Impact of Blade Geometric Parameters on the Specific Cutting Energy of Willow (Salix viminalis) Stems

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Materials

- MC—moisture content of the fresh sample, %;

- mw—weight of the fresh sample, g;

- ms—weight of the sample after drying, g.

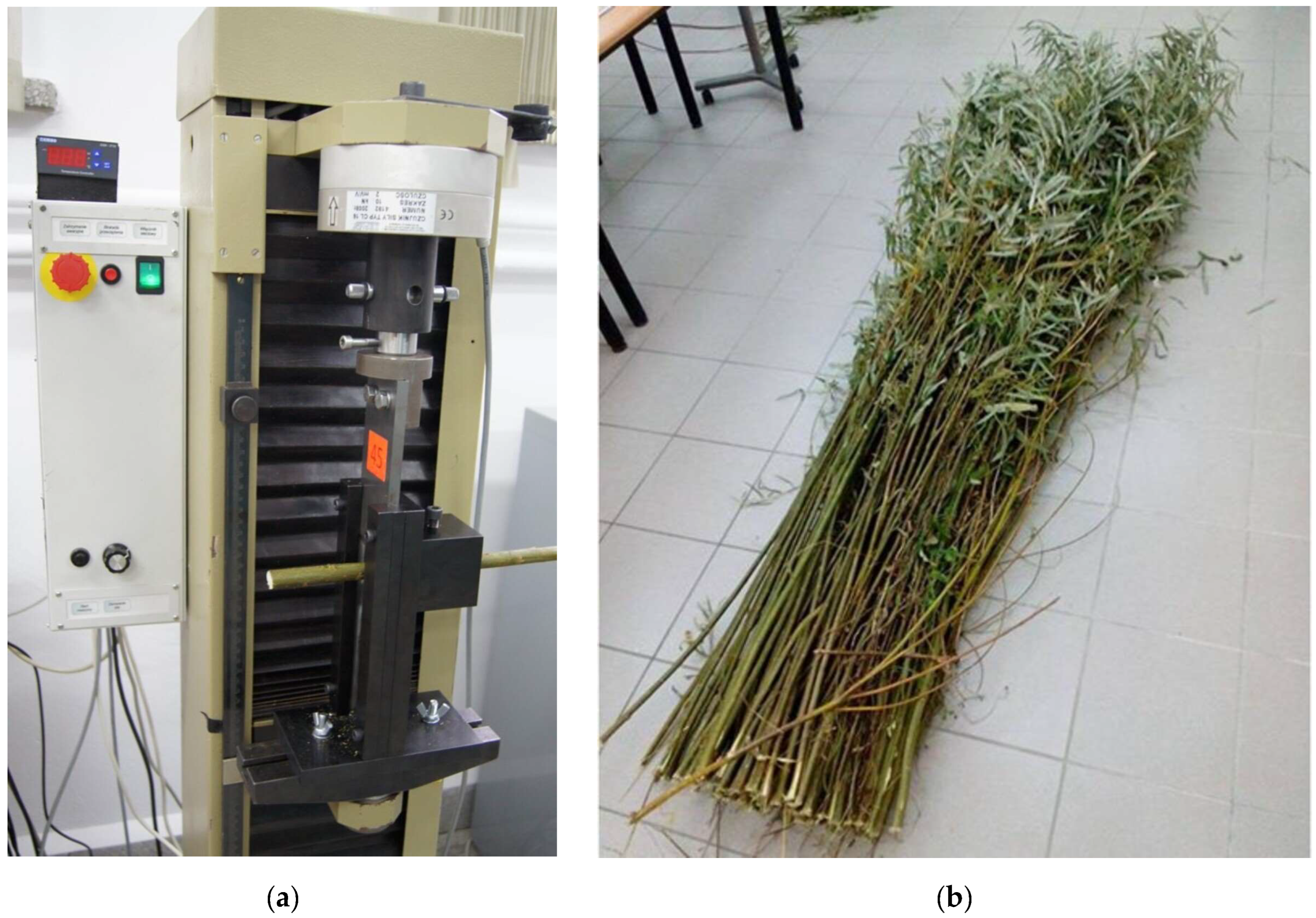

2.2. Test Stand

- τt—shear stress, MPa;

- Ftmax—maximum cutting force, N;

- St—cross-sectional area of the sample at the cutting point, mm2;

- Ejt—specific cutting energy, mJ⋅mm−2;

- Ft—cutting force, N;

- St—cross-sectional area of the sample at the cutting point, mm2;

- x—deformation (blade displacement), mm.

