Modern Trends in the Application of Electronic Nose Systems: A Review

Abstract

1. Introduction

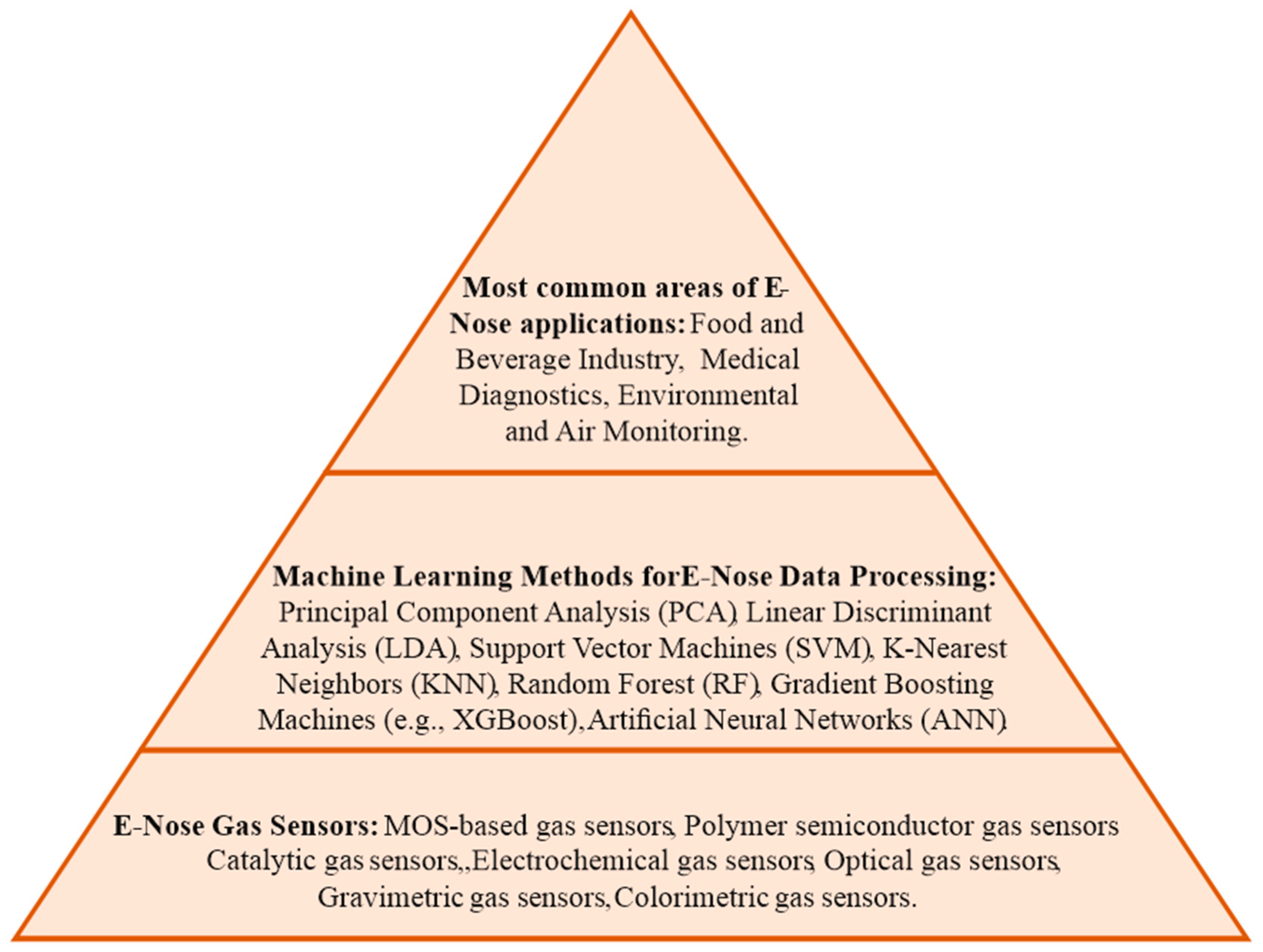

2. Trends in Structure and Functioning of E-Noses

3. Areas of Application

3.1. E-Noses in Healthcare

3.2. Food Detection and Classification

3.3. Environmental Monitoring

3.4. Key Application Requirements for E-Nose Systems

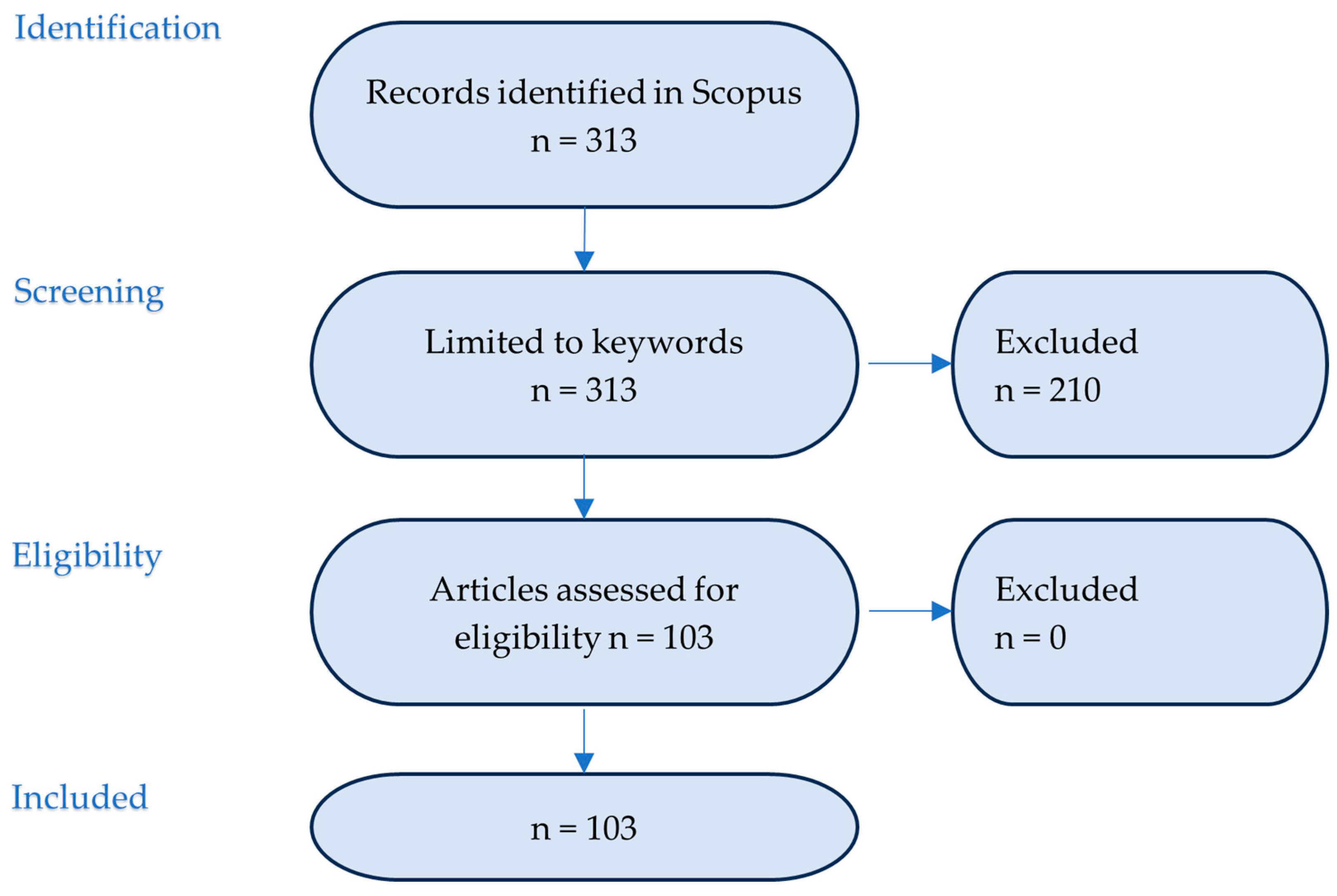

4. Statistical Information

- Abstract of an article contains the phrase “Electronic Nose Detector” or “Electronic Gas Detector”;

- Years of publication from 2015 to 2024;

- Language of publication is English;

- Limited to keywords: “Principal Component Analysis”, “Feature Extraction”, “Support Vector Machines”, “Machine Learning”, “Learning Systems”, “Neural Networks”, “Pattern Recognition” or “Classification”.

