Comparative Corrosion and Wear Behaviors of Cermet Coatings Obtained from Conventional and Recycled Powders

Abstract

1. Introduction

2. Materials and Methods

2.1. Analysis and Preparation of the Feedstock Powder and Coating Deposition

2.2. Coatings Microstructure and Properties

- Uncritical: There are no cracks, or only cracks within the loaded area.

- Critical: Cracks that extend beyond the loaded area.

- Insufficient: Delamination, pronounced crack networks, or coating spallation.

2.3. Corrosion Tests

- A 3.5% sodium chloride solution to simulate seawater-like conditions (M1);

- A 3.5% sodium chloride solution acidified with HCl to a pH of 3.5 to simulate corrosive acidic media (M2).

3. Results and Discussion

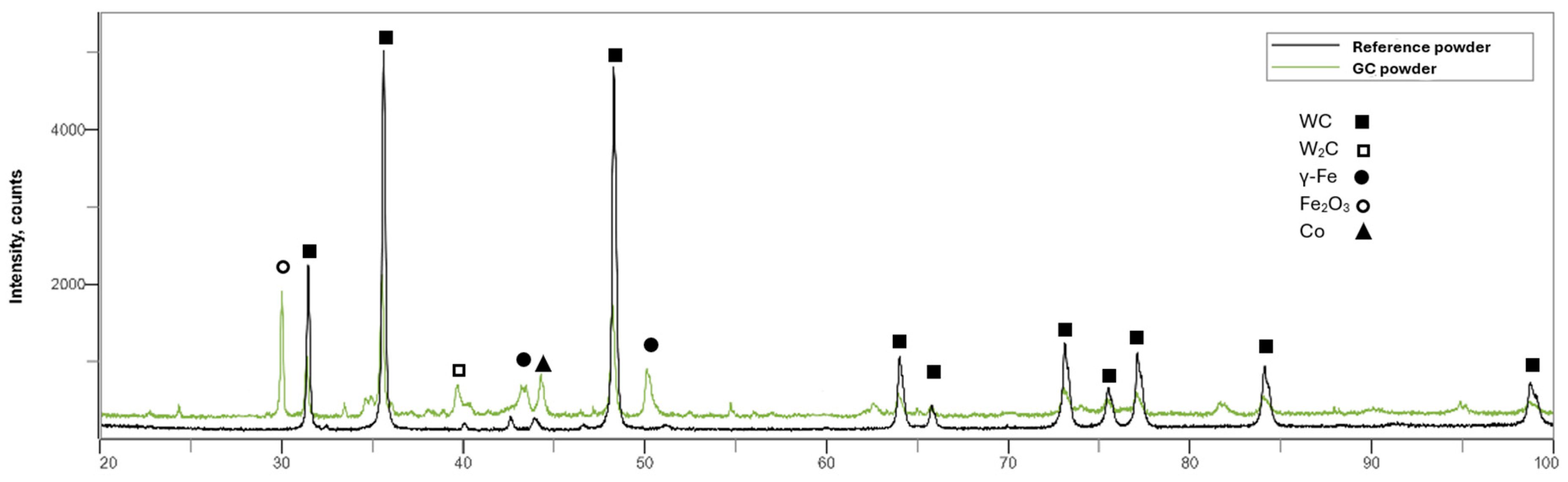

