Traditional and Advanced Curing Strategies for Concrete Materials: A Systematic Review of Mechanical Performance, Sustainability, and Future Directions

Abstract

1. Introduction

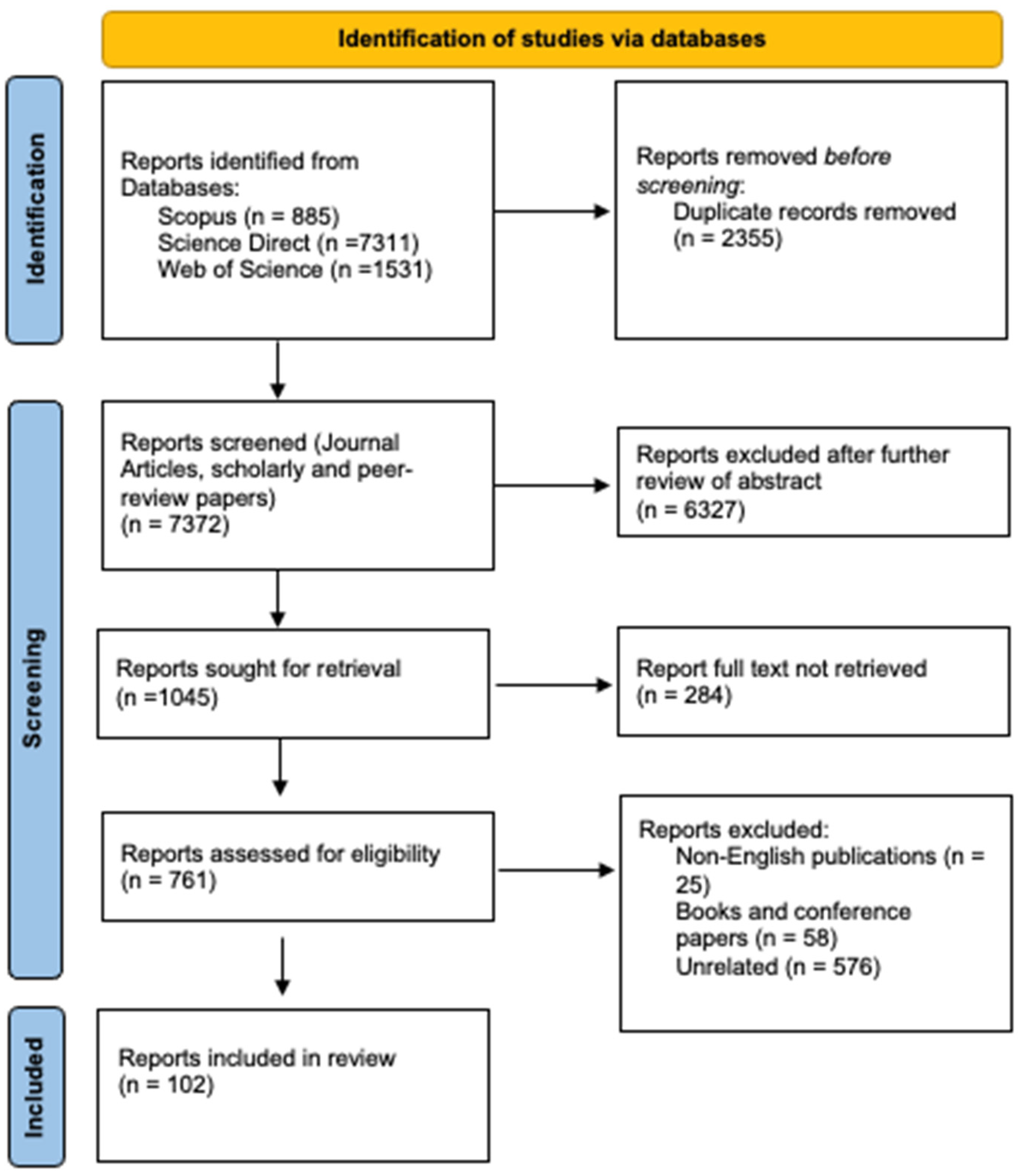

2. Research Significance and Methodologies

- Identification: The research articles were searched on Scopus, Web of Science, and ScienceDirect using titles, keywords, and abstracts.

- Screening: Duplicate, irrelevant, non-English, and full-text unavailability items were removed in the selected databases.

- Inclusion: Articles on curing systems for concrete were included in the research.

