Optimization of Parameters in Multi-Spot Projection Welding of Thin Aluminized Steel Sheets

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

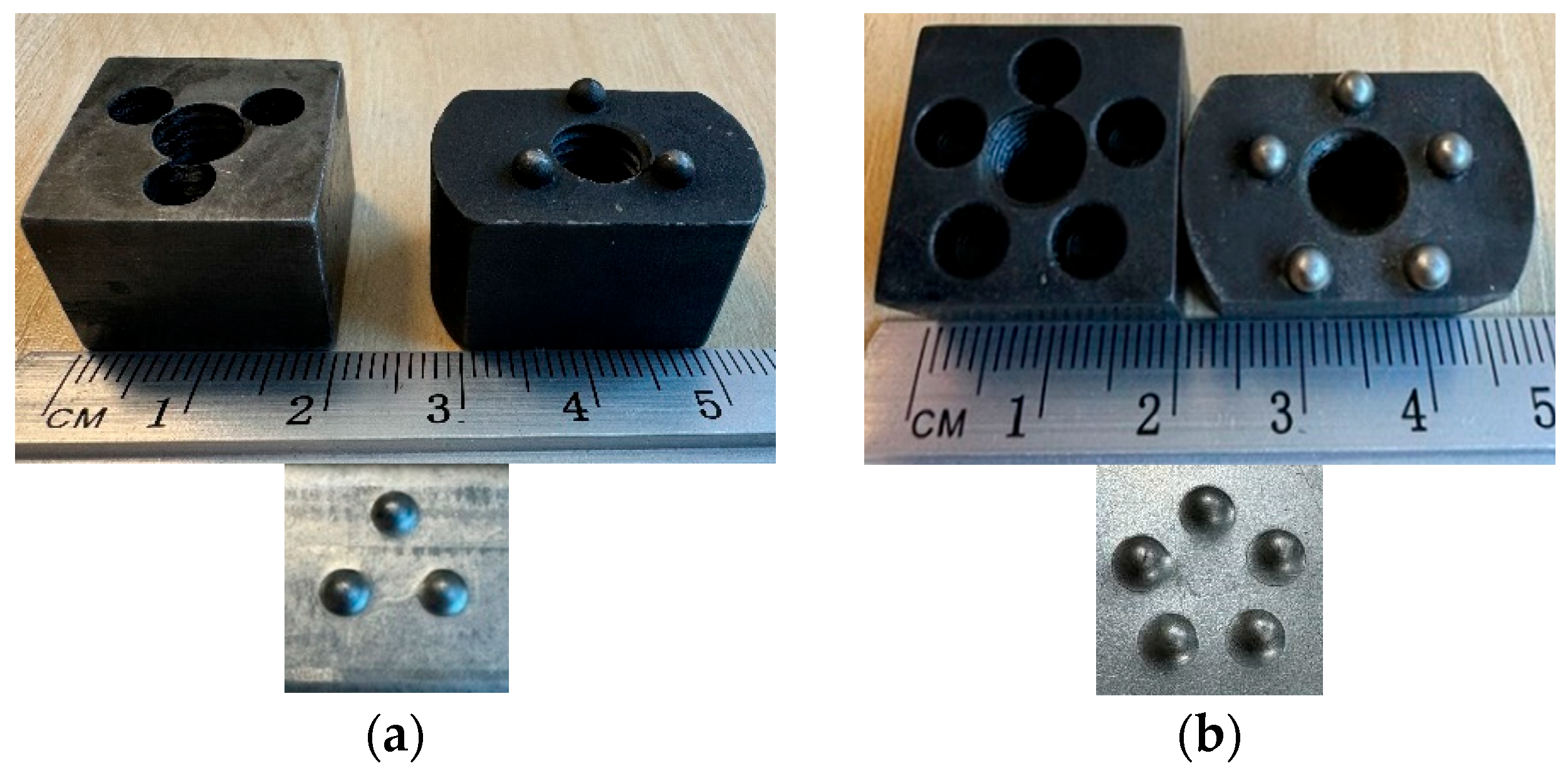

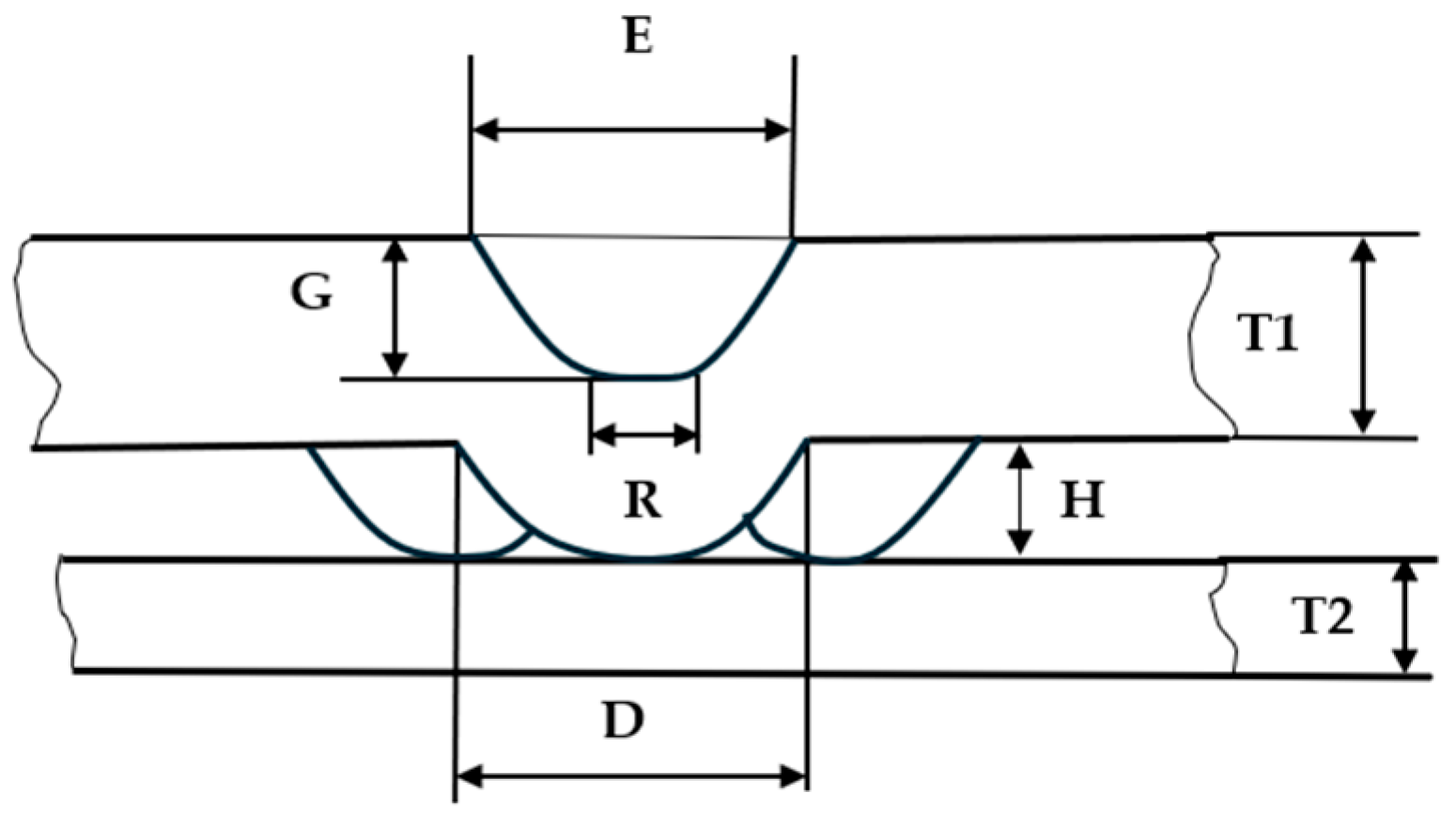

2.2.1. Welding Process

2.2.2. ANOVA and Taguchi-Based Design of Experiments (DoE)