4.1. A Publications Overview

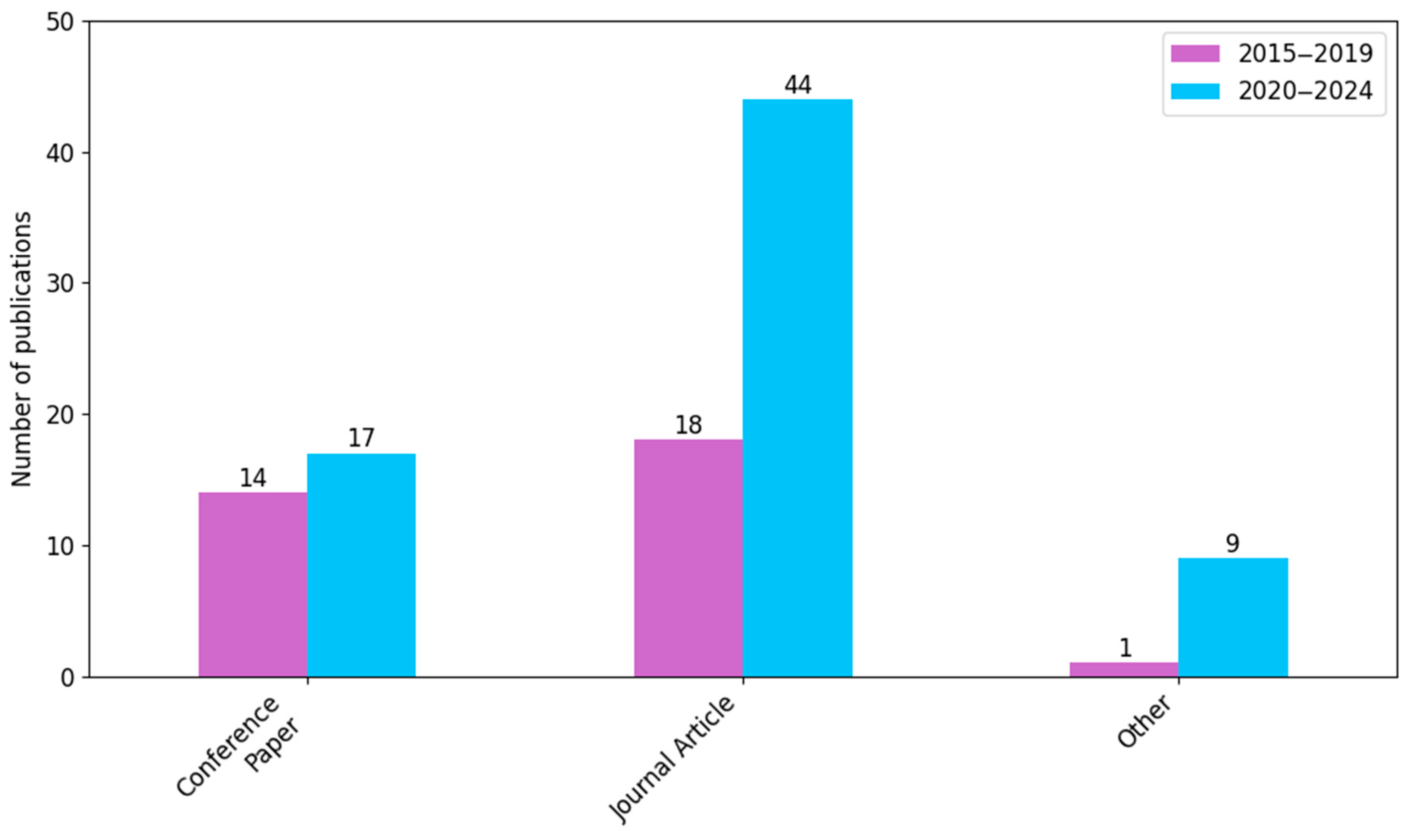

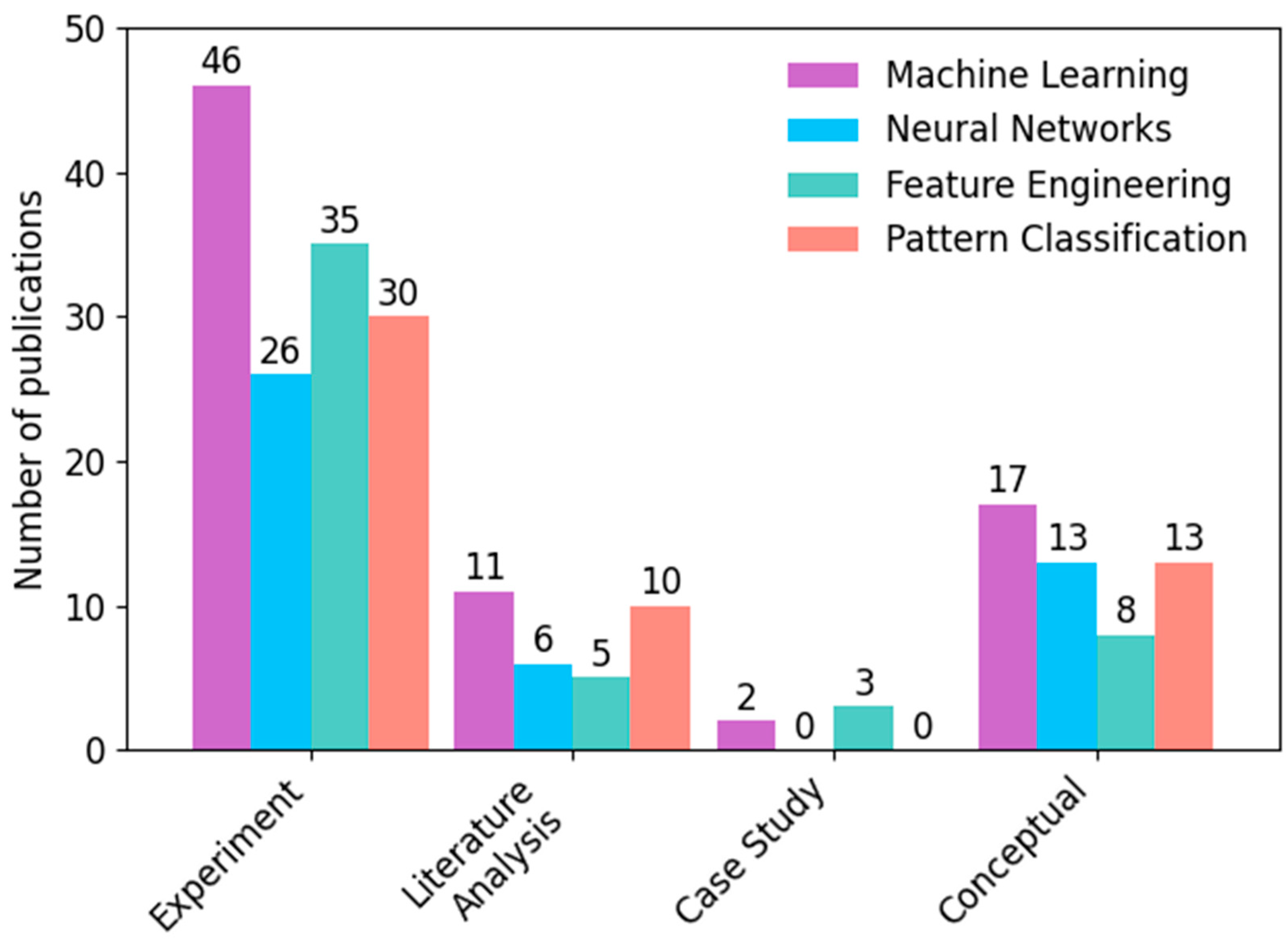

4.2. Types of Publications Reviewed

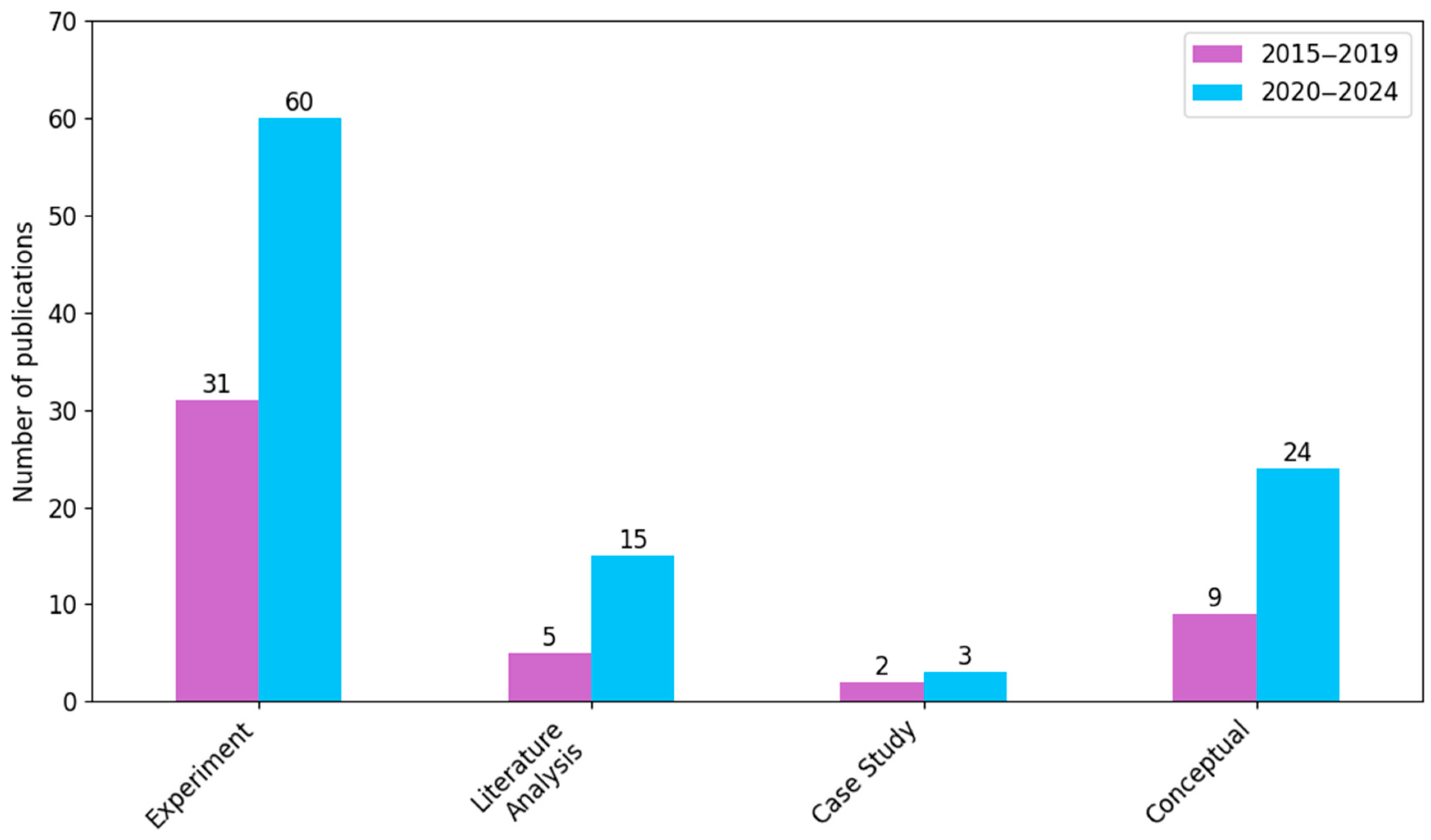

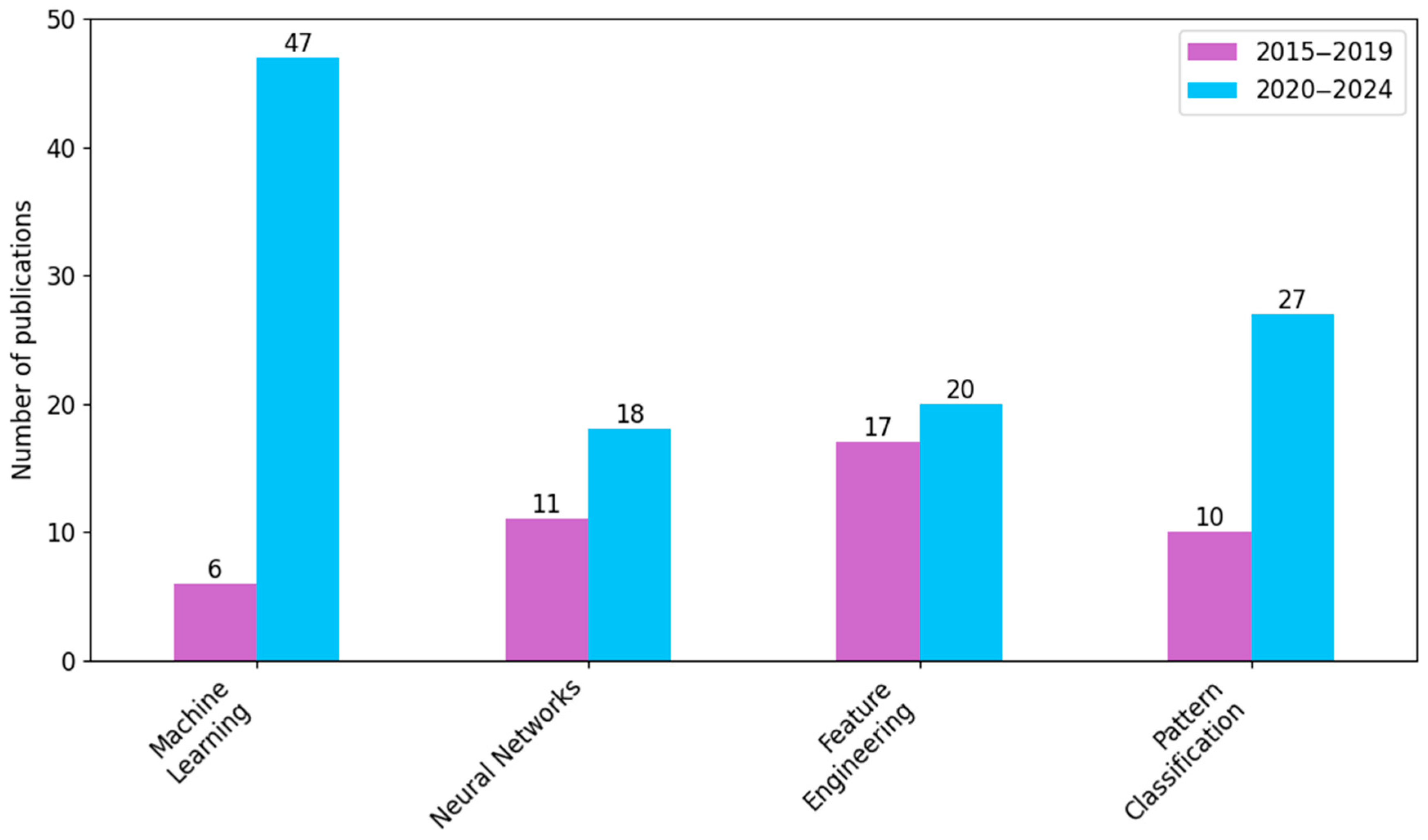

4.3. Data Processing Methods Applied in Electronic Noses

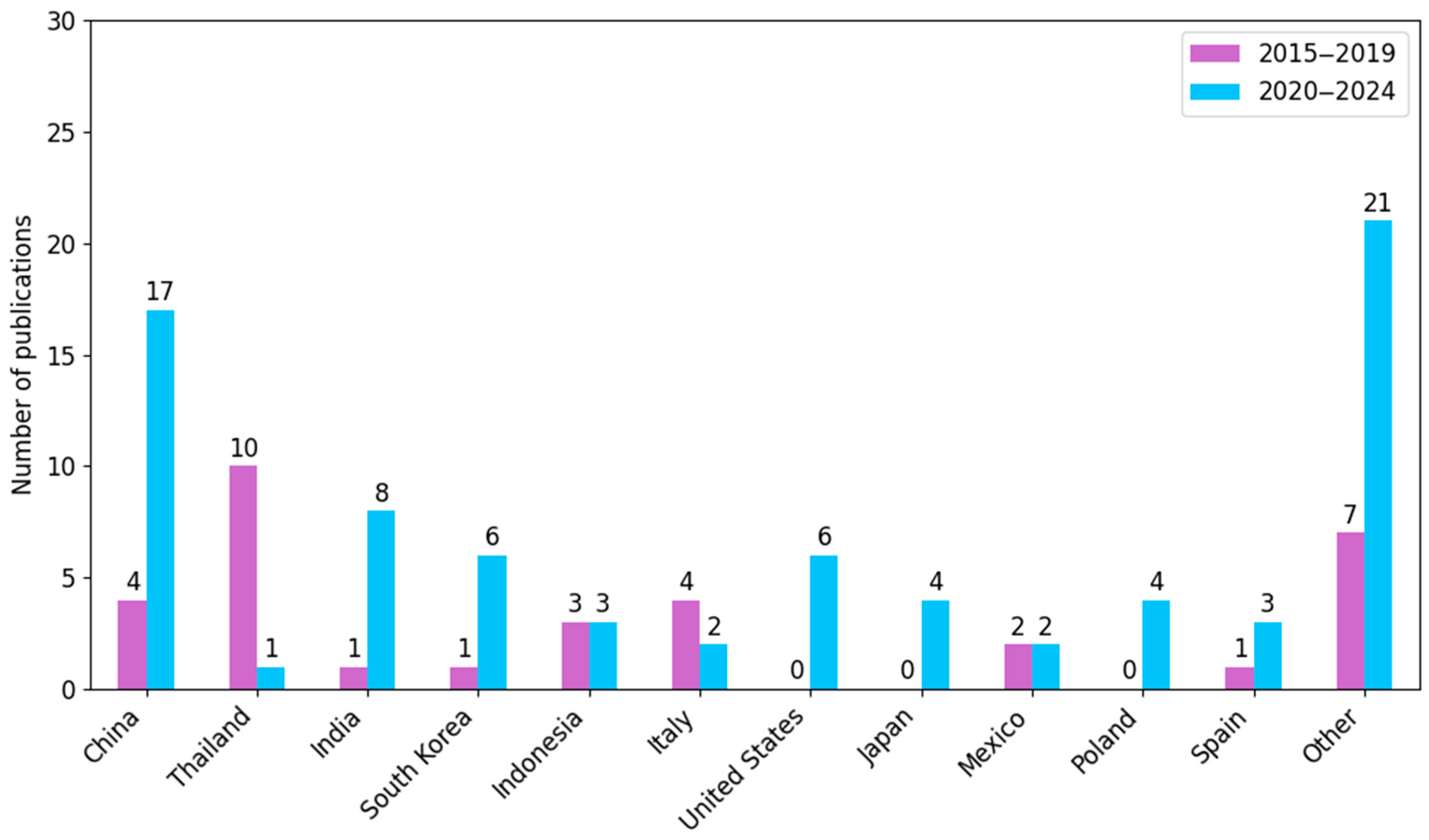

4.4. Authorship of Publications by Country

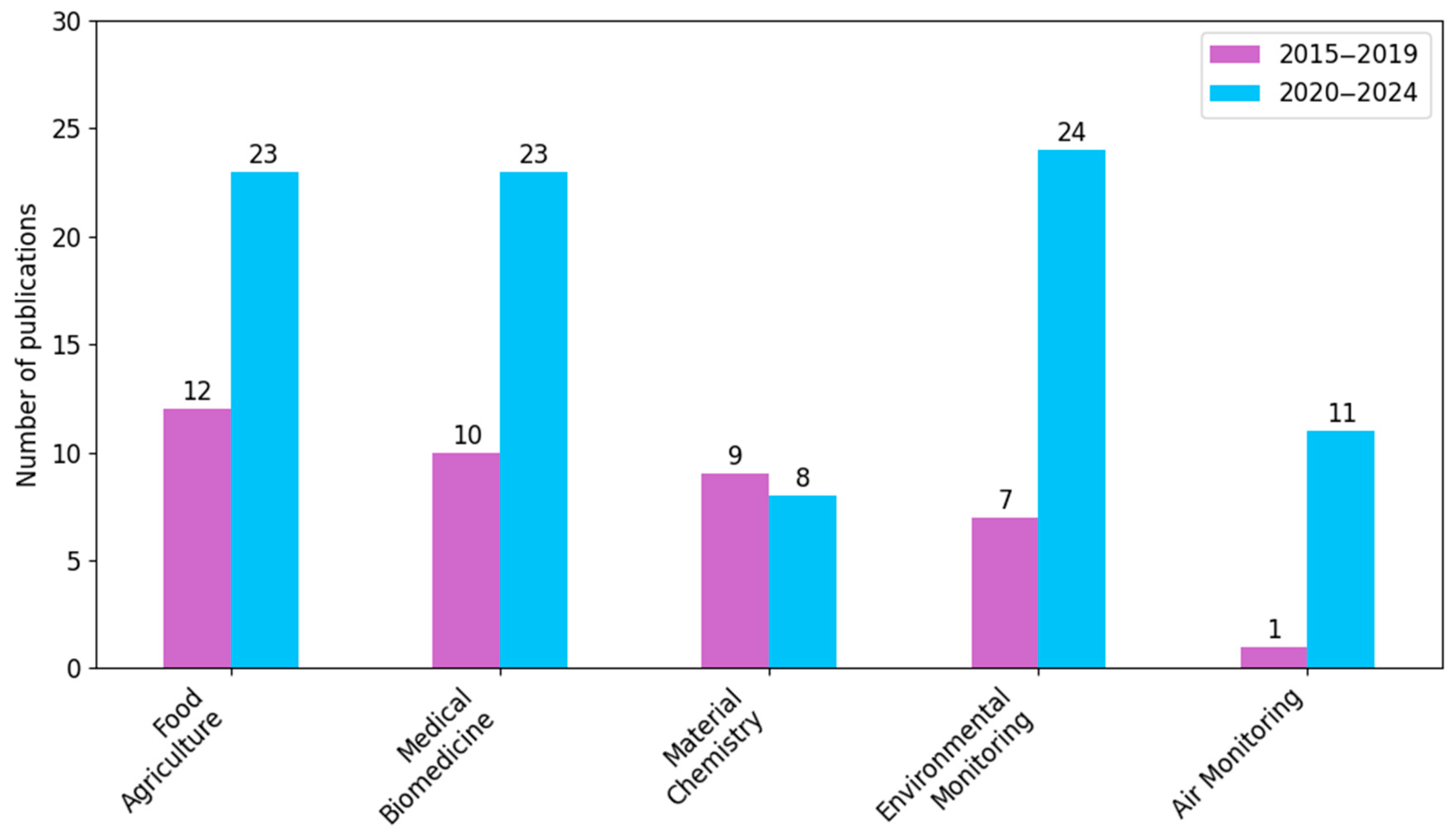

4.5. Application Areas of Electronic Noses

4.6. Electronic Nose Standards

4.7. Summary of Key Points

- Selectivity remains a challenge in e-nose systems. MEMS-based sensor arrays combined with PCA or other dimensionality reduction algorithms help improve discrimination by filtering noise and enhancing signal clarity. Using modern techniques as artificial neural networks can also be beneficial to solve problems with cross-sensitivity of gas sensors and to increase the selectivity of e-noses.

- There is always the possibility for over-fitting when ML methods such as artificial neural networks are used. It depends on the structure of the training data as well as the number of artificial neurons used and the structure of the neural network. Often the training of proper neural network is an iterative process during which the researchers have to be able to find eventual over-fitting and to take the necessary measures against it, making additional processing of training data or changing the structure of artificial neural network.

- The GC-MS (Gas Chromatography–Mass Spectrometry) are traditional methods for analyses with very good resolution and accuracy, but they are expensive. The e-noses give low-cost measurements, but they depend on software methods used for data processing to achieve the accuracy of GC-MS.

- Electronic noses distinguish between different diseases based on a set of sensor readings, rather than a single piece of data. These sets of readings are processed using machine learning methods and, thus, using different ML methods, even small fluctuations in the input dataset can detect different diseases.

- Combining e-nose data with spectroscopy (e.g., Raman, NIR) can boost diagnostic confidence. Such multimodal systems improve specificity. For instance, according to some publications, breath analysis combining an e-nose with infrared spectroscopy enhances disease discrimination compared to either method alone.

- Reliability of IoT e-nose systems depends on data communication protocols used, the cryptography of transferred data, algorithms for error compensation, and many other factors. As examples of IoT e-nose systems such devices can be pointed that use the following communication protocols: LoRa/LoRaWAN, Wi-Fi, NB-IoT, Bluetooth, BLE (Bluetooth Low Energy), etc.

- Edge computing allows processing, analysis, and decision-making to occur locally on e-nose systems. The characteristics of edge computing are low latency, reduced bandwidth used for data exchange, and possibility for e-noses to operate without need for connectivity with other devices such as servers and cloud services. Working offline the e-noses with edge computing also provide good privacy.

- Wearable e-noses, as other wearable devices, have to use little energy because the concept of all wearable devices is to be autonomous and to use batteries or energy harvesters as sources of energy. Being battery powered, the wearable e-noses have to use sensors which have low consumption, fast response time, and low weight. There are also different techniques that can optimize the energy consumption of such e-noses; these techniques depend on electronics used (as microcontrollers, voltage regulators, etc.) and also depend on software algorithms for reducing the consumption and increasing the battery life.