3. Traditional and Advanced Curing Methods

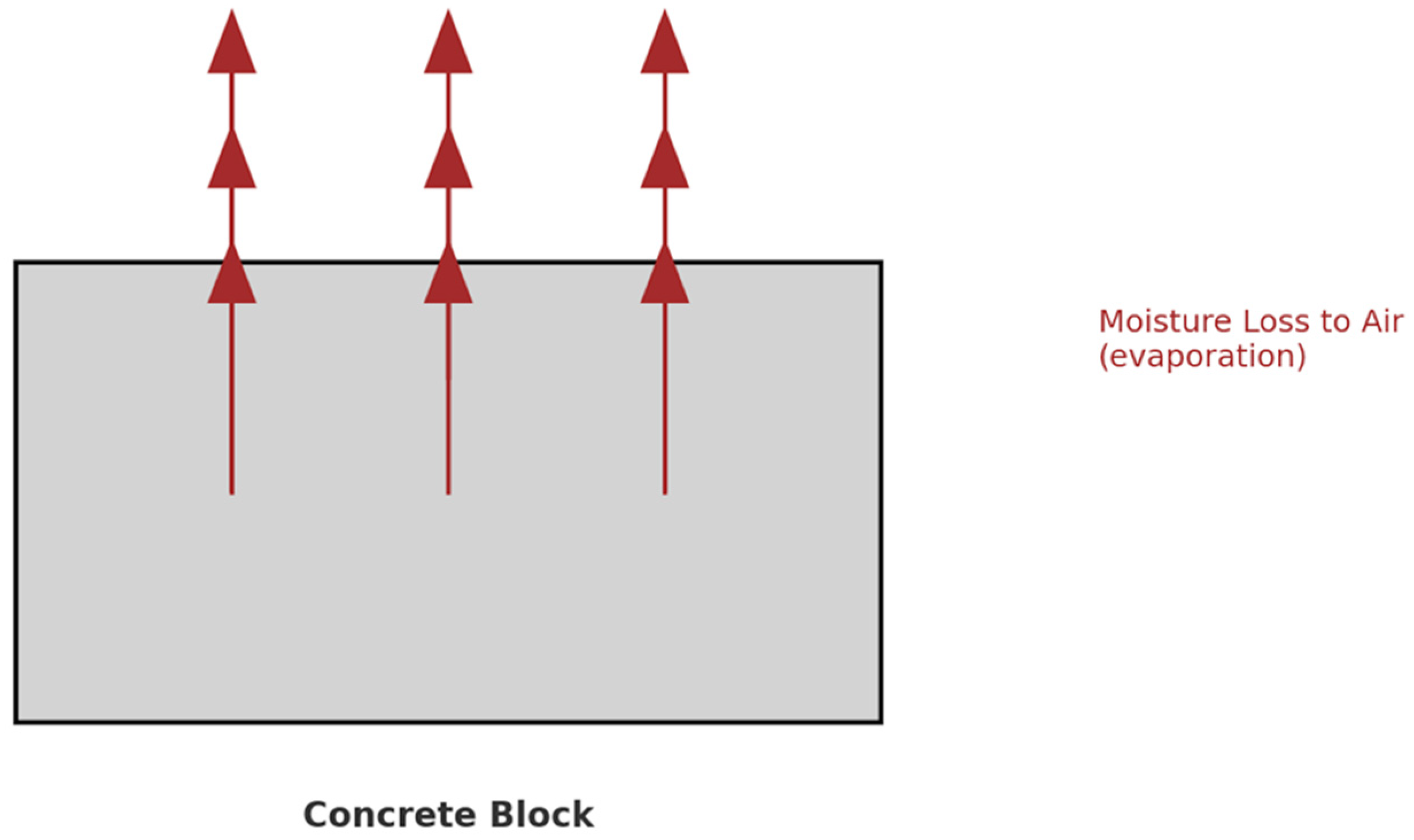

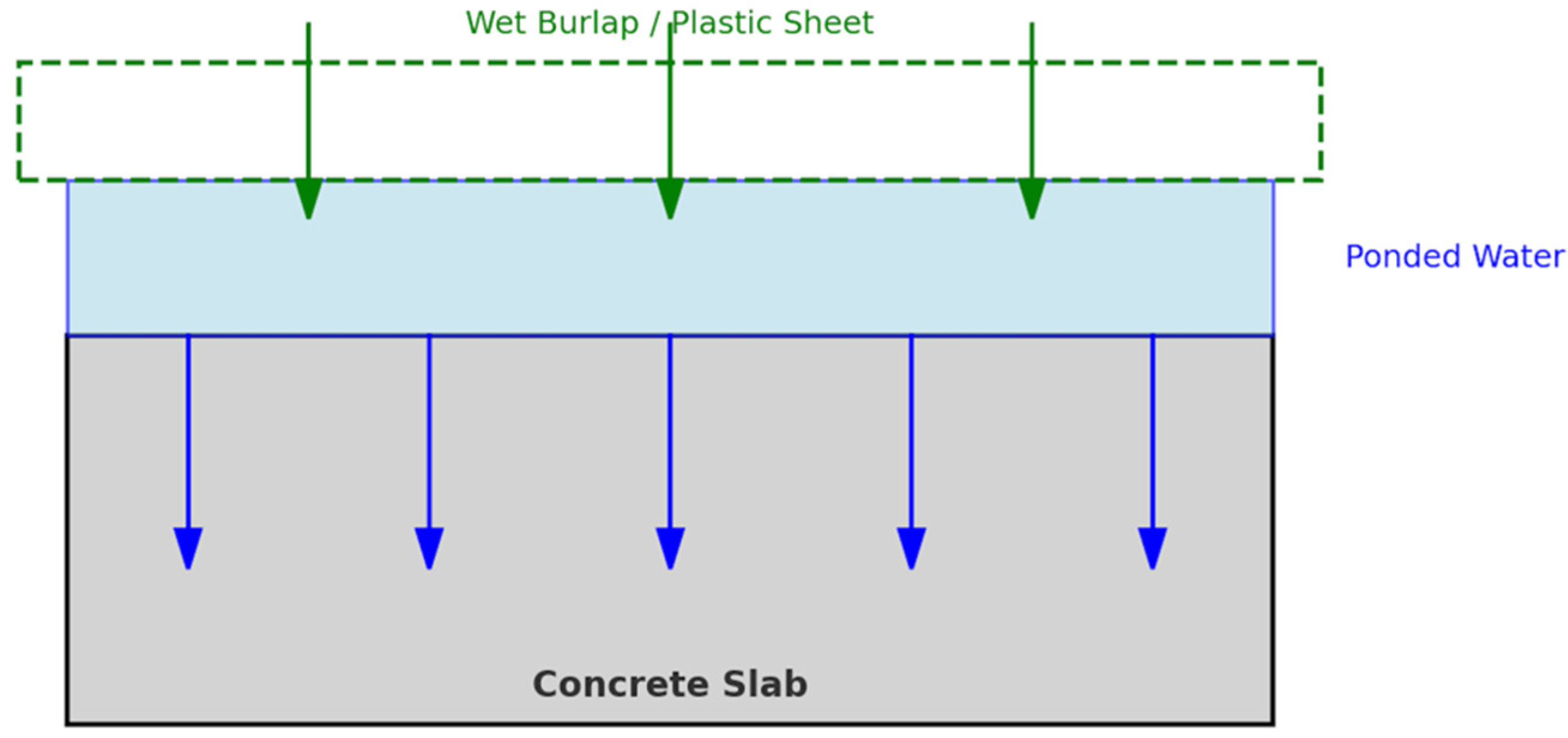

3.1. Wet Curing

3.2. Steam Curing

3.3. Microwave Curing

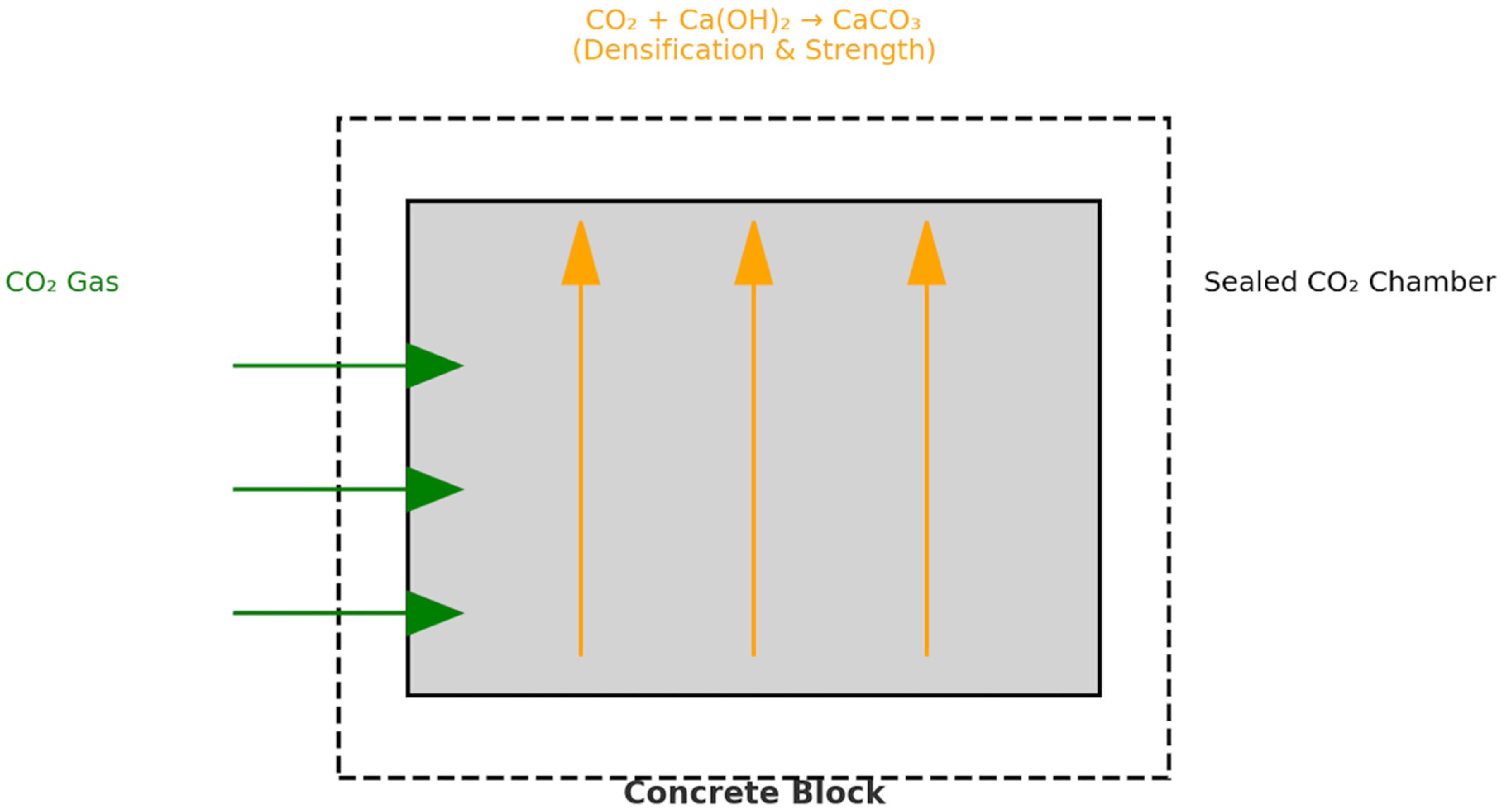

3.4. Carbonation Curing

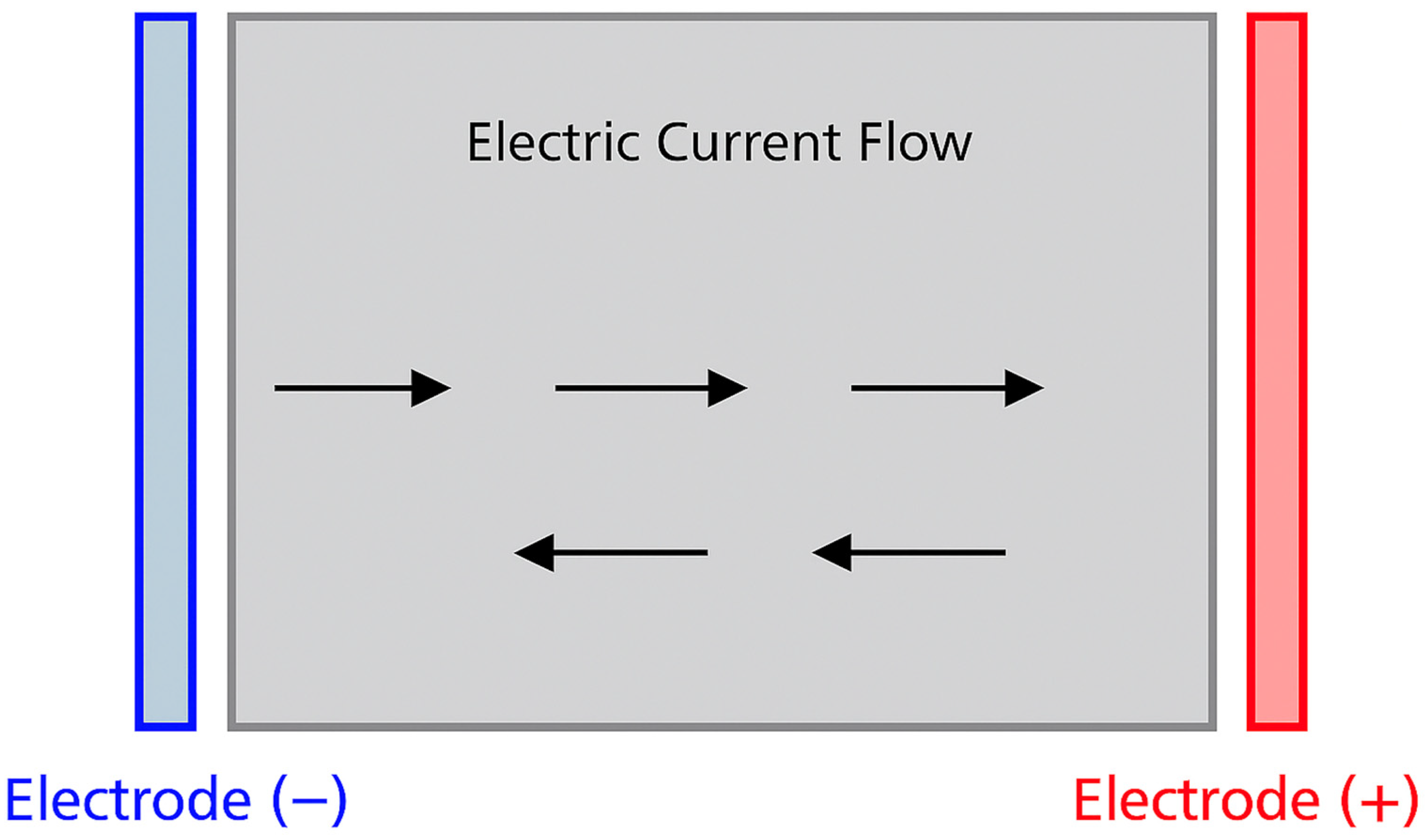

3.5. Electric Thermal Curing

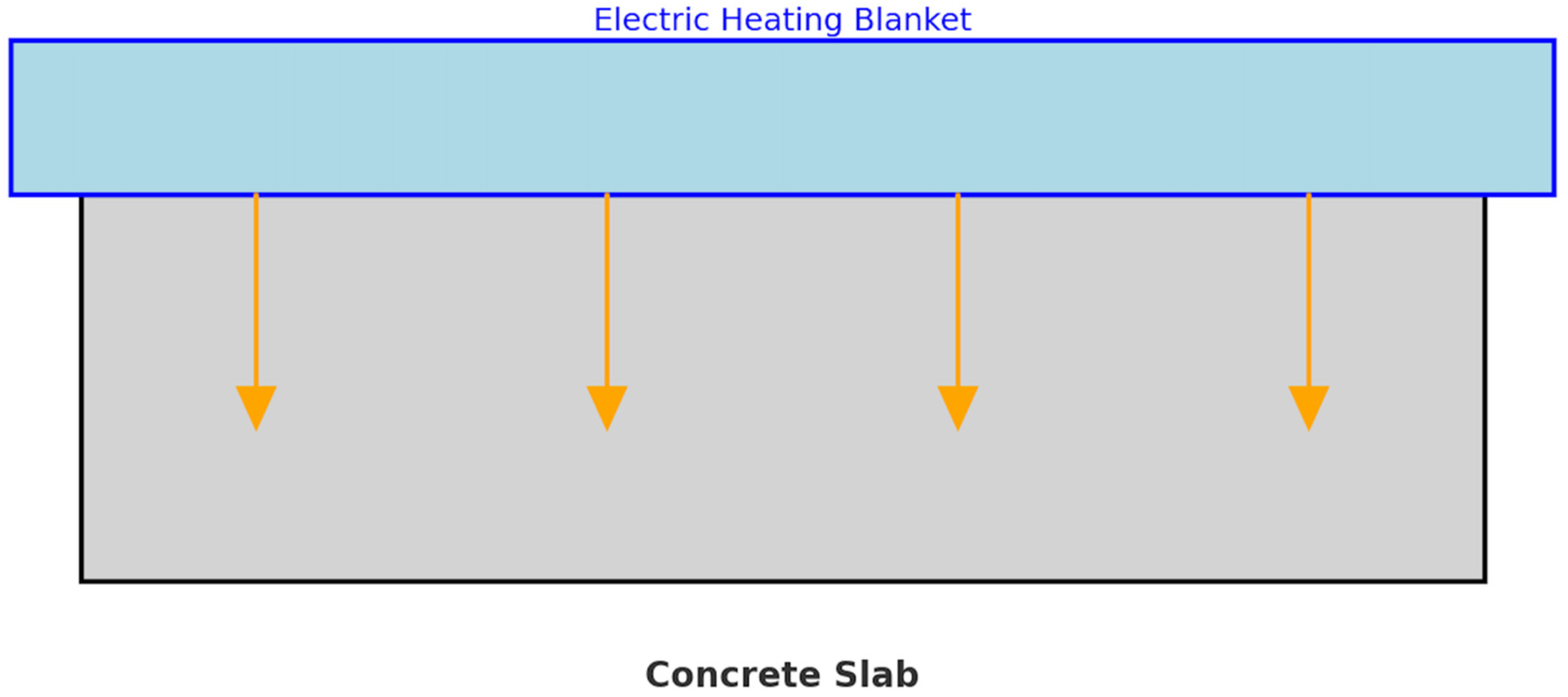

Electric Blanket Curing

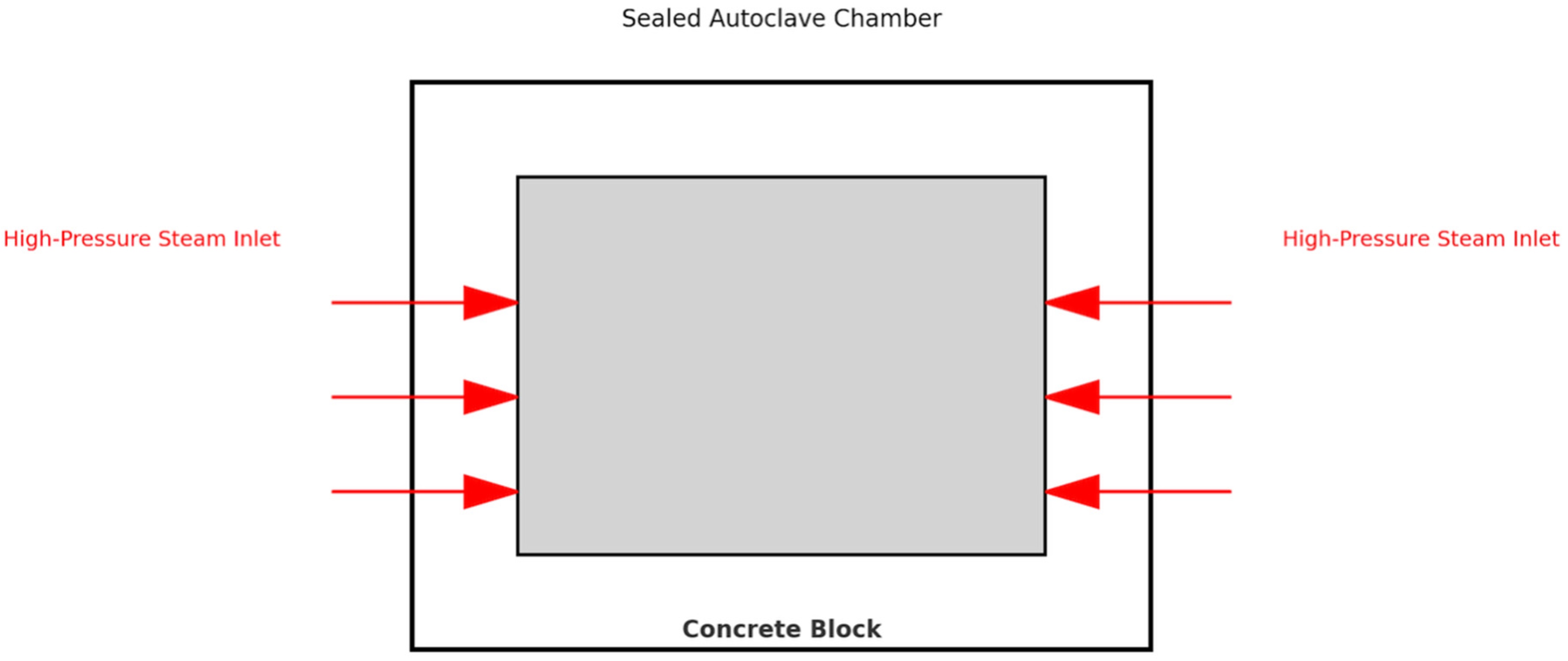

3.6. Autoclave Curing

Autoclaved Alternative Material Integration

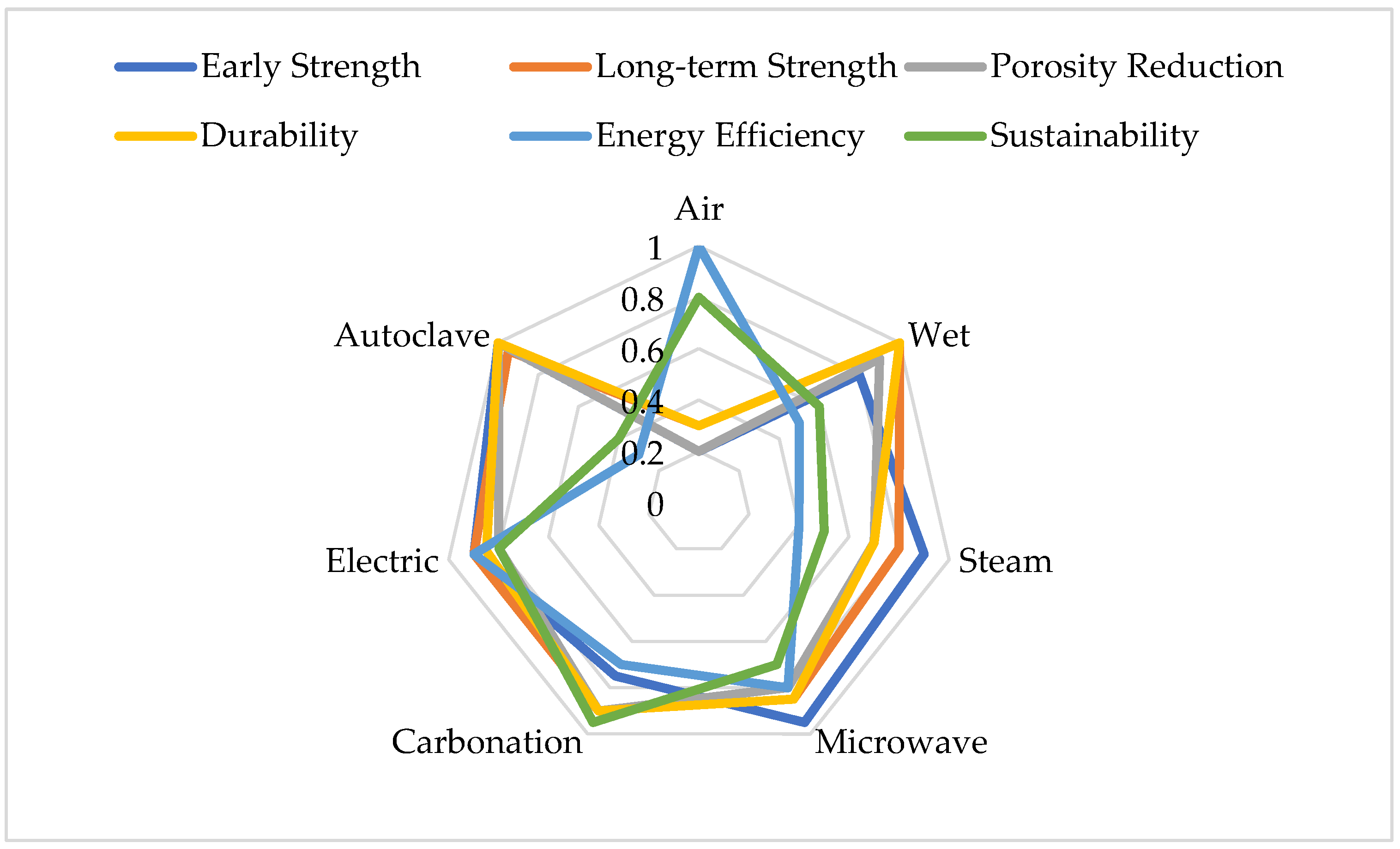

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Pang, R.; Jiang, H.; Dang, L.; Lei, H.; Chen, L.; Jia, H. Shear resistance of high strength soft wire rope loop-UHPC joint for precast concrete components. Structures 2025, 80, 109871. [Google Scholar] [CrossRef]

- Machado, B.R.; Silva, L.S.; Amario, M.; Haddad, A.N.; de Vargas, A.S.; Stolz, C.M. Effect of curing methods on the long-term properties of concrete containing crystallizing additives. Next Mater. 2025, 8, 100759. [Google Scholar] [CrossRef]

- Si, P.; Ding, C.; Xue, K.; Zhou, Z.; Li, S.; Yan, X. Research on the influence of steam curing on the strength, hydration reaction and high temperature resistance of barite radiation-shielding concrete. Constr. Build. Mater. 2025, 494, 143408. [Google Scholar] [CrossRef]

- Bai, M.; Wu, Y.; Xiao, J.; Ding, T.; Yu, K. Workability and hardened properties of 3D printed engineered cementitious composites incorporating recycled sand and PE fibers. J. Build. Eng. 2023, 71, 106477. [Google Scholar] [CrossRef]

- Li, Y.; Xu, K.; Wang, S.; Gao, J.; Maropoulos, P. A step-wise numerical thermal control method for advanced composite curing process using digital image based programming. CIRP Ann. 2023, 72, 441–444. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Nigussie, E. Automated concrete curing and assessment of strength and durability using IoT system. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- He, Y.; Li, W.; Zhang, M.; Li, S.; Li, M.; Tian, D.; Deng, G.; Sarmah, A.K. Automated electric heating and curing system for concrete in actual cold environments based on the Internet of Things. Constr. Build. Mater. 2025, 489, 142344. [Google Scholar] [CrossRef]