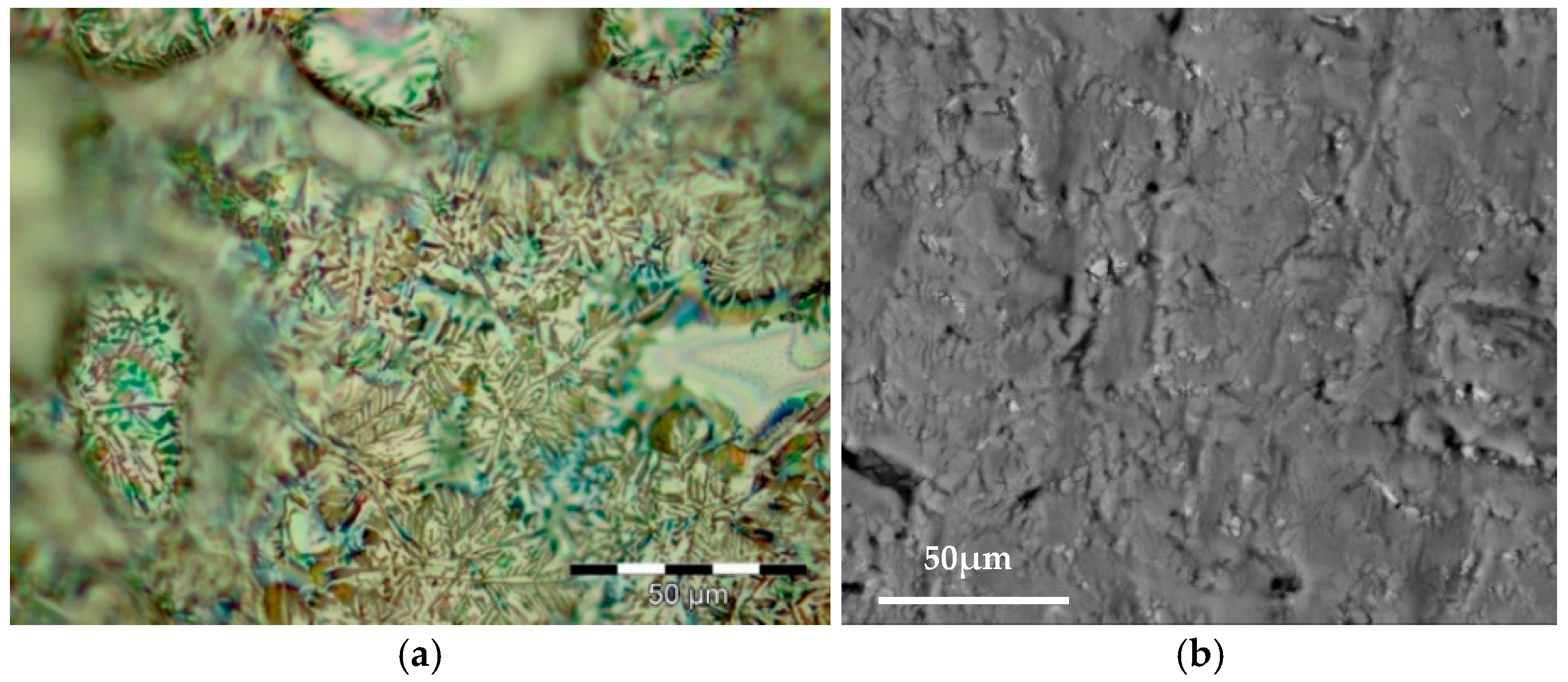

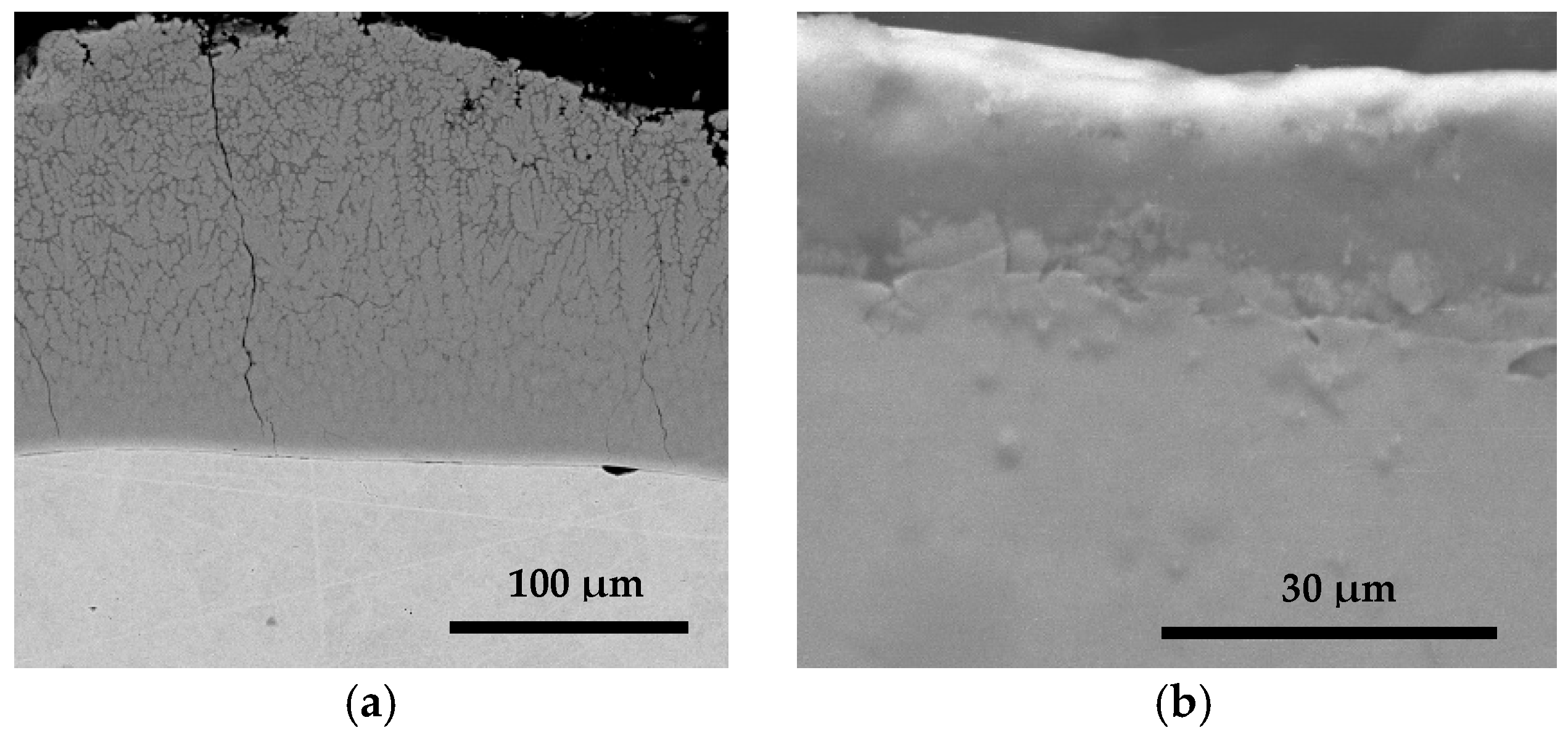

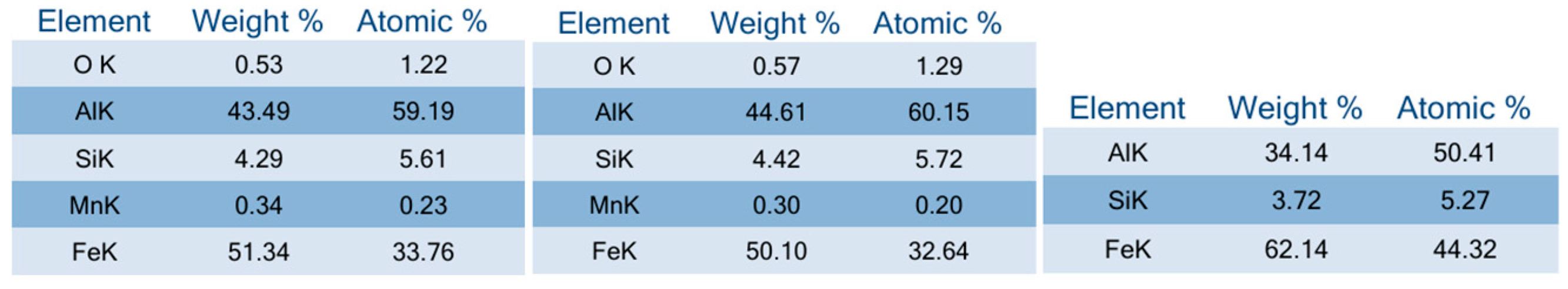

2.2.3. Coating Microstructure

2.2.4. Tensile Tests

2.2.5. Microhardness

3. Results and Discussion

3.1. Weld Microstructure

3.2. Tensile Test Behavior