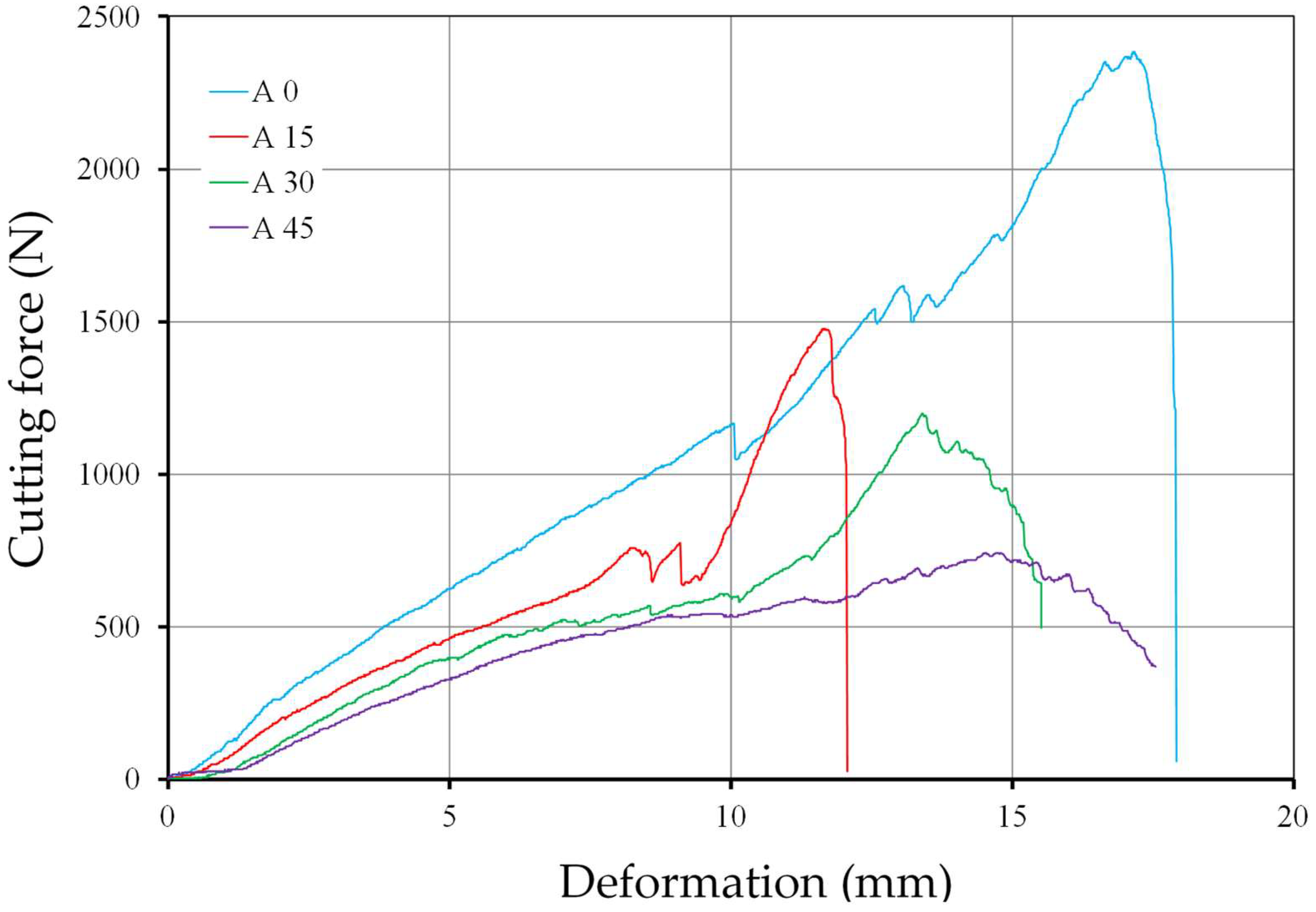

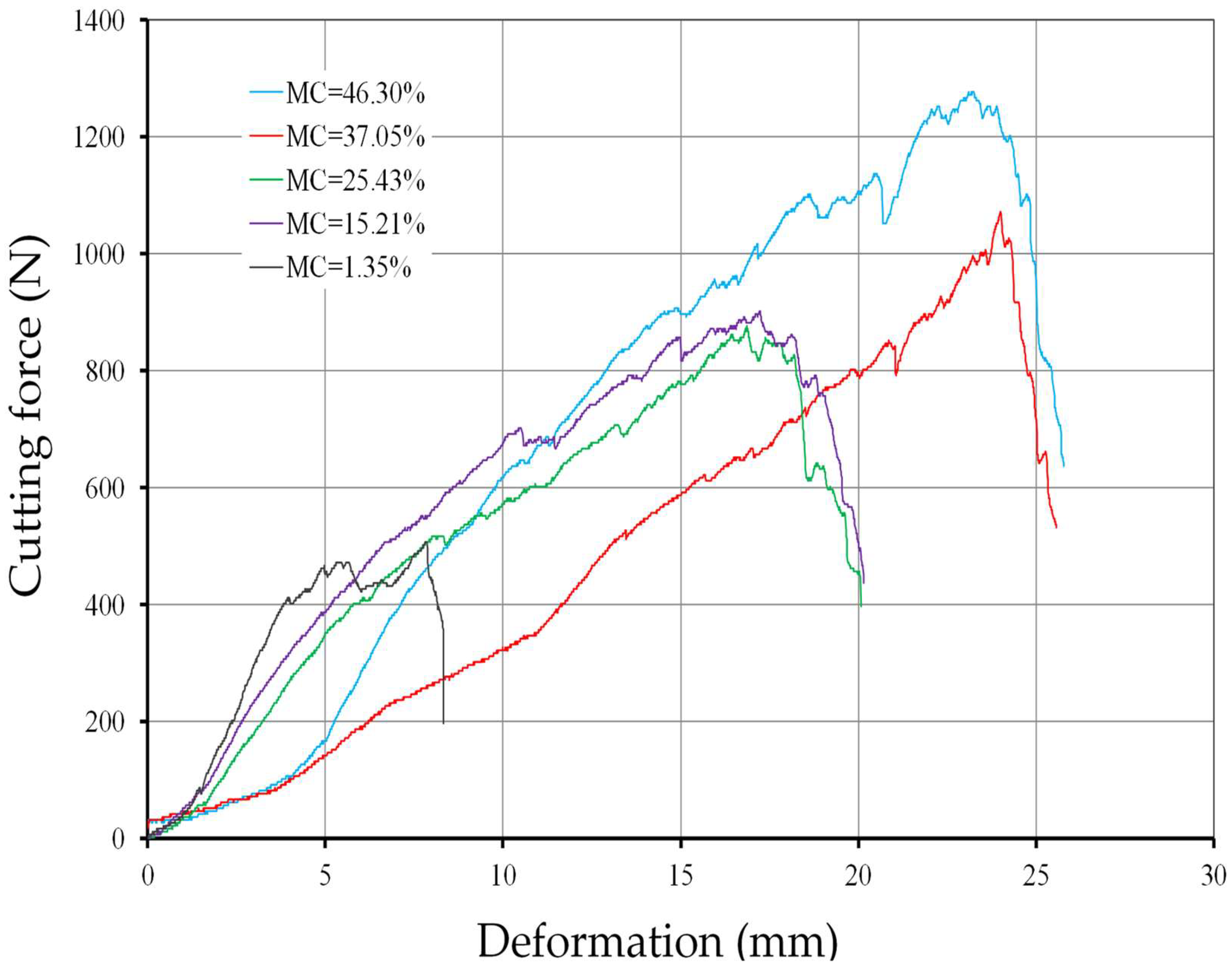

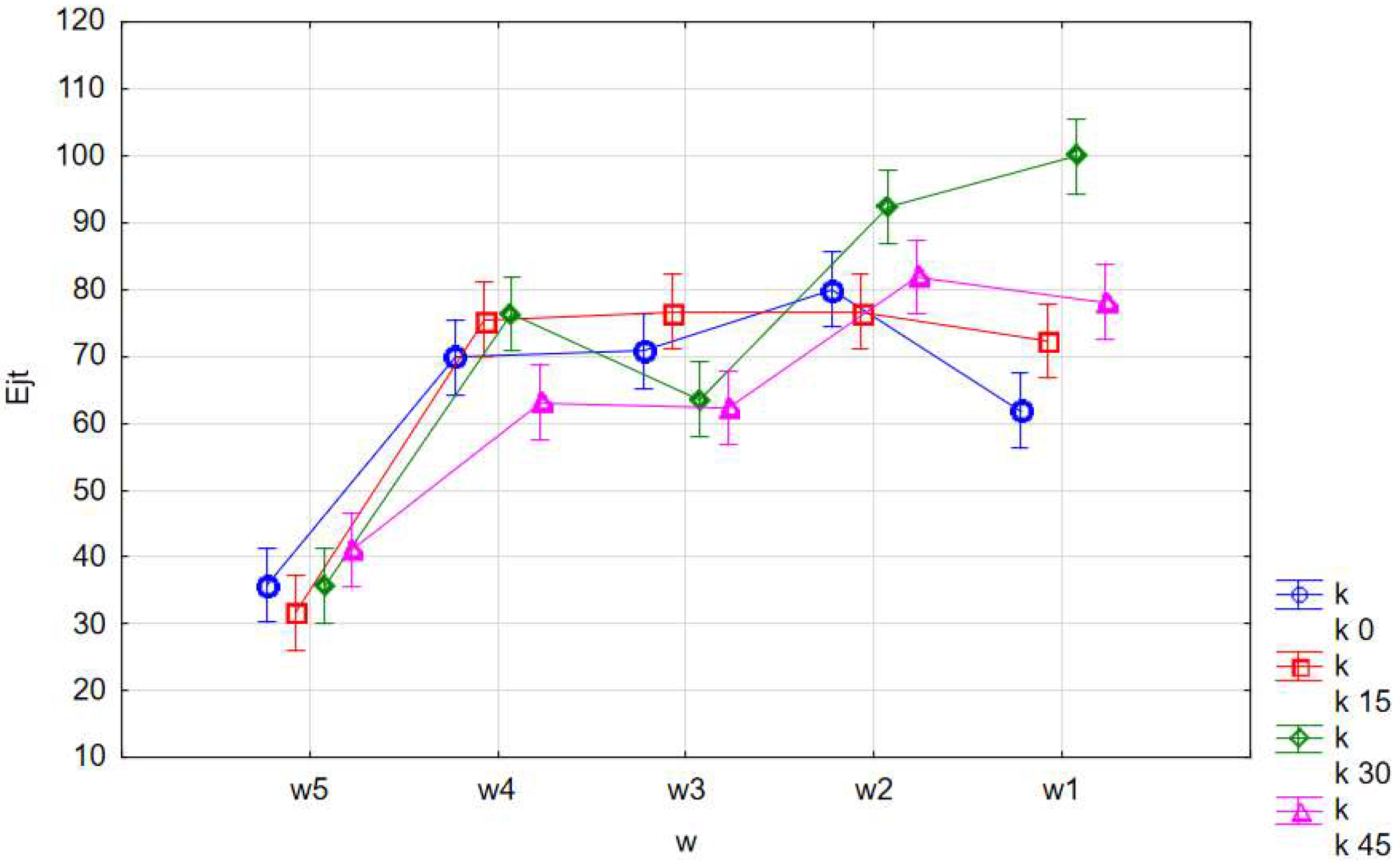

3. Results

- Ejt—specific cutting energy, mJ⋅mm−2;

- MC—moisture content of the fresh sample, %;

- A—sliding-cutting angle, °, with a correlation coefficient R of 0.8350.

4. Conclusions

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tutak, M.; Krenicky, T.; Pirník, R.; Brodny, J.; Grebski, W.W. Predicting Methane Concentrations in Underground Coal Mining Using a Multi-Layer Perceptron Neural Network Based on Mine Gas Monitoring Data. Sustainability 2024, 16, 8388. [Google Scholar] [CrossRef]

- López, I.; Goitia-Zabaleta, N.; Milo, A.; Gómez-Cornejo, J.; Aranzabal, I.; Gaztañaga, H.; Fernandez, E. European energy communities: Characteristics, trends, business models and legal framework. Renew. Sustain. Energy Rev. 2024, 197, 114403. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M.; Grebski, W. Empirical Assessment of the Efficiency of Poland’s Energy Transition Process in the Context of Implementing the European Union’s Energy Policy. Energies 2024, 17, 2689. [Google Scholar] [CrossRef]

- Energy Statistics—An Overview. Available online: https://ec.europa.eu/eurostat/statistics-explained/SEPDF/cache/29046.pdf (accessed on 25 November 2024).