- To address the longevity of the gas sensor, interdisciplinary collaboration is essential. Combining materials science and AI can help to discover new and more stable sensing materials and predict the degradation and aging effect using machine learning. Materials science and electrical engineering can work together to create materials and circuits that compensate for sensor drift over time. This collaboration can significantly extend sensor lifespan and reliability in real-world applications.

- The trends in e-noses from the last five years include innovations in integration of artificial intelligence and machine learning in their structure as deep neural networks and ML methods as Random Forests, XGBoost, KNN, and Nave Bayes. Other trends include the increasing use of IoT and edge computing. For the processing of data from e-nose sensors, specialized neuromorphic chips and TPUs (Tensor Processing Units) can be used. Other trends are innovations in the field of sensor materials such as specialized polymers. All mentioned above trends lead to miniaturization of e-nose systems, improving their accuracy and making them a real low-cost alternative of specialized measurement equipment in the fields of healthcare, food industry, and environment monitoring.

- The discovery of new material properties that can be used to build new sensors may also have a significant impact on the further development of e-nose devices. For example, Ref. [172] describes the gas adsorption and sensing properties of a nickel-decorated WS2-WSe2 (Ni@WS2-WSe2) heterojunction on C2H2 and C2H4, for dissolved gas analysis and evaluation of oil-filled transformers. This technology enables the construction of highly sensitive, reusable sensors.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, S.; Cuniberti, G. Low-Dimensional Nanomaterials-Based Smart Gas Sensors for Odor Identification. In Proceedings of the International Symposium on Olfaction and Electronic Nose (ISOEN), Grapevine, TX, USA, 12–15 May 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024. [Google Scholar]

- Homma, C.; Tsukiiwa, M.; Noguchi, H.; Tanaka, M.; Okochi, M.; Tomizawa, H.; Sugizaki, Y.; Isobayashi, A.; Hayamizu, Y. Designable Peptides on Graphene Field-Effect Transistors for Selective Detection of Odor Molecules. Biosens. Bioelectron. 2023, 224, 115047. [Google Scholar] [CrossRef]

- Yang, S.; Lei, G.; Xu, H.; Lan, Z.; Wang, Z.; Gu, H. Nanostructured Metal Oxide for High-Performance Electronic Nose. In Nanostructured Materials for Electronic Nose; Springer: Singapore, 2024; Volume 213, pp. 127–161. [Google Scholar]

- Rehman, A.U.; Bermak, A. Heuristic Random Forests (HRF) for Drift Compensation in Electronic Nose Applications. IEEE Sensors J. 2019, 19, 1443–1453. [Google Scholar] [CrossRef]

- Tian, Y.; Yan, J.; Zhang, Y.; Yu, T.; Wang, P.; Shi, D.; Duan, S. A Drift-Compensating Novel Deep Belief Classification Network to Improve Gas Recognition of Electronic Noses. IEEE Access 2020, 8, 121385–121397. [Google Scholar] [CrossRef]

- Nath, V.G.; Bharath, S.P.; Dsouza, A.; Subramanian, A. Machine Learning Algorithms for Smart Gas Sensor Arrays. In Nanostructured Materials for Electronic Nose; Springer: Singapore, 2024; Volume 213, pp. 185–225. [Google Scholar]