3.3. Relation Between Welding Energy and Tensile Tests

3.4. Taguchi and ANOVA Optimization of Projection Welding Process Parameters for Maximizing Weld Mechanical Performance

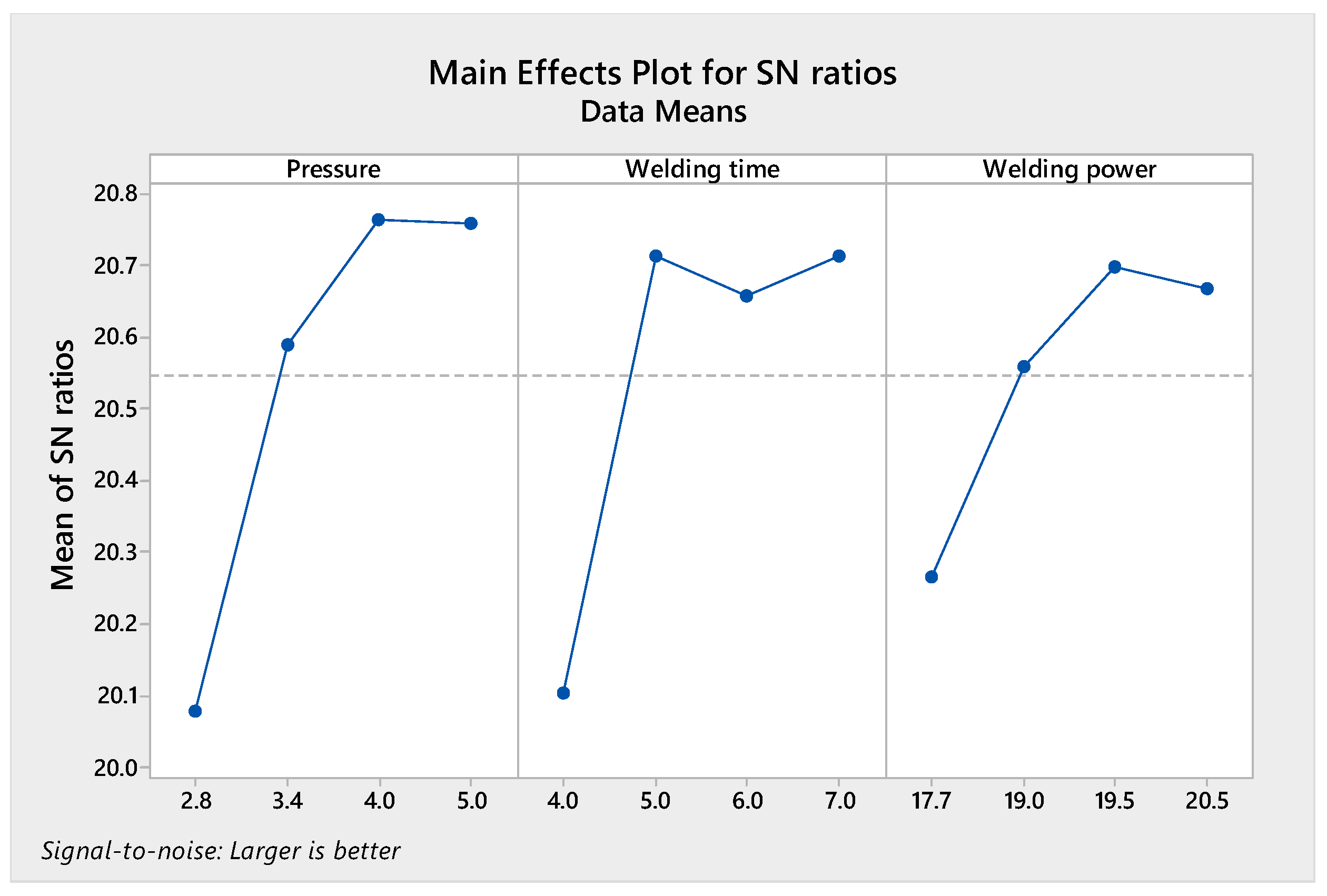

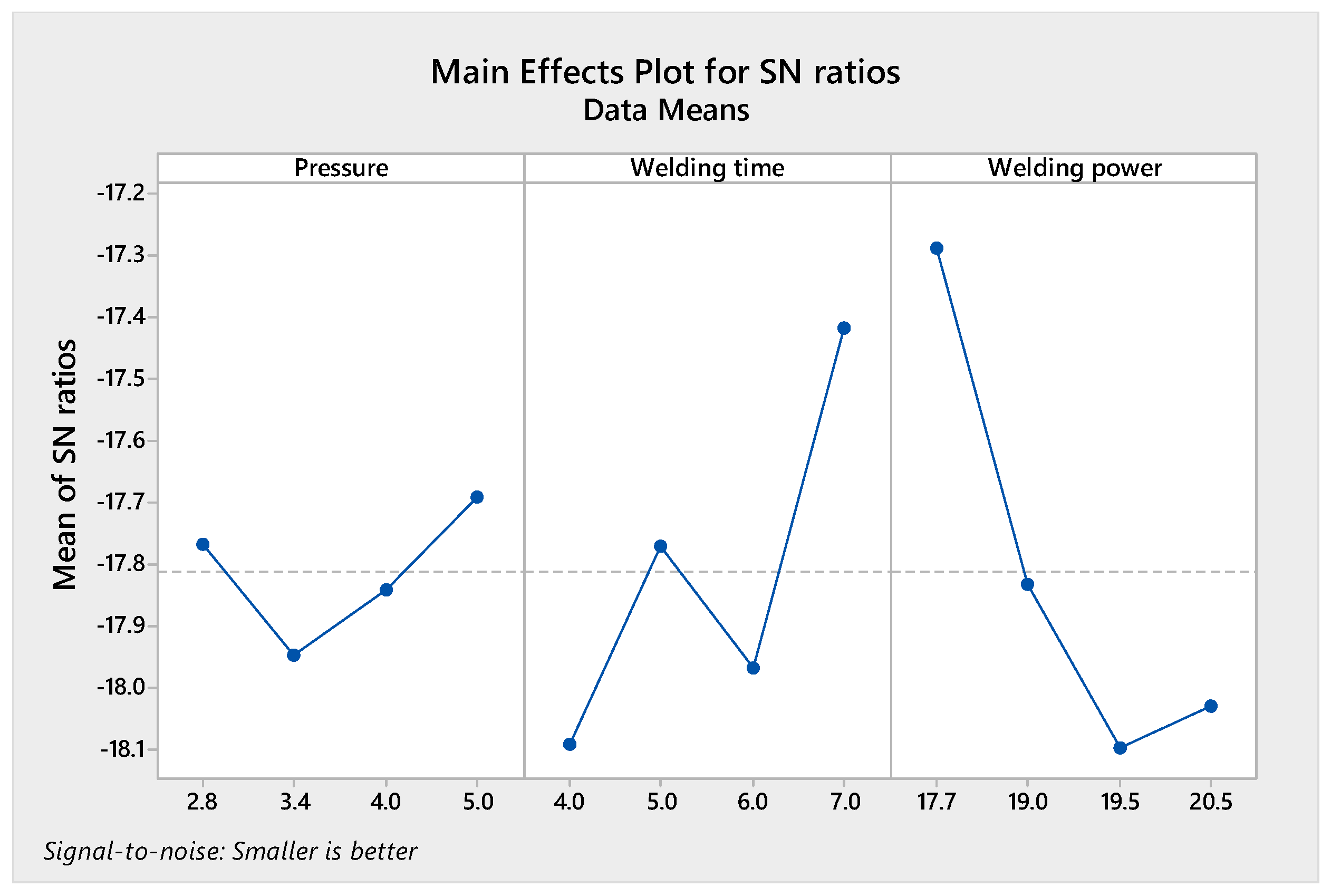

3.4.1. Taguchi Method

3.4.2. Analysis of Variance (ANOVA)

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aslanlar, S.; Ogur, A.; Ozsarac, U.; Ilhan, E. Welding time effect on mechanical properties of automotive sheets in electrical resistance spot welding. Mater. Des. 2008, 29, 1427–1431. [Google Scholar] [CrossRef]

