On the Rheological Memory and Cumulative Damage of Thermoplastic Starch Biodegradable Films Reinforced with Nanoclay

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

2.2.1. Rheological Memory

2.2.2. Cumulative Damage Test

2.3. Film Preparation

2.4. Tensile Tests

2.5. Statistical Analysis

2.5.1. Rheological Memory

2.5.2. Cumulative Damage Test

- −

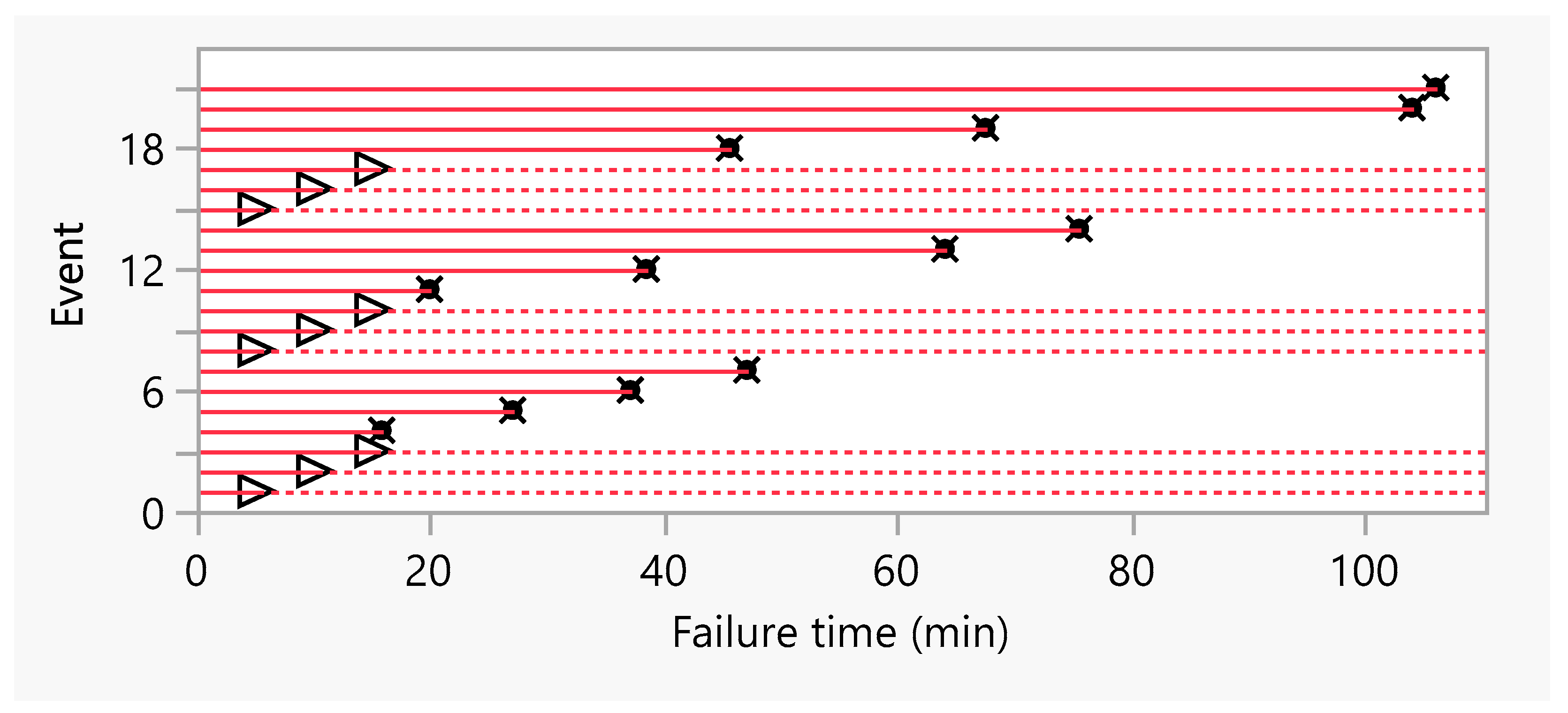

- The plot of events, which details the response of each studied experimental unit for a specific time record. Notably, because reliability experiments are conducted over a finite duration, any unit that has not failed by the end of the study is considered right censored, as its actual failure time is only known to exceed the study period.