- Al Agha, W.; Pal, S.; Dev, N. Challenges for structural health monitoring of concrete curing using piezoelectric sensor and electromechanical impedance (EMI) technique: A critical review. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Dong, S.; Ouyang, X.; Yoo, D.-Y.; Han, B. Influence of early thermal curing regimes on properties of ultra-high performance concrete: A review. J. Build. Eng. 2024, 96, 110494. [Google Scholar] [CrossRef]

- Sidhu, A.S.; Siddique, R. Review on effect of curing methods on high strength concrete. Constr. Build. Mater. 2024, 438, 136858. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A life cycle assessment of cardboard waste in low stress grade concrete applications. Environ. Manag. 2024, 354, 120428. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Joseph, P.; Yaghoubi, E.; Vrcelj, Z. The mechanical and microstructural performance of waste textile and cardboard materials in concrete. Struct. Concr. 2024, 25, 4033–4047. [Google Scholar] [CrossRef]

- Chen, L.; Huang, Z.; Pan, W.; Su, R.K.L.; Zhong, Y.; Zhang, Y. Low carbon concrete for prefabricated modular construction in circular economy: An integrated approach towards sustainability, durability, cost, and mechanical performances. J. Build. Eng. 2024, 90, 109368. [Google Scholar] [CrossRef]

- Haigh, R. A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy. Waste 2023, 1, 935–959. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, R.; Wang, J.; Pan, H.; Zhang, G.; Cheng, L. Innovative and environmentally friendly MICP surface curing: Enhancing mechanical and durability properties of concrete. J. Clean. Prod. 2024, 478, 143962. [Google Scholar] [CrossRef]

- Chen, B.; Tang, G.; Lu, X.; Xiong, B.; Guan, B.; Tian, B. Thermal property evolution and prediction model of early-age low-heat cement concrete under different curing temperatures. J. Build. Eng. 2024, 82, 108020. [Google Scholar] [CrossRef]

- Zeng, J.; Feng, D.; Liu, C.; Ye, G.; Ma, C.; Tian, J.; Mu, Y. Effect of ageing on the hydration and carbonation reactivity of ordinary Portland cement. J. Build. Eng. 2025, 111, 113598. [Google Scholar] [CrossRef]

- Liang, L.; Wang, Q.; Shi, Q. Flexural toughness and its evaluation method of ultra-high performance concrete cured at room temperature. J. Build. Eng. 2023, 71, 106516. [Google Scholar] [CrossRef]

- Wang, D.; Sas, G.; Das, O. The importance of volumetric w/c for porous supplementary cementitious materials in concrete. J. Build. Eng. 2025, 111, 113290. [Google Scholar] [CrossRef]