3.1. Particle Size Distribution and Powder Composition

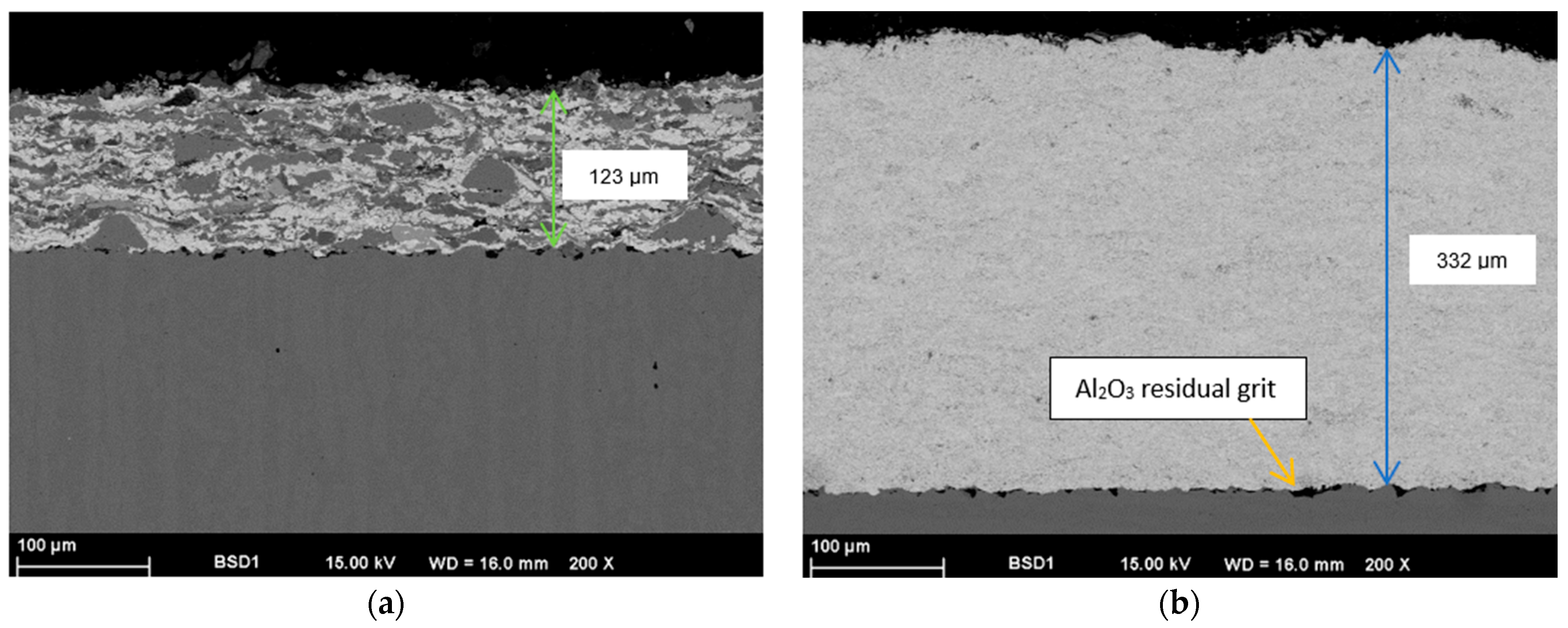

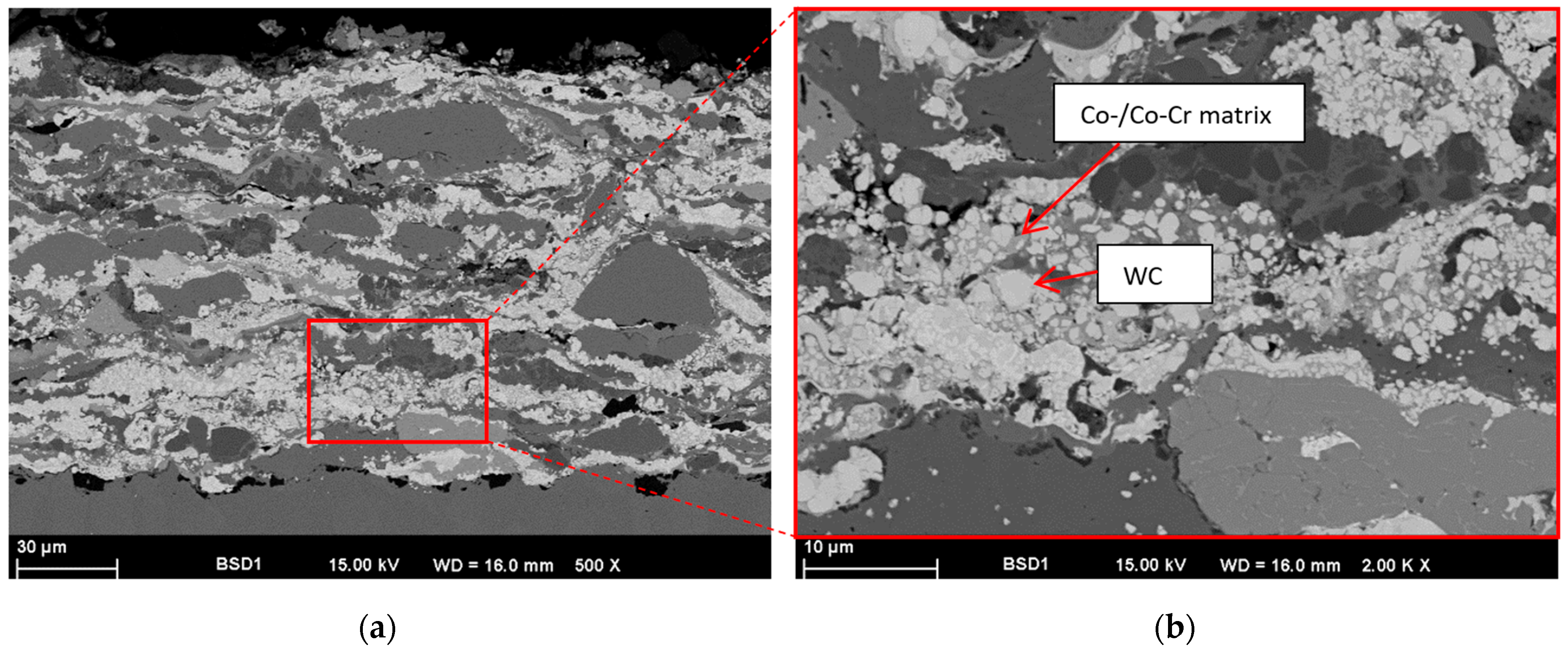

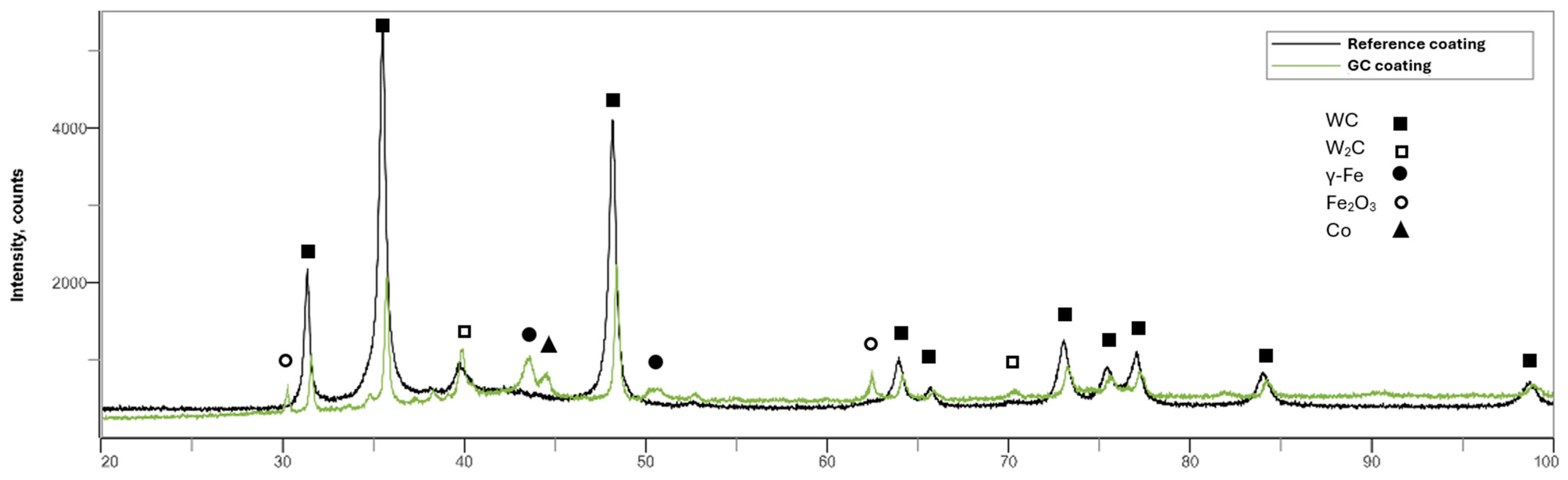

3.2. Microstructure of the Deposited Coatings

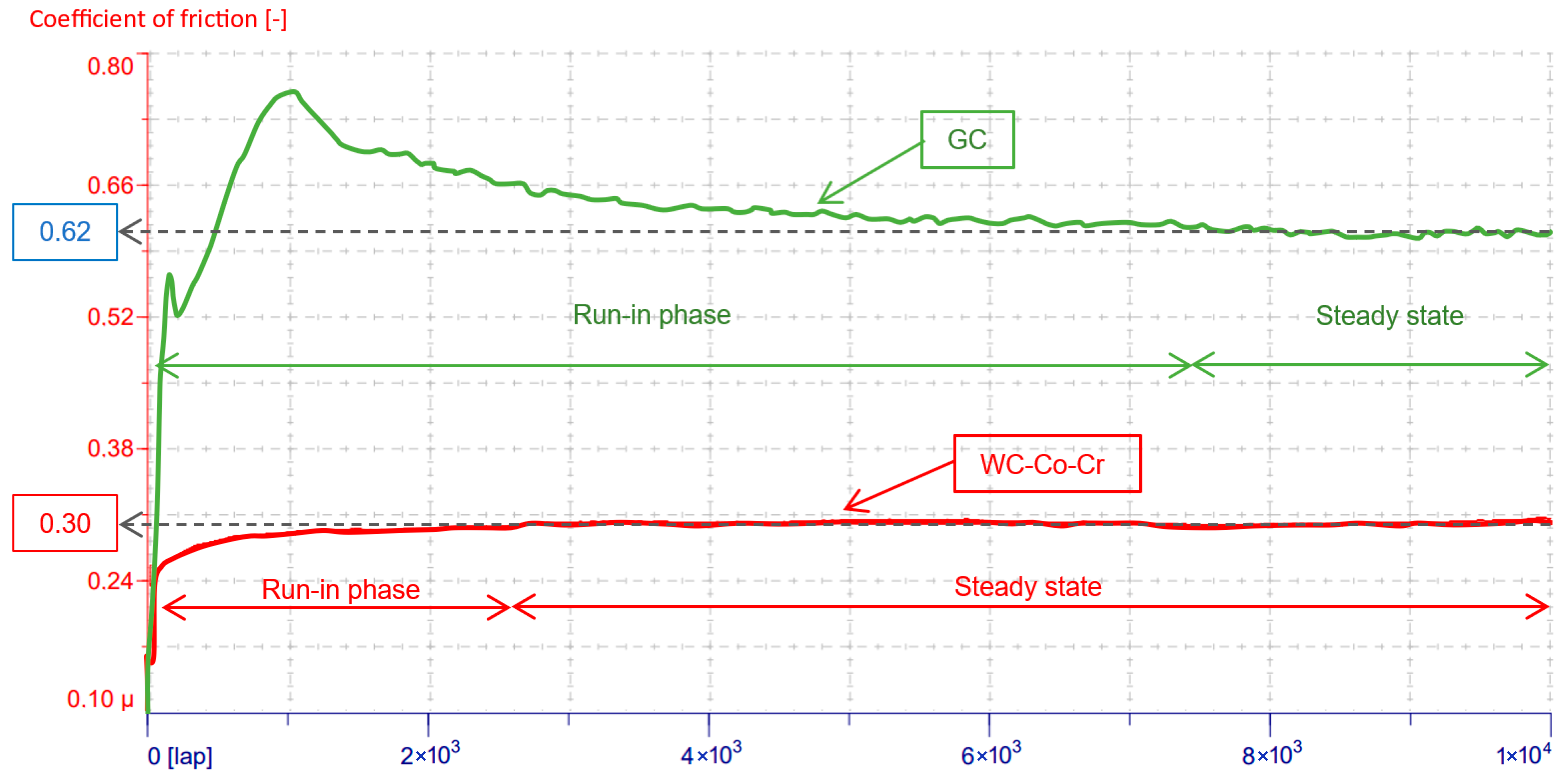

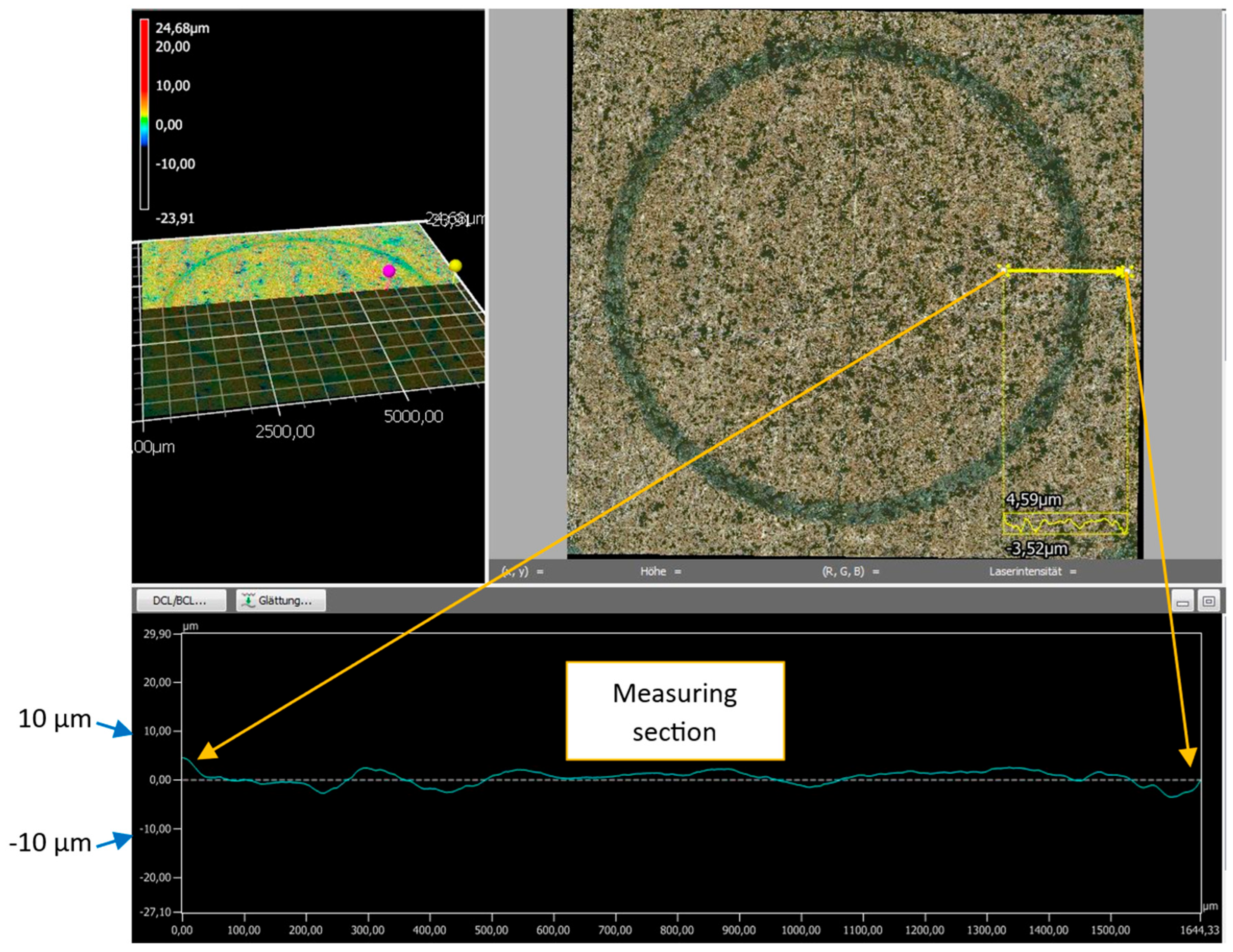

3.3. Mechanical and Tribological Properties