- Fact Sheets on the European Union. Renewable Energy. Available online: https://www.europarl.europa.eu/factsheets/en/sheet/70/energia-ze-zrodel-odnawialnych (accessed on 25 November 2024).

- Energy Transition in Poland. Available online: https://www.teraz-srodowisko.pl/media/pdf/aktualnosci/15260-forum-energii-transformacja-2024.pdf (accessed on 25 November 2024).

- Statistics Poland. Energy from Renewable Sources in 2022. Available online: https://stat.gov.pl/en/topics/environment-energy/energy/energy-from-renewable-sources-in-2022,9,2.html (accessed on 25 November 2024).

- Babaei, A.; Tirkolaee, A.B.; Boz, E. Optimizing energy consumption for blockchain adoption through renewable energy sources. Renew. Energy 2025, 238, 121936. [Google Scholar] [CrossRef]

- Güler, B. Biomass valorization: Comparative analysis of tea waste pellets and wood pellets for steam generation and emission profiles. Sustain. Energy Technol. Assess. 2024, 72, 104103. [Google Scholar] [CrossRef]

- Czeczotko, R. Growing selected energy crops. Autobusy 2012, 13, 170–172. [Google Scholar]

- Jezierska-Thöle, A.; Rudnicki, R.; Kluba, M. Development of energy crops cultivation for biomass production in Poland. Renew. Sustain. Energy Rev. 2016, 62, 534–545. [Google Scholar] [CrossRef]

- Energy Crops Grown in Poland. Can They Be Compared? Available online: https://magazynbiomasa.pl/porownanie-roslin-energetycznych-uprawianych-polsce/ (accessed on 25 November 2024).

