Performance-Based Maintenance and Operation of Multi-Campus Critical Infrastructure Facilities Using Supply Chain Multi-Choice Goal Programming

Abstract

1. Introduction

2. Literature Review

2.1. Building Maintenance Management: Definitions and Knowledge Base

2.2. Maintenance of Critical Buildings and Infrastructure

2.3. Energy Efficiency in Maintenance

2.4. Maintenance Resource Sharing Across Multi-Campus Systems

3. Methods

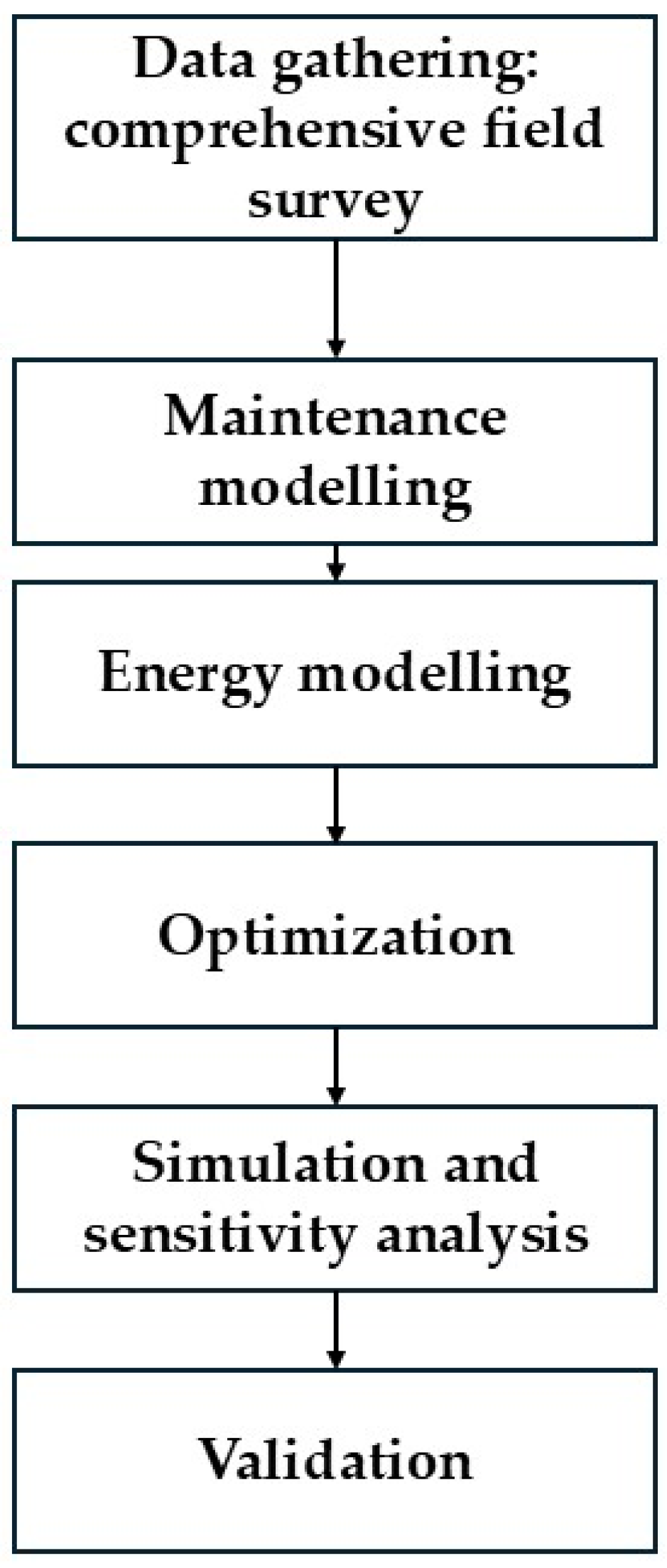

Research Stages

- Data gathering: Development of performance and maintenance databases for facilities and campuses, including estimated costs per square meter. This stage included a comprehensive field survey of the buildings and infrastructures using B.P.I. survey and estimated costs of maintenance based on the buildings age and occupancy (low, standard and high).

- Energy modeling: Development of an energy-efficiency model incorporating replacement of low-grade lighting with LED systems, accounting for life cycle, failure rates, and reduced corrective maintenance.

- Optimization: Application of the MCGP framework to integrate maintenance and energy costs under performance constraints.

- Simulation and sensitivity analysis: Evaluation of scenarios with varying facility life cycle expectancies to determine optimal trade-offs between costs and performance continuity.

- Validation: Case-study implementation of the model on campus infrastructures, with results compared against baseline assumptions and tested through sensitivity analysis.