- Gong, P.; Mei, K.; Zhang, L.; Xue, Q.; Wang, X.; Wei, T.; Zhang, C.; Cheng, X. Hydration and carbonation reaction dynamics in CO2-rich environment for tricalcium silicate (C3S) and dicalcium silicate (C2S). Powder Technol. 2025, 452, 120535. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Yaghoubi, E.; Joseph, P.; Vrcelj, Z. The mechanical and microstructural investigations of concrete incorporating waste textile and cardboard fibers following thermal and freeze–thaw cycles. Struct. Concr. 2025; preprint. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. The durability performance of waste cardboard kraft fibre reinforced concrete. J. Build. Eng. 2023, 67, 106010. [Google Scholar] [CrossRef]

- Kumar, G.; Bansal, T.; Sharma, D. Monitoring hydration and strength development of E-waste concrete: A passive sensing approach using piezo sensors. Clean. Mater. 2025, 17, 100326. [Google Scholar] [CrossRef]

- Zheng, H.; Duan, Y.; Liu, L.; Wang, P.; Pang, B.; Duan, H.; Hou, D. Molecular structure and dynamics of water on the surfaces of cement hydration products and associated Minerals: Nanoscale wettability behavior. Appl. Surf. Sci. 2025, 687, 162274. [Google Scholar] [CrossRef]

- Gereziher Atsbha, T.; Zhutovsky, S. The effect of external curing methods on the development of mechanical and durability-related properties of normal-strength concrete. Constr. Build. Mater. 2022, 324, 126706. [Google Scholar] [CrossRef]

- Poongodi, K.; Murthi, P. Effects of using autoclaved aerated concrete block debris as lightweight aggregate on internal curing of concrete. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Zou, D.; Que, Z.; Su, D.; Liu, T.; Zhou, A.; Li, Y. Sustainable use of recycled autoclaved aerated concrete waste as internal curing materials in ultra-high performance concrete. J. Clean. Prod. 2022, 373, 133910. [Google Scholar] [CrossRef]

- Guan, Q.; Zhou, Y. Utilizing ferrochrome slag and autoclaved artificial aggregates for eco-friendly and economical ultra-high-performance concrete: Mechanical performance and shrinkage control. Case Stud. Constr. Mater. 2025, 22, e04234. [Google Scholar] [CrossRef]

- Ibrahim, M.; Shameem, M.; Al-Mehthel, M.; Maslehuddin, M. Effect of curing methods on strength and durability of concrete under hot weather conditions. Cem. Concr. Compos. 2013, 41, 60–69. [Google Scholar] [CrossRef]

