Towards an Automated Design Evaluation Method for Wire Arc Additive Manufacturing

Abstract

:1. Introduction

2. State of the Art

2.1. Current Methods for Manufacturability Evaluation

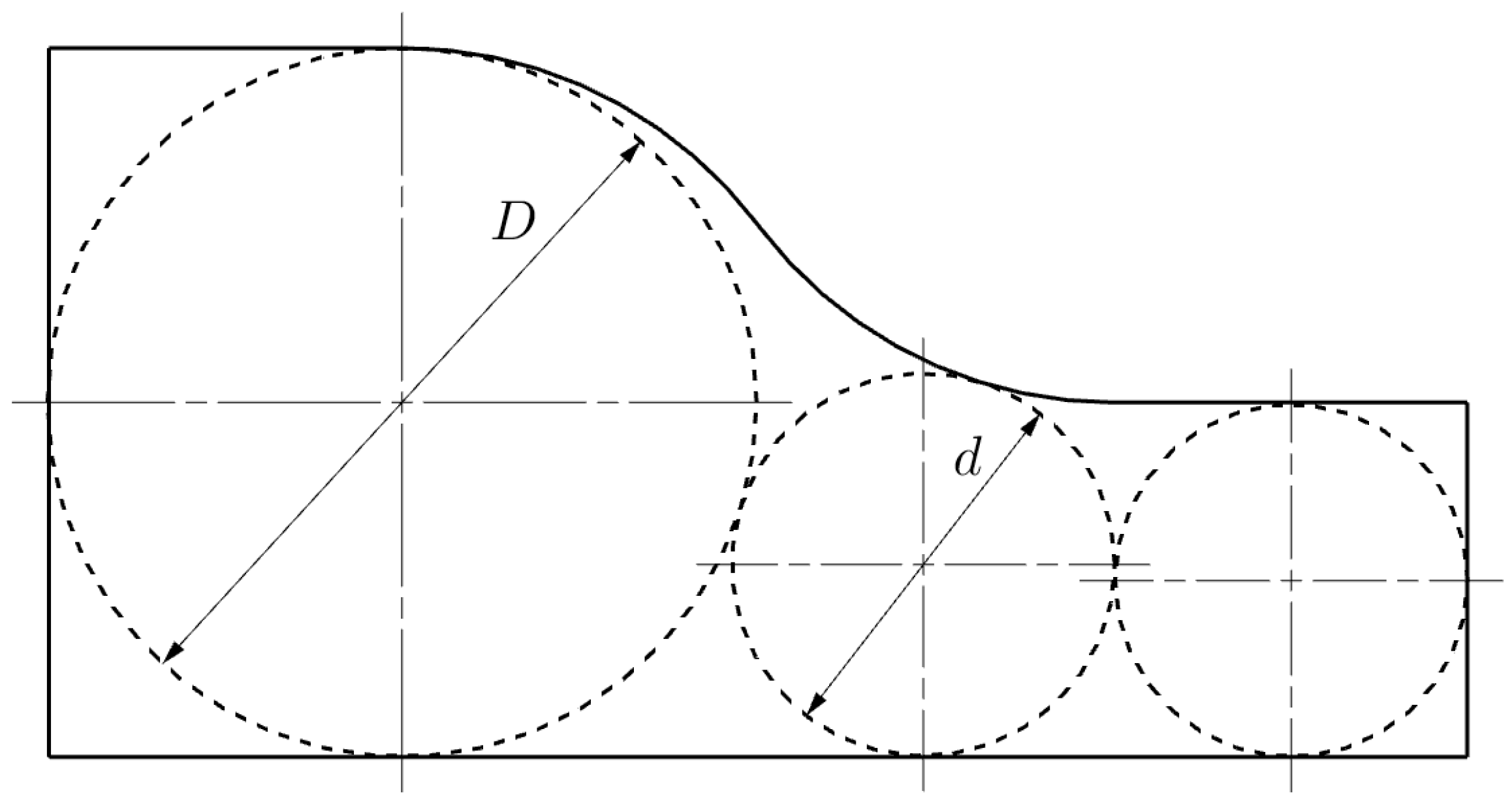

2.1.1. Heuvers’ Circles Method for Casting

2.1.2. Evaluation Methods for Additive Manufacturing

2.2. Design Guidelines for WAAM

3. Methods

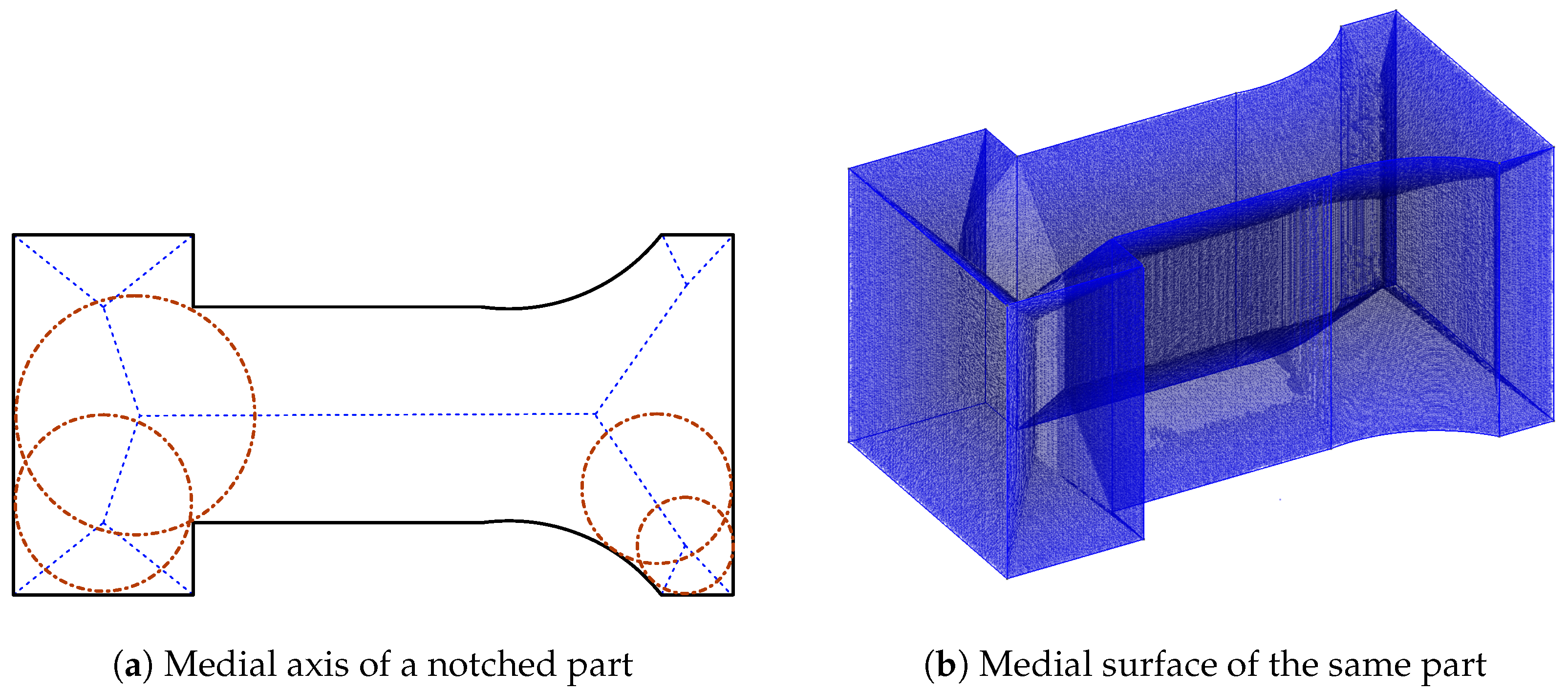

3.1. Medial Axis and Medial Surface Transformation

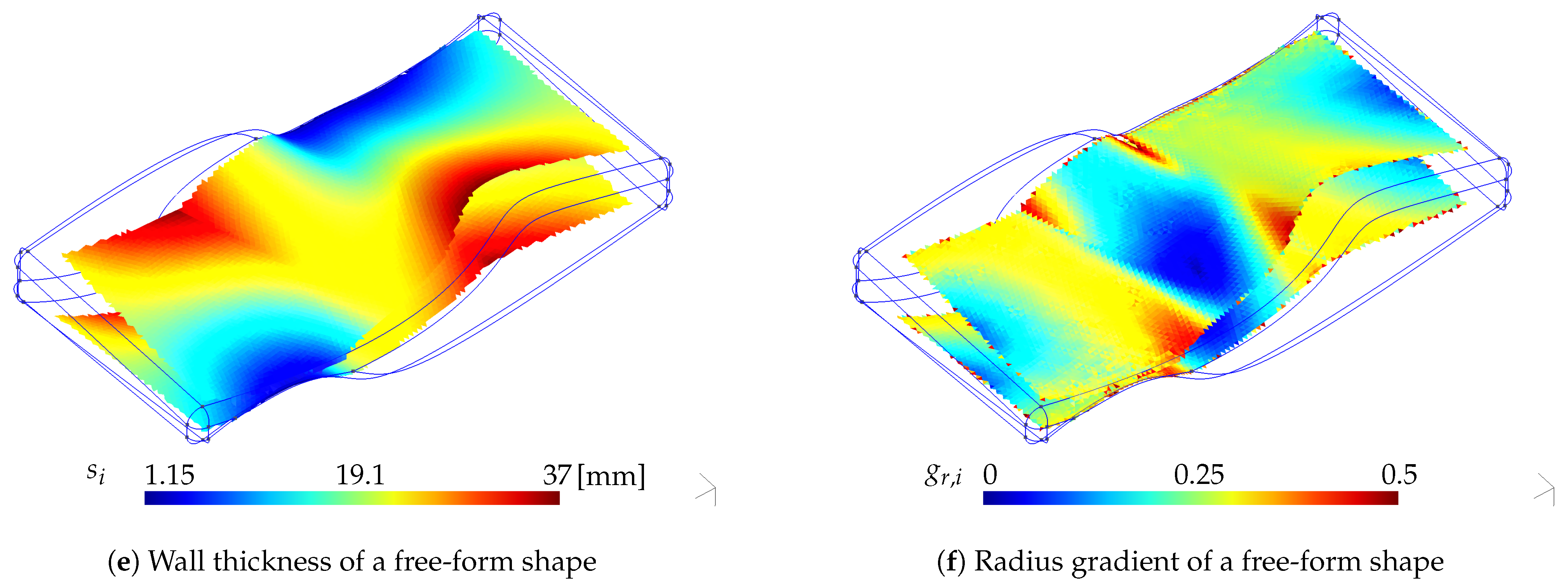

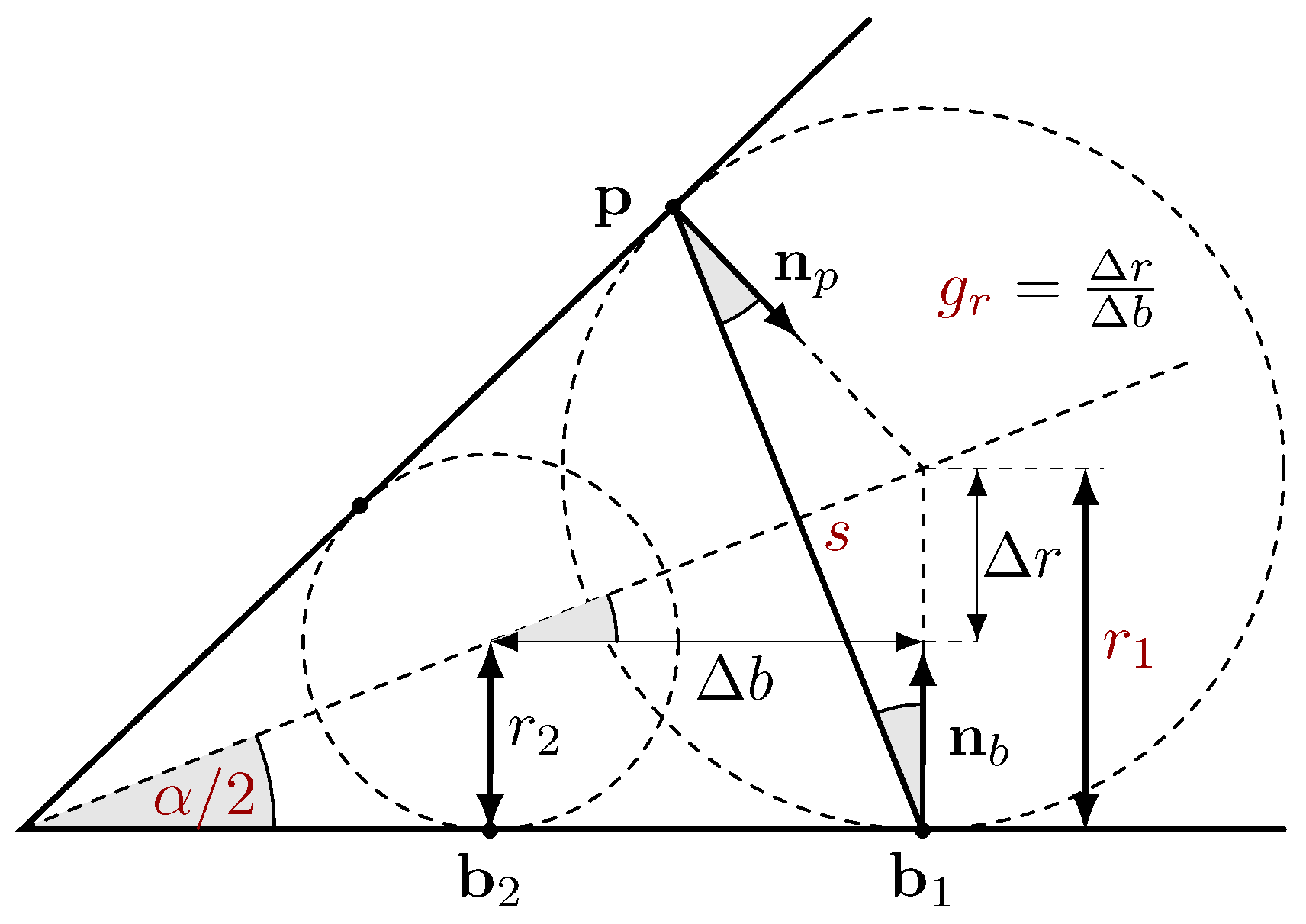

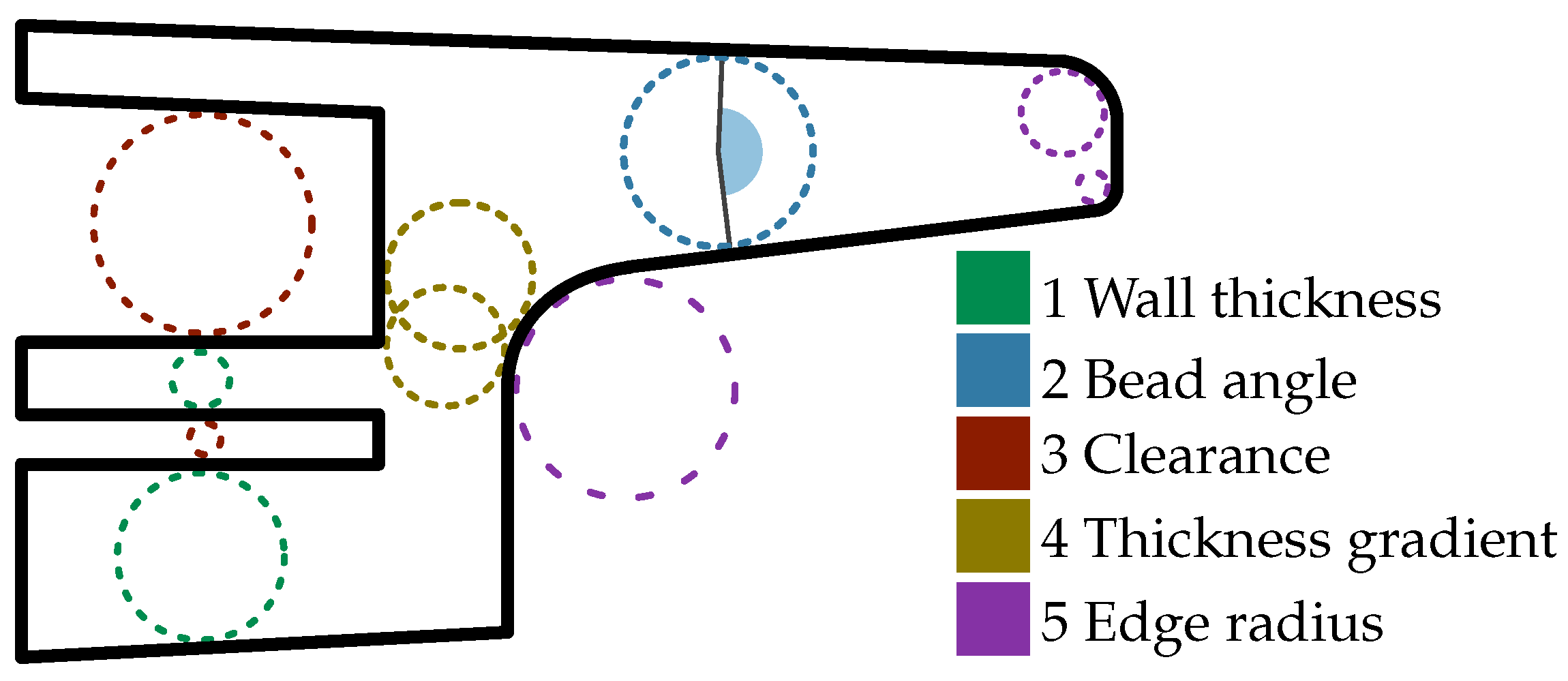

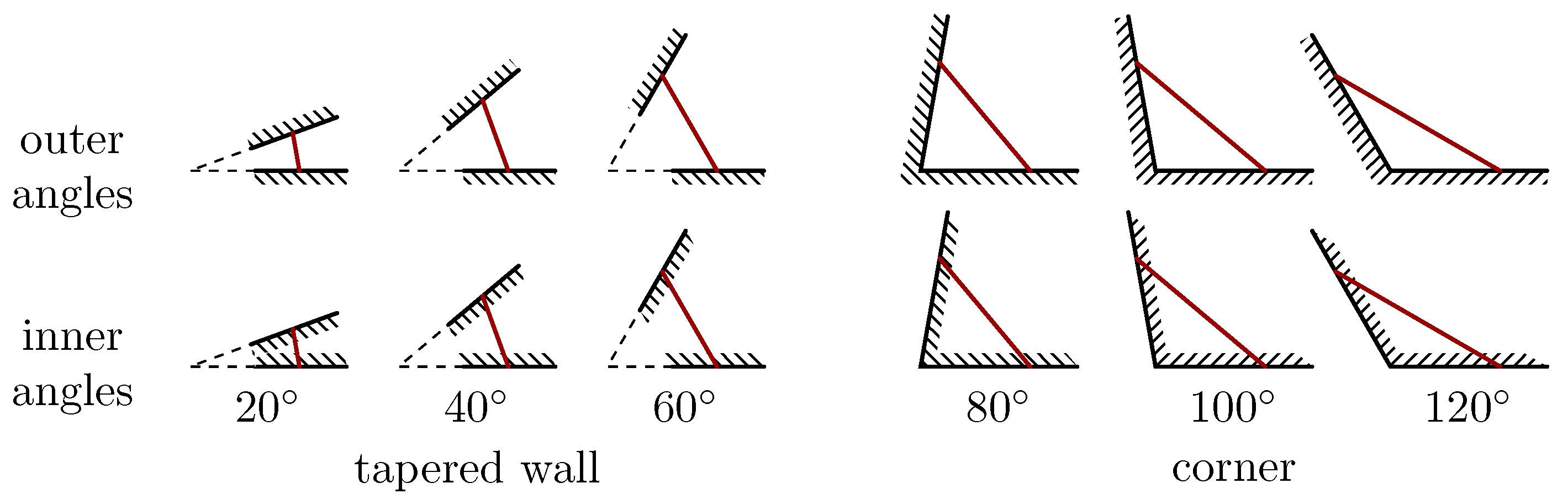

3.2. Definition of Geometry Indicators Based on the 3D-MAT

3.3. Application of WAAM Design Rules to 3D-MAT Geometry Indicators