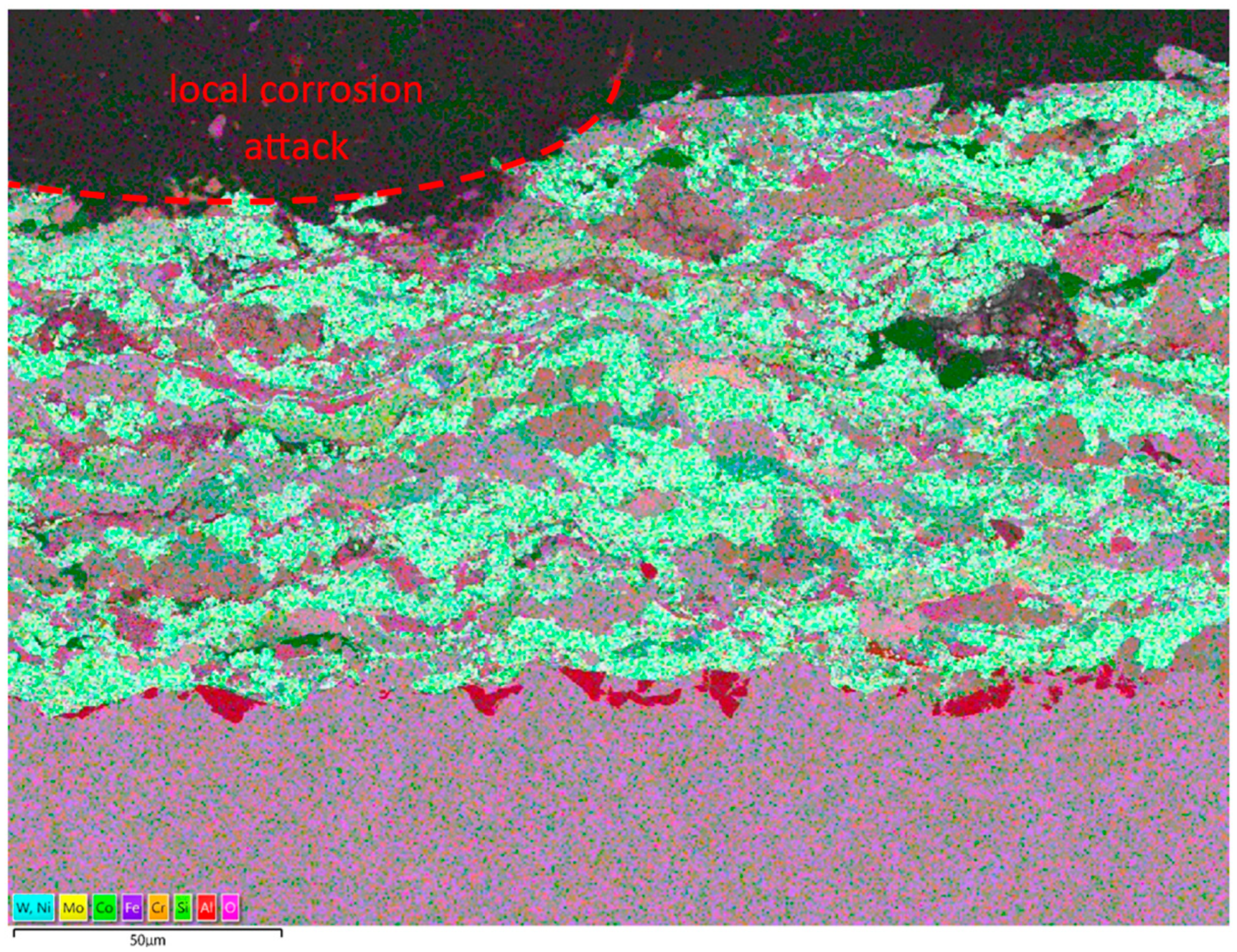

3.4. Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, X.; Li, C.; Li, S.; Han, X.; Liu, P. Mechanism evaluations of conventional and suspended HVOF thermal spraying based on EDC and EDM combustion models. Appl. Therm. Eng. 2024, 241, 122405. [Google Scholar] [CrossRef]

- Anusha, K.; Routara, B.C.; Guha, S. A review on High-Velocity Oxy-Fuel (HVOF) coating technique. J. Inst. Eng. (India) Ser. D 2023, 104, 831–848. [Google Scholar] [CrossRef]

- Jonda, E.; Łatka, L.; Godzierz, M.; Maciej, A. Investigations of microstructure and corrosion resistance of WC-Co and WC-Cr3C2-Ni coatings deposited by HVOF on magnesium alloy substrates. Surf. Coat. Technol. 2023, 459, 129355. [Google Scholar] [CrossRef]