- Atiş, C.D.; Özcan, F.; Kılıç, A.; Karahan, O.; Bilim, C.; Severcan, M.H. Influence of dry and wet curing conditions on compressive strength of silica fume concrete. Build. Environ. 2005, 40, 1678–1683. [Google Scholar] [CrossRef]

- Lü, C.; Liu, D.; Ding, Y.; Lü, X.; Zhou, Z.; Mu, S.; Sun, Y. Effect of early dry-wet cycles on the mechanical performance and microstructure characteristics of ultra-high performance concrete (UHPC) with varying metakaolin (MK) contents. Constr. Build. Mater. 2025, 490, 142471. [Google Scholar] [CrossRef]

- Zhao, Q.; He, X.; Zhang, J.; Jiang, J. Long-age wet curing effect on performance of carbonation resistance of fly ash concrete. Constr. Build. Mater. 2016, 127, 577–587. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Y.; Jiang, S.; Xia, Z.; Zhang, Q. Effect of silica fume with various fineness levels on the strength degradation of concrete after steam curing. Constr. Build. Mater. 2025, 464, 140169. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.; Li, Y.; Liu, Y. An orthogonal experimental study on the influence of steam-curing on mechanical properties of foam concrete with fly ash. Case Stud. Constr. Mater. 2024, 20, e02665. [Google Scholar] [CrossRef]

- Liu, C.; Chen, F.; Deng, X.; Wu, Y.; Zheng, Z.; Yang, B.; Yao, D.; Yang, J.; Yang, J. Comparison of nano-silica-modified manufactured-sand concrete under steam curing and standard curing. J. Build. Eng. 2023, 72, 106443. [Google Scholar] [CrossRef]

- Li, C.; Hu, S.; Hu, Y.; Ye, Y. Investigating the impact of steam curing parameters on the chloride ion penetration resistance of the prestressed concrete cylinder pipe (PCCP) protective layer. J. Build. Eng. 2024, 92, 109777. [Google Scholar] [CrossRef]

- Su, C.; Shi, J.; Tambara, L.U.D., Jr.; Yang, Y.; Liu, B.; Revilla-Cuesta, V. Improving the mechanical properties and durability of steam-cured concrete by incorporating recycled clay bricks aggregates from C&D waste. Powder Technol. 2024, 438, 119571. [Google Scholar] [CrossRef]

- Wang, P.; Li, X.; Huo, X.; Ali, S.; Sun, J.; Qin, J.; Liang, K.; Liu, Y. Early hydration and compressive strength of steam cured high-strength concrete based on simplex centroid design method. Case Stud. Constr. Mater. 2022, 17, e01583. [Google Scholar] [CrossRef]

- Zou, P.; Chang, H.-J.; Wang, F.; Cai, Y.-L.; Zhang, Z.; Zhao, Z.; Lv, Z.-D. Effect of steam curing scheme on the early-age temperature field of a prefabricated concrete T-beam. Case Stud. Constr. Mater. 2024, 20, e02787. [Google Scholar] [CrossRef]

- Shen, D.; Yu, Y.; Jin, Z.; Li, N. Effects of crumb rubber particles on the evolution of pore structure in steam-cured concrete under freeze-thaw cycles. J. Build. Eng. 2025, 103, 112138. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, J.; Shen, S.; Zhou, F.; Shi, J.; He, Z. Effects of curing methods of concrete after steam curing on mechanical strength and permeability. Constr. Build. Mater. 2020, 256, 119441. [Google Scholar] [CrossRef]

- An, J.; Yu, Y.; Jin, Z.; Li, N.; Shen, D.; Xiong, C. Experimental and simulation study on capillary water absorption of modified crumb rubber concrete with steam-cured. J. Build. Eng. 2023, 73, 106756. [Google Scholar] [CrossRef]

- Ogawa, Y.; Suzuki, S.; Kawai, K. Impact of air exposure post-steam curing on the internal curing efficiency of porous ceramic roof-tile waste fine aggregate in steam-cured fly ash concrete. Mater. Lett. 2024, 366, 136576. [Google Scholar] [CrossRef]

- Qian, Y.; Yang, D.; Zhao, J.; Mao, X.; Ren, G.; Cao, Z. Development of cementless alkali-activated ultra-high performance concrete under various steam curing regimes: Mechanical properties, permeability, and microstructure. J. Build. Eng. 2025, 101, 111857. [Google Scholar] [CrossRef]

- Yao, B.; Ren, G.; Huang, J.; Gao, X. Influence of self-ignition coal gangue on properties of foam concrete with steam curing. Case Stud. Constr. Mater. 2022, 17, e01316. [Google Scholar] [CrossRef]

- Zhu, X.; Lei, P.; Chen, X.; Bu, J. Influence of steam curing on cyclic triaxial characteristics of recycled aggregate concrete: Experimental analysis and DEM simulation. Eng. Fract. Mech. 2024, 312, 110643. [Google Scholar] [CrossRef]

- Nguyen, H.V.; Nakarai, K.; Okazaki, A.; Karasawa, H.; Tadokoro, Y.; Tsujino, M. Applicability of a simplified estimation method to steam-cured expansive concrete. Cem. Concr. Compos. 2019, 95, 217–227. [Google Scholar] [CrossRef]

- Davraz, M.; Isildar, N.; Kaplan, A.N. Investigation of the effects of steam curing of concrete at different temperatures on cost and compressive strength by response surface methodology. Constr. Build. Mater. 2025, 489, 140589. [Google Scholar] [CrossRef]

- Han, X.; Wei, D.; Wang, P.; Wang, M.; Du, Z.; Ling, Z. Microstructure characteristics and evolution of pipe pile concrete under centrifugation and steam curing. Constr. Build. Mater. 2024, 450, 138554. [Google Scholar] [CrossRef]

- Kong, Y.; Liu, S.; Wang, P. Effects of microwave curing on the compressive strength development and hydration of cement-granulated blast furnace slag composite system. Constr. Build. Mater. 2021, 270, 121432. [Google Scholar] [CrossRef]

- Rattanadecho, P.; Makul, N.; Pichaicherd, A.; Chanamai, P.; Rungroungdouyboon, B. A novel rapid microwave-thermal process for accelerated curing of concrete: Prototype design, optimal process and experimental investigations. Constr. Build. Mater. 2016, 123, 768–784. [Google Scholar] [CrossRef]

- Kastiukas, G.; Ruan, S.; Liang, S.; Zhou, X. Development of precast geopolymer concrete via oven and microwave radiation curing with an environmental assessment. J. Clean. Prod. 2020, 255, 120290. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, R.; Shui, Z.; Liu, K. Hydration kinetics and microstructure development of Ultra-High Performance Concrete (UHPC) subjected to microwave pre-curing. Cem. Concr. Compos. 2022, 129, 104484. [Google Scholar] [CrossRef]

- Mangat, P.S.; Grigoriadis, K.; Abubakri, S. Microwave curing parameters of in-situ concrete repairs. Constr. Build. Mater. 2016, 112, 856–866. [Google Scholar] [CrossRef]

- Mohammed, H.; Sadique, M.; Shaw, A.; Bras, A. The influence of incorporating plastic within concrete and the potential use of microwave curing; A review. J. Build. Eng. 2020, 32, 101824. [Google Scholar] [CrossRef]

- Han, Y.; Meng, L.-Y.; Lin, R.; Kim, S.; Kim, T.; Wang, X.-Y. Evaluating the sustainability of microwave pre-cured high-volume slag concrete: Mechanical properties, environmental impact and cost-benefit analysis. J. Build. Eng. 2024, 96, 110663. [Google Scholar] [CrossRef]

- Deng, P.; Chang, Z.; Leng, H.; Zhong, H.; Chen, Y.; Ren, Y. Experimental investigation on properties of gold tailings recycled brick-concrete aggregate concrete under microwave curing. J. Build. Eng. 2024, 95, 110104. [Google Scholar] [CrossRef]

- Tang, T.; Cai, L.; You, K.; Liu, M.; Han, W. Effect of microwave pre-curing technology on carbide slag-fly ash autoclaved aerated concrete (CS-FA AAC): Porosity rough body formation, pore characteristics and hydration products. Constr. Build. Mater. 2020, 263, 120112. [Google Scholar] [CrossRef]

- Zhou, F.; Pan, G.; Meng, H.; Mi, R. Effect of secondary curing on the performance of microwave cured concrete. Constr. Build. Mater. 2022, 330, 127256. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, Y.; Li, S. Effects of isothermal microwave curing on steel fibre-reinforced reactive powder concrete: Strength, microstructure and hydration products. Constr. Build. Mater. 2021, 302, 124435. [Google Scholar] [CrossRef]

- Han, Y.; Park, K.-B.; Yang, B.; Wang, X.-Y. Optimizing and designing the effects of microwave pre-curing on the properties of ternary blended concrete with slag and fly ash using the simplex centroid method. Constr. Build. Mater. 2024, 419, 135443. [Google Scholar] [CrossRef]

- Chen, J.; Li, S.; Gao, X.; Li, X. Study of the effects of microwave curing on ultra-high-performance concrete based on dielectric properties. Case Stud. Constr. Mater. 2024, 21, e04104. [Google Scholar] [CrossRef]

- Liu, X.; Guo, Y.; Zhang, Y.; Xia, J.; Ma, G. Synergistic integration of electromagnetic wave absorption and microwave curing technologies: Early-strength optimization in microwave-cured concrete with absorbent materials. Constr. Build. Mater. 2025, 489, 142229. [Google Scholar] [CrossRef]