3.4. Test Implementation

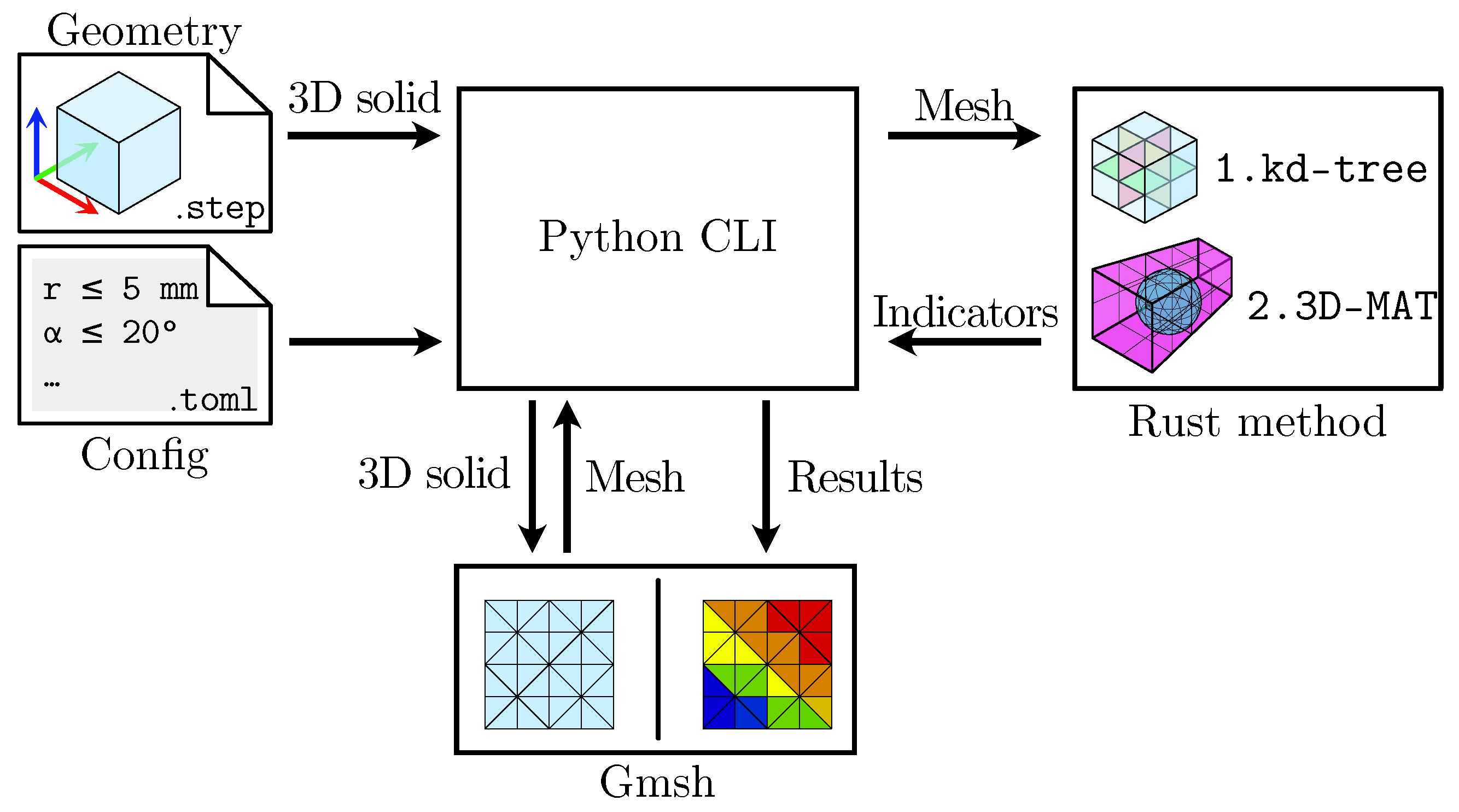

- Via Python, Gmsh is controlled to load the 3D solid geometry in the Step format. Gmsh then triangulates the surface according to a specified element size.

- The generated mesh data, which are the triangles’ center points and face normals, are then handed over to a Rust method. In the Rust method, first, a kd-tree is built from the point data, and then the 3D-MAT is calculated using the shrinking ball algorithm [48].A kd-tree is a space-partitioning method that enables efficient nearest neighbor search on point clouds, which improves the computational performance of the 3D-MAT algorithm. The kd-tree is a binary search tree that is built by alternatingly dividing the geometry along the three spatial axes into subspaces until in every subspace only a defined number of points is left [49].The shrinking ball algorithm developed by Ma et al. approximates the 3D-MAT for every surface point and the corresponding surface normal by iteratively shrinking spheres to fit them into the 3D point cloud. Starting with the initial radius set to the maximum diameter of the axis-aligned bounding box, the current sphere center is calculated:An updated radius is then derived according to Equations (5) and (6) with being the nearest neighbor to that is within the radius and is different from the base point (cmp. Figure 3) [50]. The nearest neighbor is efficiently found by performing the search on the kd-tree. This iteration is repeated until no point is found that satisfies the criteria, indicating an empty sphere.Finally, the angle is calculated using Equation (1), and the calculated radii, distances (secant lengths), and angles are returned to the Python program.

- In the Python program, the radii gradients are calculated over neighboring facets (Equation (2)). Then, for every feature, the particular indicator data are filtered by another indicator as specified in the configuration file. To visualize the results, the filtered data are feature-wise added to Gmsh, whereby the highlighted faces are restricted to those critical according to the specified manufacturing limits.

