A Review of Worldwide Strategies for Promoting High-Temperature Heat Pumps

Abstract

:1. Introduction

1.1. Setting the Context

1.2. State of Art

1.3. Contribution

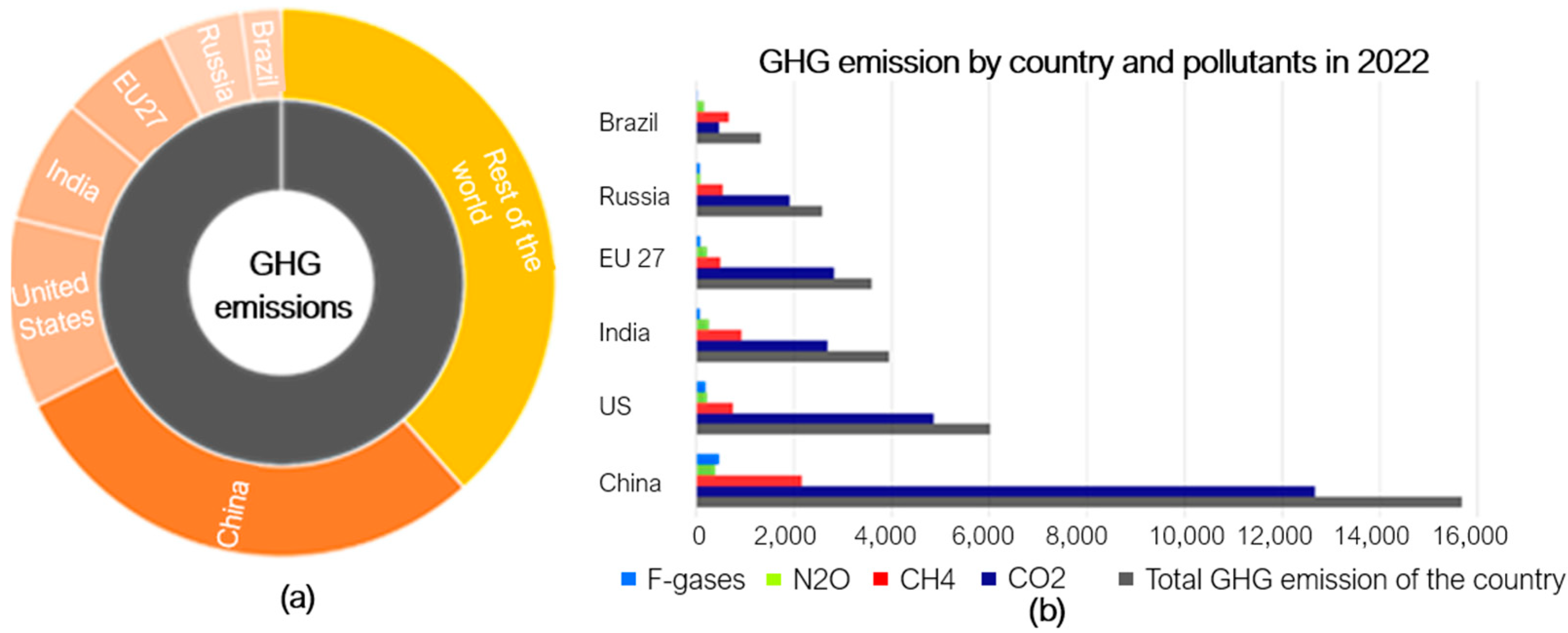

2. The Decarbonization of the Industrial Sector

2.1. Electrification of Industrial Heat Demand

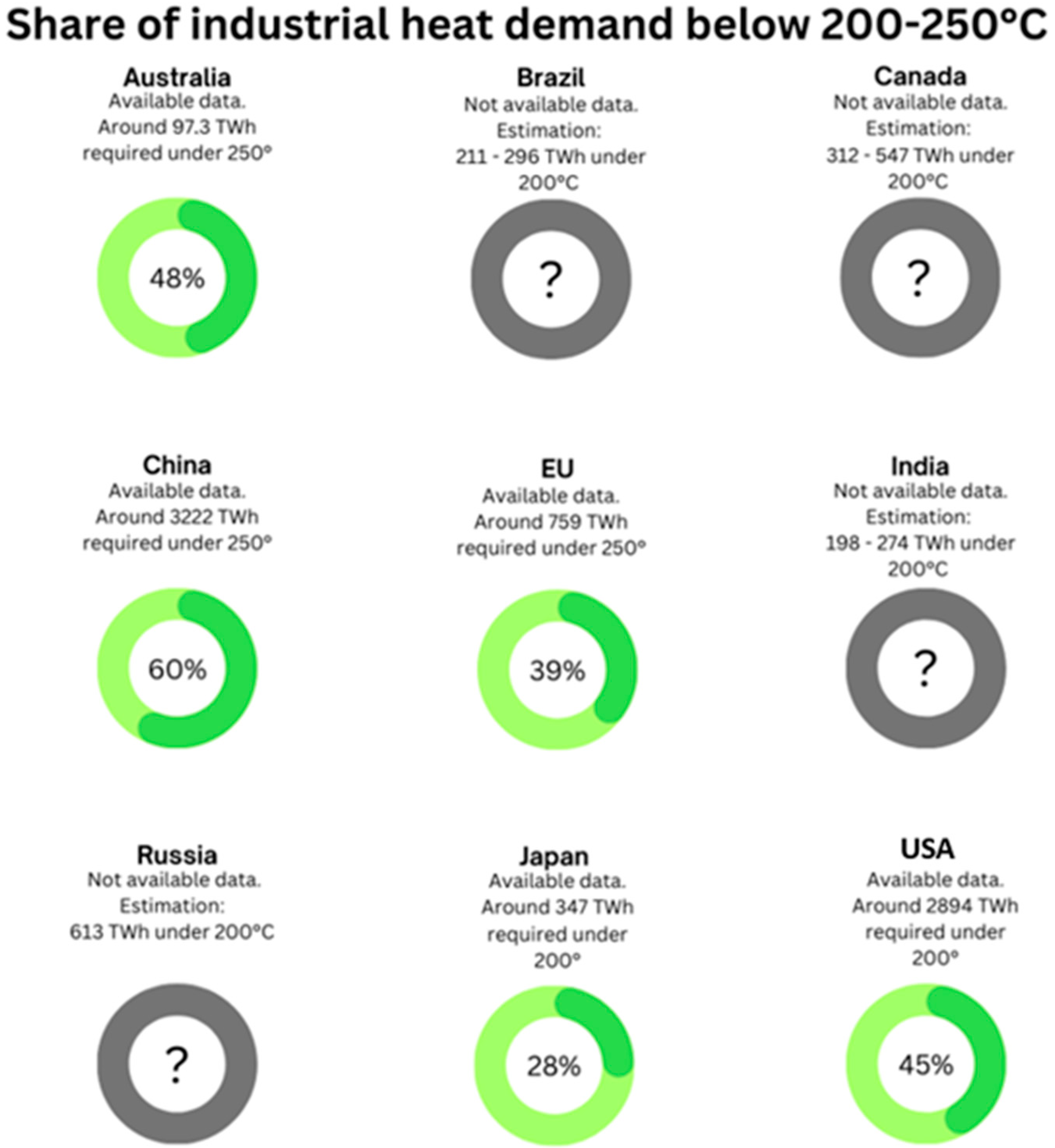

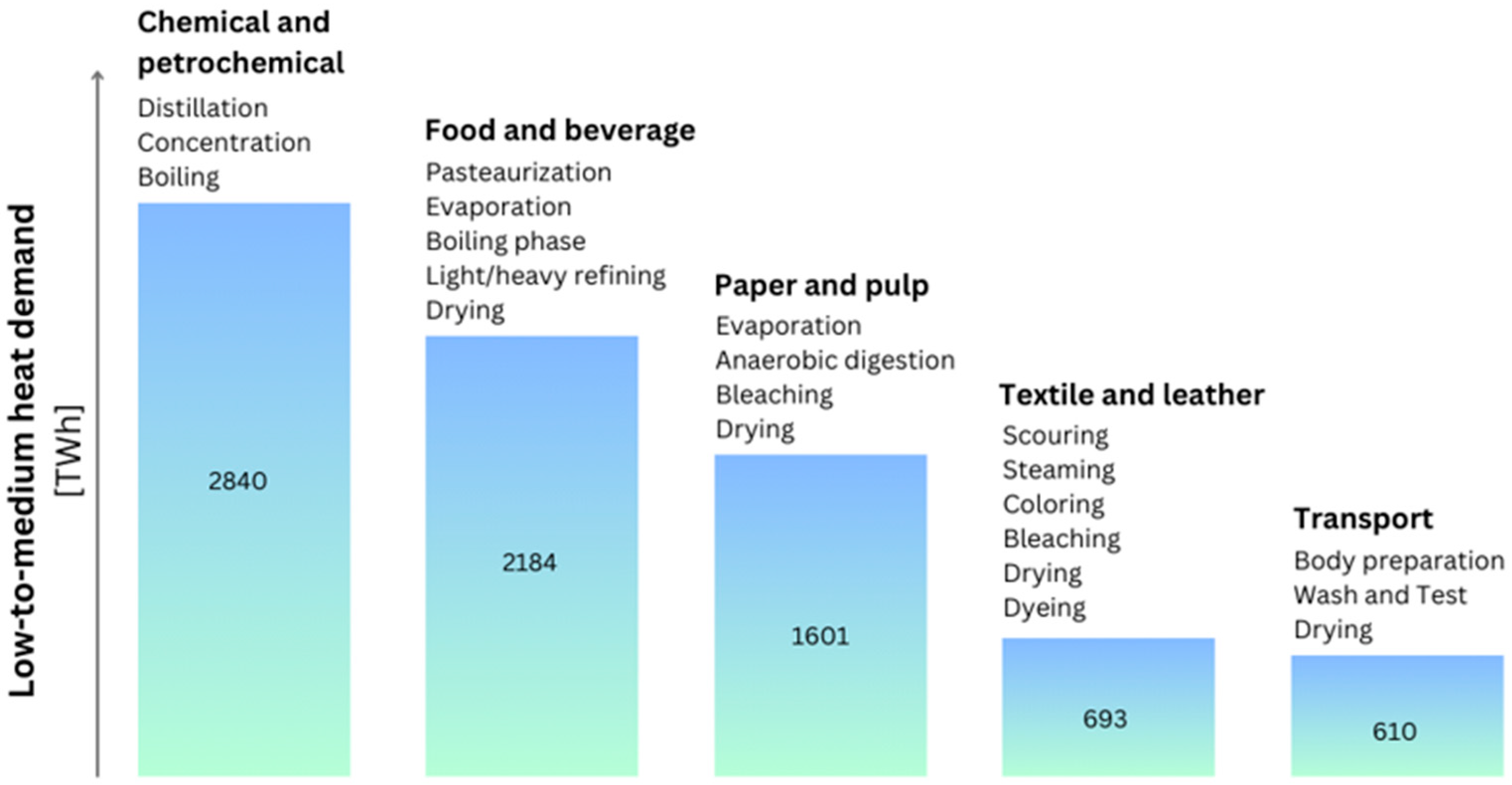

2.2. Low-to-Medium-Temperature Heat Processes

- -

- Ultra-low (<100 °C);

- -

- Low (<200 °C);

- -

- Medium (200–500 °C);

- -

- High (>500 °C).

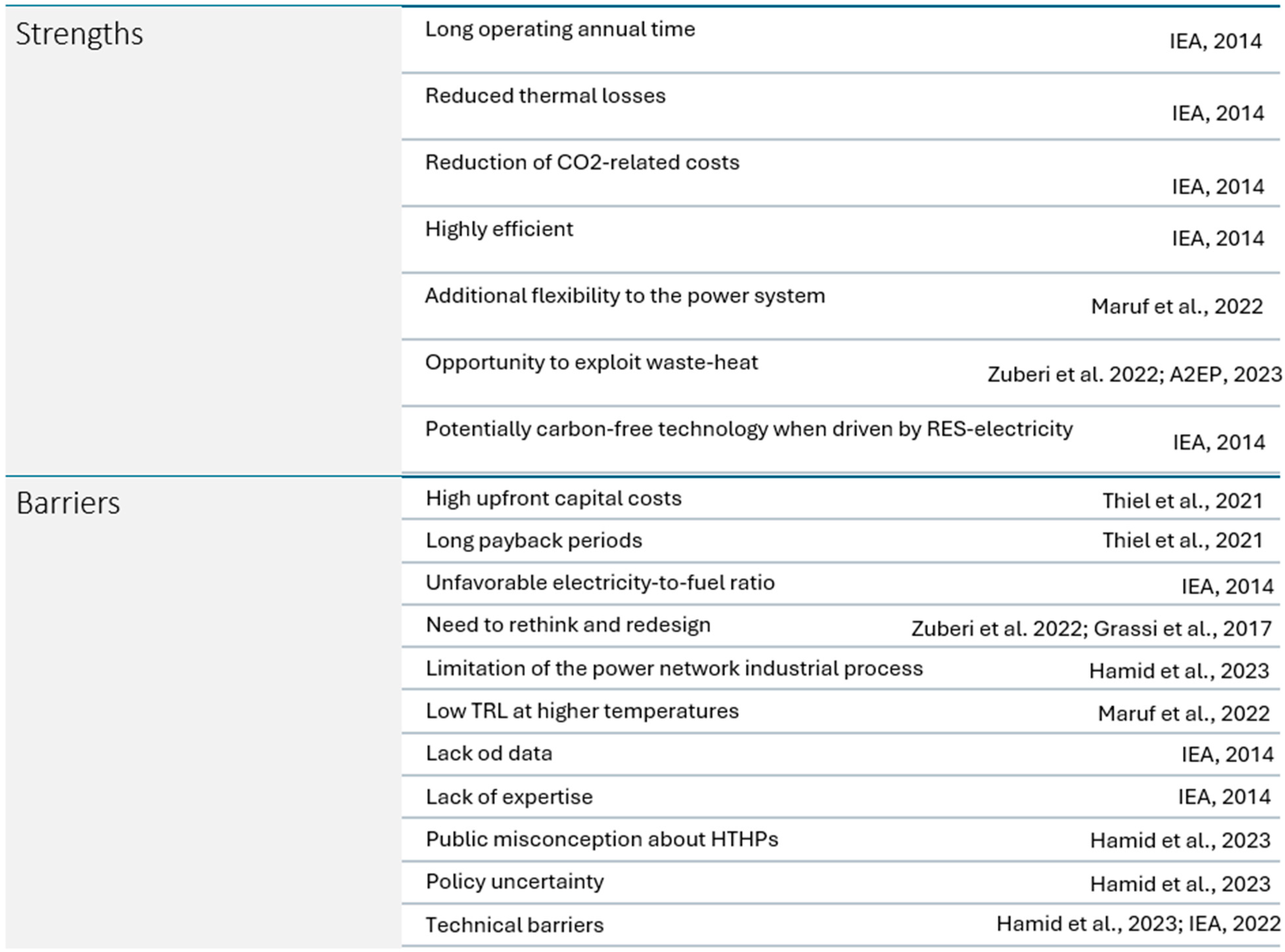

3. Heat Pumps: Technological Principles, Challenges, and Potential

3.1. Physical Principle

3.2. Strengths and Barriers

4. The Promotion of IHPs over the World

4.1. Australia

- AUD 305 million allocated for abatement projects at high-emitting manufacturing and mining facilities;

- AUD 55 million earmarked for the establishment of clean manufacturing precincts in the Hunter and Illawarra regions, along with support for their infrastructure and supply chains;

- An additional AUD 300 million dedicated to new low-carbon industry foundations.

4.2. Canada

4.3. China

4.4. Japan

- Implementing the Paris Agreement and achieving 2030 targets NDCs;

- Developing, deploying, and innovating clean energy technologies;

- Supporting decarbonization efforts in other countries, especially in the Indo-Pacific.