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Zhao, J.; Xiong, Z.; Zhuang, J.; Wang, M. Integrating Grey–Green Infrastructure in Urban Stormwater Management: A Multi–Objective Optimization Framework for Enhanced Resilience and Cost Efficiency. Appl. Sci. 2025, 15, 3852. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, M.; Zhang, D.; Lu, Z.; Bakhshipour, A.E.; Liu, M.; Jiang, Z.; Li, J.; Tan, S.K. Multi-stage planning of LID-GREI urban drainage systems in response to land-use changes. Sci. Total Environ. 2023, 859, 160214. [Google Scholar] [CrossRef]

- Shohet, I.M.; Straub, A. Performance-based-maintenance: A comparative study between the Netherlands and Israel. Int. J. Strateg. Prop. Manag. 2013, 17, 199–209. [Google Scholar] [CrossRef]

- Stenbeck, T. Effects of outsourcing and performance-based contracting on innovations. Transp. Res. Rec. 2006, 1948, 3–8. [Google Scholar] [CrossRef]

- Shohet, I.M.; Nobili, L. Performance-Based Maintenance of Public Facilities: Principles and Implementation in Courthouses. J. Perform. Constr. Facil. 2016, 30, 835. [Google Scholar] [CrossRef]

- Selviaridis, K.; Wynstra, F. Performance-based contracting: A literature review and future research directions. Int. J. Prod. Res. 2015, 53, 3505–3540. [Google Scholar] [CrossRef]

- Signorini, M.; Pomè, A.P. Shaping the future of facility management. Market and literature insights on digital twin adoption. Facilities 2025, 43, 818–834. [Google Scholar] [CrossRef]

- Wang, T.; Gan, V.J.L. Automated joint 3D reconstruction and visual inspection for buildings using computer vision and transfer learning. Autom. Constr. 2023, 149, 104810. [Google Scholar] [CrossRef]

- Abidi, M.H.; Mohammed, M.K.; Alkhalefah, H. Predictive Maintenance Planning for Industry 4.0 Using Machine Learning for Sustainable Manufacturing. Sustainability 2022, 14, 3387. [Google Scholar] [CrossRef]

- IS-1525 (Part 3); Building Maintenance: Non-Residential Buildings and Their Nearby Surroundings. Israel Standards Institute: Tel Aviv, Israel, 2002.

- Wang, K.C.; Almassy, R.; Wei, H.H.; Shohet, I.M. Integrated Building Maintenance and Safety Framework: Educational and Public Facilities Case Study. Buildings 2022, 12, 770. [Google Scholar] [CrossRef]

- Scolaro, T.P. Life cycle integrated multi-criteria decision model for roof assessment. Energy Build. 2025, 336, 115628. [Google Scholar] [CrossRef]

- Shohet, I.M. Building evaluation methodology for setting maintenance priorities in hospital buildings. Constr. Manag. Econ. 2003, 21, 681–692. [Google Scholar] [CrossRef]

- Shohet, I.M.; Lavy, S. Facility maintenance and management: A health care case study. Int. J. Strateg. Prop. Manag. 2017, 21, 170–182. [Google Scholar] [CrossRef]

- Tamburić, J.; Nikolić, V.; Stojić, D.; Nikolić, O. Life Cycle Approach to Shopping Mall Redevelopment: A Model for Service Life Design. Appl. Sci. 2025, 15, 7509. [Google Scholar] [CrossRef]

- Zbiciak, A.; Walasek, D.; Nagirniak, M.; Walasek, K.; Koda, E. Markov Chain Modeling for Predicting the Service Life of Buildings and Structural Components. Appl. Sci. 2025, 15, 9287. [Google Scholar] [CrossRef]

- E1670 Standard Classification for Serviceability of an Office Facility for Management of Operations and Maintenance. Available online: https://store.astm.org/e1670-95ar18.html (accessed on 2 October 2025).

- BS 8210:2020|31 Oct 2020|BSI Knowledge. Available online: https://knowledge.bsigroup.com/products/facilities-maintenance-management-code-of-practice (accessed on 2 October 2025).

- Ministry of Defense. General Building Works Specifications. 2025. Available online: https://mifratclali.mod.gov.il/ (accessed on 2 October 2025).

- NFPA 96 Standard Development. Available online: https://www.nfpa.org/codes-and-standards/nfpa-96-standard-development/96 (accessed on 2 October 2025).

- Sharif, S.A.; Hammad, A. Developing surrogate ANN for selecting near-optimal building energy renovation methods considering energy consumption, LCC and LCA. J. Build. Eng. 2019, 25, 100790. [Google Scholar] [CrossRef]

- Zhu, X.; Du, Z.; Jin, X.; Chen, Z. Fault diagnosis based operation risk evaluation for air conditioning systems in data centers. Build. Environ. 2019, 163, 106319. [Google Scholar] [CrossRef]

- Gunay, H.B.; Shen, W.; Newsham, G. Data analytics to improve building performance: A critical review. Autom. Constr. 2019, 97, 96–109. [Google Scholar] [CrossRef]

- Louadah, H.; Papadakis, E.; McCluskey, T.L.; Tucker, G. Supporting the Management of Rolling Stock Maintenance with an Ontology-Based Virtual Depot. Appl. Sci. 2024, 14, 1220. [Google Scholar] [CrossRef]