- −

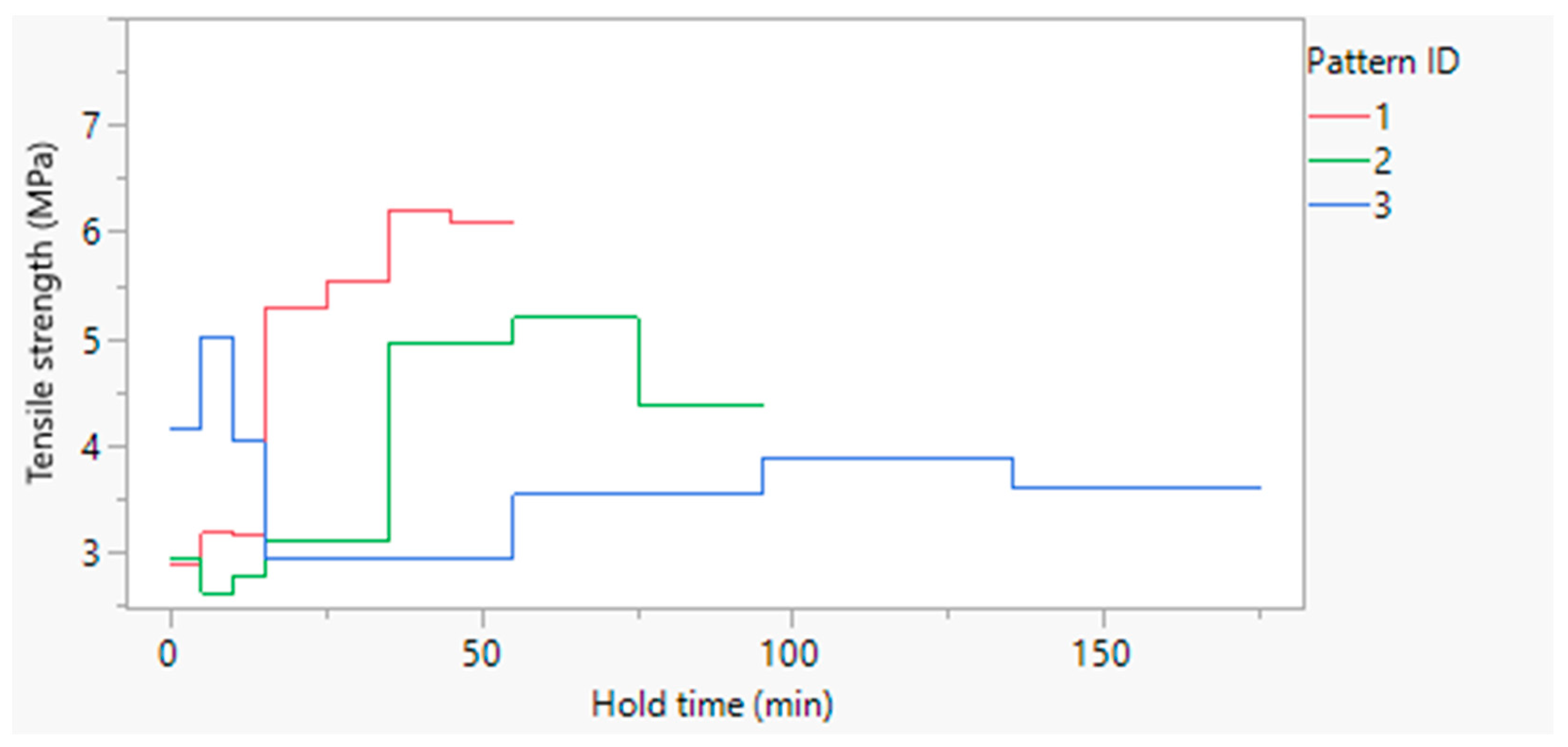

- The cumulative damage diagram, which plots the tensile strength versus failure time.

- −

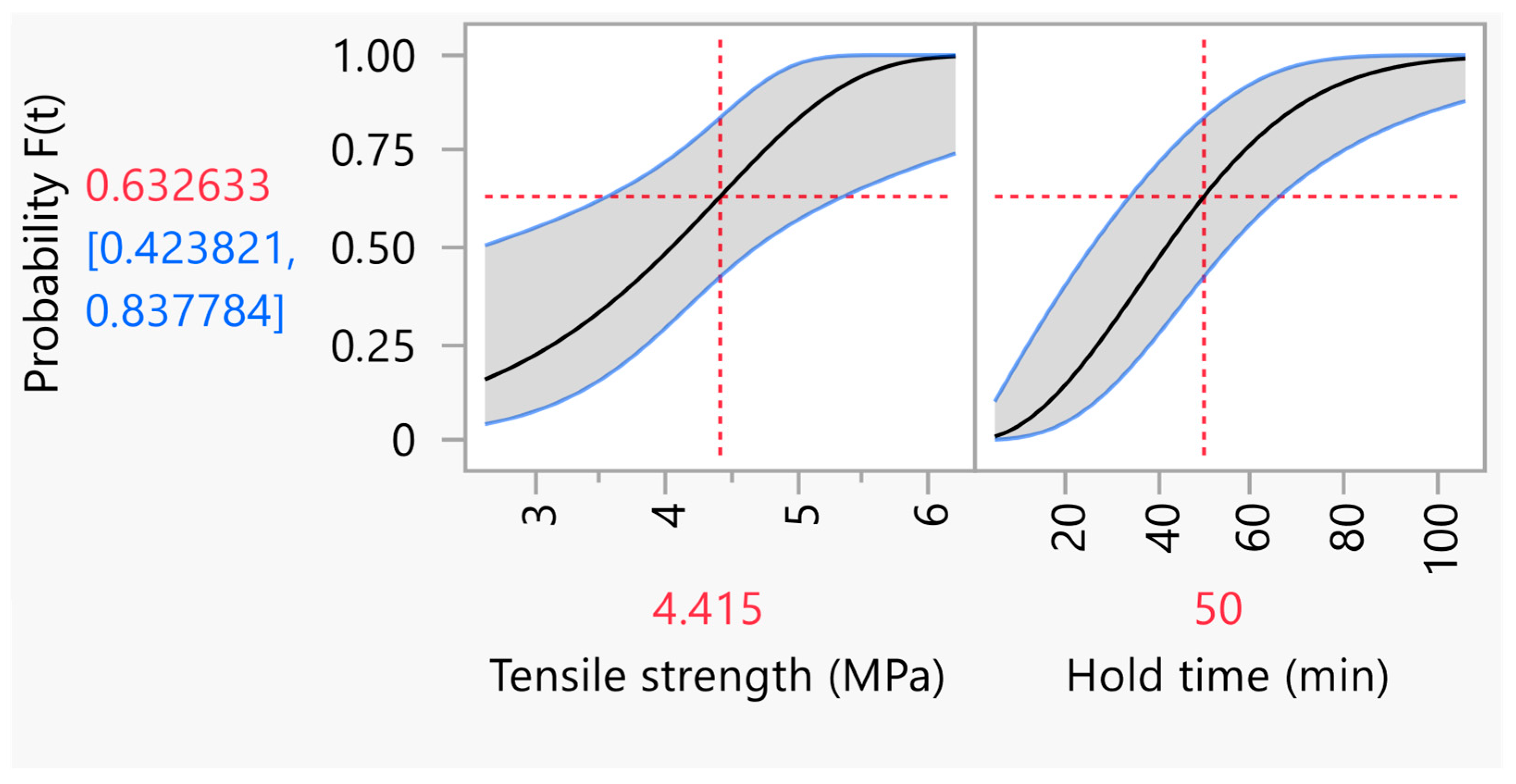

- The F(t) distribution diagram, which represents the cumulative probability of failure as a function of the lifetime of the units.