4.5. EU

4.6. USA

- Initiative for Better Energy, Emissions, and Equity (E3 Initiative): this initiative encourages the use of HPs in cold climates. It was further strengthened by the Residential Cold Climate Heat Pumps Technology Challenge introduced in December 2021 [106];

- Japan–USA Clean Energy Partnership: this partnership aims to accelerate the adoption of HPs in domestic and local markets, fostering a collaborative approach between Japan and the USA to promote clean energy technologies [91];

- ICEE HOT (Installing Clean Efficiency Energy Hastens Our Transition) Act: enacted in May 2022, this act provides discounts for distributors and manufacturers of heat pumps, HP water heaters, and HP clothes dryers made in the USA, incentivizing the production of these energy-efficient appliances [107];

- HEATR (Heating Efficiency and Affordability through Tax Relief): this legislation offers tax incentives to manufacturers to increase the production of HPs and phase out inefficient air conditioners (ACs), promoting more efficient heating solutions [108];

- Defense Production Act Invocation: in June 2022, the Defense Production Act was invoked to boost the manufacturing of key energy technologies, including HPs, ensuring a stronger focus on energy independence and technological advancement [109];

- Inflation Reduction Act: this act includes provisions to support energy efficiency and the adoption of renewable energy technologies, contributing to a broader strategy to reduce inflation through sustainable practices [110];

- New Efficiency Ratings for AC and Heat Pumps: effective January 2023, new efficiency ratings for ACs and HPs were introduced, setting higher standards for energy performance and encouraging the use of more efficient cooling and heating systems [111].

5. Brief Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | |

| EU | European Union |

| TTF | Title Transfer Facility |

| ETS | Emission Trading System |

| GHG | Greenhouse Gases |

| CT | Carbon Tax |

| WCC | World Climate Conference |

| UN | United Nations |

| IPCC | International Panel on Climate Change |

| UNFCCC | UN Framework Convention on Climate Change |

| COP | Conference of the Parties |

| USA | United States of America |

| SDGs | Sustainable Development Goal |

| NDC | Nationally Determined Contributions |

| RES | Renewable Energy Sources |

| CFE | Carbon-free Energy |

| CAAA | Climate Action Acceleration Agenda |

| OECD | Organization for Economic Cooperation and Development |

| HP | Heat Pump |

| IHP | Industrial Heat Pump |

| HTHP | High-Temperature Heat Pump |

| P2H | Power to Heat |

| TFEC | Total Final Energy Consumption |

| NG | Natural Gas |

| TRL | Technology Readiness Level |

| HEI | High Emitting Industries |

| NZIIP | Net-Zero Industry and Innovation Program |

| ERF | Emissions Reduction Fund |

| RET | Renewable Energy Target |

| ACCU | Australian Carbon Credit Unit |

| NZA | Net-Zero Accelerator |

| SIF | Strategic Innovation Fund |

| OHPA | Oil-to-Heat Pump Affordability |

| CCSU | Carbon Capture, Utilization, and Storage |

| CHP | Combined Heat and Power |

| HSCW | Hot Summer Cold Winter |

| APS | Announced Pledges Scenario |

| NEDO | New Energy and Industrial Technology Development Organization |

| R&D | Research and Development |

| EPBD | Energy Performance of Building Directive |

| RED | Renewable Energy Directive |

| EED | Energy Efficiency Directive |

| NGO | Non-Governmental Organization |

| NZIA | Net-Zero Industry Act |

| EIB | European Investment Bank |

| EIF | European Investment Fund |

| RD&I | Research, Development, and Innovation |

| HEP | Horizon Europe Programme |

| MSCA | Marie Sklodowska-Curie Action |

| ICEE HOT | Installing Clean Efficiency Energy Hastens Our Transition |

| HEATR | Heating Efficiency and Affordability through Tax Relief |

| DOE | Department of Energy |

| TIEReD | Technologies for Industrial Emissions Reduction Development |

| Subscripts | |

| Co | Condenser |

| H | Hot heat reservoir |

| Ext,co | External fluid exchanging heat in the condenser |

| Ext,ev | External fluid exchanging heat in the evaporator |

| Ref | Refrigerant |

| Cold | Cold heat reservoir |

| Ev | Evaporator |

| II | Second Law of Thermodynamics |

| Rev, Carnot | Reverse Carnot Cycle |

| 1 | Compressor inlet |

| 2 | Compressor outlet |

| 3 | Condenser outlet |

| 4 | Evaporator inlet |

| Variables | |

| COP | Coefficient of Performance |

| η | Performance |

| Thermal power | |

| Exergy rate | |

| Electric power | |

| Mass rate | |

| h | Specific enthalpy |

| T0 | Reference thermal state temperature |

| s | Specific entropy |

Appendix A. Energy and Exergy Analysis

- -

- Operation under steady-state and steady-flow conditions;

- -

- Pressure drops are assumed to be negligible, except in the evaporator and condenser;

- -

- The compressor and expansion valve are considered adiabatic;

- -

- Saturated refrigerant states are assumed at both the condenser and evaporator outlets;

- -

- The power consumption for the evaporator and condenser fans is neglected.

Appendix A.1. Energy Analysis

Appendix A.2. Exergy Analysis

References

- Rocque, R.J.; Beaudoin, C.; Ndjaboue, R.; Cameron, L.; Poirier-Bergeron, L.; Poulin-Rheault, R.A.; Fallon, C.; Tricco, A.C.; Witteman, H.O. Health Effects of Climate Change: An Overview of Systematic Reviews. BMJ Open 2021, 11, e046333. [Google Scholar] [CrossRef] [PubMed]

- European Council. Council of the European Union. A Market Mechanism to Limit Excessive Gas Price Spikes. 8 February 2024. Available online: https://www.consilium.europa.eu/it/infographics/a-market-mechanism-to-limit-excessive-gas-price-spikes/ (accessed on 13 May 2024).

- World Bank Group. State and Trends of Carbon Pricing Dashboard. Available online: https://carbonpricingdashboard.worldbank.org/compliance/instrument-detail (accessed on 13 May 2024).

- European Commission, Joint Research Centre; Crippa, M.; Guizzardi, D.; Schaaf, E.; Monforti-Ferrario, F.; Quadrelli, R.; Risquez Martin, A.; Rossi, S.; Vignati, E.; Muntean, M.; et al. GHG Emissions of All World Countries—2023; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- European Commission. EDGAR—Emissions Database for Global Atmospheric Research. [Online]. Available online: https://edgar.jrc.ec.europa.eu/ (accessed on 23 May 2024).

- European Commission. What Is the EU ETS? Available online: https://climate.ec.europa.eu/eu-action/eu-emissions-trading-system-eu-ets/what-eu-ets_en (accessed on 28 May 2024).

- Roser, M. The Argument for a Carbon Price. Our World in Data. 1 June 2021. Available online: https://ourworldindata.org/carbon-price (accessed on 12 May 2024).

- The Climate Reality Project. Available online: https://www.climaterealityproject.org/blog/global-climate-agreements-through-years (accessed on 23 May 2024).

- European Council. Council of the European Union. Paris Agreement on Climate Change. Available online: https://www.consilium.europa.eu/en/policies/climate-change/paris-agreement/ (accessed on 22 May 2024).

- United Nations. The Paris Agreement. Available online: https://www.un.org/en/climatechange/paris-agreement (accessed on 11 May 2024).

- Commonwealth of Australia. Available online: https://www.climatechangeauthority.gov.au/2035-emissions-reduction-targets (accessed on 15 June 2024).

- The United States Department of State and the United States Executive Office of the President. The Long-Term Strategy of the United States: Pathways to Net-Zero Greenhouse Gas Emissions by 2050. s.l.; Global Publishing Solutions: Matteson, IL, USA, 2021. [Google Scholar]

- Government of Canada. 2030 Emissions Reduction Plan—Canada’s Next Steps for Clean Air and a Strong Economy. 29 March 2022. Available online: https://www.canada.ca/en/environment-climate-change/news/2022/03/2030-emissions-reduction-plan--canadas-next-steps-for-clean-air-and-a-strong-economy.html (accessed on 29 May 2024).

- The State Council. The People’s Republic of China. China, EU Hold Environment, Climate Dialogue. 19 June 2024. Available online: https://english.www.gov.cn/news/202406/19/content_WS66722319c6d0868f4e8e84c2.html (accessed on 19 June 2024).

- The European Commission. The European Green Deal, COM(2019) 640 Final. 12 December 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2019%3A640%3AFIN (accessed on 20 May 2024).