- Lipiński, A.J.; Żejmo, A.A. Cultivation of Salix viminalis willow and possibilities of improving the energy balance of Eastern Poland voivodships. Tech. Sci. Univ. Warm. Mazury Olszt. 2012, 15, 5–14. [Google Scholar]

- Bieniek, J.; Żołnierz-Rusinek, A. The willow Salix viminalis as a source of renewable energy, exemplified by plantations established in the Kłodzko Valley. Agric. Eng. 2008, 12, 111–118. [Google Scholar]

- Liberacki, D.; Kocięcka, J.; Stachowski, P.; Rolbiecki, R.; Rolbiecki, S.; Sadan, H.A.; Figas, A.; Jagosz, B.; Wichrowska, D.; Ptach, W. Water Needs of Willow (Salix L.) in Western Poland. Energies 2022, 15, 484. [Google Scholar] [CrossRef]

- Yin, L.; Zhou, Y.; Huang, J.; Wenninger, J.; Hou, G.; Zhang, E.; Wang, X.; Dong, J.; Zhang, J.; Uhlenbrook, S. Dynamics of willow tree (Salix matsudana) water use and its response to environmental factors in the semi-arid Hailiutu River catchment, Northwest China. Environ. Earth Sci. 2014, 71, 4997–5006. [Google Scholar] [CrossRef]

- Fillion, M.; Brisson, J.; Teodorescu, T.I.; Sauvé, S.; Labrecque, M. Performance of Salix viminalis and Populus nigra×Populus maximowiczii in short rotation intensive culture under high irrigation. Biomass Bioenergy 2009, 33, 1271–1277. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, T.; Liao, H. Fuel economy standards: Regulatory loopholes and firms’ heterogeneous responses. J. Environ. Econ. Manag. 2024, 123, 102904. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A.; Wichłacz, J. The Impact of Fuel Type on the Output Parameters of a New Biofuel Burner. Energies 2019, 12, 1383. [Google Scholar] [CrossRef]

- Cherwoo, L.; Gupta, I.; Flora, G.; Verma, R.; Kapil, M.; Arya, S.K.; Ravindran, B.; Khoo, K.S.; Bhatia, S.K.; Chang, S.W.; et al. Biofuels an alternative to traditional fossil fuels: A comprehensive review. Sustain. Energy Technol. Assess. 2023, 60, 103503. [Google Scholar] [CrossRef]

- Frączek, J.; Mudryk, K.; Wróbel, M. Unit power demand for willow sprout shredding in a flywheel cutter. Inżynieria Rol. 2009, 13, 69–77. [Google Scholar]

- Frączek, J.; Mudryk, K. The method of energy consumption measurement in the proces of willow sprouts chipping. Inżynieria Rol. 2007, 7, 47–53. [Google Scholar]

- Frączek, J.; Mudryk, K. The analysis of the process involving static cutting of Salix viminalis L. willow stem. Inżynieria Rol. 2009, 13, 61–68. [Google Scholar]

- Groppi, D.; Pastore, L.M.; Nastasi, B.; Prina, M.G.; Garcia, D.A.; Santoli, L. Energy modelling challenges for the full decarbonisation of hard-to-abate sectors. Renew. Sustain. Energy Rev. 2025, 209, 115103. [Google Scholar] [CrossRef]

- Angelidis, O.; Ioannou, A.; Friedrich, D.; Thomson, A.; Falcone, G. District heating and cooling networks with decentralised energy substations: Opportunities and barriers for holistic energy system decarbonisation. Energy 2023, 269, 126740. [Google Scholar] [CrossRef]

- Malec, M. The prospects for decarbonisation in the context of reported resources and energy policy goals: The case of Poland. Energy Policy 2022, 161, 112763. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A.; Dybaś, W. Capacity Market Implementation in Poland: Analysis of a Survey on Consequences for the Electricity Market and for Energy Management. Energies 2019, 12, 839. [Google Scholar] [CrossRef]

- Thomaßen, G.; Kavvadias, K.; Navarro, J.P.J. The decarbonisation of the EU heating sector through electrification: A parametric analysis. Energy Policy 2021, 148, 111929. [Google Scholar] [CrossRef]

- Bui, V.D.; Vu, H.P.; Nguyen, H.P.; Duong, X.Q.; Nguyen, D.T.; Pham, M.T.; Nguyen, P.Q.P. Techno-economic assessment and logistics management of biomass in the conversion progress to bioenergy. Sustain. Energy Technol. Assess. 2023, 55, 102991. [Google Scholar] [CrossRef]

- Cannava, L.; Javan, F.D.; Najafi, B.; Perotti, S. Green warehousing practices: Assessing the impact of PV self-consumption enhancement strategies in a logistics warehouse. Sustain. Energy Technol. Assess. 2024, 72, 104054. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M.; Saki, S.A. Forecasting the structure of energy production from renewable energy sources and biofuels in Poland. Energies 2020, 13, 2539. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Junga, R.; Błaszczuk, A.; Modliński, N.; Sobek, S.; Marczak-Grzesik, M.; Adrian, Ł.; Dzikuć, M. Numerical modeling of the co-firing process of an in situ steam-torrefied biomass with coal in a 230 MW industrial-scale boiler. Energy 2023, 263, 125918. [Google Scholar] [CrossRef]

- Coupan, R.; Baccouche, A.; Szymanski, P. Thermodynamic Modelling and Performance Analysis of Power Plant for Switching from Coal to Biomass. Comput. Aided Chem. Eng. 2023, 52, 2853–2859. [Google Scholar] [CrossRef]