- Ding, Y.; Xia, T.; Zhou, Y.; Wang, Y.; Luo, F.; Zhu, Y.; Xi, L. A hybrid metaheuristic for joint decision-making in remanufacturing-integrated operation and maintenance of complex manufacturing systems. Adv. Eng. Inform. 2026, 69, 103827. [Google Scholar] [CrossRef]

- Gan, S.; Zhang, X.; Coit, D.W.; Wang, X. Optimization of maintenance and spares inventory with dependence between the system and environment. Reliab. Eng. Syst. Saf. 2026, 265, 111479. [Google Scholar] [CrossRef]

- Tan, S.; Hu, Q.; Guo, C.; Zhu, D.; Dong, E.; Zhang, F. Operational readiness-oriented condition-based maintenance and spare parts optimization for multi-state systems. Reliab. Eng. Syst. Saf. 2025, 264, 111367. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Z.; Guo, K.; Gu, L.; Wei, H. Integrated maintenance and spare parts inventory optimization with transshipments for multi-fleet systems. Reliab. Eng. Syst. Saf. 2026, 265, 111529. [Google Scholar] [CrossRef]

- Shi, Y.; Xiang, Y.; Xiao, H.; Xing, L. Joint optimization of budget allocation and maintenance planning of multi-facility transportation infrastructure systems. Eur. J. Oper. Res. 2021, 288, 382–393. [Google Scholar] [CrossRef]

- Seyedashraf, O.; Bottacin-Busolin, A.; Harou, J.J. A design framework for considering spatial equity in sustainable urban drainage infrastructure. Sustain. Cities Soc. 2022, 85, 103960. [Google Scholar] [CrossRef]

- Khalifi, N.B.; Avgoustaki, D.D.; Bartzanas, T. Integrating life cycle assessment into green infrastructure: A systematic review and meta-analysis of urban sustainability strategies. Front. Sustain. Cities 2025, 7, 1601091. [Google Scholar] [CrossRef]

- Hernández-Chover, V.; Castellet-Viciano, L.; Hernández-Sancho, F. Cost analysis of the facilities deterioration in wastewater treatment plants: A dynamic approach. Sustain. Cities Soc. 2019, 49, 101613. [Google Scholar] [CrossRef]

- Ighravwe, D.E.; Oke, S.A. A multi-criteria decision-making framework for selecting a suitable maintenance strategy for public buildings using sustainability criteria. J. Build. Eng. 2019, 24, 100753. [Google Scholar] [CrossRef]

- Wang, B.; Xia, X.; Cheng, Z.; Liu, L. Optimal maintenance planning in building retrofitting with interacting energy effects. Optim. Control Appl. Methods 2020, 41, 2023–2036. [Google Scholar] [CrossRef]

- Dulce-Chamorro, E.; Martinez-de-Pison, F.J. An advanced methodology to enhance energy efficiency in a hospital cooling-water system. J. Build. Eng. 2021, 43, 102839. [Google Scholar] [CrossRef]

- Loli, A.; Bertolin, C. Application of the Zero Emission Refurbishment method at a district scale. Int. J. Disaster Risk Reduct. 2021, 62, 102393. [Google Scholar] [CrossRef]

- Koroxenidis, E.; Theodosiou, T. Comparative environmental and economic evaluation of green roofs under Mediterranean climate conditions—Extensive green roofs a potentially preferable solution. J. Clean. Prod. 2021, 311, 127563. [Google Scholar] [CrossRef]

- Shivani; Rani, D.; Ebrahimnejad, A.; Gupta, G. Multi-objective non-linear programming problem with rough interval parameters: An application in municipal solid waste management. Complex Intell. Syst. 2024, 10, 2983–3002. [Google Scholar] [CrossRef]

- Singh, S.K.; Yadav, V. Modified goal programming approach for solving multi-objective environmental management problem. Ann. Oper. Res. 2025, 346, 1767–1783. [Google Scholar] [CrossRef]

- Chang, C.T. Multi-choice goal programming model for the optimal location of renewable energy facilities. Renew. Sustain. Energy Rev. 2015, 41, 379–389. [Google Scholar] [CrossRef]

- Abdallah, A.S.H.; Mahmoud, R.M.A.; Aloshan, M.A. Optimizing Urban Spaces: A Parametric Approach to Enhancing Outdoor Recreation Between Residential Areas in Riyadh, Saudi Arabia. Buildings 2025, 15, 1527. [Google Scholar] [CrossRef]

- Baesmat, K.H.; Regentova, E.E.; Baghzouz, Y. A Hybrid machine learning–statistical based method for short-term energy consumption prediction in residential buildings. Energy AI 2025, 21, 100552. [Google Scholar] [CrossRef]

- Aalaei, A.; Davoudpour, H. Revised multi-choice goal programming for incorporated dynamic virtual cellular manufacturing into supply chain management: A case study. Eng. Appl. Artif. Intell. 2016, 47, 3–15. [Google Scholar] [CrossRef]

- Karydas, D.M.; Gifun, J.F. A method for the efficient prioritization of infrastructure renewal projects. Reliab. Eng. Syst. Saf. 2006, 91, 84–99. [Google Scholar] [CrossRef]