- Robin, Y.; Amann, J.; Goodarzi, P.; Schneider, T.; Schütze, A.; Bur, C. Deep Learning Based Calibration Time Reduction for MOS Gas Sensors with Transfer Learning. Atmosphere 2022, 13, 1614. [Google Scholar] [CrossRef]

- Ivanov, S.; Todorov, T.; Nenov, T.; Wilk-Jakubowski, J. Multisensor Sunflower Oil Quality Assessment System Based on “Electronic Nose”. In Proceedings of the 2023 International Conference Automatics and Informatics (ICAI), Varna, Bulgaria, 5–7 October 2023; pp. 290–294. [Google Scholar] [CrossRef]

- Kumar, A.; Castro, M.; Feller, J.-F. Review on Sensor Array-Based Analytical Technologies for Quality Control of Food and Beverages. Sensors 2023, 23, 4017. [Google Scholar] [CrossRef]

- Ye, Z.; Liu, Y.; Li, Q. Recent Progress in Smart Electronic Nose Technologies Enabled with Machine Learning Methods. Sensors 2021, 21, 7620. [Google Scholar] [CrossRef]

- Kim, B.-J.; Kim, J.-S. Identification of Gas Mixture with the MEMS Sensor Arrays by a Pattern Recognition. Korean J. Mater. Res. 2024, 34, 235–241. [Google Scholar] [CrossRef]

- Liu, H.; Meng, G.; Deng, Z.; Nagashima, K.; Wang, S.; Dai, T.; Li, L.; Yanagida, T.; Fang, X. Discriminating BTX Molecules by the Nonselective Metal Oxide Sensor-Based Smart Sensing System. ACS Sensors 2021, 6, 4167–4175. [Google Scholar] [CrossRef] [PubMed]

- Moreira, I.P.; Sato, L.; Alves, C.; Palma, S.; Roque, A.C. Fish Gelatin-Based Films for Gas Sensing. In Proceedings of the 14th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2021), Virtual event, 11–13 February 2021; Gehin, C., Wacogne, B., Fred, A., Gamboa, H., Eds.; SciTePress: Setúbal, Portuga, 2021; pp. 32–39. [Google Scholar]

- Yi, S.H.; Song, J.; Yi, S. Discrimination of Biomarkers with Optical Gas Sensor. In Proceedings of the 2019 13th International Conference on Sensing Technology (ICST), Sydney, NSW, Australia, 2–4 December 2019; IEEE Computer Society: Los Alamitos, CA, USA, 2019. [Google Scholar]

- Capman, N.S.S.; Zhen, X.V.; Nelson, J.T.; Chaganti, V.R.S.K.; Finc, R.C.; Lyden, M.J.; Williams, T.L.; Freking, M.; Sherwood, G.J.; Bühlmann, P.; et al. Machine Learning-Based Rapid Detection of Volatile Organic Compounds in a Graphene Electronic Nose. ACS Nano 2022, 16, 19567–19583. [Google Scholar] [CrossRef]

- Reiner-Rozman, C.; Pichler, B.; Madi, V.; Weißenböck, P.; Hegedüs, T.; Aspermair, P.; Bintinger, J. Optimization of Printed Polyaniline Composites for Gas Sensing Applications. Sensors 2022, 22, 5379. [Google Scholar] [CrossRef] [PubMed]

- Santos, G.; Alves, C.; Pádua, A.C.; Palma, S.; Gamboa, H.; Roque, A.C. An Optimized E-Nose for Efficient Volatile Sensing and Discrimination. In Proceedings of the 12th International Joint Conference on Biomedical Engineering Systems and Technologies, Prague, Czech Republic, 22–24 February 2019; Roque, A., Fred, A., Gamboa, H., Eds.; SciTePress: Setúbal, Portuga, 2019; pp. 36–46. [Google Scholar]

- Hrachowina, L.; Domènech-Gil, G.; Pardo, A.; Seifner, M.S.; Gràcia, I.; Cané, C.; Romano-Rodríguez, A.; Barth, S. Site-Specific Growth and In Situ Integration of Different Nanowire Material Networks on a Single Chip: Toward a Nanowire-Based Electronic Nose for Gas Detection. ACS Sens. 2018, 3, 727–734. [Google Scholar] [CrossRef]

- Seesaard, T.; Lorwongtragool, P.; Kerdcharoen, T. Development of Fabric-Based Chemical Gas Sensors for Use as Wearable Electronic Noses. Sensors 2015, 15, 1885–1902. [Google Scholar] [CrossRef]

- Chattopadhyay, A.; Huertas, A.; Rebeiro-Hargrave, A.; Fung, P.L.; Varjonen, S.; Hieta, T.; Tarkoma, S.; Petaja, T. Low-Cost Formaldehyde Sensor Evaluation and Calibration in a Controlled Environment. IEEE Sens. J. 2022, 22, 11791–11802. [Google Scholar] [CrossRef]

- Laref, R.; Losson, E.; Sava, A.; Siadat, M. Calibration Transfer to Address the Long Term Drift of Gas Sensors for in Field NO2Monitoring. In Proceedings of the 2021 International Conference on Control, Automation and Diagnosis, Grenoble, France, 5–7 July 2021; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2021. [Google Scholar]

- Pan, X.; Zhao, X.; Xu, W.; Fan, Z.; Bermak, A. Programmable Nanoarchitectonics of Pore Array for Electronic-Nose-Based Early Disease Diagnose. IEEE Trans. Electron. Devices 2022, 69, 4514–4520. [Google Scholar] [CrossRef]

- Chang, I.-S.; Byun, S.-W.; Lim, T.-B.; Park, G.-M. A Study on E-Nose System in Terms of the Learning Efficiency and Accuracy of Boosting Approaches. Sensors 2024, 24, 302. [Google Scholar] [CrossRef] [PubMed]

- Schober, S.A.; Carbonelli, C.; Wille, R. Gas Discrimination Analysis of Neural Network Algorithms for a Graphene-Based Electronic Nose. In Proceedings of the 2022 IEEE 9th International Conference on Computational Intelligence and Virtual Environments for Measurement Systems and Applications (CIVEMSA), Chemnitz, Germany, 15–17 June 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar]

- Grasso, J.; Zhao, J.; Willis, B.G. Utilizing Machine Learning for Rapid Discrimination and Quantification of Volatile Organic Compounds in an Electronic Nose Sensor Array. Int. J. High Speed Electron. Syst. 2023, 32, 2350005. [Google Scholar] [CrossRef]

- Jang, M.; Bae, G.; Kwon, Y.M.; Cho, J.H.; Lee, D.H.; Kang, S.; Yim, S.; Myung, S.; Lim, J.; Lee, S.S.; et al. Artificial Q-Grader: Machine Learning-Enabled Intelligent Olfactory and Gustatory Sensing System. Adv. Sci. 2024, 11, 2308976. [Google Scholar] [CrossRef]

- Freddi, S.; Rodriguez Gonzalez, M.C.; Casotto, A.; Sangaletti, L.; De Feyter, S. Machine-Learning-Aided NO2 Discrimination with an Array of Graphene Chemiresistors Covalently Functionalized by Diazonium Chemistry. Chem. Eur. J. 2023, 29, e202302154. [Google Scholar] [CrossRef]

- Sharma, V.; Panchariya, P.C. Experimental Use of Electronic Nose for Odour Detection. Int. J. Eng. Syst. Model. Simul. 2015, 7, 238–243. [Google Scholar] [CrossRef]

- Hsieh, Y.-C.; Yao, D.-J. Intelligent Gas-Sensing Systems and Their Applications. J. Micromechanics Microengineering 2018, 28, 093001. [Google Scholar] [CrossRef]

- Jeong, S.-Y.; Kim, J.-S.; Lee, J.-H. Rational Design of Semiconductor-Based Chemiresistors and Their Libraries for Next-Generation Artificial Olfaction. Adv. Mater. 2020, 32, 2002075. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.-H.; Shih, C.-H.; Abbod, M.F.; Shieh, J.-S.; Hsiao, Y.-J. Development of an E-Nose System Using Machine Learning Methods to Predict Ventilator-Associated Pneumonia. Microsyst Technol 2022, 28, 341–351. [Google Scholar] [CrossRef]

- Zhai, Z.; Liu, Y.; Li, C.; Wang, D.; Wu, H. Electronic Noses: From Gas-Sensitive Components and Practical Applications to Data Processing. Sensors 2024, 24, 4806. [Google Scholar] [CrossRef]

- Khorramifar, A.; Karami, H.; Lvova, L.; Kolouri, A.; Łazuka, E.; Piłat-Rożek, M.; Łagód, G.; Ramos, J.; Lozano, J.; Kaveh, M.; et al. Environmental Engineering Applications of Electronic Nose Systems Based on MOX Gas Sensors. Sensors 2023, 23, 5716. [Google Scholar] [CrossRef]

- Mostafa, S.; Salehi, A. An electronic nose based on carbon nanotube-titanium dioxide hybrid nanostructures for detection and discrimination of volatile organic compounds. Sens. Actuators B: Chem. 2022, 357, 131418. [Google Scholar] [CrossRef]

- Eamsa-Ard, T.; Seesaard, T.; Kitiyakara, T.; Kerdcharoen, T. Screening and Discrimination of Hepatocellular Carcinoma Patients by Testing Exhaled Breath with Smart Devices Using Composite Polymer/Carbon Nanotube Gas Sensors. In Proceedings of the 2016 9th Biomedical Engineering International Conference (BMEiCON), Laung Prabang, Laos, 7–9 December 2016; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017. [Google Scholar]

- Rodríguez-Torres, M.; Altuzar, V.; Mendoza-Barrera, C.; Beltrán-Pérez, G.; Castillo-Mixcóatl, J.; Muñoz-Aguirre, S. Acetone Detection and Classification as Biomarker of Diabetes Mellitus Using a Quartz Crystal Microbalance Gas Sensor Array. Sensors 2023, 23, 9823. [Google Scholar] [CrossRef]

- Xu, M.; Tian, W.; Lin, Y.; Xu, Y.; Tao, J. Development of a Compact NDIR CO2 Gas Sensor for a Portable Gas Analyzer. Micromachines 2024, 15, 1203. [Google Scholar] [CrossRef] [PubMed]

- Defense Advanced Research Projects Agency. DARPA Sound Based Fire Extinguisher. Available online: https://www.extremetech.com/extreme/132859-darpa-creates-sound-based-fire-extinguisher (accessed on 4 June 2025).

- Loboichenko, V.; Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Harabin, R.; Shevchenko, R.; Strelets, V.; Levterov, A.; Soshinskiy, A.; Tregub, N.; Antoshkin, O. The Use of Acoustic Effects for the Prevention and Elimination of Fires as an Element of Modern Environmental Technologies. Environ. Clim. Technol. 2022, 26, 319–330. [Google Scholar] [CrossRef]

- Cliftmann, J.M.; Anderson, B.E. Remotely extinguishing flames through transient acoustic streaming using time reversal focusing of sound. Sci. Rep. 2024, 14, 30049. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Wilk-Jakubowski, G.; Yılmaz-Atay, H.; Harabin, R.; Ciosmak, J.; Ivanov, S.; Stankov, S. Acoustic Firefighting Method on the Basis of European Research: A Review: Acoustic Firefighting Method. Akustika 2023, 46, 31–45. [Google Scholar] [CrossRef]

- Medium. Literature Review–Extinguishing Fire with Acoustics. Available online: https://medium.com/@fullstackcreative/literature-review-extinguishing-fire-with-accoustics-e47f314f791e (accessed on 4 June 2025).