- Li, Q.; Wang, H.; Xue, H.; Zhang, Q.; Dong, H. The effect of microwave curing on the static and dynamic mechanical properties and thermal brittleness of coal gangue concrete. Constr. Build. Mater. 2025, 463, 140025. [Google Scholar] [CrossRef]

- Rashid, K.; Fatima, N.; Ul Haq, E.; Shaheen, N.; Ju, M. Feasibility assessment of microwave-cured lightweight aggregate concrete by mineral encapsulated self-healing. J. Build. Eng. 2023, 76, 107084. [Google Scholar] [CrossRef]

- Yuan, C.; Yong, L.; Ziao, C.; Tianyi, Y.; Rui, Y. Development of Ultra-High Performance Concrete (UHPC) matrix based on recycled concrete fines subjected to coupling curing of microwave and wet carbonation. J. Build. Eng. 2024, 95, 110038. [Google Scholar] [CrossRef]

- Prommas, R.; Rungsakthaweekul, T. Effect of Microwave Curing Conditions on High Strength Concrete Properties. Energy Procedia 2014, 56, 26–34. [Google Scholar] [CrossRef]

- Cai, L.; Tang, T.; Liu, M.; Xie, D. Comparative study of carbide slag autoclaved aerated concrete (AAC) manufactured under thermal oven and microwave pre-curing process: Foaming course, rough body strength and physic-mechanical properties. Constr. Build. Mater. 2020, 236, 117550. [Google Scholar] [CrossRef]

- Makul, N.; Rattanadecho, P.; Pichaicherd, A. Accelerated microwave curing of concrete: A design and performance-related experiments. Cem. Concr. Compos. 2017, 83, 415–426. [Google Scholar] [CrossRef]

- Li, Q.; Wang, H.; Xue, H.; Su, H.; Tang, C. The impact of microwave curing on the strength and microstructure of coal gangue concrete. Constr. Build. Mater. 2024, 443, 137802. [Google Scholar] [CrossRef]

- Jeon, S.-M.; Liyew, G.; Kim, H.-K. Service life assessment of accelerated carbonation-cured concrete considering weathering carbonation and chloride ingression. J. Build. Eng. 2025, 103, 112094. [Google Scholar] [CrossRef]

- Adem, J.K.; Seo, J.; Park, S.; Kim, G.M. Effects of low-lime calcium silicate cement addition on the hydration, carbonation, and microstructural characteristics of OPC pastes by carbonation curing. J. Build. Eng. 2025, 107, 112683. [Google Scholar] [CrossRef]

- Xian, X.; Zhang, D.; Lin, H.; Shao, Y. Ambient pressure carbonation curing of reinforced concrete for CO2 utilization and corrosion resistance. J. CO2 Util. 2022, 56, 101861. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, M.; Li, M.; Mao, J.; Wu, Z.; Cheng, Z.; Shi, R.; Du, S.; Ren, J. Study on the properties and eco-sustainability of early-age carbonation cured cement paste with recycled concrete slurry waste substitution. Case Stud. Constr. Mater. 2024, 21, e03862. [Google Scholar] [CrossRef]

- Shang, X.; Chen, Y.; Qi, Y.; Chang, J.; Yang, J.; Qu, N. Comparative life cycle environmental assessment of recycled aggregates concrete blocks using accelerated carbonation curing and traditional methods. Constr. Build. Mater. 2023, 404, 133207. [Google Scholar] [CrossRef]

- Han, X.; Yan, J.; Huo, Y.; Chen, T. Effect of carbonation curing regime on 3D printed concrete: Compressive strength, CO2 uptake, and characterization. J. Build. Eng. 2024, 98, 111341. [Google Scholar] [CrossRef]

- Beltrame, N.A.M.; Dias, R.L.; Witzke, F.B.; Medeiros-Junior, R.A. Effect of carbonation curing on the physical, mechanical, and microstructural properties of metakaolin-based geopolymer concrete. Constr. Build. Mater. 2023, 406, 133403. [Google Scholar] [CrossRef]

- Zheng, Y.; Ye, T.; Qian, X.; Zhao, Y.; Cui, K.; Cheng, Y.; Yang, J.; Li, H.; Shen, P.; Poon, C.-s. Deciphering the degradation mechanism of carbonation-cured phosphogypsum concrete under wet–dry cycles: A multiscale insight into microstructural evolution. J. Build. Eng. 2025, 112, 113878. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Ishak, S.; Zhang, G.-Z.; Wang, X.-Y. Carbonation curing behavior and performance improvement of recycled coral waste concrete. J. Build. Eng. 2024, 90, 109473. [Google Scholar] [CrossRef]

- Liu, C.; Liu, P.; Tang, K.; Guan, S.; Luo, X.; Zhang, L.; Liu, L. Carbonation curing and long-term shrinkage performance of manufactured sand concrete with different strength grades from tunnel muck. Constr. Build. Mater. 2025, 467, 140406. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, J.; Zhang, P. Effects of carbonation curing regimes on alkalinity of self-compacting concretes for marine artificial reef. Constr. Build. Mater. 2023, 369, 130614. [Google Scholar] [CrossRef]

- Sun, R.; Shen, P.; Zhang, X.; Qin, Q.; Tao, Y.; Wang, D.; Liu, Z.; Poon, C.-s. Effects of curing regimes and binder designs on steel slag-based carbonated aerated concrete (CAC): Reaching a balance between pre-hydration and carbonation. Cem. Concr. Res. 2025, 195, 107905. [Google Scholar] [CrossRef]

- Guo, B.; Chu, G.; Yu, R.; Wang, Y.; Yu, Q.; Niu, D. Effects of sufficient carbonation on the strength and microstructure of CO2-cured concrete. J. Build. Eng. 2023, 76, 107311. [Google Scholar] [CrossRef]

- Cao, S.; She, A.; Ye, C.; Chu, W.; Liao, G.; Wang, T.; Wei, Y.; Yao, W. Fenton-like catalytic cementitious coating with CoMnFe-LDH@recycled concrete powder for water treatment: In-situ degradation of oxytetracycline and enhanced carbonation curing. Constr. Build. Mater. 2025, 472, 140908. [Google Scholar] [CrossRef]

- Jeon, I.K.; Qudoos, A.; Kim, H.G. Influence of carbonation curing on hydration and microstructure of magnesium potassium phosphate cement concrete. J. Build. Eng. 2021, 38, 102203. [Google Scholar] [CrossRef]

- Zuo, W.; Zhao, X.; Luo, J.; He, Z.; Zhao, J. Investigating the impact of carbonation curing concentrations on the mechanical properties and microstructure of recycled concrete. J. Build. Eng. 2024, 96, 110465. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, A.; Singh, A.; Tam, V.W.Y. Performance enhancement of recycled concrete through carbonation during ready-mix and curing. Constr. Build. Mater. 2025, 458, 139665. [Google Scholar] [CrossRef]

- Zhang, D.; Feng, B.; Jaworska, B.; Ellis, B.R.; Fancy, S.; Sick, V.; Li, V.C. Pilot-scale validation of CO2 utilization for greener and tougher infrastructure through carbonation curing of bendable concrete. J. Clean. Prod. 2025, 491, 144845. [Google Scholar] [CrossRef]

- Xian, X.; Mahoutian, M.; Shao, Y. Production of concrete pipes by carbonation curing in an inflatable enclosure. Constr. Build. Mater. 2023, 363, 129861. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, C.; Shi, Q.; Tan, X.; Meng, W. Recycling waste glass aggregate in concrete: Mitigation of alkali-silica reaction (ASR) by carbonation curing. J. Clean. Prod. 2022, 370, 133545. [Google Scholar] [CrossRef]

- Liu, T.; Wang, H.; Zou, D.; Long, X.; Miah, M.J.; Li, Y. Strength recovery of thermally damaged high-performance concrete subjected to post-fire carbonation curing. Cem. Concr. Compos. 2023, 143, 105273. [Google Scholar] [CrossRef]

- Guo, B.; Yu, R.; Chen, N.; Han, P.; Wang, Y.; Niu, D. Bond behaviors between GFRP bars and CO2-cured seawater sea-sand concrete with sufficient carbonation. Constr. Build. Mater. 2024, 436, 136903. [Google Scholar] [CrossRef]

- Ezzati, H.R.; Rahmani, H. Sulfuric acid attack neutralizing through carbonation curing of hydrated lime-modified concretes. Constr. Build. Mater. 2024, 417, 135130. [Google Scholar] [CrossRef]

- Bawab, J.; El-Hassan, H.; El-Dieb, A.; Khatib, J. Accelerated carbonation curing of concrete incorporating calcium carbide residue. J. Build. Eng. 2024, 88, 109258. [Google Scholar] [CrossRef]

- Liang, C.; Lu, N.; Ma, H.; Ma, Z.; Duan, Z. Carbonation behavior of recycled concrete with CO2-curing recycled aggregate under various environments. J. CO2 Util. 2020, 39, 101185. [Google Scholar] [CrossRef]

- Yang, Z.; Xie, Y.; He, J.; Wang, F.; Zeng, X.; Ma, K.; Long, G. Influence of direct electric curing on the hydration and microstructure of cement paste excluding ohmic heating. Constr. Build. Mater. 2023, 369, 130546. [Google Scholar] [CrossRef]