- −

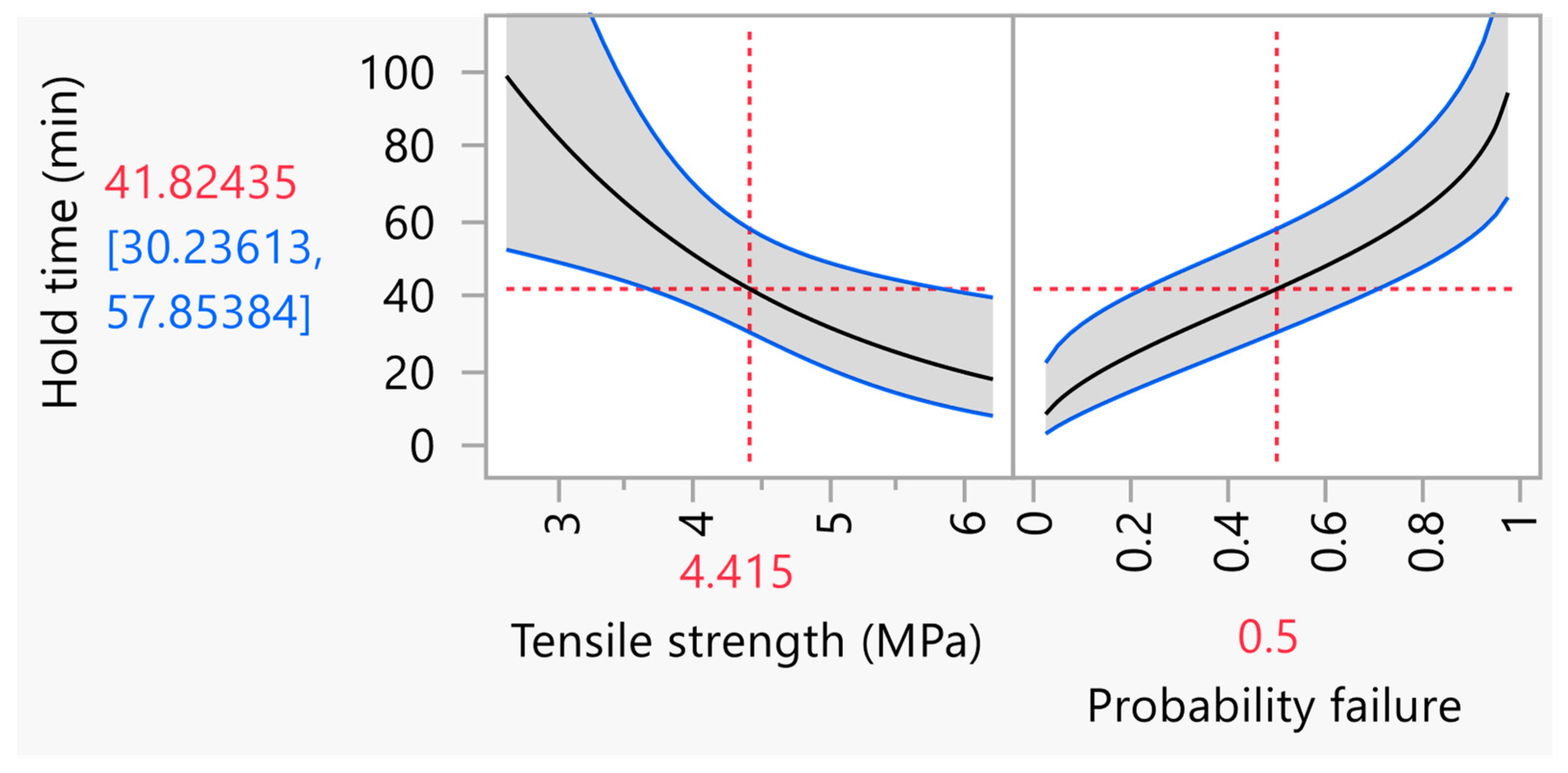

- The quantile plot of time, which describes the hold time as a function of the cumulative probability.