- Loboichenko, V.; Wilk-Jakubowski, G.; Wilk-Jakubowski, J.L.; Ciosmak, J. Application of Low-Frequency Acoustic Waves to Extinguish Flames on the Basis of Selected Experimental Attempts. Appl. Sci. 2024, 14, 8872. [Google Scholar] [CrossRef]

- Fegade, R.; Rai, K.; Dalvi, S. Extinguishing Fire Using Low Frequency Sound from Subwoofer. Gradiva Rev. J. 2022, 8, 708–713. [Google Scholar]

- Friedman, A.N.; Stoliarov, S.I. Acoustic extinction of laminar line-flames. Fire Saf. J. 2017, 93, 102–113. [Google Scholar] [CrossRef]

- Vovchuk, T.S.; Wilk-Jakubowski, J.L.; Telelim, V.M.; Loboichenko, V.M.; Shevchenko, R.I.; Shevchenko, O.S.; Tregub, N.S. Investigation of the use of the acoustic effect in extinguishing fires of oil and petroleum products. SOCAR Proc. 2021, 2, 24–31. [Google Scholar] [CrossRef]

- Loboichenko, V.; Wilk-Jakubowski, J.L.; Levterov, A.; Wilk-Jakubowski, G.; Statyvka, Y.; Shevchenko, O. Using the burning of polymer compounds to determine the applicability of the acoustic method in fire extinguishing. Polymers 2024, 16, 3413. [Google Scholar] [CrossRef]

- Radomiak, H.; Mazur, M.; Zajemska, M.; Musiał, D. Gaszenie płomienia dyfuzyjnego przy pomocy fal akustycznych. Bezpie–czeństwo i Tech. Pożarnicza 2015, 40, 29–38. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, M.; Yang, K.; Xu, C.; Wu, K. Role of Acoustic Wave on Extinguishing Flames Coupling with Water Mist. Case Stud. Therm. Eng. 2022, 38, 102367. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Experimental Investigation of Amplitude-Modulated Waves for Flame Extinguishing: A Case of Acoustic Environmentally Friendly Technology. Environ. Clim. Technol. 2023, 27, 627–638. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Loboichenko, V. Experimental Attempts of Using Modulated and Unmodulated Waves in Low-Frequency Acoustic Wave Flame Extinguishing Technology: A Review of Selected Cases. Stroj. Vestn.-J. Mech. Eng. 2024, 70, 270–281. [Google Scholar] [CrossRef]

- Niegodajew, P.; Łukasiak, K.; Radomiak, H.; Musiał, D.; Zajemska, M.; Poskart, A.; Gruszka, K. Application of acoustic oscillations in quenching of gas burner flame. Combust. Flame 2018, 194, 245–249. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Núñez-Carmona, E.; Sberveglieri, V.; Zappa, D.; Comini, E.; Sberveglieri, G. An Array of Mox Sensors and ANNs to Assess Grated Parmigiano Reggiano Cheese Packs’ Compliance with CFPR Guidelines. Biosensors 2020, 10, 47. [Google Scholar] [CrossRef]

- Sberveglieri, V.; Bhandari, M.P.; Carmona, E.N.; Betto, G.; Sberveglieri, G. A Novel MOS Nanowire Gas Sensor Device (S3) and GC-MS-Based Approach for the Characterization of Grated Parmigiano Reggiano Cheese. Biosensors 2016, 6, 60. [Google Scholar] [CrossRef] [PubMed]

- Aulia, D.; Sarno, R.; Hidayati, S.C.; Rivai, M. Optimization of the Electronic Nose Sensor Array for Asthma Detection Based on Genetic Algorithm. IEEE Access 2023, 11, 74924–74935. [Google Scholar] [CrossRef]

- Binson, V.A.; Thomas, S.; Ragesh, G.K.; Kumar, A. Non-Invasive Diagnosis of COPD with E-Nose Using XGBoost Algorithm. In Proceedings of the 2021 2nd International Conference on Advances in Computing, Communication, Embedded and Secure Systems (ACCESS), Ernakulam, India, 2–4 September 2021; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2021; pp. 297–301. [Google Scholar]

- Makarichian, A.; Chayjan, R.A.; Ahmadi, E.; Mohtasebi, S.S.; Zafari, D. Use of E-Nose in Inspecting the Effect of Processing Type on the Aroma of Garlic (Allium Sativum L.): A Critical Hint in the Quality Assessment. Food Prod. Process. Nutr. 2024, 6, 52. [Google Scholar] [CrossRef]

- Seesaard, T.; Sriphrapradang, C.; Kitiyakara, T.; Kerdcharoen, T. Self-Screening for Diabetes by Sniffing Urine Samples Based on a Hand-Held Electronic Nose. In Proceedings of the 2016 9th Biomedical Engineering International Conference (BMEiCON), Laung Prabang, Laos, 7–9 December 2016; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017. [Google Scholar]

- Chongthanaphisut, P.; Seesaard, T.; Kerdcharoen, T. Monitoring of Microbial Canned Food Spoilage and Contamination Based on E-Nose for Smart Home. In Proceedings of the 2015 12th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Hua Hin, Thailand, 24–27 June 2015; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2015. [Google Scholar]

- Ye, Z.; Wang, J.; Hua, H.; Zhou, X.; Li, Q. Precise Detection and Quantitative Prediction of Blood Glucose Level with an Electronic Nose System. IEEE Sens. J. 2022, 22, 12452–12459. [Google Scholar] [CrossRef]

- Guo, L.; Wang, J.; Han, H.; Wang, P.; Lu, Y.; Yuan, Q.; Du, C.; Yin, S.; Zhou, Y.; Zhang, C. MXene/WO3 Sensor Array with Improved SNN Algorithm for Accurate Identification of Toxic Gases. ACS Appl. Mater. Interfaces 2024, 16, 62421–62428. [Google Scholar] [CrossRef] [PubMed]

- Sosa-Ramos, O.; Castillo-Mixcóatl, J.; Beltrán-Pérez, G.; Altuzar, V.; Mendoza-Barrera, C.O.; Bravo-Sánchez, A.I.; Rodríguez-Torres, M.; Moreno-Acosta, M.A.; Muñoz-Aguirre, S. Study of the effect of relative humidity on the classification of volatile organic compounds for a quartz crystal microbalance sensors array. Sens. Actuators A Phys. 2025, 387, 116465. [Google Scholar] [CrossRef]

- Mascini, M.; Gaggiotti, S.; Della Pelle, F.; Di Natale, C.; Qakala, S.; Iwuoha, E.; Pittia, P.; Compagnone, D. Peptide Modified ZnO Nanoparticles as Gas Sensors Array for Volatile Organic Compounds (VOCs). Front. Chem. 2018, 6, 105. [Google Scholar] [CrossRef]

- Abideen, Z.U.; Arifeen, W.U.; Bandara, Y.N.D. Emerging trends in metal oxide-based electronic noses for healthcare applications: A review. Nanoscale 2024, 16, 9259–9283. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Núñez-Carmona, E.; Sberveglieri, V.; Zappa, D.; Comini, E.; Sberveglieri, G. Application of a Novel S3 Nanowire Gas Sensor Device in Parallel with GC-MS for the Identification of Rind Percentage of Grated Parmigiano Reggiano. Sensors 2018, 18, 1617. [Google Scholar] [CrossRef]

- Barbosa, A.J.; Oliveira, A.R.; Roque, A.C. Protein-and peptide-based biosensors in artificial olfaction. Trends Biotechnol. 2018, 36, 1244–1258. Available online: https://www.cell.com/trends/biotechnology/fulltext/S0167-7799(18)30195-1 (accessed on 20 May 2025). [CrossRef]

- Pizzoni, D.; Mascini, M.; Lanzone, V.; Del Carlo, M.; Di Natale, C.; Compagnone, D. Selection of peptide ligands for piezoelectric peptide based gas sensors arrays using a virtual screening approach. Biosens. Bioelectron. 2014, 52, 247–254. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, L.; Lee, C. Recent Advances in Artificial Intelligence Sensors. Adv. Sens. Res. 2023, 2, 2200072. [Google Scholar] [CrossRef]

- Wang, Z.L. Self-Powered Nanosensors and Nanosystems. Adv. Mater. 2012, 24, 280–285. [Google Scholar] [CrossRef] [PubMed]

- Dahlin, A.B. Size Matters: Problems and Advantages Associated with Highly Miniaturized Sensors. Sensors 2012, 12, 3018–3036. [Google Scholar] [CrossRef]

- Maity, A.; Maidantchik, V.D.; Weidenfeld, K.; Larisch, S.; Barkan, D.; Haick, H. Chemical Tomography of Cancer Organoids and Cyto-Proteo-Genomic Development Stages Through Chemical Communication Signals. Adv. Mater. 2025, 2413017. [Google Scholar] [CrossRef]

- Binson, V.A.; Subramoniam, M.; Mathew, L. Prediction of Lung Cancer with a Sensor Array Based E-Nose System Using Machine Learning Methods. Microsyst. Technol. 2024, 30, 1421–1434. [Google Scholar] [CrossRef]

- Li, W.; Jia, Z.; Xie, D.; Chen, K.; Cui, J.; Liu, H. Recognizing Lung Cancer Using a Homemade E-Nose: A Comprehensive Study. Comput. Biol. Med. 2020, 120, 103706. [Google Scholar] [CrossRef]

- Choden, P.; Seesaard, T.; Eamsa-Ard, T.; Sriphrapradang, C.; Kerdcharoen, T. Volatile Urine Biomarkers Detection in Type II Diabetes towards Use as Smart Healthcare Application. In Proceedings of the 2017 9th International Conference on Knowledge and Smart Technology (KST), Chonburi, Thailand, 1–4 February 2017; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017; pp. 178–181. [Google Scholar]

- Choden, P.; Seesaard, T.; Dorji, U.; Sriphrapradang, C.; Kerdcharoen, T. Urine Odor Detection by Electronic Nose for Smart Toilet Application. In Proceedings of the 2017 14th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phuket, Thailand, 27–30 June 2017; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017; pp. 190–193. [Google Scholar]

- Méndez-Rodríguez, K.B.; Figueroa-Vega, N.; Ilizaliturri-Hernandez, C.A.; Cardona-Alvarado, M.; Borjas-García, J.A.; Kornhauser, C.; Malacara, J.M.; Flores-Ramírez, R.; Pérez-Vázquez, F.J. Identification of Metabolic Markers in Patients with Type 2 Diabetes by Ultrafast Gas Chromatography Coupled to Electronic Nose. A Pilot Study. Biomed. Chromatogr. 2020, 34, e4956. [Google Scholar] [CrossRef]

- Tozlu, B.H.; Şimşek, C.; Aydemir, O.; Karavelioglu, Y. A High Performance Electronic Nose System for the Recognition of Myocardial Infarction and Coronary Artery Diseases. Biomed. Signal Process. Control 2021, 64, 102247. [Google Scholar] [CrossRef]

- Rodríguez-Aguilar, M.; Ramírez-García, S.; Ilizaliturri-Hernández, C.; Gómez-Gómez, A.; Van-Brussel, E.; Díaz-Barriga, F.; Medellín-Garibay, S.; Flores-Ramírez, R. Ultrafast Gas Chromatography Coupled to Electronic Nose to Identify Volatile Biomarkers in Exhaled Breath from Chronic Obstructive Pulmonary Disease Patients: A Pilot Study. Biomed. Chromatogr. 2019, 33, e4684. [Google Scholar] [CrossRef]

- Kladsomboon, S.; Thippakorn, C.; Seesaard, T. Development of Organic-Inorganic Hybrid Optical Gas Sensors for the Non-Invasive Monitoring of Pathogenic Bacteria. Sensors 2018, 18, 3189. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, Y.; Zhang, Y.; Ding, X.; Zhang, H.; Cao, T.; Qu, Z.-B.; Ren, J.; Li, L.; Guo, Z.; et al. Modular Assembly of MXene Frameworks for Noninvasive Disease Diagnosis via Urinary Volatiles. ACS Nano 2022, 16, 17376–17388. [Google Scholar] [CrossRef]

- Esfahani, S.; Shanta, M.; Specht, J.P.; Xing, Y.; Cole, M.; Gardner, J.W. Wearable IoT Electronic Nose for Urinary Incontinence Detection. In Proceedings of the 2020 IEEE SENSORS, Rotterdam, Netherlands, 25–28 October 2020; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2020; Volume 2020-October. [Google Scholar]

- Pace, C.; Fragomeni, L.; Khalaf, W. Developments and Applications of Electronic Nose Systems for Gas Mixtures Classification and Concentration Estimation. In Applications in Electronics Pervading Industry, Environment and Society. Lecture Notes in Electrical Engineering; De Gloria, A., Ed.; Springer: Cham, Switzerland, 2016; Volume 351, pp. 1–7. [Google Scholar]

- Zhang, Z.; Zheng, Z.; He, X.; Liu, K.; Debliquy, M.; Zhou, Y.; Zhang, C. Electronic Nose Based on Metal Oxide Semiconductor Sensors for Medical Diagnosis. Prog. Nat. Sci. 2024, 34, 74–88. [Google Scholar] [CrossRef]