- Mao, J.; Xia, Y.; Li, H.; Dai, F.; Guan, S.; Ren, J. Feasibility and application of novel electrical curing method for constant-temperature hardening of concrete at cold regions. J. Build. Eng. 2024, 97, 110899. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Y.; Liu, Y.; Ma, G. Flexural performance of RC beams with electric activation curing at subzero temperatures followed by 800-day natural exposure. Eng. Struct. 2025, 343, 121145. [Google Scholar] [CrossRef]

- Cecini, D.; Austin, S.A.; Cavalaro, S.; Palmeri, A. Accelerated electric curing of steel-fibre reinforced concrete. Constr. Build. Mater. 2018, 189, 192–204. [Google Scholar] [CrossRef]

- Wang, P.-J.; Peng, G.-F.; Ding, H.; Guo, X.-H.; Jia, Y.-J. Mechanical properties and microstructure of cementless ultra-high performance concrete activated by calcium carbide residue under thermal curing with electrical-blanket covering. Constr. Build. Mater. 2025, 492, 143024. [Google Scholar] [CrossRef]

- Kovtun, M.; Ziolkowski, M.; Shekhovtsova, J.; Kearsley, E. Direct electric curing of alkali-activated fly ash concretes: A tool for wider utilization of fly ashes. J. Clean. Prod. 2016, 133, 220–227. [Google Scholar] [CrossRef]

- Fang, K.; Mao, J.; Wang, P.; He, J.; Jin, L. Durability control of sea-sand concrete components utilizing strong electric field during early curing period. Constr. Build. Mater. 2022, 344, 128221. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Cai, Y.; Ren, X.; Xiang, Y.; Yang, K.; Li, Y.; Tang, Z.; Long, G. Effect of precuring time on the strength, microstructure, and energy consumption of direct electric curing concrete. J. Build. Eng. 2023, 80, 107963. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, W.; Ma, G. Electric activation curing behaviour of reinforced concrete beam under severely-cold environment: Breakthrough of rapid concrete manufacturing at cold region. Constr. Build. Mater. 2023, 384, 131443. [Google Scholar] [CrossRef]

- He, Y.; Zhang, M.; Li, W.; Li, M.; Zhang, S.; Deng, G.; Wang, X. Electric heating curing regimes of temperature self-controlled concrete with nano-carbon black for performance improvement in cold regions. Cem. Concr. Compos. 2024, 152, 105689. [Google Scholar] [CrossRef]

- Wang, J.; An, J.; Li, Y.; Xiang, Y.; Xiao, Q.; Tang, Z.; Long, G. Influencing factors of the temperature rise of direct electric curing concrete and its effect on concrete properties. Constr. Build. Mater. 2024, 438, 137110. [Google Scholar] [CrossRef]

- Dong, S.; Ouyang, X.; Ding, S.; Ashour, A.; Han, B. Tailoring mechanical properties and microstructure of stainless steel wires-modified ultra-high performance concrete via direct electric curing. Constr. Build. Mater. 2025, 479, 141425. [Google Scholar] [CrossRef]

- Li, G.; Zhou, J.; Yue, J.; Gao, X.; Wang, K. Effects of nano-SiO2 and secondary water curing on the carbonation and chloride resistance of autoclaved concrete. Constr. Build. Mater. 2020, 235, 117465. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, Z.; Li, G.; Jiang, H.; Li, Z.; Yang, X.; Lu, S. Influence mechanism of autoclaved aerated concrete waste on the hydration of blended cement with high-volume slag. Constr. Build. Mater. 2024, 447, 138180. [Google Scholar] [CrossRef]

- Watcharapong Wongkeo, A.C. Compressive strength, microstructure and thermal analysis of autoclaved and air cured structural lightweight concrete made with coal bottom ash and silica fume. Mater. Sci. Eng. 2010, 527, 3676–3684. [Google Scholar] [CrossRef]

- Chen, T.; Gao, X.; Ren, M. Effects of autoclave curing and fly ash on mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2018, 158, 864–872. [Google Scholar] [CrossRef]

- Luo, S.; Li, S.; Wang, Y.; Liu, S.; Zhang, H.; Yang, L.; Sun, G. Mechanism of hydration and structure formation of autoclaved aerated concrete with multiple solid wastes. Constr. Build. Mater. 2025, 467, 140344. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Jaafar, M.S.; Al-Negheimish, A.; Abdullah, A.; Taufiq-Yap, Y.H.; Noorzaei, J.; Alawad, O.A. Properties of high strength concrete using white and dune sands under normal and autoclaved curing. Constr. Build. Mater. 2012, 27, 218–222. [Google Scholar] [CrossRef]

- Tian, C.; Zhao, L.; He, X.; Su, Y.; Wang, Y.; Yang, J.; Li, Y.; Dong, Z.; Chen, N.; Li, S. Enhancing mechanism of mechanical properties of lightweight and high-strength concrete prepared with autoclaved silicate lightweight aggregate. J. Build. Eng. 2024, 98, 111102. [Google Scholar] [CrossRef]

- Wei, R.; Ji, G.; Sakai, Y. Enhancing performance and achieving carbon negativity in botanical concrete via autoclave pre-treatment and high kraft lignin addition. Dev. Built Environ. 2025, 23, 100694. [Google Scholar] [CrossRef]

- Yang, J.; Wang, F.; He, X.; Su, Y.; Wang, T.; Ma, M. Potential usage of porous autoclaved aerated concrete waste as eco-friendly internal curing agent for shrinkage compensation. J. Clean. Prod. 2021, 320, 128894. [Google Scholar] [CrossRef]

- Khunt, Y.; Nathwani, V.; Patel, H.; Joshi, T.; Gandhi, D. Investigation on properties of autoclave aerated concrete using different pre-curing and curing techniques. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Li, G.; Chen, X.; Zhang, Y.; Zhuang, Z.; Lv, Y. Studies of nano-SiO2 and subsequent water curing on enhancing the frost resistance of autoclaved PHC pipe pile concrete. J. Build. Eng. 2023, 69, 106209. [Google Scholar] [CrossRef]

- Ren, Z.; Ding, M.; Li, D. Study on the monotonic axial compression behavior of the GFRP confined autoclaved steel slag blocks compound concrete circular column. J. Build. Eng. 2025, 105, 112397. [Google Scholar] [CrossRef]

- Yu, Z.; Zhou, H.; Wang, J.; Meng, H.; Sun, J.; Wei, S.; Hu, Y.; Ye, J. The influence of uncalcined coal gangue on the products and reaction processes of autoclaved aerated concrete (AAC): A comparison study. J. Build. Eng. 2025, 110, 113081. [Google Scholar] [CrossRef]

- Shi, L.; Zheng, Z.; Yao, Y.; Li, Y.; Ma, X. The quaternary relationship between pore structure-hydration products-compressive strength-thermal conductivity of Autoclaved Aerated Concrete-a review. J. Build. Eng. 2025, 112, 113720. [Google Scholar] [CrossRef]

- Mesecke, K.; Malorny, W.; Warr, L.N. Understanding the effect of sulfate ions on the hydrothermal curing of autoclaved aerated concrete. Cem. Concr. Res. 2023, 164, 107044. [Google Scholar] [CrossRef]

- Mesecke, K.; Malorny, W.; Warr, L.N. Effect of ground quartz sand on properties of high-strength concrete in the steam-autoclaved curing. Cem. Concr. Res. 2000, 30, 193–198. [Google Scholar]

- Wei, J.; Yu, X.; Gao, W.; Yang, Z.; Li, X.; Zhang, H. High-performance autoclaved aerated concrete fabricated by alkali-activated low-silica molybdenum tailings. Constr. Build. Mater. 2025, 484, 141869. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

| Matrix | Application | Water Curing Duration | Effect | Ref |

|---|---|---|---|---|

| OPC, FA | Lightweight concrete | 7–90 days | Autoclaved aerated aggregates improved shrinkage resistance | [27] |

| OPC, SF, steel fibers | UHPC | 7–28 days | Autoclaved aerated concrete waste reduced shrinkage, microstructure densified | [28] |

| OPC, GGBFS, FA, steel fibers | UHPC | 28 days | Autoclaved artificial aggregate improved pore refinement, compressive strength | [29] |

| OPC, SF | In situ concrete | 1–7 days | Short-term water curing followed by sealing compounds can achieve high durability in hot climates. | [30] |

| OPC, SF | Cube samples | 28 days | SF wet cured concrete achieved 13% higher compressive strength than air cured concrete | [31] |

| OPC, SF, MK, FA, steel fibers | UHPC | 7 days | Compressive strength increased for MK concrete samples after 21 wet cycles | [32] |

| OPC, FA | Concrete samples | 28–90 days | 90 days wet curing reduced carbonation depths of 53.5% | [33] |

| Matrix | Application | Temperature °C | Duration | Effect | Ref |

|---|---|---|---|---|---|

| OPC, FA, SF | Precast high strength concrete | 85–20 | 18 h | Increased early compressive strength, lower porosity, reduced CH content | [39] |

| OPC, FA, Slag powder | Prefabricated T beams | 50–60 | 10 h | Increased compressive and elastic modulus | [40] |

| OPC, FA, crumb rubber | Precast elements | 20–60 | 12 h | Increased porosity | [41] |

| OPC, admixtures | Prefabricated elements | 20–60 | 12 h | Increased early strength, increased porosity | [42] |