- Saha, D.C.; Park, Y.-D. A Review on Al-Al/Al-Steel Resistance Spot Welding Technologies for Light Weight Vehicles. J. Weld. Join. 2011, 29, 397–402. [Google Scholar]

- Zhang, W.H.; Qiu, X.M.; Sun, D.Q.; Han, L.J. Effects of resistance spot welding parameters on microstructures and mechanical properties of dissimilar material joints of galvanized high strength steel and aluminum alloy. Sci. Technol. Weld. Join. 2011, 16, 153–161. [Google Scholar] [CrossRef]

- Taufiqurrahman, I.; Ahmad, A.; Mustapha, M.; Lenggo Ginta, T.; Ady Farizan Haryoko, L.; Ahmed Shozib, I. The Effect of Welding Current and Electrode Force on the Heat Input, Weld Diameter, and Physical and Mechanical Properties of SS316L/Ti6Al4V Dissimilar Resistance Spot Welding with Aluminum Interlayer. Materials 2021, 14, 1129. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Xue, X.; Wang, B.; Yang, J.; Zhang, Z.; Tyrer, N.; Barber, G.C. Investigation on shearing strength of resistance spot-welded joints of dissimilar steel plates with varying welding current and time. J. Mat. Res. Technol. 2022, 16, 1021–1028. [Google Scholar]

- Pasau, K.; Salam, N.; Aminy, A.Y.; Hayat, A. Effect of Welding Time Variation in Resistance Spot Welding on Mechanical Properties of Dissimilar Joints on Mild Steel and AISI 304 Stainless Steel. J. Phys. Conf. Ser. 2024, 2739, 012044. [Google Scholar]

- Pouranvari, M.; Marashi, P. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Summerville, C.; Compston, P.; Doolan, M. A comparison of resistance spot weld quality assessment techniques. Procedia Manuf. 2019, 29, 305–312. [Google Scholar] [CrossRef]

- Polyakov, A.Y.; Furmanov, S.M.; Bendik, T.I.; Kurlenkov, A.M. Development of an energy-saving method of resistance projection welding of multilayer welded structures. Weld. Intern. 2017, 31, 868–873. [Google Scholar]

- Paliakou, A.Y.; Kulikau, V.P.; Stsiapanau, A.A. Resistance Projection Welding of Sheet Metal Without Formation of a Mutual Melting Zone in The Form of a Cast Nugget. Adv. Eng. Res. 2019, 188, 264–270. [Google Scholar]

- Zhao, D.; Wang, Y.; Zhang, P.; Liang, D. Modeling and Experimental Research on Resistance Spot Welded Joints for Dual-Phase Steel. Materials 2019, 12, 1108. [Google Scholar] [CrossRef] [PubMed]

- Sun, X. Modeling of Projection Welding Processes Using Coupled Finite Element Analyses. Weld. Res. Supp. 2000, 79, 245-s–251-s. [Google Scholar]

- Voiculescu, I.; Geanta, V.; Vasile, I.M.; Stefănoiu, R.; Iacob, M. Research Regarding the Obtaining of the Electrode for Spot Welding. Metal. Int. 2013, 18, 52–55. [Google Scholar]

- Huang, H.-Y.; Tseng, K.-H. Process Parameters in Resistance Projection Welding for Optical Transmission Device Package. J. Mat. Eng. Perform. 2011, 20, 244–249. [Google Scholar] [CrossRef]

- Han, G.Y.; Ha, S.; Marimuthu, K.P.; Murugan, S.P.; Park, Y.; Lee, H. Shape optimization of square weld nut in projection welding. Int. J. Adv. Manuf. Tech. 2021, 113, 1–14. [Google Scholar] [CrossRef]

- Kumar, N.; Minda Ramakrishnan, S.; Panchapakesan, K.; Subramaniam, D.; Dowson, M.; Das, A. Utilizing a novel multi-electrode approach for improving micro-resistance spot welding productivity for electric-mobility battery interconnects. Sci. Technol. Weld. Join. 2023, 28, 643–652. [Google Scholar]

- Kuntz, M. Modeling projection welding of fasteners to advanced high-strength steel (AHSS) sheet using finite element method. In Proceedings of the Sheet Metal Welding Conference XII, Livonia, MI, USA, 10–12 May 2006; Conference Proceedings. AWS Detroit Section: Detroit, MI, USA, 2006. [Google Scholar]

- Mikno, Z. Projection Welding with Pneumatic and Servomechanical Electrode Operating Force Systems. Weld. Res. 2016, 95, 286–299. [Google Scholar]

- Bohr, J.C.; Brafford, W.H.; Daumeyer, G.J., III; Kelly, B.G.; Kelly, D.P.; Kimchi, M.; Zhang, H. Chapter 2, Projection welding. In AWS Welding Handbook, 9th ed.; AWS (American Welding Society): Doral, NW, USA, 2007; Volume 3, Part 2, pp. 55–65. [Google Scholar]

- Raut, M.; Achwal, V. Optimization of Spot-Welding Process Parameters for Maximum Tensile Strength. Int. J. Mech. Eng. Rob. Res. 2014, 3, 506–517. [Google Scholar]

- Aslanlar, S. The effect of nucleus size on mechanical properties in electrical resistance spot welding of sheets used in automotive industry. Mater. Des. 2006, 27, 125–131. [Google Scholar] [CrossRef]

- Mikno, Z.; Kowieski, S.; Pilarczyk, A. Projection Welding of Nuts with Full Projections with Use of Electromechanical Operating Force System. Biul. Inst. Spaw. 2019, 63, 7–15. [Google Scholar] [CrossRef]