- Zhao, X.; Li, C.; Li, S.; Han, X.; Jiang, H. Mechanism study on the influence of combustion models and spray gun geometric parameters on HVOF thermal spraying. J. Manuf. Process. 2023, 98, 178–185. [Google Scholar] [CrossRef]

- Pradeep, D.G.; Venkatesh, C.V.; Nithin, H.S. Review on tribological and mechanical behavior in HVOF thermal-sprayed composite coatings. J. Bio- Tribo-Corros. 2022, 8, 30. [Google Scholar] [CrossRef]

- Zhao, X.; Li, C.; Li, S.; Jiang, H.; Han, X. Time-varying evolutionary mechanism analysis of the multiphase flow during HVOF thermal spraying WC-12Co particle. Surf. Coat. Technol. 2023, 461, 129435. [Google Scholar] [CrossRef]

- Saharkhiz, R.; Valefi, Z.; Mirjani, M.; Mirak, A. Comprehensive study on the effect of HVOF processing parameters and particle size on high-temperature properties of NiCoCrAlYTa coatings. Surf. Coat. Technol. 2023, 473, 129951. [Google Scholar] [CrossRef]

- Feizabadi, A.; Salehi Doolabi, M.; Sadrnezhaad, S.K.; Rezaei, M. Cyclic oxidation characteristics of HVOF thermal-sprayed NiCoCrAlY and CoNiCrAlY coatings at 1000 °C. J. Alloys Compd. 2018, 746, 509–519. [Google Scholar] [CrossRef]

- Russell, Z.; Gaier, M.; Froning, M.J.; Plucknett, K.P. The aqueous corrosion and wear responses of HVOF-deposited TiC-Ni3Al, WC-Co, and WC-CoCr coatings on AISI 4130 steel substrates. Surf. Coat. Technol. 2023, 473, 130018. [Google Scholar] [CrossRef]

- Picas, J.A.; Forn, A.; Matthäus, G. HVOF coatings as an alternative to hard chrome for pistons and valves. Wear 2006, 261, 477–484. [Google Scholar] [CrossRef]

- Lakshmi, D.V.; Babu, P.S.; Alroy, R.J.; Kumar, G.S.; Prasad, M.J.N.V. Performance Evaluation of Thin Cermet Coatings Produced by HVAF Spray: A New Approach for Hard Chrome Replacement. J. Therm. Spray. Tech. 2023, 32, 904–917. [Google Scholar] [CrossRef]

- Prasad, C.D.; Soni, P.K.; Nagaraja, K.C.; Eswaran, A.; Kumar, S.R.; Deshmukh, K.; Shrivastava, R.; Tiwari, A. Studies on wear and microstructure assessment of WC-Co reinforced iron based HVOF coating. Results Surf. Interfaces 2024, 15, 100237. [Google Scholar] [CrossRef]

- Cao, S.; Chang, Z.; Li, S.; Zhang, W.; Xu, S. Effect of binder phases on the microstructure and sliding wear properties of HVOF-sprayed WC-based coatings. Int. J. Refract. Met. Hard Mater. 2024, 122, 106742. [Google Scholar] [CrossRef]

- Lekatou, A.G.; Sioulas, D.; Grimanelis, D. Corrosion and wear of coatings fabricated by HVOF-spraying of nanostructured and conventional WC–10Co-4Cr powders on Al7075-T6. Int. J. Refract. Met. Hard Mater. 2023, 112, 106164. [Google Scholar] [CrossRef]

- Baumann, I.; Hagen, L.; Tillmann, W.; Hollingsworth, P.; Stangier, D.; Schmidtmann, G.; Tolan, M.; Paulus, M.; Sternemann, C. Process characteristics, particle behavior and coating properties during HVOF spraying of conventional, fine and nanostructured WC-12Co powders. Surf. Coat. Technol. 2021, 405, 126716. [Google Scholar] [CrossRef]

- Gallego, M.; Chávez, S.C.; De La Roche, J.; Toro, A. Effect of heat treatment on the wet abrasion resistance of WC-10Co4Cr coatings deposited onto stainless steel by HVOF. Tribol. Mater. Surf. Interfaces 2022, 16, 168–176. [Google Scholar] [CrossRef]

- Mi, P.; Wang, T.; Ye, F. Influences of the compositions and mechanical properties of HVOF sprayed bimodal WC-Co coating on its high temperature wear performance. Int. J. Refract. Met. Hard Mater. 2017, 69, 158–163. [Google Scholar] [CrossRef]

- Geng, Z.; Li, S.; Duan, D.L.; Liu, Y. Wear behaviour of WC–Co HVOF coatings at different temperatures in air and argon. Wear 2015, 330–331, 348–353. [Google Scholar] [CrossRef]

- Rúa Ramirez, E.; Silvello, A.; Torres Diaz, E.; Tornese, F.; Gnoni, M.G.; Cano, I.G. A comparison of cold spray, atmospheric plasma spray and high velocity oxy fuel processes for WC-Co coatings deposition through LCA and LCCA. Heliyon 2024, 10, e38961. [Google Scholar] [CrossRef]