- Regulation (EU) 2021/1119 of the European Parliament and of the Council. European Climate Law, Official Journal of the European Union. 30 June 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32021R1119 (accessed on 20 May 2024).

- Ministry of Environment, Forest and Climate Change. Government of India. India’s Long-Term Low-Carbon. Development strategy. 2022. Available online: https://unfccc.int/sites/default/files/resource/India_LTLEDS.pdf (accessed on 20 May 2024).

- Agency for Natural Resources and Energy. Japan’s Newest “Strategic Energy Plan” Toward Carbon Neutrality by 2050. 2 September 2022. Available online: https://www.enecho.meti.go.jp/en/category/special/article/detail_168.html (accessed on 20 May 2024).

- United Nations, UN Energy. 24/7 Carbon-Free Energy Compact. Available online: https://www.un.org/en/energy-compacts/page/compact-247-carbon-free-energy#:~:text=In%20response%20to%20the%20urgent%20need%20to%20drive,adopting%2C%20enabling%2C%20and%20advancing%2024%2F7%20Carbon-free%20Energy%20%28CFE%29 (accessed on 20 May 2024).

- United Nations. Climate Ambition Summit. 20 September 2023. Available online: https://www.un.org/climatechange/climate-ambition-summit (accessed on 10 May 2024).

- REN21. Renewables 2023 Global Status Report Collection, Global Overview. 2023. Available online: https://www.ren21.net/gsr-2023/modules/global_overview/ (accessed on 20 May 2024).

- REN21. Renewables Energy Systems & Infrastructure; REN21 Secretariat: Paris, France, 2024; Available online: https://www.ren21.net/wp-content/uploads/2019/05/gsr2024_SYSTEMS_module.pdf (accessed on 20 May 2024).

- Fischer, D.; Madani, H. On heat pumps in smart grids: A review. Renew. Sustain. Energy Rev. 2017, 70, 342–357. [Google Scholar] [CrossRef]

- Boess, A.; Schill, W.; Zerrahn, A. Power-to-heat for renewable energy integration: A review of technologies, modeling approaches, and flexibility potentials. Appl. Energy 2018, 212, 1611–1626. [Google Scholar] [CrossRef]

- Charalambous, C.; Heracleous, C.; Michael, A.; Efthymiou, V. Hybrid AC-DC distribution system for building integrated photovoltaics and energy storage solutions for heating-cooling purposes. A case study of a historic building in Cyprus. Renew. Energy 2023, 216, 119032. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Sun, J.; Wang, T.; Zong, S.; Zhou, T.; Wang, X. Operational Strategy of a DC Inverter Heat Pump System Considering PV Power Fluctuation and Demand-Side Load Characteristics. Buildings 2024, 14, 1139. [Google Scholar] [CrossRef]

- Maruf, M.N.I.; Morales-España, G.; Sijm, J.; Helistö, N.; Kiviluoma, J. Classification, potential role, and modeling of power-to-heat and thermal energy storage in energy systems: A review. Sustain. Energy Technol. Assess. 2022, 53, 102553. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Schiffmann, J.; Bertsch, S.S. High temperature heat pumps: Market overview, state of the art, research status, refrigerants, and application potentials. Energy 2018, 252, 985–1010. [Google Scholar] [CrossRef]

- Marina, A.; Spoelstra, S.; Zondag, H.A.; Wemmers, A.K. An estimation of the European industrial heat pump market potential. Renew. Sustain. Energy Rev. 2021, 139, 110545. [Google Scholar] [CrossRef]

- Hamid, K.; Sajjad, U.; Ahrens, M.U.; Ren, S.; Ganesan, P.; Tolstorebrov, I.; Arshad, A.; Said, Z.; Hafner, A.; Wang, C.-C.; et al. Potential evaluation of integrated high temperature heat pumps: A review of recent advances. Appl. Therm. Eng. 2023, 230, 120720. [Google Scholar] [CrossRef]

- Walden, J.V.M.; Wellig, B.; Stathopoulos, P. Heat pump integration in non-continuous industrial processes by Dynamic Pinch Analysis Targeting. Appl. Energy 2023, 352, 121933. [Google Scholar] [CrossRef]

- Sadjjadi, B.S.; Gerdes, J.-N.; Sauer, A. Energy flexible heat pumps in industrial energy systems: A review. Energy Rep. 2023, 9 (Suppl. S3), 386–394. [Google Scholar] [CrossRef]

- Wu, W.; Du, Y.; Qian, H.; Fan, H.; Jiang, Z.; Zhang, X.; Huang, S. Enhancing the waste heat utilization of industrial park: A heat pump-centric network integration approach for multiple heat sources and users. Energy Convers. Manag. 2024, 306, 118306. [Google Scholar] [CrossRef]

- Thiel, G.P.; Stark, A.K. To decarbonize industry, we must decarbonize heat. Joule 2021, 5, 531–550. [Google Scholar] [CrossRef]

- Sorknæs, P.; Johannsen, R.M.; Korberg, A.D.; Nielsen, T.B.; Petersen, U.R.; Mathiesen, B.V. Electrification of the industrial sector in 100% renewable energy scenarios. Energy 2022, 254, 124339. [Google Scholar] [CrossRef]

- Lechtenböhmer, S.; Nilsson, L.J.; Åhman, M.; Schneider, C. Decarbonising the energy intensive basic materials industry through electrification—Implications for future EU electricity demand. Energy 2016, 115, 1623–16313. [Google Scholar] [CrossRef]

- Zuberi, M.J.S.; Hasanbeigi, A.; Morrow, W. Bottom-up assessment of industrial heat pump applications in U.S. Food manufacturing. Energy Convers. Manag. 2022, 272, 116349. [Google Scholar] [CrossRef]

- Flórez-Orrego, D.; Domingos, M.E.R.; Maréchal, F. Techno-economic and environmental analysis of high temperature heat pumps integration into industrial processes: The ammonia plant and pulp mill cases. Sustain. Energy Technol. Assess. 2023, 60, 103560. [Google Scholar] [CrossRef]

- International Energy Agency, IEA. Global CO2 Emissions by Sector, 2019–2022. March 2023. Available online: https://www.iea.org/data-and-statistics/charts/global-co2-emissions-by-sector-2019-2022 (accessed on 24 April 2024).

- IEA, International Energy Agency. Industry. Available online: https://www.iea.org/energy-system/industry (accessed on 16 May 2024).

- Statista. Total Energy Consumption in the United States from 1975 to 2022, by Sector. Available online: https://www.statista.com/statistics/239790/total-energy-consumption-in-the-united-states-by-sector/ (accessed on 11 April 2024).

- Eurostat. 2021. Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_bal_s/default/table?lang=en (accessed on 23 January 2024).

- Eurostat. Complete Energy Balances. 2024. Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_bal_c/default/table?lang=en (accessed on 23 January 2024).

- Statista. Distribution of Electricity Consumption Across India in Financial Year 2023, by Sector. Available online: https://www.statista.com/statistics/1130112/india-electricity-consumption-share-by-sector/ (accessed on 11 April 2024).

- International Energy Agency, IEA. The Future of Heat Pumps in China. 2024. Available online: https://www.iea.org/reports/the-future-of-heat-pumps-in-china (accessed on 11 April 2024).

- Jia, T.; Huang, J.; Li, R.; He, P.; Dai, Y. Status and prospect of solar heat for industrial processes in China. Renew. Sustain. Energy Rev. 2018, 90, 475–489. [Google Scholar] [CrossRef]

- International Energy Agency, IEA. Annex 58, High-Temperature Heat Pumps. Task 1—Technologies. Task Report, IEA Heat Pump Centre. August 2023. Available online: https://heatpumpingtechnologies.org/annex58/task1/ (accessed on 22 April 2024).

- World Economic Forum, WEC. Decarbonising Heating. Community Report. In Energy Technologies 2030; World Economic Forum: Geneva, Switzerland, 2021. [Google Scholar]

- International Energy Agency, IEA. Renewable Energy for Industry. Paris. 2017. Available online: https://www.iea.org/reports/renewable-energy-for-industry (accessed on 11 April 2024).

- World Business Council for Sustainable Development, WBCSD. Industrial Heat Pumps: It’s Time To Go Electric. Available online: https://www.wbcsd.org/wp-content/uploads/2023/10/Industrial_heat_pumps_time_to_go_electric.pdf (accessed on 24 April 2024).