- Oprea, A.V.; Vasile, I.M.; Voiculescu, I.; Ciocoiu, R.C. The Multipoint Relief Projection Study. PriMera Sci. Eng. 2023, 3, 33–39. [Google Scholar] [CrossRef]

- Choi, I.; Kim, Y.D.; Park, Y.-D. Study on coating melting behavior on weld growth mechanism for Al-Si coated hot-stamped boron steels in resistance spot welding. Korean J. Met. Mater. 2014, 52, 931–941. [Google Scholar]

- Mathiszik, C.; Johannes Koal, J.; Zschetzsche, J.; Füssel, U.; Schmale, H.C. Study on precise weld diameter validations by comparing destructive testing methods in resistance spot welding. Weld. World 2024, 68, 1825–1835. [Google Scholar] [CrossRef]

- Hamedi, M.; Atashparva, M. A review of electrical contact resistance modelling in resistance spot welding. Weld. World 2017, 61, 269–290. [Google Scholar] [CrossRef]

- Mikno, Z. Analysis of projection welding in relation to the non-parallelism of electrodes. Int. J. Adv. Manuf. Technol. 2024, 135, 2087–2095. [Google Scholar] [CrossRef]

- Pouranvari, M.; Abedi, A.; Marashi, P.; Goodarzi, M. Effect of expulsion on peak load and energy absorption of low carbon steel resistance spot welds. Sci. Technol. Weld. Join. 2008, 13, 39–43. [Google Scholar] [CrossRef]

- Kim, J.; Jun, H.; Cheon, J.; Kim, Y.; Ji, C. Effect of the melting behaviour of the coating layer on weldability in the bolt projection resistance welding of Al-Si coated hot-stamped boron steel. J. Weld. Join 2020, 38, 33–40. [Google Scholar] [CrossRef]

- Bangukira, I.M. Aluminizing of Plain Carbon Steel—Effect of Temperature on Coating and Alloy Phase Morphology at Constant Holding Time. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2012. [Google Scholar]

- Voiculescu, I.; Oprea, A.V.; Vasile, I.M. Case Study About Resistance Projection Welding of Aluminized Steel Parts. Ann. “Dunarea De Jos” Univ. Galati. Fasc XII Weld. Equip. Technol. 2021, 32, 23–29. [Google Scholar]

- Ji, C.-W.; Jo, I.; Lee, H.; Choi, I.-D.; Do Kim, Y.; Park, Y.-D. Effects of surface coating on weld growth of resistance spot-welded hot-stamped boron steels. J. Mech. Sci. Technol. 2014, 28, 4761–4769. [Google Scholar] [CrossRef]

- Saha, D.; Ji, C.; Park, Y. Coating behavior and nugget formation during resistance welding of hot forming steels. Sci. Technol. Weld. Join. 2015, 20, 708–720. [Google Scholar] [CrossRef]

- DIN 50049:1992-04; Metallic Products; Types of Inspection Documents; Products; German Version of EN 10204:1991. German Institute for Standardization: Berlin, Germany, 1992.

- EN ISO 6892-1; Metallic Materials—Tensile Testing. Part 1: Method of Test At Room Temperature. CEN: Brussels, Belgium, 2009.

- EN 1993-1-3; Eurocode 3: Design of Steel Structures. Part 1–3: General Rules. Supplementary Rules for Cold-Formed Thin Gauge Members and Sheeting. CEN: Brussels, Belgium, 2006.

- Karna, S.K.; Sahai, R. An Overview on Taguchi Method. Int. J. Eng. Math. Sci. 2012, 1, 1–7. [Google Scholar]

- Sherepenko, O.; Kazemi, O.; Rosemann, P.; Wilke, M.; Halle, T.; Jüttner, S. Transient Softening at the Fusion Boundary of Resistance Spot Welds: A Phase Field Simulation and Experimental Investigations for Al-Si-coated 22MnB5. Metals 2019, 10, 10. [Google Scholar] [CrossRef]

- Gajbhiye, A.M.; Sonawane, P.R.; Karle, A.H.; Campli, S. Optimization of welding parameters for En8D and SAE1018 materials by Taguchi. Int. J. Interact. Des. Manuf. 2024, 18, 7511–7520. [Google Scholar] [CrossRef]

- Nakowong, K.; Sillapasa, K. Optimized Parameter for Butt Joint in Friction Stir Welding of Semi-Solid Aluminum Alloy 5083 Using Taguchi Technique. J. Manuf. Mater. Process. 2021, 5, 88. [Google Scholar] [CrossRef]

- Nobrega, G.; Souza, M.S.; Rodríguez-Martín, M.; Rodríguez-Gonzálvez, P.; Ribeiro, J. Parametric Optimization of the GMAW Welding Process in Thin Thickness of Austenitic Stainless Steel by Taguchi Method. Appl. Sci. 2021, 11, 8742. [Google Scholar] [CrossRef]

- Rojas, H.; Vargas, Z.; Valdez, S.; Serrano, M.; del Pozo, A.; Alcántara, M. Taguchi, Grey Relational Analysis, and ANOVA Optimization of TIG Welding Parameters to Maximize Mechanical Performance of Al-6061 T6 Alloy. J. Manuf. Mater. Process. 2024, 8, 246. [Google Scholar] [CrossRef]

- Costa, H.R.M.; Dias, J.S.; Aguiar, R.A.A.; Lima, R.A.A.; Lopes, D.M.M. The effect of process parameters on the lifetime of copper electrodes used in spot welding of interstitial free steel sheets. Ann. “Dunarea De Jos” Univ. Galati. Fasc XII Weld. Equip. Technol. 2016, 27, 55–61. [Google Scholar]

- Khan, M.I.; Kuntz, M.L.; Biro, E.; Zhou, Y. Microstructure and mechanical properties of resistance spot welded advanced high strength steels. Mater. Trans. 2008, 49, 1629–1637. [Google Scholar] [CrossRef]

- AWS D1.1/D1.1M:2002; American Welding Society (AWS) Committee on Structural Welding. Structural Welding Code—Steel. American Welding Society: Miami, FL, USA, 2002.