| OPC, crumb rubber | Prefabricated elements | 20–60 | 12 h | Reduced compressive strength | [43] |

| OPC, FA | Geopolymer concrete | 20–50 | 24 h | Increased porosity when exposed to air curing after steam duration- reducing mechanical strengths | [44] |

| GGBS | Precast elements | 60–90 | 1–7 days | Higher temperatures reduce strength and increase porosity | [45] |

| OPC, coal gangue | Foam concrete | 40 | 12 h | Increased early strength but had a reduced strength at later stages | [46] |

| OPC, GGBFS | Recycled aggregate concrete | 40–80 | 11–14 h | Increased temperature increases internal damage | [47] |

| OPC, admixtures | Expansive concrete | 20–65 | 24 h | Increased expansive strain on specimens | [48] |

| OPC, admixtures | Prefabricated concrete elements | 60–80 | 4 h | Early increase in strength, reduced strength with increased temperatures | [49] |

| OPC, SCMs | Prestressed high strength concrete | 85 | 8 h | Increased porosity, faster hydration | [50] |

| Matrix | Application | Temperature °C | Heating Duration | Effect | Ref |

|---|---|---|---|---|---|

| OPC, slag | Concrete | 70–110 | 2–4 min | Increased strength and porosity at 28-days | [57] |

| OPC, gold tailing recycled brick aggregate | Concrete | 40–60 | 6 h | Accelerate early compressive strength by 12% | [58] |

| OPC, carbide, slag, FA | Aerated concrete | 40–70 | 1–2.5 h | Accelerates foaming and thickening of slurry, increased porosity and early strength | [59] |

| OPC | Concrete | 55 | 7.5 h | Increased microcracks and early strength | [60] |

| OPC, steel fibers | Reactive powder concrete | 40–80 | 30 min | 30-min curing achieved 45% of the 28-day compressive strength | [61] |

| FA, GGBS, OPC | Concrete | N/A | 2 min | Increased compressive and durability characteristics | [62] |

| OPC and SF | UHPC | 30–50 | 10–30 min | Accelerated hydration, denser microstructure | [63] |

| OPC | Rapid strength concrete | 40–65 | 40 min | Accelerated hydration, denser microstructure, early strength improvement | [64] |

| OPC, coal gangue | Precast slope protection | N/A | 6–50 min | 79% compressive strength increase compared to standard | [65] |

| OPC, FA | Autonomous self-healing concrete | N/A | 4–5 min | 100% crack closure, 87% compressive strength recovery | [66] |

| OPC, recycled concrete | UHPC | 60–80 | 5 min | Efficient carbonation of recycled concrete fines, reduced energy requirement by 27% | [67] |

| OPC | Precast elements/repair works | N/A | 5–30 min | Rapid compressive strength increase, denser matrix | [68] |

| OPC, carbide slag | Aerated concrete | 40–70 | 25–90 min | Accelerated foaming, reduced energy use | [69] |

| OPC | Precast elements, repair works | 78–158.5 | 15–45 min | Long term strength reduction and shrinkage | [70] |

| OPC, coal gangue | Prefabricated elements | 60–80 | 9–50 min | Increase compressive strength at early and later stages, improved durability | [71] |

| Matrix | Application | Carbonation Duration | Effect | Ref |

|---|---|---|---|---|

| OPC, GGBS, phosphogypsum | Precast concrete | 0.5–1 h 99% CO2 3 bar pressure | Improved durability, densified matrix with CaCO3 | [79] |

| OPC, SF, limestone powder | UHPC | 5 min | Combination of carbonation and microwave curing to improve later strength | [67] |

| OPC, coral powder | Mortar | 28 days 10–37% CO2 | Refines microstructure, enhances durability | [80] |

| OPC, muck sand | Manufactured sand concrete | 5 h | Reduced mechanical strength in later stages | [81] |

| OPC | Self-compacting concrete | 14–28 days | Maintained compressive strength and lowered surface pH levels | [82] |

| OPC, FA, GGBFS, flue gas, gypsum, lime | Aerated concrete | 2–48 h | Improved pore structure, increased compressive strength | [83] |

| OPC, FA | Precast elements | 28 days | Increased compressive strength and refined interfacial transitional zones | [84] |

| OPC | Stormwater treatment pipes | 48 h | Increased durability and bonding of the coating | [85] |

| Magnesia, potassium dihydrogen phosphate, and borax | Repair material | 2–60 days | Improved interfacial transitional zones, refined microstructure | [86] |

| Composite silicate cement, FA | Recycled aggregate concrete | 12 h | Improved compressive strength and freeze/thaw resistance | [87] |

| OPC, recycled aggregates | Ready-mix recycled concrete | 28 days | 93.8% increase of compressive strength, denser interfacial transitional zones | [88] |

| OPC, FA, PVA fibers | Bendable concrete | 24 h | Improved mechanical properties, denser microstructure, improved durability | [89] |

| OPC | Precast reinforced pipes | 12 h | Higher early strength, reduced absorption | [90] |

| OPC, waste glass | Mortar/concrete | 6–12 h | Mitigation of alkali silica reaction, improved strength and reduced porosity | [91] |

| OPC, SF, PP fibers | High performance concrete | 30 days | Denser microstructure | [92] |

| OPC, FA, GFRP bars | Corrosion resistant reinforced concrete | 56 days | 30% increase of compressive strength, pH level reduced | [93] |

| OPC, hydrated lime | Concrete pipes | 6–24 h | 68% reduction in acid-induced mass loss | [94] |

| OPC, calcium carbide residue | Precast concrete | 4–20 h | Porosity reduction | [95] |

| OPC, recycled fine aggregate | Recycled aggregate concrete | 56 days | 37% higher compressive strength, improved durability | [96] |

| Matrix | Application | Heating Duration (Intermittent) | Effect | Ref |

|---|---|---|---|---|

| OPC | In situ concrete | 21 days | Improved mechanical results, lower energy requirement than steam curing | [7] |

| OPC, FA | Reinforced concrete beams | 2 days | Higher ultimate load, reduced cracking | [99] |

| OPC, SF, FA | Steel fiber concrete | 7 h | Increased porosity, increased early age flexural strength | [100] |

| FA | Alkali activated FA concrete | 2–8 h | High early strength gain | [102] |

| OPC | Reinforced concrete columns | 2 h | Sustained durability in sea conditions | [103] |

| OPC | Rapid curing concrete | 7 h | Early age strength development and reduced porosity | [104] |

| OPC, FA | Reinforced concrete beams | 2 days | Higher flexural strength | [105] |

| OPC | In situ concrete | 3–7 days | Promotion of hydration, denser microstructure | [106] |

| OPC, FA | Precast concrete | 6 h | Increased porosity, increased early age strength | [107] |

| OPC, FA, SF | Steel fiber in UHPC | 8–12 h | Increased compressive strength | [108] |

| Matrix | Application | Temperatures °C | Effect | Ref |

|---|---|---|---|---|

| OPC, cloud concrete stone | Lightweight concrete | 125–200 | Reduced shrinkage, improved density and strength | [115] |

| Recycled concrete powder, natural fibers | Botanical concrete | 160–180 | Improved water resistance and bonding strength of fibres | [116] |

| OPC | Aerated concrete | 20–55 | Reduced shrinkage, delayed cracking, refined microstructure | [117] |

| OPC, FA, lime powder | Aerated concrete blocks | 185 | Higher strength and denser microstructure | [118] |

| OPC | Prestressed pipes | 180 | Addition of Nano-SiO2 improved durability when utilising autoclave | [119] |

| OPC, FA, slag | Steel slag concrete blocks | 192 | Reduced strength | [120] |

| OPC, gypsum, FA, coal gangue | Aerated concrete | 180 | Lower mechanical strength | [121] |

| OPC, gypsum, FA | Lightweight concrete | 180–200 | Refined pore structure, enhanced strength | [122] |

| OPC, lime, aluminum powder | Aerated concrete | 184–193 | Sulfate delayed C-S-H formation, fewer pores, improved durability | [123] |

| OPC | Prestressed concrete pipes | 182 | Improved microstructure and increased strength | [124] |

| OPC, lime, gypsum | Aerated concrete | 180 | Strength increased with 1% NaOH, pore structure refined | [125] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haigh, R.; Ameri Sianaki, O. Traditional and Advanced Curing Strategies for Concrete Materials: A Systematic Review of Mechanical Performance, Sustainability, and Future Directions. Appl. Sci. 2025, 15, 11055. https://doi.org/10.3390/app152011055

Haigh R, Ameri Sianaki O. Traditional and Advanced Curing Strategies for Concrete Materials: A Systematic Review of Mechanical Performance, Sustainability, and Future Directions. Applied Sciences. 2025; 15(20):11055. https://doi.org/10.3390/app152011055

Chicago/Turabian StyleHaigh, Robert, and Omid Ameri Sianaki. 2025. "Traditional and Advanced Curing Strategies for Concrete Materials: A Systematic Review of Mechanical Performance, Sustainability, and Future Directions" Applied Sciences 15, no. 20: 11055. https://doi.org/10.3390/app152011055

APA StyleHaigh, R., & Ameri Sianaki, O. (2025). Traditional and Advanced Curing Strategies for Concrete Materials: A Systematic Review of Mechanical Performance, Sustainability, and Future Directions. Applied Sciences, 15(20), 11055. https://doi.org/10.3390/app152011055