- Guo, Z.; Guo, C.; Sun, L.; Zuo, M.; Chen, Q.; El-Seedi, H.R.; Zou, X. Identification of the Apple Spoilage Causative Fungi and Prediction of the Spoilage Degree Using Electronic Nose. J. Food Process Eng. 2021, 44, e13816. [Google Scholar] [CrossRef]

- Affognon, L.; Diallo, A.; Diallo, C.; Ezin, E.C. Supervised Learning Models for Tomato Quality Prediction Using Electronic Nose Data. In Proceedings of the 2023 International Conference on Electrical, Computer and Energy Technologies (ICECET), Cape Town, South Africa, 16–17 November 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar]

- Mahata, B.; Acharyya, S.; Banerji, P.; Guha, P.K. Assessment of Fish Adulteration Using SnO2 Nanopetal-Based Gas Sensor and Machine Learning. Food Chem. 2024, 438, 138039. [Google Scholar] [CrossRef]

- Jia, W.; Liang, G.; Tian, H.; Sun, J.; Wan, C. Electronic Nose-Based Technique for Rapid Detection and Recognition of Moldy Apples. Sensors 2019, 19, 1526. [Google Scholar] [CrossRef] [PubMed]

- Radi, S.T.P.; Ciptohadijoyo, S.; Litananda, W.S.; Rivai, M.; Purnomo, M.H. Electronic Nose Based on Partition Column Integrated with Gas Sensor for Fruit Identification and Classification. Comput. Electron. Agric. 2016, 121, 429–435. [Google Scholar] [CrossRef]

- Gaggiotti, S.; Della Pelle, F.; Masciulli, V.; Di Natale, C.; Compagnone, D. Monitoring Shelf Life of Carrots with a Peptides Based Electronic Nose. In Lecture Notes in Electrical Engineering; Baldini, F., Siciliano, P., Rossi, M., Scalise, L., Di Natale, C., Ferrari, V., Militello, V., Miolo, G., Andò, B., Marletta, V., et al., Eds.; Springer: Cham, Switzerland, 2019; Volume 539, pp. 69–74. [Google Scholar]

- Jia, Y.; Zheng, B.; Zhang, Y. Research on Chemical Constituents of Apple Odour and Design of Its Identification System. Chem. Eng. Trans. 2017, 57, 2035–2040. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, D.; Xing, C.; Wu, Q.; Xu, L. Optimal Gas Sensor Combination Selection Method for Low Cost Machine Olfaction Applicated in Food Discrimination. Sens. Actuators A Phys. 2024, 365, 114936. [Google Scholar] [CrossRef]

- Thazin, Y.; Eamsa-Ard, T.; Pobkrut, T.; Kerdcharoen, T. Formalin Adulteration Detection in Food Using E-Nose Based on Nanocomposite Gas Sensors. In Proceedings of the 2019 IEEE International Conference on Consumer Electronics-Asia (ICCE-Asia), Bangkok, Thailand, 12–14 June 2019; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2019; pp. 64–67. [Google Scholar]

- Oates, M.J.; Gonzalez-Teruel, J.D.; Ruiz-Abellon, M.C.; Guillamon-Frutos, A.; Ramos, J.A.; Torres-Sanchez, R. Using a Low-Cost Components e-Nose for Basic Detection of Different Foodstuffs. IEEE Sensors J. 2022, 22, 13872–13881. [Google Scholar] [CrossRef]

- Swe, M.M.; Eamsa-Ard, T.; Srikhirin, T.; Kerdcharoen, T. Monitoring the Freshness Level of Beef Using Nanocomposite Gas Sensors in Electronic Nose. In Proceedings of the 2019 IEEE International Conference on Consumer Electronics—Asia (ICCE-Asia), Bangkok, Thailand, 12–14 June 2019; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2019; pp. 100–103. [Google Scholar]

- Ren, X.; Wang, Y.; Huang, Y.; Sun, D.; Xu, L.; Wu, F. E-Nose System Using CNN and Abstract Odor Map to Classify Meat Freshness. In Proceedings of the 2023 IEEE 6th Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 24–26 February 2023; Xu, B., Ed.; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023; pp. 1200–1204. [Google Scholar]

- Tayagornkul, N.; Nimsuk, N. Analysis of Chicken Meat Degradation Using Electronic Nose Technology. In Proceedings of the 2018 15th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Rai, Thailand, 18–21 July 2018; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2018; pp. 356–359. [Google Scholar]

- Astuti, S.D.; Tamimi, M.H.; Pradhana, A.A.S.; Alamsyah, K.A.; Purnobasuki, H.; Khasanah, M.; Susilo, Y.; Triyana, K.; Kashif, M.; Syahrom, A. Gas Sensor Array to Classify the Chicken Meat with E. Coli Contaminant by Using Random Forest and Support Vector Machine. Biosens. Bioelectron. X 2021, 9, 100083. [Google Scholar] [CrossRef]

- Bhuiyan, Z.W.; Redwanul Haider, S.A.; Haque, A.; Hasan, M.; Uddin, M.R. Meat Freshness Classifier with Machine and AI. In Proceedings of the 2023 IEEE Region 10 Symposium (TENSYMP), Canberra, Australia, 6–8 September 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar]

- Dokic, K.; Radisic, B.; Kukina, H. Application of Machine Learning Algorithms for Monitoring of Spoilage of Cow’s Milk Using the Cheap Gas Sensor. In Proceedings of the 2024 16th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Iasi, Romania, 27–28 June 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Balbin, J.R.; Camat, S.D.; Magalona, K.D.; Rosete, J.P.; Valdez, V.N.S. Determination of Condition of Mussel in the Market Using Electronic Nose Through Principal Component Analysis. In Proceedings of the 2023 IEEE 15th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Coron, Philippines, 19–23 November 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar]

- Wu, K.; Debliquy, M.; Zhang, C. Metal–Oxide–Semiconductor Resistive Gas Sensors for Fish Freshness Detection. Compr. Rev. Food Sci. Food Saf. 2023, 22, 913–945. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, B.; Yi, C.; Gong, W. Gas Sensing Technology for Meat Quality Assessment: A Review. J. Food Process Eng. 2022, 45, e14055. [Google Scholar] [CrossRef]

- Wawrzyniak, J. Advancements in Improving Selectivity of Metal Oxide Semiconductor Gas Sensors Opening New Perspectives for Their Application in Food Industry. Sensors 2023, 23, 9548. [Google Scholar] [CrossRef]

- En Lee, H.; Mercer, Z.J.A.; Ng, S.M.; Shafiei, M.; Chua, H.S. Metal Oxide Semiconductor Gas Sensors-Based E-Nose and Two-Stage Classification: Authentication of Malaysia and Vietnam Black Pepper Samples. In Proceedings of the 2022 IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), Aveiro, Portugal, 29 May–1 June 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar]

- Mohammad-Razdari, A.; Ghasemi-Varnamkhasti, M.; Yoosefian, S.H.; Izadi, Z.; Siadat, M. Potential Application of Electronic Nose Coupled with Chemometric Tools for Authentication Assessment in Tomato Paste. J. Food Process Eng. 2019, 42, e13119. [Google Scholar] [CrossRef]

- Amkor, A.; Aboulkacem, A.; Bannay, O.E.; El Barbri, N. Determining the Potato Samples Processed Manner with an Electronic Nose System Supported by a Machine-Learning Approach. Meas. Sci. Technol. 2024, 35, 085104. [Google Scholar] [CrossRef]

- Lee, H.E.; Siang Chua, H.; Mercer, Z.J.A.; Muk Ng, S.; Shafiei, M. Fraud Detection of Black Pepper Using Metal Oxide Semiconductor Gas Sensors. In Proceedings of the 2021 IEEE Sensors, Sydney, Australia, 31 October–4 November 2021; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2021; Volume 2021-October. [Google Scholar]

- Valdez, L.F.; Gutiérrez, J.M. Chocolate Classification by an Electronic Nose with Pressure Controlled Generated Stimulation. Sensors 2016, 16, 1745. [Google Scholar] [CrossRef] [PubMed]

- Blit, I.W.; Juwita, A.B. Prototype Instruments for Determination of Aroma and Flavor Quality of Brewed Black Tea. In Proceedings of the 2015 4th International Conference on Instrumentation, Communications, Information Technology, and Biomedical Engineering (ICICI-BME), Bandung, Indonesia, 2–3 November 2015; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2016; pp. 138–142. [Google Scholar]

- Feltes, G.; Ballen, S.C.; Soares, A.C.; Soares, J.C.; Paroul, N.; Steffens, J.; Steffens, C. Discrimination of Artificial Strawberry Aroma by Electronic Nose Based on Nanocomposites. J. Food Process Eng. 2024, 47, e14501. [Google Scholar] [CrossRef]

- Gupta, Y.; Partani, K.; Rao, M. Machine Learning Powered E-Nose for Liquid Food Classification. In Proceedings of the 2024 16th International Conference on Computer and Automation Engineering (ICCAE), Melbourne, Australia, 14–16 March 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024; pp. 357–361. [Google Scholar]

- Caya, M.V.C.; Cruz, F.R.G.; Blas, P.J.R.; Cagalingan, M.M.; Malbas, R.G.L.; Chung, W.-Y. Determining Spoilage Level against Time and Temperature of Tomato-Based Filipino Cuisines Using Electronic Nose. In Proceedings of the 017IEEE 9th International Conference on Humanoid, Nanotechnology, Information Technology, Com-munication and Control, Environment and Management (HNICEM), Manila, Philippines, 1–3 December 2017; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017; Volume 2018-January, pp. 1–5. [Google Scholar]

- Rivai, M.; Purnomo, M.H. Study on Electronic-Nose-Based Quality Monitoring System for Coffee under Roasting. J. Circuits Syst. Comput. 2016, 25, 1650116. [Google Scholar] [CrossRef]

- Liu, S.; Sun, G.; Ren, X.; Qin, Y. Real Time Detection and Identification of Fish Quality Using Low-Power Multimodal Artificial Olfaction System. Talanta 2024, 279, 126601. [Google Scholar] [CrossRef]

- Rivai, M.; Aulia, D. Use of Electronic Nose to Identify Levels of Cooking Cookies. IEEE Access 2024, 12, 97235–97247. [Google Scholar] [CrossRef]

- Affognon, L.; Diallo, A.; Diallo, C.; Ezin, E.C. Design of an Experimental Electronic Nose for Data Collection for Food Quality. In Proceedings of the IEEE EUROCON 2023—20th International Conference on Smart Technologies, Torino, Italy, 6–8 July 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023; pp. 406–411. [Google Scholar]

- Anticuando, M.K.D.; Directo, C.K.R.; Padilla, D.A. Electronic Nose and Deep Learning Approach in Identifying Ripe Lycopersicum Esculentum L. TomatoFruit. In Proceedings of the 2022 13th International Conference on Computing Communication and Networking Technologies (ICCCNT), Kharagpur, India, 3–5 October 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar]

- Sharma, C.; Dey, A.; Khatun, H.; Das, J.; Sarma, U. Design and Development of a Gas Sensor Array to Detect Salinity Stress in Khasi Mandarin Orange Plants. IEEE Trans. Instrum. Meas. 2023, 72, 2006409. [Google Scholar] [CrossRef]

- Jing, L.; Yingchun, S.; Wenhui, C.; Xufang, B. Application Research on Gas Detection with Artificial Olfactory System. In Proceedings of the 2014 Fifth International Conference on Intelligent Systems Design and Engineering Applications, Hunan, China, 15–16 June 2014; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2014; pp. 234–237. [Google Scholar]

- Han, Y.; Yin, J.; Jiang, Z.; Zhuang, H.; Cao, H.; Cao, Y.; Yin, Z.; Zhu, Z. Metal Oxide Based Sensor Arrays with MultiBoosting Algorithm for Detection of Milk Spoilage Gases and Freshness Assessment. IEEE Sens. J. 2025, 25, 13995–14004. [Google Scholar] [CrossRef]

- Jiang, M.; Li, N.; Li, M.; Wang, Z.; Tian, Y.; Peng, K.; Sheng, H.; Li, H.; Li, Q. E-Nose: Time–Frequency Attention Convolutional Neural Network for Gas Classification and Concentration Prediction. Sensors 2024, 24, 4126. [Google Scholar] [CrossRef]