- International Energy Agency, IEA. Industrial Heat Demand by Temperature Range, 2018. 31 March 2022. Available online: https://www.iea.org/data-and-statistics/charts/industrial-heat-demand-by-temperature-range-2018 (accessed on 23 May 2024).

- Australian Government, Australian Renewable Energy Agency. Heat Pumps Electrifying Industrial Processes. Available online: https://arena.gov.au/blog/heat-pumps-electrifying-industrial-processes/ (accessed on 28 April 2024).

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. Carbon mitigation potential of solar industrial process heating: Paper industry in India. J. Clean. Prod. 2016, 112, 1683–1691. [Google Scholar] [CrossRef]

- Ministry of Statistics and Programme Implementation. Energy Statistics in India. Available online: https://mospi.gov.in/publication/energy-statistics-india-2023 (accessed on 1 June 2024).

- Statistics Canada; Government of Canada. Energy Consumption by the Manufacturing Sector. 2022. Available online: https://www150.statcan.gc.ca/n1/daily-quotidien/231030/dq231030c-eng.htm (accessed on 13 May 2024).

- Mazurova, O.V.; Gal’perova, E.V. Energy Consumption in Russia: Current State and Forecast; Pleiades Publishing, Ltd.: New York, NY, USA, 2023; Volume 34. [Google Scholar]

- International Energy Agency, IEA. Brazil. Available online: https://www.iea.org/countries/brazil/efficiency-demand (accessed on 23 May 2024).

- Global Carbon Budget (2023)—With Major Processing by Our World in Data. “Annual CO2 Emissions from Other Industry—GCB” [Dataset]. Global Carbon Project, “Global Carbon Budget” [Original Data]. 24 June 2024. Available online: https://ourworldindata.org/grapher/annual-co2-other-industry (accessed on 25 April 2024).

- European Heat Pump Assosiation, EHPA. Available online: https://www.ehpa.org/news-and-resources/press-releases/accelerator-launch/ (accessed on 23 January 2024).

- U.S. Department of Energy. The U.S. Lawrence Berkeley National Laboratory. Electrification through Industrial Heat Pump Applications in U.S. Manufacturing. Available online: https://eta-publications.lbl.gov/sites/default/files/us_industrial_heat_pump-final.pdf (accessed on 4 May 2024).

- American Council for an Energy-Efficient Economy, ACEEE; Rightor, E.; Scheihing, P.; Hoffmeister, A.; Papar, R. Industrial Heat Pumps: Electrifying Industry’s Process Heat Supply. 30 March 2022. Available online: https://www.aceee.org/research-report/ie2201 (accessed on 13 April 2024).

- International Energy Agency, IEA. Annex XIII. Application of Industrial Heat Pumps. Available online: https://iea-industry.org/tasks/annex-xiii-application-of-industrial-heat-pumps-and-electrification-in-industry-to-be-continued-in-2018/ (accessed on 16 May 2024).

- International Energy Agency, IEA. The Future of Heat Pumps. November 2022. Available online: https://www.iea.org/reports/the-future-of-heat-pumps (accessed on 11 May 2024).

- Aghagoli, A.; Sorin, M.; Khennich, M. Exergy Efficiency and COP Improvement of a CO2 Transcritical Heat Pump System by Replacing an Expansion Valve with a Tesla Turbine. Energies 2022, 5, 4973. [Google Scholar] [CrossRef]

- Australian Alliance for Energy Productivity, A2EP. Heat Pumps. 2023. Available online: https://www.futureheat.info/heat-pumps (accessed on 22 April 2024).

- Grassi, W. Heat Pumps. Fundamentals and Applications; Springer: Berlin/Heidelberg, Germany, 2017; Vol. Green Energy and Technology. [Google Scholar]

- Australian Alliance for Energy Productivity, A2EP, Energy Efficiency Council, EEC, for the Australian Government. Harnessing Heat Pumps for Net Zero. The Role of Heat Pumps in Saving Energy and Cutting Emissions. February 2023. Available online: https://static1.squarespace.com/static/5b514ee57e3c3a1fbf675baf/t/63f568c08cedcf707ae0e3d0/1677027541433/Harnessing+heat+pumps+for+net+zero.pdf (accessed on 22 May 2024).

- Vine, D.; Hnderson, C.; Centre for Climate and Energy Solution, C2ES. Clean Heat Pathways for Industrial Decarbonization. August 2021. Available online: https://www.c2es.org/document/clean-heat-pathways-for-industrial-decarbonization/ (accessed on 11 May 2024).

- Australian Government Department of Climate Change, Energy, the Environment and Water. Annual Climate Change. Statement 2023. 2023. Available online: https://unfccc.int/sites/default/files/resource/annual-climate-change-statement-2023.pdf (accessed on 22 May 2024).

- Australian Alliance for Energy Productivity (A2EP) for the Australian Hydrogen Council (AHC). Bringing the Heat. Hydrogen’s Role in Decarbonising. Australian Industrial Process Heat; Australian Alliance for Energy Productivity: Ultimo, Australia, 2023. [Google Scholar]

- New South Wales Government. NWS Climate and Energy Action. Net Zero Manufacturing Initiative. 13 May 2024. Available online: https://www.energy.nsw.gov.au/business-and-industry/programs-grants-and-schemes/net-zero-manufacturing (accessed on 1 June 2024).

- New South Wales Government, NWS Climate and Energy Action. High Emitting Industries. Reducing Industrial Emissions for NSW. 10 October 2022. Available online: https://www.energy.nsw.gov.au/business-and-industry/programs-grants-and-schemes/high-emitting-industries (accessed on 1 June 2024).

- New South Wales through Office of Energy and Climate Change. Net Zero Industry and Innovation Inveestment Plan 2022–2024. October 2022. Available online: https://www.energy.nsw.gov.au/sites/default/files/2022-10/NSW-Net-Zero-Industry-Innovation-Investment-Plan-2022-2024-FINAL.pdf?trk=public_post_comment-text (accessed on 14 May 2024).

- Government of Canada. The Canada Green Building Strategy. July 2023. Available online: https://natural-resources.canada.ca/sites/nrcan/files/engagements/green-building-strategy/CGBS%20Discussion%20Paper%20-%20EN.pdf (accessed on 1 June 2024).

- Office of the Autor General of Canada. 2024 Reports 1 to 5 of the Commissioner of the Environment and Sustainable Development to the Parliament of Canada. 2024. Available online: https://www.oag-bvg.gc.ca/internet/English/parl_cesd_202404_04_e_44471.html (accessed on 30 May 2024).

- Government of Canada. Expanded Heat Pump Program Helps British Columbians Save on Home Energy Costs. 13 May 2024. Available online: https://www.canada.ca/en/environment-climate-change/news/2024/05/expanded-heat-pump-program-helps-british-columbians-save-on-home-energy-costs.html (accessed on 24 May 2024).

- ISO50001; Energy Management System. ISO Central Secretariat: Geneve, Switzerland, 2018.

- Government of Canada. 2030 Emissions Reduction Plan—Sector-by-Sector Overview. www.canada.ca. Available online: https://www.canada.ca/en/services/environment/weather/climatechange/climate-plan/climate-plan-overview/emissions-reduction-2030/sector-overview.html (accessed on 15 June 2024).

- International Energy Agency, IEA. National Energy Conservation Law of China (Amendments in 2016). 2016. Available online: https://www.iea.org/policies/7910-national-energy-conservation-law-of-china-amendments-in-2016 (accessed on 31 May 2024).

- The Supreme People’s Court of the People’s Republic of China. Law of the People’s Republic of China on Energy Conservation. 17 July 2015. Available online: https://english.court.gov.cn/2015-07/17/c_761534_2.htm (accessed on 11 May 2024).

- National People’s Congress of the People’s Republic of China. Renewable Energy Law of the People’s Republic of China. 20 December 2013. Available online: https://leap.unep.org/sites/default/files/legislation/CHN/China_RE_law.pdf (accessed on 17 May 2024).

