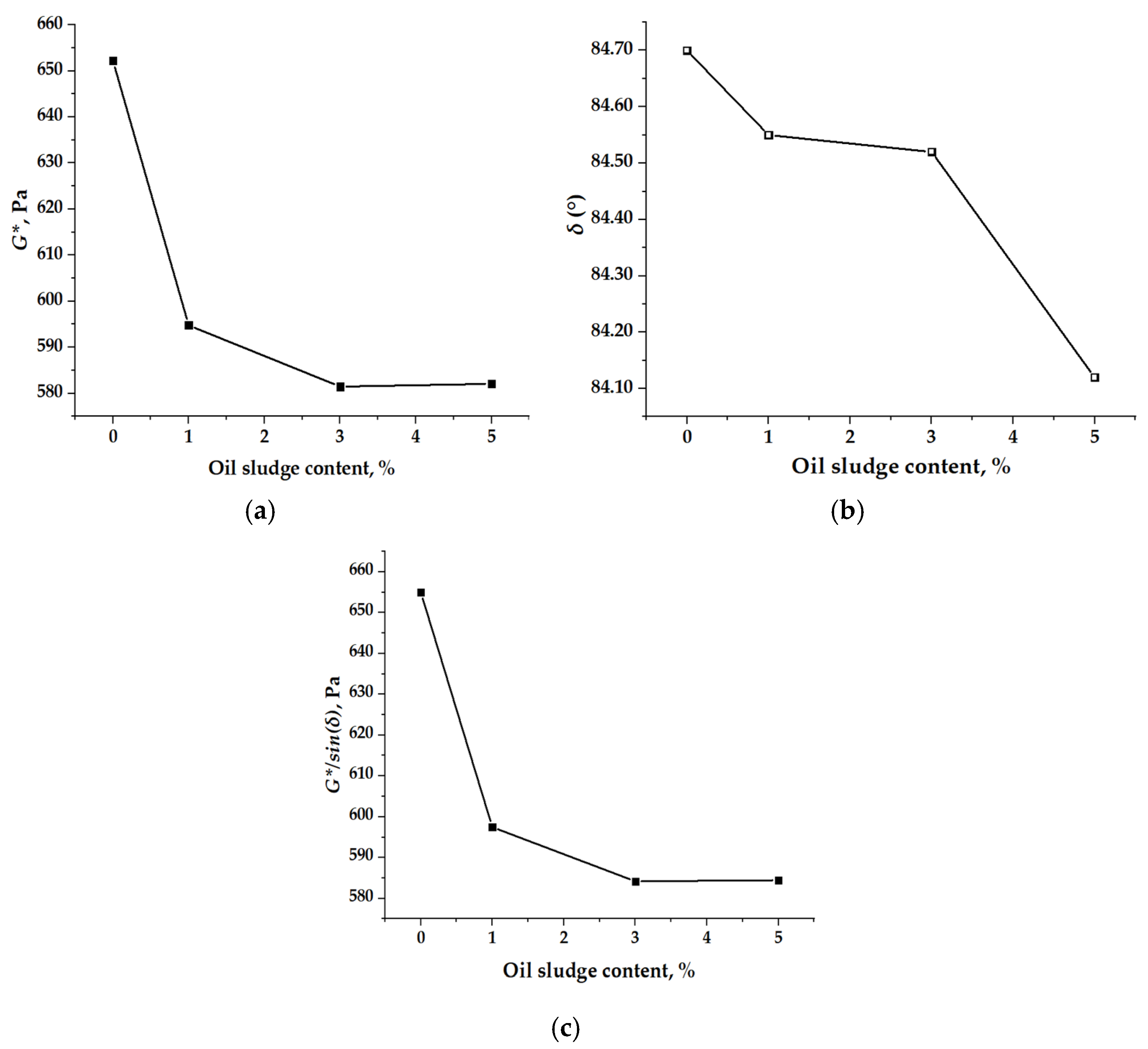

3.2. Effect of Oil Sludge on the Rheological Properties of Bitumen

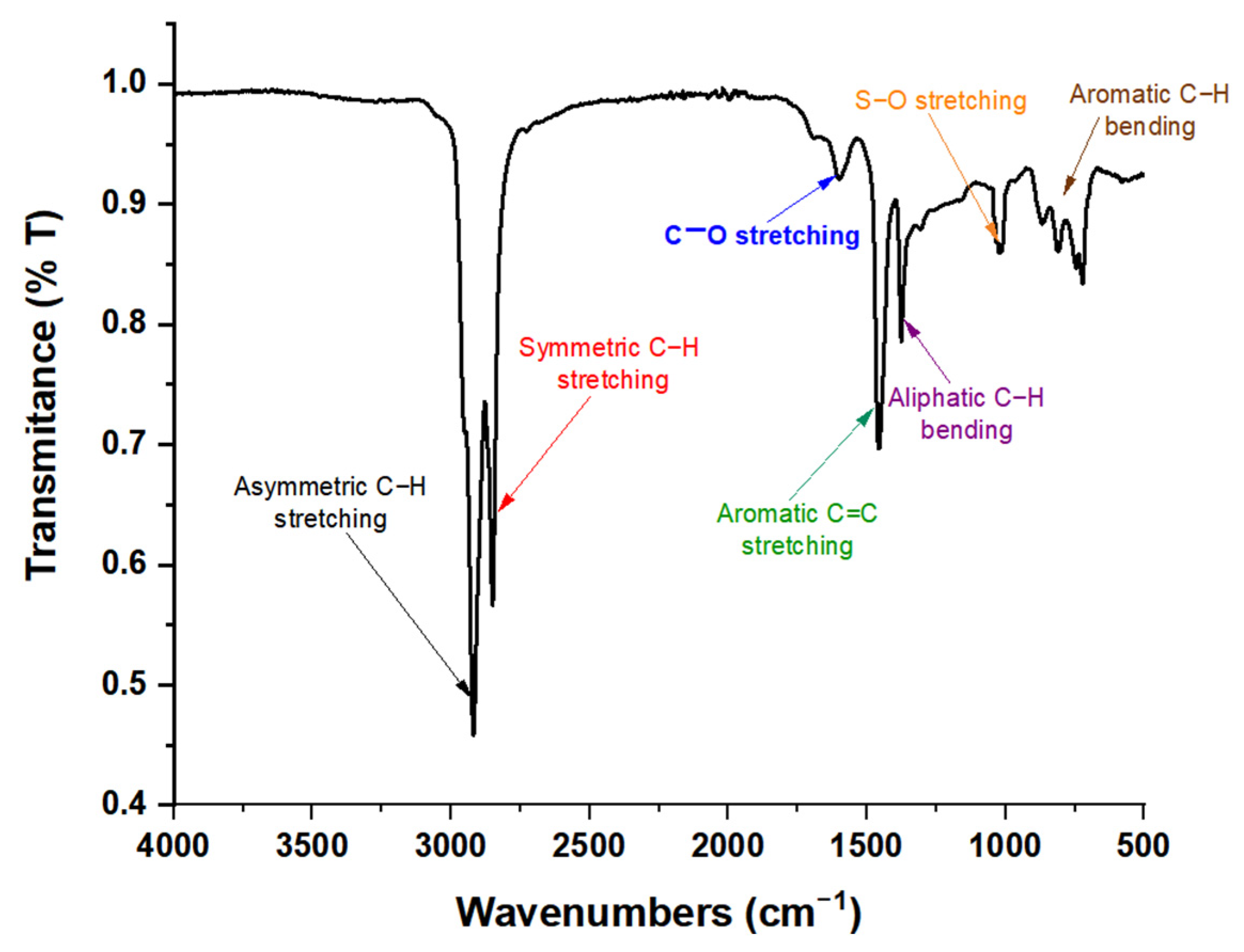

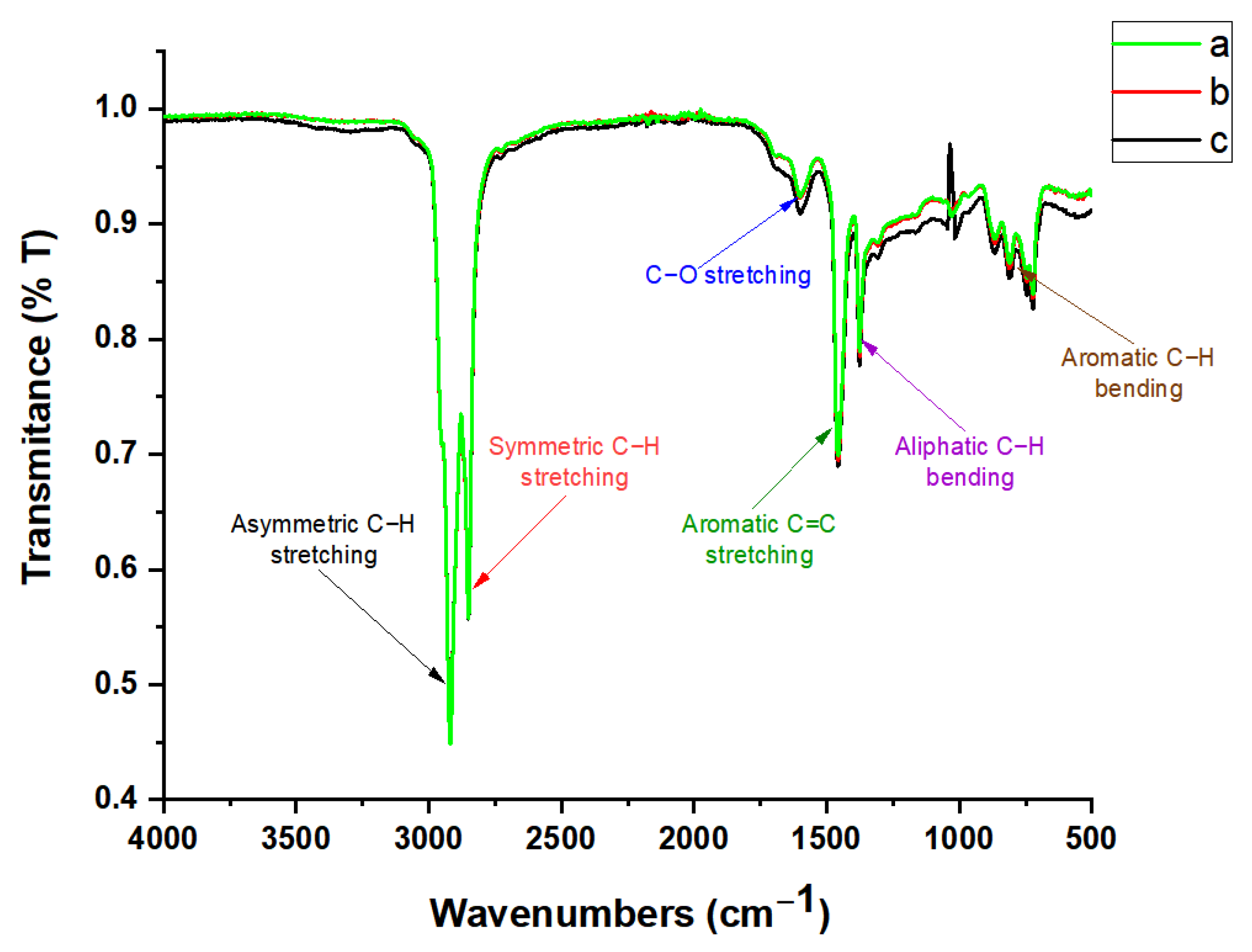

3.3. Analysis of the Impact of Oil Sludge on the Chemical Composition and Structure of Bitumen

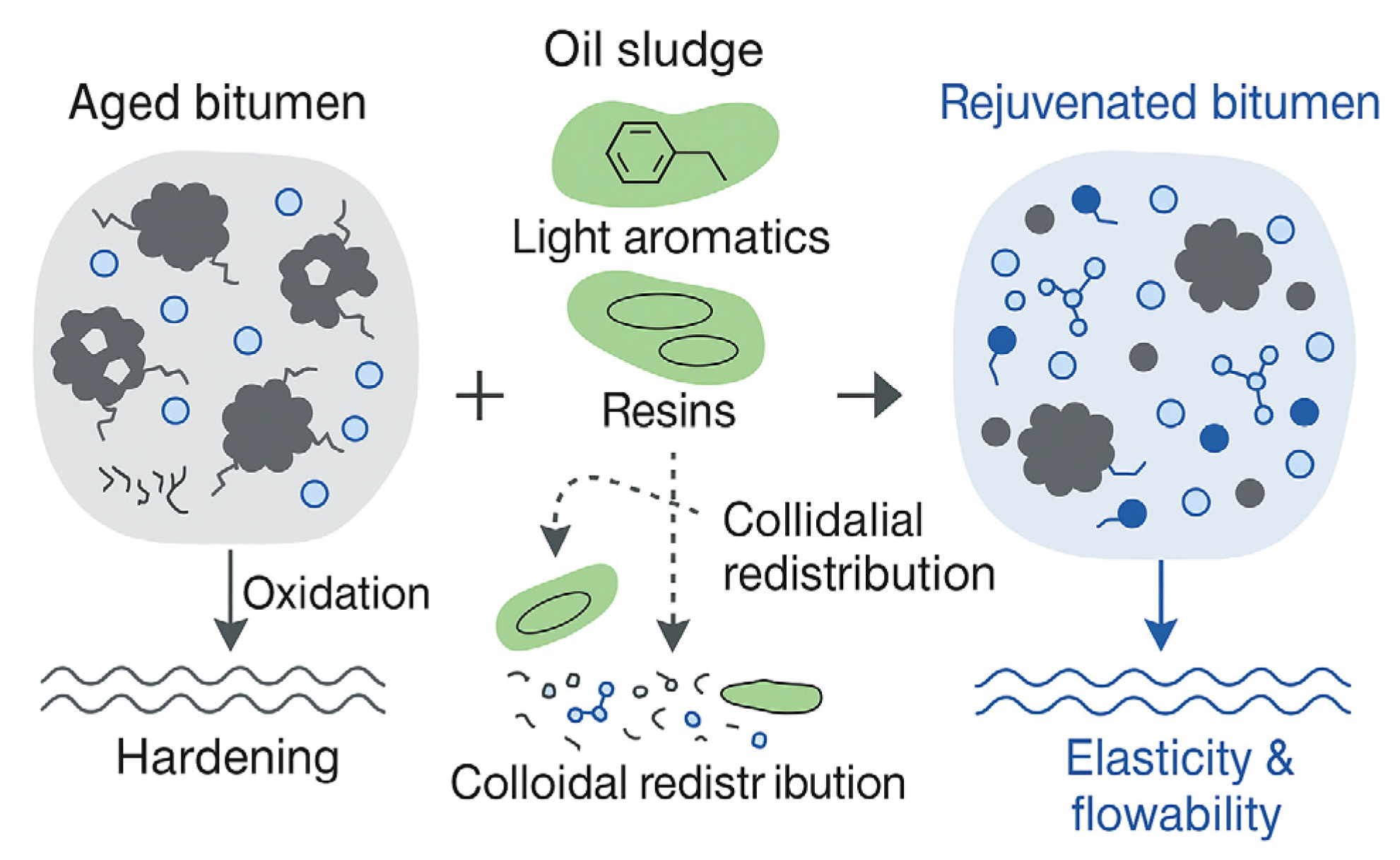

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmad, T.; Ahmad, N.; Jamal, M.; Badin, G.; Suleman, M. Investigation into the possibility of rejuvenating aged asphalt binder using mustard oil. Int. J. Pavement Eng. 2022, 23, 1738–1753. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar]

- Shen, J.; Amirkhanian, S.; Tang, B. Effects of rejuvenator on performance-based properties of rejuvenated asphalt binder and mixtures. Constr. Build. Mater. 2007, 21, 958–964. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Putra Jaya, R. The tailored traits of reclaimed asphalt pavement incorporating maltene: Performance analyses. Int. J. Pavement Eng. 2022, 23, 1800–1813. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Hasan, H.G.M.; Mohialdeen, O.K.; Dulaimi, A. Assessing the effectiveness of bio-based oil in rejuvenating aged asphalt: A comprehensive physical, rheological, chemical, and mechanical examination. Innov. Infrastruct. Solut. 2024, 9, 456. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Wang, H.; Fan, W.; Erkens, S. Evaluation of rheological behaviors and anti-aging properties of recycled asphalts using low-viscosity asphalt and polymers. J. Clean. Prod. 2020, 253, 120048. [Google Scholar] [CrossRef]