- Nguyen, T.D.H.N.; Ly, D.H.; Jang, H.; Dinh, H.N.N.; Ahn, Y. Digital twin framework to enhance facility management for relocatable modular buildings. Autom. Constr. 2025, 176, 106249. [Google Scholar] [CrossRef]

- Biswas, S.; Belamkar, P.; Sarma, D.; Tirkolaee, E.B.; Bera, U.K. A multi-objective optimization approach for resource allocation and transportation planning in institutional quarantine centres. Ann. Oper. Res. 2025, 346, 781–825. [Google Scholar] [CrossRef]

- He-Lambert, L.; English, B.C.; Lambert, D.M.; Shylo, O.; Larson, J.A.; Yu, T.E.; Wilson, B. Determining a geographic high resolution supply chain network for a large scale biofuel industry. Appl. Energy 2018, 218, 266–281. [Google Scholar] [CrossRef]

- Asdrubali, F.; Venanzi, D.; Evangelisti, L.; Guattari, C.; Grazieschi, G.; Matteucci, P.; Roncone, M. An Evaluation of the Environmental Payback Times and Economic Convenience in an Energy Requalification of a School. Buildings 2021, 11, 12. [Google Scholar] [CrossRef]

- Alamin, E.; Kamaruzaman, N.; Kamar, H.M. A pragmatic retrofitting approach to enhancing the thermal, energy and economic performance of an educational building: A case study in Malaysia. Clean. Energy 2023, 7, 1282–1299. [Google Scholar] [CrossRef]

- Papangelopoulou, M.D.; Alexakis, K.; Askounis, D. Assessment Methods for Building Energy Retrofits with Emphasis on Financial Evaluation: A Systematic Literature Review. Buildings 2025, 15, 2562. [Google Scholar] [CrossRef]

- Azouz, M.; Elariane, S. Towards energy efficiency: Retrofitting existing office buildings using smart technologies. J. Eng. Appl. Sci. 2023, 70, 147. [Google Scholar] [CrossRef]

- Walter, T.; Sohn, M.D. A regression-based approach to estimating retrofit savings using the Building Performance Database. Appl. Energy 2016, 179, 996–1005. [Google Scholar] [CrossRef]

- Kim, A.A.; Medal, L. Factors Influencing Energy-Efficiency Retrofits in Commercial and Institutional Buildings: A Systematic Literature Review. J. Facil. Manag. Educ. Res. 2024, 7, 42–63. [Google Scholar] [CrossRef]

| B.P.I. Range | Building Performance |

|---|---|

| BPI ≥ 80 | Good and above |

| 70 ≤ BPI < 80 | Borderline |

| 60 ≤ BPI < 70 | Deteriorating |

| BPI < 60 | Poor or hazardous |

| Building System Component | [%] |

|---|---|

| Interior finishes | 24 |

| Structural frame | 17 |

| HVAC (Heating, Ventilation, Air Conditioning) | 16 |

| Exterior envelope | 14 |

| Electrical systems | 13 |

| Plumbing and sanitation | 7 |

| Communication and low voltage | 5 |

| Peripheral infrastructure | 4 |

| Building Type | MEI |

|---|---|

| Residential | 0.17 |

| Offices | 0.19 |

| Clinics | 0.24 |

| Education | 0.20 |

| Dining | 0.27 |

| Campus | Number of Buildings | Built Area [m2] | Weighted MEI | Current Maintenance Cost [NIS] |