- Seesaard, T.; Kamjornkittikoon, K.; Wongchoosuk, C. A Comprehensive Review on Advancements in Sensors for Air Pollution Applications. Sci. Total Environ. 2024, 951, 175696. [Google Scholar] [CrossRef]

- Azarenko, O.; Honcharenko, Y.; Divizinyuk, M.; Mirnenko, V.; Strilets, V.; Wilk-Jakubowski, J.L. Influence of anthropogenic factors on the solution of applied problems of recording language information in the open area. Soc. Dev. Secur. 2022, 12, 135–143. [Google Scholar] [CrossRef]

- Azarenko, O.; Honcharenko, Y.; Divizinyuk, M.; Mirnenko, V.; Strilets, V.; Wilk-Jakubowski, J.L. The influence of air environment properties on the solution of applied problems of capturing speech information in the open terrain. Soc. Dev. Secur. 2022, 12, 64–77. [Google Scholar] [CrossRef]

- Prasad, P.; Raut, P.; Goel, S.; Barnwal, R.P.; Bodhe, G.L. Electronic Nose and Wireless Sensor Network for Environmental Monitoring Application in Pulp and Paper Industry: A Review. Environ. Monit. Assess 2022, 194, 855. [Google Scholar] [CrossRef]

- Goldsmith, A. Wireless Communications; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Zeng, L.; Zhang, C.; Qin, P.; Zhou, Y.; Cai, Y. One Method for Predicting Satellite Communication Terminal Service Demands Based on Artificial Intelligence Algorithms. Appl. Sci. 2024, 14, 6019. [Google Scholar] [CrossRef]

- Recommendation ITU-R, P. Recommendation ITU-R P.1238-7; Propagation Data and Prediction Methods for the Planning of Indoor Radiocommunication Systems and Radio Local Area Networks in the Frequency Range 900 MHz to 100 GHz. International Telecommunication Union: Geneva, Switzerland, 2012.

- Wilk-Jakubowski, J. Predicting Satellite System Signal Degradation due to Rain in the Frequency Range of 1 to 25 GHz. Pol. J. Environ. Stud. 2018, 27, 391–396. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Measuring Rain Rates Exceeding the Polish Average by 0.01%. Pol. J. Environ. Stud. 2018, 27, 383–390. [Google Scholar] [CrossRef]

- Suematsu, N.; Oguma, H.; Eguchi, S.; Kameda, S.; Sasanuma, M.; Kuroda, K. Multi-mode SDR VSAT against big disasters. In Proceedings of the European Microwave Conference ’13, Nuremberg, Germany, 6–10 October 2013. [Google Scholar] [CrossRef]

- Yang, W.; Kavak, A.; Kim, S.-Y.; Xu, G.; Hansen, L. Evaluation of spatially selective receiving/transmission techniques for a smart antenna system operating at 1.8 GHz in non-stationary scenarios. In Proceedings of the 49th Vehicular Technology Conference IEEE, Houston, TX, USA, 16–20 May 1999. [Google Scholar] [CrossRef]

- Hakim, G.P.N.; Habaebi, M.H.; Toha, S.F.; Islam, M.R.; Yusoff, S.H.B.; Adesta, E.Y.T.; Anzum, R. Near Ground Pathloss Propagation Model Using Adaptive Neuro Fuzzy Inference System for Wireless Sensor Network Communication in Forest, Jungle and Open Dirt Road Environments. Sensors 2022, 22, 3267. [Google Scholar] [CrossRef]

- Xu, C.; Sun, S.; Zhou, Y.; Ding, Z. Research on a Vehicle-Mounted Emergency Communication System Using BeiDou Regional Short Message Communication (RSMC) for Firefighting Operations in Forest Areas without a Public Network. Forests 2024, 15, 1185. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Total Signal Degradation of Polish 26–50 GHz Satellite Systems Due to Rain. Pol. J. Environ. Stud. 2018, 27, 397–402. [Google Scholar] [CrossRef]

- Battistoni, P.; Cantone, A.A.; Martino, G.; Passamano, V.; Romano, M.; Sebillo, M.; Vitiello, G. A Cyber-Physical System for Wildfire Detection and Firefighting. Future Internet 2023, 15, 237. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Overview of broadband information systems architecture for crisis management. Informatyka, Automatyka, Pomiary W Gospodarce I Ochronie Środowiska 2020, 10, 20–23. [Google Scholar] [CrossRef]

- Abdalla, M.; Alarabi, L.; Hendawi, A. Crisis Management Art from the Risks to the Control: A Review of Methods and Directions. Information 2021, 12, 18. [Google Scholar] [CrossRef]

- Park, J.; Kang, D. Artificial Intelligence and Smart Technologies in Safety Management: A Comprehensive Analysis Across Multiple Industries. Appl. Sci. 2024, 14, 11934. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, G.; Harabin, R.; Ivanov, S. Robotics in crisis management: A review. Technol. Soc. 2022, 68, 101935. [Google Scholar] [CrossRef]

- Molarius, R.; Keränen, J.; Kekki, T.; Jukarainen, P. Developing Indicators to Improve Safety and Security of Citizens in Case of Disruption of Critical Infrastructures Due to Natural Hazards–Case of a Snowstorm in Finland. Safety 2022, 8, 60. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, G.; Harabin, R.; Skoczek, T.; Wilk-Jakubowski, J. Preparation of the Police in the Field of Counter-terrorism in Opinions of the Independent Counter-terrorist Sub-division of the Regional Police Headquarters in Cracow. Slovak Journal of Political Sciences 2022, 22, 174–208. [Google Scholar] [CrossRef]

- NASA. Earth Science–Applied Sciences. Monitoring Fires with Fast-Acting Data. Available online: https://web.archive.org/web/20241217082056/https://appliedsciences.nasa.gov/our-impact/story/monitoring-fires-fast-acting-data (accessed on 3 January 2025).

- Šerić, L.; Stipanicev, D.; Krstinić, D. ML/AI in Intelligent Forest Fire Observer Network. In Proceedings of the International Conference on Management of Manufacturing Systems ‘18, Dubrovnik, Croatia, 6–8 November 2018. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Divizinyuk, M.; Wilk-Jakubowski, G.; Shevchenko, R.; Ivanov, S.; Strelets, V. Acoustic Waves and Their Application in Modern Fire Detection Using Artificial Vision Systems: A Review. Sensors 2025, 25, 935. [Google Scholar] [CrossRef]

- Lloret, J.; Garcia, M.; Bri, D.; Sendra, S. A Wireless Sensor Network Deployment for Rural and Forest Fire Detection and Verification. Sensors 2009, 9, 8722–8747. [Google Scholar] [CrossRef]

- Bolourchi, P.; Uysal, S. Forest Fire Detection in Wireless Sensor Network Using Fuzzy Logic. In Proceedings of the 2013 Fifth International Conference on Computational Intelligence, Communication Systems and Networks, Madrid, Spain, 5–7 June 2013; pp. 83–87. [Google Scholar] [CrossRef]

- Liu, Z.-G.; Yang, Y.; Ji, X.-H. Flame detection algorithm based on a saliency detection technique and the uniform local binary pattern in the YCbCr color space. Signal Image Video Process. 2016, 10, 277–284. [Google Scholar] [CrossRef]

- Thokale, A.; Sonar, P. Hybrid approach to detect a fire based on motion color and edge. Digit. Image Process. 2015, 7, 273–277. Available online: http://www.ciitresearch.org/dl/index.php/dip/article/view/DIP102015003 (accessed on 2 June 2025).

- Li, X.; Liu, Y.; Zheng, L.; Zhang, W. A Lightweight Convolutional Spiking Neural Network for Fires Detection Based on Acoustics. Electronics 2024, 13, 2948. [Google Scholar] [CrossRef]

- Khaldi, S.; Dibi, Z. Neural Network Technique for Electronic Nose Based on High Sensitivity Sensors Array. Sens. Imaging 2019, 20, 15. [Google Scholar] [CrossRef]

- Agbonlahor, O.G.; Muruganathan, M.; Banerjee, A.; Mizuta, H. Machine Learning Identification of Atmospheric Gases by Mapping the Graphene-Molecule van Der Waals Complex Bonding Evolution. Sens. Actuators B Chem. 2023, 380, 133383. [Google Scholar] [CrossRef]

- Piłat-Rożek, M.; Łazuka, E.; Majerek, D.; Szeląg, B.; Duda-Saternus, S.; Łagód, G. Application of Machine Learning Methods for an Analysis of E-Nose Multidimensional Signals in Wastewater Treatment. Sensors 2023, 23, 487. [Google Scholar] [CrossRef]

- Kang, M.; Cho, I.; Park, J.; Jeong, J.; Lee, K.; Lee, B.; Del Orbe Henriquez, D.; Yoon, K.; Park, I. High Accuracy Real-Time Multi-Gas Identification by a Batch-Uniform Gas Sensor Array and Deep Learning Algorithm. ACS Sensors 2022, 7, 430–440. [Google Scholar] [CrossRef] [PubMed]

- Borowik, P.; Dyshko, V.; Tarakowski, R.; Tkaczyk, M.; Okorski, A.; Oszako, T. Analysis of the Response Signals of an Electronic Nose Sensor for Differentiation between Fusarium Species. Sensors 2023, 23, 7970. [Google Scholar] [CrossRef]

- Borowik, P.; Tarakowski, R.; Tkaczyk, M.; Slusarski, S.; Oszako, T. Application of a Low-Cost Electronic Nose to Detect of Forest Tree Pathogens: Fusarium Oxysporum and Phytophthora Plurivora. IEEE Access 2022, 10, 93475–93487. [Google Scholar] [CrossRef]

- Domènech-Gil, G.; Puglisi, D. A Virtual Electronic Nose for the Efficient Classification and Quantification of Volatile Organic Compounds. Sensors 2022, 22, 7340. [Google Scholar] [CrossRef]

- Zhu, L.; Jia, H.; Chen, Y.; Wang, Q.; Li, M.; Huang, D.; Bai, Y. A Novel Method for Soil Organic Matter Determination by Using an Artificial Olfactory System. Sensors 2019, 19, 3417. [Google Scholar] [CrossRef]

- Palacín, J.; Rubies, E.; Clotet, E.; Martínez, D. Classification of Two Volatiles Using an eNose Composed by an Array of 16 Single-Type Miniature Micro-Machined Metal-Oxide Gas Sensors. Sensors 2022, 22, 1120. [Google Scholar] [CrossRef]

- Noh, D.; Oh, E. Chemical Detection Using Mobile Platforms and AI-Based Data Processing Technologies. J. Sens. Actuator Netw. 2025, 14, 6. [Google Scholar] [CrossRef]

- Li, X.; Hu, X.; Li, A.; Kometani, R.; Yamada, I.; Sashida, K.; Noma, M.; Nakanishi, K.; Takemori, T.; Maehara, K.; et al. An Olfactory Figure-Ground Segregation: The Resistance Fluctuation Analysis of Acetone Gas for Acetone/Random Gas Mixtures Recognition. Sens. Actuators A Phys. 2024, 376, 115627. [Google Scholar] [CrossRef]

- Zhang, Y. Diagnosis and Detection Method of Critical Equipment Failure Based on Electronic Nose Technology. Chem. Eng. Trans. 2018, 68, 241–246. [Google Scholar] [CrossRef]

- Raja, V.K.B.; Baskar, V.V.; Premi, M.S.G.; Kavvampally, R.; Raja, I. Microcontroller Based Toxic Gases Detection and Forestallment in Automobiles. In Proceedings of the 2021 5th International Conference on Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 2–4 December 2021; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2021; pp. 388–395. [Google Scholar]

- Mumyakmaz, B.; Karabacak, K. An E-Nose-Based Indoor Air Quality Monitoring System: Prediction of Combustible and Toxic Gas Concentrations. Turk. J. Electr. Eng. Comput. Sci. 2015, 23, 729–740. [Google Scholar] [CrossRef]

- Rabehi, A.; Helal, H.; Zappa, D.; Comini, E. Advancements and Prospects of Electronic Nose in Various Applications: A Comprehensive Review. Appl. Sci. 2024, 14, 4506. [Google Scholar] [CrossRef]

- International Standard. Available online: https://cdn.standards.iteh.ai/samples/55227/f055e282a43f4dc6894b4aaddb4b7dc0/ISO-16000-29-2014.pdf (accessed on 28 June 2025).