- Li, M.; Ren, S.; Liu, X.; Wu, Z.; Zhang, H.; Fan, W.; Lin, P.; Xu, J. A Comprehensive Study on the Rejuvenation Efficiency of Compound Rejuvenators. Materials. 2022, 15, 5458. [Google Scholar] [CrossRef]

- Primerano, K.; Mirwald, J.; Lohninger, J.; Hofko, B. Characterization of long-term aged bitumen with FTIR spectroscopy. Constr. Build. Mater. 2023, 409, 133956. [Google Scholar] [CrossRef]

- Malluru, S.; Islam, S.M.I.; Saidi, A.; Baditha, A.K.; Chiu, G.; Mehta, Y. A State-of-the-Practice Review on the Challenges of Asphalt Binder and a Roadmap Towards Sustainable Alternatives—A Call to Action. Materials 2025, 18, 2312. [Google Scholar] [CrossRef]

- Oldham, D.; Rajib, A.; Dandamudi, K.P.R.; Liu, Y.; Deng, S.; Fini, E.H. Transesterification of waste cooking oil for rejuvenating asphalt. Resour. Conserv. Recycl. 2021, 168, 105297. [Google Scholar] [CrossRef]

- Munoz-Caceres, O.; Raposeiras, A.C.; Movilla-Quesada, D.; Castro-Fresno, D.; Lagos-Varas, M.; Andrés-Valeri, V.C.; Valdés-Vidal, G. Mechanical performance of asphalt with copper slag and RAP. Constr. Build. Mater. 2021, 304, 124653. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, W.; Polaczyk, P.A.; Han, B.; Xiao, R.; Zhang, M.; Huang, B. Rheological and aging characteristics of the recycled asphalt binders with different rejuvenator incorporation methods. J. Clean. Prod. 2020, 262, 121249. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Eltwati, A.; Aziz, E.E.; Yaacob, H.; Dawood, H.A.; Jaya, R.P.; Jawahery, M.S.A.; Shaffie, E. The Use of Vacuum Residue as a Potential Rejuvenator in Reclaimed Asphalt Pavement: Physical, Rheological, and Mechanical Traits Analysis. Recycling. 2023, 8, 47. [Google Scholar]

- Zeng, M.; Li, J.; Zhu, W.; Xia, Y. Laboratory evaluation on residue in castor oil production as rejuvenator for aged paving asphalt binder. Constr. Build. Mater. 2018, 193, 276–285. [Google Scholar] [CrossRef]

- Zhang, X.; Ning, Y.; Zhou, X.; Xu, X.; Chen, X. Quantifying the rejuvenation effects of soybean-oil on aged asphalt-binder using molecular dynamics simulations. J. Clean. Prod. 2021, 317, 128375. [Google Scholar] [CrossRef]

- Gooi, S.; Kong, D. Performance of palm oil fractions as rejuvenators in bitumen. In Proceedings of ASEAN-Australian Engineering Congress (AAEC2022)—Engineering Solutions in the Age of Digital Disruption; Choo, C.S., Wong, B.T., Sharkawi, K.H.B., Kong, D., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2023; pp. 167–176. [Google Scholar] [CrossRef]

- Zhou, T.; Wan, S.; Dong, Z. Changes in rheological and low temperature characteristics of rubberized asphalt containing casing tor-based bio-oil under thermal-oxidative exposure. Constr. Build. Mater. 2024, 411, 134503. [Google Scholar] [CrossRef]

- Hu, Y.; Omairey, E.; Hughes, D.; Bailey, H.; Watkins, M.; Twitchen, J.; Airey, G.D.; Sreeram, A. Recovering the properties of aged bitumen using bio-rejuvenators derived from municipal wastes. Constr. Build. Mater. 2024, 438, 137268. [Google Scholar] [CrossRef]

- Girimath, S.; Singh, D. Effects of bio-oil on performance characteristics of base and recycled asphalt pavement binders. Constr. Build. Mater. 2019, 227, 116684. [Google Scholar] [CrossRef]