- −

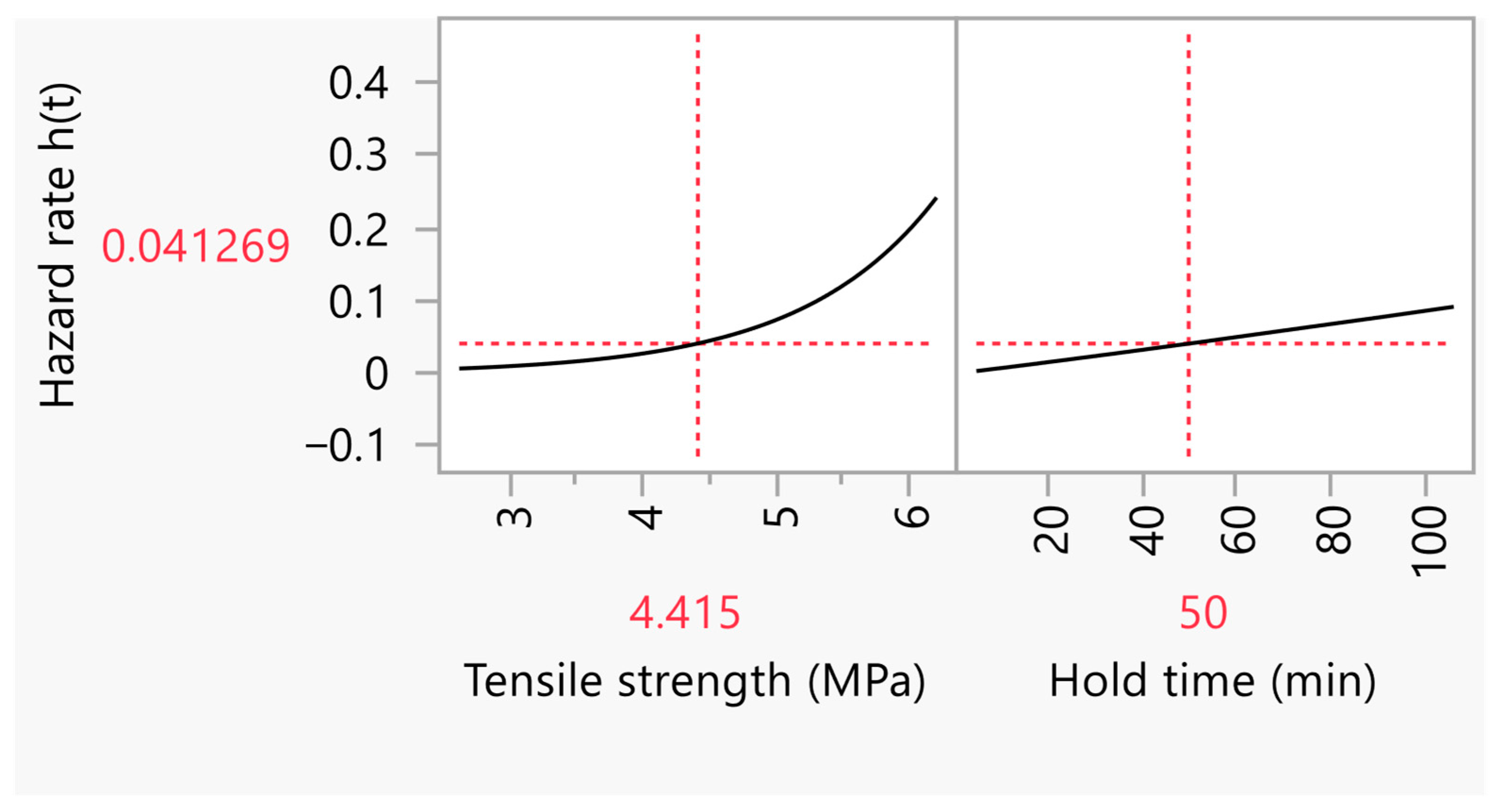

- The hazard plot h(t), which illustrates the hazard rate as a function of the hold time.