- Toner, H.; Ding, J.; Kania, E.; U.S.-China Economic and Security Review Commission. U.S.-China Economic and Security Review Commission hearing on “Technology, Trade, and Military-Civil Fusion: China’s Pursuit of Artificial Intelligence, New Materials, and New Energy”. 7 June 2019. Available online: https://cset.georgetown.edu/article/us-china-economic-security-review-commission-hearing-on-technology-trade-and-military-civil-fusion/ (accessed on 19 May 2024).

- National Development and Reform Commisiion, NDRC. People’s Republic of China. Action Plan for Carbon Dioxide Peaking Before 2030. 27 October 2021. Available online: https://en.ndrc.gov.cn/policies/202110/t20211027_1301020.html#:~:text=ACTION%20PLAN%20FOR%20CARBON%20DIOXIDE%20PEAKING%20BEFORE%202030,action%20for%20promoting%20green%20and%20low-carbon%20transportation%20 (accessed on 1 June 2024).

- Japan Ministry of Economy, Trade and Industry. Green Growth Strategy Through Achieving Carbon Neutrality in 2050. 17 October 2022. Available online: https://www.meti.go.jp/english/policy/energy_environment/global_warming/ggs2050/index.html (accessed on 29 May 2024).

- Heat Pump and Thermal Storage Technology Center of Japan. FY2020 Survey on Heat Pump Diffusion Prospects. Report. August 2020. Available online: https://www.hptcj.or.jp/Portals/0/data0/e/publication/FY2020/FY2020%20Survey%20on%20Heat%20Pump%20Diffusion%20Prospects.pdf (accessed on 1 June 2024).

- International Energy Agency, IEA. IEA Technology Collaboration Programme on Heat Pumping Technologies (HPT TCP). Available online: https://heatpumpingtechnologies.org/annex57/wp-content/uploads/sites/69/2024/05/hptannex57webinarwiebkemeesenburg.pdf (accessed on 1 June 2024).

- The Government of Japan. Long-Term Low Greenhouse Gas Emission Development Strategies (LT-LEDS). October 2021. Available online: https://unfccc.int/documents/307817 (accessed on 13 May 2024).

- Ministry of Economy, Trade and Industry. Agency for Natural Resources and Energy. Outline of Strategic Energy Plan. October 2021. Available online: https://www.enecho.meti.go.jp/en/category/others/basic_plan/pdf/6th_outline.pdf (accessed on 13 May 2024).

- New Energy and Industrial Technology Development Organization, NEDO. Contributing to Society by Accelerating Innovation and Achieving Results in Timely Manner. Available online: https://www.nedo.go.jp/english/ (accessed on 23 May 2024).

- Takenobu KAIDA. Central Research Institute of Electric Power Industry (CRIEPI). High-Temperature Heat Pumps in Japan. 25 April 2023. Available online: https://heatpumpingtechnologies.org/annex58/wp-content/uploads/sites/70/2023/09/japan20230425high-temperature-heat-pumps-in-japan.pdf (accessed on 12 April 2024).

- The White House. FACT SHEET: U.S.-Japan Climate Partnership. 23 May 2022. Available online: https://www.whitehouse.gov/briefing-room/statements-releases/2022/05/23/u-s-japan-climate-partnership-fact-sheet/ (accessed on 19 May 2024).

- The Energy Conservation Centre Japan, ECCJ and Asia Energy Efficiency and Conservation Collaboration Center, AEEC. Awarding Programs to Energy Conservation Efforts. Energy Conservation Grand Prize Award in Japan. Available online: https://www.asiaeec-col.eccj.or.jp/awarding-programs/ (accessed on 30 May 2024).

- Directive 2010/31/EU on the Energy Performance of Buildings, Official Journal of the European Union. 19 May 2010. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32010L0031 (accessed on 31 January 2024).

- Directive (EU) 2018/2001 on the Promotion of the Use of Energy from Renewable Sources., European Parliament and of the Council, Official Journal of the European Union. 11 December 2018. Available online: http://data.europa.eu/eli/dir/2018/2001/oj (accessed on 31 January 2024).

- Directive (EU) 2023/1791 on Energy Efficiency and Amending Regulation (EU) 2023/955, Official Journal of the European Union. 13 September 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:JOL_2023_231_R_0001 (accessed on 31 January 2024).

- Proposal for a Council Directive Restructuring the Union Framework for the Taxation of Energy Products and Electricity, European Commission, Brussels, 14 July 2021, COM (2021) 563 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/HIS/?uri=CELEX:52021PC0563 (accessed on 7 January 2025).

- European Union, EU. Next Generation EU. Available online: https://next-generation-eu.europa.eu/index_en (accessed on 12 January 2024).

- REPowerEU Plan, European Commission, Communication from the Commission, Brussels, 18 of May 2022, COM (2022) 230 Final. Available online: https://commission.europa.eu/publications/key-documents-repowereu_en?prefLang=es (accessed on 22 January 2024).

- energy.ec.europa. Available online: https://energy.ec.europa.eu/news/heat-pumps-action-plan-online-consultation-launched-commission-accelerate-roll-out-across-eu-2023-06-07_en (accessed on 23 January 2024).

- Net Zero Industry Act, European Commission, 16 of March 2023, COM (2023) 161, SWD (2023) 68. Available online: https://single-market-economy.ec.europa.eu/publications/net-zero-industry-act_en (accessed on 11 May 2024).

- A Green Deal Industrial Plan for the Net-Zero Age, Brussels, 1 of February 2023, COM (2023) 62 Final. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/green-deal-industrial-plan_en (accessed on 30 April 2024).

- European Investment Bank, EIB. Available online: https://www.eib.org/en/projects/topics/climate-action/index (accessed on 27 May 2024).

- Austrian Institute of Technology, AIT. DRYFICIENCY: WASTE HEAT RECOVERY IN INDUSTRIAL DRYING PROCESSES. Available online: https://www.ait.ac.at/en/research-topics/efficiency-in-industrial-processes-systems/projects/dryficiency (accessed on 12 May 2024).

- Centre Efficacité énergétique des Systèmes. Projet TransPAC, Développé en Partenariat Avec EDF R&D. Available online: https://www.ces.minesparis.psl.eu/Projets/Projet-TransPAC/ (accessed on 19 May 2024).

- Norwegian Centres for Environment-Friendly Energy Research. HighEff. Available online: https://www.sintef.no/projectweb/higheff/ (accessed on 14 May 2024).

- Office of Energy Efficiency & Renewable Energy. Energy, Emissions and Equity (E3) Initiative. Buildings. Available online: https://www.energy.gov/eere/buildings/energy-emissions-and-equity-e3-initiative (accessed on 24 May 2024).

- The Senate of the United States. Installing Clean Efficient Energy Hastens Our Transition Act of 2022 or the ICEE HOT Act of 2022, S.4144—ICEE HOT Act of 2022. Available online: https://www.congress.gov/bill/117th-congress/senate-bill/4144 (accessed on 12 May 2024).

- The Senate of the United States. HEATR Act, Heating Efficiency and Affordability through Tax Relief Act. Available online: https://www.congress.gov/bill/117th-congress/senate-bill/4139/all-info#:~:text=Heating%20Efficiency%20and%20Affordability%20through%20Tax%20Relief%20Act,commercial%20heat%20pumps%20and%20heat%20pump%20water%20heaters (accessed on 26 May 2024).

- Congressional Research Service. 2022 Invocation of the Defense Production Act for Large-Capacity Batteries: In Brief. 27 May 2022. Available online: https://crsreports.congress.gov/product/pdf/R/R47124 (accessed on 23 May 2024).

- U.S. Department of Tresury. Inflation Reduction Act. 16 August 2022. Available online: https://home.treasury.gov/policy-issues/inflation-reduction-act#:~:text=Inflation%20Reduction%20Act%20On%20August%2016%2C%202022%2C%20President,that%20Congress%20has%20made%20in%20the%20nation%E2%80%99s%20history (accessed on 11 May 2024).

- Air-Conditioning, Heating, and Refrigeration Institute, AHRI. 2023 Energy Efficiency Standards. 2024. Available online: https://www.ahrinet.org/2023-energy-efficiency-standards (accessed on 18 May 2024).

- Office of NEPA Policy and Compliance. EO 14008: Tackling the Climate Crisis at Home and Abroad (2021). 27 January 2021. Available online: https://www.energy.gov/nepa/articles/eo-14008-tackling-climate-crisis-home-and-abroad-2021#:~:text=Executive%20Order%2014008%2C%20of%20January%2027%2C%202021%2C%20places,put%20the%20world%20on%20a%20sustainable%20climate%20pathway (accessed on 14 May 2024).