- International Standard. Available online: https://cdn.standards.iteh.ai/samples/62641/7b2e11f3ab464d4aad4dbad93d369283/ISO-12219-7-2017.pdf (accessed on 28 June 2025).

- International Standard. Available online: https://cdn.standards.iteh.ai/samples/42778/330aed36b9f94afe879ba18999835dda/ISO-25140-2010.pdf (accessed on 28 June 2025).

- International Standard. Available online: https://www.iso.org/files/live/sites/isoorg/files/store/en/PUB100424.pdf (accessed on 28 June 2025).

- VDI Standards. Available online: https://www.dinmedia.de/en/technical-rule/vdi-3880/143516979 (accessed on 28 June 2025).

- International Standard. Available online: https://cdn.standards.iteh.ai/samples/69111/ae231f15f03341da9699f3ca7d3e8dcd/ISO-13320-2020.pdf (accessed on 28 June 2025).

- Wu, H.; Zhong, S.; Bin, Y.; Jiang, X.; Cui, H. Ni-Decorated WS2-WSe2 Heterostructure as a Novel Sensing Candidate upon C2H2 and C2H4 in Oil-Filled Transformers: A First-Principles Investigation. Mol. Phys. 2025, e2492391. [Google Scholar] [CrossRef]

- Nedev, N.; Nenova, Z.; Ivanov, S. Virtual Instruments for Humidity and Temperature Measurements. In Proceedings of the 2014 Information Technology Based Higher Education and Training (ITHET), York, UK, 11–13 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Robbiani, S.; Lotesoriere, B.J.; Dellacà, R.L.; Capelli, L. Physical Confounding Factors Affecting Gas Sensors Response: A Review on Effects and Compensation Strategies for Electronic Nose Applications. Chemosensors 2023, 11, 514. [Google Scholar] [CrossRef]

| Sensor Type | Principle of Operation | Purpose (Application and Gases) | Size of a Sensor | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Metal Oxide (MOS/MOX) [31,32,33,34] | Change in electrical resistance in a metal oxide layer upon gas adsorption | Air quality, food, medical VOCs, CO, NOX, NH3, H2, alcohols | Small to very small | Low cost, fast response, miniaturization | Sensor drift, low selectivity, sensitive to humidity |

| Conductive Polymer [35] | Change in conductivity/capacitance in polymer upon VOC exposure | Food quality, environmental VOCs, solvents | Small/medium | Flexible design, many target VOCs, low cost | Aging, drift, limited stability |

| Electrochemical [20] | Current generated by redox reaction at electrode in contact with analyte gas | Industrial safety, environmental, toxic gases (CO, SO2, NO2) | Medium | Good selectivity, linearity, low power | Finite lifespan, more costly, cross-interferences |

| QCM (Quartz Crystal) [36] | Change in resonance frequency due to mass of adsorbed gas molecules | Trace VOCs, environmental, medical, research | Medium | Very high sensitivity, can detect ppb | Sensitive to temp/humidity, complex, more costly |

| Optical (e.g., NDIR) [37] | Absorption of specific IR wavelengths by target gas in optical cell | CO2, CH4, refrigerants, air monitoring, safety | Large/medium | Very selective, stable, requires little maintenance | More expensive, larger size, not for all gases |

| Acoustic (SAW/BAW) [38,39,40,41,42,43,44,45,46,47,48,49,50,51,52] | Shift in surface/bulk acoustic wave caused by gas adsorption on sensor surface | VOCs, industrial processes, research | Small/medium | High sensitivity, fast response | Sensitive to environmental changes, complex packaging |

| Biosensors/Biomimetic [53,54] | Interaction of volatile molecules with biological (or biomimetic) receptors | Medical diagnostics, specific biomarker VOCs | Small/medium | Ultra-high selectivity, unique specificity | Fragility, complexity, stability, cost |

| Technique | Category | Strengths | Use Cases in Manuscript |

|---|---|---|---|

| PCA [11] | Unsupervised | Dimensionality reduction, clustering | Breath analysis, food spoilage |

| SVM [17] | Supervised | Effective on small datasets | Diabetes, pneumonia, asthma |

| Random Forest [4] | Ensemble | High robustness to noise | Food fraud, VOC classification |

| CNN/1D-CNN [55] | Deep Learning | Temporal/spatial signal feature extraction | Asthma detection, meat classification |

| Autoencoders [10] | Unsupervised | Denoising, anomaly detection | Air quality drift correction |

| XGBoost [23,56] | Boosting | High accuracy, interpretable | Ammonia, acetone detection |

| Transfer Learning [7] | Cross-domain | Reduces calibration effort | Gas classification in new contexts |

| LDA (Linear Discriminant Analysis) [57] | Supervised | High interpretability of results. Effective for small and medium-sized datasets. Low computational requirements. Resistant to overfitting with proper feature selection. Easy implementation | Classification of garlic aroma profiles based on e-nose data to distinguish processing methods; enhanced discrimination of different garlic treatments |

| Sensing Material | Structure Type | Fabrication Technique | VOCs Detected |

|---|---|---|---|

| Graphene (e.g., aryl-functionalized) [27] | Single-layer 2D nanomaterial | Diazonium chemistry, CVD, laser-induced | NO2, benzene, acetone, ethanol |

| SWCNT/polymer composite [19,35,58,59] | Nanocomposite, 1D+polymer | Solution casting, drop casting | Acetone, ammonia, H2S, ethanol, body/breath VOCs |

| Metal oxide nanowires (e.g., SnO2, WO3, Ge) [18,60] | 1D nanowire array | Glancing angle deposition, thermal oxidation | CO, NO2, CH4, NH3, acetone, CH3OCH3 |

| MXene/WO3 hybrid [61] | Layered 2D–3D nanohybrid | Solution-based assembly, drop casting | Toxic gases (NO2, NH3, CO, CH4, acetone) |

| QCM—coated with ethyl cellulose, PMMA, Apiezon [62] | Film-coated quartz crystal | Spin-coating, drop-casting on QCM | Acetone, mixed VOCs (diabetes biomarkers) |

| ZnO–peptide hybrid [2,63,64] | Functionalized nanostructure | Self-assembly, peptide functionalization | Limonene, menthol, plant VOCs |

| MOS (e.g., TGS, MQ-series, BME688) [1,64,65] | Granular/pellet/film arrays | Thick-film, screen-printing, MEMS integration | H2, CO, CH4, NOx, NH3, food VOCs |

| Optical (Fabry–Perot, pyroelectric) [14] | Thin film, IR module | E-beam evaporation, FPI integration | Hydrocarbons, BTX (benzene, toluene, xylenes) |

| Polyaniline/F4TCNQ-doped [16] | Conducting polymer composite | Chemical doping, drop casting | Acetone, ammonia, formaldehyde |

| Peptide-based (for QCM, FET) [66,67] | Peptide monolayer or film | Self-assembly, drop-casting | Carrot VOCs, other food markers |

| Area of Application | Key Requirements | Challenges |

|---|---|---|

| Healthcare and Medical [36,55,56,58,60,73,77] | High sensitivity and selectivity; non-invasiveness; robust validation; reproducibility | High interpretability of results; clinical relevance; data privacy; resistance to environmental interference |

| Food Quality and Safety [54,84,85,86,89,90,93] | Detection of freshness/spoilage; selectivity for complex mixtures; rapid analysis; cost-effectiveness | Robustness to matrix effects; traceability; detection of adulteration; sensors stability |

| Environmental Monitoring [118,121,122,125,127,134] | Rapid response/real-time detection; long-term stability; remote/autonomous operation; wide analyte range | Timely prediction; resistance to sensor drift; operation in harsh/outdoor conditions |

| Industrial Safety and Security [148,149,150] | Fast detection of hazardous/toxic gases; low false alarm rate; integration with alarm systems | Reliability over time; operation under variable conditions; network capability |

| Name | 2015–2019 | 2020–2024 | All years | Share [%] |

|---|---|---|---|---|

| Total | 33 | 70 | 103 | 100.0 |

| Document Type | ||||

| Conference Paper | 14 | 17 | 31 | 30.1 |

| Journal Article | 18 | 44 | 62 | 60.19 |

| Other | 1 | 9 | 10 | 9.71 |

| Data Analysis Methods | ||||

| Machine Learning | 6 | 47 | 53 | 51.46 |

| Neural Networks | 11 | 18 | 29 | 28.16 |

| Feature Engineering | 17 | 20 | 37 | 35.92 |

| Pattern Classification | 10 | 27 | 37 | 35.92 |

| Electronic Nose Applications | ||||

| Food Agriculture | 12 | 23 | 35 | 33.98 |

| Medical Biomedicine | 10 | 23 | 33 | 32.04 |

| Material Chemistry | 9 | 8 | 17 | 16.5 |

| Environmental Monitoring | 7 | 24 | 31 | 30.1 |

| Air Monitoring | 1 | 11 | 12 | 11.65 |

| Research Methodology | ||||

| Experiment | 31 | 60 | 91 | 88.35 |

| Literature Analysis | 5 | 15 | 20 | 19.42 |

| Case Study | 2 | 3 | 5 | 4.85 |

| Conceptual | 9 | 24 | 33 | 32.04 |

| Application Area | Example Application | Sensed Compounds |

|---|---|---|

| Medicine | Diabetes monitoring from urine/breath | Acetone, ethanol |

| Food industry | Detection of fish/spoiled meat | Ammonia, H2S, VOCs |

| Environmental | Pollution monitoring in urban areas | CO, NO2, NH3, VOCs |

| Security/Material Chemistry | Detection of explosives | TNT, DNT vapors |

| Air monitoring | Indoor air quality measurement | CO2, VOCs, formaldehyde |

| Standard Number | Standard Title | Part (If Applicable) | Purpose |

|---|---|---|---|

| ISO 16000-29 [166] | Indoor air—Determination of volatile organic compounds (VOCs) | Part 29: Measurement of VOCs using electronic noses | Describes the use of e-noses for determining VOC concentrations in indoor air. |

| ISO 12219-7 [167] | Interior air of road vehicles | Part 7: Odor determination by olfactory measurement with e-nose | Specifies methods for evaluating odors inside vehicles with e-nose technology. |

| ISO 25140 [168] | Stationary source emissions—Automatic method for the determination of the methane concentration using flame ionisation detection (FID) | — | Provides procedures for the determination of odor concentrations in gases, including e-nose methods. |

| ISO 16000-29:2014 [166] | Indoor air | Part 29: Test methods for VOC detectors | Specifies performance testing procedures for electronic noses detecting volatile organic compounds. |

| ISO/IEC 17025 [169] | General requirements for the competence of testing and calibration laboratories | — | General requirements for laboratory quality and competence, relevant to e-nose test/analysis labs. |

| VDI 3880 [170] | Olfactometry-Static sampling | — | German guideline providing comprehensive procedures for validation and performance evaluation of e-noses. |

| ISO 13320 [171] | Particle size analysis—Laser diffraction methods | — | Specifies methods for particle size analysis by laser diffraction; not directly related to e-noses, but often cited in laboratory measurement practice. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanov, S.; Wilk-Jakubowski, J.Ł.; Ciopiński, L.; Pawlik, Ł.; Wilk-Jakubowski, G.; Mihalev, G. Modern Trends in the Application of Electronic Nose Systems: A Review. Appl. Sci. 2025, 15, 10776. https://doi.org/10.3390/app151910776

Ivanov S, Wilk-Jakubowski JŁ, Ciopiński L, Pawlik Ł, Wilk-Jakubowski G, Mihalev G. Modern Trends in the Application of Electronic Nose Systems: A Review. Applied Sciences. 2025; 15(19):10776. https://doi.org/10.3390/app151910776

Chicago/Turabian StyleIvanov, Stefan, Jacek Łukasz Wilk-Jakubowski, Leszek Ciopiński, Łukasz Pawlik, Grzegorz Wilk-Jakubowski, and Georgi Mihalev. 2025. "Modern Trends in the Application of Electronic Nose Systems: A Review" Applied Sciences 15, no. 19: 10776. https://doi.org/10.3390/app151910776

APA StyleIvanov, S., Wilk-Jakubowski, J. Ł., Ciopiński, L., Pawlik, Ł., Wilk-Jakubowski, G., & Mihalev, G. (2025). Modern Trends in the Application of Electronic Nose Systems: A Review. Applied Sciences, 15(19), 10776. https://doi.org/10.3390/app151910776