- Mollanoori, M.; Dehghan, A.A. Estimating the higher heating value and chemical exergy of solid, liquid, and natural gas fossil fuels. Energy 2024, 302, 131835. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.J. Thermochemical conversion of biomass: Potential future prospects. Renew. Sustain. Energy Rev. 2023, 187, 113754. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Ikubanni, P.P.; Emmanuel, S.S.; Fajobi, M.O.; Nwachukwu, P.; Adesibikan, A.A.; Odusote, J.O.; Adeyemi, E.O.; Abioye, O.M.; Okolie, J.A. A comprehensive review on the similarity and disparity of torrefied biomass and coal properties. Renew. Sustain. Energy Rev. 2024, 199, 114502. [Google Scholar] [CrossRef]

- Kijo-Kleczkowska, A.; Szumera, M.; Gnatowski, A.; Sadkowski, D. Comparative thermal analysis of coal fuels, biomass, fly ash and polyamide. Energy 2022, 258, 124840. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. Analysis of the efficiency and structure of energy consumption in the industrial sector in the European Union countries between 1995 and 2019. Sci. Total Environ. 2022, 808, 152052. [Google Scholar] [CrossRef] [PubMed]

- Bisen, D.; Chouhan, A.P.S.; Pant, M.; Chakma, S. Advancement of thermochemical conversion and the potential of biomasses for production of clean energy: A review. Renew. Sustain. Energy Rev. 2025, 208, 115016. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.C.; Loha, C.; Akinlabi, E.T. An overview of biomass solid fuels: Biomass sources, processing methods, and morphological and microstructural properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- Nguyen, T.Q.; Luu, L.Q.; Martínez-Ramón, N.; Longo, S.; Cellura, M.; Dufour, J. Sustainability and circularity assessment of biomass-based energy supply chain. Heliyon 2024, 10, e38557. [Google Scholar] [CrossRef]

- Bays, H.C.M.; Bolding, M.C.; Conrad, J.L.; Munro, H.L.; Barrett, S.M.; Peduzzi, A. Assessing the sustainability of forest biomass harvesting practices in the southeastern US to meet European renewable energy goals. Biomass Bioenergy 2024, 186, 107267. [Google Scholar] [CrossRef]

- Bełdycka-Bórawska, A.; Bórawski, P.; Borychowski, M.; Wyszomierski, R.; Bórawski, M.B.; Rokicki, T.; Ochnio, L.; Jankowski, K.; Mickiewicz, B.; Dunn, J.W. Development of Solid Biomass Production in Poland, Especially Pellet, in the Context of the World’s and the European Union’s Climate and Energy Policies. Energies 2021, 14, 3587. [Google Scholar] [CrossRef]

- Davis, S.C.; Anderson-Teixeira, K.J.; DeLucia, E.H. Life-cycle analysis and the ecology of biofuels. Trends in Plant Science 2009, 14, 140–146. [Google Scholar] [CrossRef]

- Hodžić, N.; Kazagić, A.; Smajević, I. Influence of multiple air staging and reburning on NOx emissions during co-firing of low rank brown coal with woody biomass and natural gas. Appl. Energy 2016, 168, 38–47. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Mladenović, M.; Paprika, M.; Marinković, A. Denitrification techniques for biomass Combustion. Renew. Sustain. Energy Rev. 2018, 82, 3350–3364. [Google Scholar] [CrossRef]

- Mikielewicz, D.; Kosowski, K.; Tucki, K.; Piwowarski, M.; Stępień, R.; Orynycz, O.; Włodarski, W. Influence of Different Biofuels on the Efficiency of Gas Turbine Cycles for Prosumer and Distributed Energy Power Plants. Energies 2019, 12, 3173. [Google Scholar] [CrossRef]

- Konieczny, R.; Fedko, M.; Łaska, B.; Golimowski, W. New Resource Monitoring Models Biomass and Available Technologies Its Conversion in Reze Installations (the Example of Rural Communities the Wielkopolskie Voivodeship), 1st ed.; Instytut Technologiczno-Przyrodniczy w Falentach (ITP): Falenty, Poland, 2015; pp. 83–89. [Google Scholar]

- Werner-Juszczuk, A.A.; Stempniak, A. Technical and economic analysis of the use of solid biomass as fuel. Civ. Environ. Eng. 2010, 1, 91–96. [Google Scholar]

- Mo, W.; Du, K.; Sun, Y.; Guo, M.; Zhou, C.; You, M.; Xu, J.; Jiang, L.; Wang, Y.; Su, S.; et al. Technical-economic-environmental analysis of biomass direct and indirect co-firing in pulverized coal boiler in China. J. Clean. Prod. 2023, 426, 139119. [Google Scholar] [CrossRef]

- Gómez, M.A.; Martín, R.; Chapela, S.; Porteiro, J. Steady CFD combustion modeling for biomass boilers: An application to the study of the exhaust gas recirculation performance. Energy Convers. Manag. 2019, 179, 91–103. [Google Scholar] [CrossRef]

- Bis, Z. Perspectives to Produce and Use Carbon from Biomass. Polityka Energetyczna 2005, 8, 383–394. [Google Scholar]

- Mirowski, T.; Mokrzycki, E.; Filipowicz, M.; Sornek, K. Characteristic of selected biomass technologies in distributed energy sector. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią PAN 2018, 105, 63–73. [Google Scholar]

- Kobyłecki, R.; Nowak, W.; Bis, Z. Biomass and alternative fuels—Energy conversion. Czysta Energ. 2005, 3, 23–25. [Google Scholar]

- Pawłowski, A.; Pawłowski, L. Impact of energy acquisition methods on the implementa tion of sustainable development paradigms. Annu. Set Environ. Prot. 2016, 18, 19–37. [Google Scholar]

- Szufla, S. Ways to Convert Biomass into Aim to Improve Its Properties Fuel. Available online: https://www.proakademia.eu/gfx/baza_wiedzy/165/szufa7.pdf (accessed on 27 November 2024).

- Nama, M.; Satasiya, G.; Sahoo, T.P.; Moradeeya, P.G.; Sadukha, S.; Singhal, K.; Saravaia, H.T.; Dineshkumar, R.; Kumar, M.A. Thermo-chemical behaviour of Dunaliella salina biomass and valorising their biochar for naphthalene removal from aqueous rural environment. Chemosphere 2024, 353, 141639. [Google Scholar] [CrossRef] [PubMed]

- Use of Biomass in the Light of Current Conditions. Available online: https://magazynbiomasa.pl/zastosowanie-biomasy-w-swietle-aktualnych-uwarunkowan/ (accessed on 27 November 2024).