- U.S. Department of Commerce. Justice40 Initiative. 2024. Available online: https://www.commerce.gov/justice40-initiative#:~:text=Justice40%20establishes%20a%20federal%20government-wide%20goal%20that%2040,that%20are%20marginalized%2C%20underserved%2C%20and%20overburdened%20by%20pollution (accessed on 11 May 2024).

- U.S. Department of Energy. Biden-Harris Administration Releases Bold Agenda to Reduce Emissions Across America’s Industrial Sector. 7 September 2022. Available online: https://www.energy.gov/articles/biden-harris-administration-releases-bold-agenda-reduce-emissions-across-americas (accessed on 11 May 2024).

- Biden-Harris Administration Announces $63 Million to Accelerate Electric Heat Pump Manufacturing Across America as Part of Investing in America Agenda. 14 February 2024. Available online: https://www.energy.gov/articles/biden-harris-administration-announces-63-million-accelerate-electric-heat-pump (accessed on 22 May 2024).

- The White House. FACT SHEET:Biden-Harris Administration Announces Historic Investment to Bolster Nation’s Electric Grid Infrastructure, Cut Energy Costs for Families, and Create Good-Paying Jobs. 30 October 2023. Available online: https://www.whitehouse.gov/briefing-room/statements-releases/2023/10/30/fact-sheetbiden-harris-administration-announces-historic-investment-to-bolster-nations-electric-grid-infrastructure-cut-energy-costs-for-families-and-create-good-paying-jobs/ (accessed on 12 May 2024).

- Purdue University. Purdue’s 3-Year Mission: High-Temperature Heat Pump Technology to Cut Industrial Carbon Footprint. 14 August 2023. Available online: https://www.purdue.edu/research/features/stories/purdues-3-year-mission-high-temperature-heat-pump-technology-to-cut-industrial-carbon-footprint/ (accessed on 22 May 2024).

- U.S. Department of Energy. Biden-Harris Administration Announces $135 Million to Reduce Emissions Across America’s Industrial Sector. 15 June 2023. Available online: https://www.energy.gov/articles/biden-harris-administration-announces-135-million-reduce-emissions-across-americas (accessed on 22 May 2024).

- Office of Energy efficiency and Renewable Energy. Funding Selections: Industrial Efficiency and Decarbonization FOA. Available online: https://www.energy.gov/eere/iedo/funding-selections-industrial-efficiency-and-decarbonization-foa-0 (accessed on 23 May 2024).

- Ahamed, J.U.; Saidur, R.; Masjuki, H.H. A review on exergy analysis of vapor compression refrigeration system. Renew. Sustain. Energy Rev. 2011, 15, 1593–1600. [Google Scholar] [CrossRef]

- Byrne, P.; Ghoubali, R. Exergy analysis of heat pumps for simultaneous heating and cooling. Appl. Therm. Eng. 2019, 149, 414–424. [Google Scholar] [CrossRef]

- Agarwal, S.; Arora, A.; Arora, B.B. Energy and exergy analysis of vapor compression–triple effect absorption cascade refrigeration system. Eng. Sci. Technol. Int. J. 2020, 23, 625–641. [Google Scholar] [CrossRef]

- Arora, A.; Kaushik, S.C. Theoretical analysis of a vapour compression refrigeration system with R502, R404A and R507A. Int. J. Refrig. 2008, 31, 998–1005. [Google Scholar] [CrossRef]

- Zou, L.; Liu, Y.; Yu, J. Energy, exergy and economic evaluation of a solar enhanced ejector expansion heat pump cycle. Renew. Energy 2023, 217, 119119. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Exergy Analysis of Heating, Refrigerating and Air Conditioning: Methods and Applications; Elsevier: Amsterdam, The Netherlands, 2015; Available online: https://books.google.de/books?id=m9ScBAAAQBAJ (accessed on 20 December 2024).

- Dincer, I. Refrigeration Systems and Applications; Wiley: Hoboken, NJ, USA, 2017; Available online: https://books.google.es/books?id=ru9WDgAAQBAJ (accessed on 20 December 2024).

| Country | Short-Term Decarbonization Goal | Long-Term Decarbonization Goal |

|---|---|---|

| Australia | - 43% from 2005 levels by 2030 [11] | Net-zero emissions by 2050 [11] |

| Canada | - 40% from 2005 levels by 2030 [13] | Net-zero emissions by 2050 [13] |

| China | - CO2 peak carbon emissions by 2030 [14] | Net-zero emissions by 2060 [14] |

| EU | - 40% from 1990 levels by 2030 [15,16] | Net-zero emissions by 2050 [15,16] |

| India | - 45% from 2005 levels by 2030 [17] | Net-zero emissions by 2070 [17] |

| Japan | - 46% from 2013 levels by 2030 [18] | Net-zero emissions by 2050 [18] |

| US | - 50–52% from 2005 levels by 2030 [12] | Net-zero emissions by 2050 [12] |

| Promotion Programs | Characteristics | Investment | Reference |

|---|---|---|---|

| Heat Pump Estimator | Online estimation tool to assist businesses in correctly sizing HPs | - | [65,70] |

| Net-Zero Manufacturing Initiative | It consists of the Clean Technology Innovation, the Low Carbon Product Manufacturing, and the Renewable Manufacturing programs. It aims to accelerate and develop innovative technologies | AUD 275 million | [71] |

| High Emitting Industries | It aims to decarbonize facilities and promote a zero-emissions economy | AUD 305 million | [72] |

| Net-Zero Plan Stage 1, 2020–2030 | It collaborates with industries toward the path of decarbonization | AUD 1 billion | [73] |

| Emission Reduction Fund | It gives financial incentives to adopt measures to reduce emissions and storage carbon | Depending on each case. | [69] |

| Climate Active, with the Climate Active Carbon Neutral Certification | The program rewards businesses that integrate sustainability practices and reduce their carbon footprint | - | [69] |

| Renewable Energy Target | It promotes electricity production from RESs | - | [69] |

| Australian Carbon Credit Unit Scheme | It offers support to projects that prevent GHG emissions or remove and store carbon from the atmosphere | - | [69] |

| Power the Regions Fund | It supports the Australian Carbon Credit Unit Scheme | - | [67] |

| Promotion Programs | Characteristics | Investment | Reference |

|---|---|---|---|

| Net-Zero Accelerator, administered through the Strategic Innovation Fund | It aims to accelerate GHG emissions efforts. It is based on three pillars: the Decarbonization of Large Emitters, Industrial Transformation, and Clean Technology and Battery Ecosystem Development | CAD 8 billion | [74] |

| 2030 Emissions Reduction Plan | It promotes GHG reduction across various sectors. It aims to lower CO2 from building to 53 Mt by 2030 | - | [75] |

| Canadian Net-Zero Emissions Accountability Act | It shares the same goals as the 2030 Emissions Reduction Plan, providing funds to reach decarbonization across different sectors | - | [74] |

| Oil to Heat Pump Affordability | It provides subsides to low-and-middle income households to switch from oil heating to HPs | Up to CAD 16,000 | [76] |

| Heat Pump Calculator | It is a tool provided by the Canadian Government to help individuals to evaluate the effect of the adoption of an HP in their specific circumstances |