- Zhang, R.; Shi, Q.; Hu, P.; Ji, J.; Suo, Z. Influence of castor oil-based bio-oil on the properties and microstructure of asphalt binder. Constr. Build. Mater. 2023, 408, 133564. [Google Scholar] [CrossRef]

- Hu, Y.; Sreeram, A.; Xia, W.; Wang, H.; Zhou, L.; Si, W.; Airey, G.D. Use of Hansen solubility parameters (HSP) in the selection of highly effective rejuvenators for aged bitumen. Road Mater. Pavement Des. 2024, 26, 734–752. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Kamarudin, S.N.; Mahmud, M.Z.H.; Ismail, C.R.; Hassan, S.A.; Mashros, N. A review on the usage of waste engine oil with aged asphalt as a rejuvenating agent. Mater. Today Proc. 2021, 42, 2374–2380. [Google Scholar] [CrossRef]

- Yin, F.; Kaseer, F.; Arámbula-Mercado, E.; Epps Martin, A. Characterizing the long-term rejuvenating effectiveness of recycling agents on asphalt blends and mixtures with high RAP and RAS contents. Road Mater. Pavement Des. 2017, 18, 273–292. [Google Scholar] [CrossRef]

- Eltwati, A.S.; Enieb, M.; Al-Saffar, Z.H.; Mohamed, A. Effect of glass fibers and waste engine oil on the properties of RAP asphalt concretes. Int. J. Pavement Eng. 2022, 23, 5227–5238. [Google Scholar] [CrossRef]

- Wang, F.; Fang, Y.; Chen, Z.; Wei, H. Effect of waste engine oil on asphalt reclaimed properties. AIP Conf. Proc. 2018, 1973, 020012. [Google Scholar]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Putra Jaya, R.; Ismael, C.R.; Mohamed, A.; Rogo, K.U. Physical, rheological and chemical features of recycled asphalt embraced with a hybrid rejuvenating agent. Int. J. Pavement Eng. 2021, 23, 3036–3054. [Google Scholar] [CrossRef]

- Satayeva, S.S.; Burakhta, V.A.; Urazova, A.F.; Nazarova, D.S.; Khamzina, B.E.; Begaliyeva, R.S.; Shinguzhieva, A.B.; Satybayeva, N.A.; Yerzhanova, Z.T.; Murzagaliyeva, A.A. Asphalt Concrete Production Technology Using Oil Sludge from Zhaik Munay LLP. J. Eng. Technol. Sci. 2024, 56, 71–80. [Google Scholar] [CrossRef]

- Hasan, A.M.A.; Kamal, R.S.; Farag, R.K.; Abdel-raouf, M.E. Petroleum sludge formation and its treatment methodologies: A review. Environ Sci Pollut Res. 2024, 31, 8369–8386. [Google Scholar] [CrossRef]

- BSI. Bitumen and Bituminous Binders. Determination of the Resistance to Hardening under Influence of Heat and Air. RTfot Method; BSI: London, UK, 2014. [Google Scholar]

- Aitkaliyeva, G.; Yelubay, M.; Ismailova, A.; Massakbayeva, S.; Baisariyeva, A. Oil Sludge and Methods of Its Disposal. Pol. J. Environ. Stud. 2022, 31, 5563–5569. [Google Scholar] [CrossRef]

- Aitkaliyeva, G.; Azat, S.; Baidullayev, I.; Mangazbayeva, R.; Amitova, A.; Yelubay, M.; Toleutay, G.; Ismailova, A.; Orazymbek, I.; Abutalip, M. Using oil sludge as a rejuvenator for reclaimed asphalt pavement: Improving sustainability in road maintenance. ES Mater. Manuf. 2024, 26, 1291. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Shahadan, Z. Effects of aging on the physical, rheological and chemical properties of virgin bitumen incorporating recovered reclaimed asphalt pavement binder. Aust. J. Basic Appl. Sci. 2011, 5, 1323–1331. [Google Scholar]