- Szufla, S. Use of superheated steam in the process of biomass torrefaction. Przemysł Chem. 2020, 99, 1797–1801. [Google Scholar] [CrossRef]

- Nowakowski, T. Specific energy for cutting stems of the basket willow (Salix viminalis L.). Ann. Wars. Univ. Life Sci. SGGW Agric. 2012, 60, 25–33. [Google Scholar]

- Forages ASABE S358.2 (R2008); ASABE Standards. Moisture measurement. ASABE Standards 2011. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2011; pp. 780–781.

- Lisowski, A.; Stasiak, P.; Powała, M.; Wiśniewski, G.; Klonowski, J.; Sypuła, M.; Szczesny, W.; Chlebowski, J.; Nowakowski, T.; Kostyra, K.; et al. Characteristics of chopped biomass for biogas. Autobusy: Tech. Eksploat. Syst. Transp. 2012, 13, 55–61. [Google Scholar]

- TIRAtest Universal Testing Machines. Available online: https://www.bluestar-ee.com/wp-content/uploads/2022/01/Tira-UTM.pdf (accessed on 6 January 2025).

- TIRA GmbH. Customized Material Testing Machines. Available online: https://www.tira-gmbh.de/en/material-testing/customized-material-testing-machines/ (accessed on 6 January 2025).

- MATEST. H009N Software for Universal Machines. Available online: https://www.matest.com/en/product/h009n-software-for-universal-machines (accessed on 6 January 2025).

- Jelonek, T.; Tomczak, A.; Jakubowski, M.; Pazdrowski, W. Properties of scots pine (Pinus sylvestris L.) timber growing on former arable and forest land. Acta Sci.Pol. Silv. 2005, 4, 35–47. [Google Scholar]

- Rubashevskyi, V.; Shukayev, S. Effect of constructive parameters on tensile strength of 3d-printed pla-graphite composite. ACTA TECHNICA NAPOCENSIS. Ser. Appl. Math. Mech. Eng. 2022, 65, 239–244. [Google Scholar]

- Ducan’s Multiple Range Test—Dr. Manu Melwin Joy—School of Management Studies, Cochin University of Science and Technology. Available online: https://www.slideshare.net/slideshow/ducans-multiple-range-test-dr-manu-melwin-joy-school-of-management-studies-cochin-university-of-science-and-technology/90981364 (accessed on 6 January 2025).

- Duncan’s Test to Compare Many Groups with Each Other. Available online: http://www.statoptima.com.ua/2023/01/21/dunkan_test/ (accessed on 6 January 2025).

- Kim, H.Y. Analysis of variance (ANOVA) comparing means of more than two groups. Restor. Dent. Endod. 2014, 39, 74–77. [Google Scholar] [CrossRef]

- St»hle, L.; Wold, S. Analysis of variance (ANOVA). Chemom. Intell. Lab. Syst. 1989, 6, 259–272. [Google Scholar] [CrossRef]

- Landler, L.; Ruxton, G.D.; Malkemper, E.P. Advice on comparing two independent samples of circular data in biology. Sci. Rep. Vol. 2021, 11, 20337. [Google Scholar] [CrossRef]

- Homogeneity of Variance: ANOVA’s Assumption. Available online: https://fastercapital.com/content/Homogeneity-of-Variance--ANOVA-s-Assumption.html (accessed on 7 January 2025).

- The Assumption of Homogeneity of Variance. Available online: https://www.statisticssolutions.com/the-assumption-of-homogeneity-of-variance/ (accessed on 7 January 2025).

- Stolarski, M.; Szczukowski, S.; Tworkowski, J. Biofuels obtained from energetic perennials biomass. Energetyka 2008, 1, 77–80. [Google Scholar]

- Stolarski, M.; Szczukowski, S.; Tworkowski, J.; Kwiatkowski, J.; Grzelczyk, M. Characteristic of chips and pellets from the coppice willow and Virginia mallow biomass as a fuel. Probl. Inżynierii Rol. 2005, 13, 13–22. [Google Scholar]

- Shrub Willow Biomass Producer’s Handbook. Available online: https://bpb-us-e1.wpmucdn.com/blogs.cornell.edu/dist/5/4999/files/2014/10/ProducersHandbook-2enkbl7.pdf (accessed on 7 January 2025).

- Dubas, J.W.; Grzybek, A.; Kotowski, W.; Tomczyk, A. Energy Willow Cultivation and Processing Technologies, 1st ed.; Wyższa Szkoła Ekonomii i Administracji: Bytom, Poland, 2004; pp. 23–45. [Google Scholar]

- Frączek, J.; Mudryk, K. Method of determining resistance of cutting power willow shoots. Inżynieria Rol. 2006, 10, 91–98. [Google Scholar]

- Baran, D.; Kwaśniewski, D.; Mudryk, K. Selected physical properties of a three-year-old energy willow. Inżynieria Rol. 2007, 8, 7–12. [Google Scholar]

- Yermakov, S.; Hutsol, T.; Gerasymchuk, I.; Fedirko, P.; Dubik, V. Study of the unloading and selection process of energy willow cuttings for the creation a planting machine. Eng. Sci. Prod. Technol. 2024, 3, 271–275. [Google Scholar] [CrossRef]

- Juliszewski, T.; Kwaśniewski, D.; Mudryk, K.; Wróbel, M. Assessment of the selected parameters of biomass obtained from a plantation of fast-growing trees. Inżynieria Rol. 2012, 16, 89–97. [Google Scholar]

- Kwaśniewski, D.; Płonka, A.; Mickiewicz, P. Harvesting Technologies and Costs of Biomass Production from Energy Crops Cultivated on Farms in the Małopolska Region. Energies 2022, 15, 131. [Google Scholar] [CrossRef]

- Lisowski, A. Technologie Zbioru Roślin Energetycznych; Wydawnictwo SGGW: Warszawa, Poland, 2010; ISBN 978-83-7583-222-8. [Google Scholar]

- Styles, D.; Thorne, F.; Jones, M.B. Energy crops in Ireland: An economic comparison of willow and Miscanthus giganteus production with conventional farming systems. Biomass Bioenergy 2007, 32, 5. [Google Scholar] [CrossRef]

- Nordborg, M.; Berndes, G.; Dimitriou, I.; Henriksson, A.; Mola-Yudego, B.; Rosenqvist, H. Energy analysis of willow production for bioenergy in Sweden. Renew. Sustain. Energy Rev. 2018, 93, 473–482. [Google Scholar] [CrossRef]

- Standards and Technical Conditions Applicable to the Measurement and Classification of Wood Raw Material in PGLLP. Available online: https://drewno.zilp.lasy.gov.pl/drewno/Normy/ (accessed on 6 December 2024).