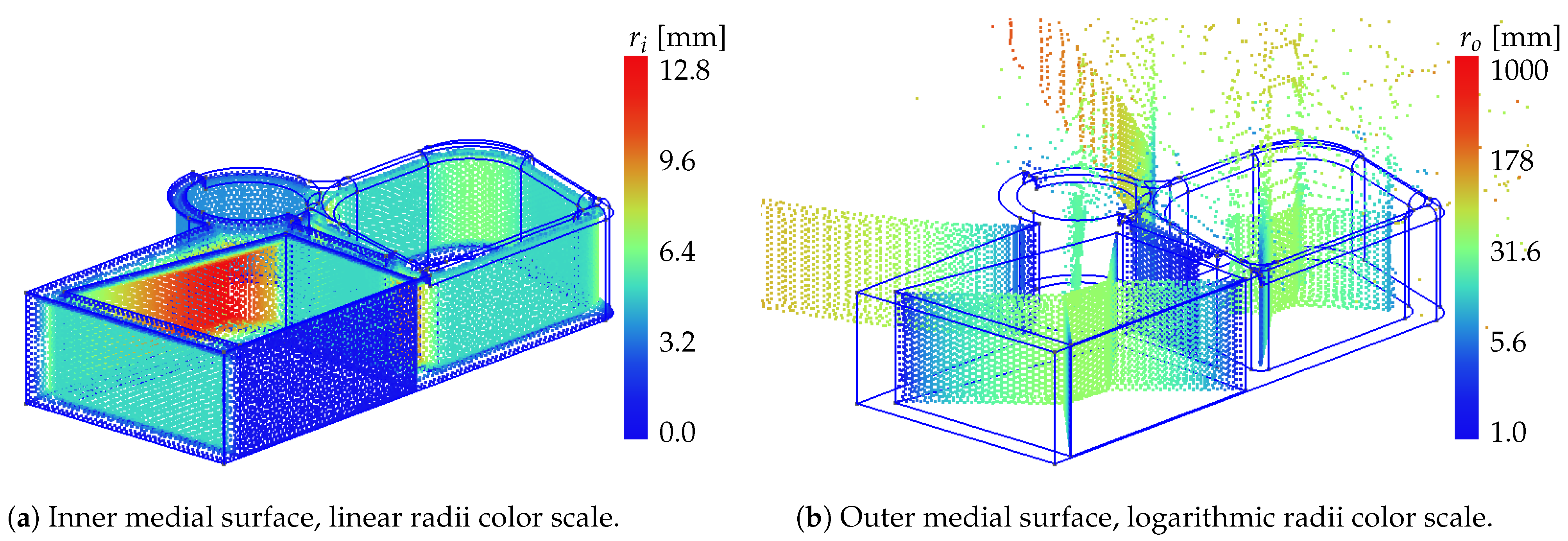

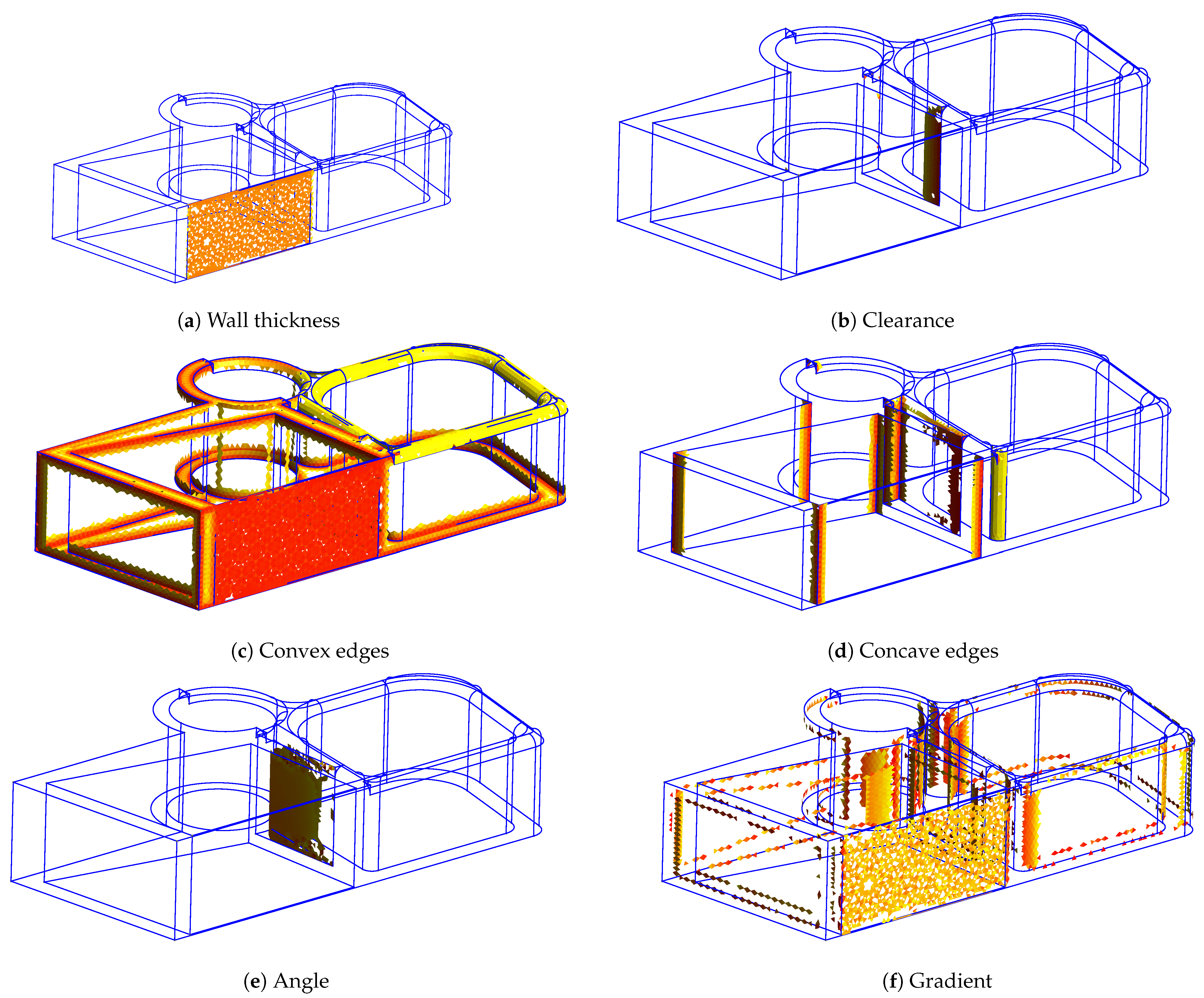

4. Results on Example Geometries

5. Discussion

6. Conclusions

- The mapping of current WAAM design recommendations to corresponding MAT geometry indicators.

- The definition of quantitative criteria for feature classification in 3D-MAT-based manufacturability evaluation.

- The addition of the radius gradient to the set of MAT geometry indicators.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-Feed Additive Manufacturing of Metal Components: Technologies, Developments and Future Interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Roy, S.; Shassere, B.; Yoder, J.; Nycz, A.; Noakes, M.; Narayanan, B.K.; Meyer, L.; Paul, J.; Sridharan, N. Mitigating Scatter in Mechanical Properties in AISI 410 Fabricated via Arc-Based Additive Manufacturing Process. Materials 2020, 13, 4855. [Google Scholar] [CrossRef] [PubMed]

- Lockett, H.; Ding, J.; Williams, S.; Martina, F. Design for Wire + Arc Additive Manufacture: Design Rules and Build Orientation Selection. J. Eng. Des. 2017, 28, 568–598. [Google Scholar] [CrossRef]

- Treutler, K.; Wesling, V. The Current State of Research of Wire Arc Additive Manufacturing (WAAM): A Review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