|---|---|---|---|---|

| 1 | 221 | 18,745 | 0.160 | 1,474,234 |

| 2 | 226 | 17,667 | 0.164 | 1,542,791 |

| 3 | 221 | 16,409 | 0.164 | 1,319,795 |

| 4 | 104 | 12,400 | 0.190 | 643,228 |

| 5 | 170 | 12,801 | 0.196 | 747,589 |

| 6 | 149 | 7491 | 0.195 | 618,119 |

| 7 | 132 | 21,275 | 0.143 | 888,531 |

| 8 | 126 | 9607 | 0.195 | 873,426 |

| 9 | 102 | 5864 | 0.192 | 510,934 |

| 10 | 95 | 6732 | 0.203 | 631,259 |

| 11 | 117 | 5731 | 0.172 | 440,108 |

| 12 | 167 | 11,849 | 0.186 | 1,076,331 |

| 13 | 95 | 7497 | 0.194 | 582,709 |

| 14 | 70 | 5750 | 0.192 | 609,127 |

| 15 | 59 | 3800 | 0.198 | 492,594 |

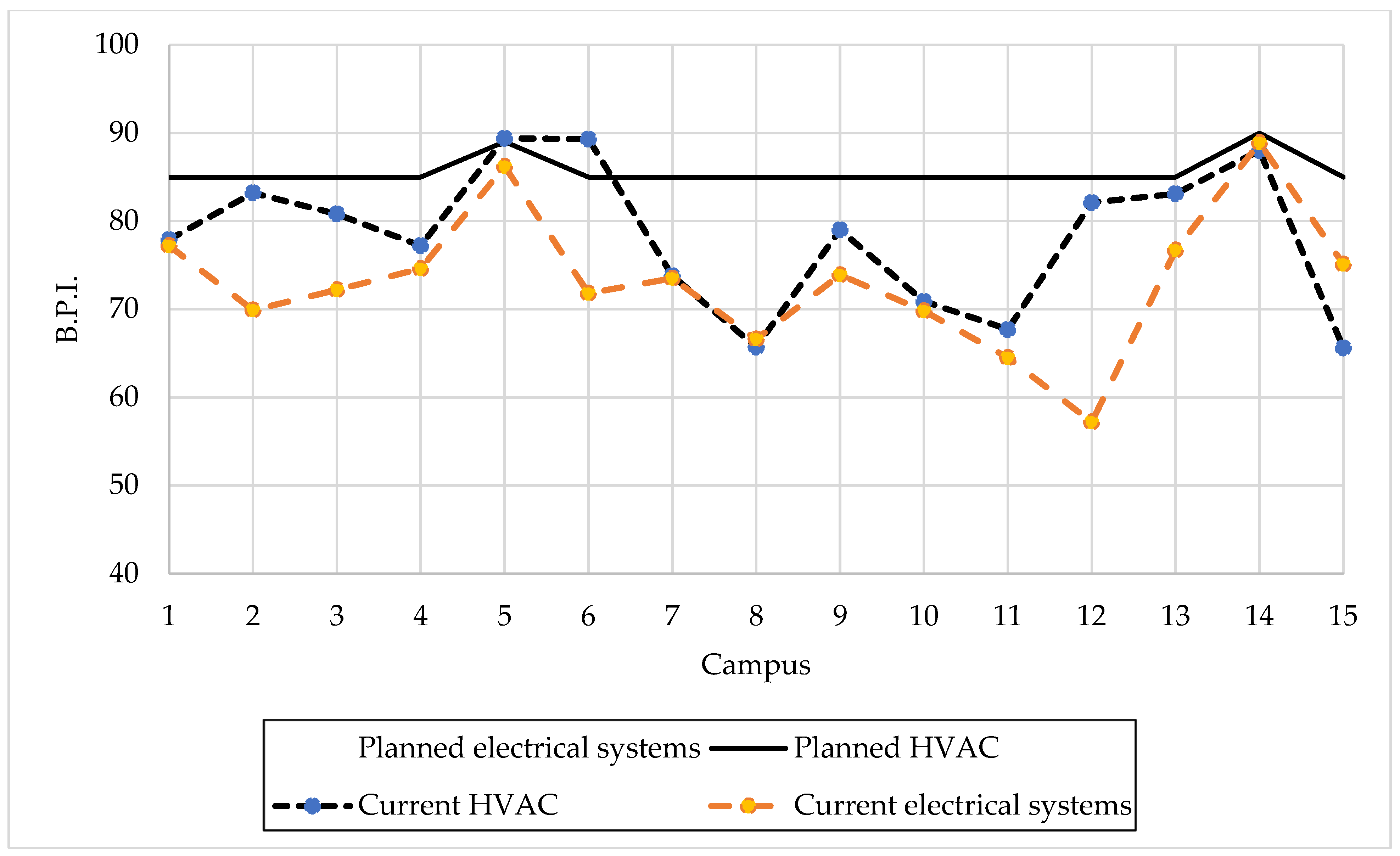

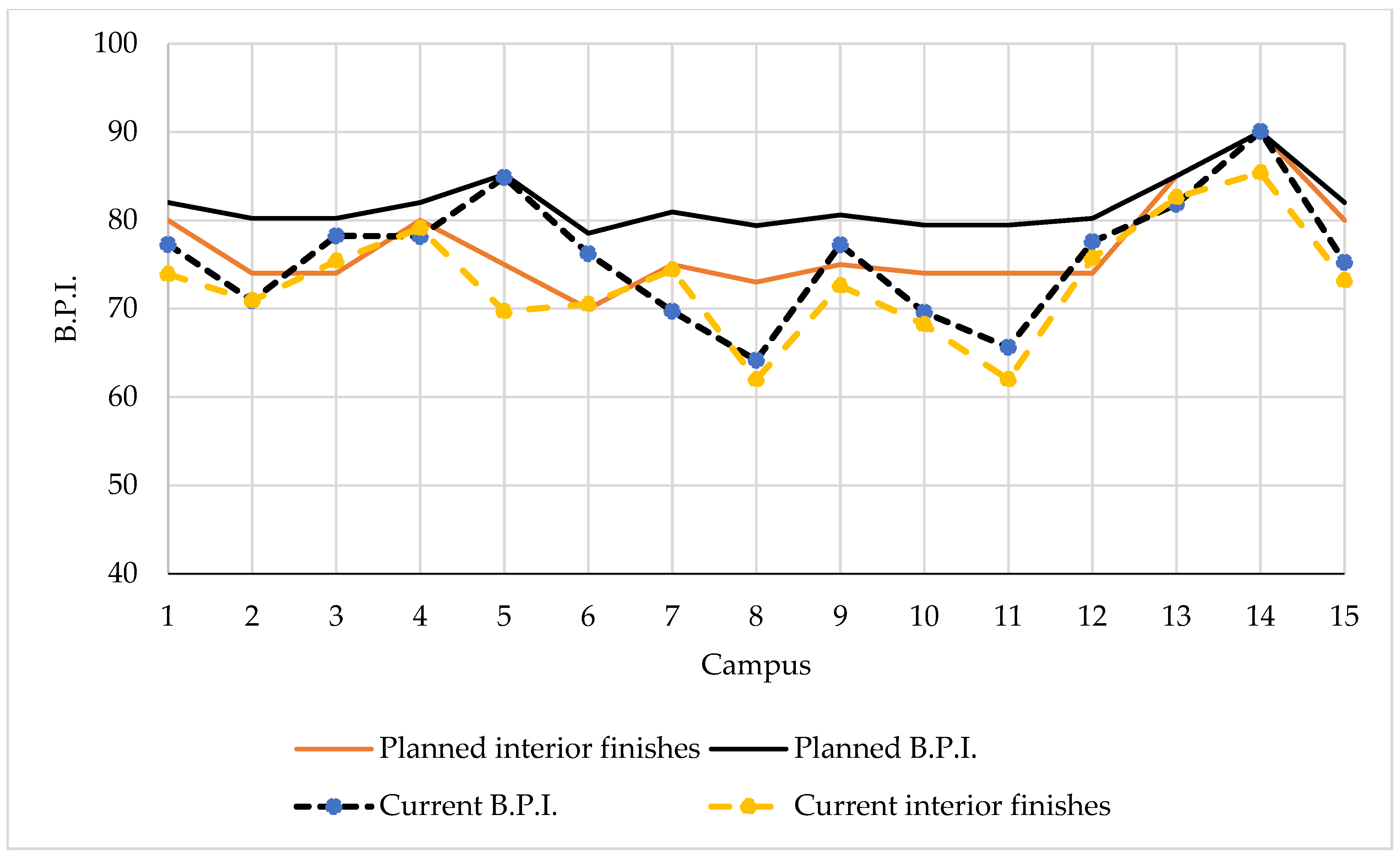

| Structural Frame | Exterior Envelope | Interior Finishes | Electrical Systems | Plumbing and Sanitation | HVAC | Communication and Low Voltage | Peripheral Infrastructure | Weighted B.P.I. | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Planned | 85.0 | 76.0 | 80.0 | 85 | 85 | 85.0 | 85 | 72.0 | 82.0 |