- PN-EN ISO 17225-4:2014-07. Solid Biofuels—Fuel Specifications and Grades—Part 4: Wood Chips for Non-Industrial Applications. Available online: https://sklep.pkn.pl/pn-en-iso-17225-4-2014-07e.html (accessed on 6 December 2024).

- Kowalski, S. Badania oporów cięcia wybranych roślin. Zeszyty Problemowe Postępów Nauk Rolniczych 1993, 408, 297–303. [Google Scholar]

- Lisowski, A.; Nowakowski, T.; Klonowski, J.; Sypuła, M.; Chlebowski, J. Shear stress and specific shearing energy of energetic plant stalks. In Biomass Production. Selected Problems, 1st ed.; Skrobacki, A., Ed.; Wieś Jutra: Warsaw, Poland, 2009; pp. 70–80. ISBN 83-89503-81-6. [Google Scholar]

- Lisowski, A.; Nowakowski, T.; Klonowski, J. Mechanical properties of the Virginia Mallow. In Biomass as an Energy Source, 1st ed.; Jackowska, I., Ed.; Wieś Jutra: Warsaw, Poland, 2009; pp. 59–69. [Google Scholar]

- Rode, H.; Szpetulski, J. The influence of the knife’s geometric parameters on the unitary energy of a cutting process of Salix viminalis. TEKA Komisji Motoryzacji i Energetyki Rolnictwa PAN Oddział w Lublinie 2012, 12, 225–229. [Google Scholar]

- Sipma. Available online: https://www.sipma.pl/produkt/sieczkarnia-do-roslin-energetycznych-sipma-sr-1010-heros/ (accessed on 6 January 2025).

| Plant No. | Unit | Geometric Mean | Median | Min * | Max * | Deviation | CV * |

|---|---|---|---|---|---|---|---|

| Whole plant weight | g | 254.45 | 237.6 | 119.7 | 448.8 | 80.99 | 31.83 |

| Leaf weight | g | 60.99 | 54.65 | 4.80 | 132.6 | 29.09 | 47.69 |

| Stem weight | g | 80.34 | 72.70 | 7.10 | 210.6 | 49.34 | 61.41 |

| Basal shoot weight | g | 152.89 | 142.75 | 89.50 | 248.0 | 36.16 | 23.65 |

| Centre of gravity of the shoot | mm | 1159.1 | 1155.0 | 770.0 | 1380.0 | 133.52 | 11.52 |

| Shoot length | mm | 2301.0 | 2295.0 | 1900.0 | 2670.0 | 237.44 | 10.32 |

| Stem Diameter at Height of: | Unit | Geometric Mean | Median | Min * | Max * | Deviation | CV * |