3. Results and Discussion

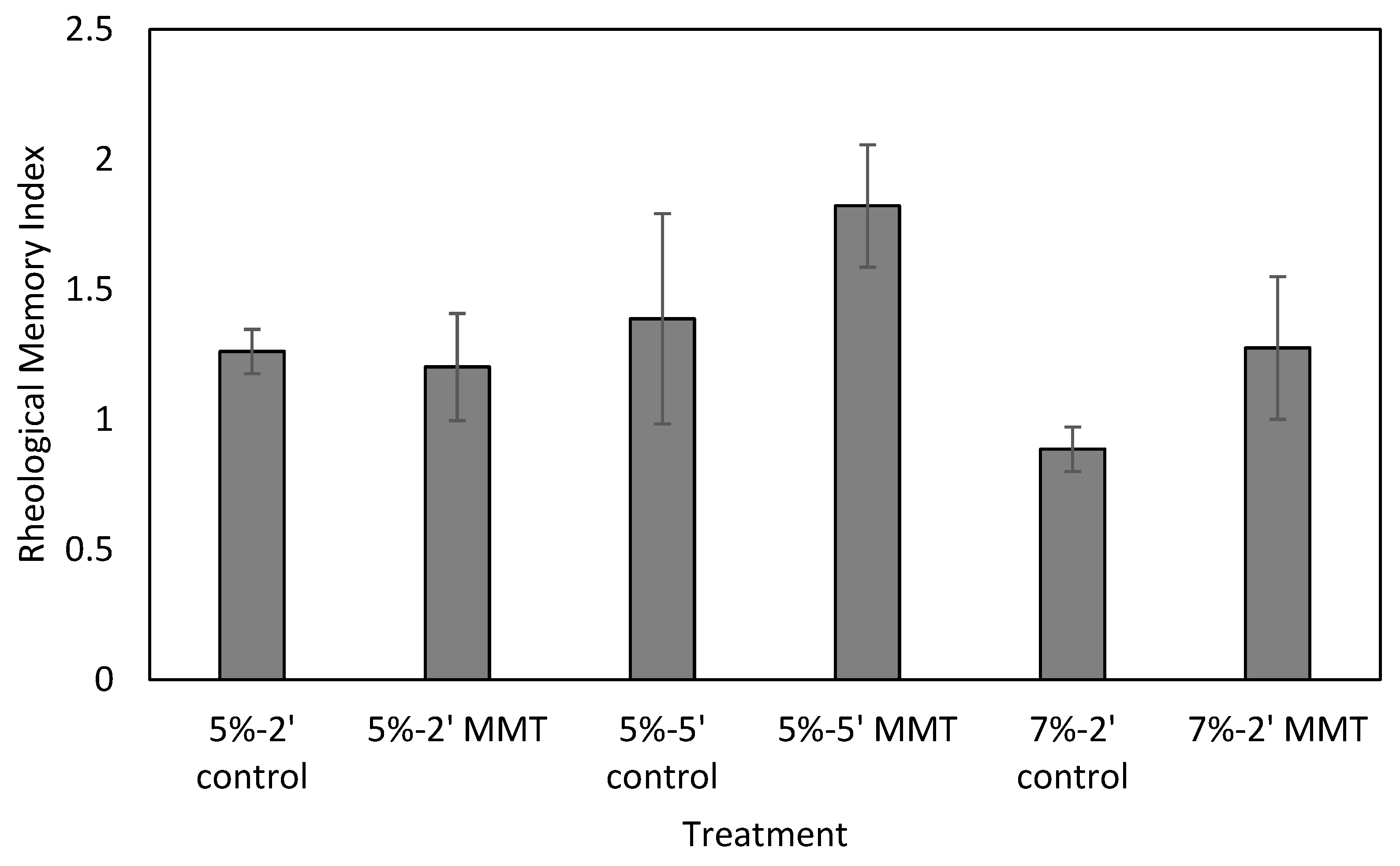

3.1. Rheological Memory

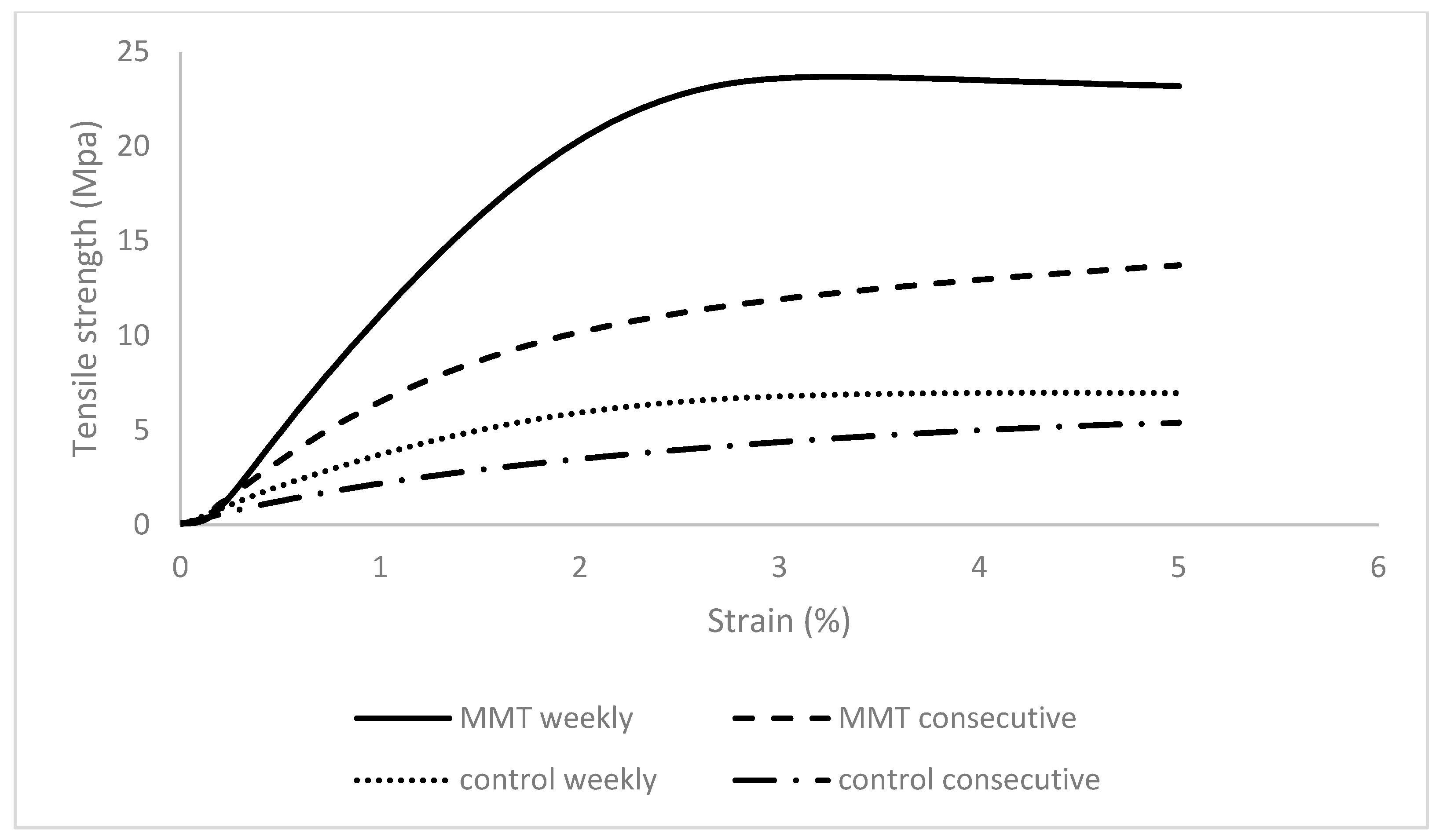

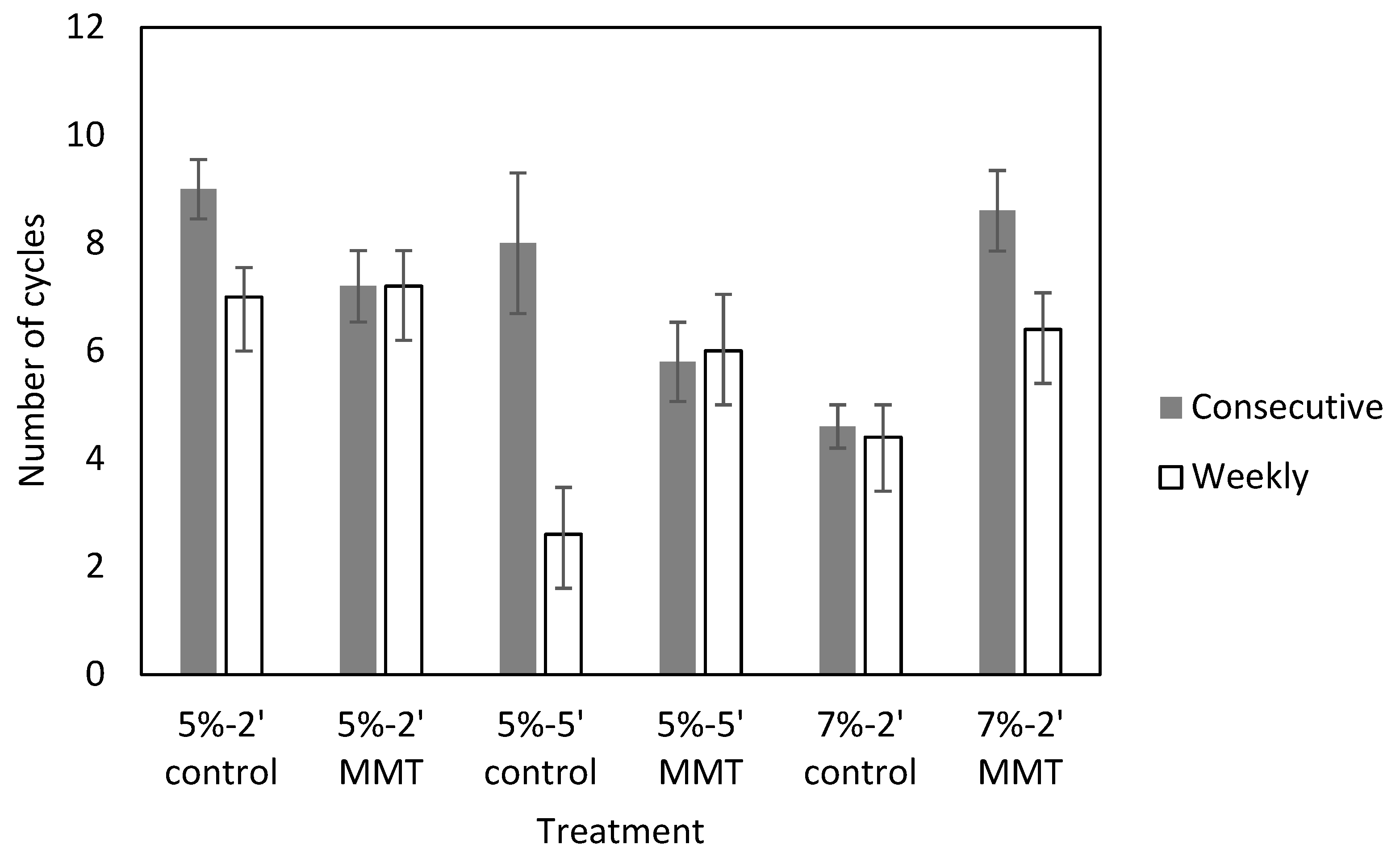

3.2. Cumulative Damage Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zannou, O.; Beşir, A.; Awad, N.M.H.; Oussou, K.F.; Odouaro, O.B.O.; Chabi, I.B.; Kpoclou, Y.E.; Kayodé, A.P.P.; Koca, I.; Selli, S. Chapter 4—Starch-based nanofibres for food packaging application. In Starch Based Nanomaterials for Food Packaging; Nayik, G.A., Hussain Dar, A., Eds.; Academic Press: Cambridge, MA, USA, 2024; pp. 83–102. [Google Scholar]

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-use plastics: Production, usage, disposal, and adverse impacts. Sci. Total Environ. 2021, 752, 141772. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Kumar, M.; Kumar, V.; Sarsaiya, S.; Anerao, P.; Ghosh, P.; Singh, L.; Liu, H.; Zhang, Z.; Awasthi, M.K. A comprehensive review on recent advancements in biodegradation and sustainable management of biopolymers. Environ. Pollut. 2022, 307, 119600. [Google Scholar] [CrossRef]

- Cheng, J.; Gao, R.; Zhu, Y.; Lin, Q. Applications of biodegradable materials in food packaging: A review. Alex. Eng. J. 2024, 91, 70–83. [Google Scholar] [CrossRef]

- Sharma, C.; Dhiman, R.; Rokana, N.; Panwar, H. Nanotechnology: An Untapped Resource for Food Packaging. Front. Microbiol. 2017, 8, 1735. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, P.; Fatima, F.; Kumar, A. Relevance of Nanomaterials in Food Packaging and its Advanced Future Prospects. J. Inorg. Organomet. Polym. Mater. 2020, 30, 5180–5192. [Google Scholar] [CrossRef]