- Welding, Brazing and Soldering; Olson, D.L., Siewert, T.A., Liu, S., Edwards, G.R., Eds.; ASM International: Almere, The Netherlands, 1993; Volume 6. [Google Scholar]

- Sina, H.; Corneliusson, J.; Turba, K.K.; Iyengar, S. A study on the formation of iron aluminide (FeAl) from elemental powders. J. Alloys Compd. 2015, 636, 261–269. [Google Scholar]

- Wang, X.; Wood, J.V.; Sui, Y.; Lu, H. Formation of intermetallic compound in iron aluminum alloys. J. Shanghai Univ. Engl. Ed. 1998, 2, 305–310. [Google Scholar] [CrossRef]

| Protrusions | T1 | T2 | G | D | H | R | E |

|---|---|---|---|---|---|---|---|

| 3 | 1.2 | 0.8 | 1.12 | 4.14 | 1.52 | 1.3 | 3.22 |

| 5 | 1.2 | 0.8 | 1.83 | 5.66 | 1.73 | 2.4 | 4.13 |

| Parameter | Symbol (Units) | Levels | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Welding power | Wp (kVA) | 17.7 | 19 | 19.5 | 20.5 |

| Welding time | t (ms) | 4 | 5 | 6 | 7 |

| Electrode pressure | P (bar) | 2.8 | 3.4 | 4 | 5 |

| Test No. | Welding Power Wp (kVA) | Welding Time t (ms) | Electrode Pressure P (Bar) |

|---|---|---|---|

| 1 (17.7) | 1 (4) | 1 (2.8) | |

| 2 (19) | 2 (5) | 2 (3.4) | |

| 3 (19.5) | 3 (6) | 3 (4) | |

| 4 (20.5) | 4 (7) | 4 (5) | |

| 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 |

| 3 | 1 | 3 | 3 |

| 4 | 1 | 4 | 4 |

| 5 | 2 | 1 | 2 |

| 6 | 2 | 2 | 1 |

| 7 | 2 | 3 | 4 |

| 8 | 2 | 4 | 3 |

| 9 | 3 | 1 | 3 |

| 10 | 3 | 2 | 4 |

| 11 | 3 | 3 | 1 |

| 12 | 3 | 4 | 2 |

| 13 | 4 | 1 | 4 |

| 14 | 4 | 2 | 3 |

| 15 | 4 | 3 | 2 |

| 16 | 4 | 4 | 1 |

| Test No. | Welding Parameters | Response Parameters | ||||

|---|---|---|---|---|---|---|

| Pressure P (Bar) | Welding Time t (ms) | Welding Power Wp (kVA) | Maximum Breaking Force Fb (kN) | Displacement at Break Db (mm) | Failure Mode | |

| 1 | 2.8 | 4 | 17.7 | 8.5851 | 1.5323 | Base material |

| 2 | 2.8 | 5 | 19.0 | 10.723 | 2.9071 | Base material |

| 3 | 2.8 | 6 | 19.5 | 10.535 | 2.7287 | Base material |

| 4 | 2.8 | 7 | 20.5 | 10.680 | 2.4025 | Base material |

| 5 | 3.4 | 4 | 19.0 | 10.202 | 2.8863 | Base material |

| 6 | 3.4 | 5 | 17.7 | 10.941 | 3.0220 | Base material |

| 7 | 3.4 | 6 | 20.5 | 10.772 | 2.9455 | Base material |

| 8 | 3.4 | 7 | 19.5 | 10.904 | 3.0986 | Base material |

| 9 | 4 | 4 | 19.5 | 10.924 | 3.3854 | Base material |

| 10 | 4 | 5 | 20.5 | 10.782 | 3.2990 | Base material |

| 11 | 4 | 6 | 17.7 | 11.033 | 3.1994 | Base material |

| 12 | 4 | 7 | 19.0 | 10.944 | 3.0800 | Base material |

| 13 | 5 | 4 | 20.5 | 10.964 | 3.1621 | Base material |

| 14 | 5 | 5 | 19.5 | 10.984 | 3.3373 | Base material |

| 15 | 5 | 6 | 19.0 | 10.805 | 3.1982 | Base material |

| 16 | 5 | 7 | 17.7 | 10.901 | 3.2650 | Base material |

| Test No. | Welding Parameters | Response Parameters | ||||

|---|---|---|---|---|---|---|

| Pressure P (Bar) | Welding Time t (ms) | Welding Power, Wp (kVA) | Maximum Breaking Force Fb (kN) | Displacement at Break Db (mm) | Failure Mode | |

| 1 | 2.8 | 4 | 17.7 | 9.1656 | 7.9475 | Base material |

| 2 | 2.8 | 5 | 19.0 | 8.8854 | 7.2448 | Base material |

| 3 | 2.8 | 6 | 19.5 | 9.156 | 7.7450 | Base material |

| 4 | 2.8 | 7 | 20.5 | 9.2385 | 8.0252 | Base material |

| 5 | 3.4 | 4 | 19.0 | 9.1857 | 8.1314 | Base material |

| 6 | 3.4 | 5 | 17.7 | 9.1032 | 7.4998 | Base material |

| 7 | 3.4 | 6 | 20.5 | 9.0174 | 7.9234 | Base material |

| 8 | 3.4 | 7 | 19.5 | 9.1857 | 8.0537 | Base material |

| 9 | 4 | 4 | 19.5 | 9.0933 | 7.9519 | Base material |

| 10 | 4 | 5 | 20.5 | 9.1692 | 7.8556 | Base material |

| 11 | 4 | 6 | 17.7 | 8.991 | 7.7833 | Base material |

| 12 | 4 | 7 | 19.0 | 9.2319 | 7.6202 | Base material |

| 13 | 5 | 4 | 20.5 | 9.3375 | 8.0887 | Base material |

| 14 | 5 | 5 | 19.5 | 9.2715 | 8.3984 | Base material |

| 15 | 5 | 6 | 19.0 | 9.156 | 8.2200 | Base material |

| 16 | 5 | 7 | 17.7 | 11.406 | 6.1885 | Base material |

| No. | Welding Parameters | Breaking Force, kN | ||||

|---|---|---|---|---|---|---|

| Pressure P (Bar) | Time T (ms) | Power P (kVA) | Thermal Energy Q (J) | 3 Protrusions | 5 Protrusions | |