|---|---|---|---|---|---|---|---|

| 0 | mm | 14.82 | 14.67 | 11.86 | 19.25 | 1.74 | 11.77 |

| 150 | mm | 14.14 | 13.79 | 11.59 | 18.5 | 1.71 | 12.06 |

| 500 | mm | 12.98 | 12.745 | 10.19 | 16.64 | 1.53 | 11.77 |

| 750 | mm | 12.20 | 12.09 | 9.84 | 15.52 | 1.38 | 11.30 |

| 1000 | mm | 11.29 | 11.25 | 8.61 | 14.84 | 1.49 | 13.21 |

| 1250 | mm | 9.76 | 9.71 | 6.55 | 13.36 | 1.66 | 17.01 |

| 1500 | mm | 8.13 | 8.195 | 4.64 | 12.02 | 1.87 | 23.05 |

| 2000 | mm | 6.04 | 6.16 | 2.28 | 10.19 | 1.59 | 26.39 |

| MC, % | Angle, ° | Shear Stress τt, MPa | CV * | |||

|---|---|---|---|---|---|---|

| Mean | Min * | Max * | SD * | |||

| 46.30 | 0 | 9.29 | 8.18 | 10.47 | 0.78 | 8.38 |

| 15 | 9.79 | 8.29 | 11.37 | 1.05 | 10.74 | |

| 30 | 8.15 | 6.80 | 9.59 | 0.93 | 11.37 | |

| 45 | 8.81 | 7.73 | 9.72 | 0.62 | 7.07 | |

| 37.05 | 0 | 13.79 | 12.31 | 15.65 | 1.04 | 7.53 |

| 15 | 13.54 | 12.35 | 15.51 | 0.94 | 6.94 | |

| 30 | 11.11 | 8.61 | 16.08 | 2.25 | 20.29 | |

| 45 | 6.84 | 6.42 | 7.32 | 0.31 | 4.55 | |

| 25.43 | 0 | 10.41 | 8.76 | 11.92 | 0.95 | 9.13 |

| 15 | 16.52 | 14.87 | 18.09 | 1.02 | 6.18 | |

| 30 | 11.17 | 9.94 | 12.21 | 0.63 | 5.65 | |

| 45 | 7.37 | 5.81 | 8.45 | 0.93 | 12.61 | |

| 15.21 | 0 | 13.51 | 10.84 | 15.34 | 1.28 | 9.51 |

| 15 | 13.93 | 11.39 | 16.89 | 1.77 | 12.70 | |

| 30 | 12.57 | 10.85 | 15.82 | 1.65 | 13.13 | |

| 45 | 9.58 | 8.20 | 11.88 | 1.11 | 11.62 | |

| 1.35 | 0 | 10.77 | 9.21 | 12.71 | 1.19 | 11.09 |

| 15 | 10.21 | 9.45 | 11.69 | 0.70 | 6.88 | |

| 30 | 12.20 | 10.39 | 15.08 | 1.48 | 12.13 | |

| 45 | 6.96 | 5.54 | 7.84 | 0.71 | 10.22 | |

| MC, % | Angle, ° | Specific Cutting Energy Ejt, mJ⋅mm−2 | CV * | |||

|---|---|---|---|---|---|---|

| Mean | Min * | Max * | SD * | |||

| 46.30 | 0 | 35.70 | 26.54 | 53.33 | 7.95 | 22.21 |

| 15 | 31.68 | 22.80 | 41.45 | 6.22 | 19.62 | |

| 30 | 35.64 | 22.87 | 46.37 | 8.03 | 22.53 | |

| 45 | 41.05 | 22.62 | 58.63 | 12.25 | 29.84 | |

| 37.05 | 0 | 69.89 | 59.17 | 90.84 | 11.85 | 16.95 |

| 15 | 75.51 | 62.66 | 89.60 | 7.40 | 9.80 | |

| 30 | 76.37 | 56.72 | 107.02 | 16.58 | 21.70 | |

| 45 | 63.05 | 54.74 | 67.81 | 3.82 | 6.06 | |

| 25.43 | 0 | 70.77 | 62.72 | 80.57 | 6.01 | 8.49 |

| 15 | 76.72 | 70.19 | 89.66 | 6.49 | 8.46 | |

| 30 | 63.56 | 55.07 | 76.92 | 7.57 | 11.91 | |

| 45 | 62.27 | 48.77 | 76.07 | 8.04 | 12.91 | |

| 15.21 | 0 | 80.05 | 58.46 | 95.34 | 13.40 | 16.74 |

| 15 | 76.63 | 66.31 | 85.09 | 5.33 | 6.95 | |

| 30 | 92.33 | 77.89 | 106.54 | 10.03 | 10.86 | |

| 45 | 81.82 | 66.38 | 97.52 | 11.40 | 13.93 | |

| 1.35 | 0 | 61.85 | 56.09 | 72.70 | 5.74 | 9.28 |

| 15 | 72.30 | 64.27 | 83.47 | 5.73 | 7.92 | |

| 30 | 99.88 | 85.14 | 110.92 | 8.68 | 8.69 | |

| 45 | 78.11 | 73.07 | 85.46 | 3.77 | 4.83 | |

| Parameter | Factor | Sum of Square | Degree of Freedom | Mean Square | Femp; F-Ratio | p-Value |

|---|---|---|---|---|---|---|

| Shear stress τt | MC: moisture content | 277.53 | 4 | 69.38 | 52.02 | <0.0001 |

| A: angle | 647.11 | 3 | 215.70 | 161.73 | <0.0001 | |

| MC × A | 375.73 | 12 | 31.31 | 23.48 | <0.0001 | |

| Error | 240.07 | 180 | 1.33 | |||

| Specific cutting energy Ej | MC: moisture content | 53,842.1 | 4 | 13,460.5 | 168.80 | <0.0001 |

| A: angle | 2850.5 | 3 | 950.2 | 11.92 | <0.0001 | |

| MC × A | 9176.9 | 12 | 764.7 | 9.59 | <0.0001 | |

| Error | 14,353.8 | 180 | 79.7 |

| Shear Stress τt | ||||||

|---|---|---|---|---|---|---|

| Moisture Content MC, % | Sample Size | Mean, % | Homogeneous Groups | |||

| Group I | Group II | Group III | Group IV | |||

| 1.35 | 40 | 9.008 | × | |||

| 46.30 | 40 | 10.036 | × | |||

| 15.21 | 40 | 11.320 | × | |||

| 25.43 | 40 | 11.368 | × | |||

| 37.05 | 40 | 12.398 | × | |||

| Angle A, ° | Sample size | Mean, % | Homogeneous groups | |||

| Group I | Group II | Group III | Group IV | |||

| 45 | 50 | 7.913 | × | |||

| 30 | 50 | 11.041 | × | |||

| 0 | 50 | 11.553 | × | |||

| 15 | 50 | 12.797 | × | |||

| Specific cutting energy Ejt | ||||||

| Moisture content MC, % | Sample size | Mean, % | Homogeneous groups | |||

| Group I | Group II | Group III | Group IV | |||

| 1.35 | 40 | 36.041 | × | |||

| 25.43 | 40 | 68.330 | × | |||

| 15.21 | 40 | 71.204 | × | |||

| 46.30 | 40 | 78.035 | × | |||

| 37.05 | 40 | 82.707 | × | |||

| Angle A, ° | Sample size | Mean, % | Homogeneous groups | |||

| Group I | Group II | |||||

| 0 | 50 | 63.668 | × | |||

| 15 | 50 | 66.568 | × | |||

| 45 | 50 | 65.262 | × | |||

| 30 | 50 | 73.556 | × | |||

| Independent Variable | RC | SE | T-Statistic | p-Value |

|---|---|---|---|---|

| Const | 34.61 | 1.886727 | 18.3445 | <0.0001 |

| MC | 2.895 | 0.197582 | 14.6505 | <0.0001 |

| MC2 | −50.23 × 10−3 | 0.004453 | −11.2795 | <0.0001 |

| MC2 A | 0.7832 × 10−3 | 0.000110 | 7.0961 | <0.0001 |

| MC A2 | −0.5694 × 10−3 | 0.000093 | −6.0919 | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowakowski, T.; Tucki, K. Impact of Blade Geometric Parameters on the Specific Cutting Energy of Willow (Salix viminalis) Stems. Appl. Sci. 2025, 15, 696. https://doi.org/10.3390/app15020696

Nowakowski T, Tucki K. Impact of Blade Geometric Parameters on the Specific Cutting Energy of Willow (Salix viminalis) Stems. Applied Sciences. 2025; 15(2):696. https://doi.org/10.3390/app15020696

Chicago/Turabian StyleNowakowski, Tomasz, and Karol Tucki. 2025. "Impact of Blade Geometric Parameters on the Specific Cutting Energy of Willow (Salix viminalis) Stems" Applied Sciences 15, no. 2: 696. https://doi.org/10.3390/app15020696

APA StyleNowakowski, T., & Tucki, K. (2025). Impact of Blade Geometric Parameters on the Specific Cutting Energy of Willow (Salix viminalis) Stems. Applied Sciences, 15(2), 696. https://doi.org/10.3390/app15020696