| Current | 88.9 | 67.7 | 73.9 | 77.2 | 78.2 | 77.9 | 76.2 | 78.8 | 77.3 | |

| 2 | Planned | 85.0 | 74.0 | 74.0 | 85 | 85 | 85.0 | 85 | 70.0 | 80.2 |

| Current | 80.7 | 70.9 | 70.9 | 69.9 | 71 | 83.2 | 5.1 | 65.4 | 70.9 | |

| 3 | Planned | 85.0 | 74.0 | 74.0 | 85 | 85 | 85.0 | 85 | 70.0 | 80.2 |

| Current | 80.0 | 81.7 | 75.4 | 72.2 | 78.5 | 80.8 | 90 | 70.0 | 78.2 | |

| 4 | Planned | 85.0 | 76.0 | 80.0 | 85 | 85 | 85.0 | 85 | 72.0 | 82.0 |

| Current | 82.7 | 76.1 | 79.1 | 74.6 | 76.9 | 77.2 | - | - | 78.2 | |

| 5 | Planned | 90.0 | 90.0 | 75.0 | 90 | 90 | 89.0 | 85 | 70.0 | 85.2 |

| Current | 94.0 | 92.8 | 69.7 | 86.2 | 87.8 | 89.4 | 85 | 81.4 | 84.9 | |

| 6 | Planned | 85.0 | 70.0 | 70.0 | 85 | 85 | 85.0 | 85 | 66.0 | 78.5 |

| Current | 81.3 | 76.5 | 70.5 | 71.8 | 73.2 | 89.3 | 59.7 | - | 76.2 | |

| 7 | Planned | 85.0 | 76.0 | 75.0 | 85 | 85 | 85.0 | 85 | 75.0 | 80.9 |

| Current | 80.8 | 68.0 | 74.4 | 73.5 | 63.3 | 73.8 | 0 | 70.0 | 69.7 | |

| 8 | Planned | 85.0 | 71.0 | 73.0 | 85 | 85 | 85.0 | 85 | 66.0 | 79.4 |

| Current | 73.0 | 54.3 | 62.0 | 66.6 | 61.3 | 65.7 | 60 | 70.0 | 64.2 | |

| 9 | Planned | 85.0 | 75.0 | 75.0 | 85 | 85 | 85.0 | 85 | 70.0 | 80.6 |

| Current | 85.6 | 73.6 | 72.6 | 73.9 | 81.8 | 79.0 | - | 78.1 | 77.2 | |

| 10 | Planned | 85.0 | 70.0 | 74.0 | 85 | 85 | 85.0 | 85 | 65.0 | 79.5 |

| Current | 78.5 | 62.2 | 68.2 | 69.8 | 61.6 | 70.9 | - | 73.9 | 69.6 | |

| 11 | Planned | 85.0 | 70.0 | 74.0 | 85 | 85 | 85.0 | 85 | 65.0 | 79.5 |

| Current | 74.9 | 60.8 | 62.0 | 64.5 | 61.3 | 67.7 | - | 67.7 | 65.6 | |

| 12 | Planned | 85.0 | 74.0 | 74.0 | 85 | 85 | 85.0 | 85 | 70.0 | 80.2 |

| Current | 86.0 | 82.4 | 75.7 | 57.2 | 81.3 | 82.1 | - | - | 77.6 | |

| 13 | Planned | 85.0 | 85.0 | 85.0 | 85 | 85 | 85.0 | 85 | 85.0 | 85.0 |

| Current | 86.0 | 83.5 | 82.6 | 76.7 | 81.4 | 83.1 | 66.3 | 85.0 | 81.8 | |

| 14 | Planned | 90.0 | 90.0 | 90.0 | 90 | 90 | 90.0 | 90 | 90.0 | 90.0 |

| Current | 96.1 | 94.5 | 85.4 | 88.9 | 89.5 | 88.0 | - | - | 90.1 | |

| 15 | Planned | 85.0 | 76.0 | 80.0 | 85 | 85 | 85.0 | 85 | 72.0 | 82.0 |

| Current | 83.7 | 77.8 | 73.2 | 75.1 | 72 | 65.6 | - | 87.5 | 75.3 |

| Dining Facilities | Logistical Facilities | |||

|---|---|---|---|---|

| Item | Existing Fixture | Replacement Fixture | Existing Fixture | Replacement Fixture |

| Lighting Type | Fluorescent 2 × 36 W | LED Fixture 40 W | MH Discharge Lamp 400 W | LED Fixture 120 W |