- - | [13,76,78] |

| Promotion Programs | Characteristics | Investment | Reference |

|---|---|---|---|

| National Energy Conversation Law | The primary goal is to reduce energy consumption across all sectors. It also incorporates a strategy to integrate energy conservation and efficiency in all sectors of the economy. The Law implemented specific policies to target energy-intensive industries. It also forbids the construction of new coal-fired thermal generation units | - | [79] |

| Renewable Energy Law | It establishes a regulatory framework to promote RESs in China. It guarantees support to projects that implement RESs | - | [81] |

| China’s Five Years Plan 2011–2015 | It specifically prioritizes the transformation of the heating sector | - | [82] |

| The 14th China’s Five Years Plan 2021–2025 | It sets targets to improve energy intensity by 13.5% per unit GDP and the carbon intensity per unit GDP by 18% | - | [84] |

| The Plan for Carbon Peak Action | It promotes the integration of industrial waste heat and RESs in the urban heating systems. It contains heating recommendations for the HSCW zone | - | [83] |

| Promotion Programs | Characteristics | Investment | Reference |

|---|---|---|---|

| Green Growth Strategy | It provides action plans and energy policy for the sustainable evolution of 14 promising fields, including the industrial sector | - | [85] |

| Japan’s Long-Term Strategy under the Paris Agreement | It oversees the use of electrification technologies such as HPs and electric heating to decarbonize low-temperature heat demand, while improving the overall efficiency | - | [86] |

| Energy Efficiency Technological Strategies | It promotes both the development and the implementation of highly efficient technologies like HTHPs | - | [87] |

| Green Innovation Fund | A financial instrument to promote industry decarbonization without harming competitiveness | - | [87] |

| Electricity Business Act | A tool to reinforce the national electricity grid aiming to support the use of HPs in the building sector | - | [87] |

| The New Energy and Industrial Technology Development Organization (NEDO) | National R&D agency promoting many research projects on HTHPs. It involves many key industrial partners | - | [90] |

| Energy Conservation Grand Prize Award | It recognizes outstanding energy conservation products ad activities across all the sectors | - | [93] |

| Award for Climate Action | It rewards individuals or groups that have significantly contributed to coping with climate change | - | [93] |

| USA–Japan Climate Partnership | It consists of three pillars: the implementation of the Paris Agreement; development, deployment, and innovation in clean energy technologies; supporting decarbonization actions in other countries, especially in the Indo-Pacific area | - | [92] |

| Promotion Programs | Characteristics | Investment | Reference |

|---|---|---|---|

| Energy Performance of Building Directive (EPBD) | It offers a long-term energy renovation strategy for buildings, targeting a 80% to 95% reduction in CO2 emissions by 2050, with HPs identified as a high-efficiency alternative to fossil fuel-based heating systems. It also supports initiatives to increase awareness and knowledge about HPs among consumers, professionals, and policymakers. | - | [94] |

| Revised Renewable Energy Directive (RED) | It indicates HPs as a pivotal technology for renewable heating and cooling. | - | [95] |

| Energy Efficiency Directive (EED) | It states that when calculating the share of renewable energy within a district heating system, all heat provided to the network by HPs qualifies as renewable energy, and it establishes that the evaluation of waste heat utilization must consider HPs together with other heat-to-power technologies. | - | [96] |

| Revised Energy Taxation Directive | It offers guidelines to align between gas and electricity prices, by reducing the VAT for energy-efficient technology while taxing fossil fuels. | - | [97] |

| Next Generation EU | It provides funds for the EU’s recovery post-COVID-19 pandemic, supporting a greener economy based on efficient technologies, such as HPs. | - | [98] |

| REPowerEU | The main goal is boosting the annual sales of HPs. | It will receive up to EUR 30 billion over five years from the EIB + EUR 20 million from the Recovery and Resilience Facility Plan (RRF) | [99] |

| Heat Pump Action Plan (HPAP) | To be released after the EU elections in June 2024, it aims to accelerate HP market adoption, outlining actions such as partnerships, communication, skills development, legislation, and financing. | - | [100] |

| Heat Pump Accelerator | A cross-sectoral initiative that proposes solutions to HP sector challenges, including regulations to mandate HP use in industrial processes and to prohibit fossil fuel-based solutions for industrial heat up to 200 °C. | - | [100] |

| Net-Zero Industry Act | It aims to amplify clean technologies’ production in the EU by attracting investments and simplifying the regulatory framework. | - | [101] |

| Green Deal Industrial Plan | Its main goal is to accelerate the deployment of innovative and sustainable technologies, encouraging the transition to HPs. | - | [102] |

| The European Investment Fund (EIF) within the European Investment Bank (EIB) | The EIF is the main tool used by the EIB to finance EU actions and initiatives to tackle climate change. | EUR 250 million + funds to REPowerEU | [103] |

| The Recovery and Resilience Facility Plan (RRF) | The RRF is a tool designed to support the green transition in the industrial sector, giving funding to programs aiming to overcome the barriers hindering HP diffusion in the EU industry. It also gives support to the REPowerEU. | EUR 225 billion | [103] |

| Just Transition Mechanism (JTM) with the Just Transition Fund (JTF) | Its main goal is to face the lack of expertise on innovative technologies by financing training courses to generate the knowledge needed in a green, sustainable industry. | EUR 3 billion | [103] |

| The Innovation Fund, the InvestEU Fund, and the Strategic Technologies for Europe Platform (STEP) | All of them are designed to incentivize the transition to a clean-energy-based industry by promoting R&D and pilot projects. | Total of EUR 222.2 billion (Innovation Fund: EUR 40 billion + InvestEU: EUR 26.2 billion + STEP: EUR 160 billion) | [103] |

| LIFE Programme Clean Energy Transition (CET), within the LIFE Programme | The LIFE Programme CET includes funding to roll-out HPs in the building sector with the LIFE 2023 CET HEATPUMPS segment. | EUR 1 billion | [103] |

| European Research Council (ERC), Horizon Europe Programme (HEP), and Marie-Sklodowska-Curie Actions (MSCA) | These programs’ goal is to finance R&D projects in many fields, comprising innovative alternative like HTHPs. | Total of EUR 118.1 billion (ERC: EUR 16 billion + HEP: EUR 95.5 billion + MSCA: EUR 6.6 billion) | [103] |

| Promotion Programs | Characteristics | Investment | Reference |

|---|---|---|---|

| Initiative for Better Energy, Emissions, and Equity (E3 Initiative), strengthened by the Residential Cold Climate Heat Pumps Technology Challenge | It encourages the use of HPs in cold climates | - | [107] |

| USA–Japan Climate Partnership | It consists of three pillars: implementation of the Paris Agreement; development of, deployment of, and innovation in clean energy technologies; support decarbonization actions in other countries, especially in the Indo-Pacific area | - | [92] |

| Installing Clean Efficiency Energy Hastens Our Transition (ICEE) Act | It provides discounts for distributors and manufacturers of HPs, HP water heaters, and HP clothes dryers made in the USA, incentivizing the production of these energy-efficient appliances | - | [108] |

| Heating Efficiency and Affordability through Tax Relief (HEATR) | It provides tax incentives to manufacturers to increase HP production | - | [109] |

| Defense Production Act Invocation | The main target is to enhance key technology manufacturing, including HPs | - | [110] |

| Inflation Reduction Act | It supports energy efficiency and RES technology adoption | - | [111] |

| New Efficiency Rating for AC and HPs | It defines a new efficiency rating for AC and HP systems | - | [112] |

| The Industrial Decarbonization Roadmap | It offers guidelines to follow to decarbonize industry, based on four pillars: energy efficiency; industrial electrification; low-carbon fuels, feedstocks, and energy systems; CCUS | - | [115] |

| The DOE’s Industrial Efficiency and Decarbonization Office | It gives funds to projects that aim to reduce the industrial carbon footprint | - | [116] |

| The Technologies for Industrial Emission Reduction Development (TIEReD) and the Industrial Demonstration Program | They are tools to invest in transformative technologies, boosting their development and deployment in the industrial sector | USD 135 million | [119] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamo, A.; Martín, H.; Hoz, J.d.l.; Rubio, J. A Review of Worldwide Strategies for Promoting High-Temperature Heat Pumps. Appl. Sci. 2025, 15, 839. https://doi.org/10.3390/app15020839

Adamo A, Martín H, Hoz Jdl, Rubio J. A Review of Worldwide Strategies for Promoting High-Temperature Heat Pumps. Applied Sciences. 2025; 15(2):839. https://doi.org/10.3390/app15020839

Chicago/Turabian StyleAdamo, Angela, Helena Martín, Jordi de la Hoz, and Joan Rubio. 2025. "A Review of Worldwide Strategies for Promoting High-Temperature Heat Pumps" Applied Sciences 15, no. 2: 839. https://doi.org/10.3390/app15020839

APA StyleAdamo, A., Martín, H., Hoz, J. d. l., & Rubio, J. (2025). A Review of Worldwide Strategies for Promoting High-Temperature Heat Pumps. Applied Sciences, 15(2), 839. https://doi.org/10.3390/app15020839