- Agnihotri, A.; Vasudev, H.; Singh, G.; Singh, S.; Hosalli, R.; Veeresha, G.; Prasad, C.D.; Balu, R.; Tiwari, A. Evaluation of HVOF sprayed and burnished WC-Co-Cr coatings on boiler steel: Mechanical and microstructural properties. J. Bio- Tribo-Corros. 2025, 11, 50. [Google Scholar] [CrossRef]

- Owoseni, T.A.; Gupta, M.; Joshi, S.V.; Ingmar, M.; Varis, T. Wear and Corrosion of HVAF and HVOF-Sprayed WC-CoCr Coatings on Aluminum Alloy. J. Therm. Spray. Tech. 2025, 34, 970–991. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, X.; Kang, J.; Yue, W.; Qin, W.; Ma, G.; Fu, Z.; Zhu, L.; She, D.; Wang, H.; et al. Corrosion behavior of HVOF sprayed WC-10Co4Cr coatings in the simulated seawater drilling fluid under the high pressure. Eng. Fail. Anal. 2020, 109, 104338. [Google Scholar] [CrossRef]

- Ghosh, G.; Sidpara, A.; Bandyopadhyay, P.P. Theoretical analysis of magnetorheological finishing of HVOF sprayed WC-Co coating. Int. J. Mech. Sci. 2021, 207, 106629. [Google Scholar] [CrossRef]

- Pulsford, J.; Venturi, F.; Pala, Z.; Kamnis, S.; Hussain, T. Application of HVOF WC-Co-Cr coatings on the internal surface of small cylinders: Effect of internal diameter on the wear resistance. Wear 2019, 432–433, 202965. [Google Scholar] [CrossRef]

- Bolelli, G.; Colella, A.; Lusvarghi, L.; Morelli, S.; Puddu, P.; Righetti, E.; Sassatelli, P.; Testa, V. TiC–NiCr thermal spray coatings as an alternative to WC-CoCr and Cr3C2–NiCr. Wear 2020, 450–451, 203273. [Google Scholar] [CrossRef]

- Pereira, P.; Vilhena, L.M.; Sacramento, J.; Senos, A.M.R.; Malheiros, L.F.; Ramalho, A. Abrasive wear resistance of WC-based composites, produced with Co or Ni-rich binders. Wear 2021, 482–483, 203924. [Google Scholar] [CrossRef]

- Picas, J.A.; Menargues, S.; Martin, E.; Baile, M.T. Cobalt free metallic binders for HVOF thermal sprayed wear resistant coatings. Surf. Coat. Technol. 2023, 456, 129243. [Google Scholar] [CrossRef]

- Tegelkamp, L.; Grimm, M.; Conze, S.; Berger, L.-M.; Lindner, T.; Lampke, T. Microstructure and wear resistance of environmentally friendly NbC-FeCr coatings: An evaluation of HVOF process parameters. Surf. Coat. Technol. 2025, 509, 132208. [Google Scholar] [CrossRef]

- Torkashvand, K.; Joshi, S.; Gupta, M. Advances in thermally sprayed WC-based wear-resistant coatings: Co-free binders, processing routes and tribological behavior. J. Therm. Spray Technol. 2022, 31, 342–377. [Google Scholar] [CrossRef]

- Mishra, D.; Sinha, S.; Sahu, K.K.; Agrawal, A.; Kumar, R. Recycling of secondary tungsten resources. Trans. Indian Inst. Met. 2017, 70, 479–485. [Google Scholar] [CrossRef]

- Chen, Y.; Huo, G.; Guo, X.; Wang, Q. Sustainable extraction of tungsten from the acid digestion product of tungsten concentrate by leaching-solvent extraction together with raffinate recycling. J. Clean. Prod. 2022, 375, 133924. [Google Scholar] [CrossRef]

- Liang, J.J.; Geng, Y.; Zeng, X.L.; Gao, Z.Y.; Tian, X. Toward sustainable utilization of tungsten: Evidence from dynamic substance flow analysis from 2001 to 2019 in China. Resour. Conserv. Recycl. 2022, 182, 106307. [Google Scholar] [CrossRef]

- Varis, T.; Lagerbom, J.; Suhonen, T.; Raami, L.; Terho, S.; Laurila, J.; Peura, P.; Vuoristo, P. Effect of heat treatments on the wear resistance of HVAF and HVOF sprayed tool steel coatings. Surf. Coat. Technol. 2023, 462, 129508. [Google Scholar] [CrossRef]

- Kumar, R.; Kariminejad, A.; Antonov, M.; Goljandin, D.; Klimczyk, P.; Hussainova, I. Progress in sustainable recycling and circular economy of tungsten carbide hard metal scraps for Industry 5.0 and onwards. Sustainability 2023, 15, 12249. [Google Scholar] [CrossRef]

- Gislev, M.; Grohol, M.; Mathieux, F.; Ardente, F.; Bobba, S.; Nuss, P.; Blengini, G.; Alves Dias, P.; Blagoeva, D.; Matos, C.; et al. Report on Critical Raw Materials and the Circular Economy; European Commission: Brussels, Belgium, 2018; pp. 1–76. [Google Scholar]