| Electricity Consumption (KWh) | 0.09 | 0.04 | 0.48 | 0.12 |

| Building Area (m2) | 600 | 600 | 200 | 200 |

| Number of Fixtures | 50 | 50 | 8 | 8 |

| Fixtures per building area (m2 per unit) | 12 | 12 | 25 | 25 |

| Operating Hours per Day | 15 | 15 | 10 | 10 |

| Days per Year | 365 | 365 | 250 | 250 |

| Price per KWh (NIS) | 0.5 | 0.5 | 0.5 | 0.5 |

| Annual Electricity Cost (NIS) | 12,319 | 5475 | 4800 | 1200 |

| Annual Maintenance Cost (NIS) | – | 0 | – | 0 |

| Total Annual Cost (NIS ) | 12,319 | 5475 | 4800 | 1200 |

| Annual Savings (NIS) | – | 6844 | – | 3600 |

| Lighting fixture cost (NIS) | – | 230 | – | 1000 |

| Replacement Cost (NIS ) | – | 70 | – | 70 |

| Total Fixture Replacement Cost (NIS) | – | 300 | – | 1070 |

| Total Project Cost (NIS) | – | 15,000 | – | 8560 |

| ROI (Years) | – | 2.2 | – | 2.4 |

| Savings per m2 per Year (NIS) | – | 11.41 | – | 18 |

| Cost per m2 (NIS) | – | 25 | – | 42.8 |

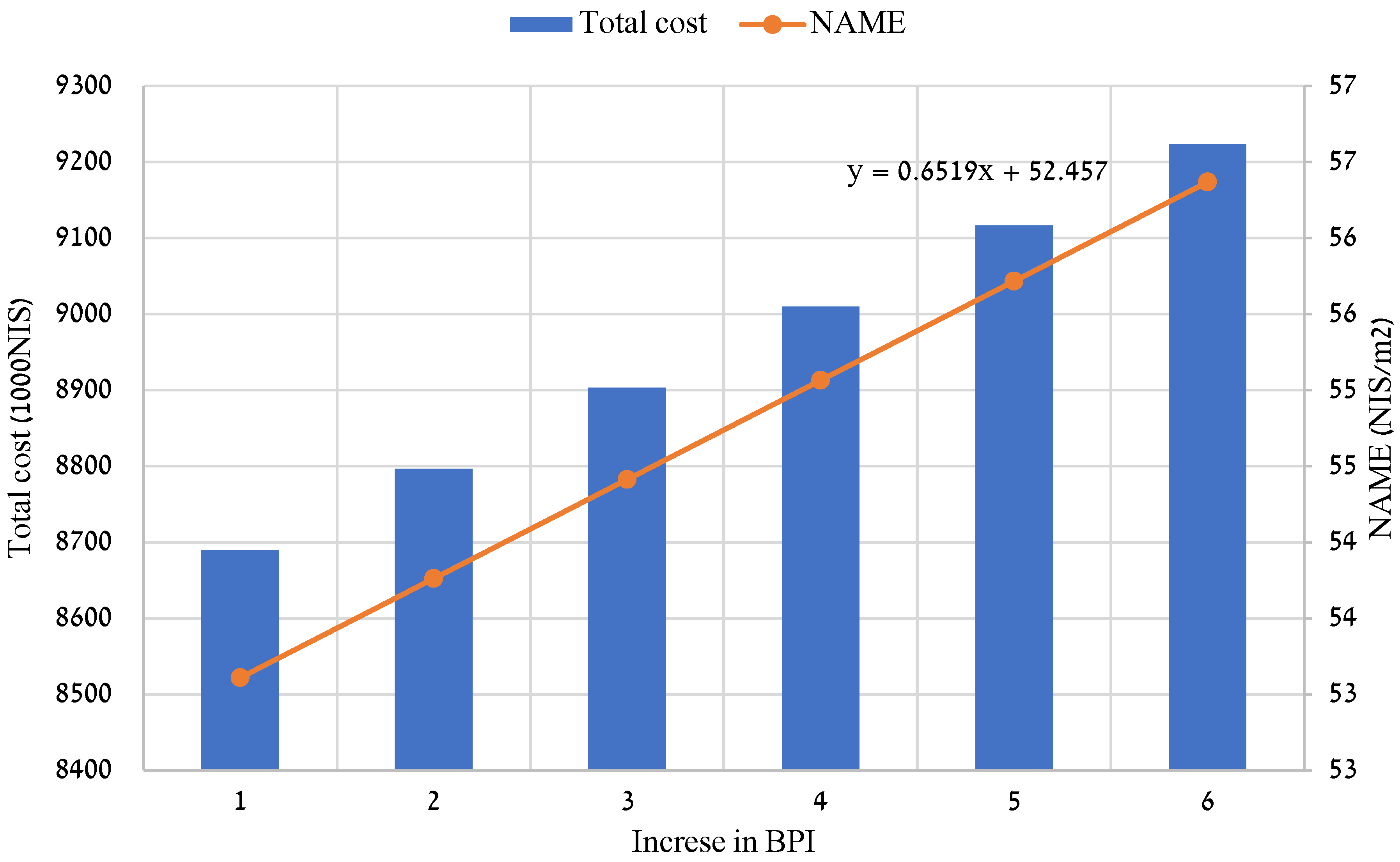

| Campus 1 | Campus 2 | Campus 3 | |

|---|---|---|---|

| MEI | 0.160 | 0.164 | 0.164 |

| Lighting energy savings for logistic facilities [NIS/m2] | 18.00 | 18.00 | 18.00 |

| Lighting energy savings for dining facilities [NIS/m2] | 11.41 | 11.41 | 11.41 |

| Building area [m2] | 18,745 | 17,667 | 17,409 |

| Energy upgrading area for dining facilities [m2] | 5063 | 1045 | 1962 |

| Energy upgrading area for logistical facilities [m2] | 686 | 936 | 873 |

| Energy investment for logistical facilities [NIS/m2] | 48,680 | 10,045 | 18,861 |

| Energy investment for dining facilities [NIS/m2] | 3855 | 5255 | 4905 |

| Energy benefit for dining facilities [NIS] | 91,141 | 18,807 | 35,313 |

| Energy benefit for logistical facilities [NIS] | 7830 | 10,674 | 9963 |

| Maintenance costs [NIS] | 911,282 | 858,153 | 796,698 |

| Total cost [NIS] | 864,845 | 843,971 | 775,189 |

| Current maintenance costs [NIS] | 1,474,234 | 1,542,791 | 1,319,795 |

| Total cost savings [%] | 41 | 45 | 41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shohet, I.M.; Levi, S.; Zeibak-Shini, R.; Shahin, F. Performance-Based Maintenance and Operation of Multi-Campus Critical Infrastructure Facilities Using Supply Chain Multi-Choice Goal Programming. Appl. Sci. 2025, 15, 11161. https://doi.org/10.3390/app152011161

Shohet IM, Levi S, Zeibak-Shini R, Shahin F. Performance-Based Maintenance and Operation of Multi-Campus Critical Infrastructure Facilities Using Supply Chain Multi-Choice Goal Programming. Applied Sciences. 2025; 15(20):11161. https://doi.org/10.3390/app152011161

Chicago/Turabian StyleShohet, Igal M., Shlomi Levi, Reem Zeibak-Shini, and Fadi Shahin. 2025. "Performance-Based Maintenance and Operation of Multi-Campus Critical Infrastructure Facilities Using Supply Chain Multi-Choice Goal Programming" Applied Sciences 15, no. 20: 11161. https://doi.org/10.3390/app152011161

APA StyleShohet, I. M., Levi, S., Zeibak-Shini, R., & Shahin, F. (2025). Performance-Based Maintenance and Operation of Multi-Campus Critical Infrastructure Facilities Using Supply Chain Multi-Choice Goal Programming. Applied Sciences, 15(20), 11161. https://doi.org/10.3390/app152011161