- Donchenko, M.; Grynyshyn, O.; Demchuk, Y.; Topilnytskyy, P.; Turba, Y. Influence of Potassium Humate on the Technological Aging Processes of Oxidized Petroleum Bitumen. Chem. Chem. Technol. 2023, 17, 681–687. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Wu, W.; Poulikakos, L. Bio-based rejuvenators in asphalt pavements: A comprehensive review and analytical study. J. Road Eng. 2024, 4, 282–291. [Google Scholar] [CrossRef]

- Caputo, P.; Ventruti, G.; Calandra, P.; Porto, M.; Teltayev, B.; Angelico, R.; Rossi, C.O. Searching effective indicators of microstructural changes in bitumens during aging: A multi-technique approach. Colloids Surf. A Physicochem. Eng. Asp. 2022, 641, 128529. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, Y.; Hassan, N.; Al-Saffar, Z.; Abdullahi Ahmad, K.; Usman, K. Performance of Aged Asphalt Binder Treated with Various Types of Rejuvenators. Civ. Eng. J. 2021, 7, 502–517. [Google Scholar] [CrossRef]

- Liu, X.; Cao, F.; Xiao, F.; Amirkhanian, S. BBR and DSR Testing of Aging Properties of Polymer and Polyphosphoric Acid–Modified Asphalt Binders. J. Mater. Civ. Eng. 2018, 30, 04018249. [Google Scholar] [CrossRef]

- Ma, L.; Varveri, A.; Jing, R.; Erkens, S. Chemical characterization of bitumen type and aging state based on FTIR spectroscopy and discriminant analysis integrated with variable selection methods. Road Mater. Pavement Des. 2023, 24, 506–520. [Google Scholar] [CrossRef]

- Petersen, J.C. A Dual, Sequential Mechanism for the Oxidation of Petroleum Asphalts. Pet. Sci. Technol. 1998, 16, 1023–1059. [Google Scholar] [CrossRef]

- Pipintakos, G.; Lommaert, C.; Varveri, A.; Van den Bergh, W. Do chemistry and rheology follow the same laboratory aging trends in bitumen? Mater. Struct. 2022, 55, 146. [Google Scholar] [CrossRef]

- Feng, Z.-g.; Bian, H.-J.; Li, X.-J.; Yu, J.-Y. FTIR analysis of UV aging on bitumen and its fractions. Mater. Struct. 2015, 49, 1381–1389. [Google Scholar] [CrossRef]

- Pipintakos, G.; Soenen, H.; Ching, H.Y.V.; Van Velde, C.; Van Doorslaer, S.; Lemière, F.; Varveri, A.; Van den Bergh, W. Exploring the oxidative mechanisms of bitumen after laboratory short- and long-term aging. Constr. Build. Mater. 2021, 289, 123182. [Google Scholar] [CrossRef]

- Calandra, P.; Caponetti, E.; Chillura Martino, D.; D’Angelo, P.; Minore, A.; Turco Liveri, V. FT-IR and Dielectric study of water/AOT liquid crystals. J. Mol. Struct. 2000, 522, 165–178. [Google Scholar] [CrossRef]

- Ansar, M.; Sikandar, M.A.; Althoey, F.; Tariq, M.A.R.; Alyami, S.H.; Elkhatib, S.E. Rheological, Aging, and Microstructural Properties of Polycarbonate and Polytetrafluoroethylene Modified Bitumen. Polymers 2022, 14, 3283. [Google Scholar] [CrossRef] [PubMed]

- Demchuk, Y.; Gunka, V.; Sidun, I.; Korchak, B.; Donchenko, M.; Drapak, I.; Poliuzhyn, I.; Pyshyev, S. Study of Road Bitumen Operational Properties Modified with Phenol–Cresol–Formaldehyde Resin. Resources 2025, 14, 91. [Google Scholar] [CrossRef]

- Boyko, G.I.; Liubchenko, N.P.; Sarmurzina, R.; Karabalin, U.S.; Tiesov, D.S.; Shaikhutdinov, E.; Aitkaliyeva, G.S.; Boyko, L.S. Inhibitor of Asphalt-Resin-Paraffin Deposits. Patent KZ No. 34491, 30 July 2020. [Google Scholar]