- Huang, L.; Chen, X.; Konovalov, S.; Su, C.; Fan, P.; Wang, Y.; Xiaoming, P.; Panchenko, I. A Review of Challenges for Wire and Arc Additive Manufacturing (WAAM). Trans. Indian Inst. Met. 2023, 76, 1123–1139. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.; Santos, T.G.; Oliveira, J. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Evans, S.I.; Wang, J.; Qin, J.; He, Y.; Shepherd, P.; Ding, J. A review of WAAM for steel construction—Manufacturing, material and geometric properties, design, and future directions. Structures 2022, 44, 1506–1522. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, Opportunities, Considerations, and Constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Mehnen, J.; Ding, J.; Lockett, H.; Kazanas, P. Design for Wire and Arc Additive Layer Manufacture. In Global Product Development; Bernard, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 721–727. [Google Scholar] [CrossRef]

- Wei, H.L.; Bhadeshia, H.K.D.H.; David, S.A.; DebRoy, T. Harnessing the scientific synergy of welding and additive manufacturing. Sci. Technol. Weld. Join. 2019, 24, 361–366. [Google Scholar] [CrossRef]

- Schmid, C. Konstruktive Randbedingungen bei Anwendung des WAAM-Verfahrens. In Konstruktion für die Additive Fertigung 2019; Lachmayer, R., Rettschlag, K., Kaierle, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 203–222. [Google Scholar] [CrossRef]