| 1 | 2.8 | 4 | 17.7 | 70.8 min | 8.5851 min | 9.1656 |

| 2 | 2.8 | 5 | 19 | 95 | 10.723 | 8.8854 min |

| 3 | 2.8 | 6 | 19.5 | 117 | 10.535 | 9.156 |

| 4 | 2.8 | 7 | 20.5 | 143.5 max | 10.680 | 9.2385 |

| 5 | 3.4 | 4 | 19 | 76 | 10.202 | 9.1857 |

| 6 | 3.4 | 5 | 17.7 | 88.5 | 10.941 | 9.1032 |

| 7 | 3.4 | 6 | 20.5 | 123 | 10.772 | 9.0174 |

| 8 | 3.4 | 7 | 19.5 | 136.5 | 10.904 | 9.1857 |

| 9 | 4 | 4 | 19.5 | 78 | 10.924 | 9.0933 |

| 10 | 4 | 5 | 20.5 | 102.5 | 10.782 | 9.1692 |

| 11 | 4 | 6 | 17.7 | 106.2 | 11.033 max | 8.991 |

| 12 | 4 | 7 | 19 | 133 | 10.944 | 9.2319 |

| 13 | 5 | 4 | 20.5 | 82 | 10.964 | 9.3375 |

| 14 | 5 | 5 | 19.5 | 97.5 | 10.984 | 9.2715 |

| 15 | 5 | 6 | 19 | 114 | 10.805 | 9.156 |

| 16 | 5 | 7 | 17.7 | 123.9 | 10.901 | 11.406 max |

| Level | Pressure (Bar) | Welding Time (s) | Welding Power (kVA) |

|---|---|---|---|

| 1 | 20.08 | 20.10 | 20.26 |

| 2 | 20.59 | 20.71 | 20.56 |

| 3 | 20.76 | 20.66 | 20.70 |

| 4 | 20.76 | 20.71 | 20.67 |

| Delta | 0.69 | 0.61 | 0.43 |

| Rank | 1 | 2 | 3 |

| Level | Pressure (Bar) | Welding Time (s) | Welding Power (kVA) |

|---|---|---|---|

| 1 | 19.19 | 19.27 | 19.66 |

| 2 | 19.20 | 19.19 | 19.19 |

| 3 | 19.20 | 19.16 | 19.25 |

| 4 | 19.78 | 19.76 | 19.27 |

| Delta | 0.59 | 0.59 | 0.47 |

| Rank | 2 | 1 | 3 |

| Source | DoF | Adj SS | Adj MS | F-Value | p-Value | Contribution, (%) | |

|---|---|---|---|---|---|---|---|

| Maximum breaking force (MBF) | Pressure | 3 | 1.6565 | 0.5522 | 1.93 | 0.227 | 31.46 |

| Welding time | 3 | 1.3397 | 0.4466 | 1.56 | 0.294 | 25.44 | |

| Welding power | 3 | 0.5502 | 0.1832 | 0.64 | 0.617 | 10.45 | |

| Error | 6 | 1.7196 | 0.2866 | -- | -- | ||

| Total | 15 | 5.2660 | -- | -- | -- | ||

| Displacement at break (DB) | Pressure | 3 | 1.9210 | 0.6403 | 6.74 | 0.024 | 61.29 |

| Welding time | 3 | 0.3354 | 0.1118 | 1.18 | 0.394 | 10.70 | |

| Welding power | 3 | 0.3078 | 0.1026 | 1.08 | 0.426 | 9.82 | |

| Error | 6 | 0.5700 | 0.0950 | -- | -- | ||

| Total | 15 | 3.1342 | -- | -- | -- |

| Source | DoF | Adj SS | Adj MS | F-Value | p-Value | Contribution (%) | |

|---|---|---|---|---|---|---|---|

| Maximum breaking force (MBF) | Pressure | 3 | 1.3639 | 0.4546 | 1.73 | 0.261 | 27.42 |

| Welding time | 3 | 1.2498 | 0.4166 | 1.58 | 0.289 | 25.12 | |

| Welding power | 3 | 0.7805 | 0.2602 | 0.99 | 0.459 | 15.69 | |

| Error | 6 | 1.5806 | 0.2634 | -- | -- | ||

| Total | 15 | 4.9747 | -- | -- | -- | ||

| Displacement at break (DB) | Pressure | 3 | 0.07803 | 0.02601 | 0.08 | 0.970 | 1.98 |

| Welding time | 3 | 0.70679 | 0.23560 | 0.70 | 0.585 | 17.96 | |

| Welding power | 3 | 1.13721 | 0.37907 | 1.13 | 0.409 | 28.89 | |

| Error | 6 | 2.01384 | 0.33564 | -- | -- | ||

| Total | 15 | 3.93588 | -- | -- | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oprea, A.V.; Ciocoiu, R.C.; Constantin, G.; Rusu, C.C.; Voiculescu, I. Optimization of Parameters in Multi-Spot Projection Welding of Thin Aluminized Steel Sheets. Appl. Sci. 2025, 15, 10530. https://doi.org/10.3390/app151910530

Oprea AV, Ciocoiu RC, Constantin G, Rusu CC, Voiculescu I. Optimization of Parameters in Multi-Spot Projection Welding of Thin Aluminized Steel Sheets. Applied Sciences. 2025; 15(19):10530. https://doi.org/10.3390/app151910530

Chicago/Turabian StyleOprea, Alexandru Vladut, Robert Catalin Ciocoiu, George Constantin, Carmen Catalina Rusu, and Ionelia Voiculescu. 2025. "Optimization of Parameters in Multi-Spot Projection Welding of Thin Aluminized Steel Sheets" Applied Sciences 15, no. 19: 10530. https://doi.org/10.3390/app151910530

APA StyleOprea, A. V., Ciocoiu, R. C., Constantin, G., Rusu, C. C., & Voiculescu, I. (2025). Optimization of Parameters in Multi-Spot Projection Welding of Thin Aluminized Steel Sheets. Applied Sciences, 15(19), 10530. https://doi.org/10.3390/app151910530