- Loise, V.; Calandra, P.; Abe, A.A.; Porto, M.; Rossi, C.O.; Davoli, M.; Caputo, P. Additives on aged bitumens: What probe to distinguish between rejuvenating and fluxing effects? J. Mol. Liq. 2021, 3391, 116742. [Google Scholar] [CrossRef]

- Primerano, K.; Mirwald, J.; Hofko, B. Asphaltenes and Maltenes in Crude Oil and Bitumen: A Comprehensive Review of Properties, Separation Methods, and Insights into Structure, Reactivity and Aging. Fuel 2024, 368, 131616. [Google Scholar] [CrossRef]

- Calandra, P.; Longo, A.; Turco Liveri, V. Preparation and Characterisation of Na₂S and ZnSO₄ Nanoparticles in Water/AOT/n-Heptane Microemulsions. Coll. Pol. Sci. 2001, 279, 1112–1117. [Google Scholar] [CrossRef]

- Hu, Y.; Yin, Y.; Sreeram, A.; Liu, J.; Si, W.; Tang, D.; Airey, G.D. Nano-Aggregation of Asphaltenes and Its Influence on the Multiscale Properties of Bitumen Recycled through Multiple Ageing and Rejuvenation Cycles. Chem. Eng. J. 2025, 512, 162348. [Google Scholar] [CrossRef]

| Name of the Characteristic | Penetration at 25 °C, 01 mm | Softening Temperature, °C | Ductility, cm |

|---|---|---|---|

| Indicators | 71 | 48 | >100 |

| Indicators | Aged Bitumen | Amount of Oil Sludge, % | ||

|---|---|---|---|---|

| 1 | 3 | 5 | ||

| Penetration, 0.1 mm at 25 °C | 60 | 63 | 67 | 71 |

| Softening point, °C | 55 | 60 | 68 | 72 |

| DSR Results | δ [°] | G* [Pa] | G*/sin δ [Pa] | T [°C] |

|---|---|---|---|---|

| Aged bitumen | 84.70 ± 0.1 | 652.2 ± 0.5 | 655 ± 0.5 | 66.5 ± 0.3 |

| 1% oil sludge | 84.55 ± 0.1 | 594.8 ± 0.8 | 597.5 ± 1.0 | 71.6 ± 0.5 |

| 3% oil sludge | 84.52 ± 0.1 | 581.5 ± 0.8 | 584.2 ± 0.8 | 71.6 ± 0.3 |

| 5% oil sludge | 84.12 ± 0.1 | 582.1 ± 0.9 | 584.5 ± 1.0 | 71.4 ± 0.3 |

| Sample | A1030/A1456 |

|---|---|

| Aged bitumen | 0.395 |

| 1% OS | 0.352 |

| 3% OS | 0.265 |

| 5% OS | 0.259 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aitkaliyeva, G.; Ashimova, S.; Baidullayev, I.; Merkibayev, Y.; Yelubay, M.; Toleutay, G.; Oliviero Rossi, C. Oil Sludge as a Rejuvenator for Aged Bitumen: Structural and Thermal Effect. Appl. Sci. 2025, 15, 6757. https://doi.org/10.3390/app15126757

Aitkaliyeva G, Ashimova S, Baidullayev I, Merkibayev Y, Yelubay M, Toleutay G, Oliviero Rossi C. Oil Sludge as a Rejuvenator for Aged Bitumen: Structural and Thermal Effect. Applied Sciences. 2025; 15(12):6757. https://doi.org/10.3390/app15126757

Chicago/Turabian StyleAitkaliyeva, Gulzat, Saltanat Ashimova, Ilyas Baidullayev, Yerik Merkibayev, Madeniyet Yelubay, Gaukhar Toleutay, and Cesare Oliviero Rossi. 2025. "Oil Sludge as a Rejuvenator for Aged Bitumen: Structural and Thermal Effect" Applied Sciences 15, no. 12: 6757. https://doi.org/10.3390/app15126757

APA StyleAitkaliyeva, G., Ashimova, S., Baidullayev, I., Merkibayev, Y., Yelubay, M., Toleutay, G., & Oliviero Rossi, C. (2025). Oil Sludge as a Rejuvenator for Aged Bitumen: Structural and Thermal Effect. Applied Sciences, 15(12), 6757. https://doi.org/10.3390/app15126757