- Greer, C.; Nycz, A.; Noakes, M.; Richardson, B.; Post, B.; Kurfess, T.; Love, L. Introduction to the design rules for Metal Big Area Additive Manufacturing. Addit. Manuf. 2019, 27, 159–166. [Google Scholar] [CrossRef]

- Ransing, R.; Sood, M.; Pao, W. Computer Implementation of Heuvers’ Circle Method for Thermal Optimisation in Castings. Int. J. Cast Met. Res. 2005, 18, 119–128. [Google Scholar] [CrossRef]

- Mehnen, J.; Ding, J.; Lockett, H.; Kazanas, P. Design Study for Wire and Arc Additive Manufacture. Int. J. Prod. Dev. 2014, 19, 2. [Google Scholar] [CrossRef]

- Besong, L.I.B.; Buhl, J. A Review of Constitutive Models Used in Macroscale Finite Element Analysis of Additive Manufacturing and Post-Processing of Additively Manufactured Components. Virtual Phys. Prototyp. 2024, 19, e2356079. [Google Scholar] [CrossRef]

- Bahlen, T.M.; Bronsvoort, W.F.; Spence, A.D. Extraction and Visualization of Dimensions from a Geometric Model. Comput.-Aided Des. Appl. 2010, 7, 579–589. [Google Scholar] [CrossRef]

- Tominski, J.; Lammers, S.; Wulf, C.; Zimmer, D. Method for a Software-Based Design Check of Additively Manufactured Components. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference, Austin, TX, USA, 13–15 August 2018; pp. 69–79. [Google Scholar] [CrossRef]

- Rudolph, J.P.; Emmelmann, C. Analysis of Design Guidelines for Automated Order Acceptance in Additive Manufacturing. Procedia CIRP 2017, 60, 187–192. [Google Scholar] [CrossRef]

- Lockett, H.; Emms, R.; Williams, S.; Ding, J.; Martina, F. The Application of Knowledge Based Engineering to Design for Wire+Arc Additive Manufacture (WAAM). In Proceedings of the 6th Aircraft Structural Design Conference, Bristol, UK, 9–11 October 2018. [Google Scholar]

- Ye, J.; Kyvelou, P.; Gilardi, F.; Lu, H.; Gilbert, M.; Gardner, L. An End-to-End Framework for the Additive Manufacture of Optimized Tubular Structures. IEEE Access 2021, 9, 165476–165489. [Google Scholar] [CrossRef]

- Heuvers, A. Was hat der Stahlgießer dem Konstrukteur über Lunker- und Rißbildung zu sagen? Stahl Und Eisen 1929, 49, 1239–1256. [Google Scholar]

- Geupel, H. Konstruktionslehre; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Fritz, A.H. (Ed.) Fertigungstechnik; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Lambourne, J.; Djuric, Z.; Brujic, D.; Ristic, M. Calculation and visualisation of the thickness of 3D CAD models. In Proceedings of the International Conference on Shape Modeling and Applications 2005, Cambridge, MA, USA, 13–17 June 2005; pp. 338–342. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, Y.; Baek, S.; De Backer, W.; Harik, R. Manufacturability Analysis for Additive Manufacturing Using a Novel Feature Recognition Technique. Comput.-Aided Des. Appl. 2018, 15, 941–952. [Google Scholar] [CrossRef]

- Tedia, S.; Williams, C.B. Manufacturability Analysis Tool for Additive Manufacturing Using Voxel-Based Geometric Modeling. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium 2016—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016; pp. 3–22. [Google Scholar]

- Jaiswal, P.; Rai, R. A Geometric Reasoning Approach for Additive Manufacturing Print Quality Assessment and Automated Model Correction. Comput.-Aided Des. 2019, 109, 1–11. [Google Scholar] [CrossRef]

- Sunil, V.B.; Pande, S.S. Automatic Recognition of Machining Features Using Artificial Neural Networks. Int. J. Adv. Manuf. Technol. 2009, 41, 932–947. [Google Scholar] [CrossRef]

- Mycroft, W.; Katzman, M.; Tammas-Williams, S.; Hernandez-Nava, E.; Panoutsos, G.; Todd, I.; Kadirkamanathan, V. A data-driven approach for predicting printability in metal additive manufacturing processes. J. Intell. Manuf. 2020, 31, 1769–1781. [Google Scholar] [CrossRef]

- Han, J.; Schaefer, D. An Ontology for Supporting Digital Manufacturability Analysis. Procedia CIRP 2019, 81, 850–855. [Google Scholar] [CrossRef]

- Mayerhofer, M.; Lepuschitz, W.; Hoebert, T.; Merdan, M.; Schwentenwein, M.; Strasser, T.I. Knowledge-Driven Manufacturability Analysis for Additive Manufacturing. IEEE Open J. Ind. Electron. Soc. 2021, 2, 207–223. [Google Scholar] [CrossRef]

- Campbell, J. Chapter 10—The 10 Rules for Good Castings. In Complete Casting Handbook; Butterworth-Heinemann: Oxford, UK, 2011; pp. 605–737. [Google Scholar] [CrossRef]

- Bralla, J.G. (Ed.) Design for Manufacturability Handbook, 2nd ed.; McGraw-Hill Handbooks; McGraw-Hill: Boston, MA, USA, 1999. [Google Scholar]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Geometric Limitation and Tensile Properties of Wire and Arc Additive Manufacturing 5A06 Aluminum Alloy Parts. J. Mater. Eng. Perform. 2017, 26, 621–629. [Google Scholar] [CrossRef]

- Song, Y.A.; Park, S.; Choi, D.; Jee, H. 3D Welding and Milling: Part I–a Direct Approach for Freeform Fabrication of Metallic Prototypes. Int. J. Mach. Tools Manuf. 2005, 45, 1057–1062. [Google Scholar] [CrossRef]