- Zeiler, B.; Bartl, A.; Schubert, W.-D. Recycling of tungsten: Current share, economic limitations, technologies and future potential. Int. J. Refract. Met. Hard Mater. 2021, 98, 105546. [Google Scholar] [CrossRef]

- Liang, J.; Geng, Y.; Su, C.; Chen, W. An emergy-based comparison between primary and secondary tungsten production in China. Environ. Impact Assess. Rev. 2024, 107, 107548. [Google Scholar] [CrossRef]

- Pacini, A.; Lupi, F.; Rossi, A.; Seggiani, M.; Lanzetta, M. Direct recycling of WC-Co grinding chip. Materials 2023, 16, 1347. [Google Scholar] [CrossRef]

- Mégret, A.; Vitry, V.; Delaunois, F. Study of the processing of a recycled WC–Co powder: Can it compete with conventional WC–Co powders? J. Sustain. Metall. 2021, 7, 448–458. [Google Scholar] [CrossRef]

- Varis, T.; Suhonen, T.; Jokipii, M.; Vuoristo, P. Influence of powder properties on residual stresses formed in high-pressure liquid fuel HVOF sprayed WC-CoCr coatings. Surf. Coat. Technol. 2020, 388, 125604. [Google Scholar] [CrossRef]

- Tillmann, W.; Kuhnt, S.; Baumann, I.T.; Kalka, A.; Becker-Emden, E.-C.; Brinkhoff, A. Statistical comparison of processing different powder feedstock in an HVOF thermal spray process. J. Therm. Spray Technol. 2022, 31, 1476–1489. [Google Scholar] [CrossRef]

- Viswanathan, V.; Katiyar, N.K.; Goel, G.; Matthews, A.; Goel, S. Role of thermal spray in combating climate change. Emergent Mater. 2021, 4, 1515–1529. [Google Scholar] [CrossRef]

- Silvello, A.; Cavaliere, P.; Yin, S.; Lupoi, R.; Garcia Cano, I.; Dosta, S. Microstructural, mechanical and wear behavior of HVOF and cold-sprayed high-entropy alloys (HEAs) coatings. J. Therm. Spray Technol. 2022, 31, 1184–1206. [Google Scholar] [CrossRef]

| Measurement Details | Setting |

|---|---|

| Pump output | 100% |

| Ultrasound for dispersion | on |

| Medium | Distilled water |

| Dispersion time | 1 min |

| Images captured | 30,000 |

| Pump power | 100% |

| Parameter | Settings |

|---|---|

| Oxygen flow rate [L/min] | 665 |

| Spraying distance [mm] | 280 |

| Kerosene flow rate [L/min] | 0.35 |

| Carrier gas N2 [L/min] | 11.0 |

| Powder feed rate [g/min] | 85 |

| Differential velocity burner/substrate [m/s] | 90 |

| Coating cycles | 3 |

| Passes per coating cycle | 5 |

| Parameter | Value |

|---|---|

| Load [N] | 10 |

| Linear speed [cm/s] | 10 |

| Wear track diameter [mm] | 6 |

| Laps [-] | 10,000 |

| Stop condition [-] | laps |

| Lubricant [-] | none |

| Temperature [°C] | 22 |

| Ball material [-] | WC-Co |

| Ball diameter [mm] | 6 |

| Sample | Ucorr [mV] | icorr [µA/cm2] |

|---|---|---|

| GC-M1 | −401 ± 24 | 11.0 ± 2.3 |

| GC-M2 | −394 ± 21 | 37.1 ± 3.1 |

| Ref-M1 | −171 ± 13 | 5.9 ± 0.8 |

| Ref-M2 | −273 ± 15 | 6.6 ± 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woelk, D.; Eßler, J.; Utu, I.-D.; Marginean, G. Comparative Corrosion and Wear Behaviors of Cermet Coatings Obtained from Conventional and Recycled Powders. Appl. Sci. 2025, 15, 7654. https://doi.org/10.3390/app15147654

Woelk D, Eßler J, Utu I-D, Marginean G. Comparative Corrosion and Wear Behaviors of Cermet Coatings Obtained from Conventional and Recycled Powders. Applied Sciences. 2025; 15(14):7654. https://doi.org/10.3390/app15147654

Chicago/Turabian StyleWoelk, Dino, Julian Eßler, Ion-Dragos Utu, and Gabriela Marginean. 2025. "Comparative Corrosion and Wear Behaviors of Cermet Coatings Obtained from Conventional and Recycled Powders" Applied Sciences 15, no. 14: 7654. https://doi.org/10.3390/app15147654

APA StyleWoelk, D., Eßler, J., Utu, I.-D., & Marginean, G. (2025). Comparative Corrosion and Wear Behaviors of Cermet Coatings Obtained from Conventional and Recycled Powders. Applied Sciences, 15(14), 7654. https://doi.org/10.3390/app15147654