- Bharathi, V.; Murugesan, P.; Moses, J.; Chinnaswamy, A. Recent Trends in Nanocomposite Packaging Materials. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Wang, J.; Misra, A. Strain hardening in nanolayered thin films. Curr. Opin. Solid State Mater. Sci. 2014, 18, 19–28. [Google Scholar] [CrossRef]

- Tu, S.; Ren, X.; He, J.; Zhang, Z. Stress-strain curves of metallic materials and post-necking strain hardening characterization: A review. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 3–19. [Google Scholar] [CrossRef]

- Mukherji, D.; Abrams, C. Microvoid formation and strain hardening in highly cross-linked polymer networks. Phys. Rev. E 2008, 78, 050801. [Google Scholar] [CrossRef]

- Münstedt, H. Various features of melt strain hardening of polymeric materials in uniaxial extension and their relation to molecular structure: Review of experimental results and their interpretation. Rheol. Acta 2023, 62, 333–363. [Google Scholar] [CrossRef]

- Schubert, D.W.; Kaschta, J.; Seidl, S.; Kunzelmann, P. Binary and Ternary Blends of Polypropylene Types—Influence on the Homogeneity of Biaxial-Oriented Films. Macromol. Symp. 2016, 365, 87–94. [Google Scholar] [CrossRef]

- Zhao, X.; Pelfrey, A.; Pellicciotti, A.; Koelling, K.; Vodovotz, Y. Synergistic effects of chain extenders and natural rubber on PLA thermal, rheological, mechanical and barrier properties. Polymer 2023, 269, 125712. [Google Scholar] [CrossRef]