- Kazanas, P.; Deherkar, P.; Almeida, P.; Lockett, H.; Williams, S. Fabrication of Geometrical Features Using Wire and Arc Additive Manufacture. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 226, 1042–1051. [Google Scholar] [CrossRef]

- Venturini, G.; Montevecchi, F.; Scippa, A.; Campatelli, G. Optimization of WAAM Deposition Patterns for T-crossing Features. Procedia CIRP 2016, 55, 95–100. [Google Scholar] [CrossRef]

- Li, R.; Zhang, H.; Dai, F.; Huang, C.; Wang, G. End lateral extension path strategy for intersection in wire and arc additive manufactured 2319 aluminum alloy. Rapid Prototyp. J. 2019, 26, 360–369. [Google Scholar] [CrossRef]

- Liu, H.H.; Zhao, T.; Li, L.Y.; Liu, W.J.; Wang, T.Q.; Yue, J.F. A Path Planning and Sharp Corner Correction Strategy for Wire and Arc Additive Manufacturing of Solid Components with Polygonal Cross-Sections. Int. J. Adv. Manuf. Technol. 2020, 106, 4879–4889. [Google Scholar] [CrossRef]

- ASTM F3413-19e1; Guide for Additive Manufacturing—Design–Directed Energy Deposition. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Blum, H. A Transformation for Extracting New Descriptors of Shape. In Models for Perception of Speech and Visual Form; Wathen-Dunn, W., Ed.; MIT Press: Cambridge, MA, USA, 1967; pp. 362–380. [Google Scholar]

- Geuzaine, C.; Remacle, J.F. Gmsh: A 3-D Finite Element Mesh Generator with Built-in Pre- and Post-Processing Facilities: THE GMSH PAPER. Int. J. Numer. Methods Eng. 2009, 79, 1309–1331. [Google Scholar] [CrossRef]

- Matsakis, N.D.; Klock, F.S., II. The rust language. ACM SIGAda Ada Lett. 2014, 34, 103–104. [Google Scholar] [CrossRef]

- Stromberg, H.; Pusicha, J. WAAM_fit GitLab Repository. Available online: https://gitlab.tu-clausthal.de/jpu18/WAAM_fit (accessed on 5 February 2024).

- Preston-Werner, T.; Gedam, P. TOML v1.0.0. Available online: https://toml.io/en/v1.0.0 (accessed on 25 May 2024).

- Ma, J.; Bae, S.W.; Choi, S. 3D Medial Axis Point Approximation Using Nearest Neighbors and the Normal Field. Vis. Comput. 2011, 28, 7–19. [Google Scholar] [CrossRef]

- Bentley, J.L. Multidimensional Binary Search Trees Used for Associative Searching. Commun. ACM 1975, 18, 509–517. [Google Scholar] [CrossRef]

- Bayardo Spadafora, J.; Gomez-Fernandez, F.; Taubin, G. Fast Non-Convex Hull Computation. In Proceedings of the 2019 International Conference on 3D Vision (3DV), Québec City, QC, Canada, 16–19 September 2019; pp. 747–755. [Google Scholar] [CrossRef]

- Friedman, J.H.; Bentley, J.L.; Finkel, R.A. An Algorithm for Finding Best Matches in Logarithmic Expected Time. ACM Trans. Math. Softw. 1977, 3, 209–226. [Google Scholar] [CrossRef]

- Peters, R. Geographical point cloud modelling with the 3D medial axis transform. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar] [CrossRef]

| Feature | Recommendations and Constraints |

|---|---|

| general features | large, simple, sparsely detailed [13] |

| limited number of bead ends [13] | |

| sudden cross-sectional changes avoided [13] | |

| surface to volume ratio | high (for optimal heat transfer) [13] |

| symmetry or similar shapes | favor, to reduce warpage |

| if applicable: base plate as symmetry plane [3,13] | |

| part size | ≥ (recommended for practical handling) [3] |

| ≤machine housing/enclosure (if applicable) [3] | |

| min. wall thickness | (depends on process parameters) [3,13] |

| min. clearance | (for Al5A06) [36] |

| post-processing allowance | process dependent, e.g., machining [37] |

| edges, corners | generously rounded [3] |

| sharp corners either avoided or built as intersection [13] | |

| overhangs | fixed torch: only angles ≥ possible [37] |

| variable torch: arbitrary angles possible [38] | |

| T-crossings | sharp, to avoid surface defects [13] |

| alternative: optimized path planning strategies [39,40] | |

| angles | simple path planning: ≥ (for multi-bead walls) [41] |

| optimized path planning: arbitrary angles [41], | |

| favor ≥ (for Al5A06) [36] |

| Feature | Indicator | Limits | Applied to Elements with … |

|---|---|---|---|

| wall thickness | ≥ | ||

| clearance | ≥ | ||

| edge radius | ≥ | ||

| wall angle | ≥ | ||

| thickness gradient | ≤ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pusicha, J.; Stromberg, H.; Quanz, M.; Lohrengel, A. Towards an Automated Design Evaluation Method for Wire Arc Additive Manufacturing. Appl. Sci. 2025, 15, 938. https://doi.org/10.3390/app15020938

Pusicha J, Stromberg H, Quanz M, Lohrengel A. Towards an Automated Design Evaluation Method for Wire Arc Additive Manufacturing. Applied Sciences. 2025; 15(2):938. https://doi.org/10.3390/app15020938

Chicago/Turabian StylePusicha, Johannes, Henrik Stromberg, Markus Quanz, and Armin Lohrengel. 2025. "Towards an Automated Design Evaluation Method for Wire Arc Additive Manufacturing" Applied Sciences 15, no. 2: 938. https://doi.org/10.3390/app15020938

APA StylePusicha, J., Stromberg, H., Quanz, M., & Lohrengel, A. (2025). Towards an Automated Design Evaluation Method for Wire Arc Additive Manufacturing. Applied Sciences, 15(2), 938. https://doi.org/10.3390/app15020938