- Walha, F.; Lamnawar, K.; Maazouz, A.; Jaziri, M. Biosourced blends based on poly (lactic acid) and polyamide 11: Structure–properties relationships and enhancement of film blowing processability. Adv. Polym. Technol. 2018, 37, 2061–2074. [Google Scholar] [CrossRef]

- Cheng, J.; Qian, Z.; Li, Z. A cumulative fatigue damage model of polysilicon films for MEMS resonator under repeated loadings. Int. J. Fatigue 2021, 147, 106186. [Google Scholar] [CrossRef]

- Zhang, L.H.; Shang, D.-G.; Liu, X.D.; Sun, Y.J.; Guo, Y.B.; Liu, F.Z.; Chen, T. A nonlinear fatigue damage-healing model for copper film by LSP. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1232–1241. [Google Scholar] [CrossRef]

- Benavides, E. General Model for Reliability-Based Engineering Design. Commun. Stat. Theory Methods 2014, 43, 2342–2356. [Google Scholar] [CrossRef]

- Tiwana, A.; Reddy, C. Life Estimation of LDPE Film under Stepped-Stress Voltage Application. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (IEEE CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 927–930. [Google Scholar]

- Frangopoulos, T.; Marinopoulou, A.; Goulas, A.; Likotrafiti, E.; Rhoades, J.; Petridis, D.; Kannidou, E.; Stamelos, A.; Theodoridou, M.; Arampatzidou, A.; et al. Optimizing the Functional Properties of Starch-Based Biodegradable Films. Foods 2023, 12, 2812. [Google Scholar] [CrossRef]

- Nelson, W. Accelerated Testing: Statistical Models, Test Plans, and Data Analyses; John Wiley & Sons: Hoboken, NJ, USA, 1990. [Google Scholar]

- ASTM D882-10; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. Plast. (I). ASTM International: West Conshohocken, PA, USA, 2010.

- Zhu, W.; Deng, Y.; Zhang, Z.; Tan, G.; Guo, X. Effect of tensile stress response for oxide films on the fatigue failure behavior of anodized AA6082 alloys. Mater. Sci. Eng. 2022, 850, 143552. [Google Scholar] [CrossRef]

- Liu, B.; Chen, K.; Zhou, R. Damage evolution and fatigue life prediction of the shape memory alloy under low cycle fatigue. Mater. Today Commun. 2021, 26, 101636. [Google Scholar] [CrossRef]

- Zuo, M.; Song, Y.; Zheng, Q. Influence of equibiaxial extensional strain on stress relaxation of glycerol plasticised wheat gluten. J. Sci. Food Agric. 2008, 88, 2350–2356. [Google Scholar] [CrossRef]

- McCann, T.H.; Homer, S.H.; Øiseth, S.K.; Day, L.; Newberry, M.; Regina, A.; Lundin, L. High amylose wheat starch increases the resistance to deformation of wheat flour dough. J. Cereal Sci. 2018, 79, 440–448. [Google Scholar] [CrossRef]

- Ranathunga, A.; Suwannaporn, P.; Kiatponglarp, W.; Wansuksri, R.; Sagis, L.M.C. Molecular structure and linear-non linear rheology relation of rice starch during milky, dough, and mature stages. Carbohydr. Polym. 2023, 312, 120812. [Google Scholar] [CrossRef]

- Zullo, R.; Iannace, S. The effects of different starch sources and plasticizers on film blowing of thermoplastic starch: Correlation among process, elongational properties and macromolecular structure. Carbohydr. Polym. 2009, 77, 376–383. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, L.; Zheng, B. New insights into the effects of starch-oleic acid-chlorogenic acid interactions on structural formation by hot-extrusion 3D printing: From perspective of nonlinear rheology. Food Hydrocol. 2023, 144, 109024. [Google Scholar] [CrossRef]

- Bagdahn, J.; Sharpe, W.N.; Jadaan, O. Fracture strength of polysilicon at stress concentrations. J. Microelectromechanical Syst. 2003, 12, 302–312. [Google Scholar] [CrossRef]

- Hedayati, R.; Alavi, M.; Sadighi, M. Effect of Degradation of Polylactic Acid (PLA) on Dynamic Mechanical Response of 3D Printed Lattice Structures. Materials 2024, 17, 3674. [Google Scholar] [CrossRef] [PubMed]

- Averett, R.D.; Realff, M.L.; Jacob, K.; Cakmak, M.; Yalcin, B. The mechanical behavior of poly(lactic acid) unreinforced and nanocomposite films subjected to monotonic and fatigue loading conditions. J. Compos. Mater. 2011, 45, 2717–2726. [Google Scholar] [CrossRef]

- Deshoulles, Q.; Gall, M.L.; Benali, S.; Raquez, J.M.; Dreanno, C.; Arhant, M.; Priour, D.; Cerantola, S.; Stoclet, G.; Gac, P.Y.L. Hydrolytic degradation of biodegradable poly(butylene adipate-co-terephthalate) (PBAT)—Towards an understanding of microplastics fragmentation. Polym. Degrad. Stab. 2022, 205, 110122. [Google Scholar] [CrossRef]

- Kianifar, M.; Azadi, M.; Heidari, F. Evaluation of stress-controlled high-cycle fatigue characteristics in PLA-wood fused deposition modeling 3D-printed parts under bending loads. PLoS ONE 2024, 19, e0300569. [Google Scholar] [CrossRef]

- Kim, W.-G.; Park, J.-Y.; Ekaputra, I.M.W.; Kim, S.-J.; Jang, J. Influence of Hold Time and Stress Ratio on Cyclic Creep Properties Under Controlled Tension Loading Cycles of Grade 91 Steel. Nucl. Eng. Technol. 2017, 49, 581–591. [Google Scholar] [CrossRef]

- Lv, Y.; Huang, Y.; Kong, M.; Yang, J.; Yang, Q.; Li, G. Creep lifetime prediction of polypropylene/clay nanocomposites based on a critical failure strain criterion. Compos. Sci. Technol. 2014, 96, 71–79. [Google Scholar] [CrossRef]

| Sample Name | Nanoclay Reinforcement | Elongation Level (%) | Application Time (min) |

|---|---|---|---|

| 5%-2’ control | no | 5 | 2 |

| 5%-2’ MMT | yes | ||

| 5%-5’ control | no | 5 | 5 |

| 5%-5’ MMT | yes | ||

| 7%-2’ control | no | 7 | 2 |

| 7%-2’ MMT | Yes |

| Stress Pattern | Step | Elongation Level (%) | Elongation Duration (min) |

|---|---|---|---|

| 1 | 1 | 3 | 5 |

| 2 | 7 | 5 | |

| 3 | 10 | 5 | |

| 4 | 12 | 10 | |

| 5 | 15 | 10 | |

| 6 | 17 | 10 | |

| 7 | 20 | 10 | |

| 2 | 1 | 3 | 5 |

| 2 | 7 | 5 | |

| 3 | 10 | 5 | |

| 4 | 12 | 20 | |

| 5 | 15 | 20 | |

| 6 | 17 | 20 | |

| 7 | 20 | 20 | |

| 3 | 1 | 3 | 5 |

| 2 | 7 | 5 | |

| 3 | 10 | 5 | |

| 4 | 12 | 40 | |

| 5 | 15 | 40 | |

| 6 | 17 | 40 | |

| 7 | 20 | 40 |

| Experiment | Composition (Based on Dry Starch) | ||

|---|---|---|---|

| Glycerol | MMT | ||

| Rheological memory | Nanoclay-reinforced films | 35% | 10.5% |

| Control films | - | ||

| Cumulative damage | 50% | 10.5% | |

| Stress Pattern | Step | Stress Duration (min) | Elongation % | Failure Time (min) | Number of Censored/Failed Films | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 1 | 1 | 5 | 3 | 5 | 10/0 | 2.9 |

| 2 | 5 | 7 | 10 | 10/0 | 3.19 | |

| 3 | 5 | 10 | 15 | 10/0 | 3.16 | |

| 4 | 10 | 12 | 15.86 | 8/2 | 5.28 | |

| 5 | 10 | 15 | 27.09 | 6/2 | 5.54 | |

| 6 | 10 | 17 | 37.17 | 1/5 | 6.21 | |

| 7 | 10 | 20 | 47.16 | 0/1 | 6.09 | |

| 2 | 1 | 5 | 3 | 5 | 10/0 | 2.94 |

| 2 | 5 | 7 | 10 | 10/0 | 2.62 | |

| 3 | 5 | 10 | 15 | 10/0 | 2.78 | |

| 4 | 20 | 12 | 19.97 | 7/3 | 3.12 | |

| 5 | 20 | 15 | 38.54 | 4/3 | 4.95 | |

| 6 | 20 | 17 | 64.14 | 1/3 | 5.2 | |

| 7 | 20 | 20 | 75.64 | 0/1 | 4.38 | |

| 3 | 1 | 5 | 3 | 5 | 10/0 | 4.16 |

| 2 | 5 | 7 | 10 | 10/0 | 5.03 | |

| 3 | 5 | 10 | 15 | 10/0 | 4.04 | |

| 4 | 40 | 12 | 45.69 | 6/4 | 2.94 | |

| 5 | 40 | 15 | 67.61 | 2/4 | 3.54 | |

| 6 | 40 | 17 | 104.17 | 1/1 | 3.89 | |

| 7 | 40 | 20 | 106.2 | 0/1 | 3.6 |

| Distribution | -2LL | N | AICc | BIC |

|---|---|---|---|---|

| Weibull | 107.12 | 3 | 114.37 | 116.51 |

| Lognormal | 109.96 | 3 | 117.20 | 119.35 |

| Loglogistic | 110.38 | 3 | 117.65 | 119.79 |

| Exponential | 113.69 | 2 | 118.29 | 119.97 |

| Frechet | 113.48 | 3 | 120.75 | 122.89 |

| Parameter | Value | SE | −95% | +95% |

| b0 | 6.021 | 0.791 | 4.470 | 7.571 |

| b1 | −0.478 | 0.183 | −0.837 | −0.117 |

| β | 2.060 | 0.497 | 1.398 | 3.914 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazantzi, E.; Christou, M.; Frangopoulos, T.; Marinopoulou, A.; Goulas, A.; Petridis, D.; Karageorgiou, V. On the Rheological Memory and Cumulative Damage of Thermoplastic Starch Biodegradable Films Reinforced with Nanoclay. Appl. Sci. 2025, 15, 11166. https://doi.org/10.3390/app152011166

Kazantzi E, Christou M, Frangopoulos T, Marinopoulou A, Goulas A, Petridis D, Karageorgiou V. On the Rheological Memory and Cumulative Damage of Thermoplastic Starch Biodegradable Films Reinforced with Nanoclay. Applied Sciences. 2025; 15(20):11166. https://doi.org/10.3390/app152011166

Chicago/Turabian StyleKazantzi, Eleni, Melpomeni Christou, Theofilos Frangopoulos, Anna Marinopoulou, Athanasios Goulas, Dimitrios Petridis, and Vassilis Karageorgiou. 2025. "On the Rheological Memory and Cumulative Damage of Thermoplastic Starch Biodegradable Films Reinforced with Nanoclay" Applied Sciences 15, no. 20: 11166. https://doi.org/10.3390/app152011166

APA StyleKazantzi, E., Christou, M., Frangopoulos, T., Marinopoulou, A., Goulas, A., Petridis, D., & Karageorgiou, V. (2025). On the Rheological Memory and Cumulative Damage of Thermoplastic Starch Biodegradable Films Reinforced with Nanoclay. Applied Sciences, 15(20), 11166. https://doi.org/10.3390/app152011166